Concentration method and concentration apparatus for wet method phosphorus acid

A concentration device, wet-process phosphoric acid technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of high scaling and thickening rate on the inner wall, shortened service life of graphite heat exchange, and decreased heat transfer capacity. Achieve the effect of reducing cost and labor intensity, guaranteeing heat exchange capacity and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

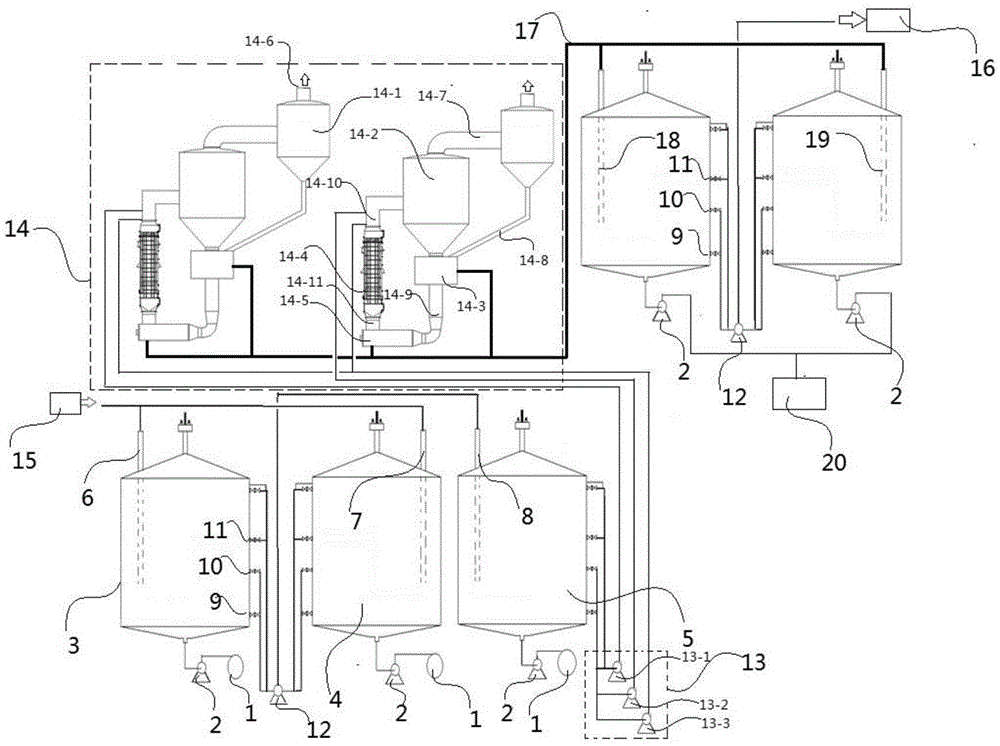

[0019] Such as figure 1 As shown, a wet-process phosphoric acid concentration device, the specific structural composition and connection relationship are: the concentrated acid precipitation unit is connected to the secondary acid pump, the secondary acid pump is connected to the concentration mechanism, and the concentration mechanism is connected to the finished acid precipitation unit; The concentrated acid precipitation unit is composed of concentrated acid tank a3, concentrated acid tank b4, and concentrated acid tank c5. The concentrated acid tank a3 is adjacent to the concentrated acid tank b4, and the concentrated acid tank a3 is opposite to the concentrated acid tank b4 Valves are arranged on the side walls of the concentrated acid tank b4, and the bottom of the concentrated acid tank a3 and the concentrated acid tank b4 upwards are the first-layer valve 9, the second-layer valve 10, the third-layer valve 11 and the overflow valve at the top. , the overflow valve and ...

Embodiment 2

[0025] Such as figure 1 Shown, above-mentioned wet-process phosphoric acid concentrating device is used for the method for concentrating wet-process phosphoric acid, and the specific gravity of the acid of control feed inlet is 1.52, the mass concentration of acid, counts as 35-37% with the content of phosphorus pentoxide, acid The solid content in the tank is 3-4.5%; after the acid is pumped into the concentrated acid tank a and the concentrated acid tank b through the cannula a and the cannula b, the acid is in the concentrated acid tank a and the concentrated acid tank b Settling and staying, after the time reaches 5-6h, the slag from the bottom of the concentrated acid tank a and the concentrated acid tank b is sent to the extraction tank through the slag dumping pump, and the upper part of the concentrated acid tank a and the concentrated acid tank b The clear liquid is pumped into the concentrated acid tank c through the acid supply pump through the action of the first l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com