Method for pre-treating phosphorus rock by titanium dioxide waste acid

A titanium white waste acid and pretreatment technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the negative impact of wet-process phosphoric acid production, low magnesium removal rate, and phosphate rock removal rate cannot meet expectations Targets and other issues, to achieve the effect of repeated use of water resources, high magnesium removal rate, and reduced consumption of sulfuric acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

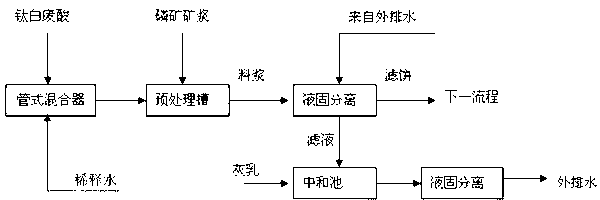

Method used

Image

Examples

Embodiment 1

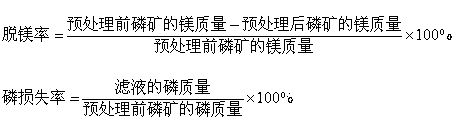

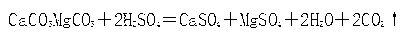

[0032] 1373.69Kg of acid waste water and 343.42Kg of titanium white waste acid (the mass percentage of sulfuric acid is 20%, the mass percentage of ferrous sulfate is 10%) is quickly mixed with 1000kg of phosphate rock with a solid content of 75% through a tube mixer (P 2 o 5 content of 28.73%, MgO content of 2.50%, mineral powder 100 mesh sieve remaining 10%) ore slurry, respectively input 5m through the pipeline 3 Pretreat the reaction tank, make the phosphate rock and titanium white waste acid react under stirring, the stirring intensity is 100rpm, the pH value of the reaction slurry is controlled at 2, the temperature is 41°C, and the residence time of the material in the pretreatment tank is 2h. The slurry out of the pretreatment tank is separated and washed through a filter press, and the P in the filter cake base is 2 o 5 The content is 29.28%, and the MgO content is 0.15%. The sulfuric acid content in the filtrate is 0.16%, the MgO content is 0.50%, and the P conte...

Embodiment 2

[0035] 2048.68 Kg of external drainage and 279.37Kg of titanium white waste acid (30% by mass of sulfuric acid, 14% by mass of ferrous sulfate) are quickly mixed with 1000kg of phosphate rock with a solid content of 75% by a tube mixer (P 2 o 5 content of 28.73%, MgO content of 2.50%, mineral powder 100 mesh sieve remaining 10%) ore slurry, respectively input 5m through the pipeline 3 Pretreat the reaction tank to make the phosphate rock and titanium white waste acid react under stirring, the stirring intensity is 100rpm, the pH value of the reaction slurry is controlled to 4, the temperature is 40°C, and the residence time of the material in the pretreatment tank is 1.8h. The slurry out of the pretreatment tank is separated and washed through a filter press, and the P in the filter cake base is 2 o 5 The content is 29.22%, and the MgO content is 0.45%. The sulfuric acid content in the filtrate is 0.06%, the MgO content is 0.50%, and the P content is 0.8ppm.

[0036] In t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com