High-desalting-rate seawater desalination method and device based on liquefied natural gas cold energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Follow the steps below to desalinate seawater:

[0062] (1) Take seawater with an original salt concentration of 3%; fully perform indirect heat exchange between liquefied natural gas and gaseous R410a to obtain gaseous natural gas and liquid R410a, then fully perform indirect heat exchange between the liquid R410a and the seawater to obtain Gaseous R410a, ice and concentrated seawater; after the separation of ice and water, recover the concentrated seawater and store ice for later use;

[0063] The concentration of salt in the ice is 39% of the original salt concentration of seawater;

[0064] (2) Take the ice gained in step (1), and let it stand under normal pressure, so that the melting rate of the ice is 49%, and separate the ice and water while standing; reclaim the liquid, and use the remaining ice for subsequent use;

[0065] (3) Take the remaining ice obtained in step (2), break it into ice crystal particles, centrifuge at 3000 rpm for 4 minutes, and separate t...

Embodiment 2

[0069] Follow the steps below to desalinate seawater:

[0070] (1) Take seawater with an original salt concentration of 3%; fully perform indirect heat exchange between liquefied natural gas and gaseous R410a to obtain gaseous natural gas and liquid R410a, then fully perform indirect heat exchange between the liquid R410a and the seawater to obtain Gaseous R410a, ice and concentrated seawater; after the separation of ice and water, recover the concentrated seawater and store ice for later use;

[0071] The concentration of salt in the ice is 60% of the original salt concentration of seawater;

[0072] (2) Take the ice gained in step (1), and let it stand under normal pressure, so that the melting rate of the ice is 39.5%, and separate the ice and water while standing; reclaim the liquid, and use the remaining ice for subsequent use;

[0073] (3) Take the remaining ice obtained in step (2), break it into ice crystal particles, centrifuge at 5000 rpm for 4 minutes, and separate...

Embodiment 3

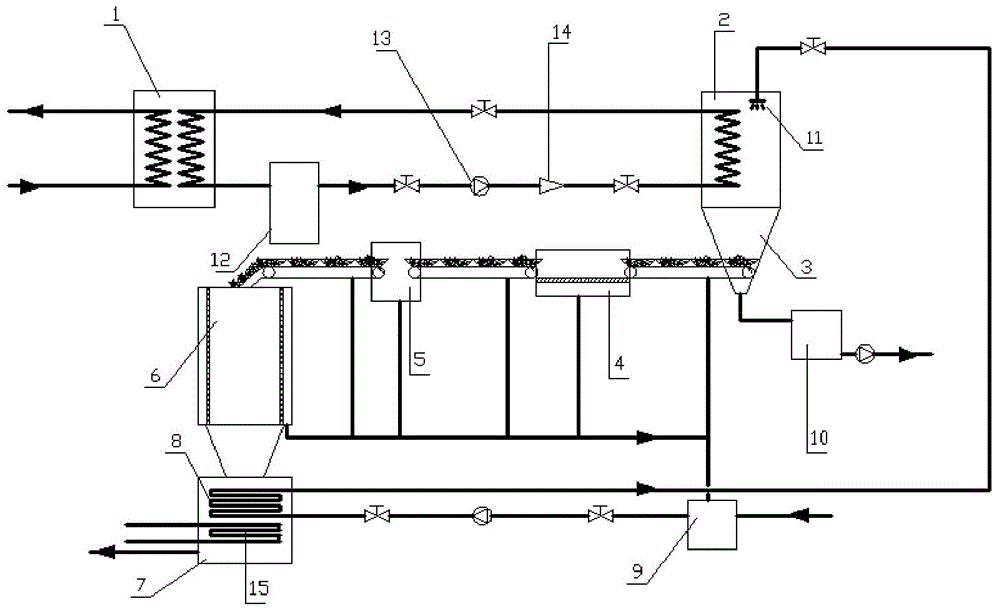

[0085] A seawater desalination device with high desalination rate based on the cold energy of liquefied natural gas (such as figure 1 shown), the device includes sequentially connected seawater supply system 9, seawater freezing and gravity centrifugal desalination system, and freshwater system; the device also includes a liquefied natural gas gasification system and a secondary refrigerant phase change circulation system for seawater freezing ;

[0086]The seawater freezing and gravity centrifugal desalination system includes an ice maker 2, an ice-water separator 3, a gravity desalination tank 4, an ice crusher 5, and a filter type centrifugal desalination device 6 connected in sequence;

[0087] The ice maker 2 includes an indirect heat exchanger; one side of the indirect heat exchanger is a secondary refrigerant circulation system, and the other side is a seawater distribution device 11 and a mechanical deicing device;

[0088] The liquefied natural gas gasification syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com