Polyamide composite sea water desalination film and preparation method thereof

A composite membrane and polyamide technology, applied in the field of water treatment, can solve the problem that the improvement is not very obvious, and achieve the effects of high desalination rate, enhanced bearing capacity, and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

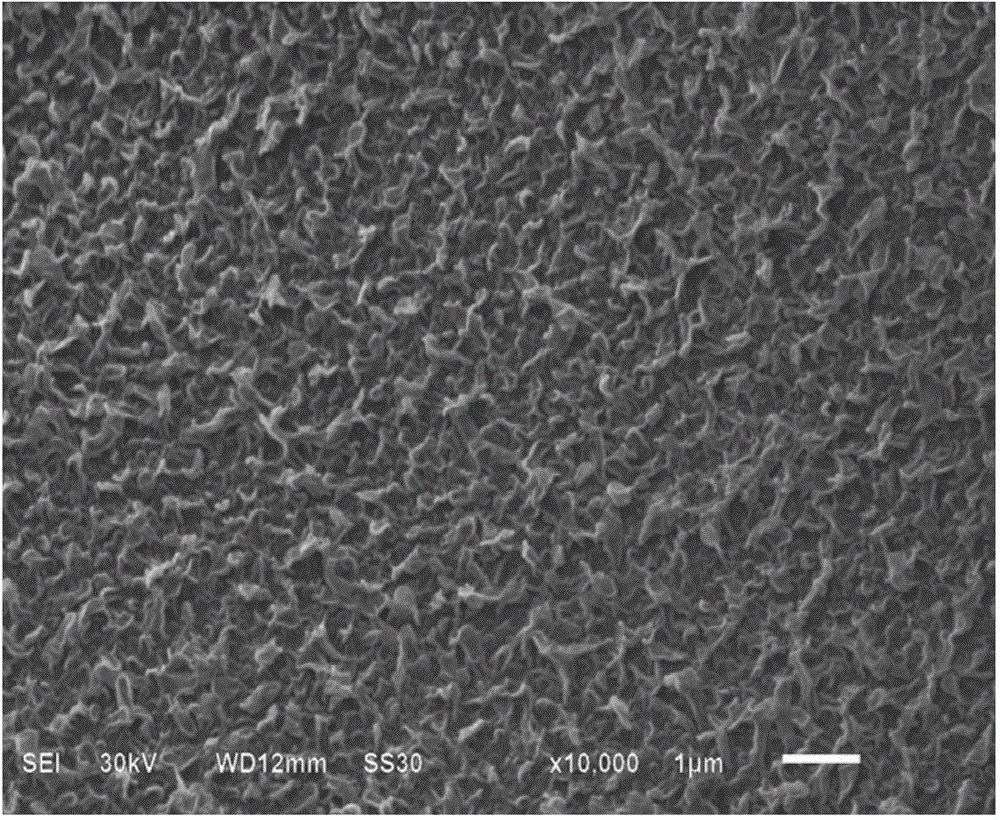

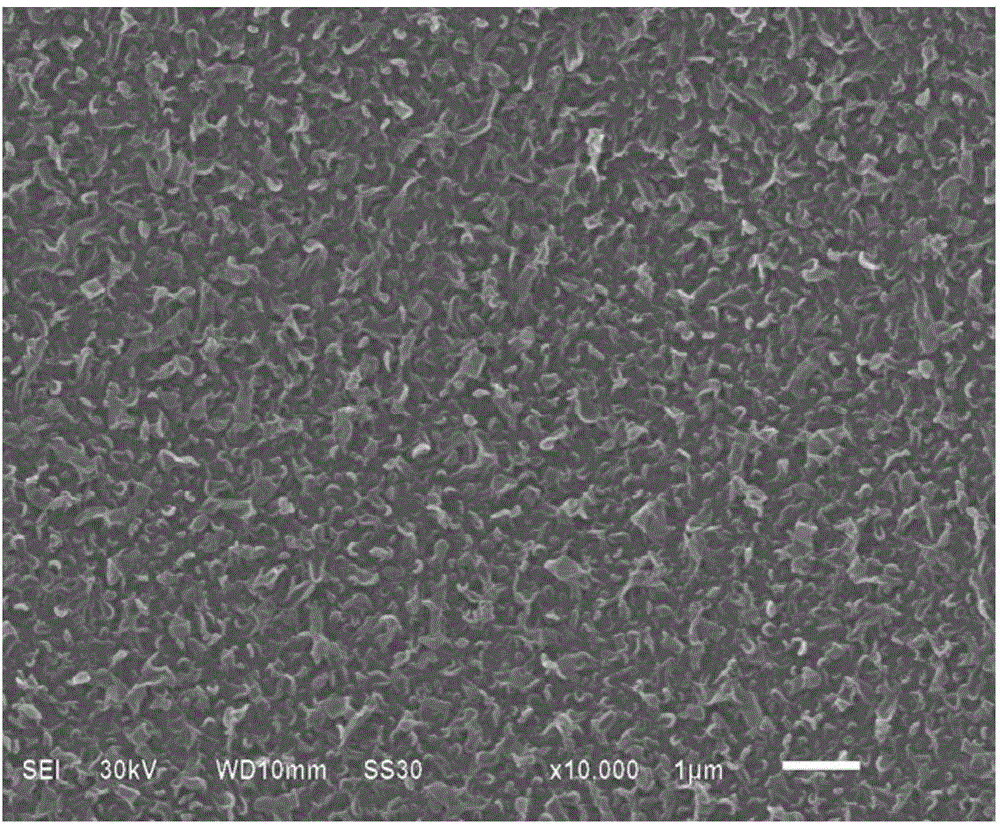

Image

Examples

Embodiment 1

[0019] Prepare a high cross-linking seawater desalination composite membrane according to the following steps:

[0020] Preparation of support base layer: Weigh 75g of polysulfone resin (PSF), 375g of N-methylpyrrolidone (NMP), and 50g of polyethylene glycol 200 (PEG200), and mix them to prepare a 500g solution. Stir at 70°C for 6 hours to prepare a uniformly dispersed casting solution. After the casting solution is filtered and vacuum degassed, it is evenly coated on the non-woven fabric on a film scraping machine. The wet film thickness is 150 μm. After evaporating at room temperature for 3 seconds, it is immersed in ultra-pure water at 16°C to gel and solidify to form a film. , and finally the membrane is completely cured by water at room temperature, and finally the membrane is treated in 75°C water for 3 minutes to obtain a supporting base layer, which is stored in a freezer at 5°C until use.

[0021] Preparation of amine-containing solution: Weigh 299g of m-phenylenedia...

Embodiment 2

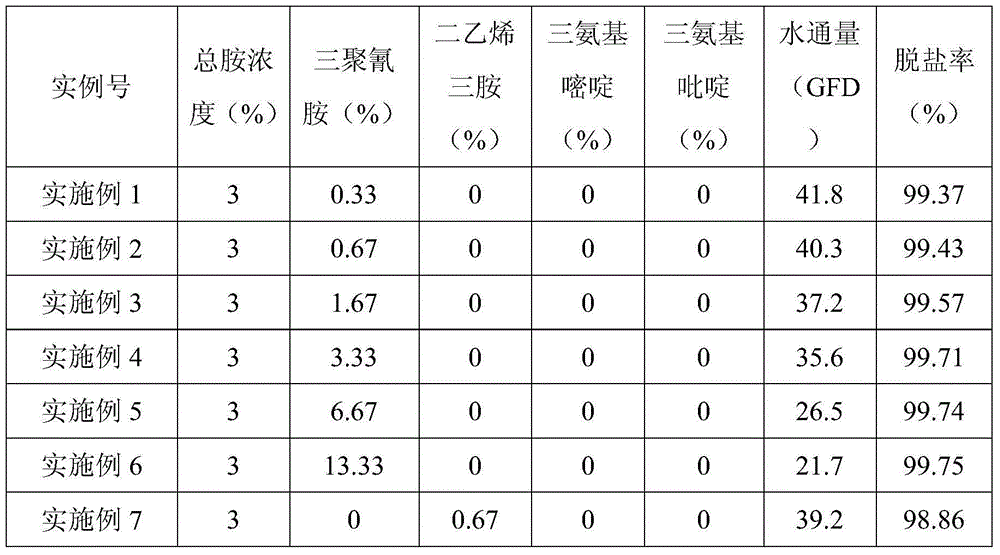

[0026] The steps are the same as in Example 1, except that the amount of phenylenediamine in the amine solution is 298 g, and the amount of melamine is 2 g. See Table 1 for the data.

Embodiment 3

[0028] The steps are the same as in Example 1, except that the amount of phenylenediamine in the amine solution is 295 g, and the amount of melamine is 5 g. See Table 1 for the data.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com