Preparation method of high water flux reverse osmosis membrane

A technology of reverse osmosis membrane and flux, applied in semi-permeable membrane separation, chemical instruments and methods, membrane technology, etc., can solve the problem of reverse osmosis membrane desalination rate of less than 99%, etc., and achieve low preparation cost and reproducibility. Good and high desalination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

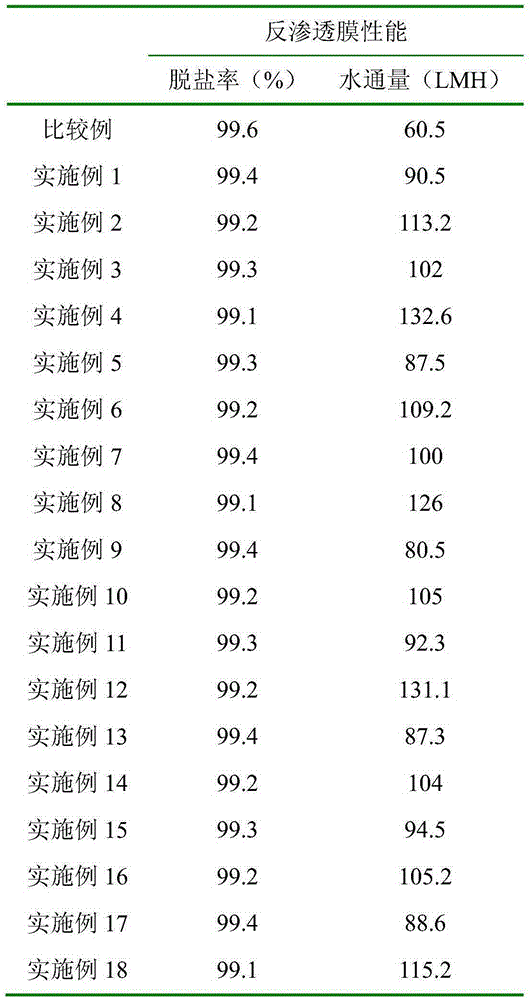

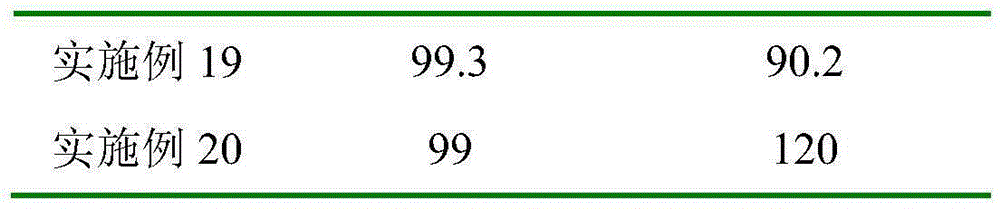

Embodiment 1

[0034]0.5% of DMI was added to the aqueous phase solution containing 2% m-phenylenediamine, and this was used to replace the aqueous phase solution containing 2% m-phenylenediamine in Comparative Example. Other than that, all other conditions were the same as those of the comparative example. The water flux of the reverse osmosis composite membrane prepared by this method is 90.5LMH and the desalination rate is 99.4%.

Embodiment 2

[0036] 2% of DMI was added to the aqueous phase solution containing 2% m-phenylenediamine to replace the aqueous phase solution containing 2% m-phenylenediamine in Comparative Example. Other than that, all other conditions were the same as those of the comparative example. The water flux of the reverse osmosis composite membrane prepared by this method is 113.2LMH, and the desalination rate is 99.2%.

Embodiment 3

[0038] Add 0.1% DMI to the organic phase solution containing 0.1% trimesoyl chloride, and use it to replace the organic phase solution containing 0.1% trimesoyl chloride in the comparative example. Other than that, all other conditions were the same as those of the comparative example. The water flux of the reverse osmosis composite membrane prepared by this method is 102LMH, and the desalination rate is 99.3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com