Membrane element, device and water processing method using the membrane element

A technology of membrane elements and water treatment devices, which is applied in the directions of water/sewage multi-stage treatment, water/sludge/sewage treatment, electrochemical water/sewage treatment, etc., can solve the problems of increasing waste water and reducing fouling, and achieve increased Effects of service life, improved recovery rate, and high desalination rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

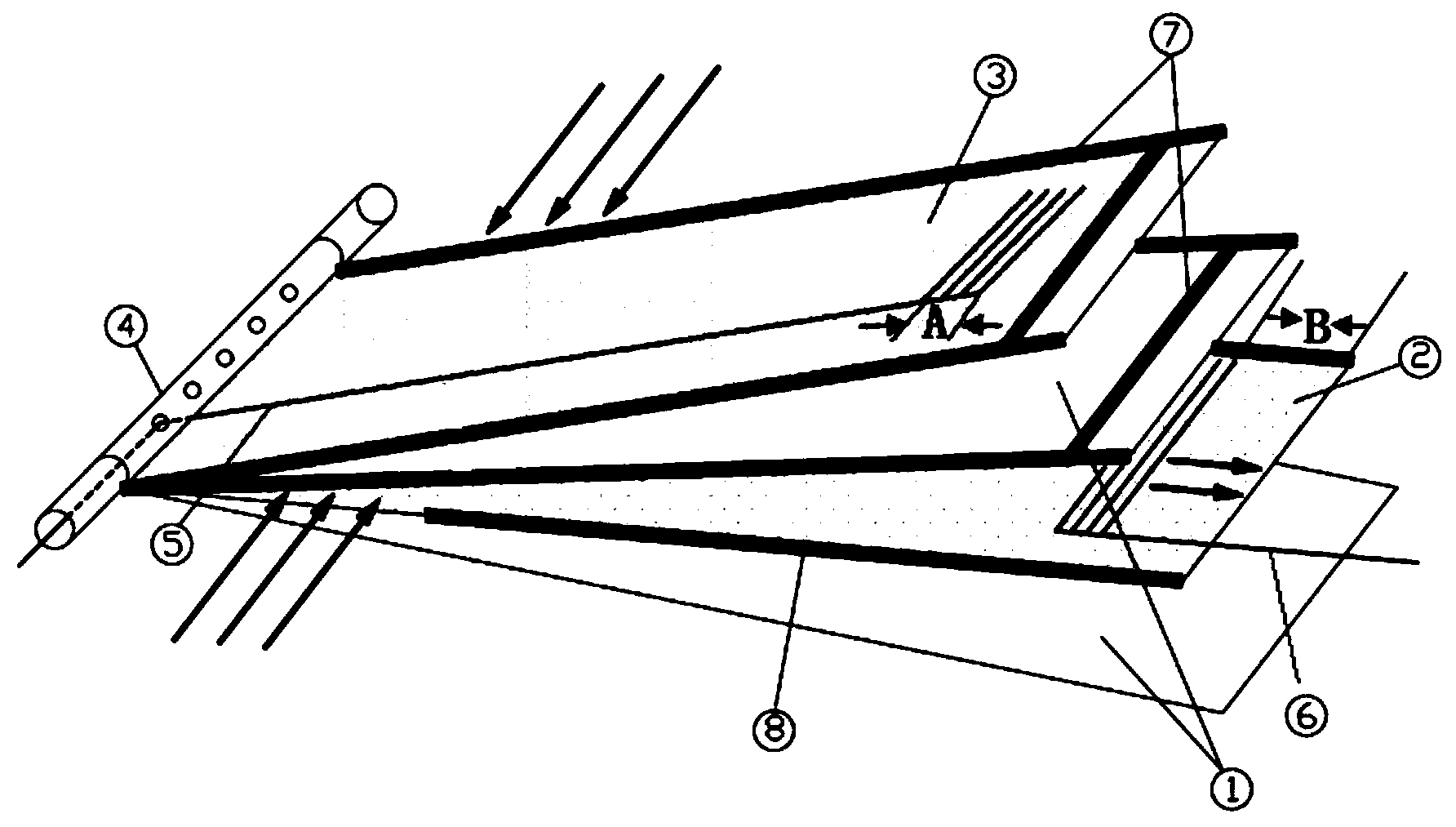

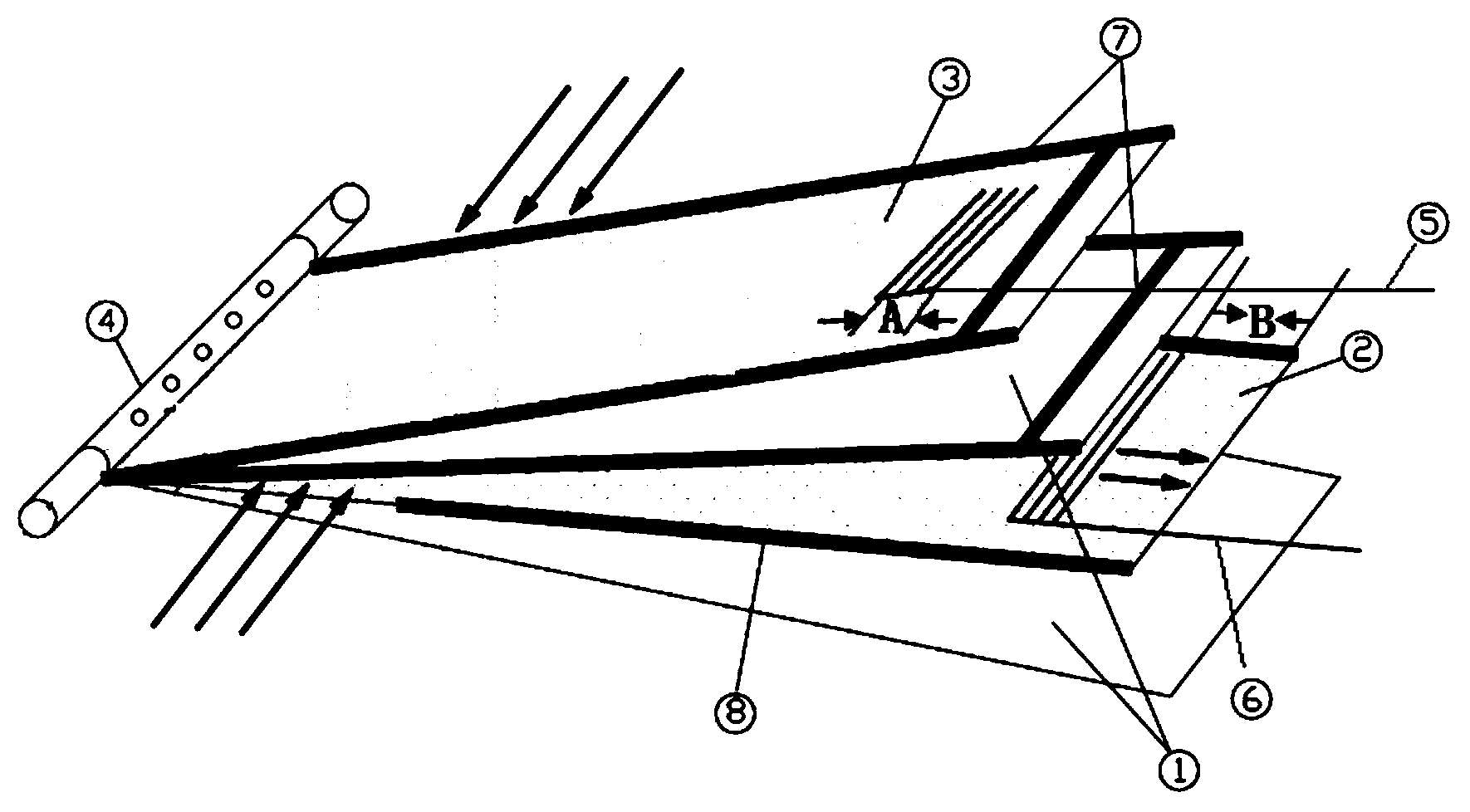

[0057] The 1810-75G-ss side flow ( figure 1 Membrane element structure shown) Seven 10cm-long 0.5mm-diameter iridium oxide-coated titanium wires are added to the inlet grid of the reverse osmosis membrane element as electrodes, and seven 5cm-long 0.5mm-diameter iridium oxide-coated titanium wires are added to the pure water guide cloth. Iridium-coated titanium wire is used as an electrode, where A is the length of the short side of the pure water electrode arrangement area, which is 5cm, and B is the distance from the electrode wire closest to the wastewater outlet to the wastewater outlet, which is 5cm, to prepare a new type of electrochemical self-cleaning The coiled membrane element of the pure water end is connected to the negative pole of the DC power supply, and the electrode wire of the water inlet end is connected to the positive pole of the DC power supply. The membrane element is cleaned by backwashing with pure water before shutdown. Specifically, the water producti...

Embodiment 2

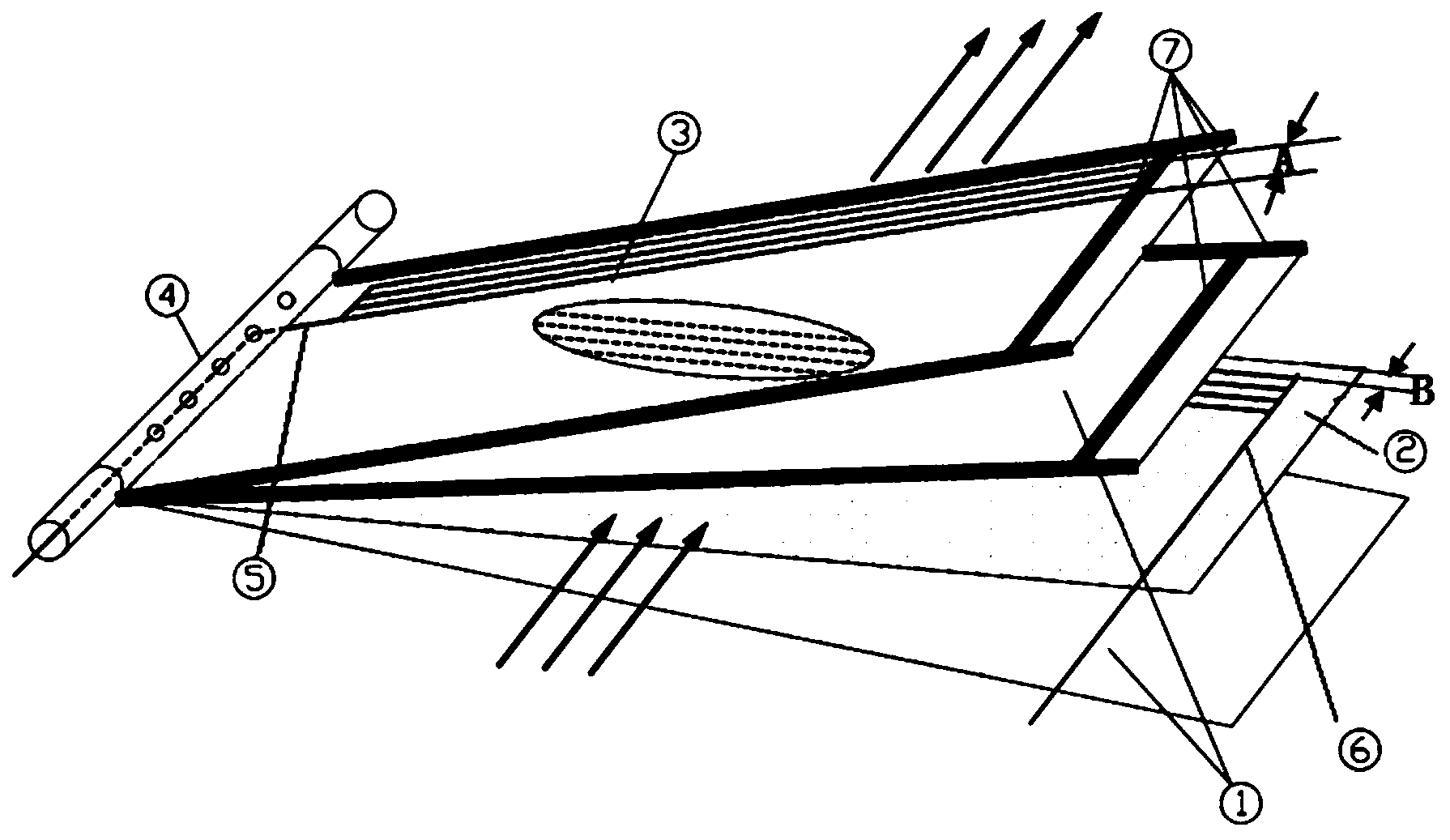

[0059] In 1810-75G ( figure 2 Membrane element structure shown) Seven 10cm-long 0.5mm-diameter iridium oxide-coated titanium wires are added to the inlet grid of the reverse osmosis membrane element as electrodes, and seven 10cm-long 0.5mm-diameter iridium oxide-coated titanium wires are added to the pure water guide cloth. Iridium-coated titanium wire is used as an electrode, where A is the length of the short side of the pure water electrode arrangement area, which is 10cm, and B is the distance from the electrode wire closest to the wastewater outlet to the wastewater outlet, which is 5cm, to prepare a new type of electrochemical self-cleaning The roll-type membrane element of the pure water end is connected to the negative pole of the DC power supply, and the electrode wire of the water inlet end is connected to the positive pole of the DC power supply. The membrane element is cleaned by backwashing with pure water before shutdown. The operation process is divided into 3 ...

Embodiment 3

[0061] Membrane elements were prepared as described in Example 1, and the membrane elements were cleaned with pure water without backflow before shutdown. The operation process was divided into 3 times, and power-on cleaning was performed after each water production operation, and power-on was performed for about 30 minutes each time. , and finally make water until the water is full. With this operation mode, the pH of the pure water in the pressure tank can reach 8.1, and when the pure water passing through the membrane element reaches 4t, the pure water flow rate decay rate has been reduced to 30%. Compared with Example 1, when the pure water flow rate decays to 30%, the amount of passing water is less, and it can be seen that the cleaning effect of pure water backflow is better than that without backflow.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com