Milk concentrating method and system based on forward osmosis technology

A technology of forward osmosis and concentration system, which is applied in the field of dairy product concentration, and can solve problems such as large amounts of steam, loss of active ingredients, failure to meet production requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

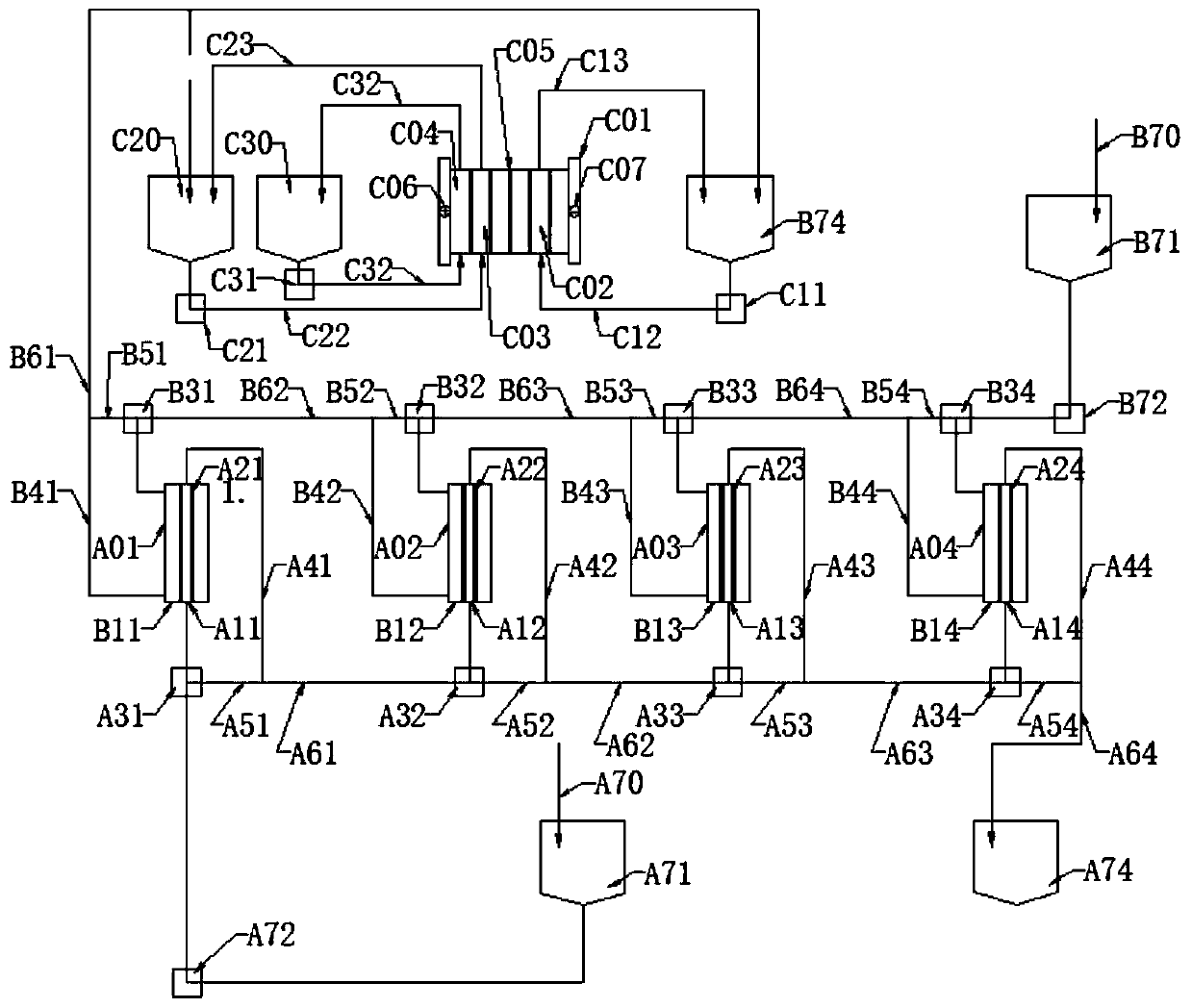

[0074] Such as figure 1 As shown, the continuous concentrated forward osmosis membrane unit is divided into four stages, of which three stages are concentrated and operated, and the remaining stage is used as a backup, which can realize 24-hour continuous operation, raw milk is continuously fed in, and concentrated milk is continuously discharged. Concentrated milk can be collected directly after passing through the unit, without the need to return to the raw milk tank for batch cycle operation; at the same time, the drawing liquid is also fed continuously, and the diluted drawing liquid is continuously discharged from the unit and collected directly in the drawing liquid collection tank The diluted draw solution in the draw solution collection tank is regenerated and reused through the diluted draw solution regeneration unit, and the diluted draw solution regeneration unit adopts homogeneous ion exchange membrane technology, which can concentrate the diluted draw solution Reg...

Embodiment 2

[0095] Select raw milk 20L, protein content 3.04g / 100g, total solids content 12.4g / 100g; choose sodium chloride as the draw solution, volume 10L, the concentration of sodium chloride in the first-level concentrated draw solution is 5%, and the second-level concentrated draw solution The sodium concentration is 7%, and the sodium chloride concentration of the three-stage concentrated draw solution is 8.2%. After three-stage concentration using the system and method of Example 1, the protein content of the concentrated milk is 15.2g / 100g, and the total solid content is 61.6g / 100g.

[0096] The operating parameters are as follows:

[0097]

[0098] The composition testing data is as follows:

[0099]

Embodiment 3

[0101] Select raw milk 20L, protein content 3.22g / 100g, total solids content 12.3g / 100g; choose calcium chloride as the draw solution, volume 10L, the calcium chloride concentration of the first-level concentrated draw solution is 5%, and the second-level concentrated draw solution The calcium concentration is 6.5%, and the calcium chloride concentration of the three-stage concentrated draw solution is 7.7%. After three-stage concentration using the system and method of Example 1, the protein content of the concentrated milk is 15.4g / 100g, and the total solid content is 60.8g / 100g.

[0102] The operating parameters are as follows:

[0103]

[0104] The composition testing data is as follows:

[0105]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com