Low-temperature vacuum thickener

A low-temperature vacuum, concentrator technology, applied in evaporation, chemical instruments and methods, separation methods, etc., can solve the problems of large loss of aroma and high energy consumption, and achieve the effects of improving quality, reducing concentration costs, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

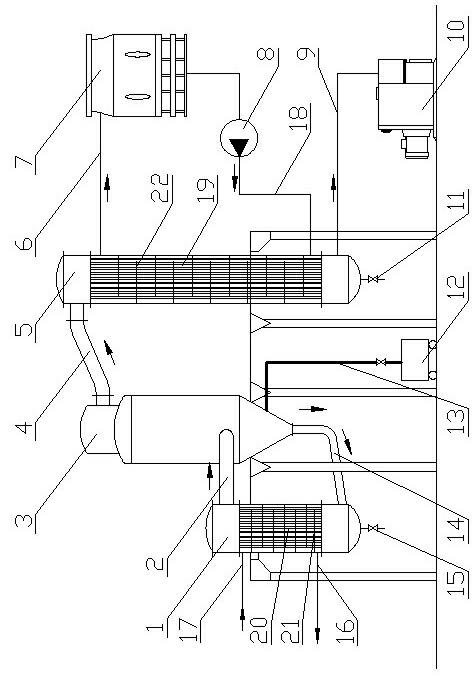

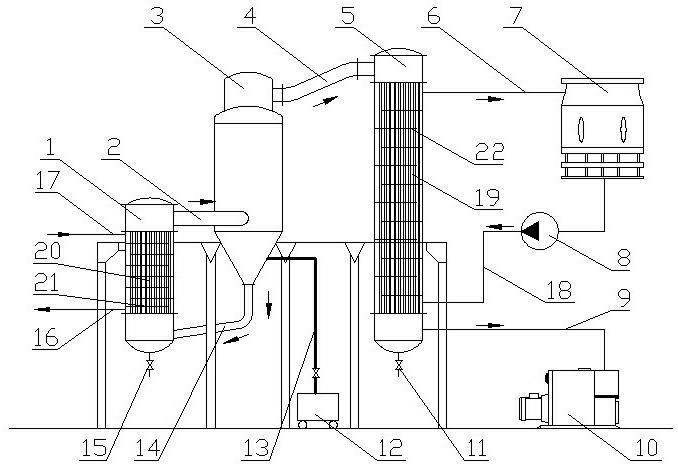

[0012] Such as figure 1 As shown, the present invention is mainly made up of heating tank 1, evaporation tank 3 and condensation tank 5.

[0013] The upper and lower parts of the heating tank 1 are respectively provided with a discharge port and a feeding port, and the lower end of the heating tank 1 is connected with a concentrated liquid discharge valve 15 .

[0014] Steam heat exchange tubes 20 are arranged in the heating tank 1, and a plurality of deflectors 21 are arranged between the heat exchange tubes. The two ends of the steam heat exchange tubes 20 are respectively provided with a hot steam inlet 17 and a condensed water discharge port 16. The inlet 17 and the condensed water discharge port 16 are respectively arranged on the side wall of the heating tank 1 .

[0015] A steam outlet is provided on the top of the evaporation tank 3 , and a feed port is provided in the middle of the evaporation tank 3 , and a feed pipe 2 is connected between the feed port of the evapo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com