Patents

Literature

750results about How to "Keep the scent" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-harm type cigarette capable of reducing cigarette harm and manufacture method thereof

ActiveCN101322579AStay in Style and FragranceComfortable aftertasteTobacco preparationTobacco treatmentTarFlavor

The invention discloses a low-hazard cigarette which can reduce the harm of the cigarette and a preparation method thereof, and the technical problem needs to be solved is to reduce the harm of the cigarette to the human health. The low-hazard cigarette of the invention adds additives in the cut tobacco of the cigarette, the additives are egg flower and coral grass extracts, the weight ratio of the egg flower and the coral grass is 8:2, the prepration method comprises that: the egg flower and the coral grass extracts are extracted, extract liquid is prepared and evenly sprayed on the ordinary cut tobacco, and the cigarette is prepared by adopting the conventional cigarette technology. Compared with the prior art, the egg flower and the coral grass extracts are added in the cut tobacco, the effective ingredients in the egg flower and the coral grass are absorbed in the human body along with the volatilization of the mainstream smoke, thereby maintaining the original style and the flavor of the cigarette, being capable of inhibiting the cancer-causing mutation of the cigarette tar to the human body and timely preventing and mitigating the smoking-induced cough, the shortness of breath, the sputum stasis and other various adverse reactions.

Owner:SHENZHEN DABAIHUI TECH

Processing process for anhua black raw tea

InactiveCN102972541ASoup color orange redSoup color orange red translucentPre-extraction tea treatmentCooking & bakingBlack tea

The invention relates to a processing process for anhua black raw tea, and in particular relates to the processing process for the anhua black raw tea. The processing process comprises the following steps of: picking fresh leaves, removing water, primarily rubbing, piling, secondarily rubbing, drying, naturally storing and pre-pressing. According to the processing process provided by the invention, the material selecting is particular, and all black tea raw materials adopt the raw materials in the producing area of liudong tea in jiangnan town; in the process of removing water, the firewood is used as fuel, so that air pollution caused by using coal as fuel is avoided and the tea is prevented from absorbing peculiar smell of sulfur dioxide released by coal combustion, and the original flavor of the tea is greatly ensured. The tea can be kept black and oily through the baking of pine firewood, and the tea color is orange red and bright. After being baked, the tea is naturally stored for over one year before being pressed, fermented in an oxidative manner, and primarily processed; no crushing process is needed before the pressing process; as space inside the tea is bigger due to raw tea-leaf pressing, oxygen needed for microbial activities is provided, and so golden flowers can be seen inside the black tea finished product.

Owner:湖南三十九铺茶业有限公司 +1

Quick roasting method of fresh grosvenor momordica

ActiveCN102100394AGuaranteed circulationExtend the baking timeFood preservationPharmaceutical product form changeTime rangeMicrowave oven

The invention discloses a quick roasting method of a fresh grosvenor momordica, which comprises the following steps: (1) classifying the ripe grosvenor momordica according to large, middle and small specifications and respectively placing into a special roasting tray used for a microwave oven; (2) placing the roasting tray filled with the grosvenor momordica into an intelligent microwave vacuum drying oven; and (3) determining the roasting time according to the weight of the grosvenor momordica and the power of the microwave oven and roasting, wherein the roasting temperature range is 20-40 DEG C, and the roasting time range is 30-150 minutes under the condition of vacuum degree less than -0.08MPa. In the method, the microwave technology for roasting is utilized, the roasting process is carried out at low temperature and constant temperature, the time consumption is short, the cost is low, and the fresh grosvenor momordica well keeps the bright yellow color and nutrition constituents and has good taste.

Owner:桂林普兰德生物科技有限公司

Method for preparing high-temperature resistant essence microcapsules

InactiveCN101708451AReduce lossesIncrease resistanceFood shapingMicroballoon preparationChemistryFirming agent

The invention discloses a method for preparing high-temperature resistant essence microcapsules, which comprises the following steps: preparing aqueous solution of gelatin and aqueous solution of Arabic gum by gelatin and Arabic gum respectively, then adding oil-soluble essence into the aqueous solution of Arabic gum and performing homogenization and emulsification on the solution, and uniformly mixing the emulsified solution and the aqueous solution of gelatin to obtain emulsified liquid; adjusting the pH of the emulsified liquid to 4.15-4.17 by using edible acetic acid; dissolving a curing agent glutamine transaminase in water, and then mixing solution of the curing agent and the emulsified liquid to perform curing; filtering the cured emulsified liquid, discarding the supernate, and collecting the sediment; dissolving a wall material obtained by mixing Arabic gum, malt dextrin, glucose and isolated soy protein in the water, then adding the collected sediment into the solution of wall material to be uniformly mixed, and preparing the mixture into the high-temperature resistant essence microcapsules by adopting a spray drying method. The method prepares the oil-soluble essence into the microcapsules so as to keep the primary fragrance of the essence and ensure the using effect in high-temperature processing.

Owner:SHAANXI UNIV OF SCI & TECH

Technology for preparing broth powder by cooking and enzymatic hydrolysis

The invention discloses a technology for preparing broth powder by cooking and enzymatic hydrolysis, which comprises the steps of carrying out the working procedures of cooking, ultrafine smashing, enzymatic hydrolysis, Maillard reaction, micro-encapsulation, spray drying and the like on small pieces of bones and meat of plain chicken which removes the head, the paws and the internal organs and seasonings of vegetable oil, onion, ginger, garlic and the like, thereby preparing the broth powder. The cooking technology is applied for enhancing the flavor and the taste of the broth powder, thereby increasing the mellow, thick and fragrant base flavor of the broth powder; the superfine smashing is carried out on the materials, thereby increasing the enzymatic hydrolysis efficiency, increasing the content of small molecular peptides and calcium and leading the nutrition thereof to be more conductive to human body absorption; a composite enzyme preparation is added for carrying out the enzymatic hydrolysis, thereby effectively degrading meat proteins into the small molecular peptides and amino acids; and the microencapsulation is conductive to retaining the flavor of the broth powder for a long time, being easy to dissolve and extending the guarantee period. The broth powder prepared by the technology is characterized by meat flavor, mellow and thick base flavor and abundant amino acids, small molecular peptides and other nutrients, thereby being an essential cooking raw material for the hospitality industry and also an essential seasoning for home cooking.

Owner:河南省南街村(集团)有限公司

Preparation method of instant flavor-conditioning fish dried bean curd stored at room temperature

The invention provides a preparation method of instant flavor-conditioning fish dried bean curd stored at room temperature, which belongs to the technical field of instant fish products. The instant fish dried bean curd is prepared from the following raw materials in percentage by weight: 30%-40% of frozen fish meat paste, 8%-10% of starch, 8%-9% of soybean protein isolate, 6%-7% of soybean oil, 0.5%-1.0% of egg white powder, 1%-3% of table salt, 0.2%-0.3% of glucose, 0.1%-0.3% of TG enzyme and the balance of pure water. The preparation method comprises the following steps of: adding the table salt into the frozen fish meat paste which is in a half-thawed state, and kneading for 10-20 minutes; then, adding the soybean protein isolate, the soybean oil and the egg white powder, and stirring uniformly; further, adding the TG enzyme, the glucose, the starch and the water, and chopping and stirring until the mixture is in a uniform exquisite pastry shape; and performing molding, streaming, vacuum frying, marinating, vacuum packaging and sterilizing on the materials, and cooling so as to obtain the instant flavor-conditioning fish dried bean curd. The fish dried bean curd can be eaten instantly after being unpacked, the shelf life of the fish dried bean curd stored at room temperature reaches 9 months, and as a healthy instant conditioning food, the fish dried bean curd is good in elasticity and toughness, fresh in taste, rich in nutrition and suitable for the young and the old.

Owner:温州市强能食品有限公司 +1

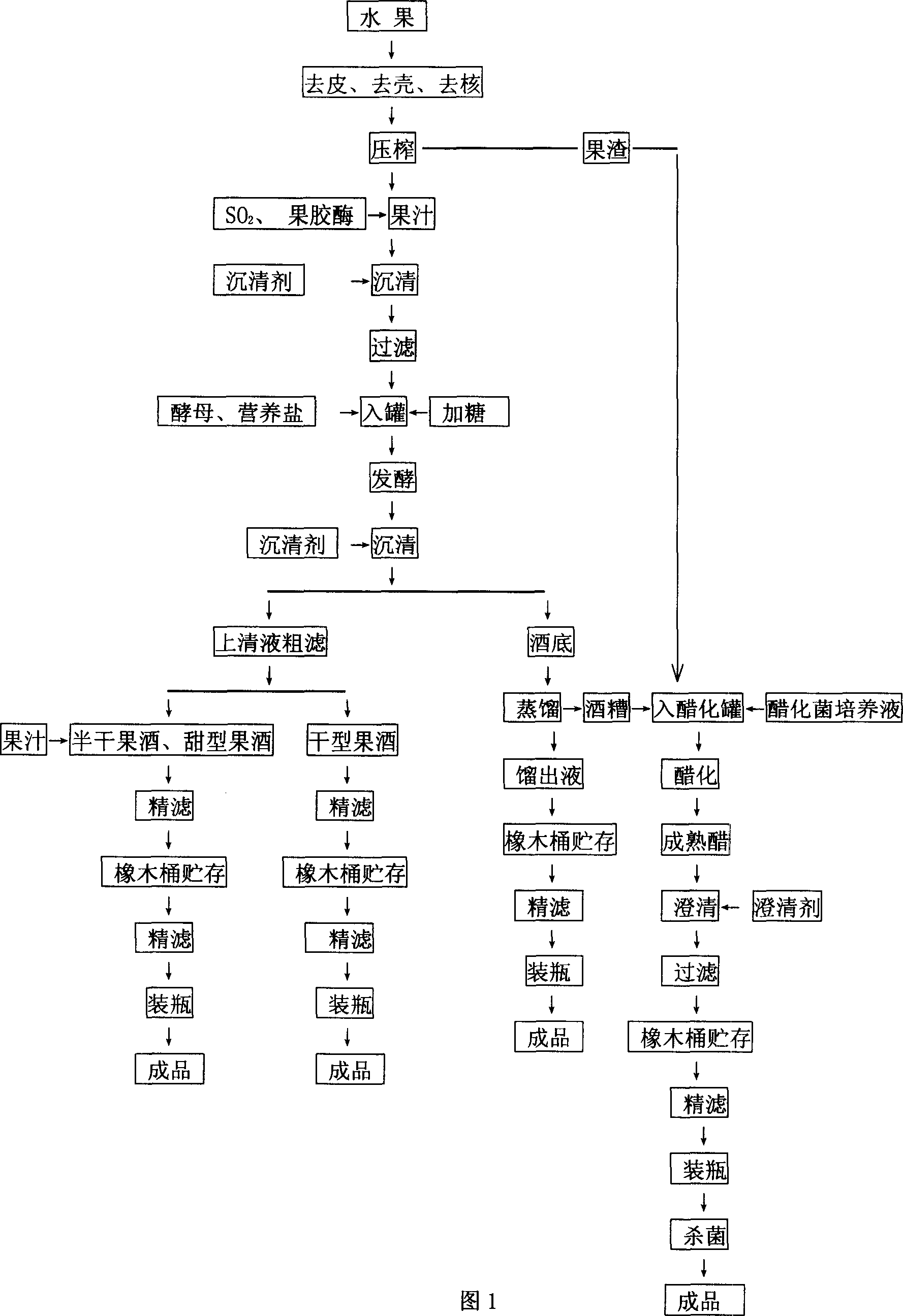

Brewage of fruit wine, vinegar and brandy

InactiveCN1530432AReduce emission lossRealize comprehensive utilizationAlcoholic beverage preparationVinegar preparationFruit wineYeast

A process for brewing fruit wine, fruit vinegar and fruit brandy includes such steps as fermenting fruit juice to obtain dry, semi-dry, or sweet fruit wine, distilling the fermented wine substrate to prepare fruit brandy, and using the distilled dregs and squeezed fruit dregs to prepare fruit vinegar. Its advantages are high utilization rate of fruit, low cost, and less pollution.

Owner:BAIWEIGUO BREWING INDAL XIAMEN CITY

Preparation method of freeze-dried fructus momordicae

ActiveCN102224838AKeep the colorMaintain colorFruit and vegetables preservationFlavorAdditive ingredient

The invention discloses a preparation method of freeze-dried fructus momordicae. The method comprises the following steps: selecting ripe fresh fructus momordicae with deep green surface; deactivating enzymes, cooling with clean water, perforating, pre-freezing and freezing; and drying with the vacuum freeze-drying technology and then discharging to obtain the entire freeze-dried fructus momordicae. Through the method disclosed by the invention, the freeze-dried fructus momordicae maintains the color, flavor, mouthfeel, shape and nutrient components of the fresh fructus momordicae.

Owner:安徽本纪控股有限公司

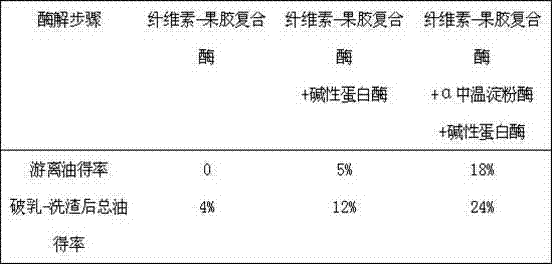

Method for extracting oil from peony seeds or peony seed dregs

ActiveCN103484235AReduce consumptionNo residueFatty-oils/fats productionEdible oils/fatsEmulsionProtein hydrolysates

The invention discloses a method for extracting oil from peony seeds or peony seed dregs. The method comprises the following steps: (1) pretreatment; (2) enzymolysis; (3) centrifuging; (4) demulsification; (5) dreg washing. Free oil, an emulsion layer, protein hydrolysate and dregs are obtained after enzymatic hydrolysate is centrifuged, wherein the free oil is peony seed oil, and a certain amount of oil can also be recovered after the emulsion layer and the dregs are subjected to demulsification and dreg washing respectively. According to the method, the peony seed oil can be extracted without drying raw materials, the operation is simple, the requirement for equipment is low, the oil yield is high, the oil quality is good, solvent residues and environmental pollution are avoided, and the obtained protein hydrolysate and dregs can also be further used comprehensively.

Owner:TONGLING RUIPU PEONY IND DEV +1

Production method of small rice vinegar

InactiveCN101984037AHigh degree of automationKeep the scentMicroorganism based processesVinegar preparationAcetic acidSlurry

The invention belongs to the technical field of edible vinegar, in particular to a production method of small rice vinegar. The invention aims at solving the technical problems of low production efficiency, unstable process conditions, high labor intensity of workers, impacts on quality and taste of the rice vinegar and the like in manual control which is mostly adopted for making the vinegar at present. The production method of the small rice vinegar comprises the following steps: 1) taking small rice, preparing into rice flour, and adding a certain amount of water for preparing into slurry; 2) adding amylase and glucoamylase into the slurry, and preparing into serous fluid; 3) adding brewing yeast and Daqu into the serous fluid for preparing into wine mash; 4) taking a certain proportion of the wine mash, rice hull and wheat bran, placing into a fermentation tank, adding acetic bacteria, preparing into fermented material, further using water to leach acetic acid in the fermentation tank and preparing into vinegar liquor; 5) sterilizing the vinegar liquor, placing the vinegar liquor after sterilization into an aging tank for hermetical aging for at least 90 days, and preparing into mature vinegar; and 6) filtering the mature vinegar, carrying out instantaneous sterilization at 125-135 DEG C for 4-6s, and preparing into the small rice vinegar. The production method of the small rice vinegar adopts the automatic mechanical vinegar making way, has high production efficiency and stable process conditions, and can reduce the labor intensity of the workers and meet the market demand.

Owner:SHANXI SANSHENGHE BREWING

Extract liquor of camellia chrysantha

InactiveCN1476767AProtect aroma substancesKeep the scentTea alkaloid content reductionAlcoholCamellia chrysantha

The present invention discloses an extract of camellia chrysantha. It adopts the combination of alcohol extraction and water extraction, and adopts the ultrasonic oscillation process to raise extraction efficiency, its all the processes adopts low-temp. condition below 60 deg.C so as to effectively protect various components with health care function and aromatic substance in the camellia chrysantha. Its extraction rate is up to above 90%.

Owner:GUANGXI FUXIN SCI & TECH

Tea coffee solid beverage and preparation method thereof

InactiveCN103202362AStrong fragranceGood rehydrationPre-extraction tea treatmentRoasted coffee treatmentCoffeaNutrition

The invention relates to a solid beverage, and in particular relates to a tea coffee solid beverage and a preparation method thereof. The tea coffee solid beverage comprises the following materials according to mass ratio: 80-120 parts of Vietnam medium coffee beans, 60-80 parts of Yunnan small coffee beans, 140-160 parts of Dianhong Kungfu tea, 55-65 parts of vegetable fat powder and 46-50 parts of white sugar. The preparation method comprises the following steps of: A. mixing; B. baking; C. crushing; D. extracting; E. concentrating; F. homogenizing; G. sterilizing; H. cooling and drying; and I. packaging. The mixing ratio of the Vietnam medium coffee beans to the Yunnan small coffee beans is proper, the tea coffee solid beverage is high in content of caffeine, fragrant, pure and mild in flavor and high in content of effective nutritional ingredients after the working procedures of baking, crushing, extracting and concentrating. The extraction of distilled water of coffee mixed powder and red tea powder is proper in temperature and moderate in time. The finished product can be good in reconstitution property without residues, and the color, the fragrance, the taste and the nutritional ingredients of coffee and red tea can be well maintained.

Owner:普洱漫崖咖啡实业有限公司

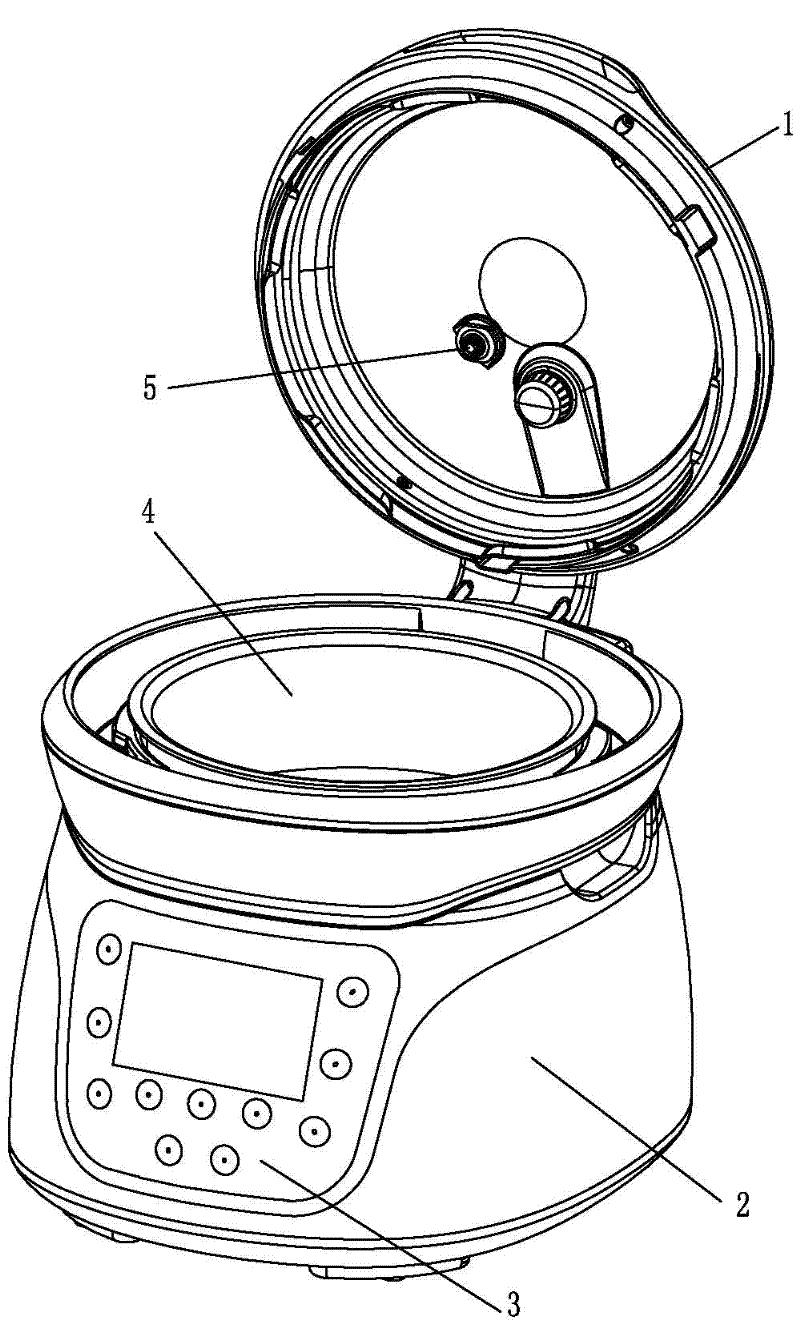

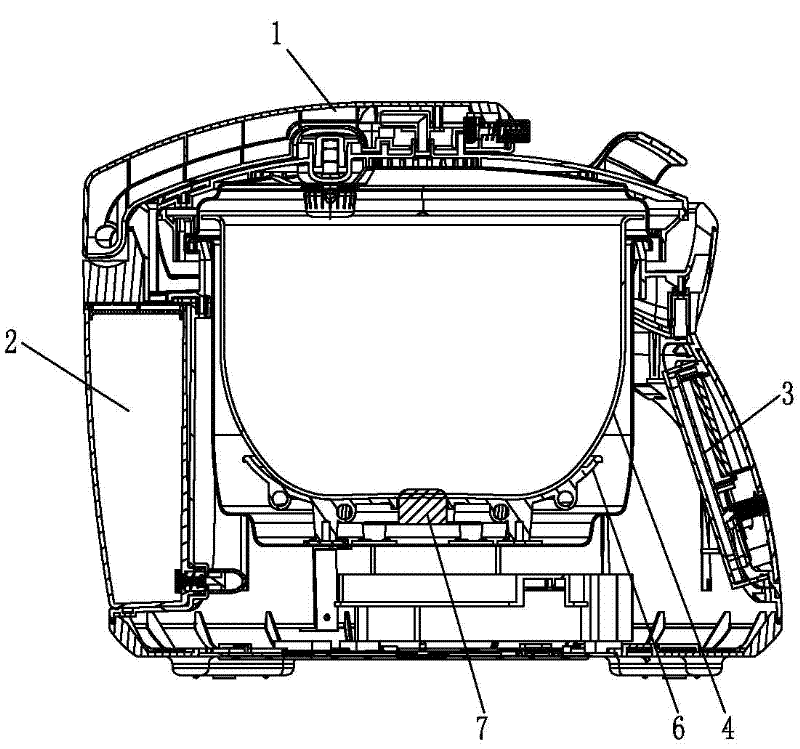

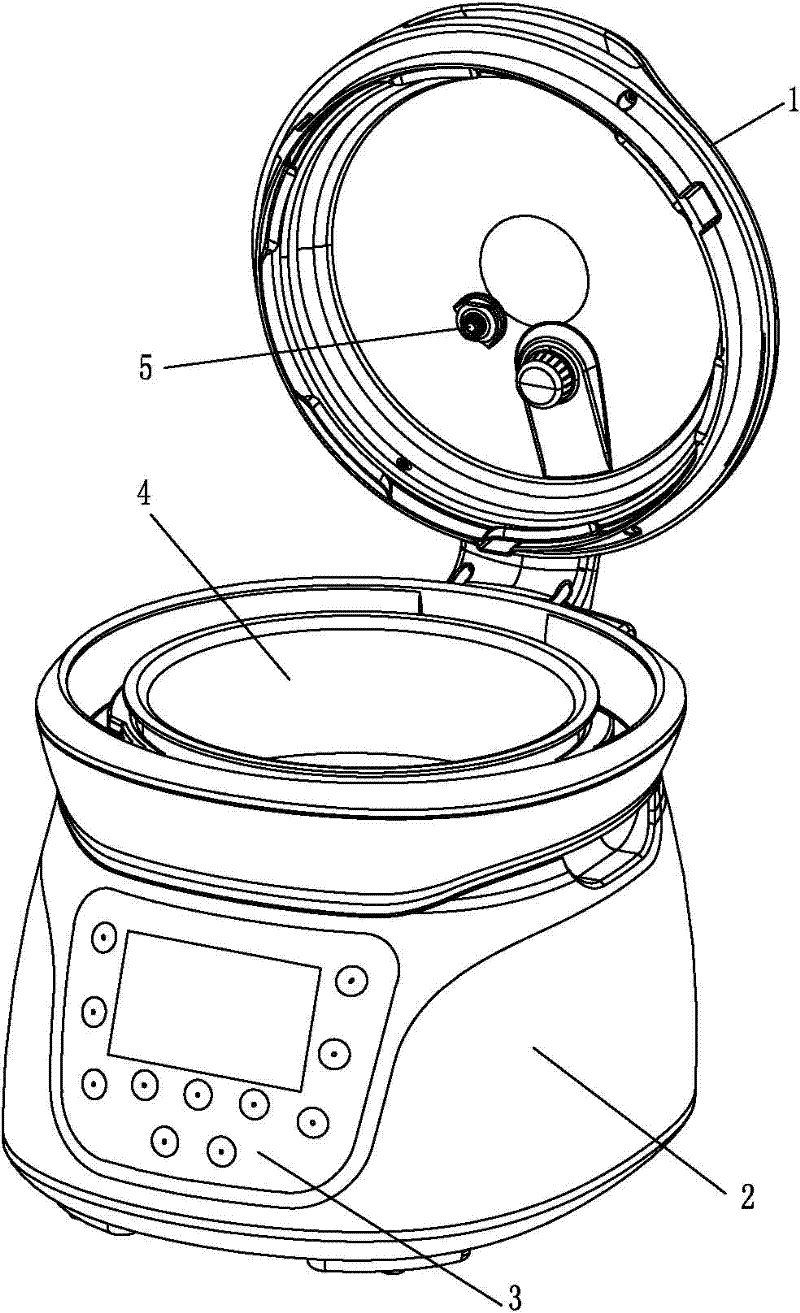

An electric pressure cooker for finely cooking rice and its control method

ActiveCN102293584AAvoid overcookedGreat tasteAuxillary controllers with auxillary heating devicesPressure-cookersThermodynamicsRice dishes

The invention discloses an electric pressure cooker for finely cooking rice and a control method thereof. The electric pressure cooker for finely cooking rice comprises a cover body, a cooker body, an inner tank, a heating disk, and a control device for controlling the heating disk to heat or stop heating; the control device comprises a soft fire heating process module, a low-temperature water-absorption process module, a medium-temperature water-absorption process module, a big fire heating process module, a sufficient boiling process module and a rick-stewing process module. The control method for finely cooking rice comprises a preparation process, a soft fire heating process, a medium-temperature water-absorption process, a big fire heating process, a sufficient boiling process and a rice-stewing process. In different heating process stages, different control temperatures and heating time are adopted according to the rice characteristics so that each grain of rice can sufficiently absorb water from outside to inside to guarantee the edible quality of the rice grains such as grain form, color, taste, flavor and the like; since the adopted heating manner mainly is an intermittent heating form, the finely cooked rice has better edible quality and contains more nutrient components.

Owner:GUANGDONG LUBY ELECTRONICS

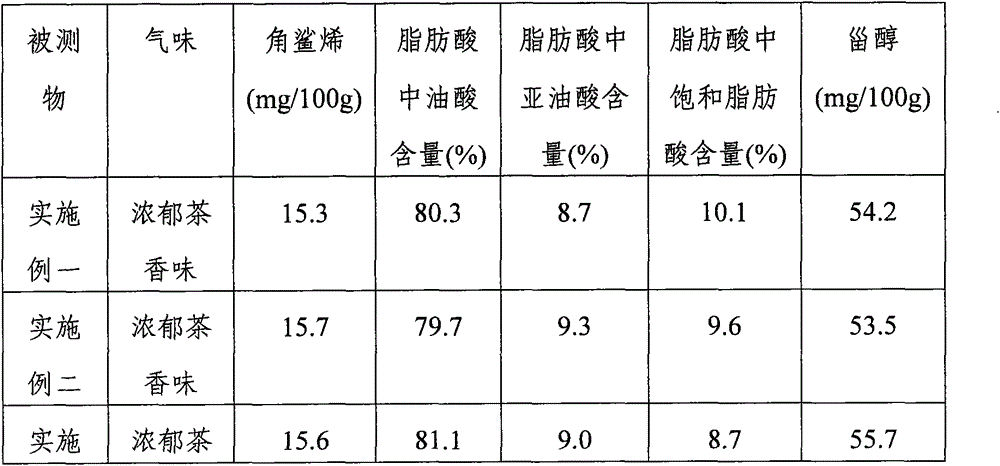

Strong-flavor camellia oil cold-pressing process

InactiveCN105886107AImprove oil yieldImprove qualityFatty-oils/fats refiningFatty-oils/fats productionActive carbonFlavor

The invention discloses a strong-flavor camellia oil cold-pressing process and belongs to the technical field of vegetable oil. Camellia seeds are sorted, then are dried and spread for cooling and are packaged for standby application, then shelling is performed to adjust a certain shell-kernel ratio, then steaming and frying are performed, repeated squeezing is performed by using a double-helix low-temperature oil press, the obtained raw camellia oil is subjected to hydrated degumming, then decoloring is performed with active carbon, and deodorization is performed by using a distillation device, namely a camellia oil finished product is obtained. The oil yield of camellia seeds is improved by evenly controlling the moisture content of the camellia seeds. In addition, the strong-flavor camellia oil cold-pressing process is simple, the production costs are low, the operating process is easy to control, and the nutritional value of produced camellia oil is high.

Owner:GUIZHOU LIPING QIANXIANGYUAN GREASE CO LTD

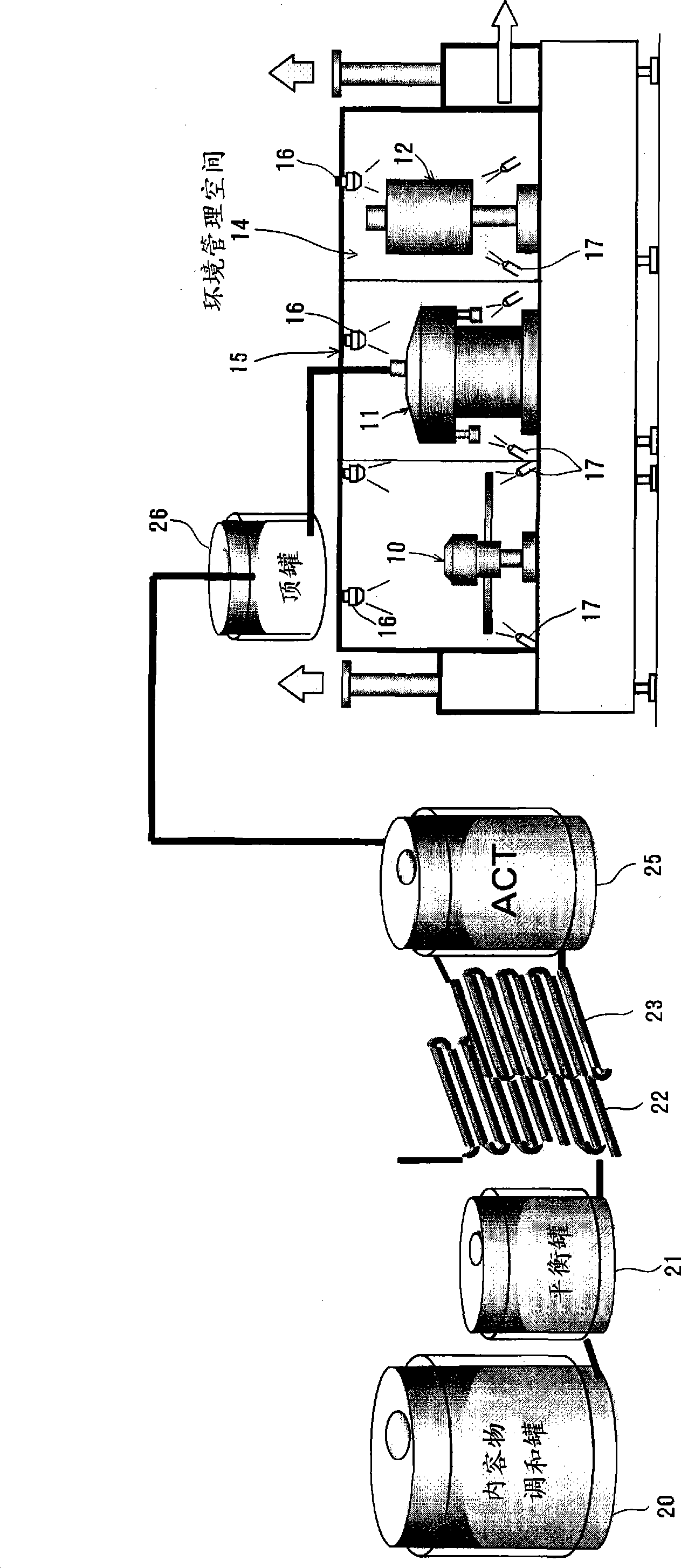

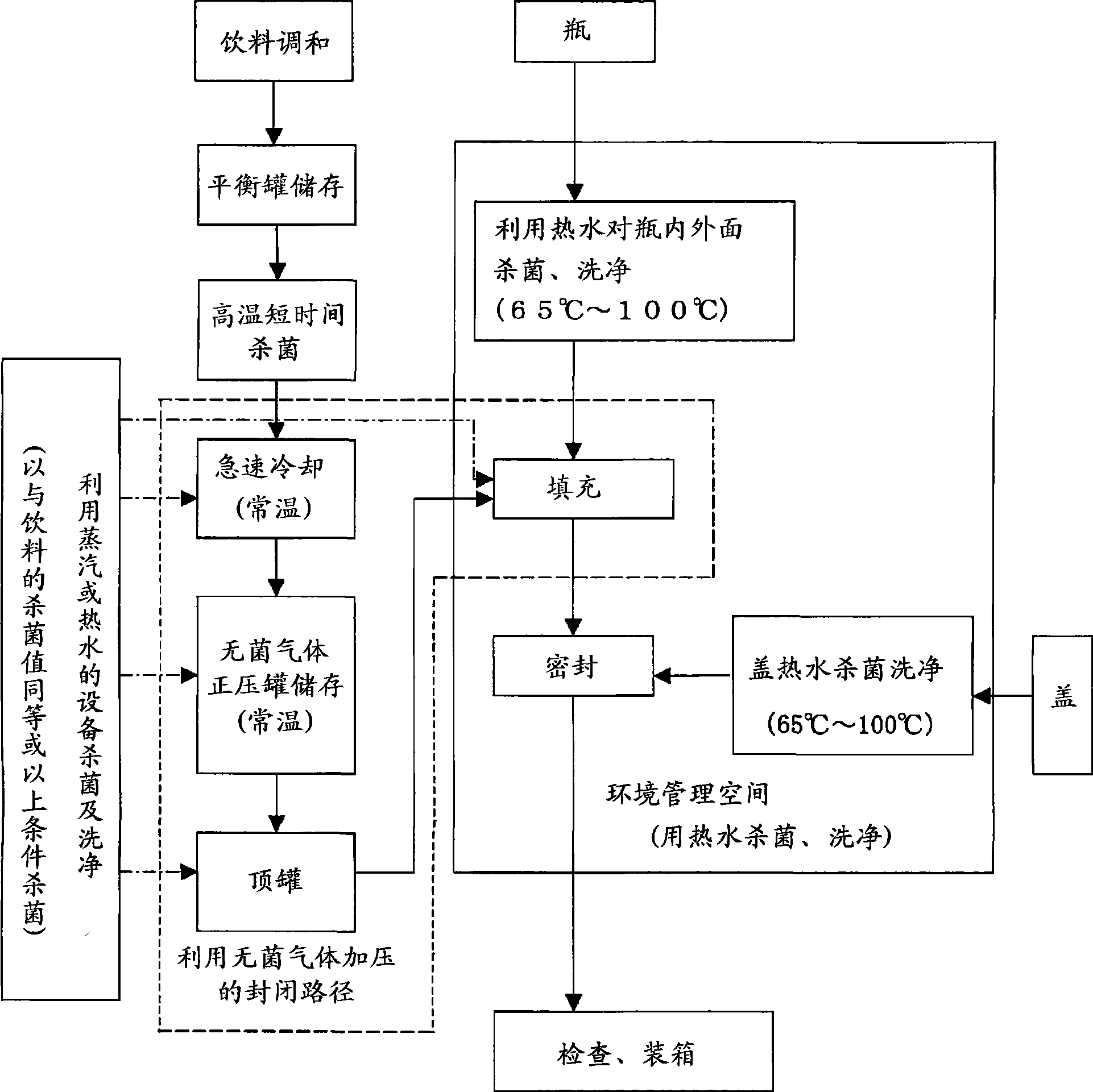

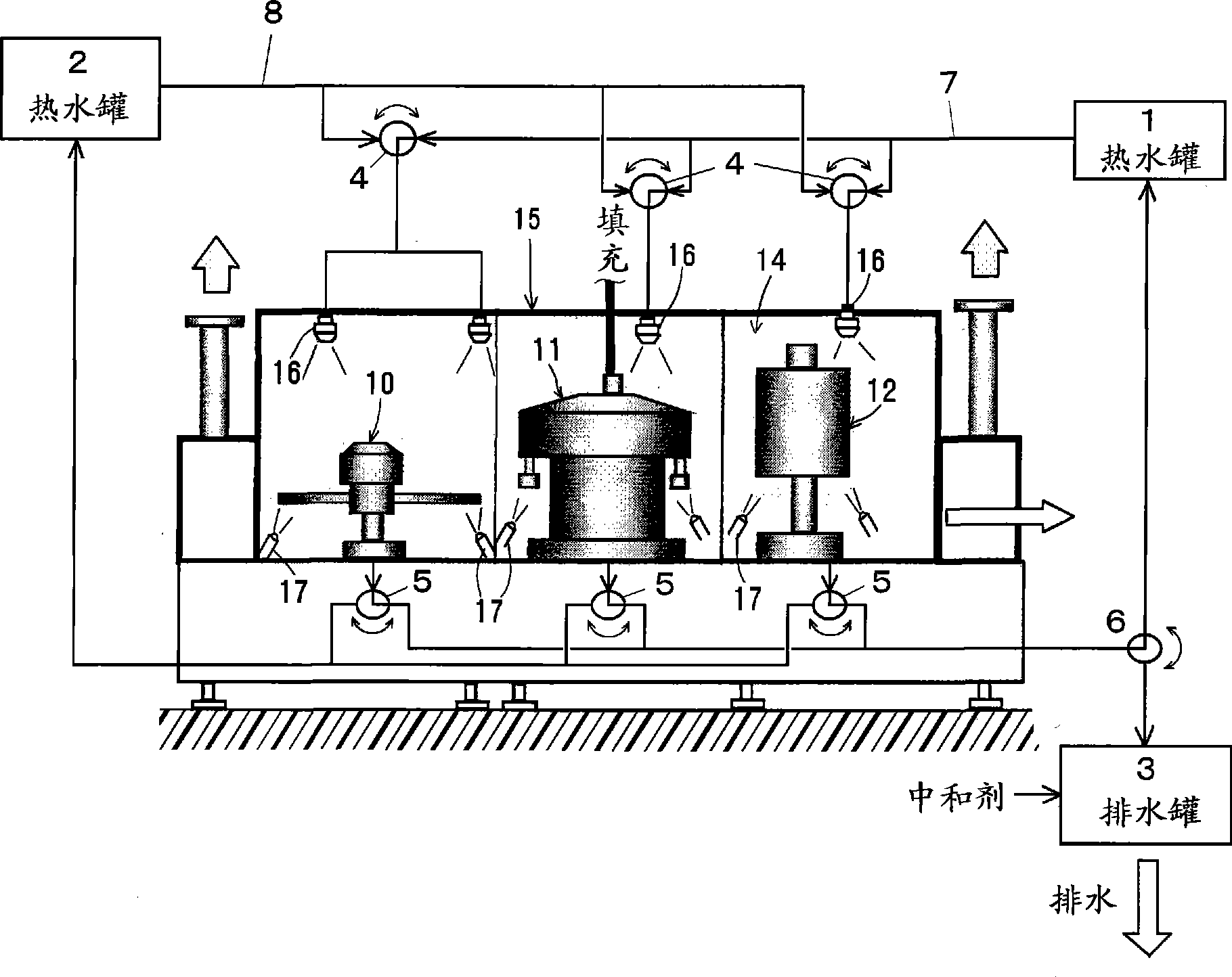

Method for manufacturing beverage filled in container

InactiveCN101489910ALow costReduce operating costsPackage sterilisationBottle-handling machinesOperational costsPositive pressure

It is intended to provide a process for producing a packaged drink whereby filling can be performed at room temperature without resorting to using a chemical or sterile water, the favorable taste and flavor of the content can be maintained while relieving the thermal degradation thereof, it becomes unnecessary to employ a heat-resistant container or to thermally sterilize or cool after sealing, and thus both of the equipment cost and the running cost can be largely reduced. After thermally sterilizing the content to give a definite sterilization value, it is quickly cooled to room temperature and then stored in a storage tank that has been preliminarily sterilized under such conditions as being equal to or exceeding the thermal sterilization conditions for the contents. While maintaining the storage tank under positive pressure with the use of a sterile gas, the content is fed into a filling machine that has been preliminarily sterilized under such conditions as being equal to or exceeding the thermal sterilization conditions for the contents. Thus, the liquid-feeding system ranging from the storage tank to the filling machine is made a closed liquid-feeding pathway free from the invasion of air from the outside. The drink is filled into a container having been sterilized with hot water in an environment-controlled space isolated from the outside wherein the surroundings have been thermally sterilized and washed with hot water at 65 DEG C to 100 DEG C.

Owner:TOYO SEIKAN KAISHA LTD

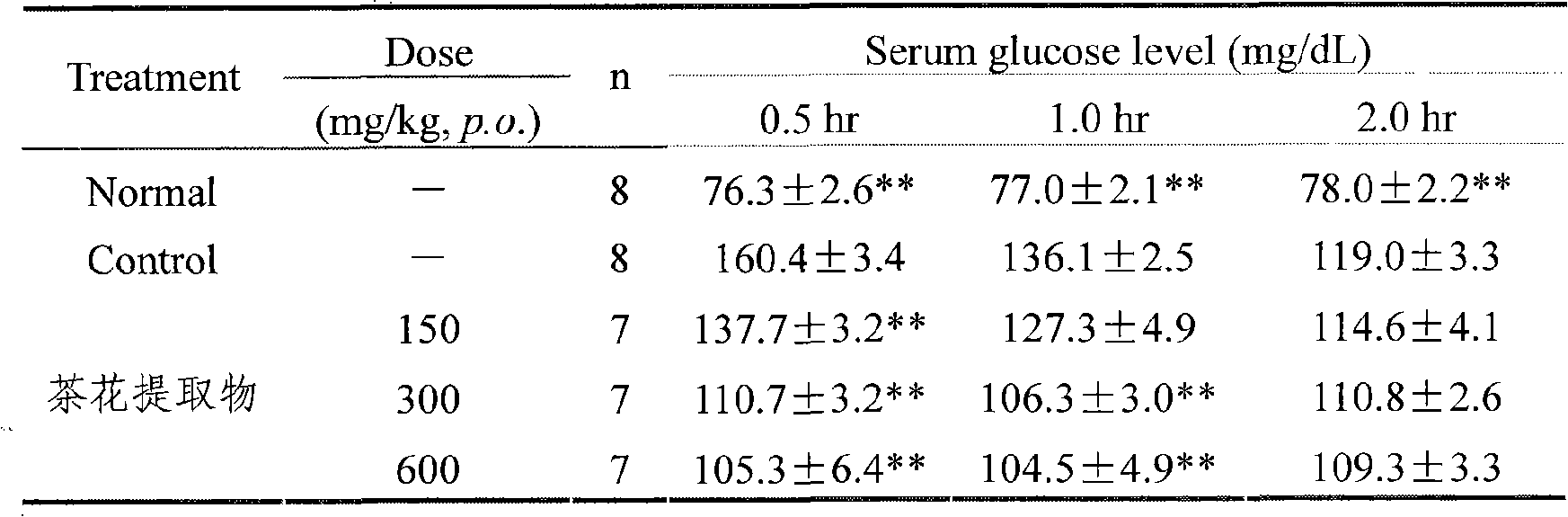

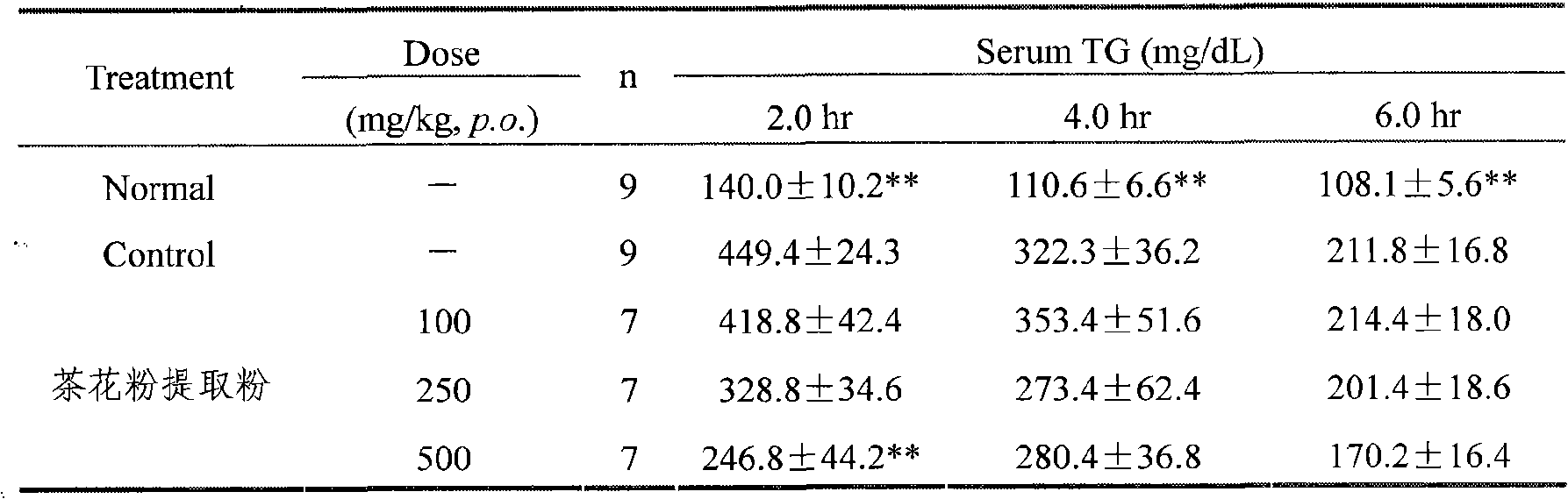

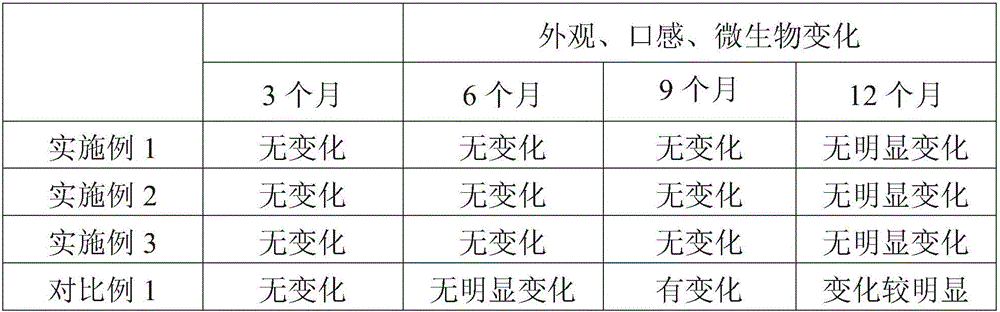

Camellia functional instant tea powder and preparation thereof

This invention belongs to the field of food technique, which relates to a functional instant tea flower powder and preparation thereof. This invention employs the tea flower as raw material and obtains the tea flower extracting solution by hot water infusion method; the tea flower extracting solution is manufactured to a tea flower concentrated solution by ultrafiltering, reverse osmosis concentrating, vacuum concentrating, sterilizing and aseptic packaging. The instant tea powder is produced by the method for spray drying or freeze drying. The functional instant tea flower powder prepared bythis invention is diffluent in cold water, the tea solution is transparent and the tea flavor is still primary taste. The tea flower powder not only is almost same as the tea infused directly by boiled water in smell, color and flavor, but also has high solubility and transparency. The processing of this invention has the advantages of high extracting efficiency, short extracting time and strong selectivity. The tea flower powder not only keeps the primary smell of tea flower and nutrition, but also has the effect of reducing blood sugar and triglyceride, is a new functional tea powder drink.

Owner:SHENYANG PHARMA UNIVERSITY

Method for preparing colorful nutrition fragrant rice

The invention discloses a preparation method of colorful nutritious scented rice. The colorful extractant that is extracted from medicine-food natural plants by the invention as is taken as raw materials; water or ethanol solution with the concentration between 1 to 45 percent are adopted as solvent which is added on the surface of the rice; after one time or two times of film lagging cover technique processing, the colorful nutritious scented rice is formed, which has the qualities of anti-oxidation, anti-bacterial, preservation, seasoning, fragrance enhancing and color increasing.

Owner:余姚市泰夫昌农庄有限公司

Preparation method of purple potato drink

The invention relates to food, in particular to a preparation method of purple potato drink, which is characterized in that: the purple potato drink finished product is finally produced through the steps such as proportioning, amount fixing, filling, sterilizing, cooling and the like. The proportioning step is that: white sugar, fruit-juice stabilizing agent and sodium citrate are dissolved in water after being dry mixed to be heated to 85 DEG C and further to be heat preserved for 10 minutes, then more than 20 times of lemon acid and fruit juice after being dissolved in the water are added to be uniformly blended, purple potato powder which is dissolved in hot water is added to be uniformly blended, and finally essence is added. The purple potato drink produced with the above method has natural fragrance of the purple potato, has no peculiar smell, has good taste and is easy to preserve.

Owner:杭州秀山美地农业科技有限公司

Manufacturing method of freeze-dried fruit slices

The invention belongs to the technical field of food, and particularly relates to a manufacturing method of freeze-dried fruit slices. The manufacturing method comprises the following steps: raw material selection, cleaning, primary freeze-drying, slicing, soaking, secondary freeze-drying and packaging. According to the manufacturing method, the freeze-drying is carried out before slicing, thereby reducing the loss of the fruit juice in the slicing process, and greatly maintaining the nutrients and fruity odor in the fruit. The slicing and other treatment processes are carried out under the condition of weak respiration of fruit tissue cells, so that the enzyme activity is lowered, thereby lowering the influence of the fruit metabolism on the fruit quality in the working process. The freeze-drying is carried out twice, thereby greatly reducing the loss of nutrients and odor, maximally removing the water in the fruit and prolonging the preservation period of the fruit slices.

Owner:四川中兴绿丰农业发展有限公司

Ham processing method

The invention provides a ham processing method, comprising the steps of rapid cooling, extruding for blood removal, washing and white wine spraying, condiment applying and kneading, fumigating and hanging for curing. By the method, the ham is free from elevation and region limitations, has less possibility of being infected by maggots, has more beneficial microorganisms breeding inside and has terrific color, aroma and taste.

Owner:YUNNAN CHUXIONG YISHAN INDAL & TRADING

Pure seabuckthorn fruit crude fruit juice and its processing method

The invention provides a processing method of seabuckthorn original juice, comprising: pulping the seabuckthorn to obtain marc and pulp of seabuckthorn; rough cleaning the pulp of seabuckthorn to form primary pulp of seabuckthorn; thoroughly removing the residual solid impurity and most of fruit oil to obtain raw juice of the seabuckthorn; alloting the raw juice of the seabuckthorn to form seabuckthorn original juice; sterilizing and pouring in, wherein the seabuckthorn is fresh or frozen. The invention also provides a seabuckthorn original juice, wherein the solids content thereof is 10-18%. The juice extraction is high and the operation is convenient. The color of the seabuckthorn original juice is orange yellow without bitterness of tannin. The color, fragrant, taste of the seabuckthorn is fully kept. The seabuckthorn original juice can be used as intensifying nourishment additive of fruit drink or directly as seabuckthorn fruit juice.

Owner:高原圣果沙棘制品有限公司

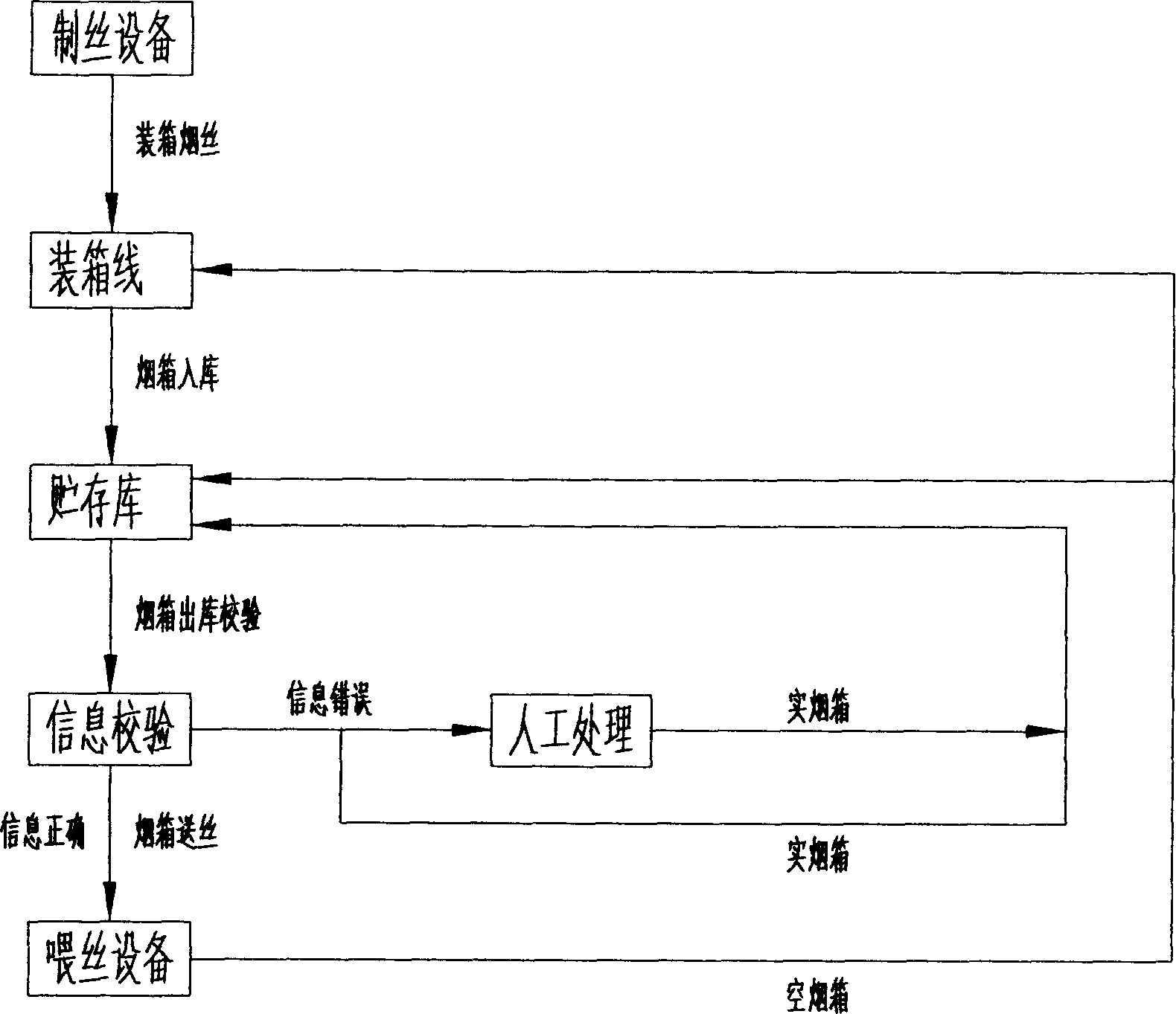

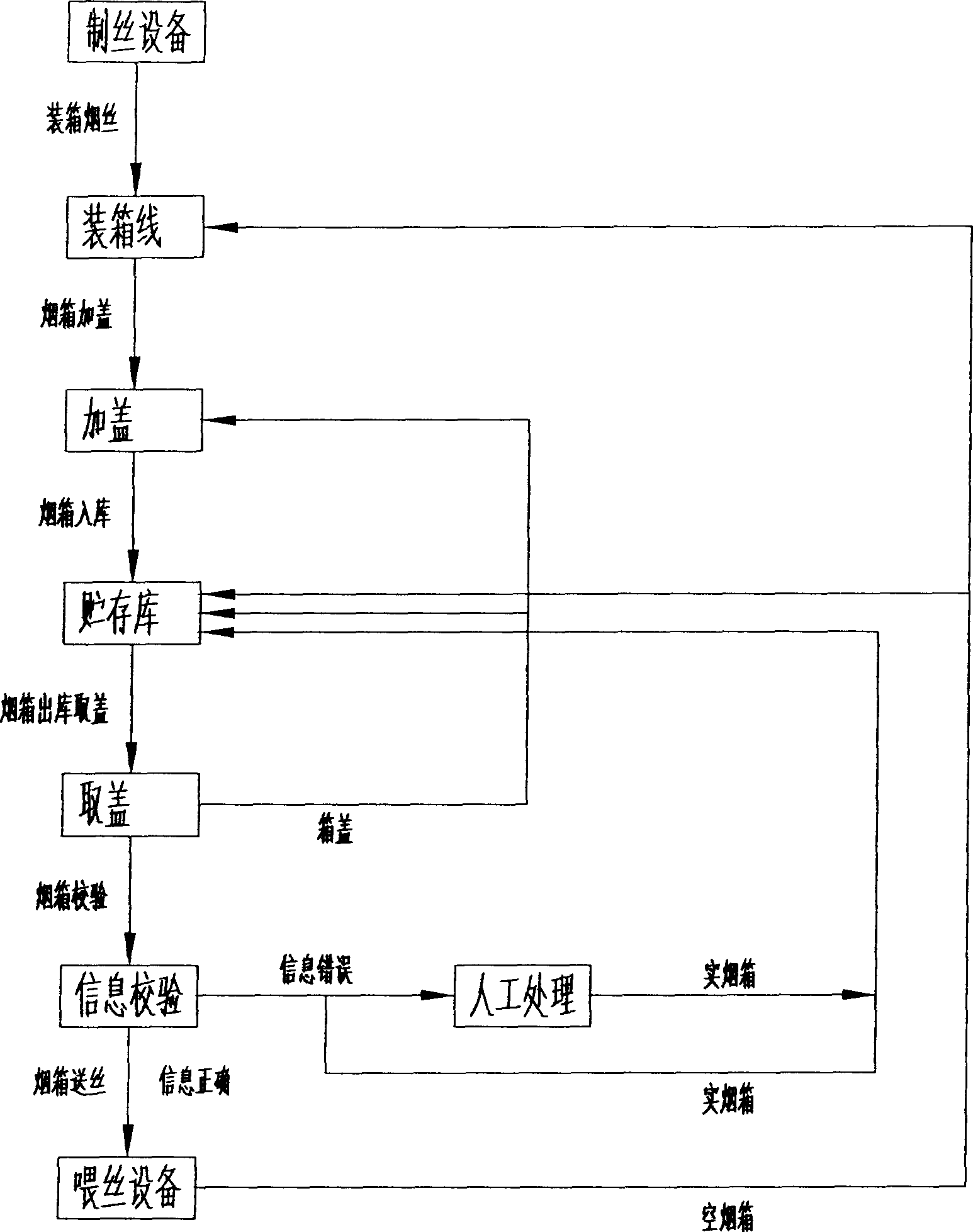

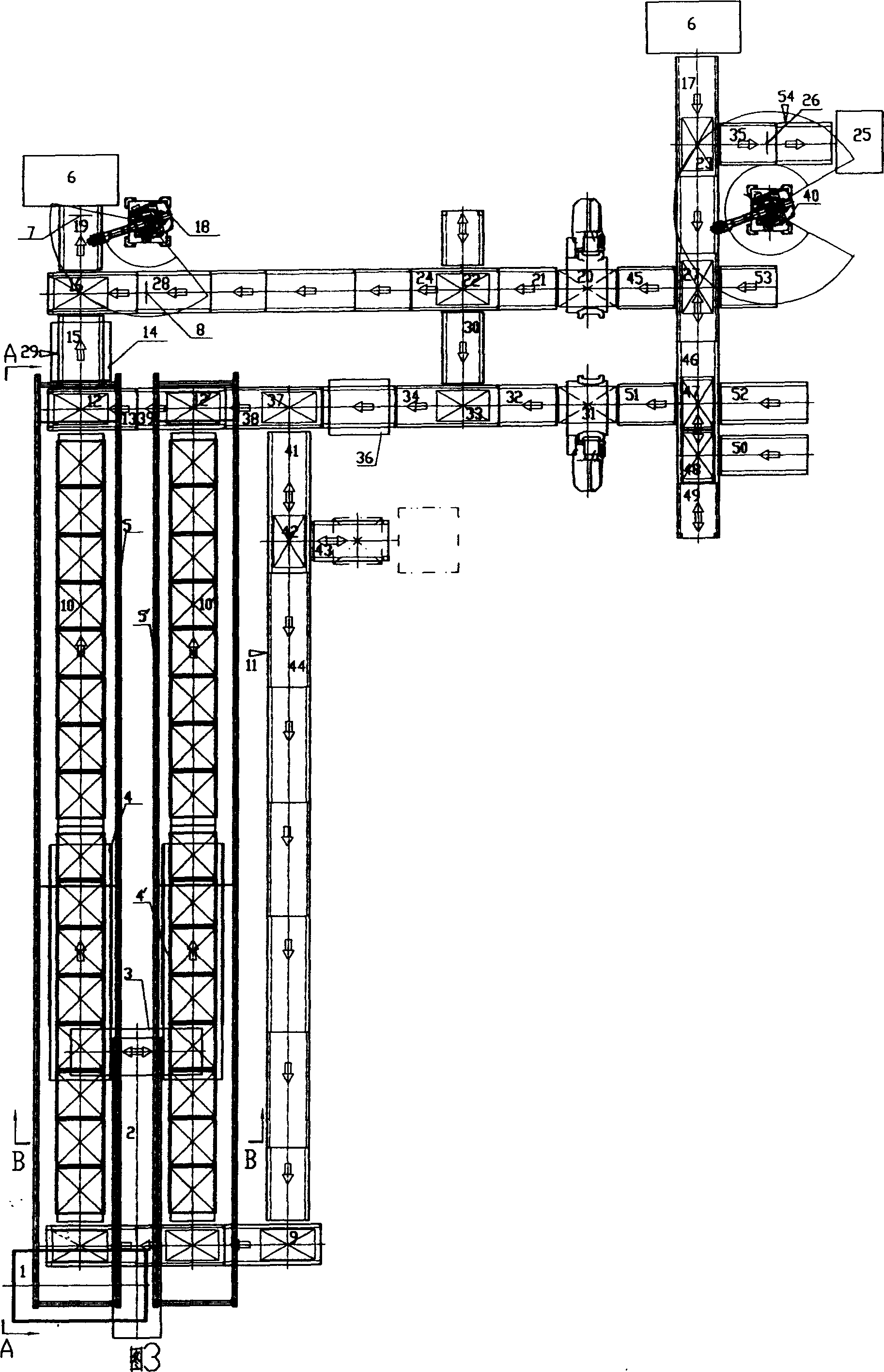

Finished tobacco shred automatic box type storage and transfer technology

Owner:YUNNAN KUNMING SHIPBUILDING DESIGN & RESEARCH INSTITUTE +1

Engineered plastic emitting flavor and its preparation method

The invention discloses an engineering plastic capable of generating fragrant smells as well as process for preparation, wherein the constituents include (by weight ratio) engineering plastic 62-92%, flavoring agents 0.5-20%, toughening agent 6-10%, anti-oxidant 0.1-1%, white oil 0.5-2%, other auxiliary agents 0.1-5%.

Owner:ANHUI KEJU NEW MATERIALS

Body-warming and health-care ginger tea

InactiveCN103385323AKeep the scentHas the function of dispelling heat and preventing coldPre-extraction tea treatmentBlack teaSpleen

The invention provides body-warming and health-care ginger tea. The technical scheme is as follows: the body-warming and health-care ginger tea is characterized by comprising the following components: 15-25 parts of ginger, 6-12 parts of brown sugar, 20-40 parts of jujube flower honey, 5-15 parts of grapefruit peels, 6-12 parts of astragalus membranaceus, 6-12 parts of angelica sinensis, 3-7 parts of donkey-hide gelatin, 6-12 parts of lemon, 3-7 parts of pawpaw and 6-12 parts of black tea. The ginger tea provided by the invention can keep the fragrance of the ginger well and also has health-care functions of driving away summer heat and preventing coldness, dispelling the effects of alcohol, regulating menstruation, tonifying middle-Jiao and Qi, regulating spleen and stomach, beautifying, resisting ageing and the like.

Owner:王振英

Rose beverage and preparation method thereof

InactiveCN102178317AKeep the scentDestruction of nutritional valueFood preparationNutritive valuesFood additive

The invention relates to beverage made of edible flowers, in particular to rose beverage and a preparation method thereof. The invention has the purpose of preparing rose beverage with good taste, excellent smell and abundant nutrition from fresh roses through a series of production technologies, and no food additive is added. The rose beverage is prepared from the roses, white granulated sugar, honey, citric acid, malic acid, sodium citrate, sodium carboxymethylcellulose, potassium sorbate and water. The rose beverage provided by the invention not only preserves the fragrance of the roses, but also can not damage nutritive value of the roses, has a good taste, does not contain essences, preservative or other ingredients, can supplement various trace elements to human bodies after drunk usually, has the efficacy of eliminating toxin and beautifying skin and is applicable for people to drink for long term.

Owner:禹治云

Peony seed oil microcapsule and preparation method of peony seed oil microcapsule

InactiveCN105028706AGood water solubility and stabilityUniform particle sizeEdible oils/fatsEmulsionChemistry

The invention discloses a peony seed oil microcapsule and a preparation method of the peony seed oil microcapsule, and belongs to the technical field of food engineering. The peony seed oil microcapsule comprises a core material phase and a wall material phase. Through being metered by weight parts, the core material phase consists of 10 to 60 parts of peony seed oil and 0.5 to 5 parts of oil soluble emulsifiers; the wall material phase consists of 20 to 75 parts of wall materials, 5 to 50 parts of wall material connecting auxiliary agents, 20 to 150 parts of water, 1 to 8 parts of water-soluble emulsifiers and 0.5 to 5 parts of stabilizers. The pressure emulsification homogenizing is used, so that the particle diameter of an emulsion reaches the nanometer level, so that the particle size of an obtained product is uniform; the reconstitution capacity is good; the solubleness is good; the peony seed oil microcapsule can be dissolved in cold water; no precipitate and no floating object exist in a solution; no floating oil exists after the still standing for 48 hours; the solution can be compounded with other emulsions such as milk; the application range of the peony seed oil is expanded. The peony seed oil microcapsule and the preparation method have the advantages that the process is simple; the production cost is low; the product stability is greatly improved; and the nutrition activity of the peony seed oil is maintained.

Owner:刘进

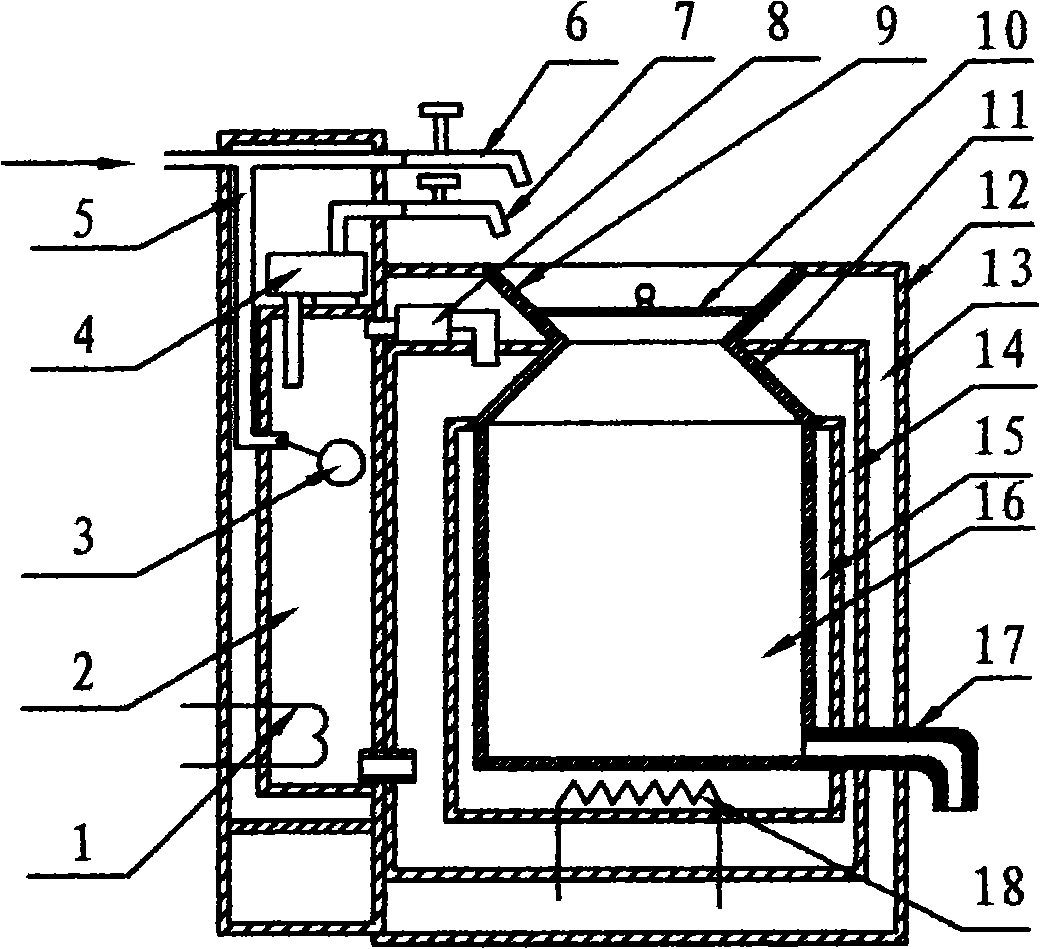

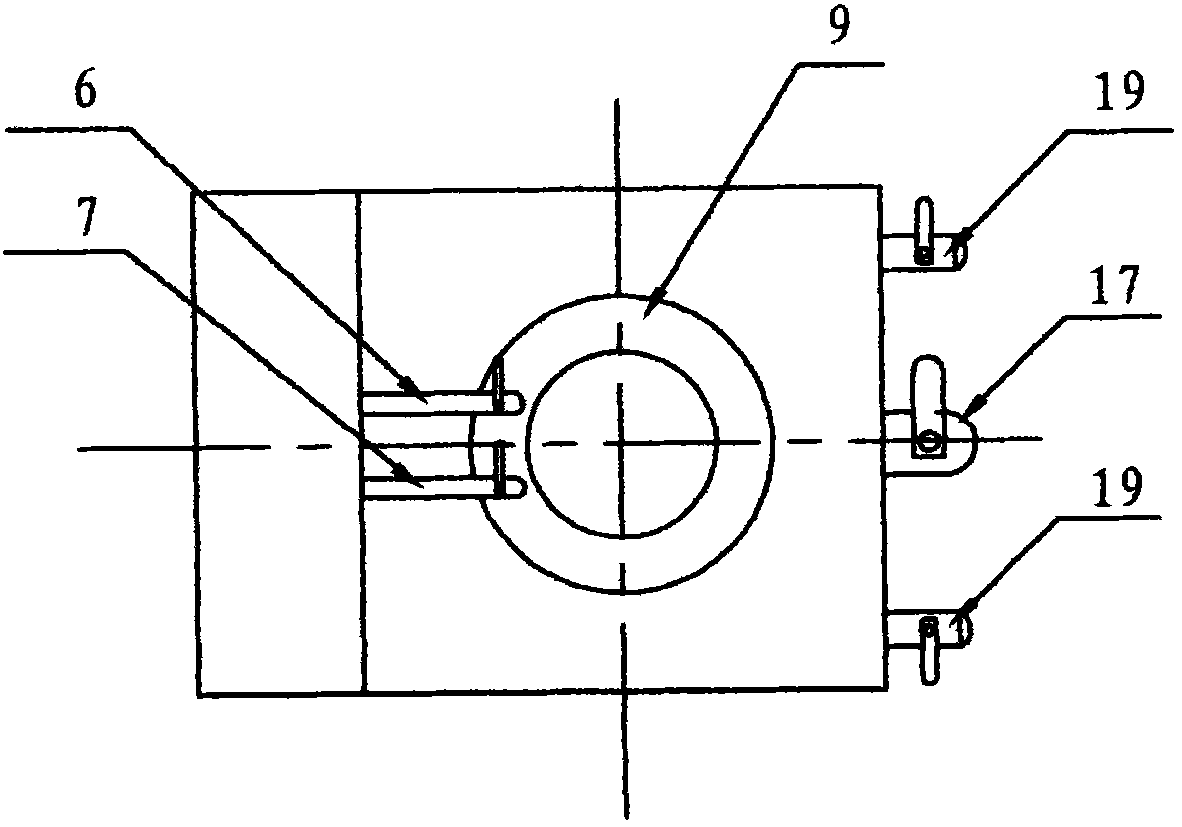

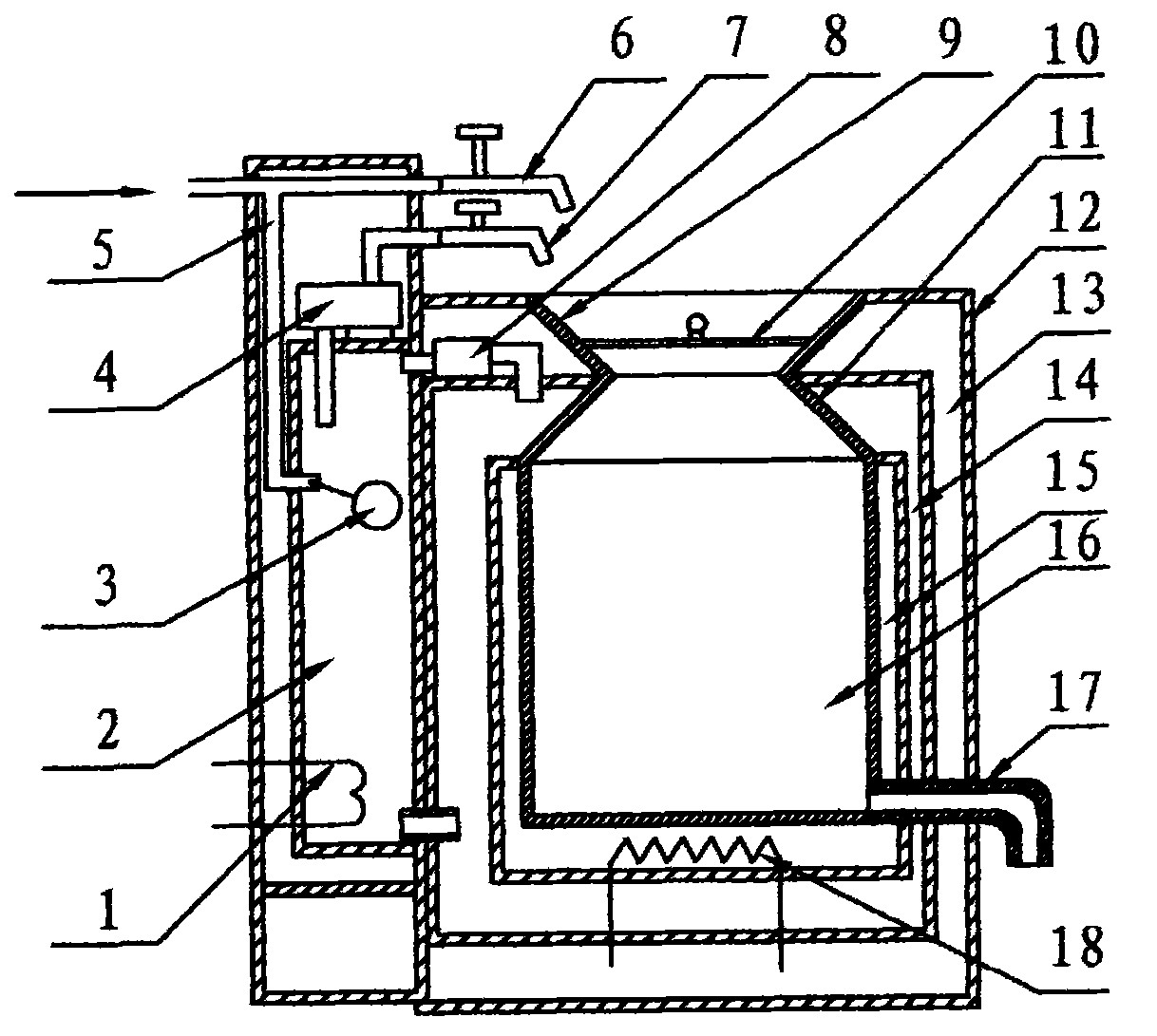

Congee cooking device

InactiveCN101862112AFast heat transferImprove cooking efficiencyStorage heatersCooking vesselsProcess engineeringEngineering

The invention relates to a congee cooking device, which comprises a congee cooking device body, a boiling water tank, a shell panel and a circuit control device. The pot opening of the congee cooking device body adopts a conical opening structure, so that the phenomenon of boiling overflow in the process of boiling the congee is avoided and the full-automatic congee cooking is realized. The congee cooking device body is provided with a heat exchange water sandwich layer which is communicated with the boiling water tank; the heat exchange water and water stored in the boiling water tank perform circular heating after the cooking of food is finished and the power is turned off, and the stored water in the boiling water tank is heated into boiling water by high temperature waste heat of a heat-conducting medium. The congee cooking device solves the problems that in the conventional congee cooking, a sandwich pot is manually operated, the efficiency is low, and the potential safety hazard exists. The congee cooking device fully realizes full-automatic cooking of the food, particularly cooking of congee and other foods, also can cook soup, stew fowl and the like, and has multiple purposes. The congee cooking device realizes congee cooking automation, reduces the operation cost, provides free boiling water by using the waste heat simultaneously, and is low-carbon, energy-saving and environment-friendly.

Owner:蔡钟坤

Cultivation method of ecological native chickens

The present invention discloses a cultivation method of ecological native chickens, and relates to the technical field of livestock and poultry cultivation. The cultivation method comprises the steps of chicken house constriction selection, variety selection, feeding, stocking, feeding management and disease control. The feeding management and the disease control run through the whole feeding process. The ecological native chickens cultivated by the cultivation method have peculiar flavor of rural native chickens, meat is delicious, and nutritive value is high.

Owner:垫江县双飞畜禽养殖股份合作社

Efficient simplified wheat flour milling technology and efficient simplified wheat flour milling device

InactiveCN103894260ADoes not destroy nutrientsKeep the scentGrain treatmentsProcess engineeringIndustrial engineering

The invention relates to an efficient simplified wheat flour milling technology comprising the working procedures of shelling, residue grinding, core grinding, tailing grinding and flour clearing, and an efficient simplified wheat flour milling device. In the shelling working procedure, an extrusion cutting grinder with a superior stripping and scraping function is used for replacing the existing tooth roller flour mill and is taken as a main residue making device; in the core grinding working procedure, an efficient impact flour mill is used for replacing a smooth roll flour mill and is taken as a main flour making device, and the grinding function of the efficient impact flour mill is more than twice as high as that of the prior art; two wraps are wetted by water, residue grinding is carried out for three times, and germ extraction is carried out during residue grinding; after the core 1 and the core 2 are slightly ground by a roller mill, the aim of rapidly and efficiently producing the high-quality flour at low temperature with low consumption can be achieved by virtue of a strong impact method of a water cooling efficient impact grinder and the like. The wheat flour milling production line extrusion process designed by the invention is simple in process, low in civil engineering equipment investment, high in production efficiency, simple in operation and management and low in energy consumption; the produced high precision flour is large in proportion; the produced flour is good in edible quality and food production performance; the produced flour has the advantages that the original fragrance of the wheat is maintained by the flour, and the like.

Owner:王洪福

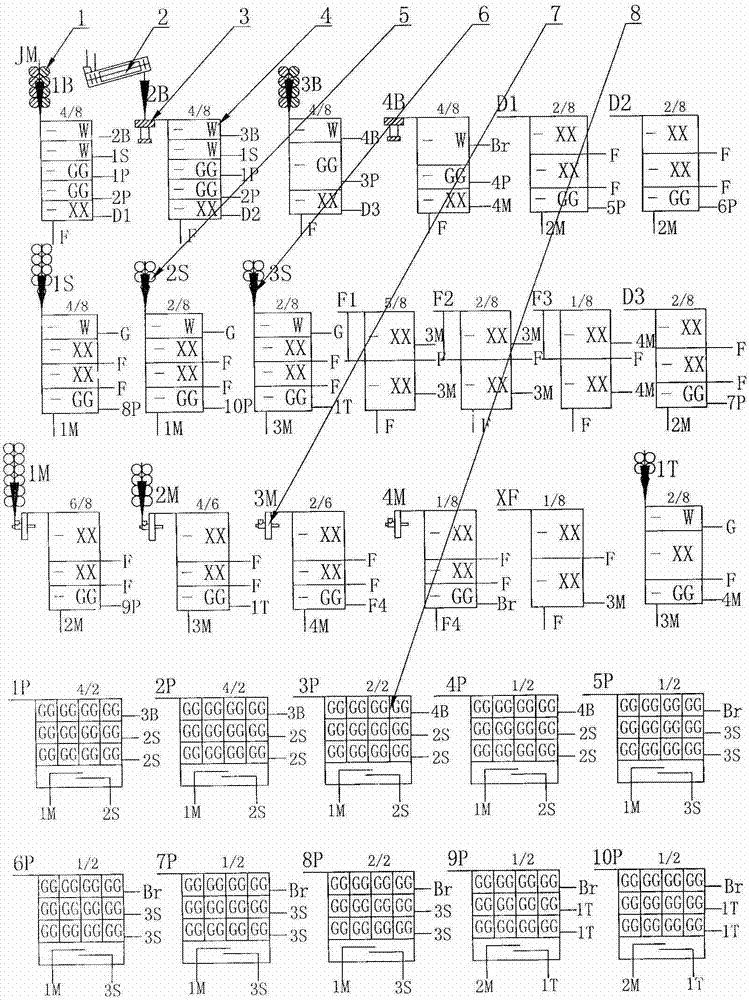

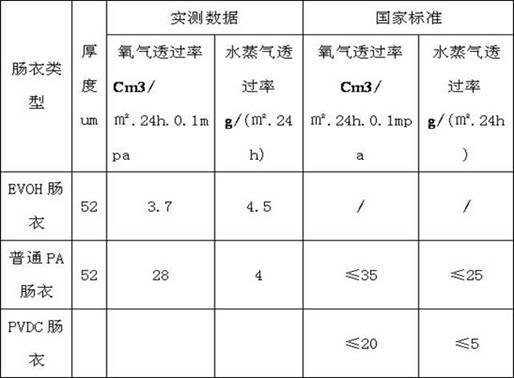

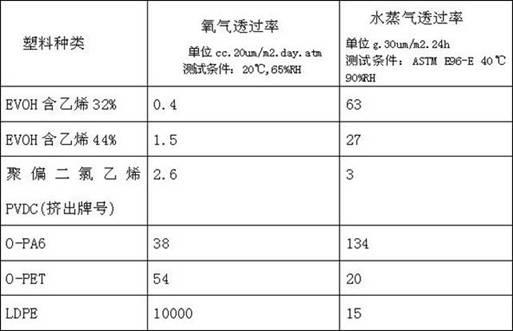

Preparation method for multi-layer co-extrusion two-way stretched high-barrier plastic casing

The invention discloses a preparation method for a multi-layer co-extrusion two-way stretched high-barrier plastic casing. The preparation method comprises the following steps of: respectively adding raw materials of each layer into an extruder for each layer for melting and plasticizing, wherein the multi-layer co-extrusion two-way stretched high-barrier plastic casing is formed by co-extruding five layers of raw materials; extruding the raw materials by a multi-layer stacked type round mold to form a multi-layer mold blank; slightly blowing and stretching the mold blank, and then immediately and rapidly cooling and molding the mold blank by using cooling water of 5-15 DEG C into a first pipe film; heating the first pipe film in a hot water tank or an infrared heating system to a proper temperature; aerating compressed air to ensure that the mold blank is transversely stretched for a multiplying power of 3 to 5 times and longitudinally stretched for a multiplying power of 2.5 to 3 times to form a second pipe film; putting the second pipe film in an infrared heating barrel for sizing; and rolling a finished product after cooling the second pipe film to a required fold diameter and shrinkage rate by using a vane. Plastic casings prepared by the preparation method have the characteristics of high barrier, high water retention and environmental protection.

Owner:南通环球塑料工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com