Method for manufacturing beverage filled in container

A manufacturing method and container packaging technology, which are applied in the field of containerized beverages, can solve the problems of lowering the temperature that cannot be filled, achieve simple equipment, reduce equipment costs and operating costs, and achieve thin-walled effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

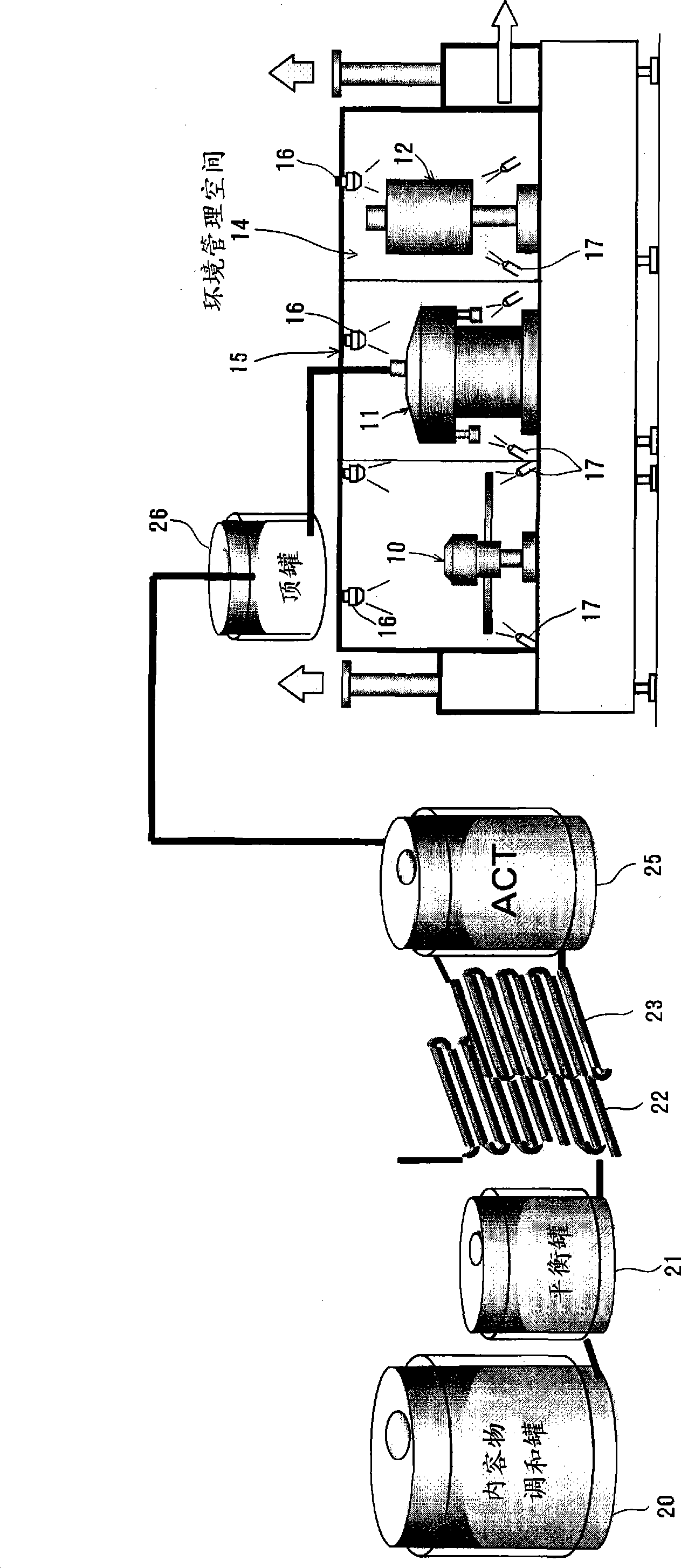

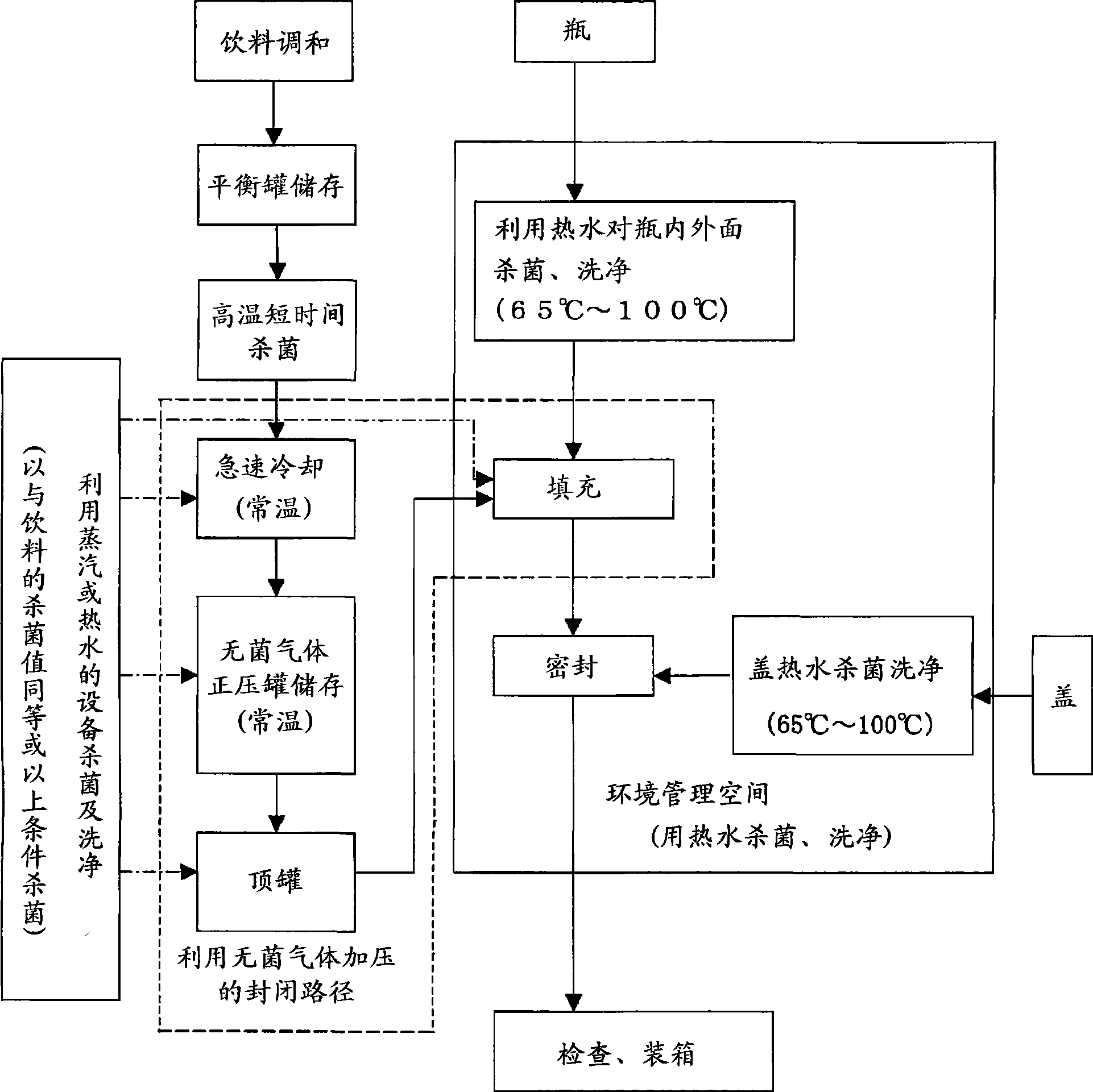

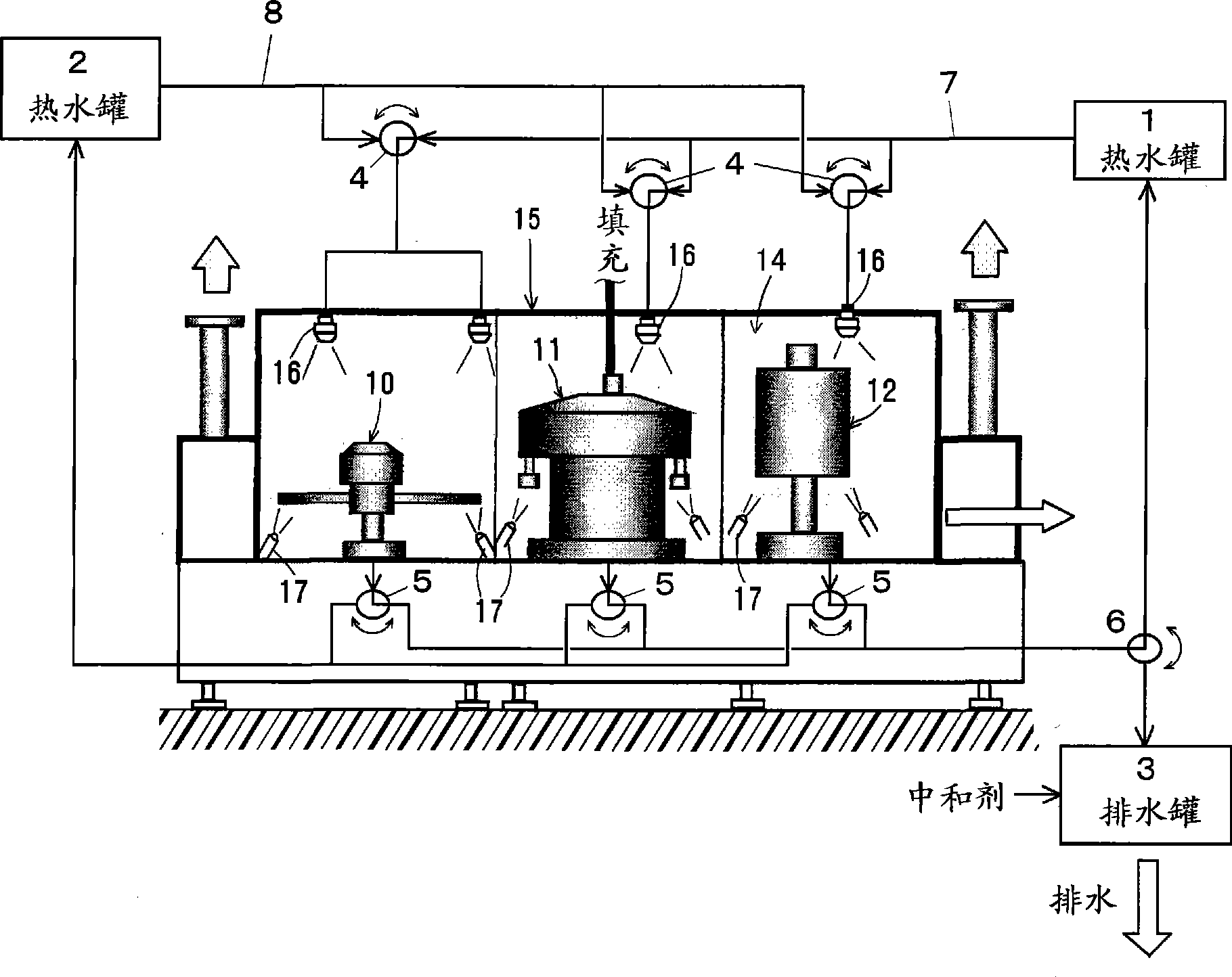

[0063] A green tea beverage (pH 5.9, catechin content 52 mg%) was produced using a PET bottle with a capacity of 2 L, and using the above-mentioned production method and apparatus.

[0064] That is, hot water is used to sterilize and clean the bottle at 90°C for 3 seconds, and the green tea beverage that has been sterilized at a high temperature of 135°C for 30 seconds and then rapidly cooled to room temperature is stored in the pre-sterilized and cleaned bottle until the contents The sterilization value is above the storage tank with positive pressure maintained by sterile gas, and then the sterile gas is used to pressurize the top tank and supply it to the filling machine, and fill it into the bottle that has been sterilized and cleaned with hot water in the management space, and use Pre-sterilized, cleaned lids are sealed. In addition, the liquid path from the rapid cooler to the filling machine is a closed path that maintains a positive pressure with sterile gas and is sep...

Embodiment 2

[0070] An acidic beverage of 100% orange juice (pH 3.61) was produced by using a PET bottle with a capacity of 1.5 L and using the above-mentioned production method and apparatus.

[0071] That is, the bottle is subjected to heat sterilization and cleaning at 90° C. for 3 seconds with hot water, and then rapidly cooled to normal temperature (31° C. to 32° C. ) of the acidic beverage is stored in pre-sterilized, cleaned to more than the sterilization value of the content and utilize sterile gas to maintain positive pressure in the storage tank, the following utilize the same method as in Example 1 to obtain bottled acidic beverage. In addition, the filling temperature at this time was 30 degreeC. Next, as in Example 1, in order to investigate changes in the color tone and taste of the acidic beverage produced by the conventional hot-fill method, the pH value and color tone of the green tea were measured for the acidic beverage after production. , Vitamin C. The respective res...

Embodiment 3

[0105] A green tea beverage (pH 5.9, catechin content 52 mg%) was produced using a PET bottle with a capacity of 2 L, and using the above-mentioned production method and apparatus.

[0106] That is, the management space where the container is cleaned, filled, and sealed is sterilized with a peracetic acid chemical (trade name: To-yo-Actibu) at a concentration of 2,000 ppm at 40°C in advance for 10 minutes, and then washed with hot water at 90°C. It is confirmed that it has a bactericidal effect of more than 6D relative to spore bacteria such as B.subtilis and B.coagulans. In addition, the bottle is heat-sterilized and cleaned at 90°C for 3 seconds with hot water, and the green tea beverage that is rapidly cooled to room temperature after heat-sterilized at 135°C for 30 seconds for a short period of time is stored in the pre-sterilized and cleaned bottle. The sterilizing value of the object is above the storage tank and the positive pressure is maintained by the sterile gas, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com