Patents

Literature

55results about How to "Realize thin wall" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

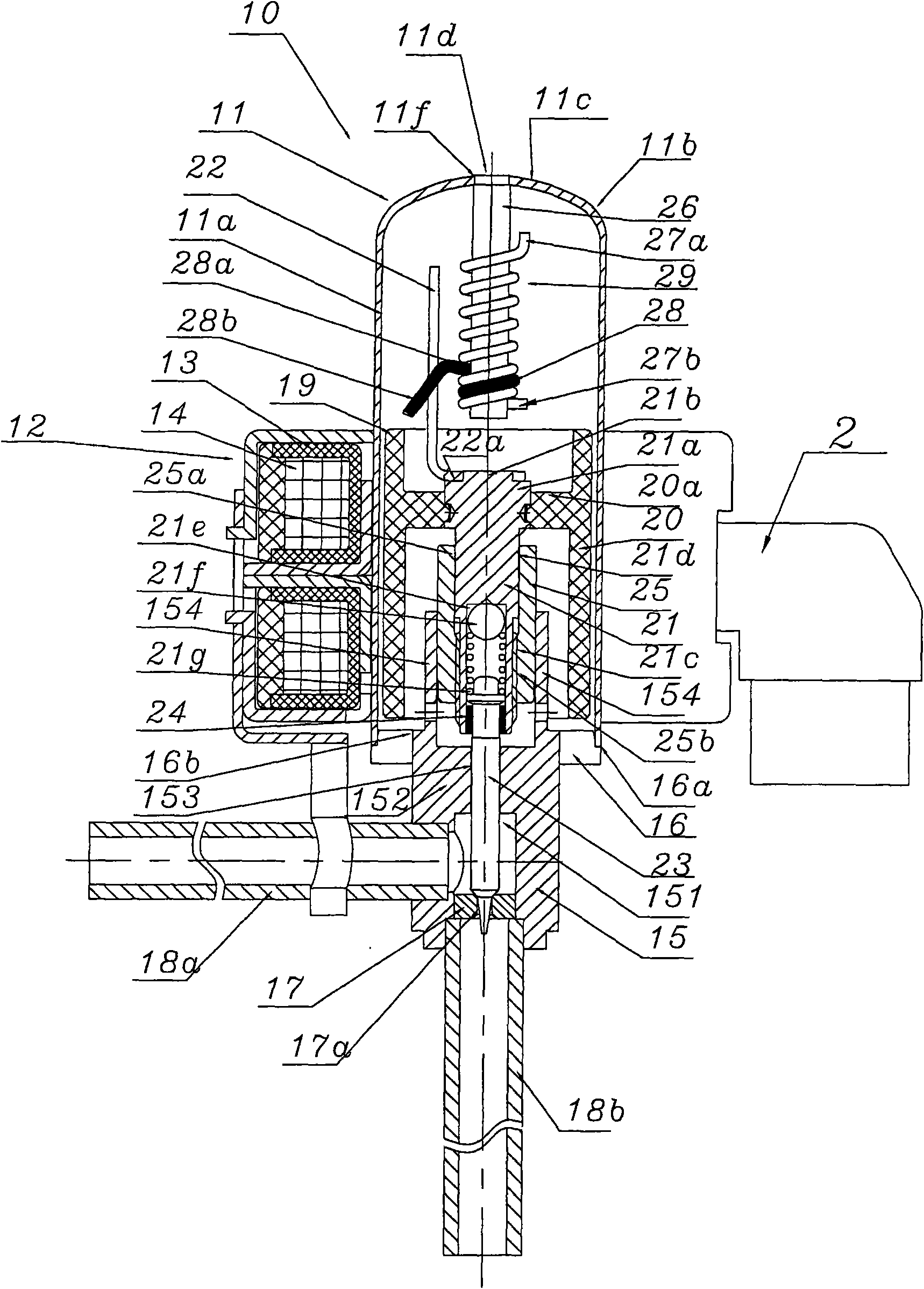

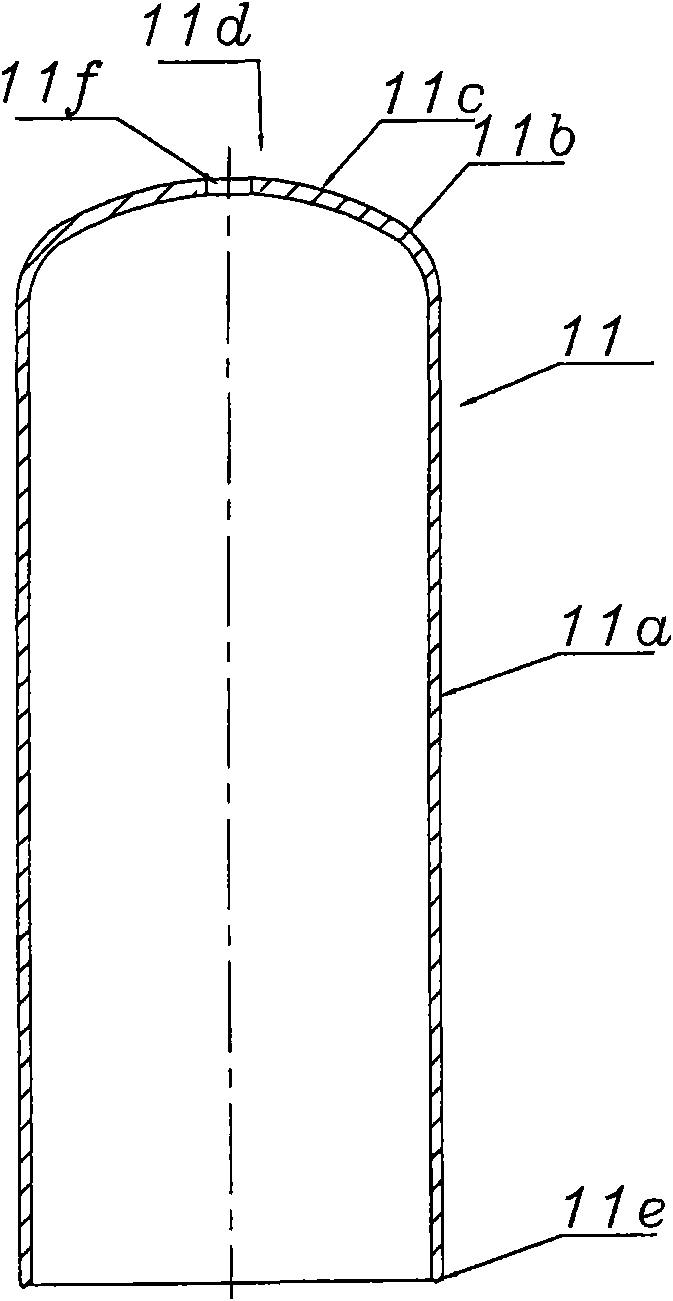

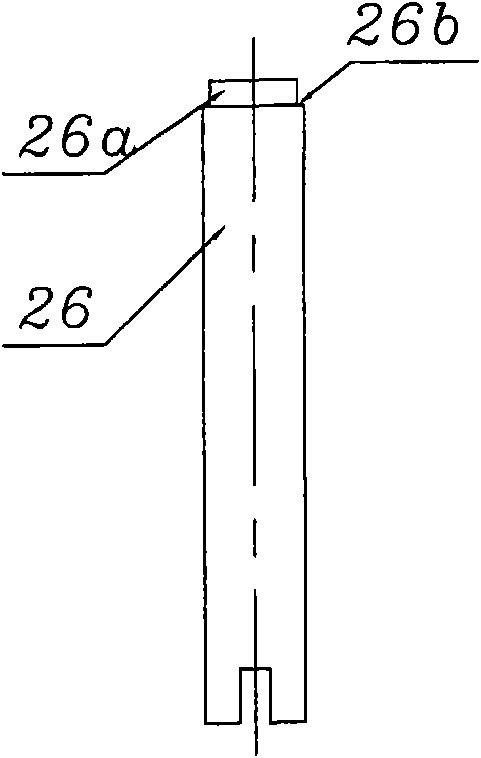

Electric valve

InactiveCN101769388ARealize thin wallNo need to increase wall thicknessOperating means/releasing devices for valvesFluid circulation arrangementEngineeringVALVE PORT

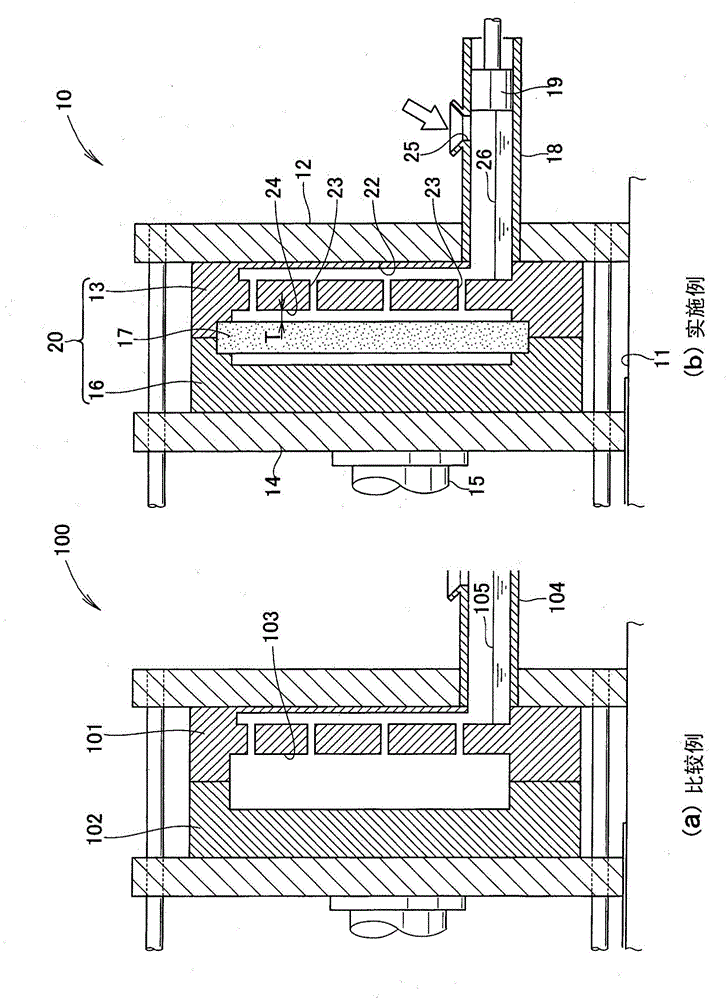

The invention discloses an electric valve. A rotor forming a step motor and a valve needle are arranged in a sealed space formed by an outer shell, the bottom of the outer shell is fixed on a valve body, the valve needle approaches or is apart from a valve seat of the valve body according to the upward and downward axial movement of the rotor, and a shaft member forming a stopping mechanism is taken as a rotation stopping mechanism of the rotor and is fixed at the top of the outer shell in a drooping state in the outer shell; the outer shell forming the seal space consists of a cylinder wall, a bending part and an arc part, and the bending part is formed by connecting the cylinder wall; and the circular edge of the bottom of the cylinder wall is fixed on the valve body, the arc part forms the top of the outer shell, and the fixation of the shaft member is implemented by laser welding.

Owner:ZHEJIANG SANHUA INTELLIGENT CONTROLS CO LTD

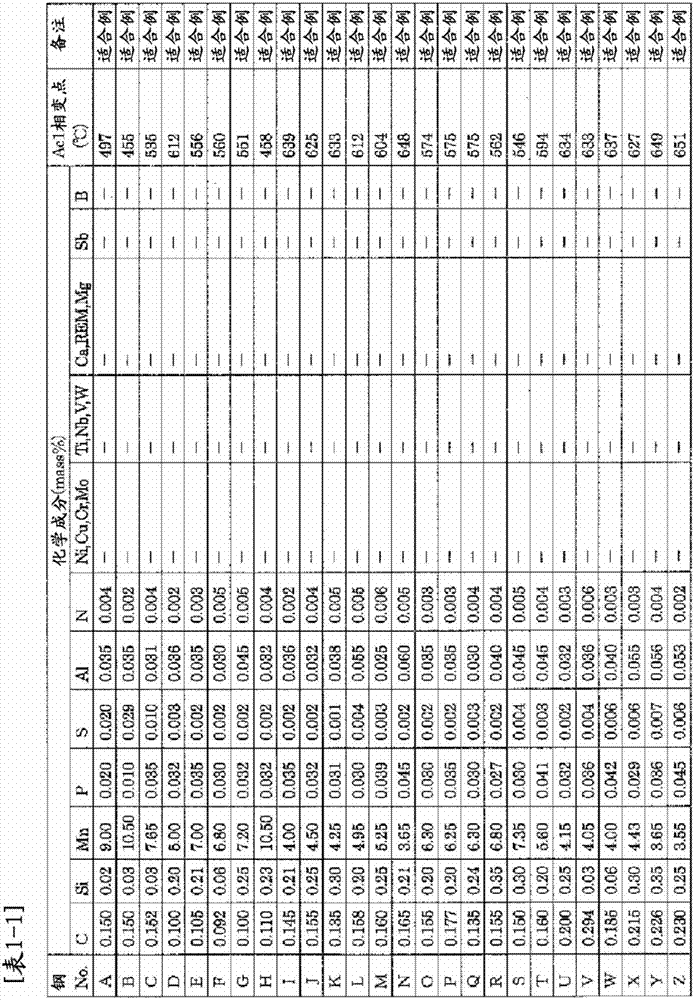

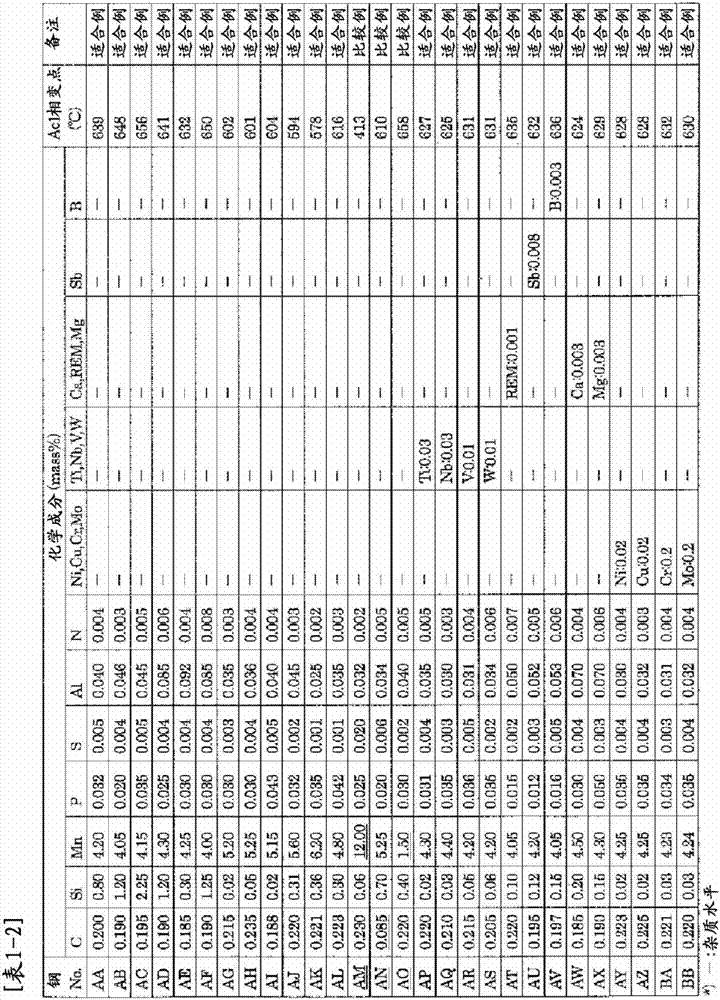

High-strength hot-pressing member and method for producing same

ActiveCN107109553ASimple and cheap to manufactureRealize thin wallHot-dipping/immersion processesFurnace typesUltimate tensile strengthMartensite

Owner:JFE STEEL CORP

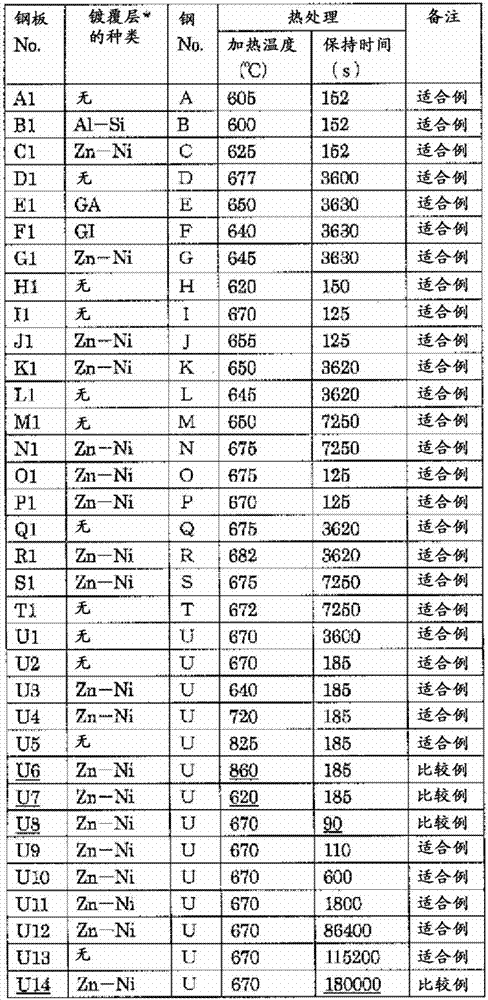

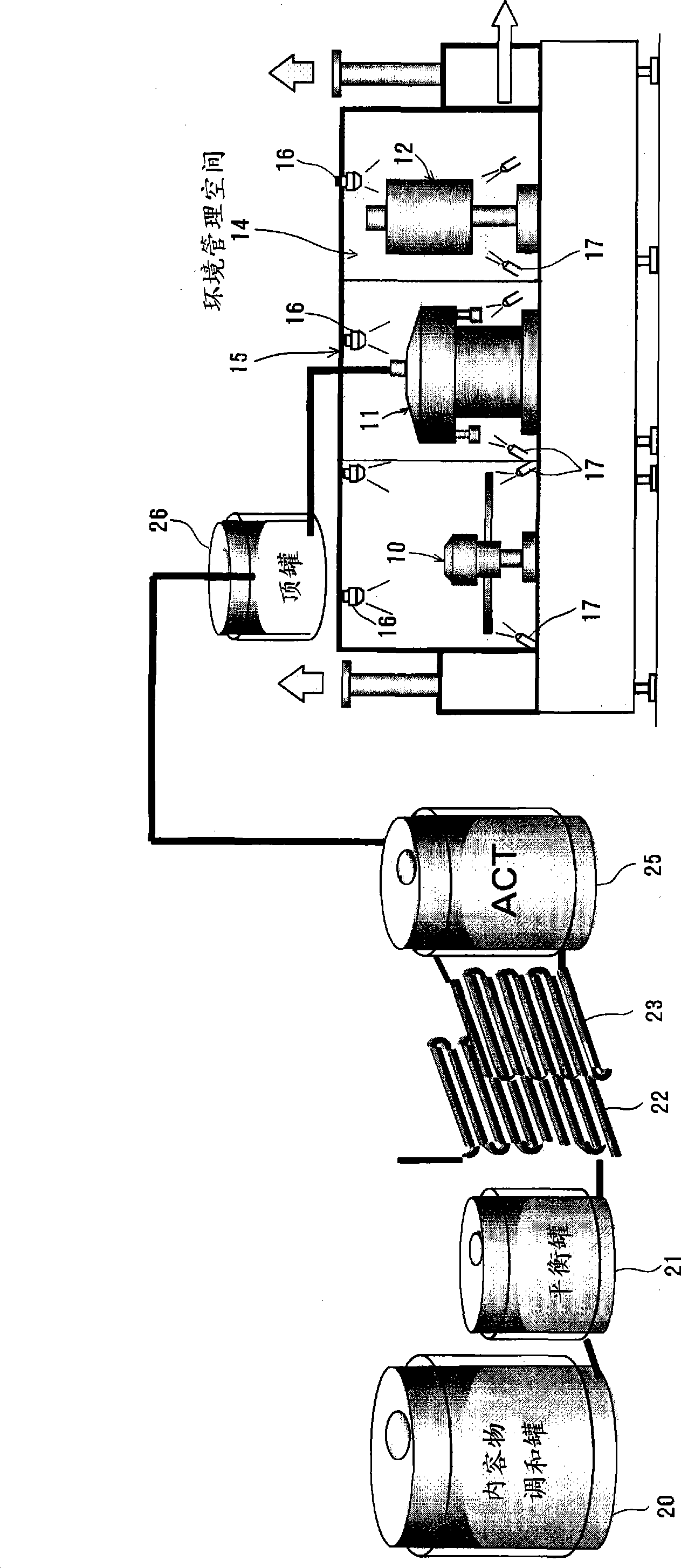

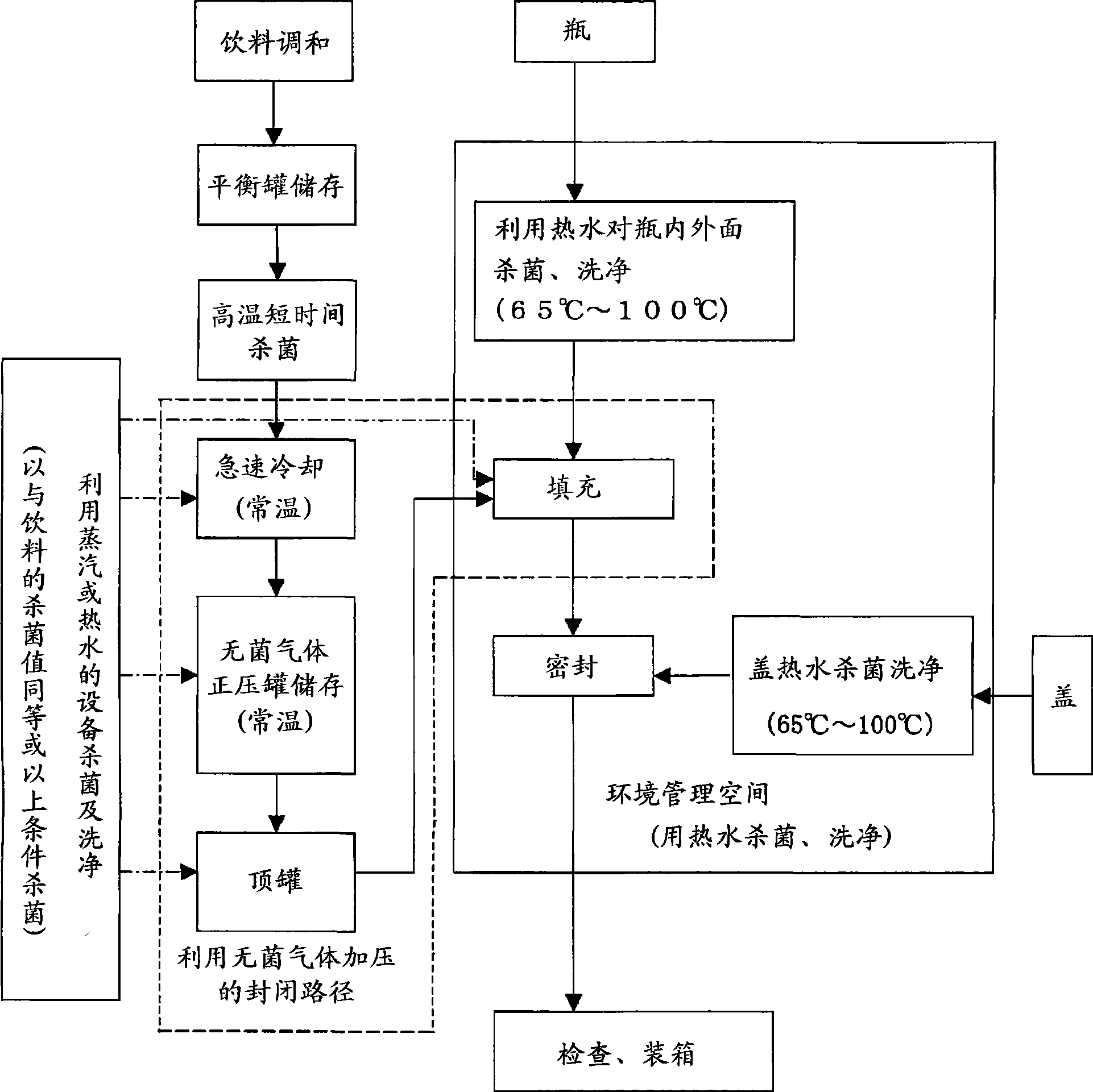

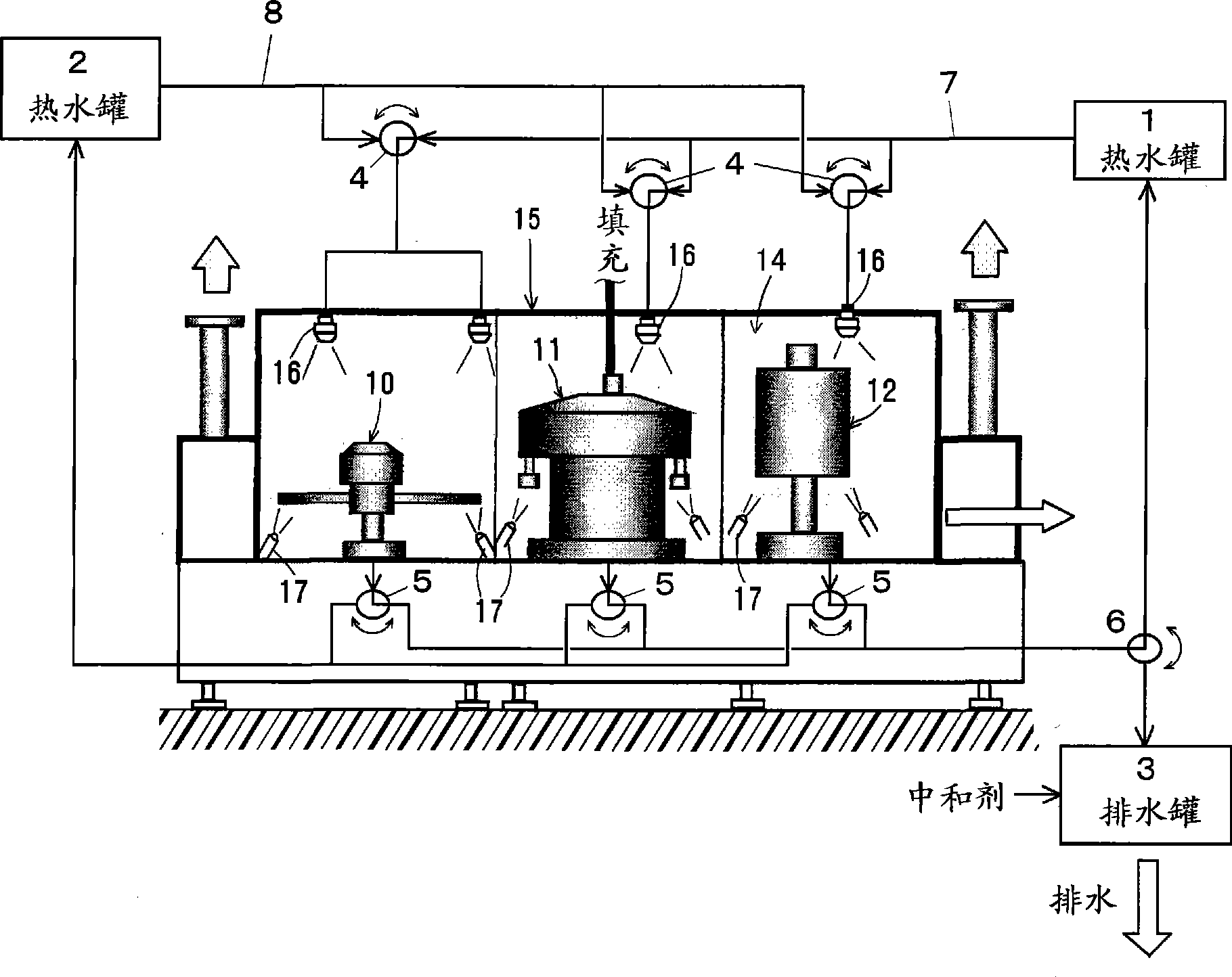

Method for manufacturing beverage filled in container

InactiveCN101489910ALow costReduce operating costsPackage sterilisationBottle-handling machinesOperational costsPositive pressure

It is intended to provide a process for producing a packaged drink whereby filling can be performed at room temperature without resorting to using a chemical or sterile water, the favorable taste and flavor of the content can be maintained while relieving the thermal degradation thereof, it becomes unnecessary to employ a heat-resistant container or to thermally sterilize or cool after sealing, and thus both of the equipment cost and the running cost can be largely reduced. After thermally sterilizing the content to give a definite sterilization value, it is quickly cooled to room temperature and then stored in a storage tank that has been preliminarily sterilized under such conditions as being equal to or exceeding the thermal sterilization conditions for the contents. While maintaining the storage tank under positive pressure with the use of a sterile gas, the content is fed into a filling machine that has been preliminarily sterilized under such conditions as being equal to or exceeding the thermal sterilization conditions for the contents. Thus, the liquid-feeding system ranging from the storage tank to the filling machine is made a closed liquid-feeding pathway free from the invasion of air from the outside. The drink is filled into a container having been sterilized with hot water in an environment-controlled space isolated from the outside wherein the surroundings have been thermally sterilized and washed with hot water at 65 DEG C to 100 DEG C.

Owner:TOYO SEIKAN KAISHA LTD

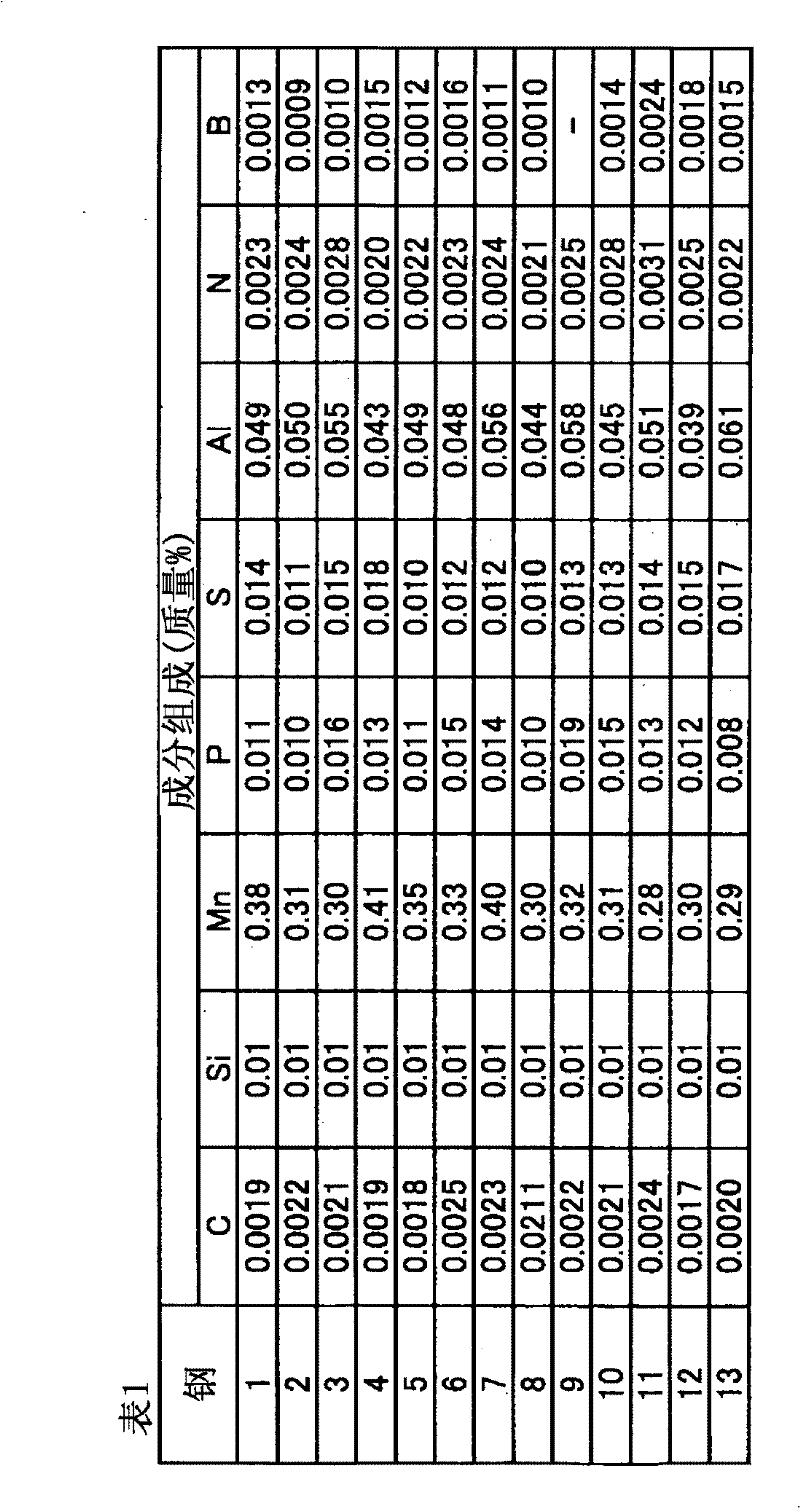

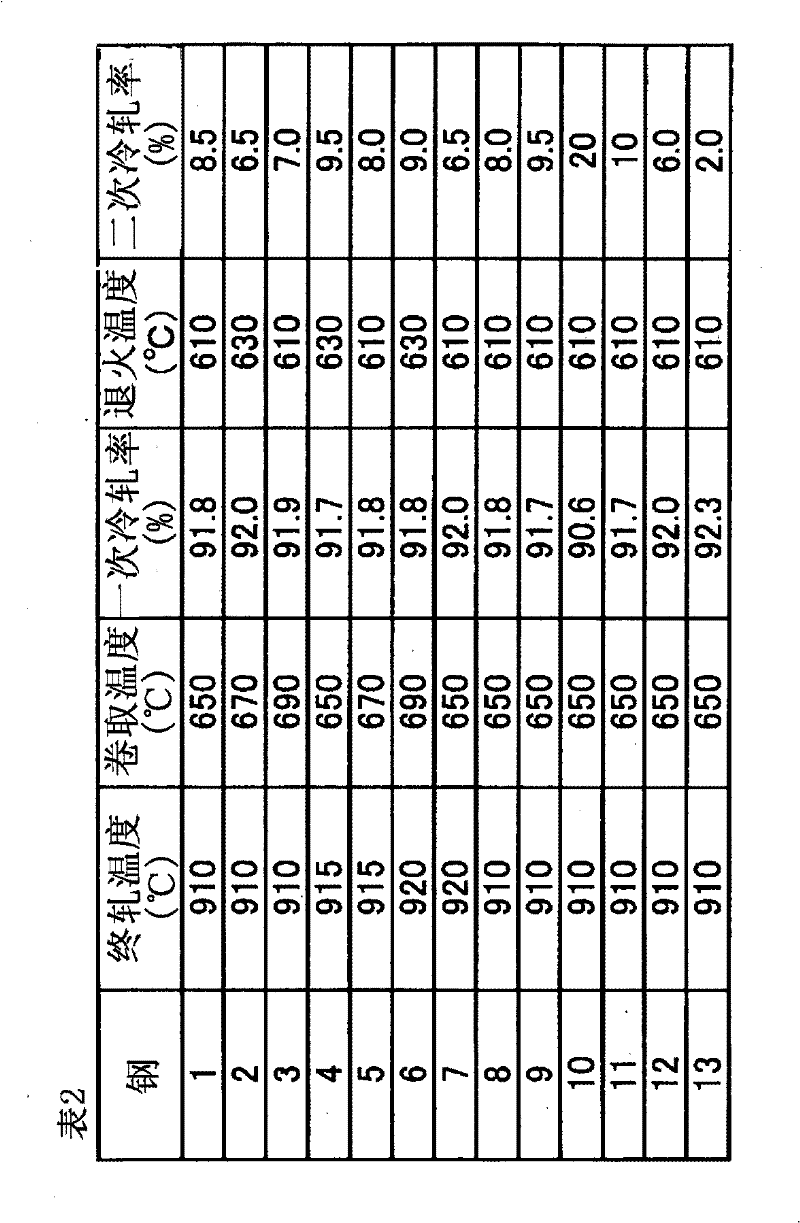

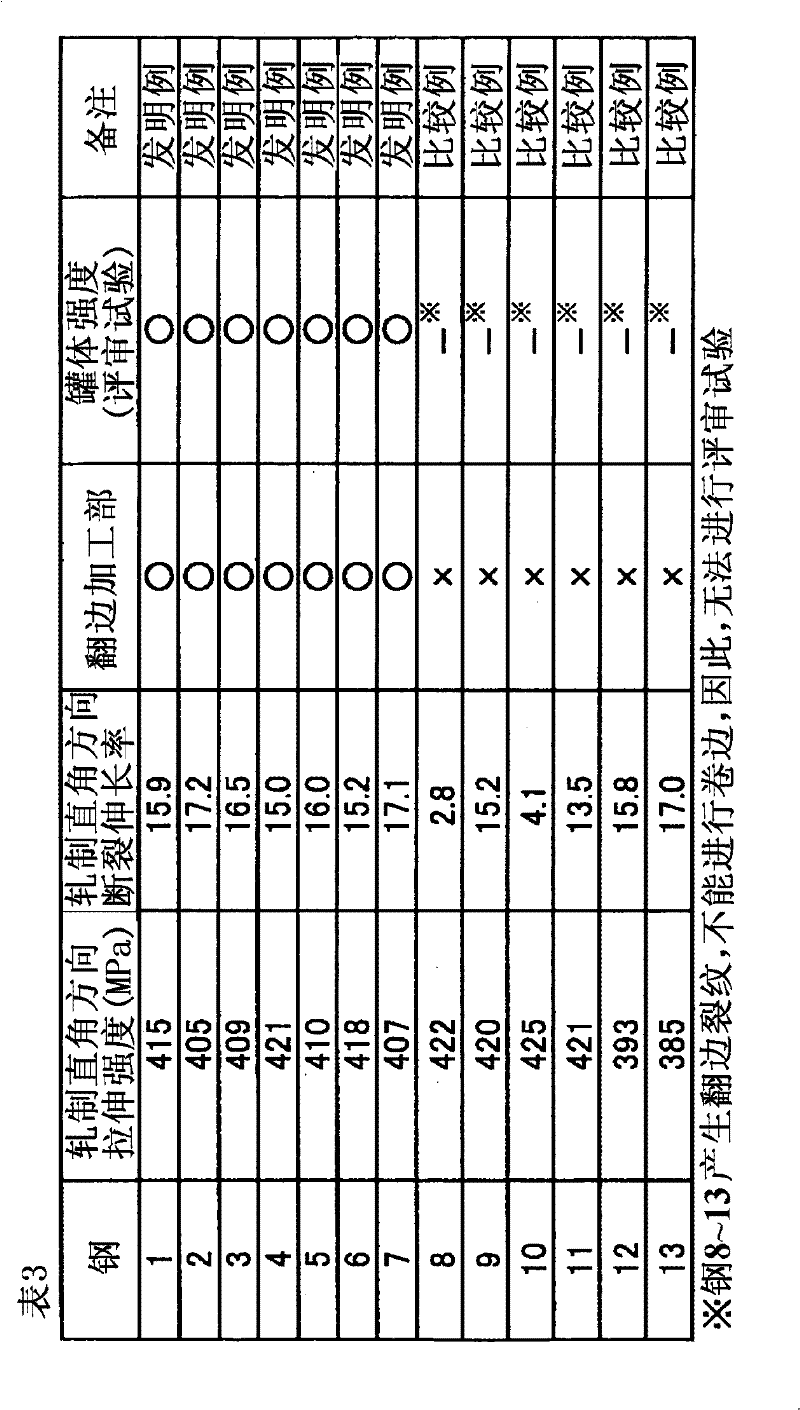

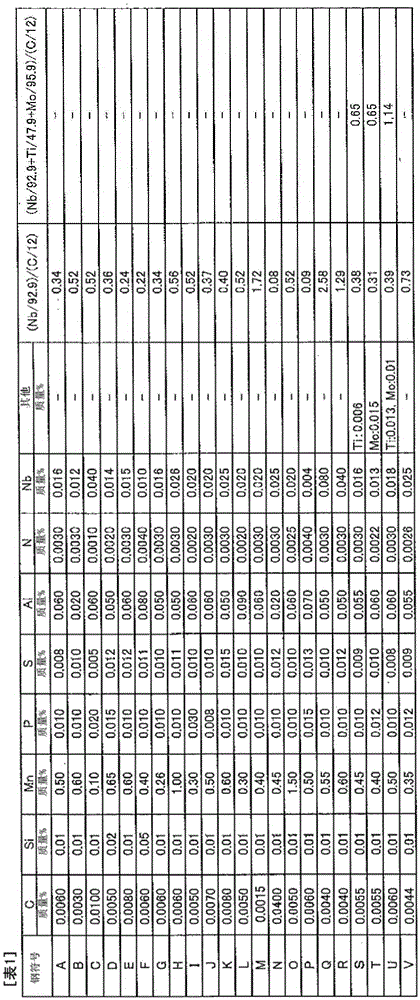

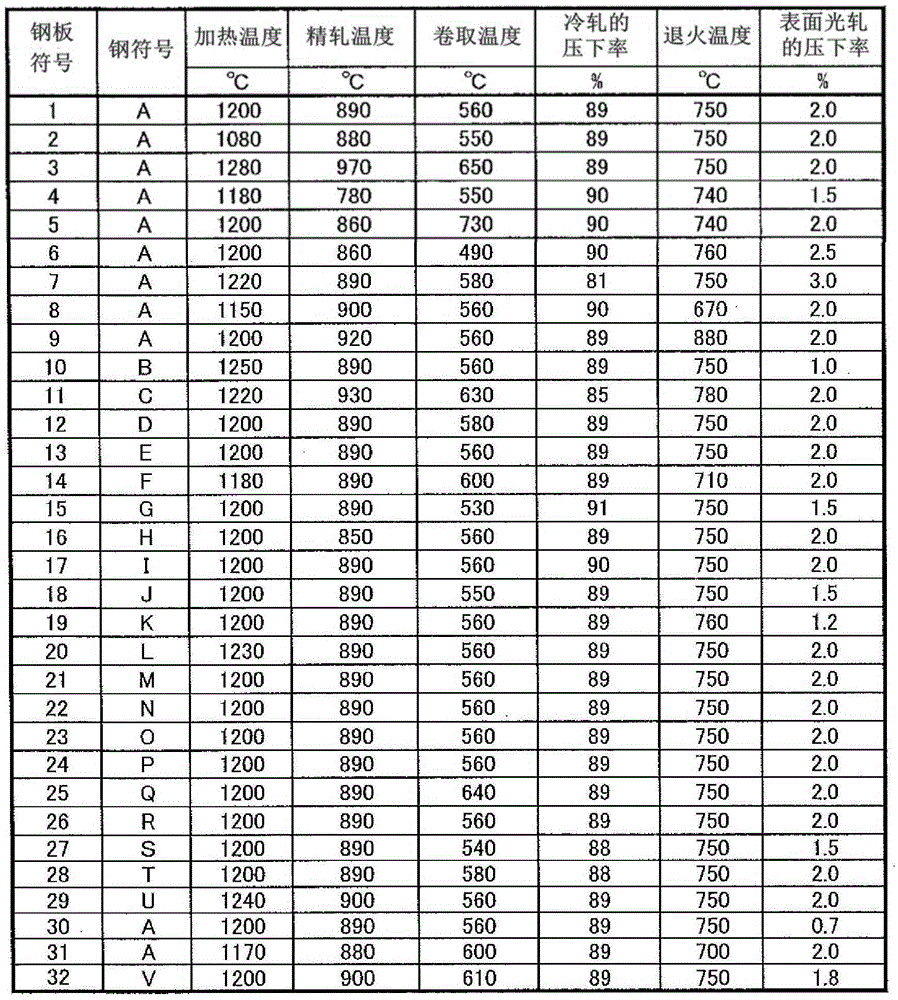

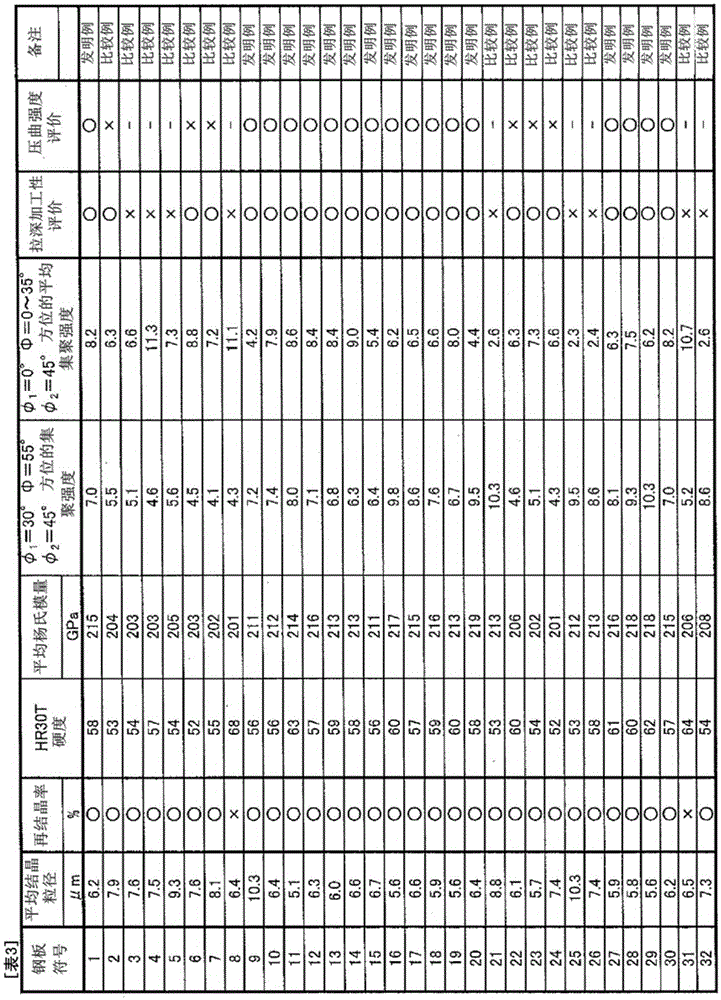

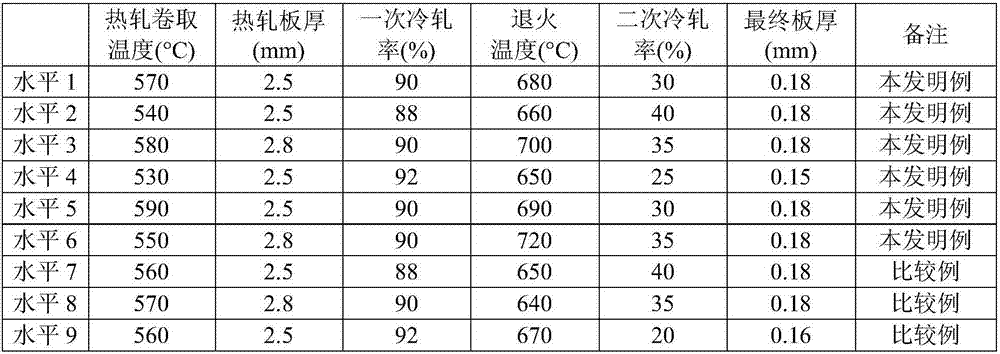

Highly processable steel sheet for three-piece welded can and method for producing same

InactiveCN102482748AExcellent flanging processabilityRealize thin wallFurnace typesHeat treatment furnacesSheet steelUltimate tensile strength

Owner:JFE STEEL CORP

Aluminum member

ActiveCN104694799AImprove melt fluidityDysgyrationFoundry mouldsFoundry coresHigh intensityMolten metal

An aluminum member produced by casting a molten metal composed of predetermined ingredients is disclosed. The aluminum member is casted by supplying the molten metal to a space between a fixed die, a movable die, and a sand core disposed between the fixed die and the movable die, and then cooling the molten metal moderately.

Owner:HONDA MOTOR CO LTD

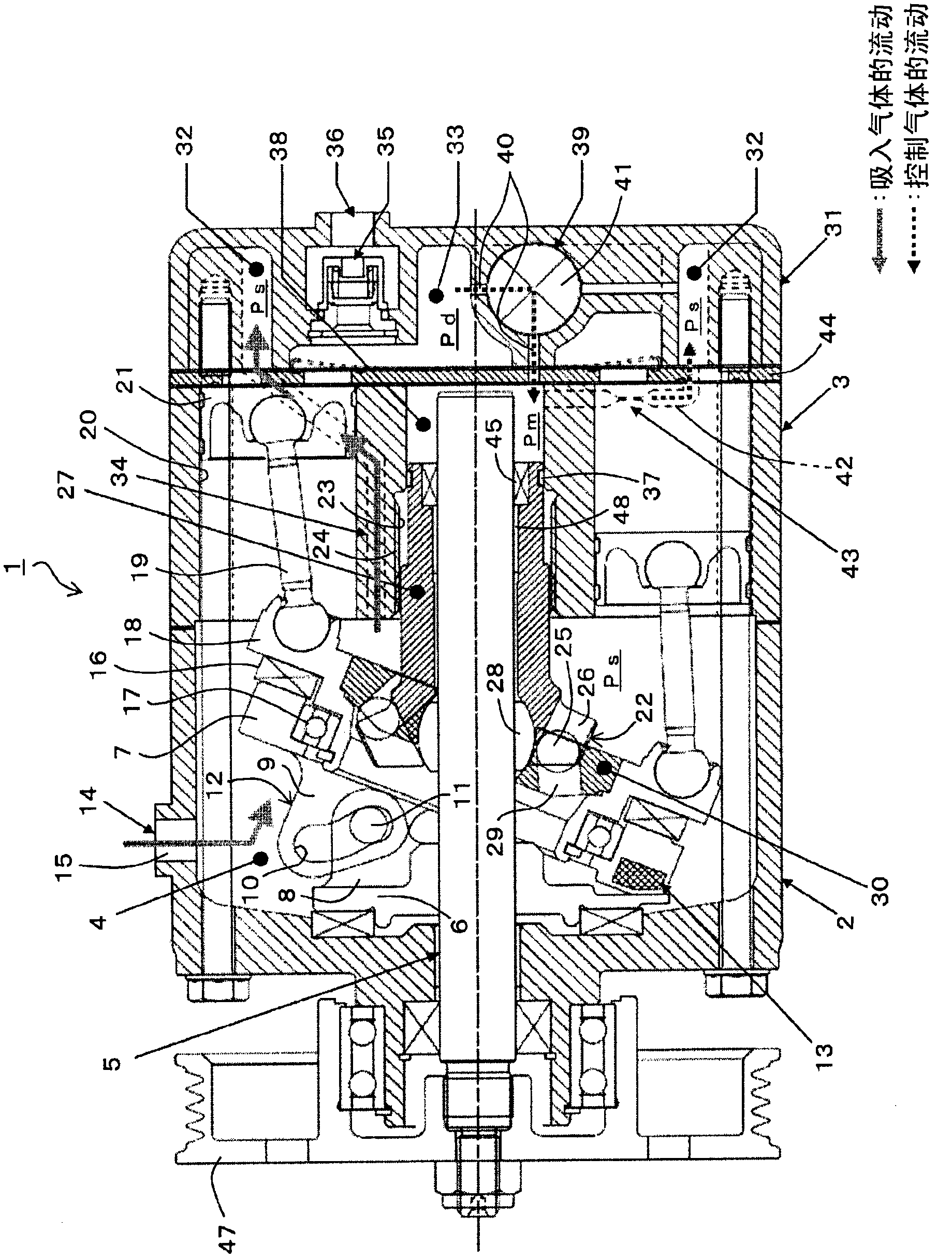

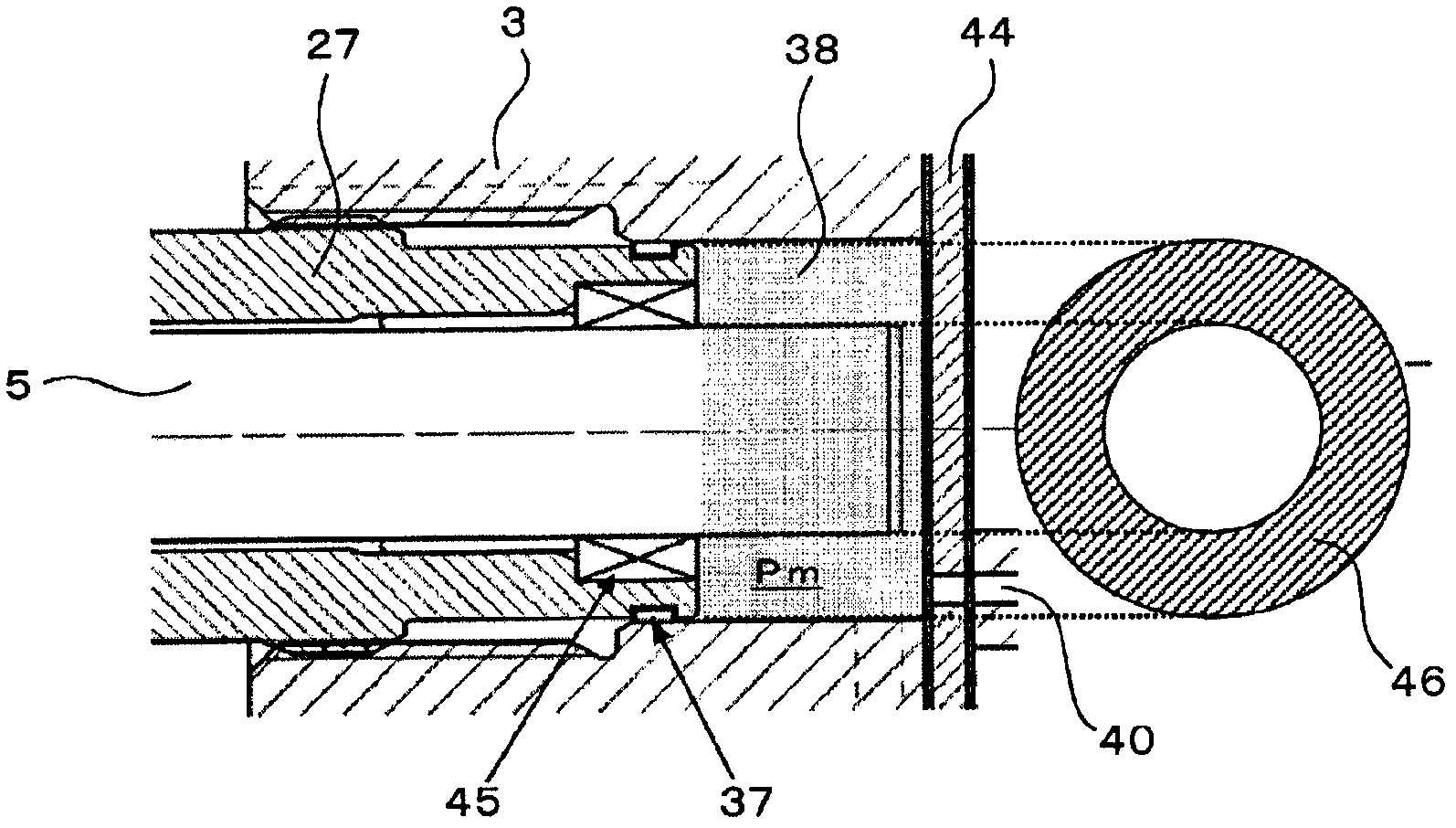

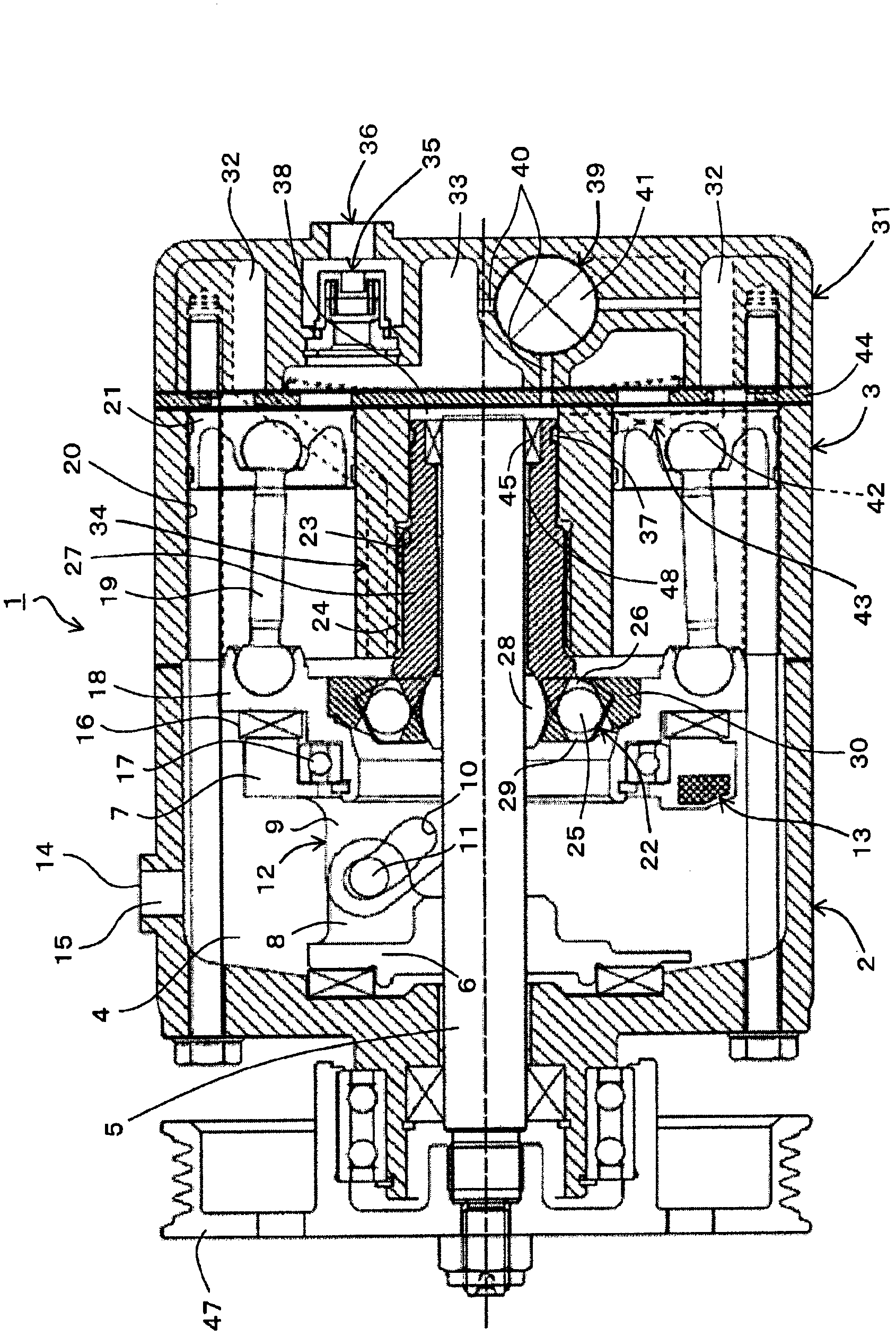

Variable displacement compressor

InactiveCN102459897AAchieve lightweightIncreased Design FreedomMulti-stage pumpsPositive-displacement liquid enginesCylinder headReciprocating motion

Disclosed is a variable displacement compressor having improved compressor performance such as reduced pulsation and improved durability and resistance to pressure and allowing smooth and high-precision control by using an axial movement member to set the swash plate tilt angle to match a target tilt angle. The variable displacement compressor is provided with a cylinder head in which are formed a suction chamber and a discharge chamber, a cylinder block having a cylinder bore such that an inserted piston is capable of reciprocating movement, a crankcase formed by said cylinder block and a front housing, a swash plate that is rotated with the main shaft and that is disposed inside said crankcase and held so that the tilt angle can be changed relative to said main shaft, and a movement conversion mechanism for converting the rotational movement of said swash plate to the reciprocating movement of a piston, wherein: the suction path for the intake of a suction gas into the compressor is constituted to open into the crankcase; a connecting path for connecting the crankcase and the suction chamber is provided in the cylinder block; around the periphery of the main shaft, an axial movement member is provided that can move along the axis of the main shaft in an essentially one-to-one correspondence with the tilt angle of the swash plate; said axial movement member is disposed such that one end is exposed to the pressure of the crankcase, and the other end is exposed to a pressure between that of the suction chamber and that of the discharge chamber; and an intermediate pressure control mechanism that can control the intermediary pressure is also provided.

Owner:SANDEN CORP

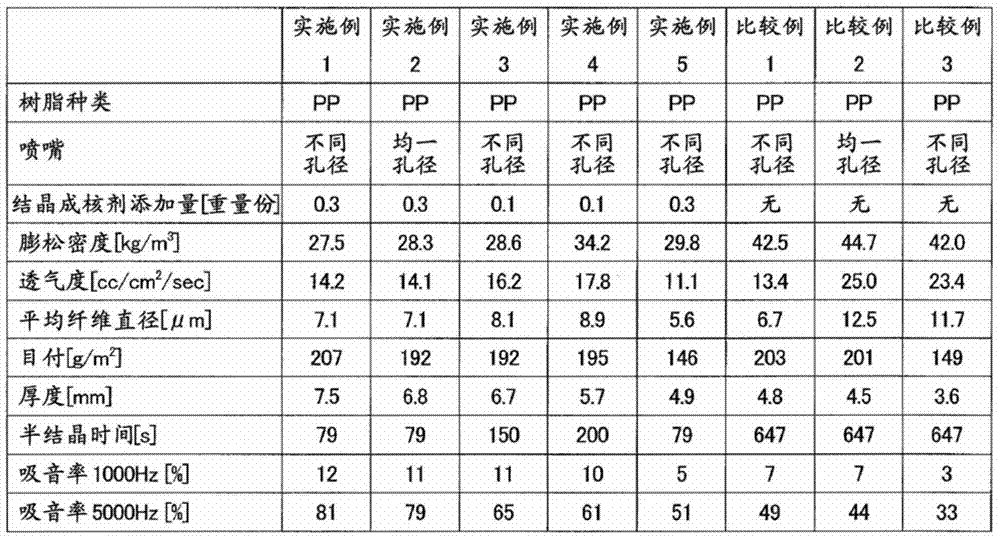

Melt-blown nonwoven fabric and use thereof

ActiveCN103842571ALow bulk densityLow costOther chemical processesLayered productsFiltrationFiber diameter

This melt-blown nonwoven fabric is formed of thermoplastic resin fibers having an average fiber diameter of 0.1-10 mum, and has a bulk density of 36 kg / m3 or less and an air permeability of 3-100 cc / cm2 / sec as measured by a Frazier type method at a weight of 200 g / m2. This melt-blown nonwoven fabric has a low bulk density and excellent sound absorption performance, oil absorption performance, heat insulation performance, dust collection performance and filtration performance. Since this melt-blown nonwoven fabric can be formed of a single kind of a resin composition, this melt-blown nonwoven fabric is able to be easily produced and have a uniform quality free from variation in the characteristics in comparison to the cases where mixed fibers or composite fibers composed of a plurality of kinds of resins are used. A sound absorbing material of the present invention can be obtained by an easy process and exhibits excellent sound absorption performance. Consequently, this sound absorbing material is suitable for use as a sound absorbing material for living environments or transportation means. In addition, the sound absorbing material of the present invention can be reduced in weight and thickness.

Owner:MITSUI CHEM INC

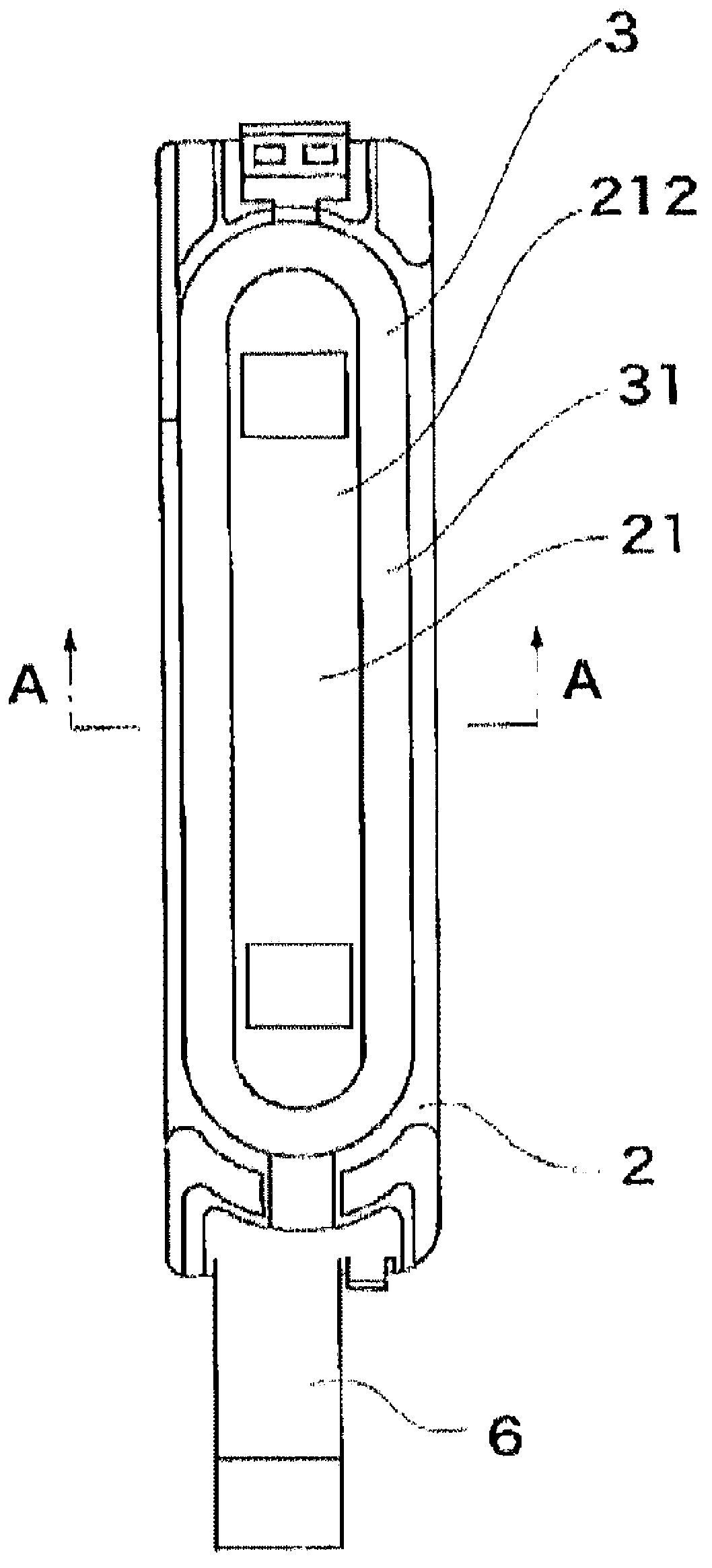

Lid member with waterproof function, and method of manufacturing thereof

InactiveCN103262354AAppropriate useWith waterproof functionCouplings bases/casesSubstation equipmentThermoplastic elastomerEngineering

The objective of the present invention is to be able to provide a lid member with a waterproof function that can be made thinner, and wherein burr leaking can be inhibited, damages to the lid member can be eliminated, and peeling off between the lid member and a sealing section can be prevented, by having the sealing section, which is made of rubber-like elastic material, formed in integration to the lid member. Provided, in order achieve this objective, is a lid member with a waterproof function that opens / closes an opening section formed on a housing, and that is configured to be composed of: a protruding section that is formed integrally onto one face of a resin body of the lid member, and that fits into the opening section; a ring-shaped protruding section that is formed integrally onto an outer circumference face of the protruding section, and that comes in close contact with the circumferential face of the opening section; a sealing section that is made of rubber-like elastic material, and that is equipped with a reinforcement section that extends from the ring-shaped protruding section to the vicinity of a joining section between the outer circumference face and the body; and a holding section that is made of a thermoplastic elastomer material, that is formed integrally onto the body side, and that is in close contact with the outer circumference face side of the reinforcement section.

Owner:NIPPON MEKTRON LTD

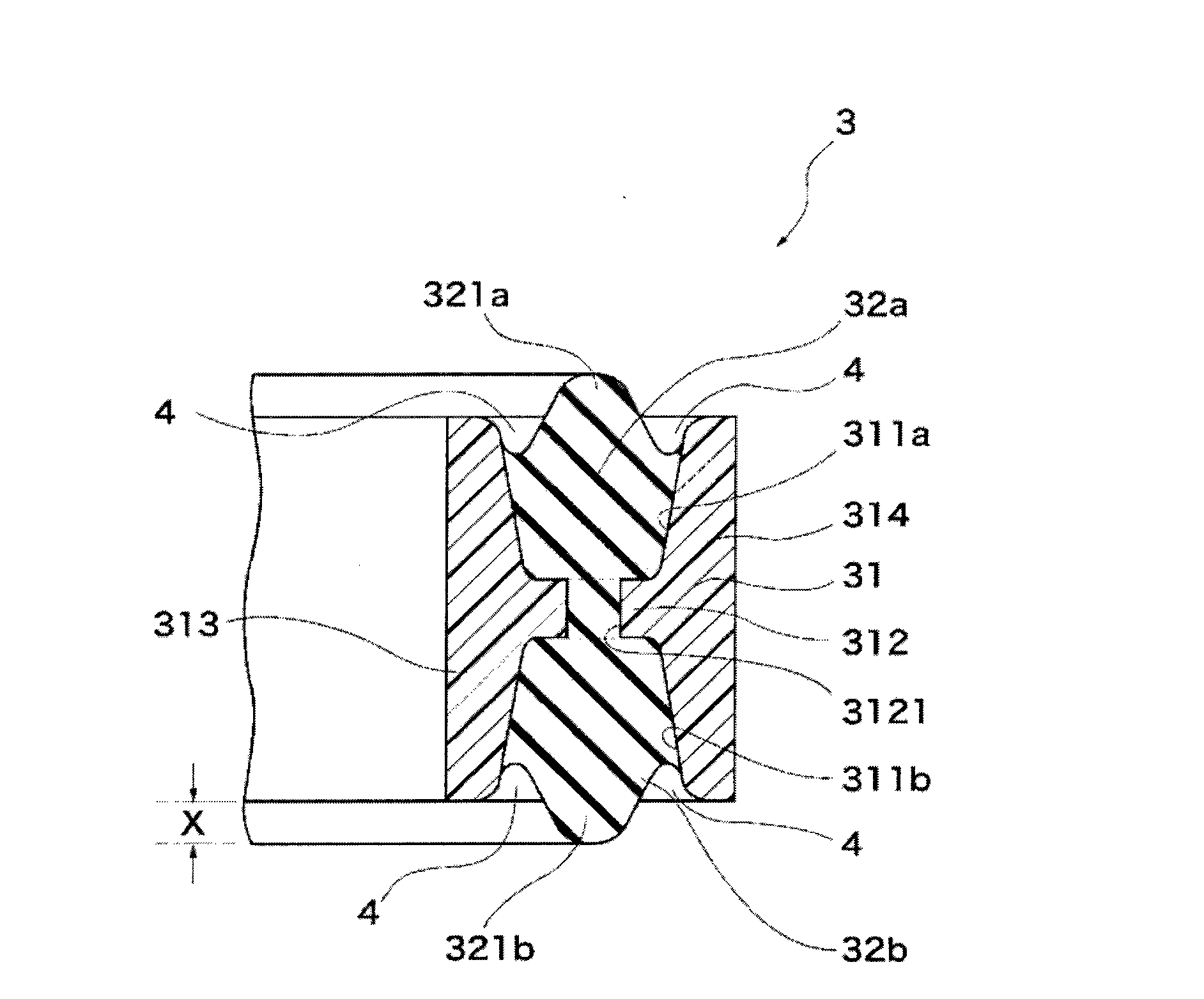

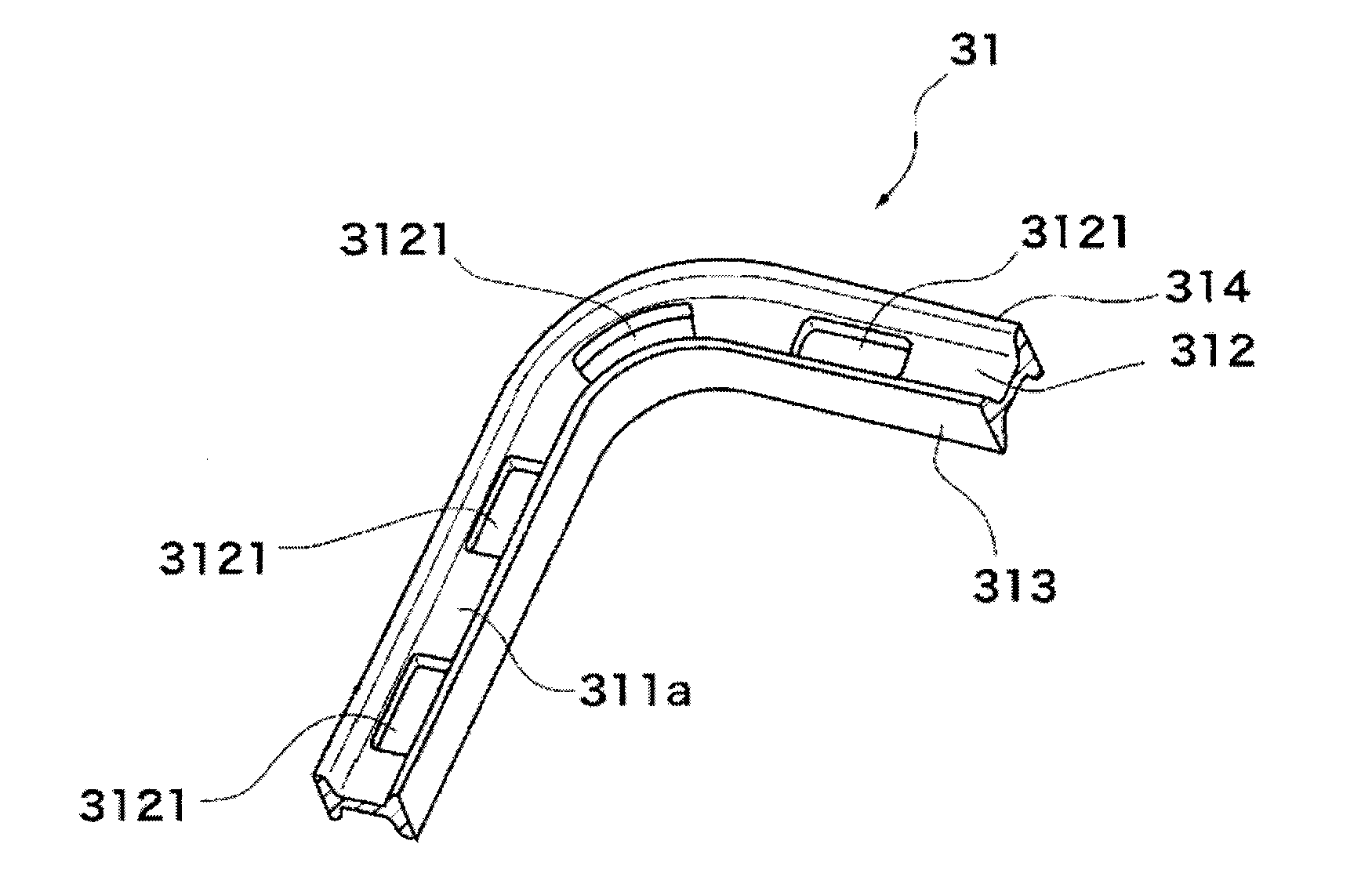

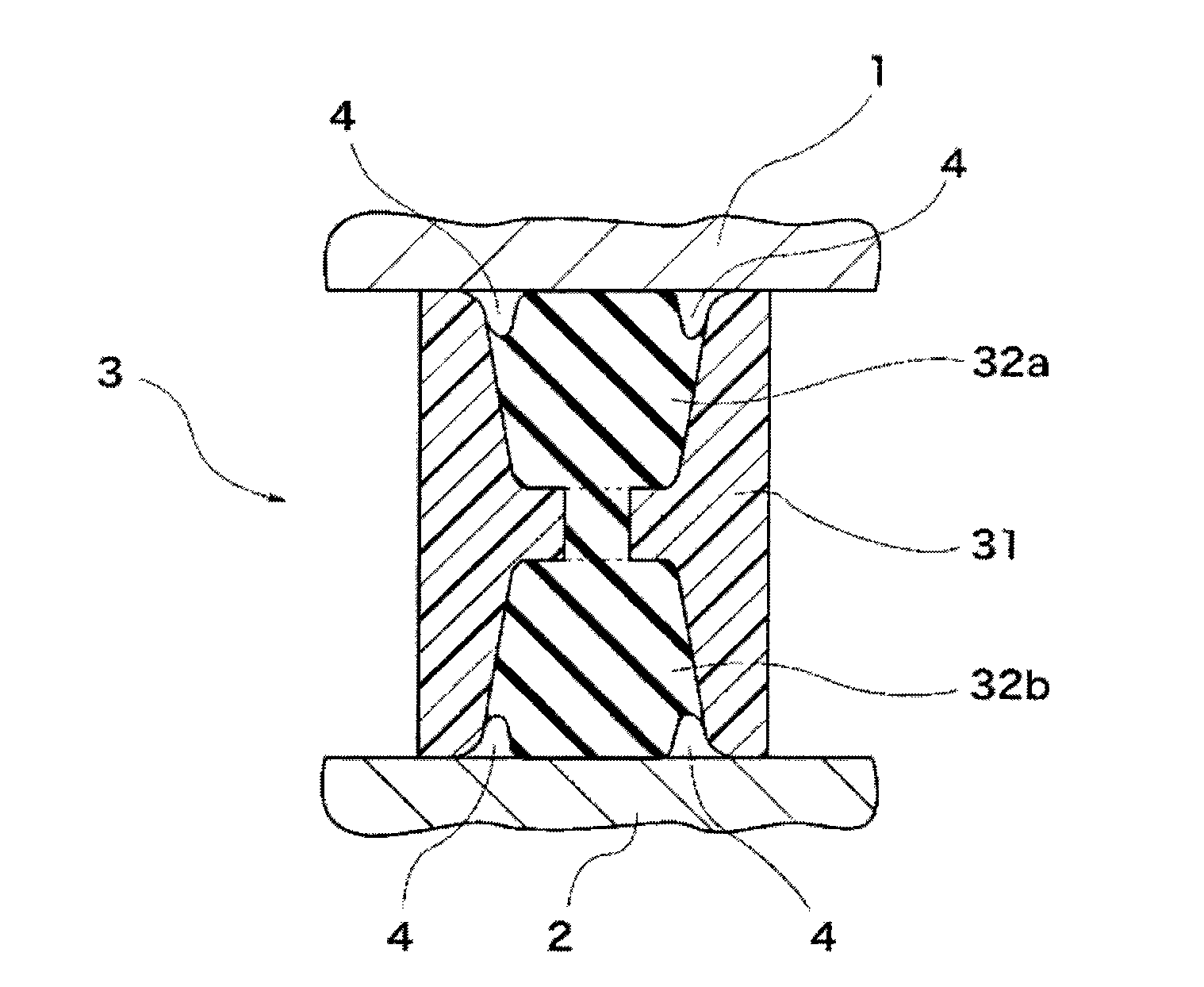

Sealing Member

InactiveCN102428301AMiniaturizationRealize thin wallEngine sealsTelephone set constructionsEngineeringH shaped

Provided is a sealing member wherein it is not necessary to provide a groove in a housing and, accordingly, the size and the thickness of a case can be reduced; a gasket can be easily handled; and a stable sealing performance can be maintained. The sealing member is provided between a housing member and another housing member, and seals a gap between both housing members. The sealing member is comprised of a retainer member composed of a resin material and having a substantially H-shaped section, and a pair of rubber seal members integrally provided in both grooves of the retainer member. Lip portions projected from both grooves are formed on both rubber seal members.

Owner:NIPPON MEKTRON LTD

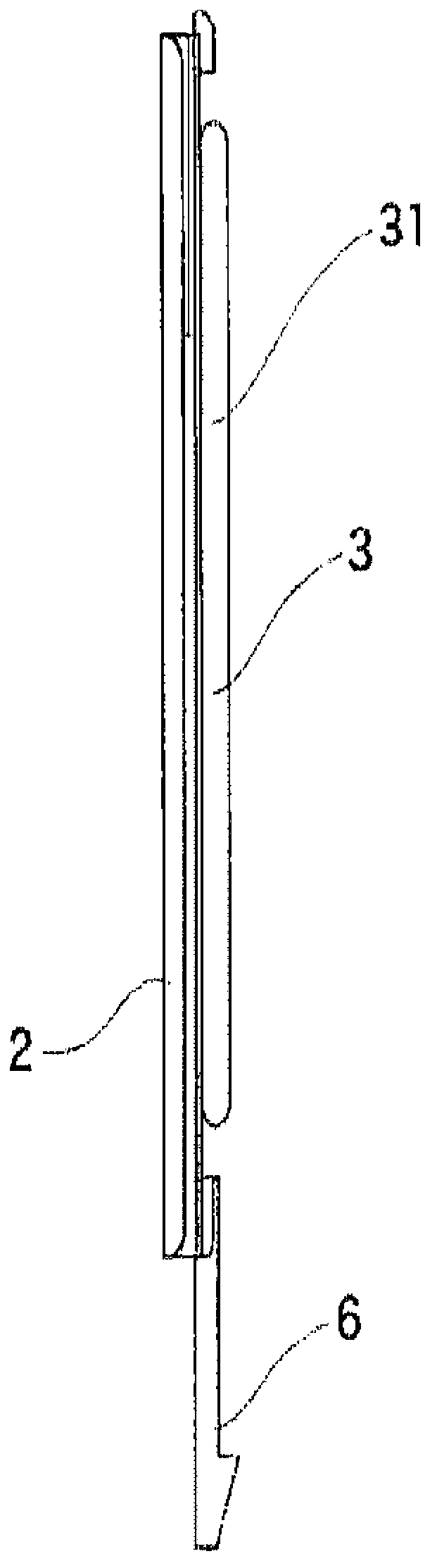

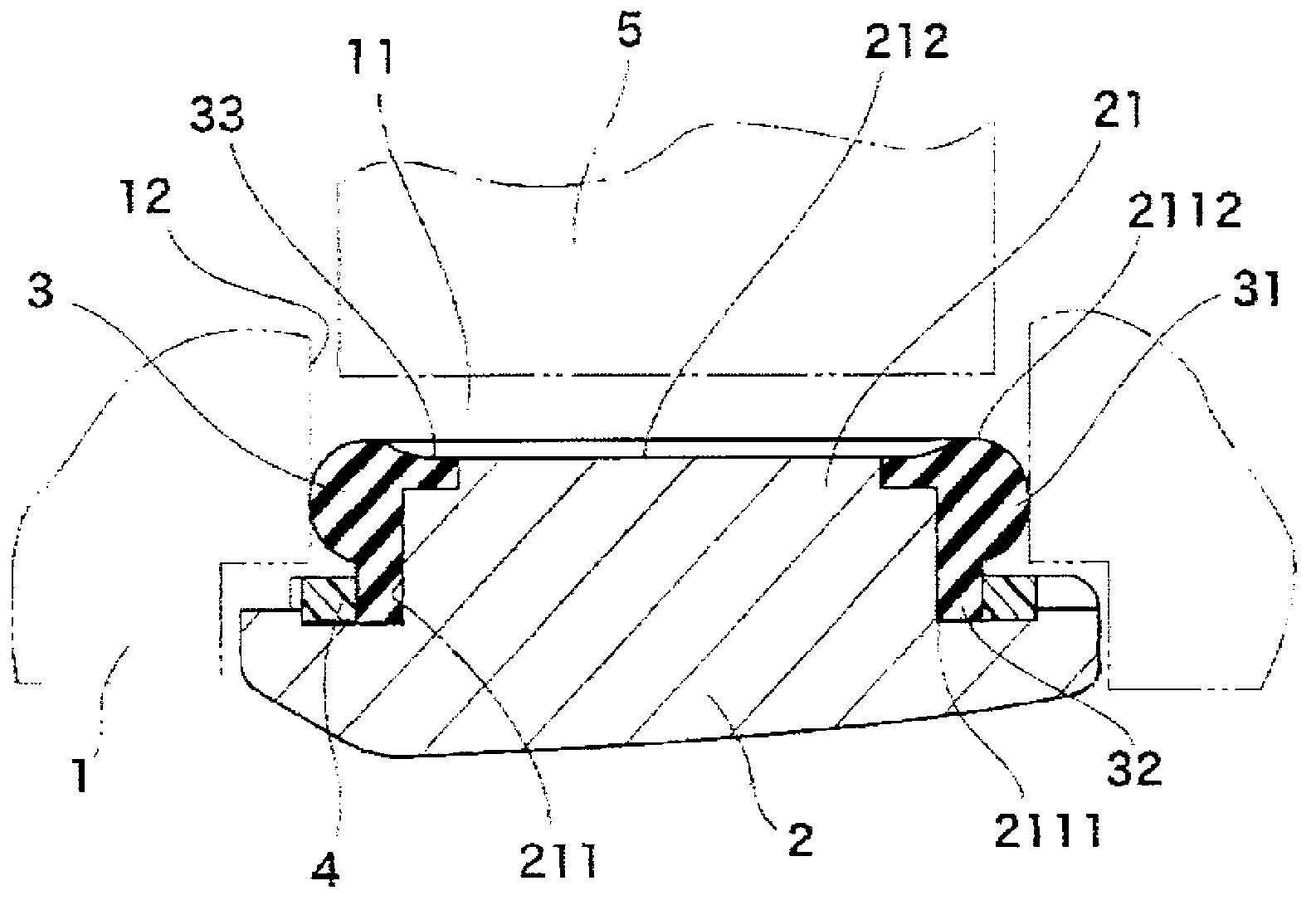

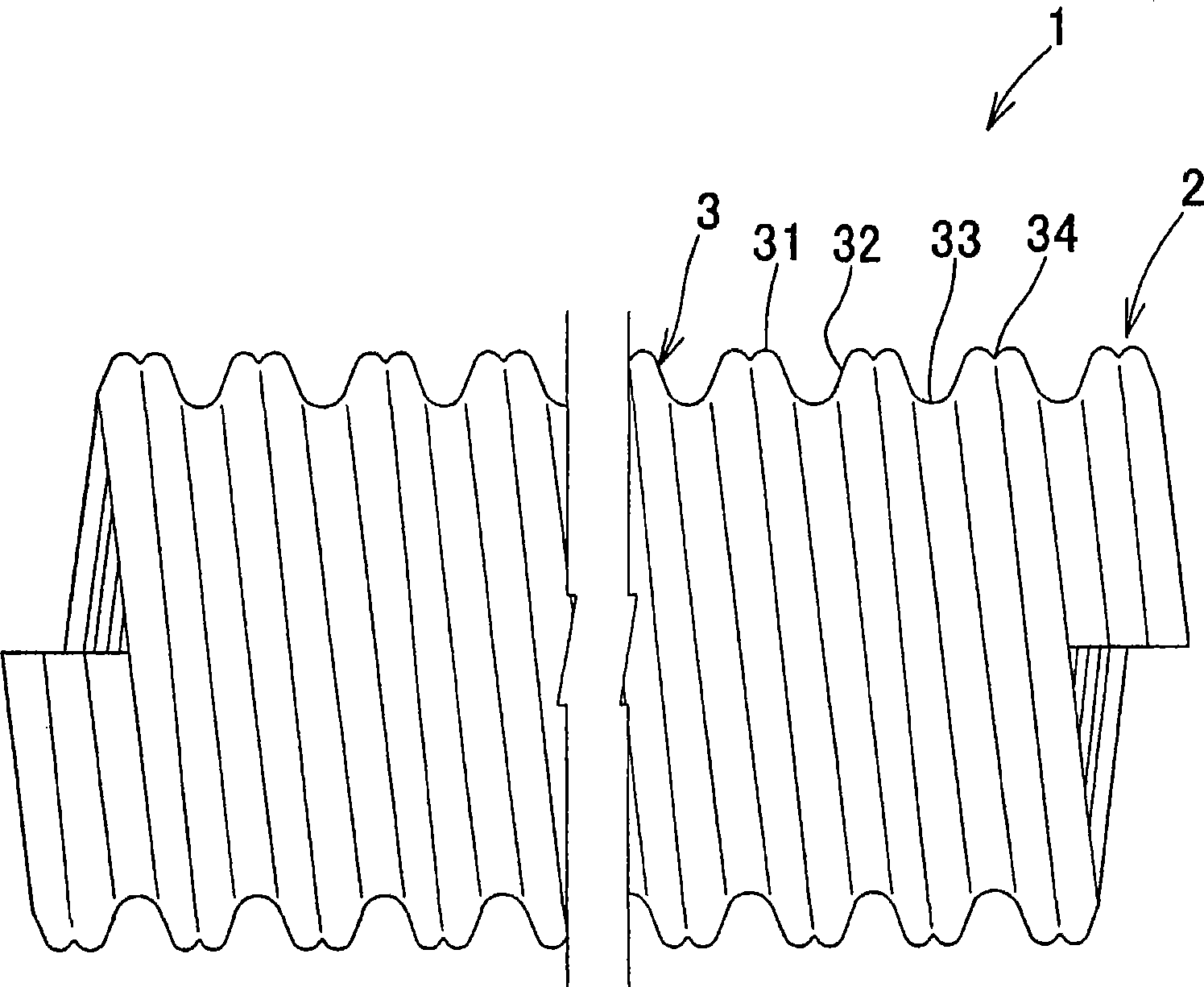

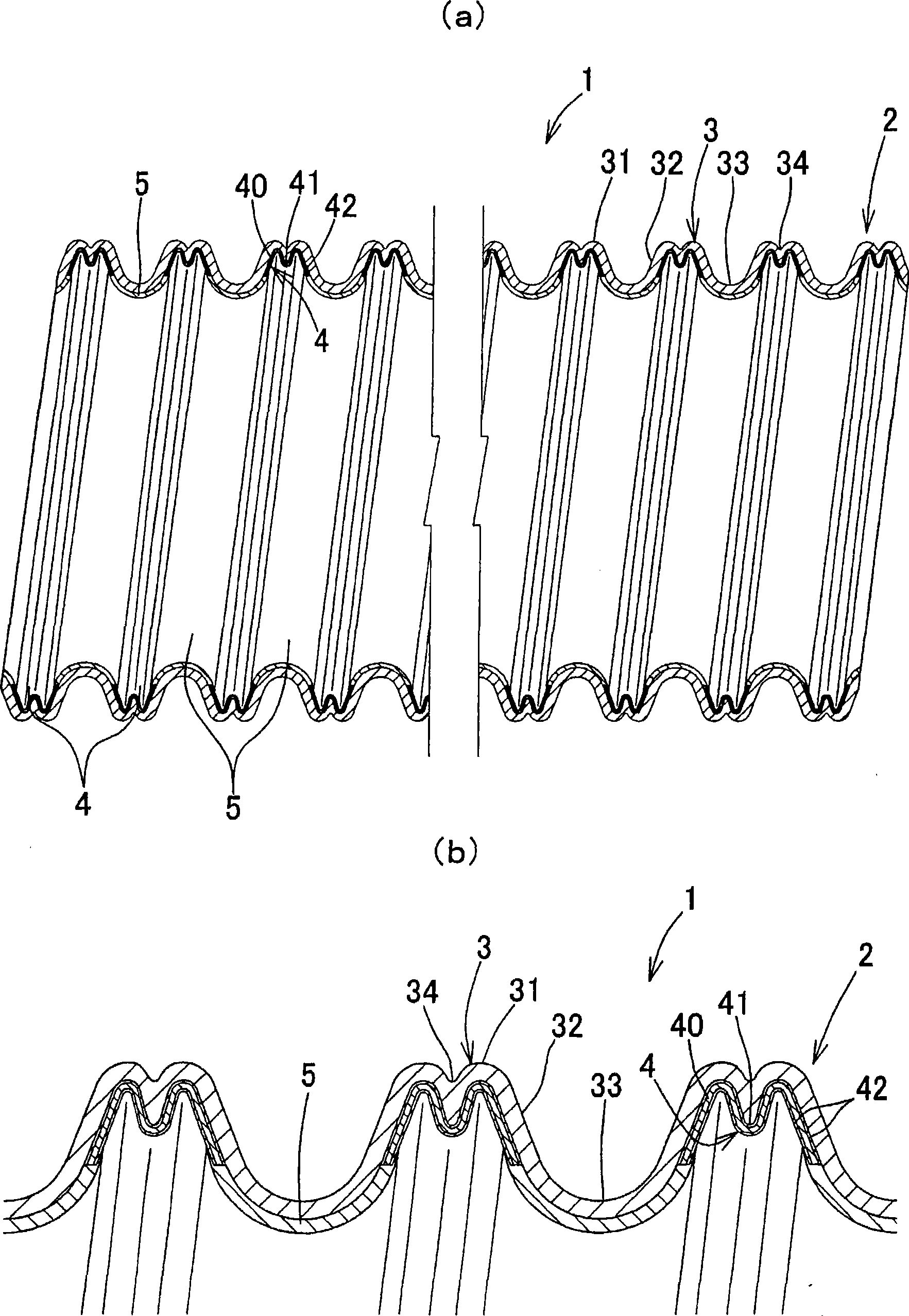

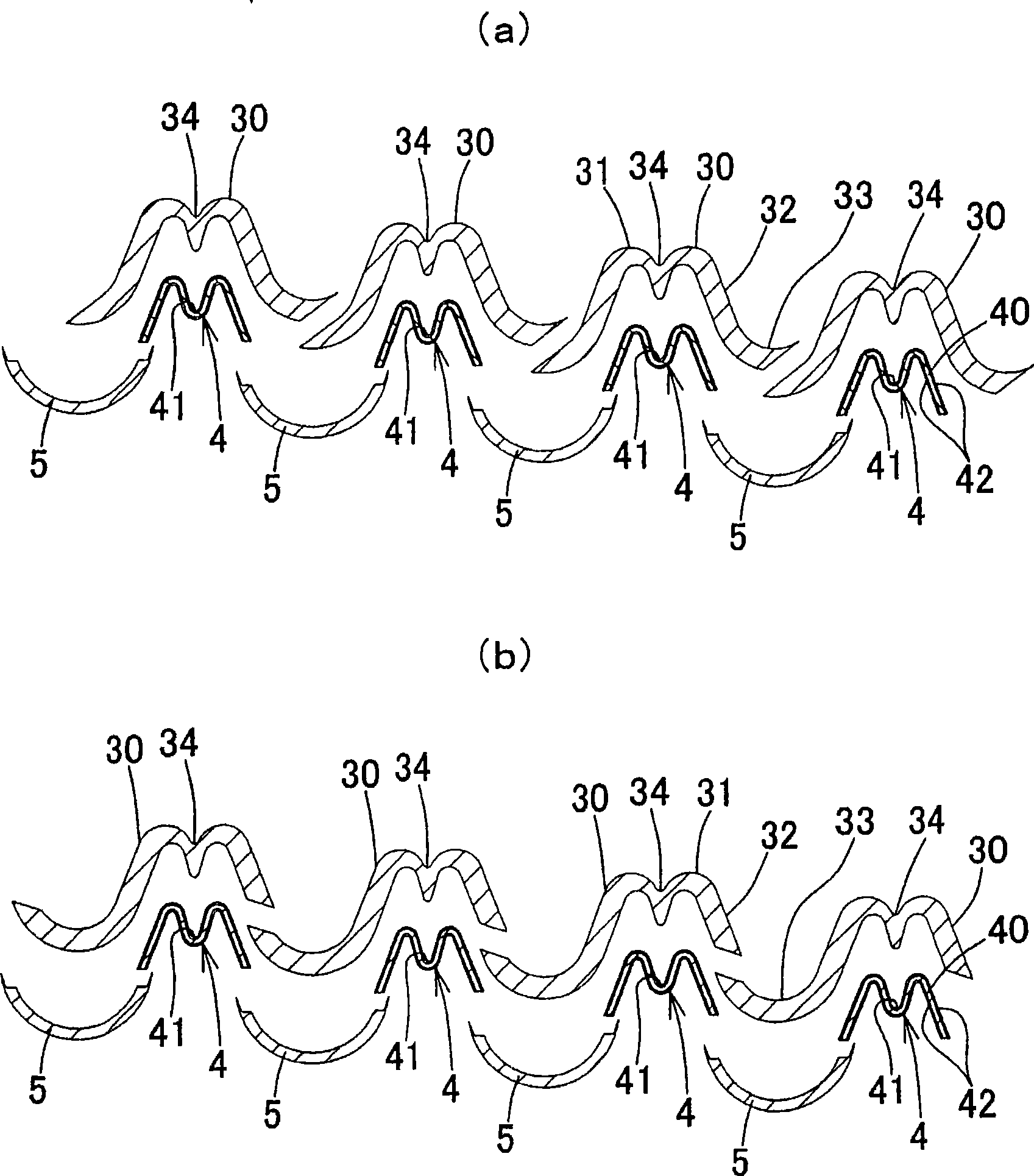

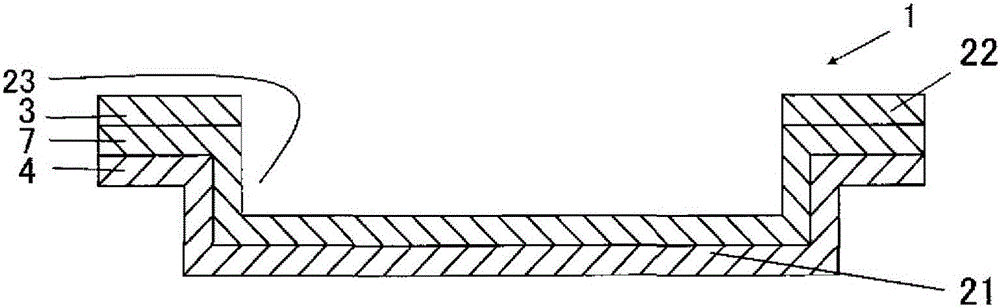

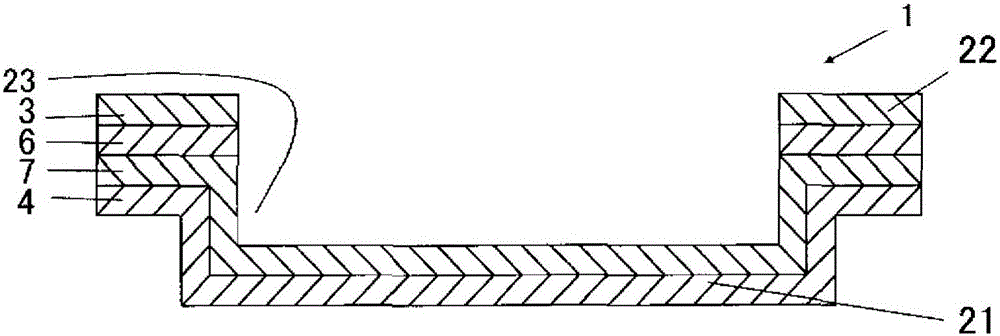

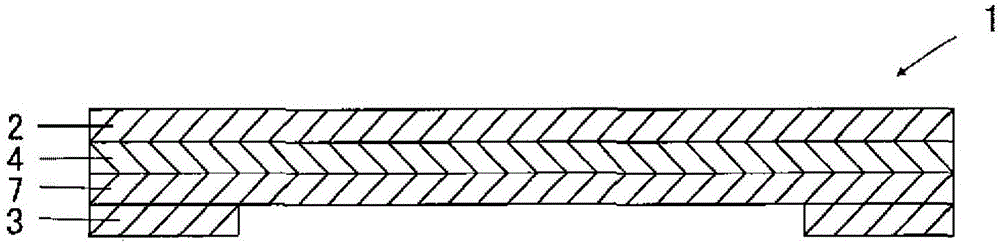

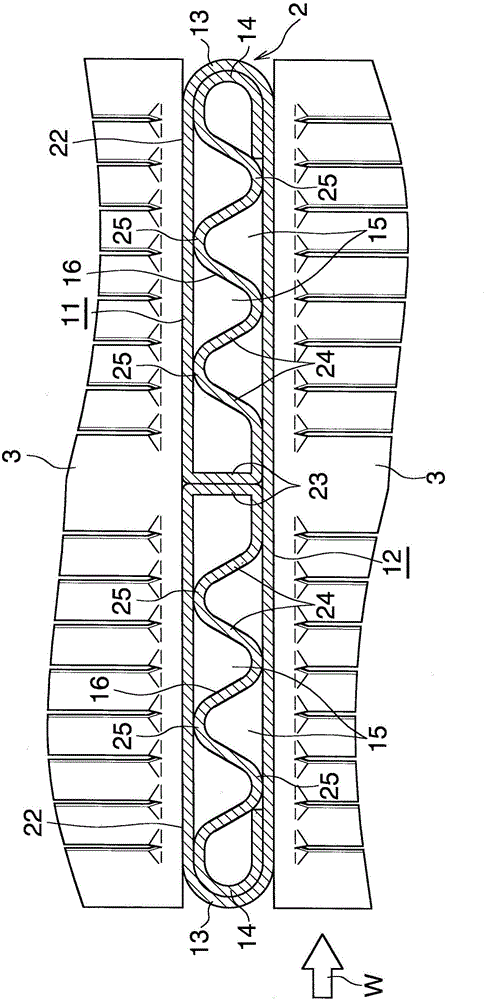

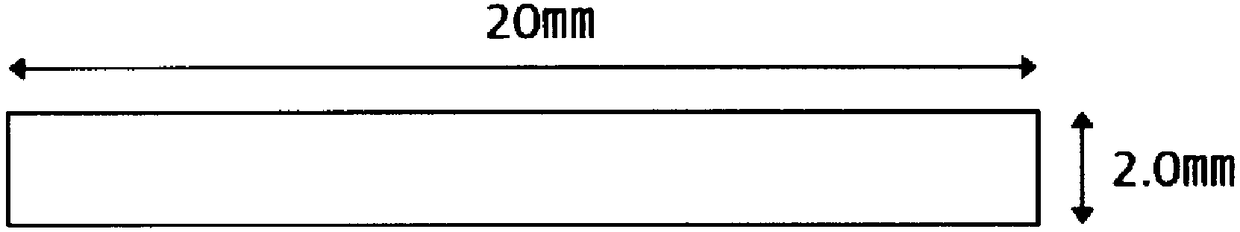

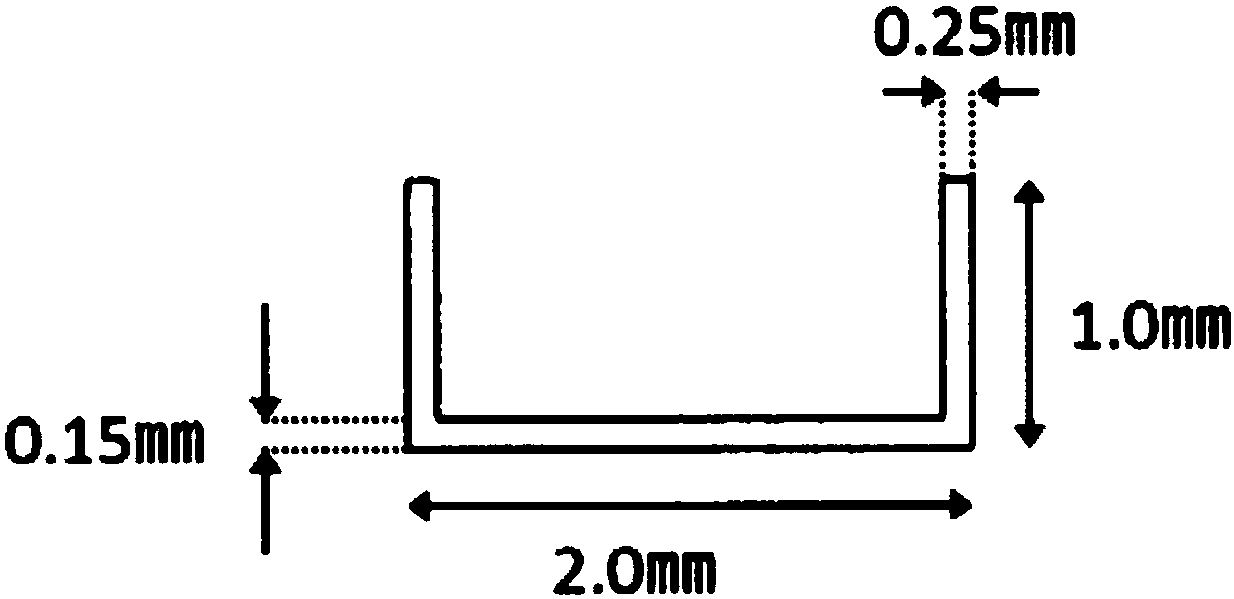

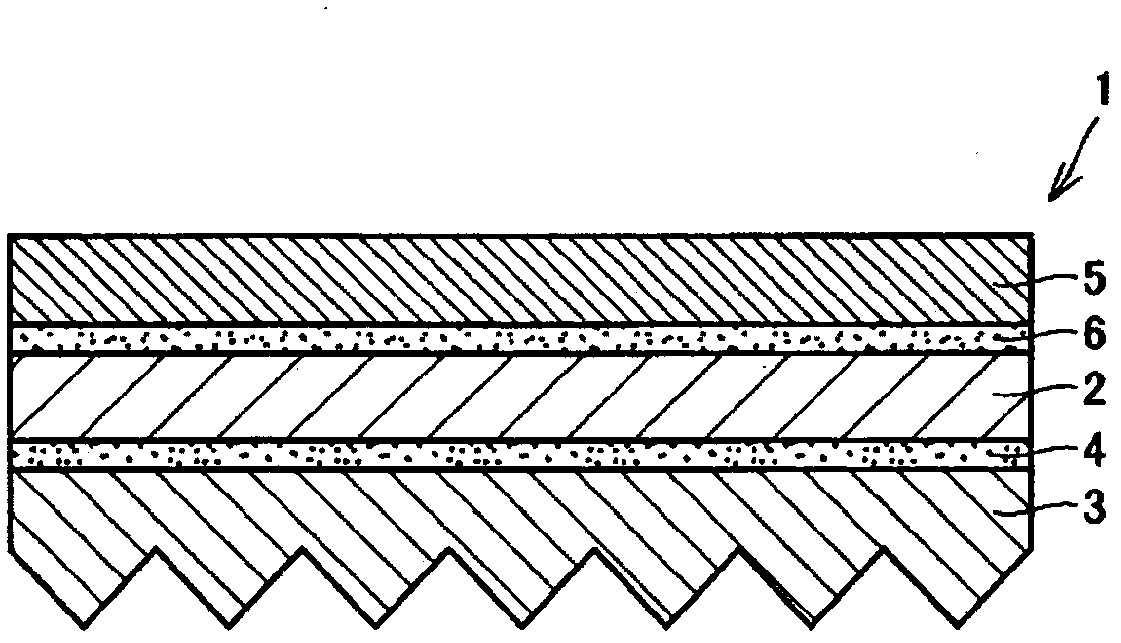

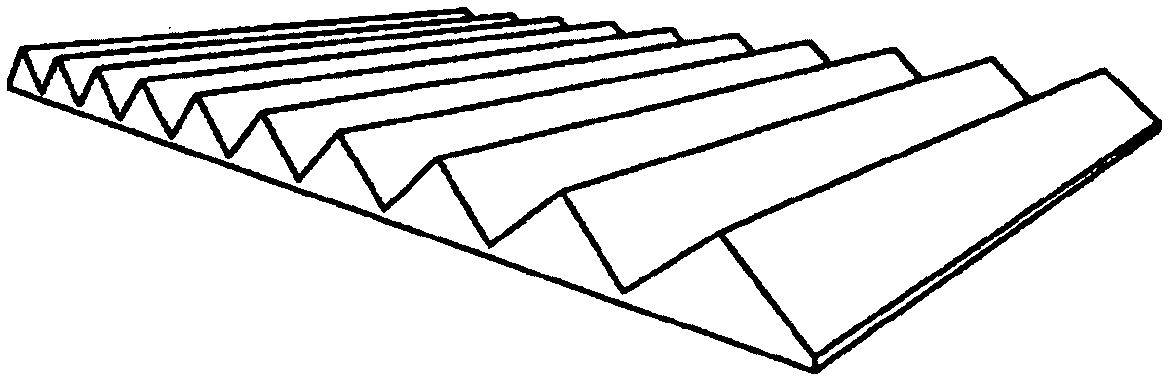

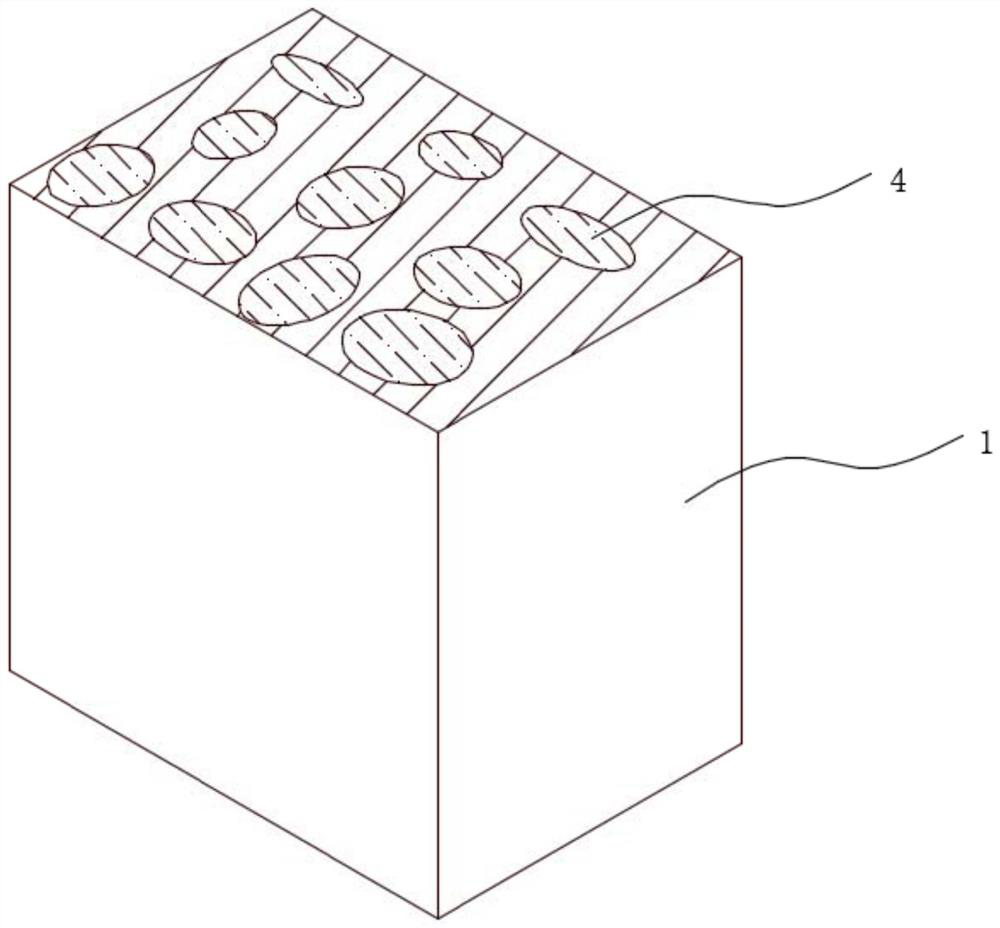

Metal-resin composite pipes

Provided is a metal-resin composite pipe provided with a spiral reinforcing strip plate formed of metal in a pipe wall, in which sufficient pressure capacity and rigidity can be maintained even if the pipe wall is made thin and in which flexibility can be improved. The metal-resin composite pipe1 includes the pipe wall 2 formed in a spiral corrugated shape and a reinforcing strip plate 4 formed of a metal sheet provided in a similar spiral on at least a mountain portion 31 and both side wall portions 32 continuous with the mountain portion 31 of a spiral synthetic resin wall portion 3 constituting the pipe wall 2, the reinforcing strip plate 4 being provided with a single or a plurality of concave portions 41 along a peak portion.

Owner:KANA FURETSUKUSU KOOHOREESHON

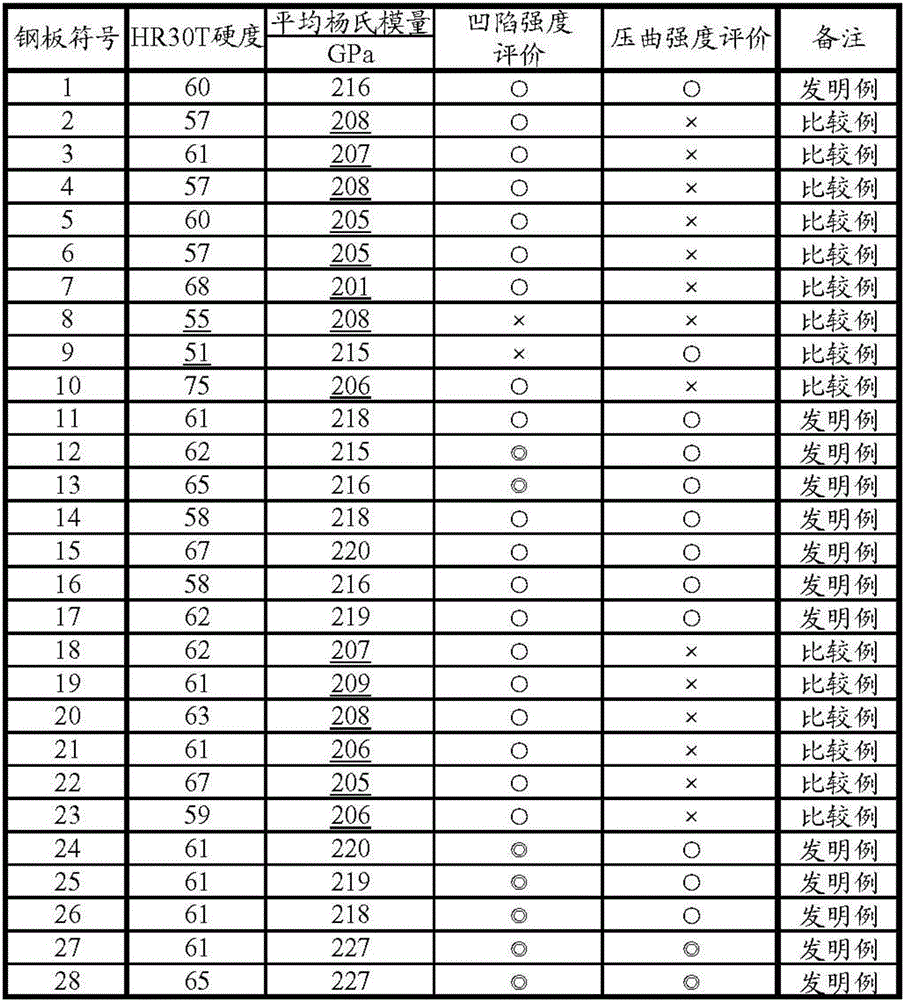

Steel sheet for can, and method for manufacturing same

ActiveCN105378134ARealize thin wallImprove rigidityFurnace typesHeat treatment furnacesYoung's modulusHardness

A purpose of the present invention is to provide a steel sheet for a can that has excellent spinning workability and exceptional strength against buckling at the base of the can resulting from external pressure, and a method for manufacturing the same. The steel sheet for a can is characterized in containing 0.0030% to 0.0100% C, 0.05% or less Si, 0.10% to 1.0% Mn, 0.030% or less P, 0.020% or less S, 0.010% to 0.100% Al, 0.0050% or less N, and 0.010% to 0.050% Nb, with the amount of C and Nb contained satisfying 0.10<=([Nb] / 92.9) / ([C] / 12)<0.60, the balance being Fe and unavoidable impurities, the HR30T hardness being 56 or greater, the average Young's modulus being 210 GPa or greater. A hot-rolled steel plate is cold-rolled with a rolling reduction of 85% or greater, and is annealed at a temperature equal to or greater than the recrystallization temperature, whereby the steel sheet for a can is obtained.

Owner:JFE STEEL CORP

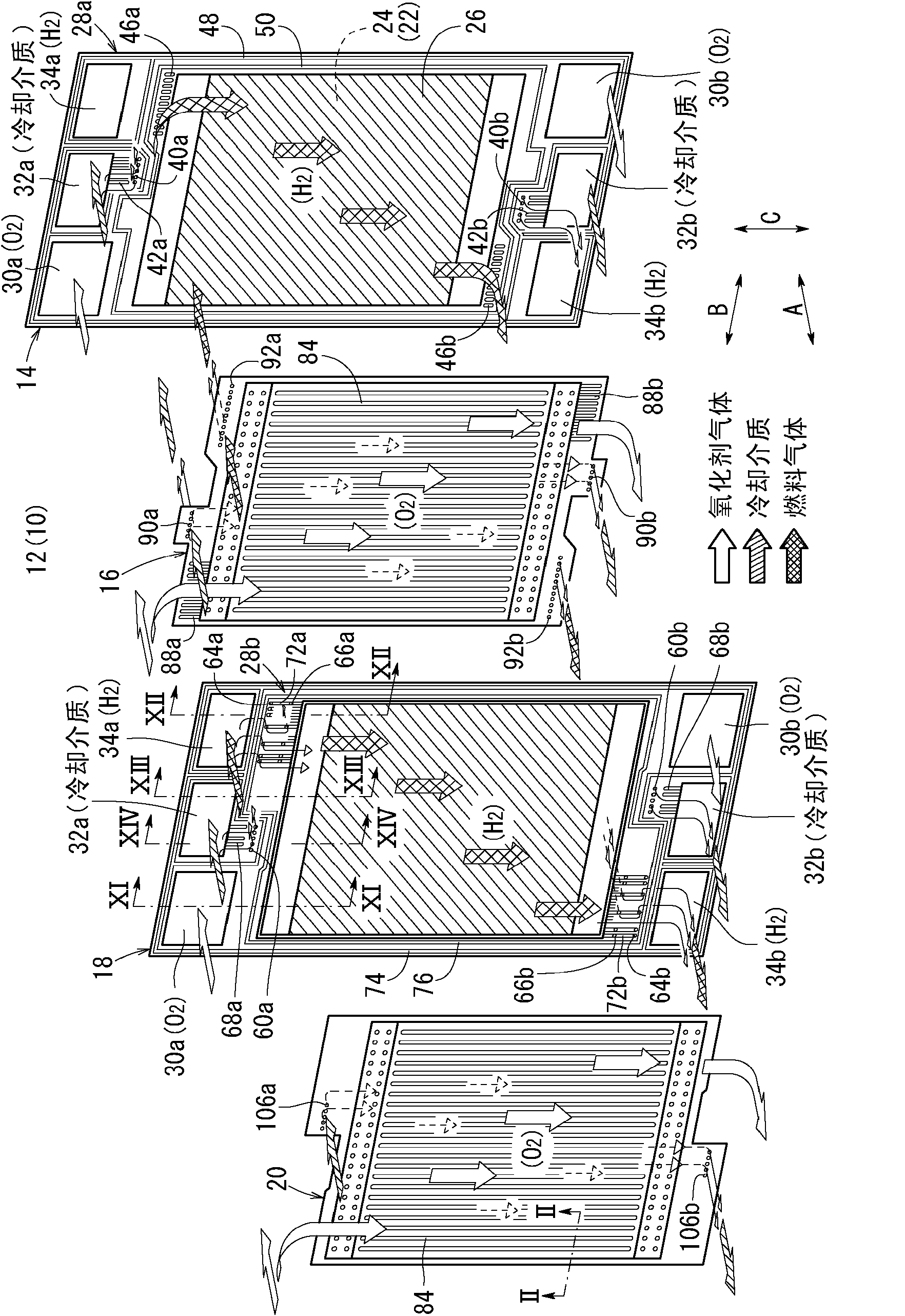

Fuel cell

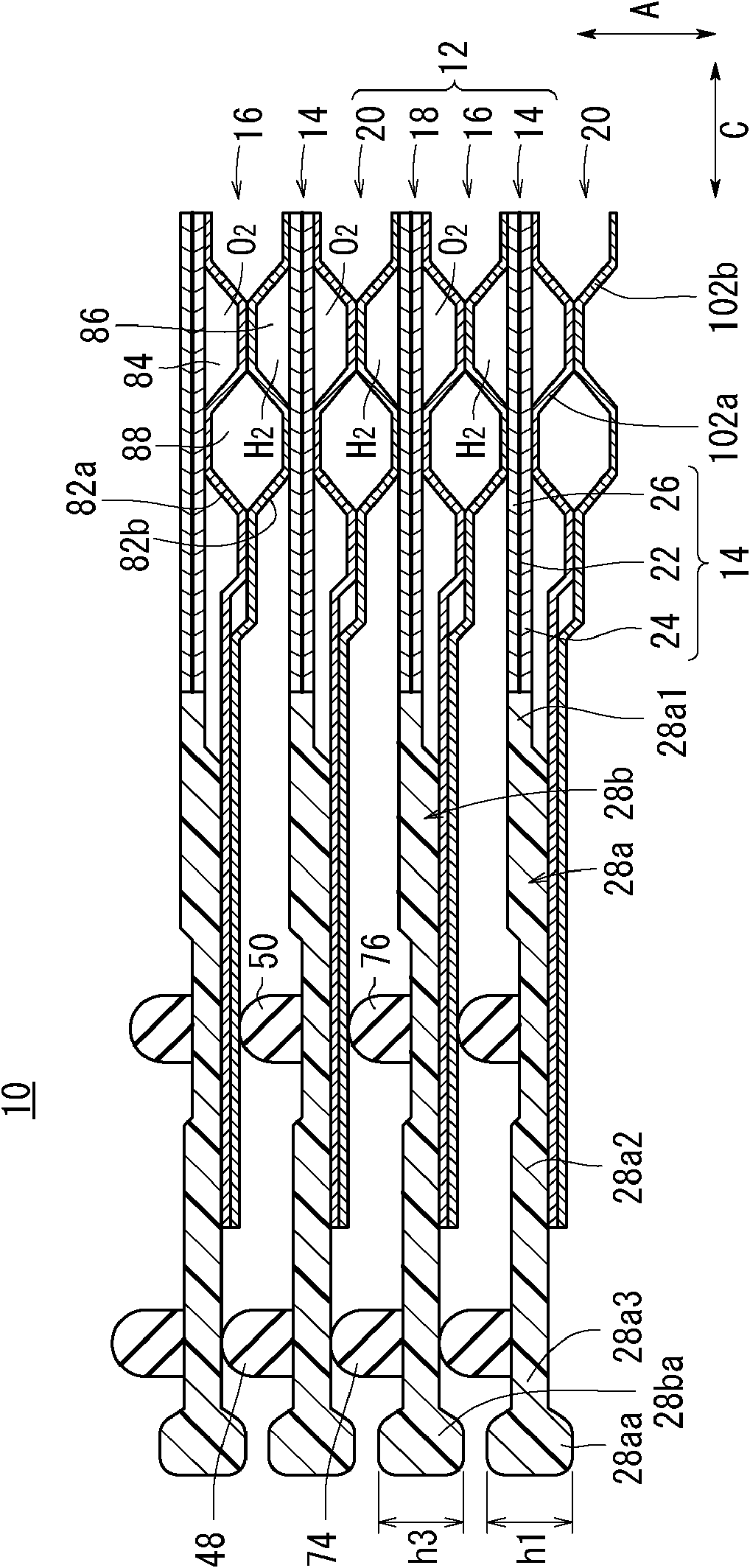

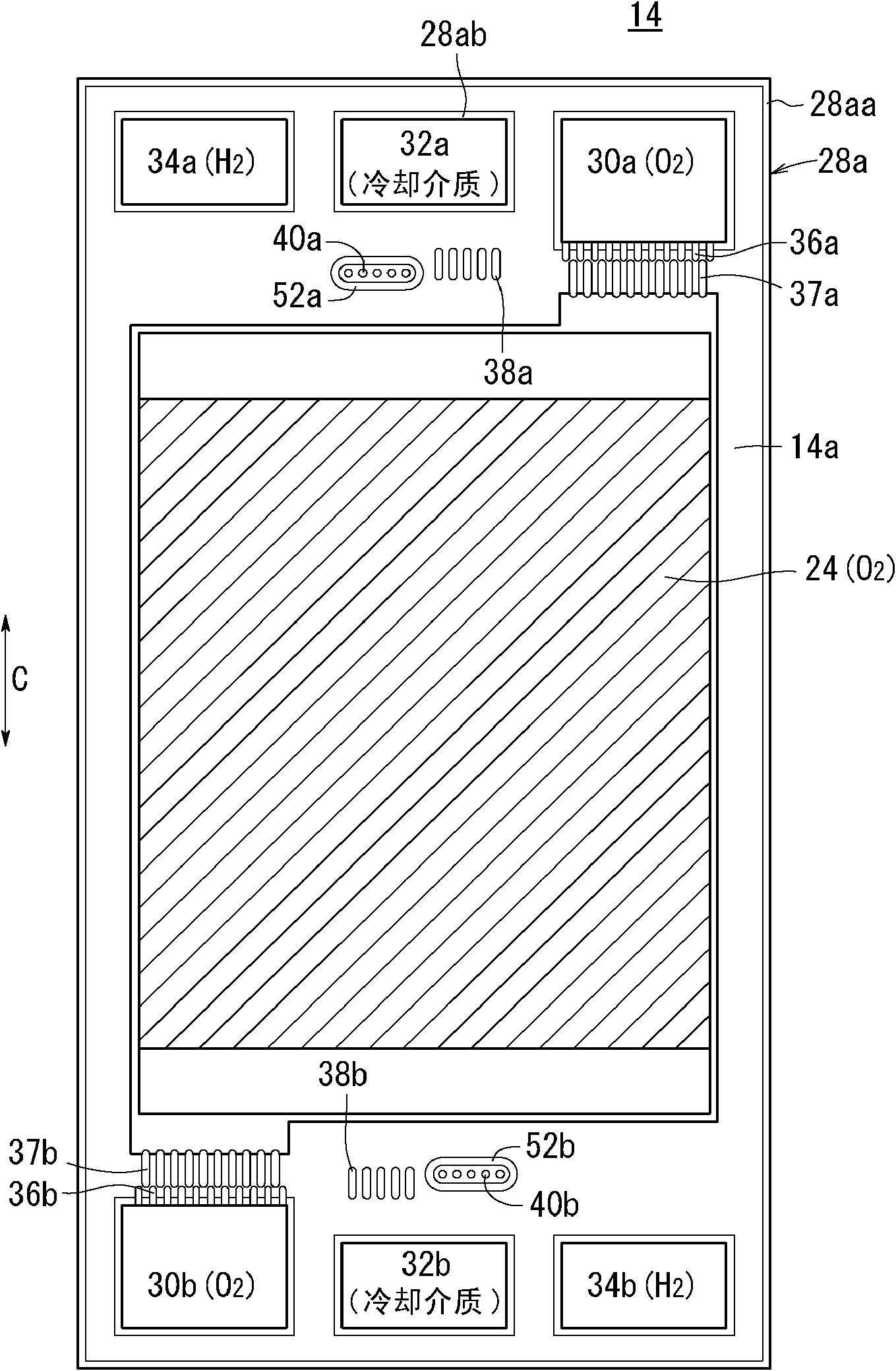

ActiveCN102593477AReduce manufacturing costEfficient preparationFinal product manufactureFuel cell detailsFuel cellsEngineering

The invention provides a furl cell wherein relatively expensive separators may be favorably miniaturized and the manufacturing cost may be reduced, and the stiffness of membrane-electrode assemblies may be effectively increased. The fuel cell (10) includes a cell unit (12) which includes a first membrane-electrode assembly (14), a first separator (16), a second membrane-electrode assembly (18), and a second separator (20). The first and second membrane-electrode assemblies (14, 18) are provided with frame members (28a, 28b), and fluid communication holes are provided in the stacking direction in each of the frame members (28a, 28b) provided with thickened portions (28aa, 28ba) around outer peripheral edges. The thicknesses of thickened portions (28aa, 28ba) are the largest dimensions among those of other regions along the respective outer peripheral edges excluding the outer peripheral edges.

Owner:HONDA MOTOR CO LTD

Package for power storage device and power storage device

ActiveCN106328834ARealize thin wallAchieve lightweightFinal product manufactureSecondary cellsInsulation layerMetal foil

A package for a power storage device includes a metal foil layer, an insulation layer laminated on at least center portion of one surface of the metal foil layer, and a heat-sealable resin layer arranged one surface of the metal foil layer or a region corresponding to a periphery of the one surface of the metal foil layer. With this, thinning, weight saving, and shortening of the production time can be attained.

Owner:LISSENOK PACKAGING CO LTD

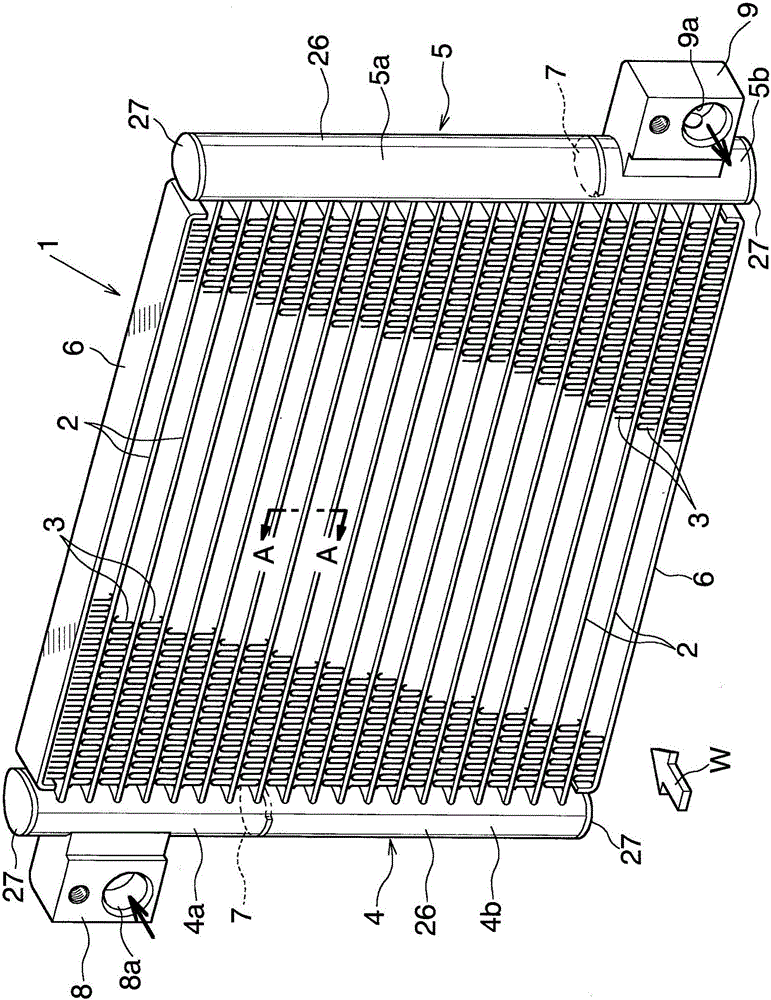

Heat exchanger and method of manufacturing the same

InactiveCN106216973AImprove corrosion resistanceLightweightEvaporators/condensersSoldering apparatusSurface layerHigh potential

Owner:KEIHIN THERMAL TECH CORP

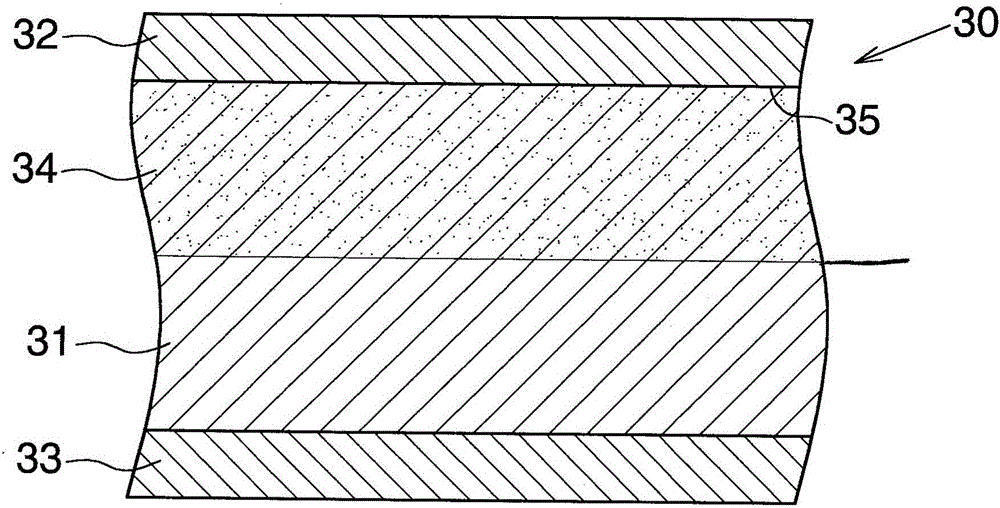

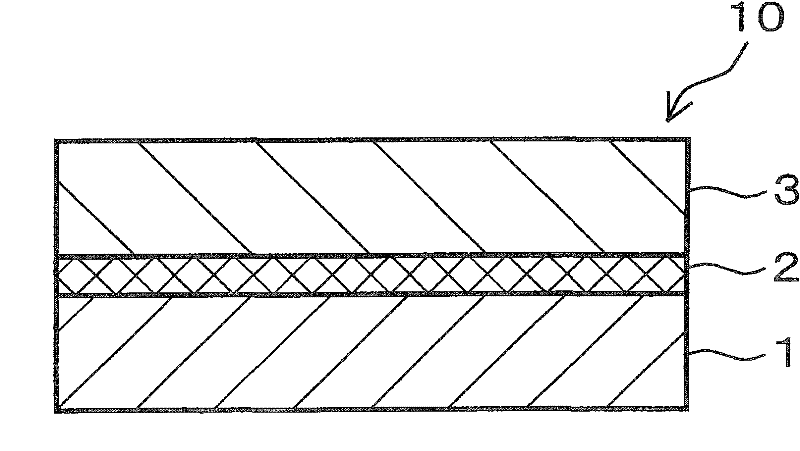

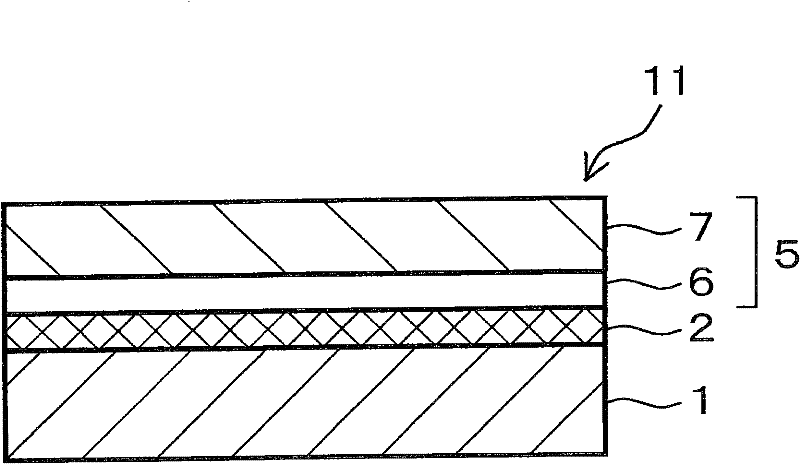

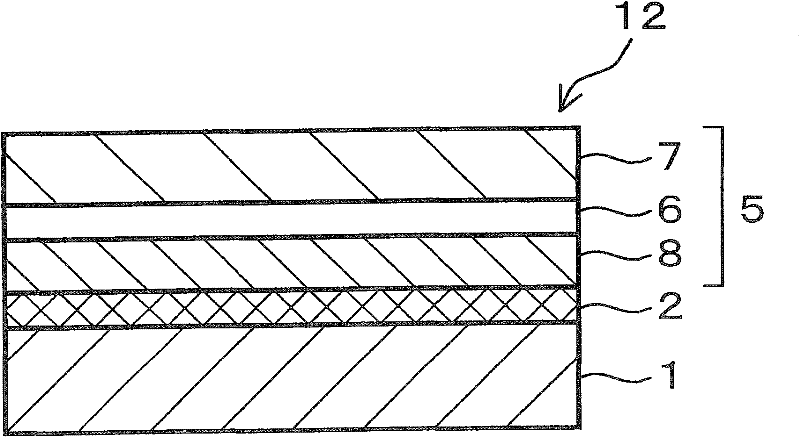

Optical laminated body and manufacture method thereof

InactiveCN102179976AExcellent adhesionRealize thin wallAdhesive processesNon-macromolecular adhesive additivesProduction lineALLYL SUCROSE

The invention provides an optical laminated body and a manufacture method thereof, wherein the optical laminated body is thin-shaped, light in weight and excellent in endurance. A polymer (such as polyacrylic acid) with a compound having alkene double bonds and carboxyls as the main monomer is adopted to form an adhesive layer (2) of a water system adhesive of the main component of the optical laminated body. A glass plate (1) is attached to a plastic sheet (3) by the adhesive layer (2) so as to form the optical laminated body (10). The optical laminated body (10) is manufactured by the following processes: (a) the attaching surface of the glass plate (1) and / or the plastic sheet (3) is provided with an adhesive composition containing the polymer aqueous solution; (b) the glass plate (1) is attached to the plastic sheet (3) by the adhesive layer; (c) the attached product is inspected. If there is a defect, the product is taken out off the production line; (d) If there is no defect, the adhesive layer of the attached product is solidified.

Owner:SUMITOMO CHEM CO LTD

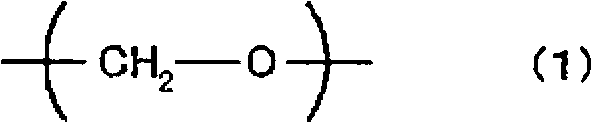

Laminate

ActiveCN102762380AReduce adverse eventsExcellent surface hardnessSynthetic resin layered productsConstructions elementsPolycarbonateStructural unit

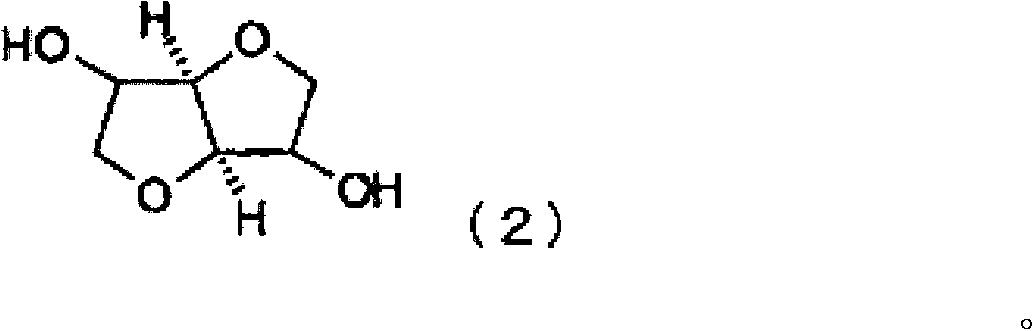

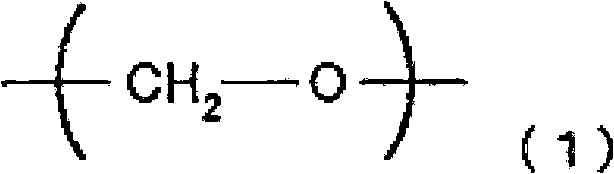

Disclosed is a laminate that exhibits excellent surface hardness, impact resistance, punch-out workability, and resistance to yellowing. Said laminate, which is suitable for use as a display cover or construction material, is characterized in that a polycarbonate resin layer (layer A) and an aromatic polycarbonate resin layer (layer B) are laminated together. The polycarbonate resin layer (layer A) contains a structural unit derived from a dihydroxy compound having, in part of the structure thereof, the site represented by formula (1). (However, the site represented by formula (1) is not part of -CH2-O-H.)

Owner:MITSUBISHI CHEM CORP

Glass tube for fluorescent lamp, fluorescent lamp, and lighting system

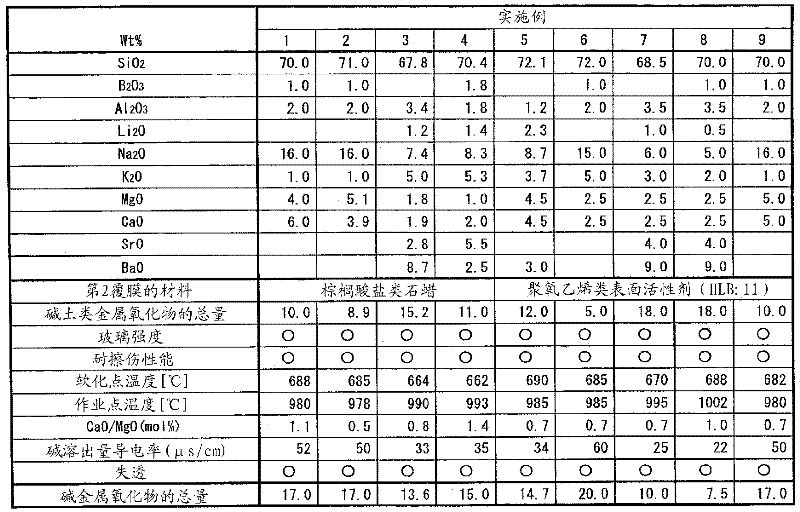

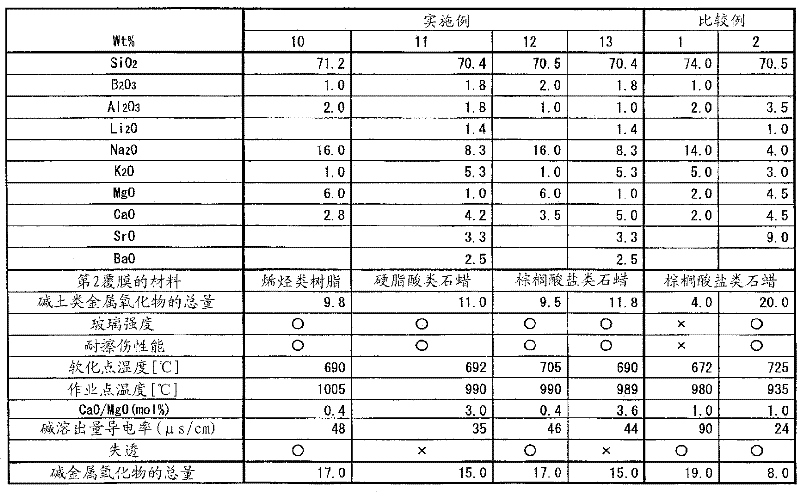

InactiveCN102057461AImprove glass strengthRealize thin wallLow-pressure discharge lampsCoatingsAlkaline earth metalSilicon oxide

Disclosed is a glass tube for a fluorescent lamp that can realize a reduction in thickness of a bulb of a fluorescent lamp. The glass tube for a fluorescent lamp comprises a tube body formed of a glass comprising 60 to 75 wt% of silicon oxide and 5 to 18 wt% of an alkaline earth metal oxide, a first film that is formed at least on the outer peripheral face of the tube body and is formed of at least one oxide selected from tin oxide, titanium oxide, zirconium oxide, and silicon oxide, and a second film that is stacked on the first film and is formed of a hydrophobic lubricant or a surfactant having an HLB value of not more than 13.

Owner:PANASONIC CORP

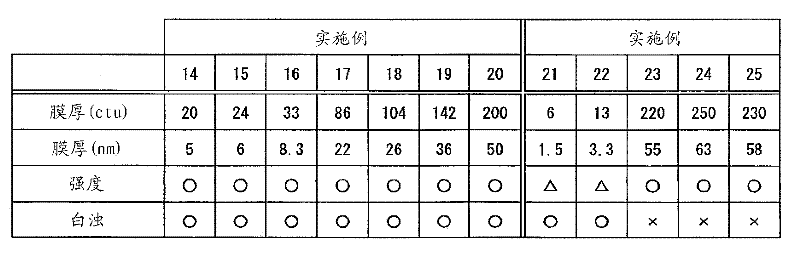

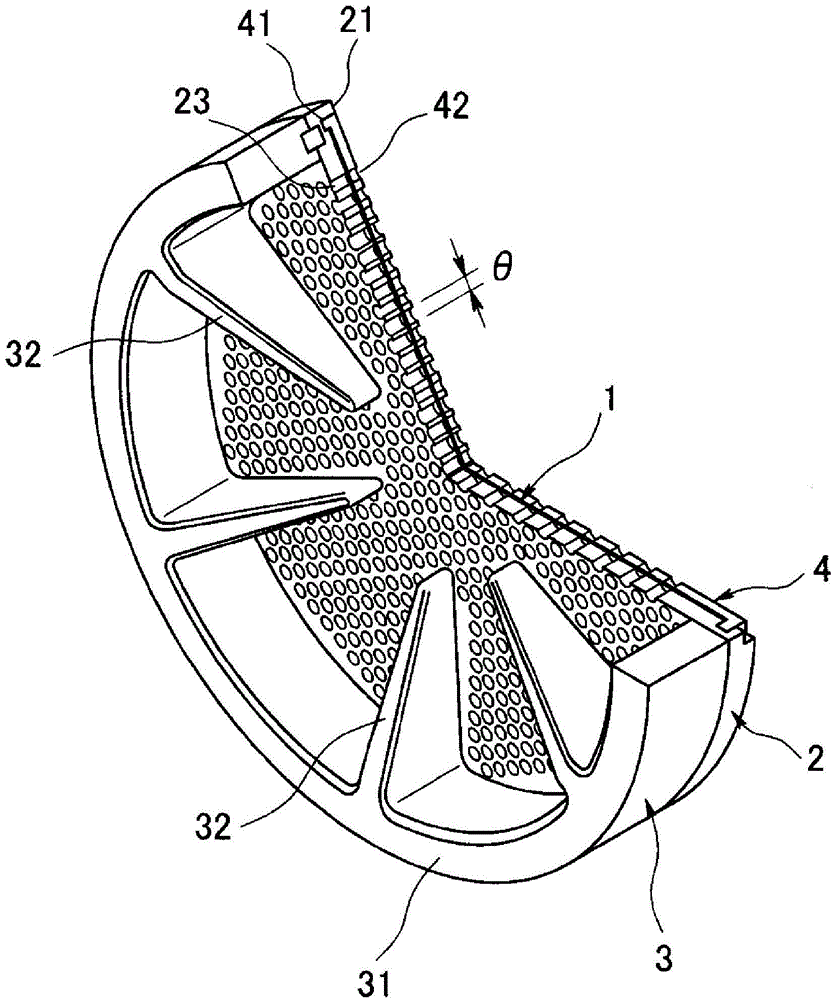

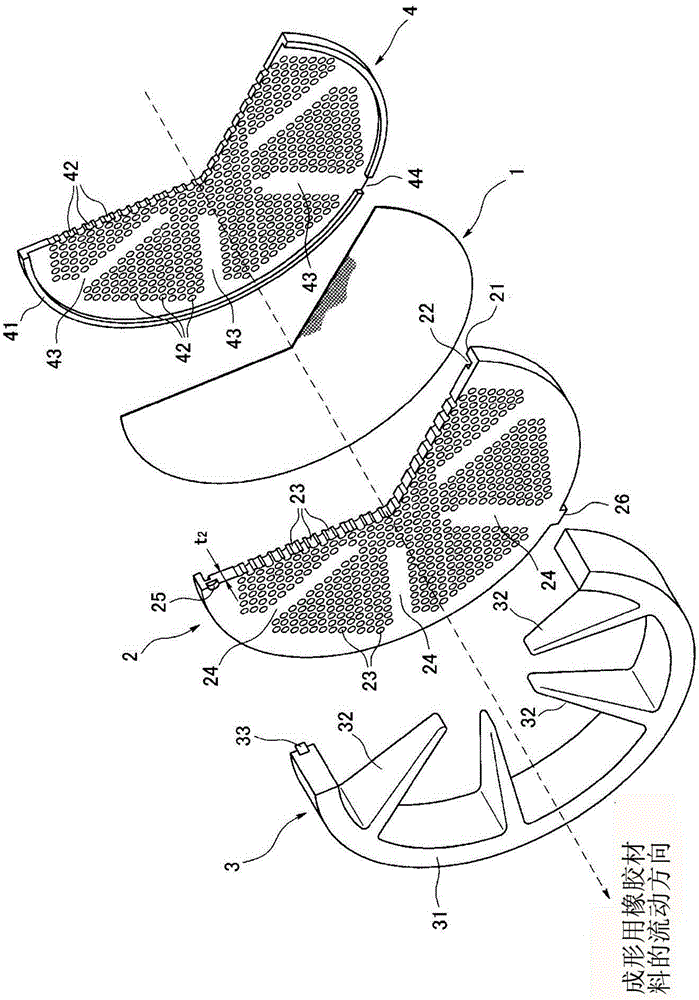

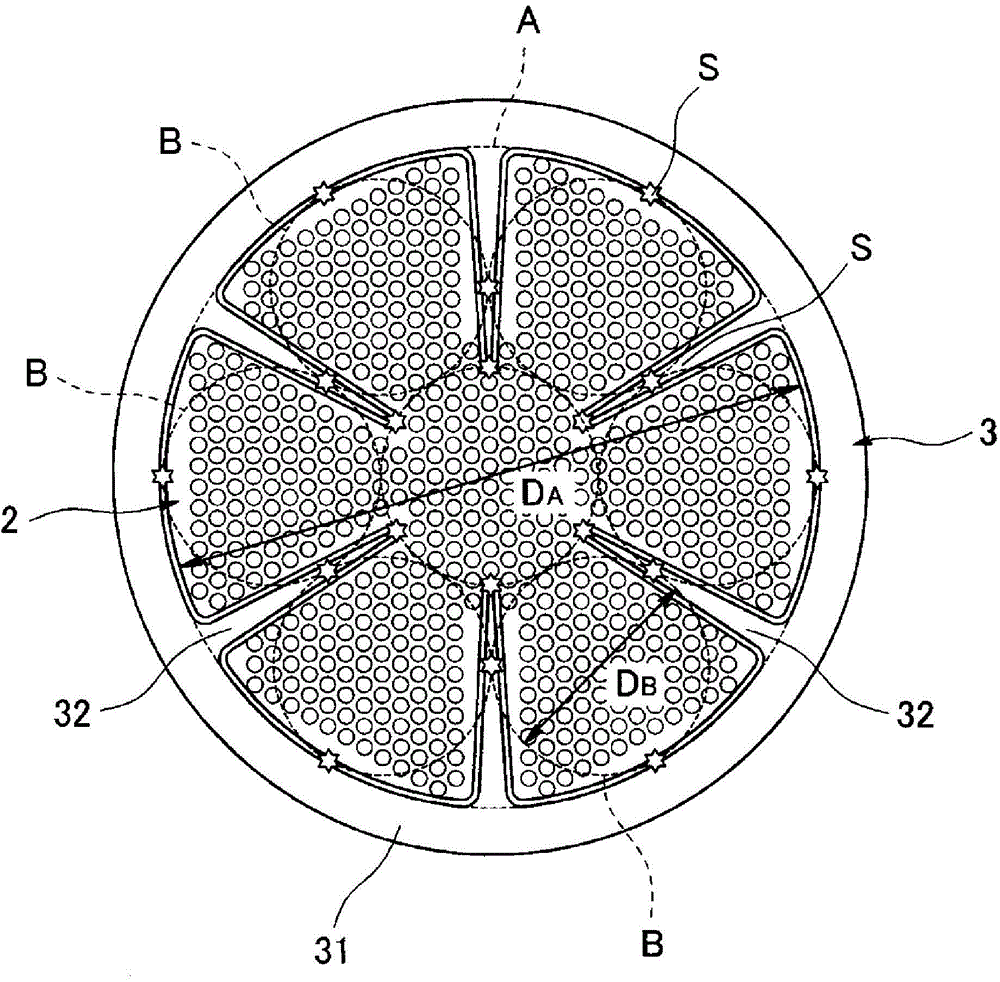

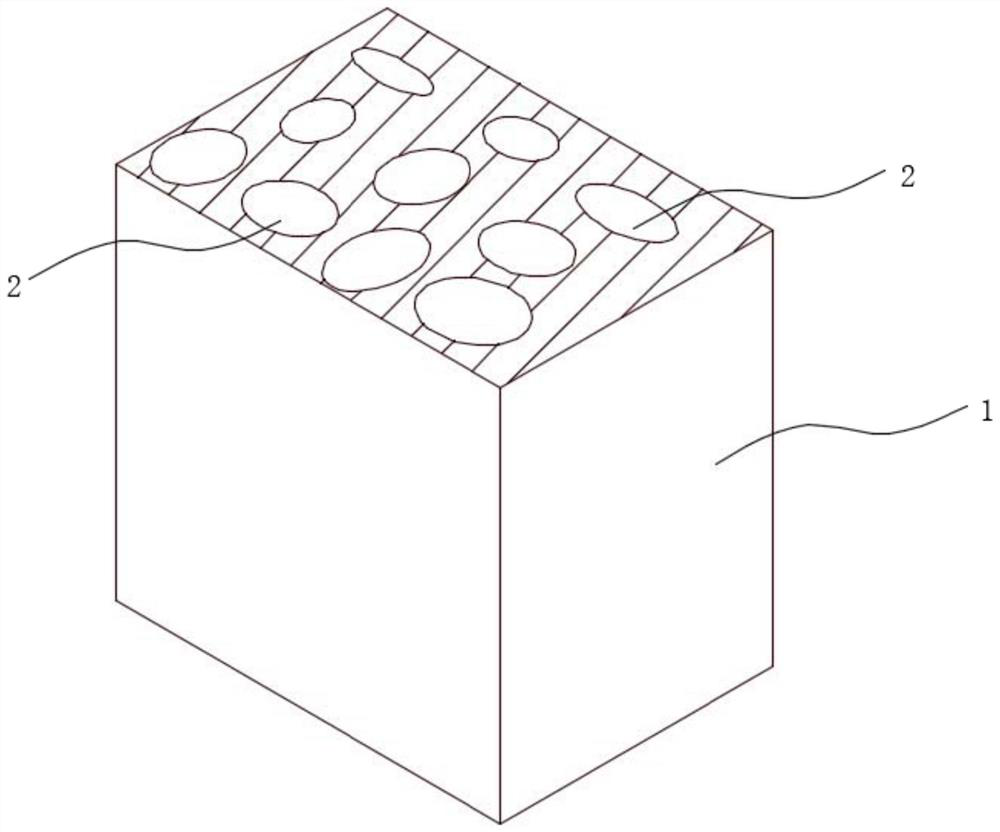

Filter for extruder

The invention provides a filter for an extruder. The filter achieves functions of protecting a filter main body (1), ensuring the intensity of a perforated plate (2), reducing pressure loss in a filtering process and preventing cleaning deterioration and weight increase. The filter for an extruder comprises a filter main body (1), a perforated plate (2) supporting the filter main body (1) from the downstream side and comprising a plurality of through holes (23) forming paths of a high molecular material and a support body (3) supporting the perforated plate (2) from the downstream side. The support body (3) is composed of a frame section (31) which can be pressed against the outer diameter part of the perforated plate (2) and a plurality of beam parts (32) extending the inner circumferential side from the frame section (31).

Owner:NOK CORP

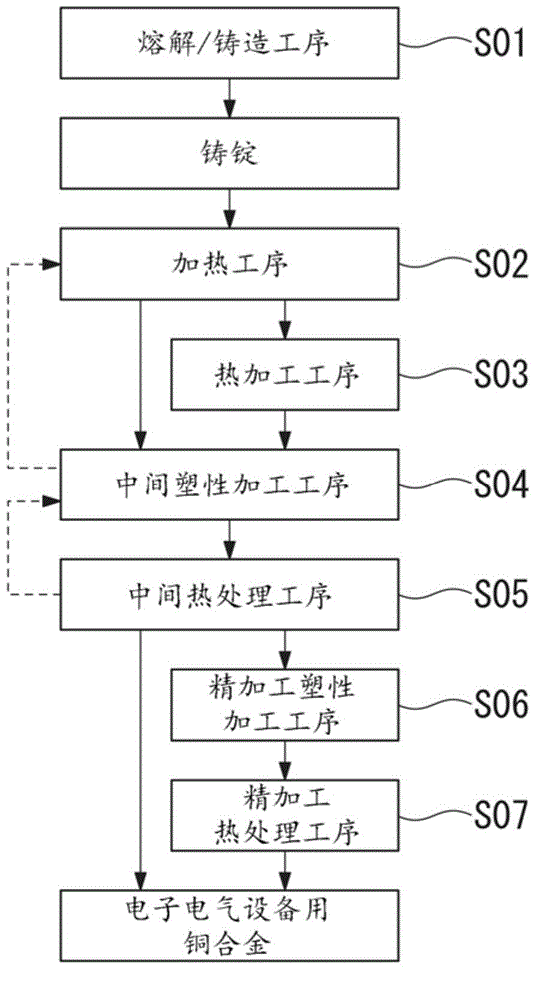

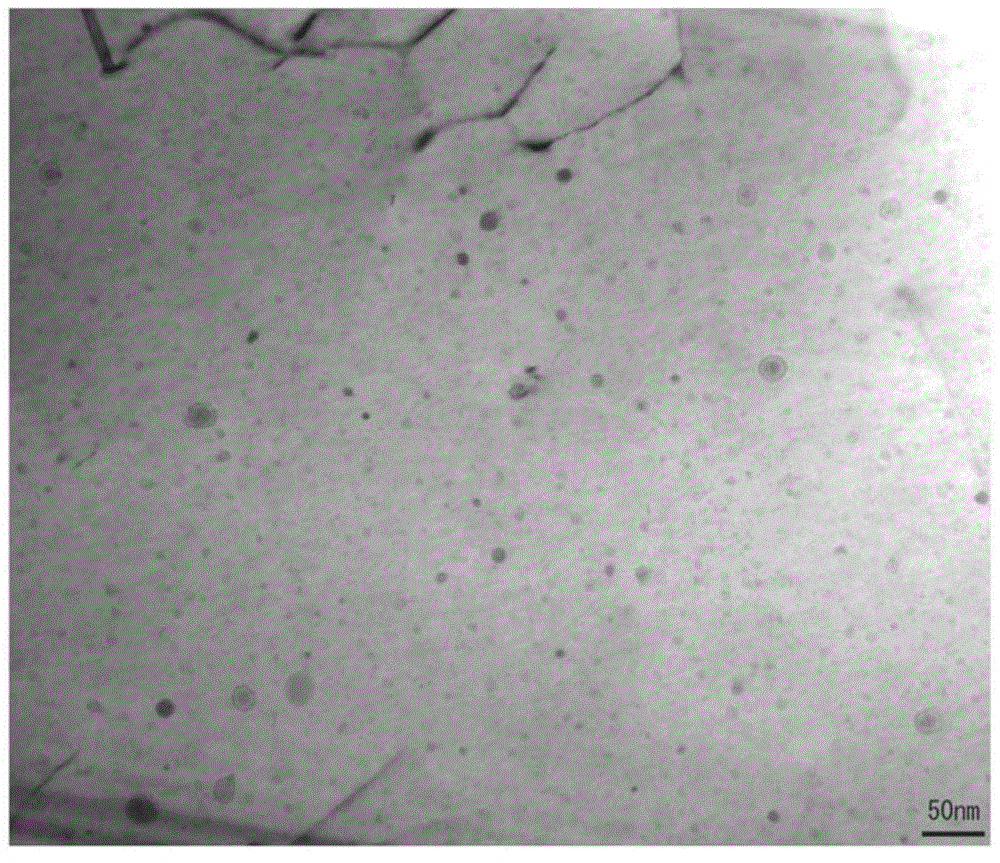

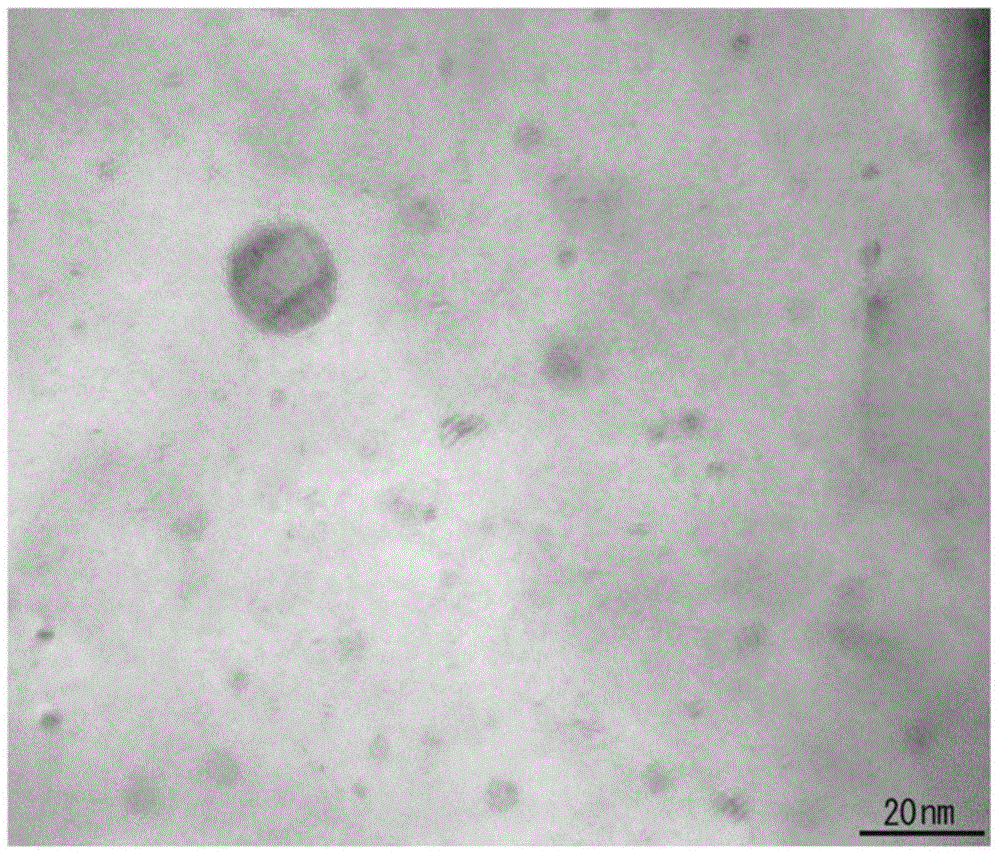

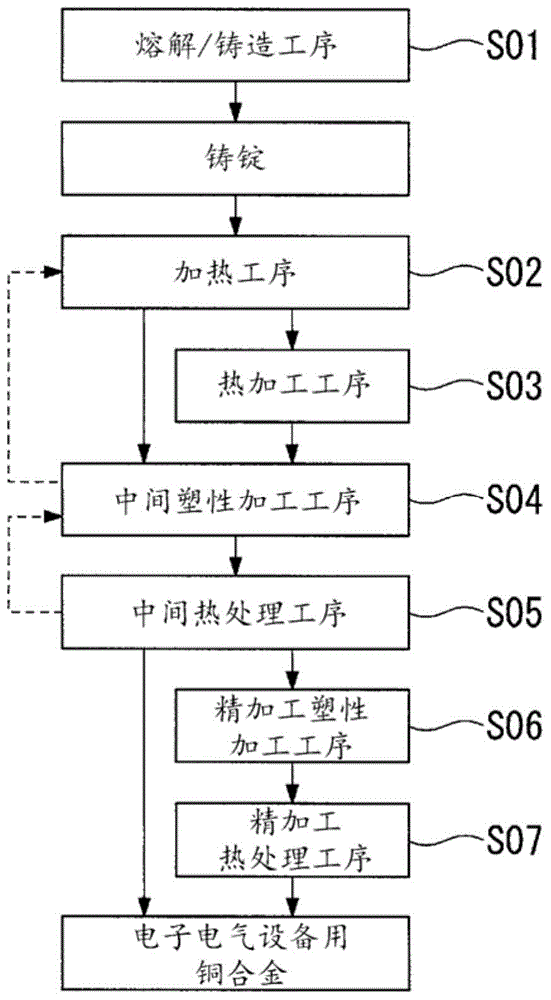

Copper alloy for electronic or electrical device, copper alloy thin sheet for electronic or electrical device, process for manufacturing copper alloy for electronic or electrical device, conductive component for electronic or electrical device, and terminal

InactiveCN104919066ARealize thin wallReliable and sufficiently excellent stress relaxation resistanceSingle bars/rods/wires/strips conductorsApparatus for heat treatmentThin sheetCopper alloy

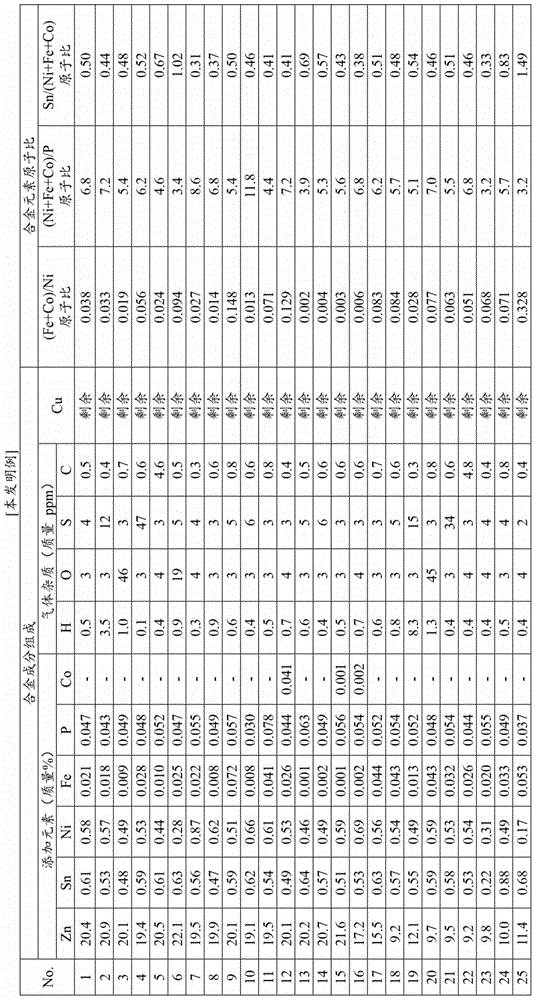

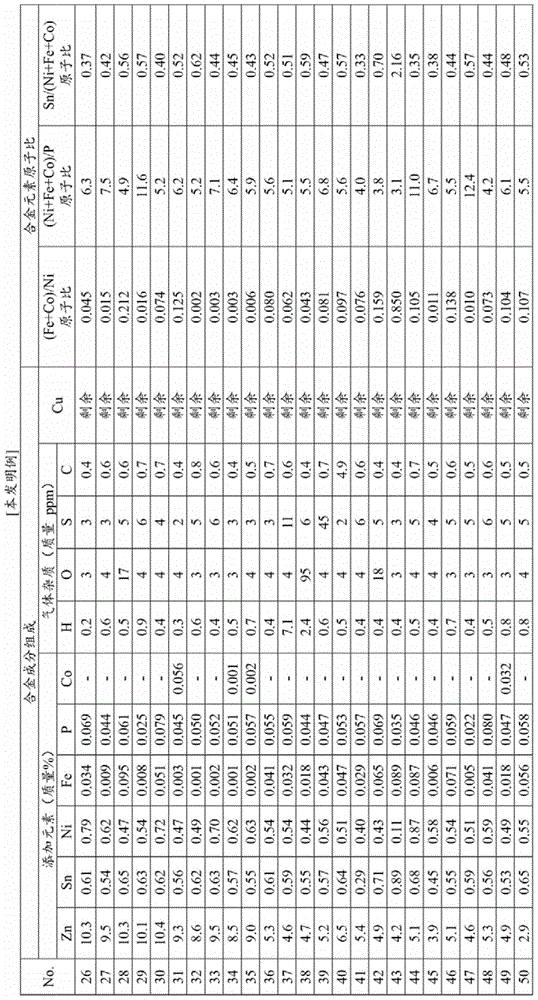

A copper ally for an electronic or electrical device, containing more than 2.0 to 36.5 mass% of Zn, 0.1 to 0.9 mass% of Sn, 0.05 to less than 1.0 mass% of Ni, 0.5 to less than 10 mass ppm of Fe, 0.001 to less than 0.10 mass% of Co, and 0.001 to 0.10 mass% of P with the balance consisting of Cu and unavoidable impurities, satisfying the relationships among the contents of these elements in atomic ratio, 0.002 ≤ Fe / Ni < 1.5, 3 < (Ni+Fe) / P < 15 and 0.3 < Sn / (Ni+Fe) < 5, and containing a precipitate that contains both P and at least one element selected from the group consisting of Fe, Co and Ni.

Owner:MITSUBISHI MATERIALS CORP +1

Copper alloy for electrical and electronic equipment, copper alloy thin sheet for electrical and electronic equipment, and conductive part and terminal for electrical and electronic equipment

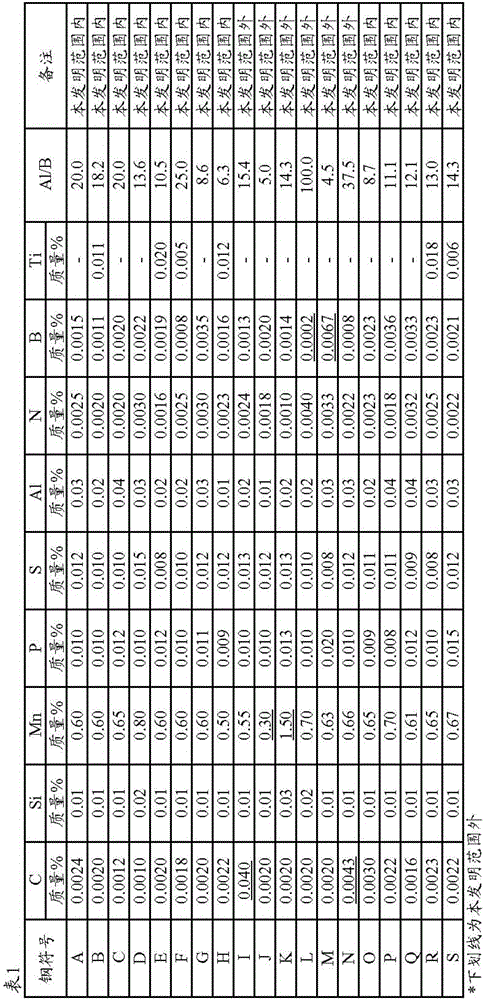

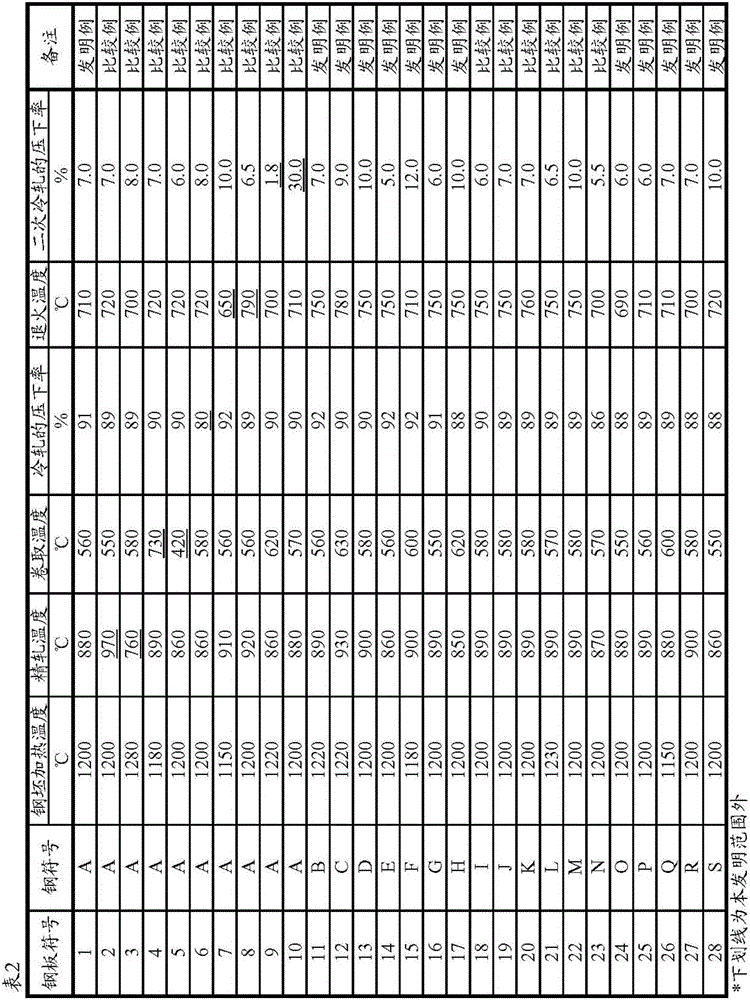

ActiveCN104822854AReliable and sufficiently excellent stress relaxation resistanceHigh strengthSingle bars/rods/wires/strips conductorsConductive materialOxygenImpurity

The present invention pertains to a copper alloy for electrical and electronic equipment, a copper alloy thin sheet for electrical and electronic equipment, and a conductive part and terminal for electrical and electronic equipment. The copper alloy for electrical and electronic equipment contains more than 2.0 mass% but less than 23.0 mass% of zinc, 0.10 mass% to 0.90 mass% of tin, 0.05 mass% to less than 1.00 mass% of nickel, 0.001 mass% to less than 0.100 mass% of iron, and 0.005 mass% to 0.100 mass% of phosphorus, with the remainder comprising copper and unavoidable impurities. The copper alloy satisfies 0.002 ≤ Fe / Ni < 1.500, 3.0 < (Ni + Fe) / P < 100.0, and 0.10 < Sn / (Ni + Fe) < 5.00 in terms of atomic ratios. The content of hydrogen is not more than 10 mass ppm, the content of oxygen is not more than 100 mass ppm, the content of sulfur is not more than 50 mass ppm, and the content of carbon is not more than 10 mass ppm.

Owner:MITSUBISHI MATERIALS CORP +1

Steel plate for can and method for producing same

InactiveCN106133167ARealize thin wallEasy to manufactureFurnace typesCans/barrels/drumsYoung's modulusUltimate tensile strength

Owner:JFE STEEL CORP

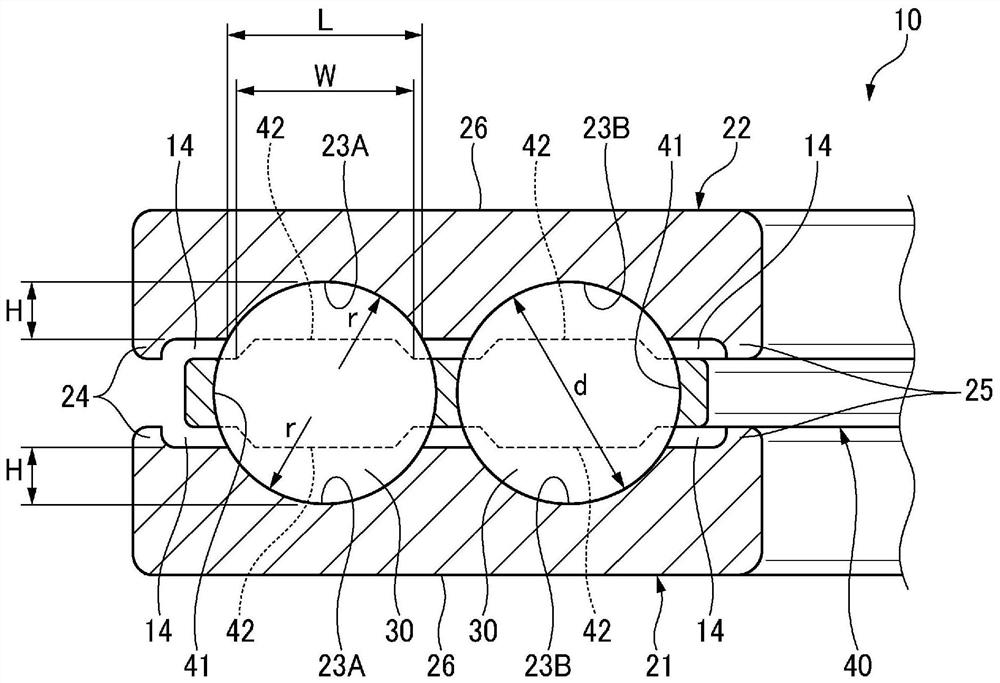

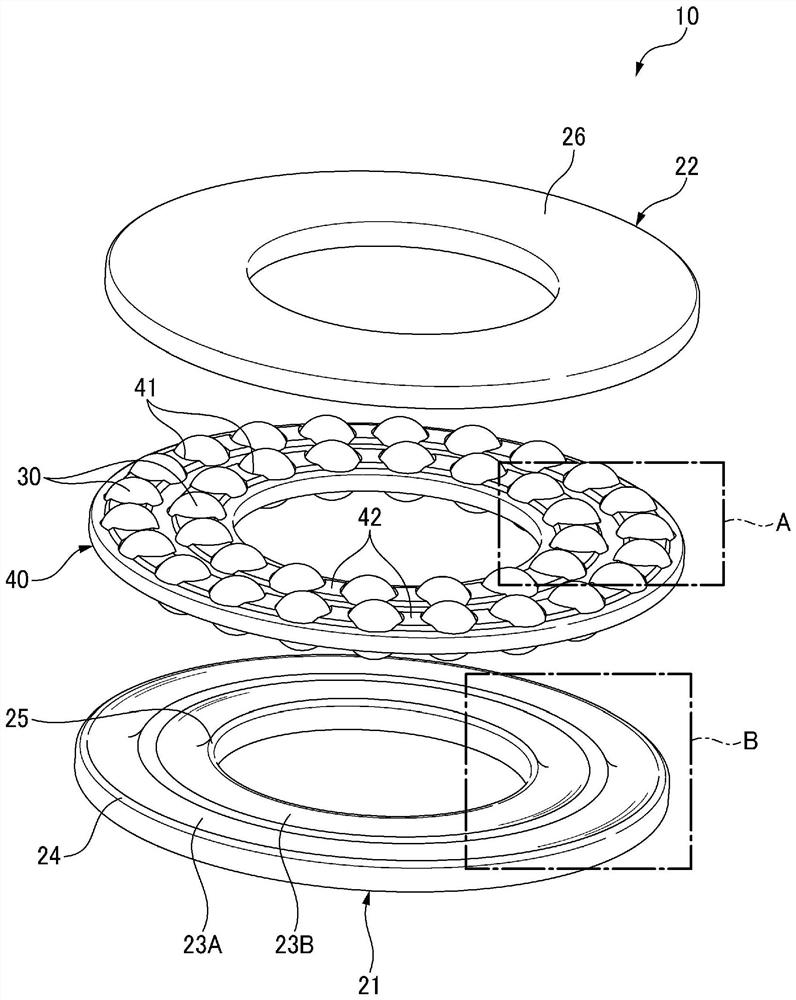

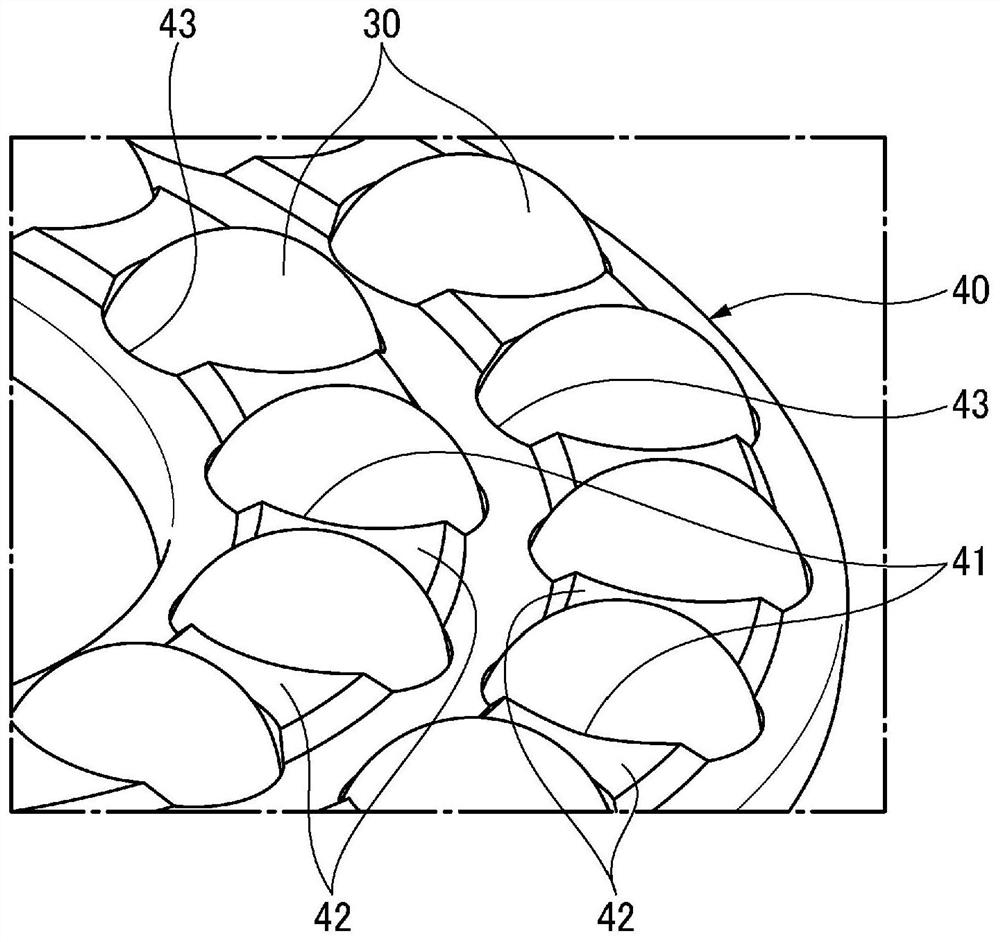

Multi-row thrust ball bearing

PendingCN113692495ALarge load capacityRealize thin wallShaftsBall bearingsBall bearingClassical mechanics

Owner:NSK LTD

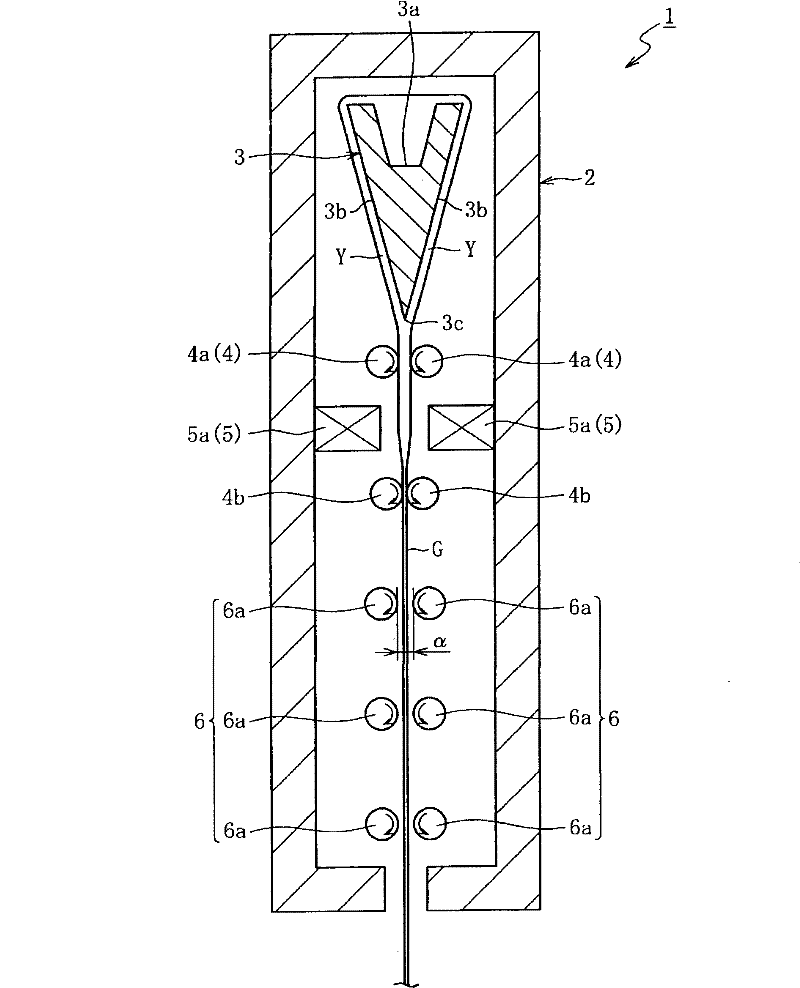

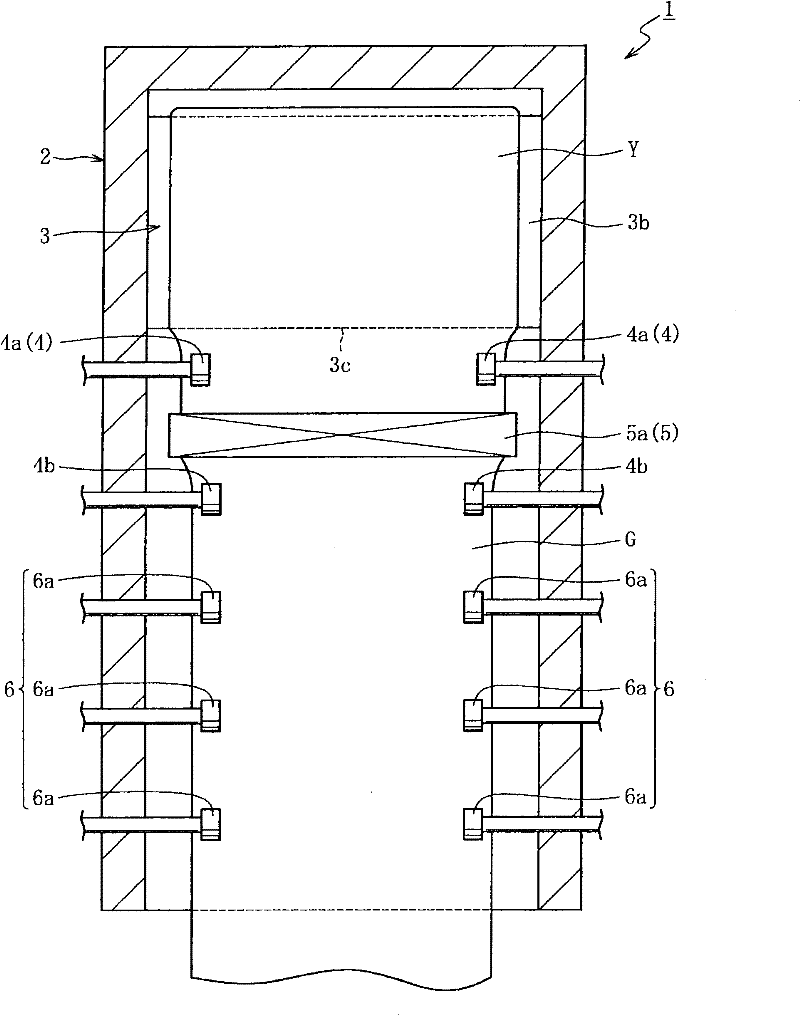

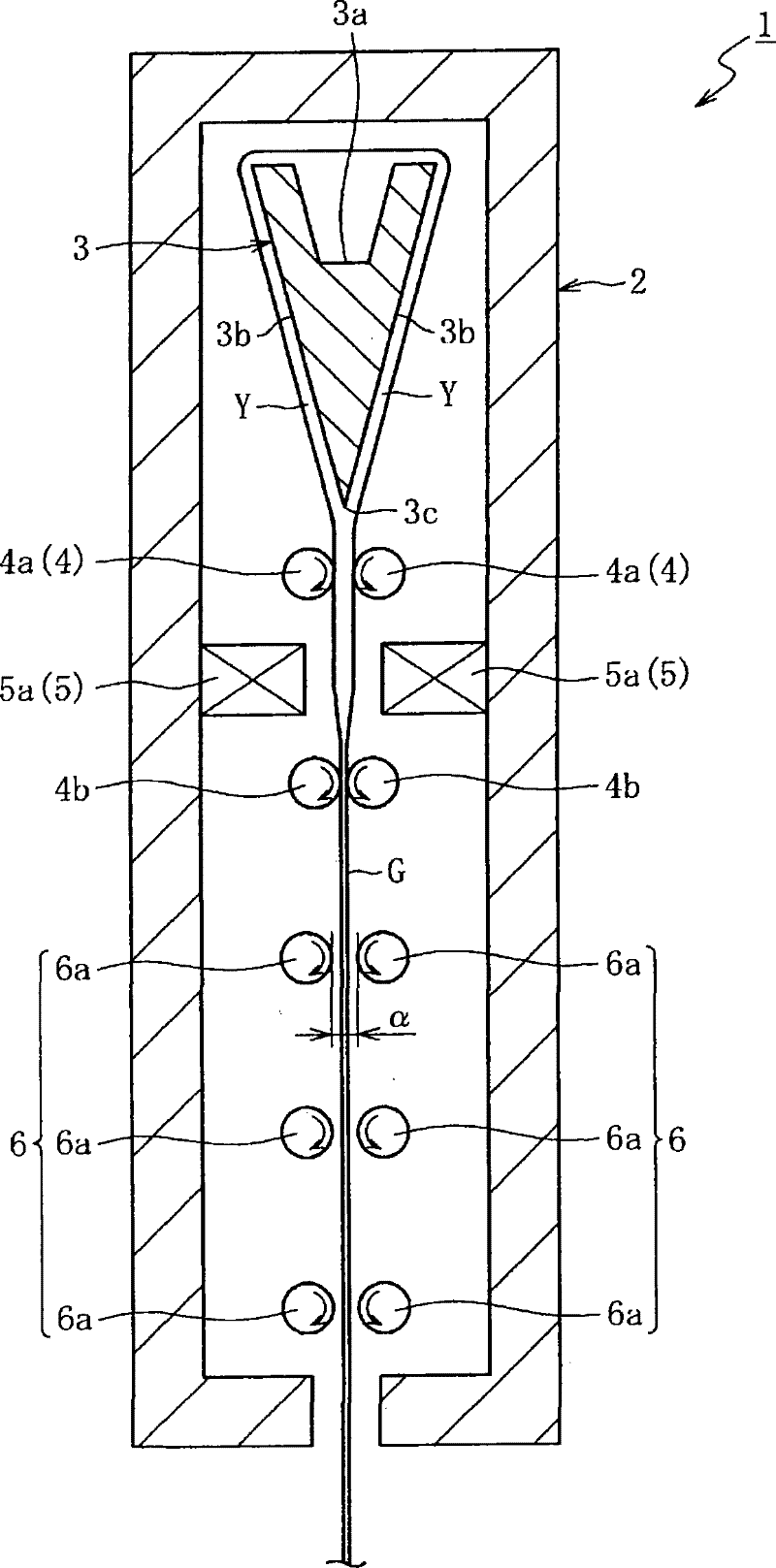

Glass ribbon producing apparatus and process for producing the same

The invention provides a glass ribbon producing apparatus (1) adapted to feed molten glass (Y) to molding member (2) and to cause the molten glass (Y) to flow downward from the molding member (2) so as to form sheetlike glass ribbon (G), comprising reheating means (5) disposed on a transport route for the glass ribbon (G) flowing downward from the molding member (2) so that the glass ribbon (G) is reheated by the reheating means (5) to thereby cause the sheet thickness of the glass ribbon (G) positioned inferior to the reheating means (5) to be smaller than that of the glass ribbon (G) positioned superior to the same.

Owner:NIPPON ELECTRIC GLASS CO LTD

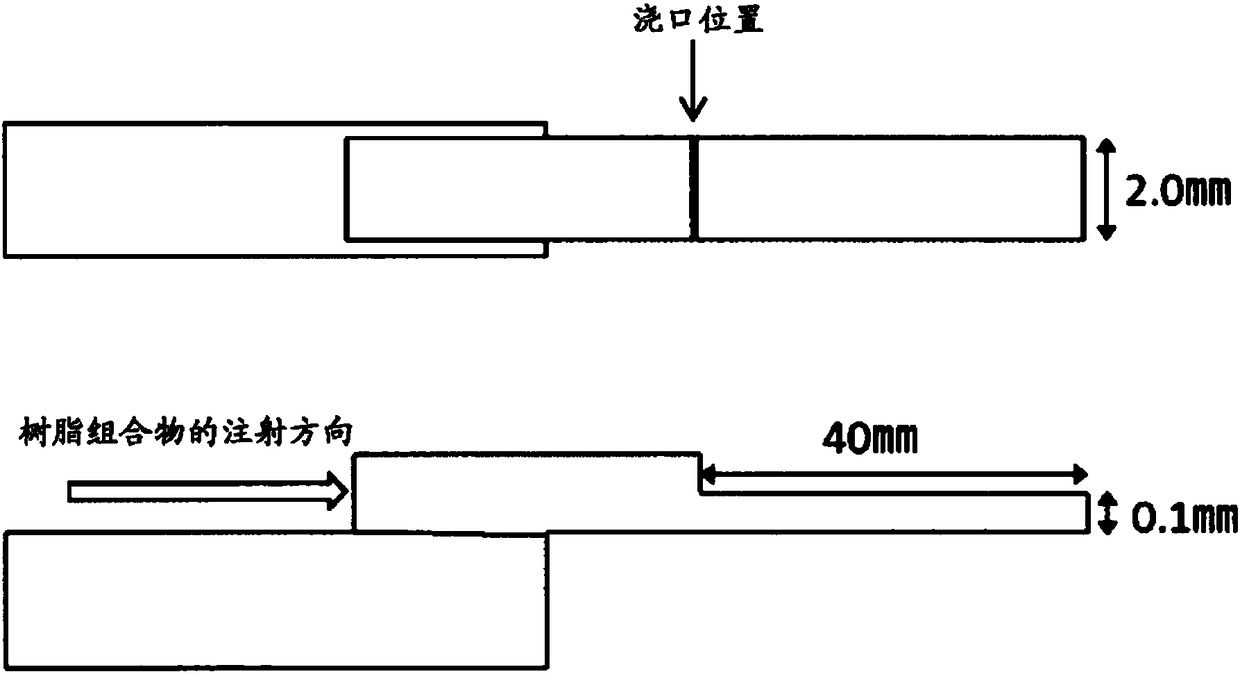

Wholly aromatic liquid crystal polyester resin and production method therefor

To provide a wholly aromatic liquid crystal polyester resin having high mechanical strength, excellent filling properties, blister resistance, and low warpage. This wholly aromatic liquid crystal polyester resin includes structural units (I) to (V), which are represented by formulas (I) to (V), and is characterized in that: the composition ratios (mol%) of the structural units (I) to (V) therein are 15 mol% <= structural unit (I) <= 35 mol%, 5 mol% <= structural unit (II) <= 15 mol%, 21 mol% <= structural unit (III) <= 29 mol%, 1 mol% <= structural unit (IV) <= 9 mol%, and 25 mol% <= structural unit (V) <= 40 mol%, wherein the structural units (I) to (V) total 100 mol%; and the melting point is at least 320 DEG C.

Owner:JXTJ NIPPON OIL & ENERGY CORP

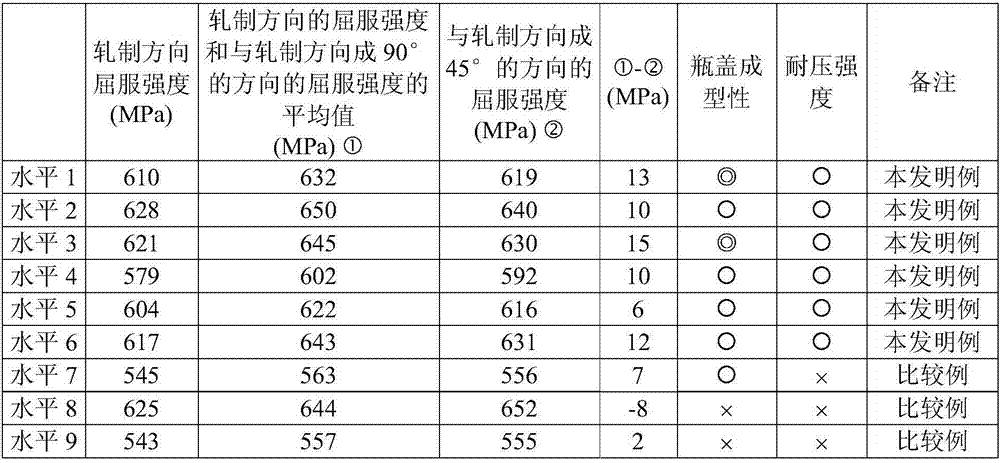

Steel sheet for crown cap, manufacturing method therefor, and crown cap

ActiveCN107109559ARealize thin wallFull strengthCapsClosure capsHeat processingUltimate tensile strength

Provided are: a steel sheet for a crown cap that has adequate strength and moldability even when used after being made thin; a manufacturing method therefor; and a crown cap. The steel sheet has a composition containing, in mass%, C: 0.010% to 0.025%, Si: not more than 0.10%, Mn: 0.05% to 0.50%, P: not more than 0.050%, S: 0.005% to 0.050%, Al: 0.020% to 0.070%, and N: less than 0.0040%, the balance being obtained from Fe and unavoidable impurities. Regarding yield strength after heat treatment for fifteen minutes at 210 DEG C, yield strength in the rolling direction is at least 550 MPa and yield strength in the rolling plane in a direction that is 45 degrees from the rolling direction is not more than the mean of the yield strength in the rolling direction and the yield strength in the rolling plane in a direction that is 90 degrees from the rolling direction.

Owner:JFE STEEL CORP

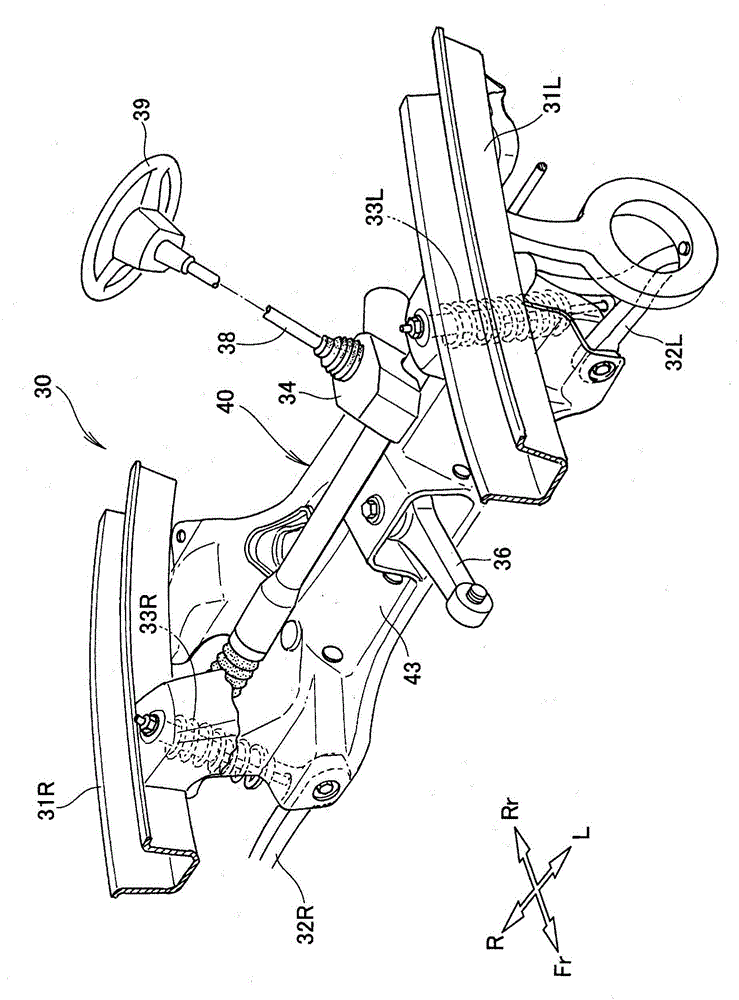

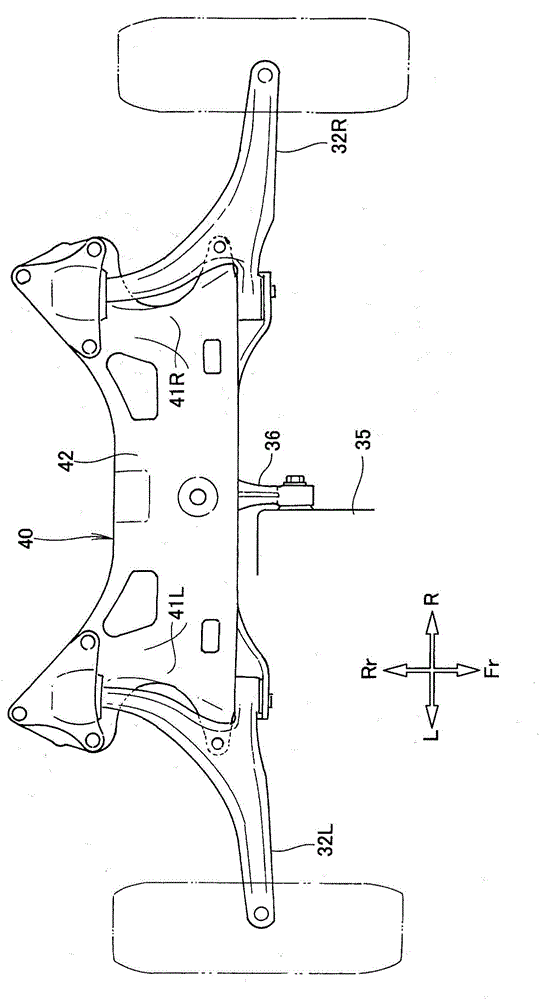

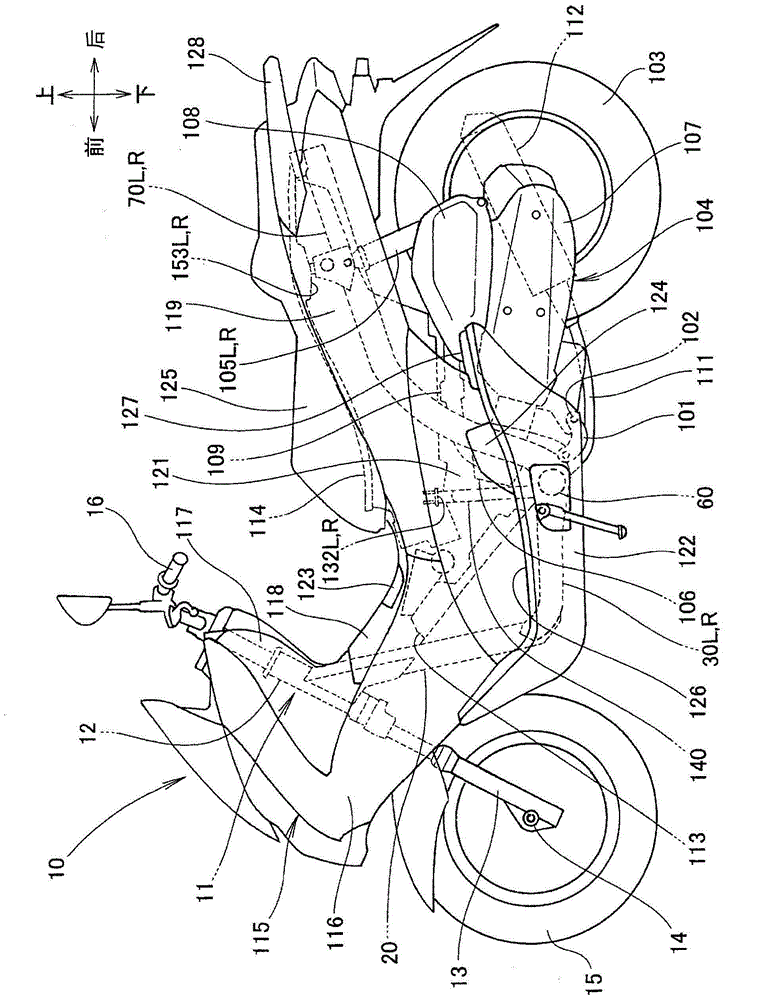

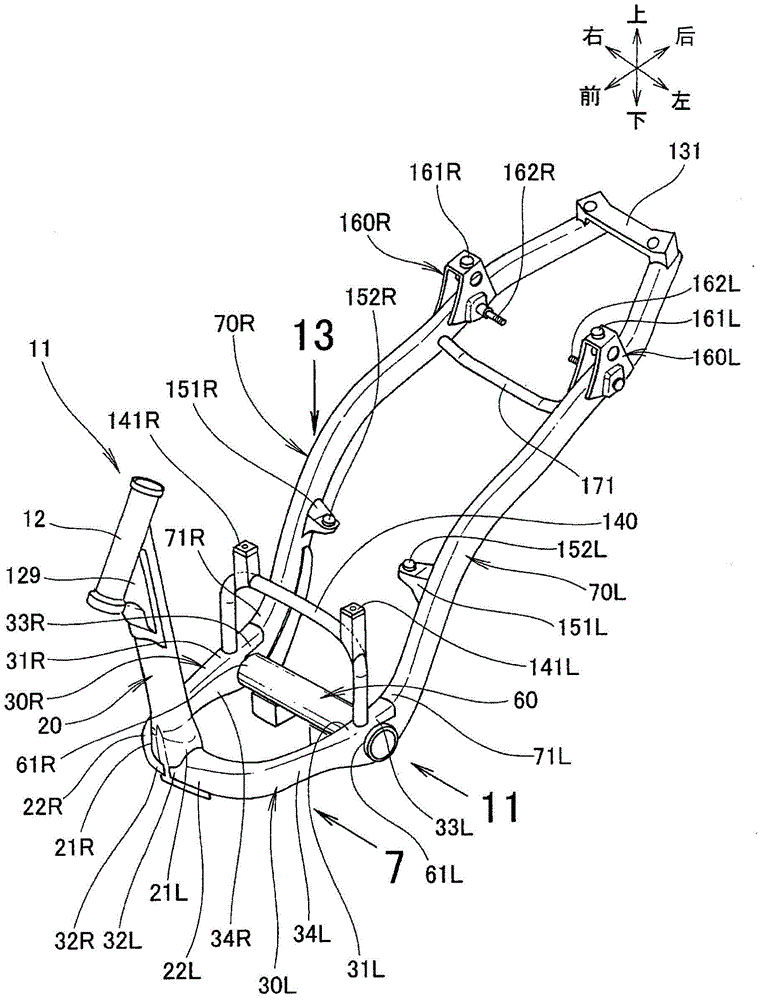

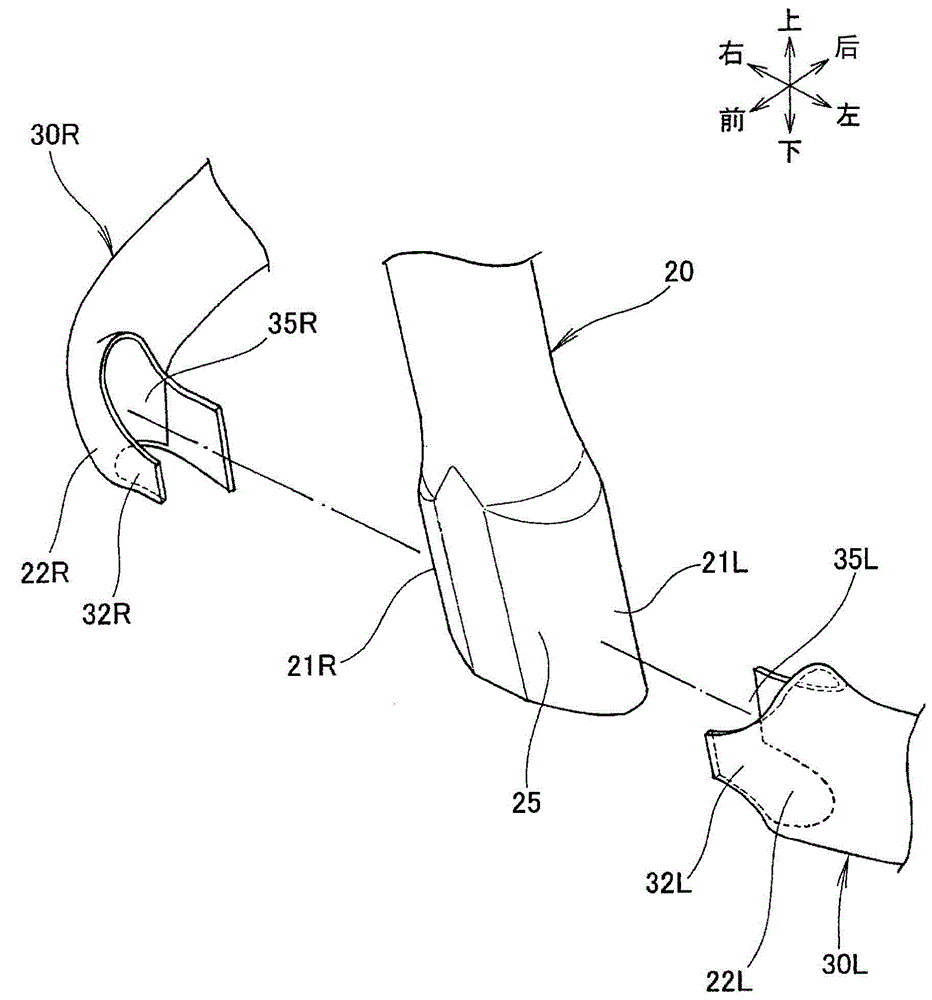

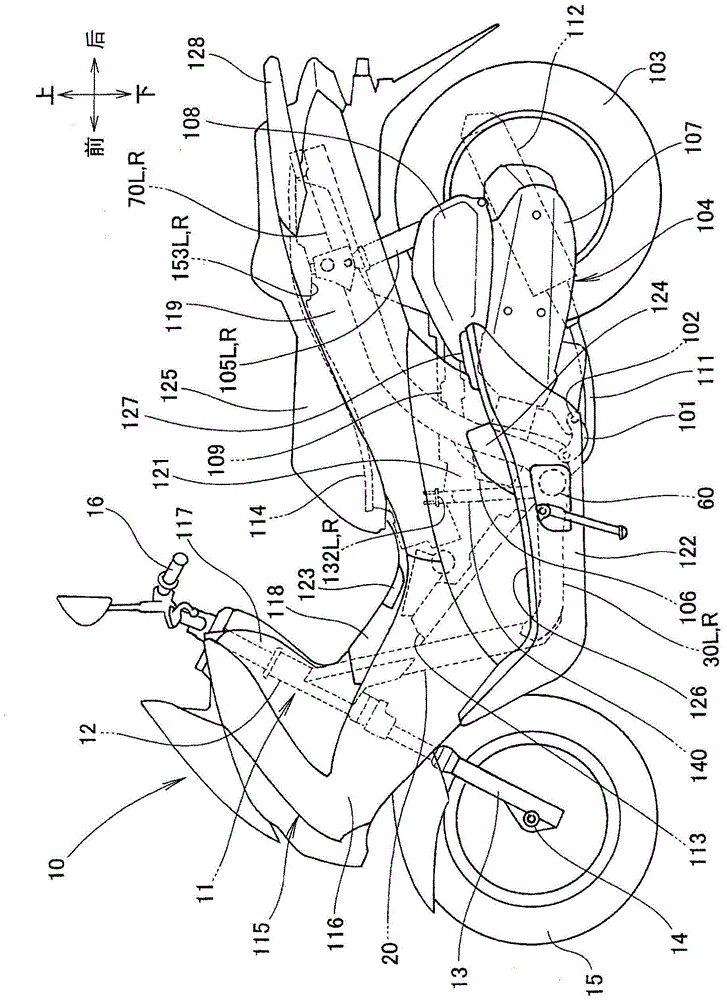

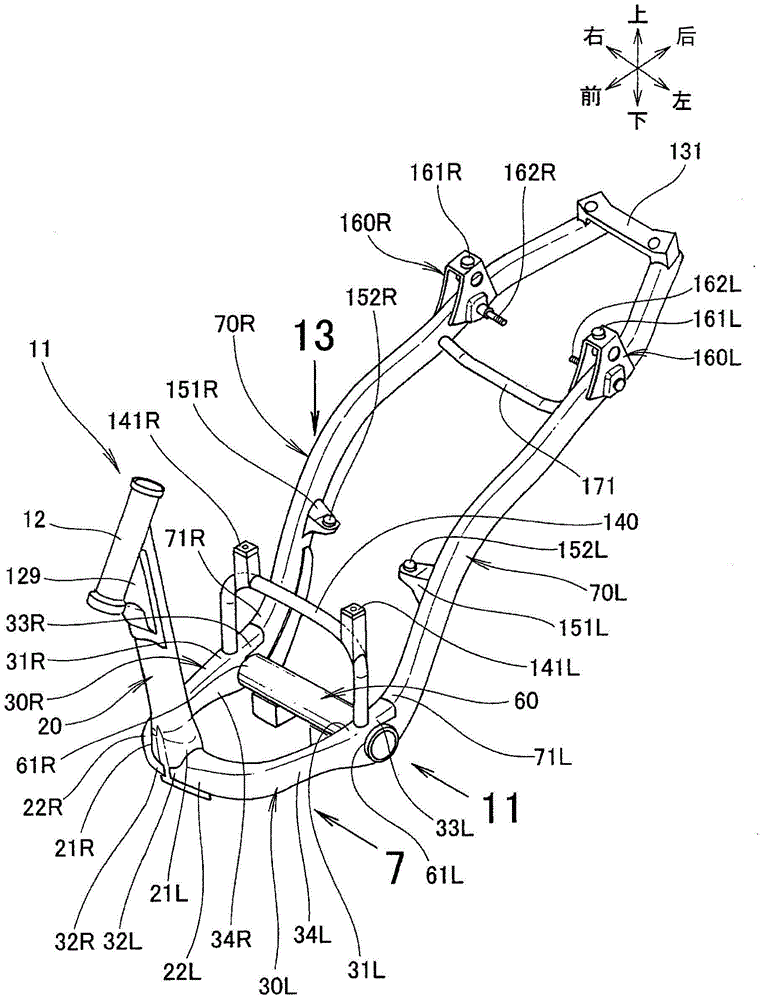

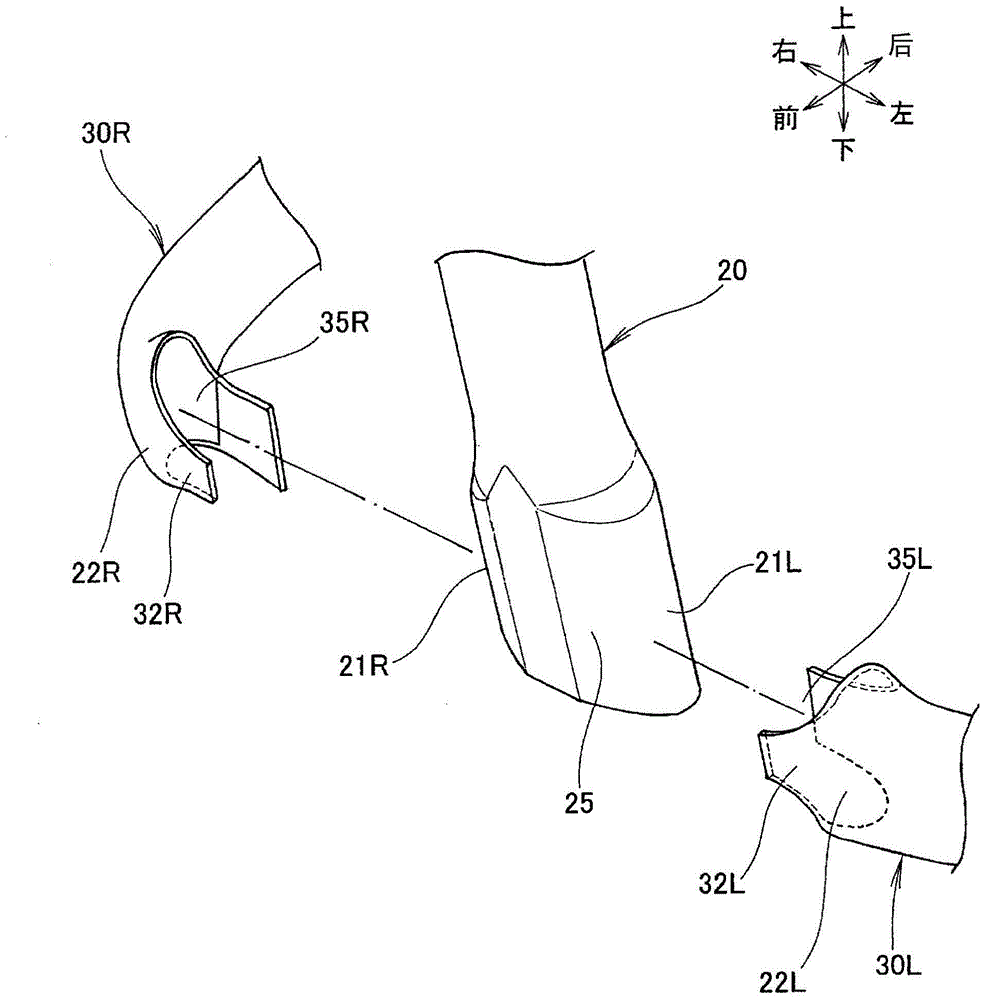

Frame structure of scooter-type vehicle

ActiveCN103958336AAvoid concentrationRealize thin wallMotorised scootersMotorcyclesAutomotive engineering

Disclosed is a frame structure that is of a scooter-type vehicle (10) and that is provided with: a header pipe (12) that steerably supports a front fork (13); a hollow main pipe (20) extending downwards and to the rear of the vehicle body from the header pipe; a left-right pair of lower frames (30L, 30R) that are joined to the bottom of the main pipe and that each extend to the rear of the vehicle body from the bottom of the main pipe; a cross pipe (60) that is connected to each of the back ends (31L, 31R) of the lower frames and extends in the widthwise direction of the vehicle; and a left-right pair of rear frames (70L, 70R) that extend upwards and to the rear of the vehicle body and of which the front ends (71L, 71R) are respectively joined to the left and right ends (63L, 63R) of the cross pipe. The lower frames and the rear frames are joined to the cross pipe, and additionally the at least a portion of the lower frames and at least a portion of the rear frames are joined.

Owner:HONDA MOTOR CO LTD

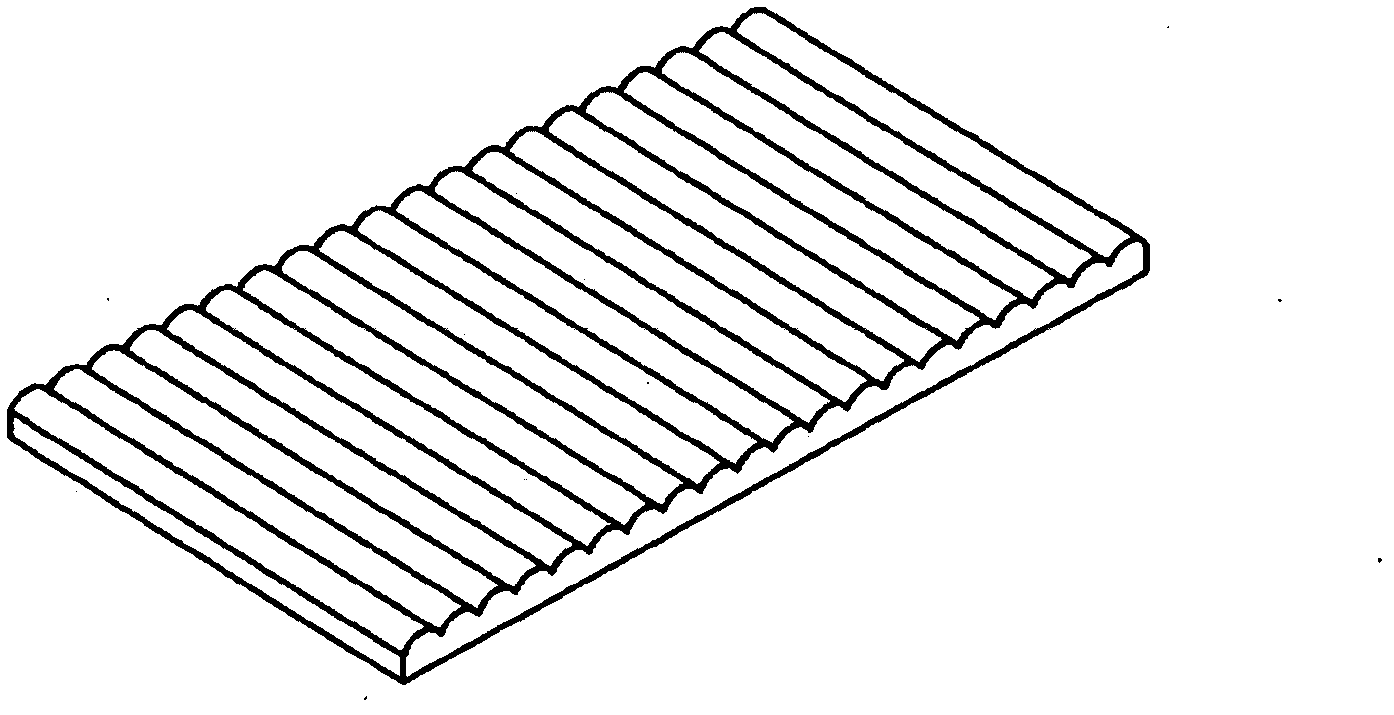

Polarizing plate, and liquid crystal panel and liquid crystal display device using said polarizing plate

InactiveCN102422188ARealize thin wallSuppress rippleDiffusing elementsPolarising elementsLiquid-crystal displayPolyvinyl alcohol

Disclosed is a polarizing plate provided with: a polarizing film (2) comprising a monoaxially-oriented polyvinyl alcohol resin film onto which iodine or a dichroic dye is absorbed and oriented; and a sheet member (3) that is layered on top of the polarizing film (2) with an adhesive layer (4) interposed therebetween and has a surface in the shape of a prism or lens. The sheet member (3) comprises a thermoplastic crystalline polymer and has internal haze due to said crystalline polymer. The level of internal haze in the sheet member (3) is between 3% and 60%. Also provided are a liquid crystal panel and a liquid crystal display device using the aforementioned polarizing plate.

Owner:SUMITOMO CHEM CO LTD

A method of making an anti-collision beam

ActiveCN113664941BHigh strengthImprove impact resistanceWood impregnation detailsHemicelluloseMechanical engineering

The invention discloses a manufacturing method of an anti-collision beam, which comprises the following steps: S1: preparing a natural wood board; S2: cleaning the lignin and hemicellulose in the wood board to form a wood board with a plurality of pores; S3: removing the wood board Put into the shear thickening liquid, so that the shear thickening liquid penetrates into the interior of the wood board through each channel and adheres to the wood board; S4: compact the wood board; S5: set a sealing layer on the end face of the wood board to seal the end. In the invention, the shear thickening liquid is filled in the wooden board to form an anti-collision beam. The anti-collision beam of the invention can fully absorb the energy generated by the collision, improve the safety performance of the vehicle, and effectively reduce the damage caused by the collision to the personnel, which belongs to the automobile anti-collision. The technical field of structure.

Owner:DONGFENG LIUZHOU MOTOR

Frame construction of a scooter type vehicle

ActiveCN103958336BAvoid concentrationRealize thin wallMotorised scootersMotorcyclesAutomotive engineering

The present invention provides a frame structure of a scooter-type vehicle. The scooter-type vehicle (10) includes: a head pipe (12) that supports a front fork (13) so as to be steerable; A hollow main pipe (20); a pair of left and right bottom frames (30L, 30R) combined with the lower part of the main pipe and extending from the bottom of the main pipe to the rear of the vehicle body; ) combined and extended along the vehicle width direction; and a pair of left and right rear frames in which the front ends (71L, 71R) are respectively combined with the left and right ends (63L, 63R) of the transverse tube and extended to the upper rear of the vehicle body (70L, 70R). The bottom frame and the rear frame are combined with the cross tube, and at least a part of the bottom frame is combined with at least a part of the rear frame.

Owner:HONDA MOTOR CO LTD

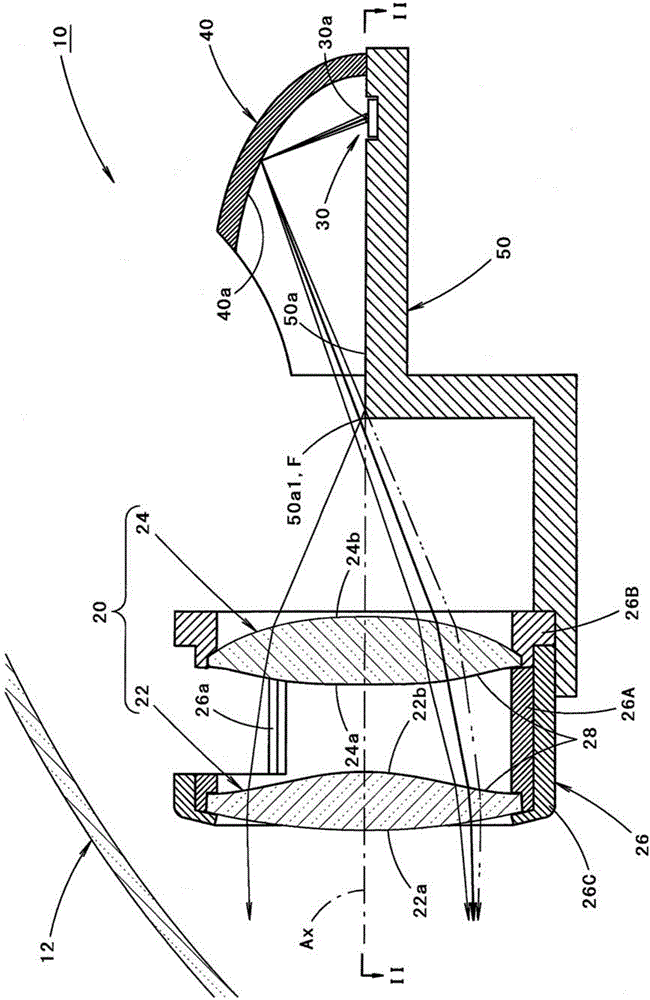

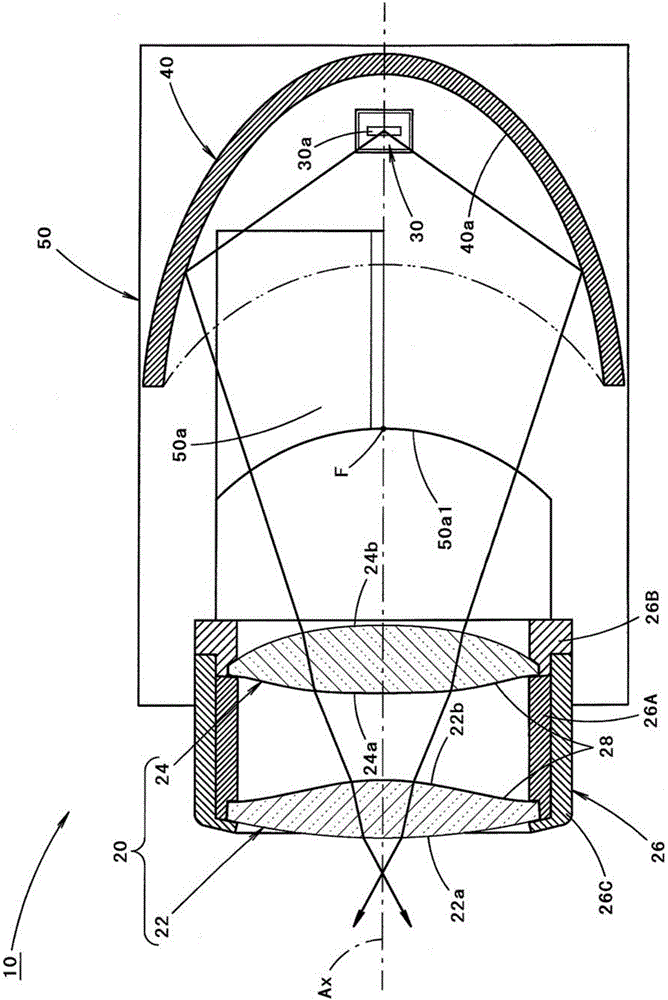

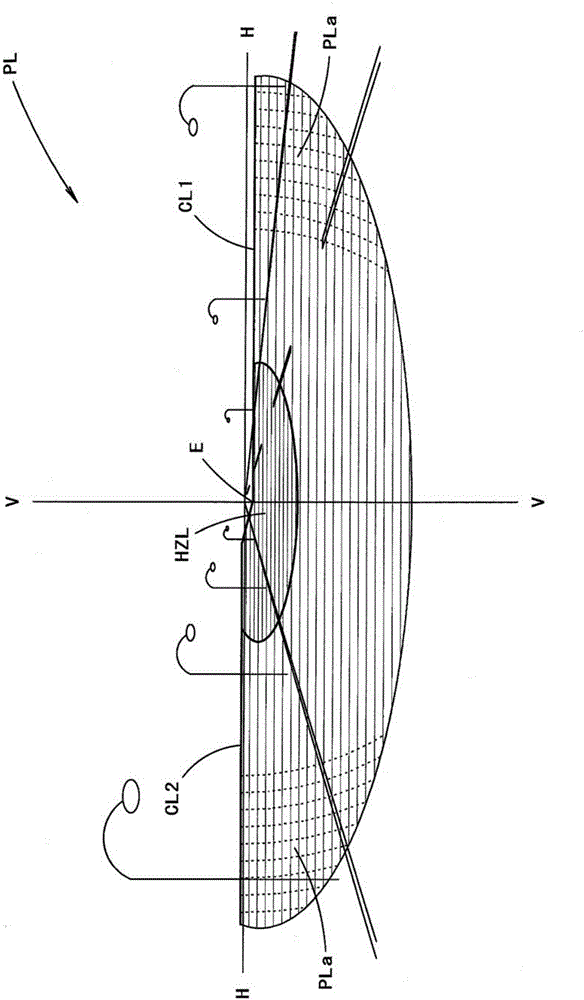

Vehicle lamp

ActiveCN106322271ARealize thin wallInhibit shrinkage cavityVehicle headlampsRoad vehiclesOptoelectronicsOptical axis

In the case of a projection type vehicle lamp, even when the projection lens is composed of a plurality of lenses, it is possible to form a light distribution pattern having a high uniformity. The projection lens (20) is composed of two lenses (22, 24) arranged on an optical axis (Ax) extending in the front-rear direction of the vehicle. In this case, the rear main surface (Pr) of the projection lens (20) is formed by a convex curved surface having a large curvature as compared with a spherical surface (S1) having a rear focal point (F) as its center. As a result, the coma aberration extending toward the inner side (the optical axis side) is generated on the imaging surface of the projection lens (20); as a result, in the light distribution pattern formed by the light emitted from the projection lens (20), blurring caused by the coma aberration can form blurring with a tail extending toward the outside of the light distribution pattern, thus improving the uniformity of the light distribution pattern.

Owner:KOITO MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com