Steel plate for can and method for producing same

A manufacturing method and steel plate technology, applied in the direction of manufacturing tools, tanks/barrels/barrels, furnace types, etc., can solve the problems of reduced strength and rigidity of the tank body, increased incidence, buckling deformation of the tank body, etc., to save resources , cost reduction, and the effect of thinning the wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

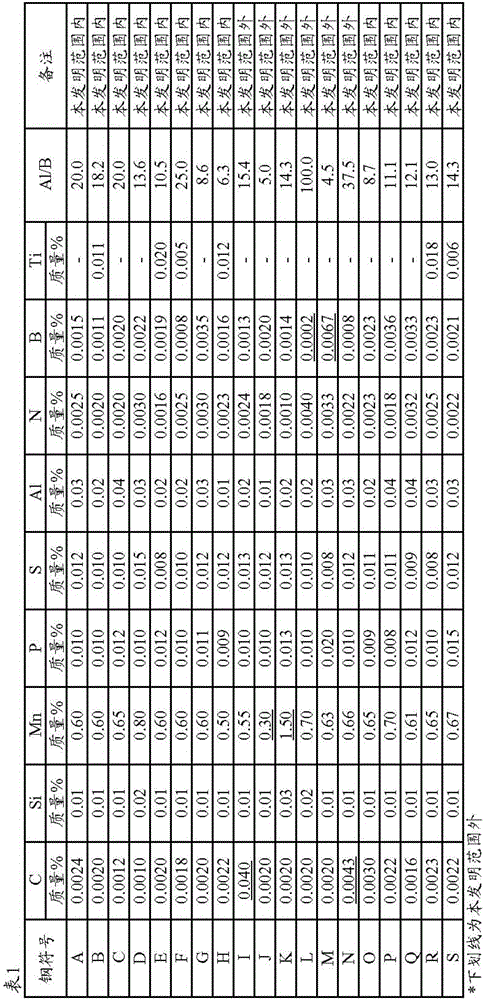

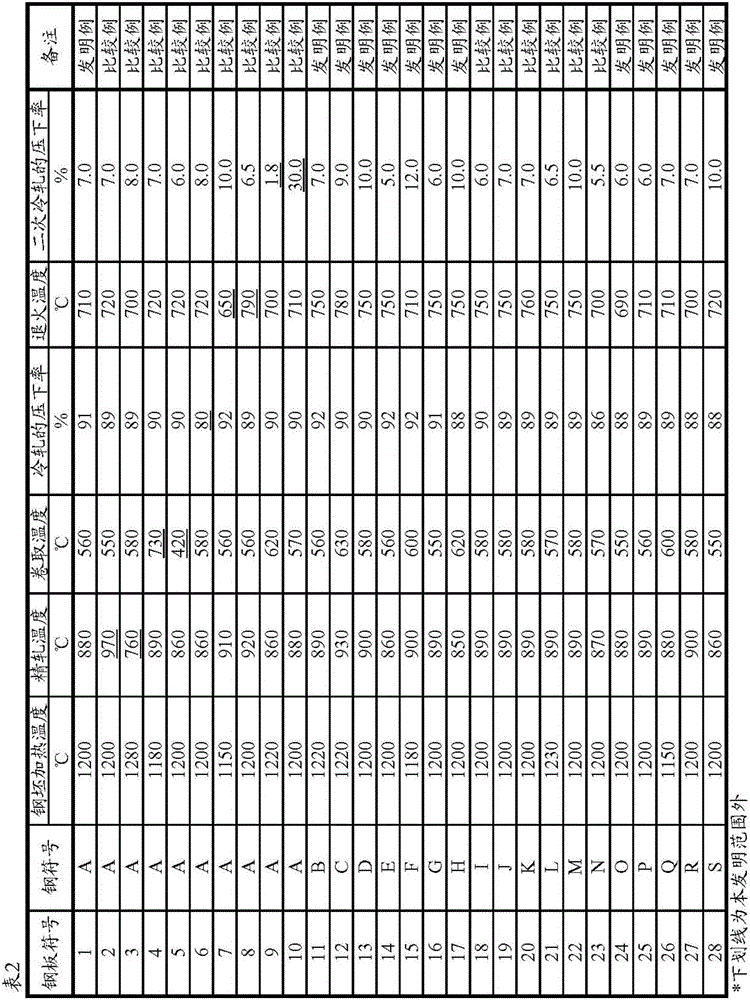

[0068] Steels having the component compositions of steel codes A to S shown in Table 1 were melted to obtain billets. The steel slab obtained was heated according to the conditions shown in Table 2, then hot-rolled, removed scale by pickling, then cold-rolled, and annealed in a continuous annealing furnace for a soaking time of 15 seconds. Next, secondary cold rolling was performed to obtain steel plates with a plate thickness of 0.220 mm (steel plate numbers 1 to 28).

[0069]

[0070]

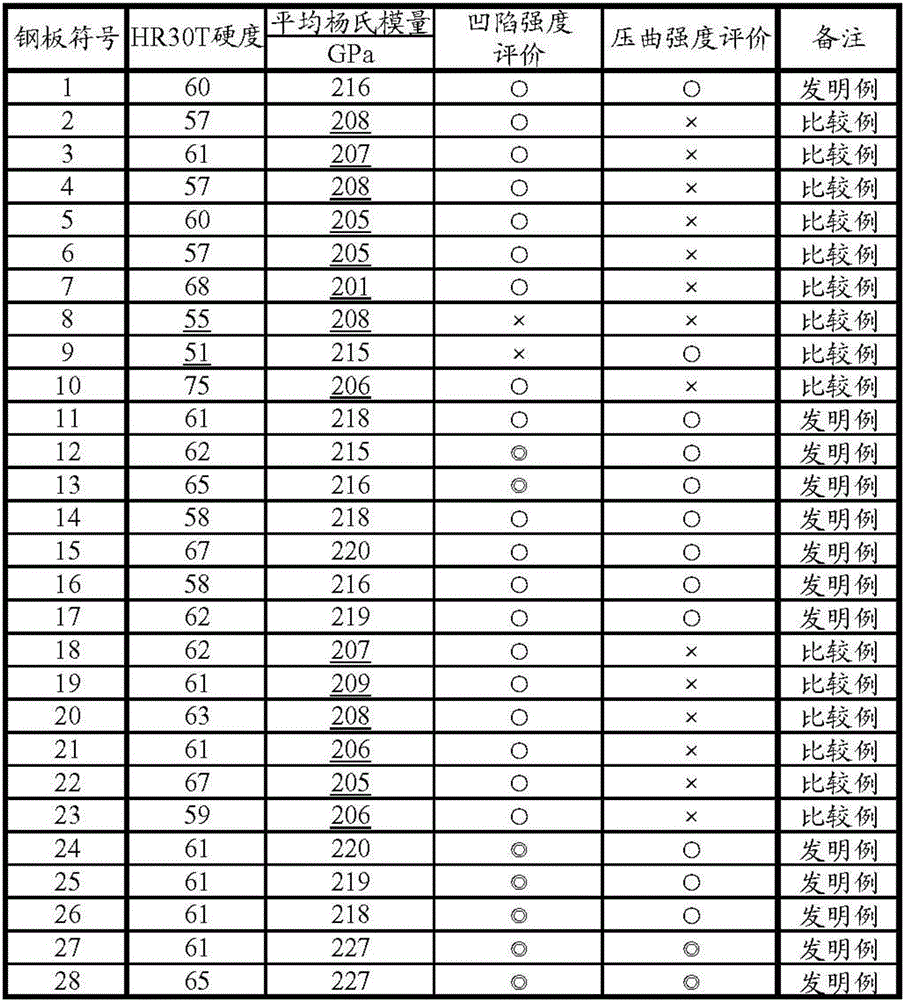

[0071] The properties of the steel sheets obtained above were evaluated by the following methods.

[0072] Evaluation of the average Young's modulus

[0073] Taking the direction of 0°, 45°, and 90° relative to the rolling direction as the longitudinal direction, cut out a test piece of 10×35mm, and use a transverse vibration type resonance frequency measuring device, according to the American Society for Testing Materials (American Society for Testing Materials ) standard (C1259) to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com