Frame construction of a scooter type vehicle

A technology for motorcycles and vehicles, applied to motorcycles, bicycle racks, bicycles, etc., can solve problems such as thinning of difficult horizontal tubes, achieve miniaturization and light weight, increase rigidity, and improve rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0047]The scooter-type vehicle according to the present invention will be described based on the drawings.

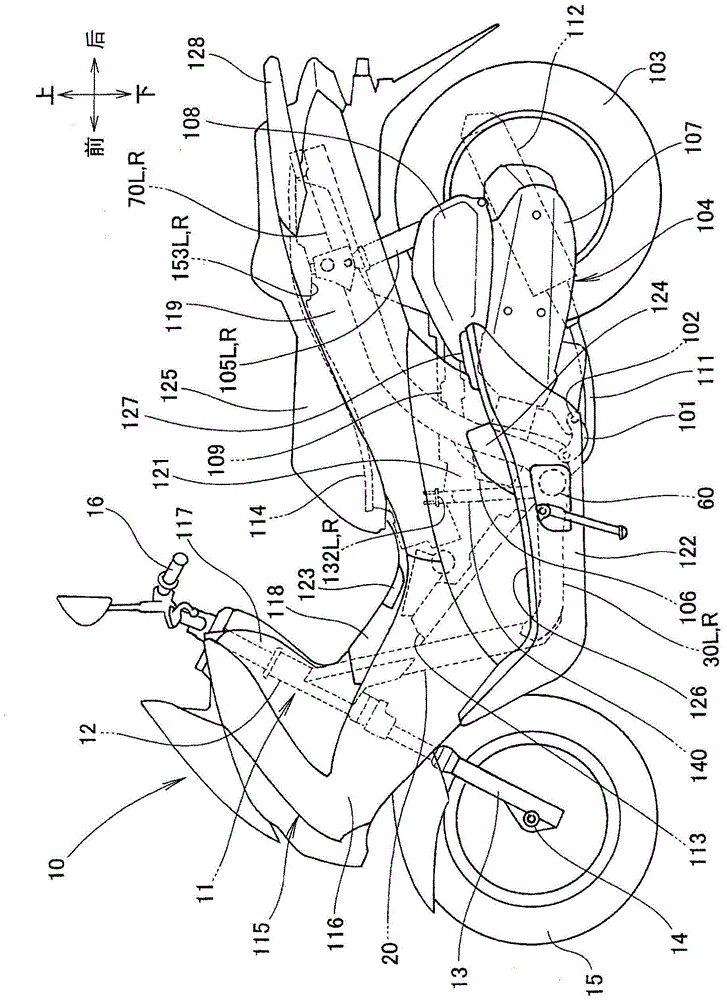

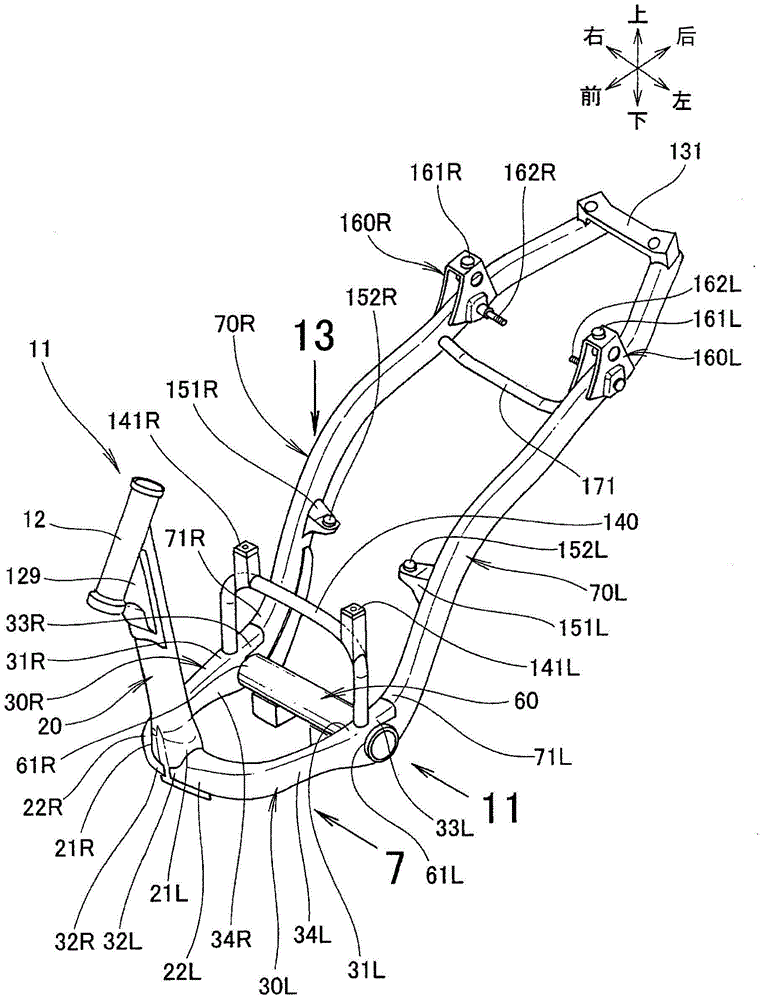

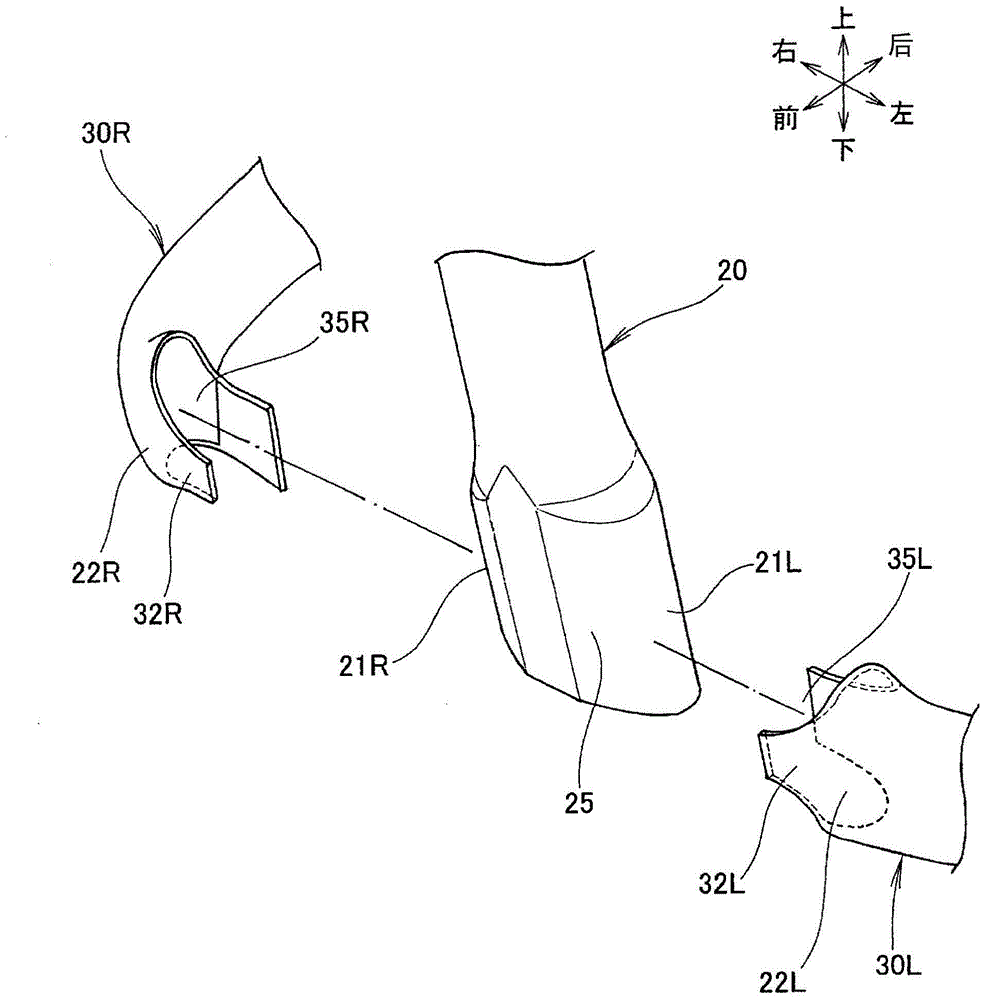

[0048] like figure 1 As shown, the scooter-type vehicle 10 includes a front fork 13 steerably supported by a head pipe 12 of a body frame 11 (described later in detail), and a front wheel 15 attached to a rotatably provided on the The front axle 14 at the lower end of the front fork 13; the handlebar 16, which is connected to the upper end of the front fork 13 for the driver to hold the front wheel 15; The lower end of 20 (see below for details) is combined and extends backward (L is the label representing the left. The same below. See below for details); rear frame 70L, its front end is combined with the horizontal tube 60 at the rear end of this bottom frame 30L (details will be described later) and extend rearward and upward (detailed later); the power unit 104 is swingably fixed to the engine suspension link 101 connected to the lower part of the front end of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com