Vehicle lamp

A technology for vehicles and lamps, which is applied in the direction of headlights, road vehicles, vehicle parts, etc., can solve the problem of large coma aberration of the projection lens, and achieve the effect of suppressing shrinkage cavity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

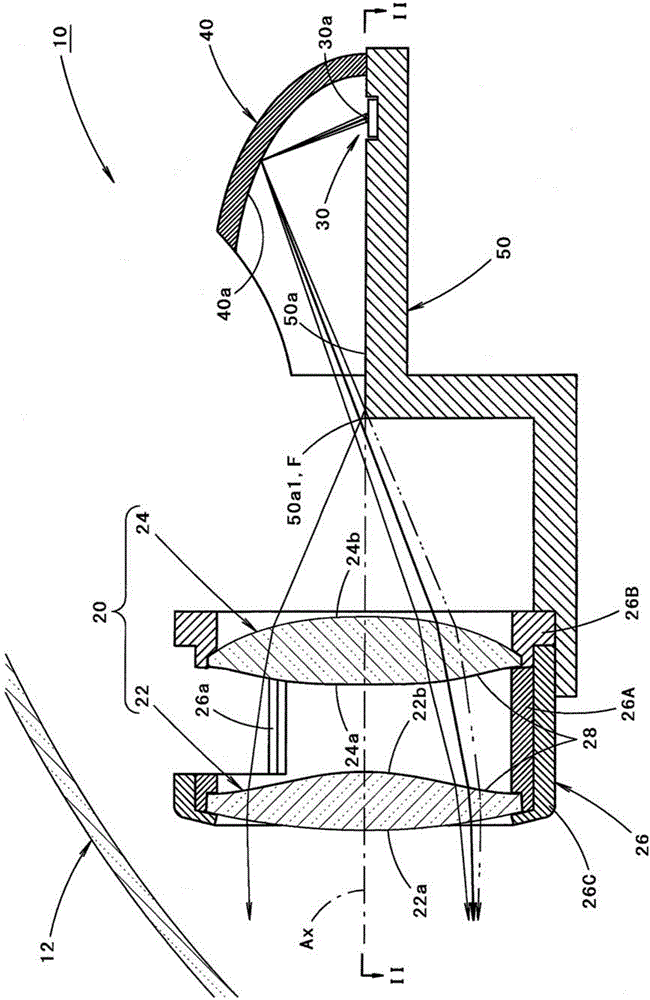

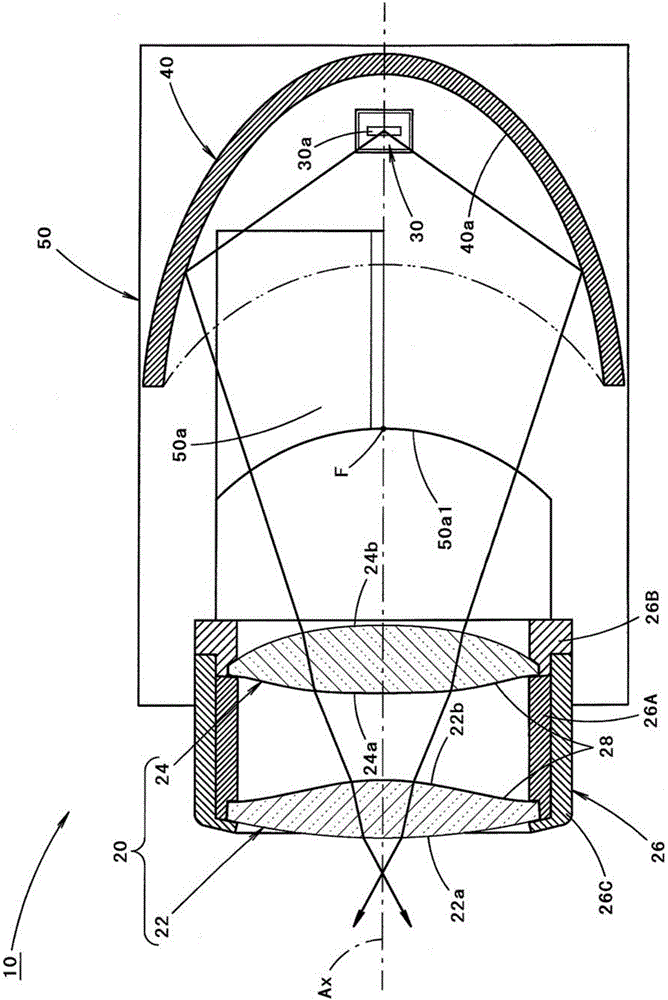

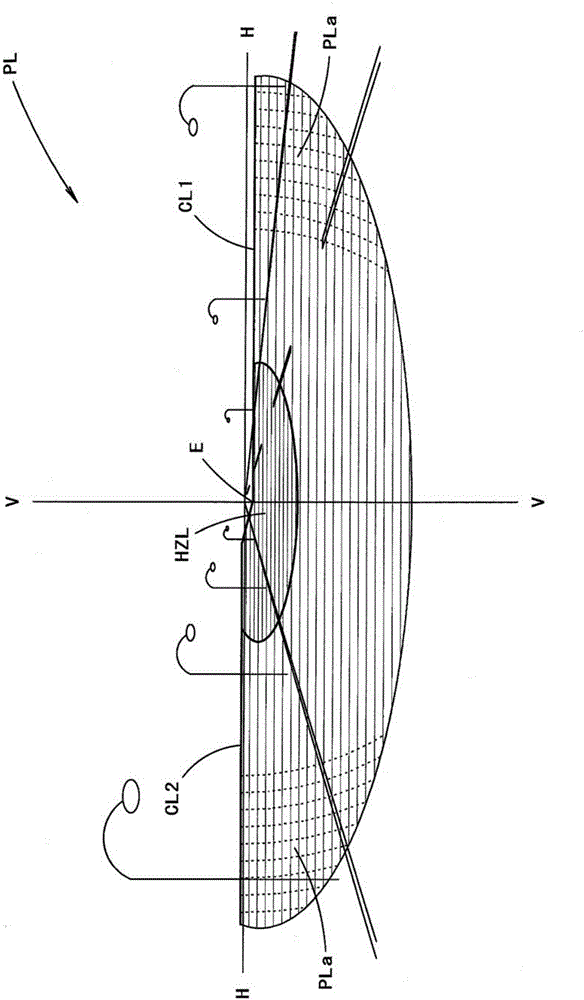

[0074] figure 1 It is a side sectional view showing a vehicle lamp according to an embodiment of the present invention. in addition, figure 2 Yes figure 1 sectional view of line II-II.

[0075] As shown in these figures, the vehicle lamp 10 according to the present embodiment is a headlamp for low beam installed at the front end of the vehicle, and is configured as a projection type lamp unit which is assembled in a lamp chamber, The lamp chamber is formed of a lamp body (not shown) and a transparent light-transmitting cover 12 attached to the front end opening of the lamp body.

[0076] That is, the vehicle lamp 10 has a structure including a projection lens 20 having an optical axis Ax extending in the vehicle front-rear direction, a light-emitting element 30, a reflector 40, and a base member 50, the light-emitting element 30 serving as a light source, The refl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com