Steel sheet for crown cap, manufacturing method therefor, and crown cap

A manufacturing method and technology of bottle caps, which are applied in the direction of manufacturing tools, bottle/container caps, and capping containers tightly with caps, which can solve the problems of reduced formability and poor sealing of bottles, and achieve the effect of thinning the wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

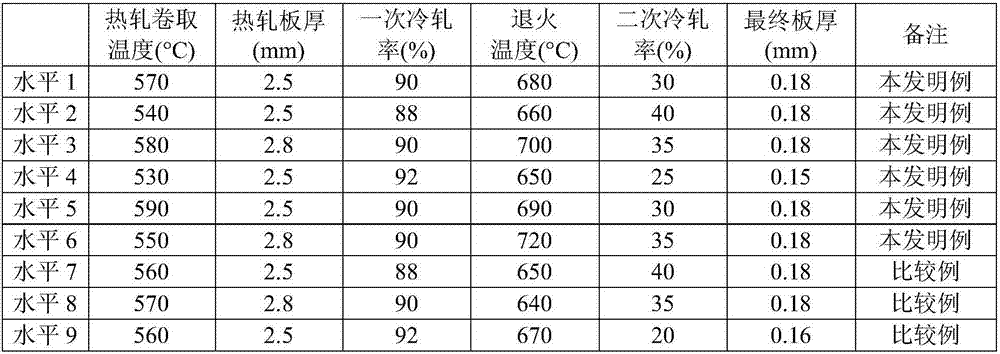

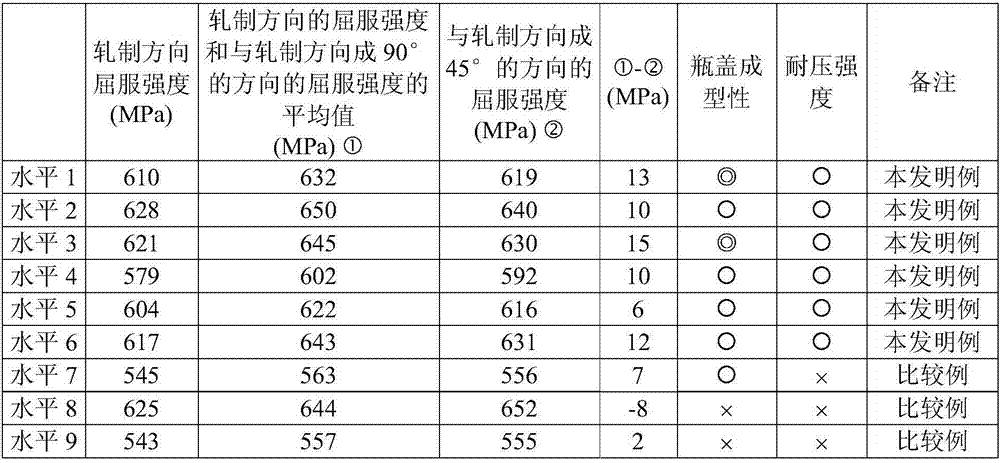

[0067] The steel was smelted in a converter and continuously casted to obtain a billet having the composition shown in Table 1, and the remainder was composed of Fe and unavoidable impurities. After heating the obtained slab to 1250°C, hot rolling was performed at a rolling start temperature of 1150°C and a finish rolling temperature of 860°C, and coiling was performed at the coiling temperature shown in Table 2. Next, after removing scale by pickling, primary cold rolling was performed at the primary cold rolling ratio shown in Table 2, annealing was performed in a continuous annealing furnace at the annealing temperature shown in Table 2, and secondary cold rolling was performed at the annealing temperature shown in Table 2. The cold rolling ratio was subjected to secondary cold rolling (DR rolling) to obtain steel sheets (horizontals 1 to 9) having a thickness of 0.15 to 0.18 mm. For both sides of the obtained steel sheet, 100 mg / m was applied to each side 2 Cr-plated to o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Plate thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com