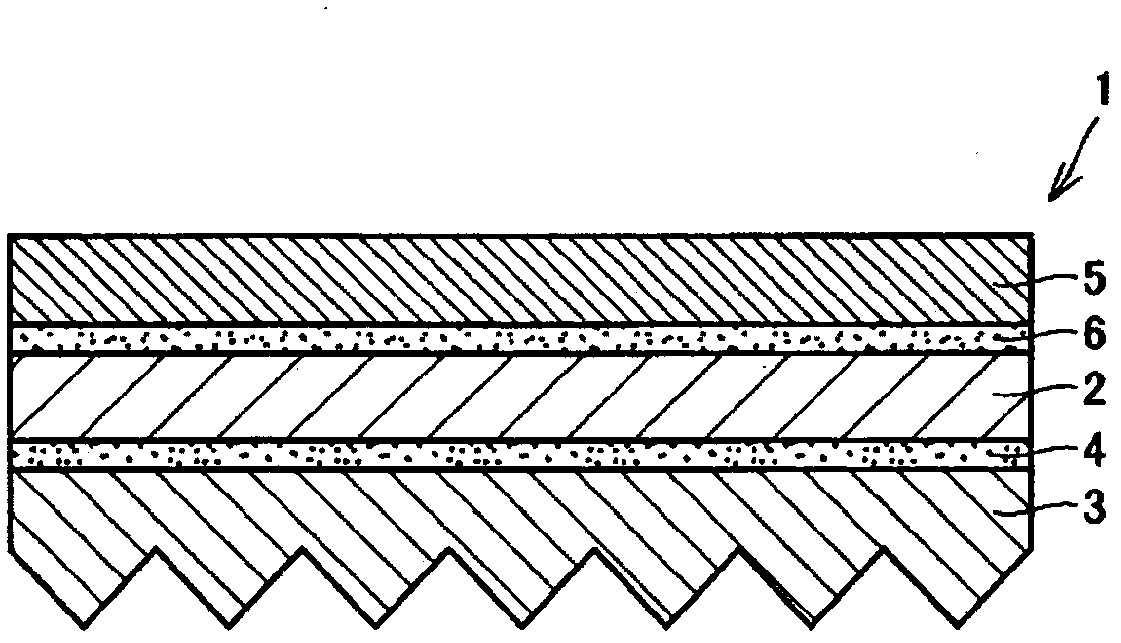

Polarizing plate, and liquid crystal panel and liquid crystal display device using said polarizing plate

A technology of liquid crystal panels and polarizers, which is applied in the field of polarizers, can solve problems such as ripples in the display, and achieve excellent display quality and the effect of suppressing poor display

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

[0090] (Manufacturing example 1: Production of polarizing film)

[0091] After immersing a polyvinyl alcohol film with an average degree of polymerization of about 2400, a degree of saponification of 99.9 mol% or more, and a thickness of 75 μm in pure water at 30°C, it is immersed in an iodine / potassium iodide / water weight ratio of 0.02 / 2 / 100 at 30°C. in aqueous solution. Then, it was immersed in the aqueous solution whose weight ratio of potassium iodide / boric acid / water was 12 / 5 / 100 at 56.5 degreeC. Next, after washing with 8° C. pure water, it was dried at 65° C. to obtain a polarizing film in which polyvinyl alcohol adsorbed iodine and iodine was oriented. Stretching is mainly carried out in the process of iodine dyeing and boric acid treatment, and the total stretching ratio is 5.3 times.

manufacture example 2

[0092] (Manufacturing Example 2: Preparation of UV Curable Adhesive)

[0093] 10.0 g of hydrogenated epoxy resin-trade name "EPIKOTEYX8000" produced by Japan Epoxy Resin Co., Ltd. (diglycidyl ether of nuclear hydrogenated bisphenol A, with an epoxy equivalent of about 205 g / equivalent), Nippon Soda Co., Ltd. 4.0 g of photocationic polymerization initiator-trade name "CI5102" manufactured by Nippon Soda Co., Ltd. and 1.0 g of photosensitizer-trade name "CS7001" manufactured by Nippon Soda Co., Ltd. were measured in a 100 ml disposable cup and mixed. Degassing, thereby preparing an ultraviolet curable adhesive.

manufacture example 3

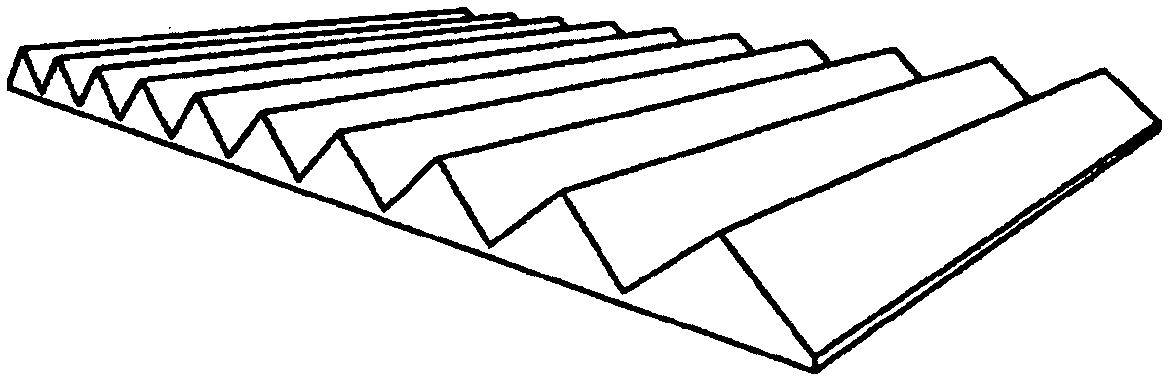

[0094] (Manufacturing Example 3: Fabrication of Triangular Prism Sheet 1)

[0095] Molten polypropylene resin was applied to a mold designed in advance so that the pitch of the molded prisms was 50 μm and the apex angle of the prisms was 65°, and pressure was applied while heating. Next, it cooled to 60 degreeC immediately after peeling off from a mold, and the triangular prism sheet 1 which consists of polypropylene resin was obtained. Any triangular prism has the same shape as designed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com