Steel sheet for can, and method for manufacturing same

A manufacturing method and steel plate technology, which is applied in the field of steel plates for cans as tank container materials, can solve the problems of reduced necking formability and flange formability, and achieve the effects of good hardness, increased rigidity, and excellent formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

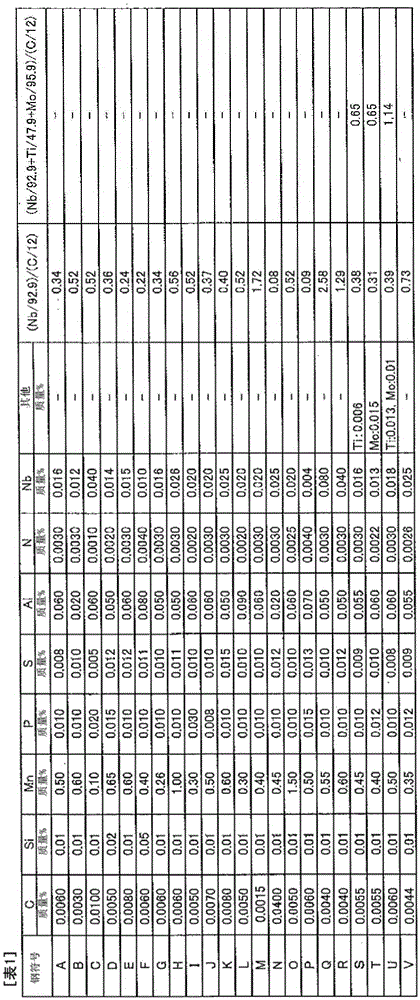

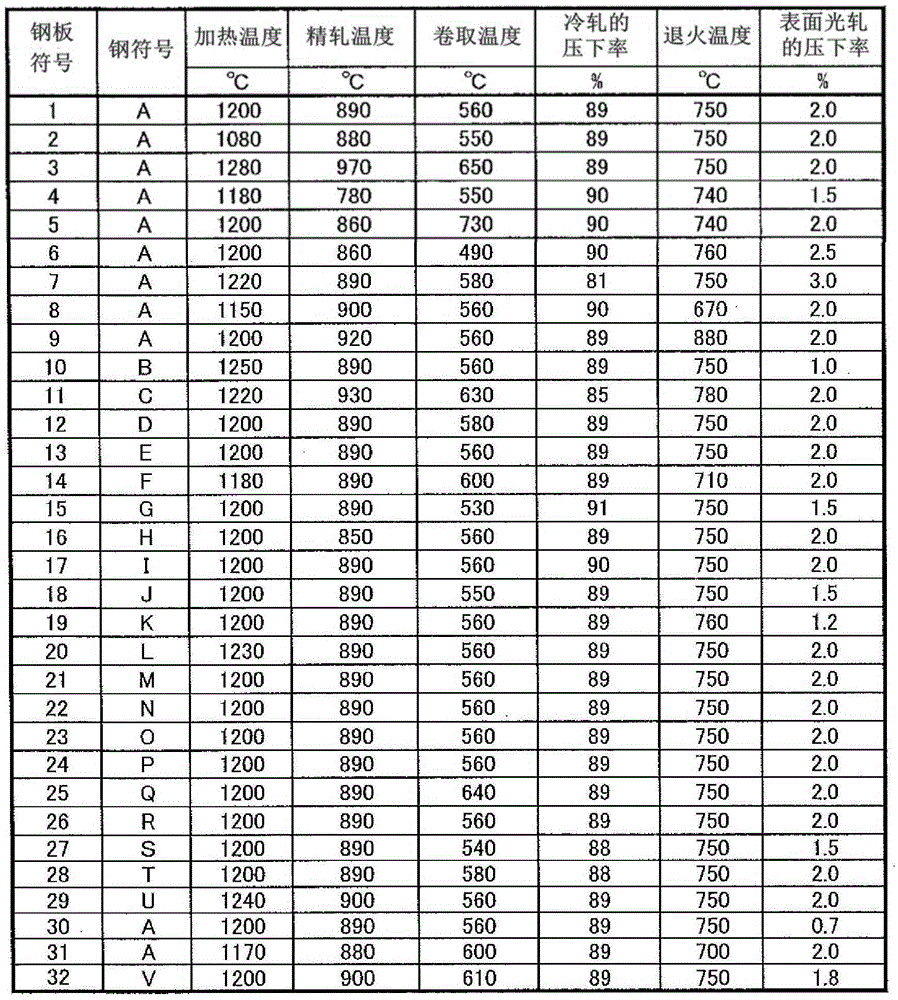

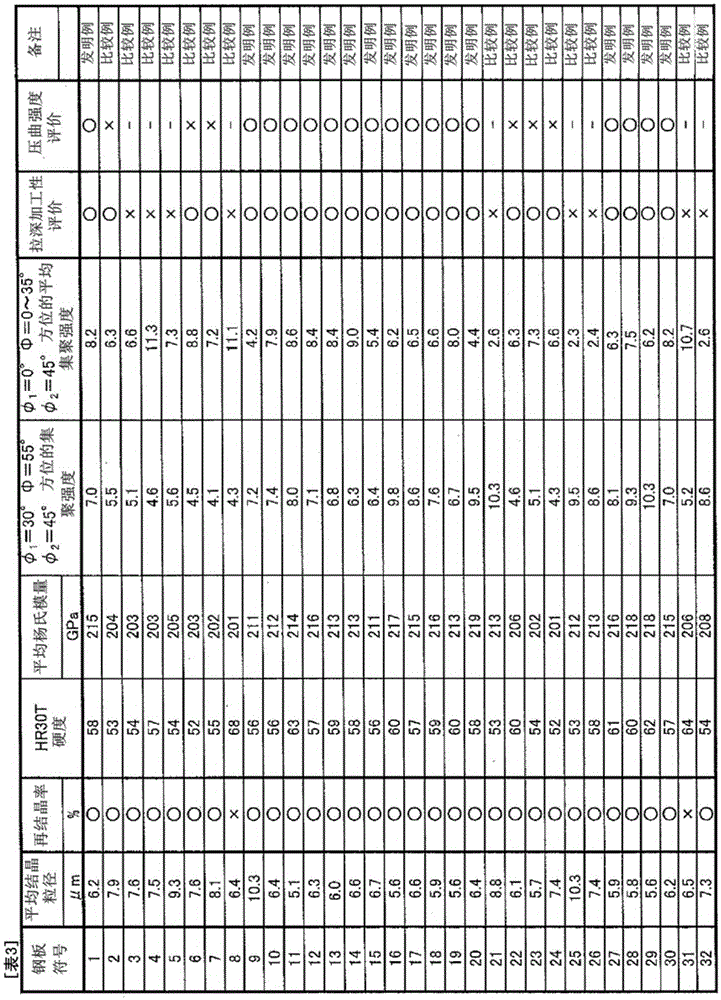

[0099]A steel containing the components of the steel codes A to V shown in Table 1, with the balance consisting of Fe and unavoidable impurities was melted to obtain a billet. The obtained slabs were heated under the conditions shown in Table 2, then hot-rolled, and then cold-rolled after removing scale by pickling. Next, in a continuous annealing furnace, after soaking at each annealing temperature for 20 seconds and cooling, temper rolling was performed to obtain steel sheets (steel sheet numbers 1 to 32) having a thickness of 0.220 mm. About the steel plate obtained by the said method, the characteristic evaluation was performed by the following method.

[0100]

[0101] [Table 2]

[0102]

[0103] Regarding the average grain size of ferrite, the ferrite structure in the cross-section in the rolling direction is etched with a 3% nital solution to reveal the grain boundaries. Using a photograph taken with an optical microscope at a magnification of 400, steel-crystall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com