Patents

Literature

115results about How to "Increased buckling strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

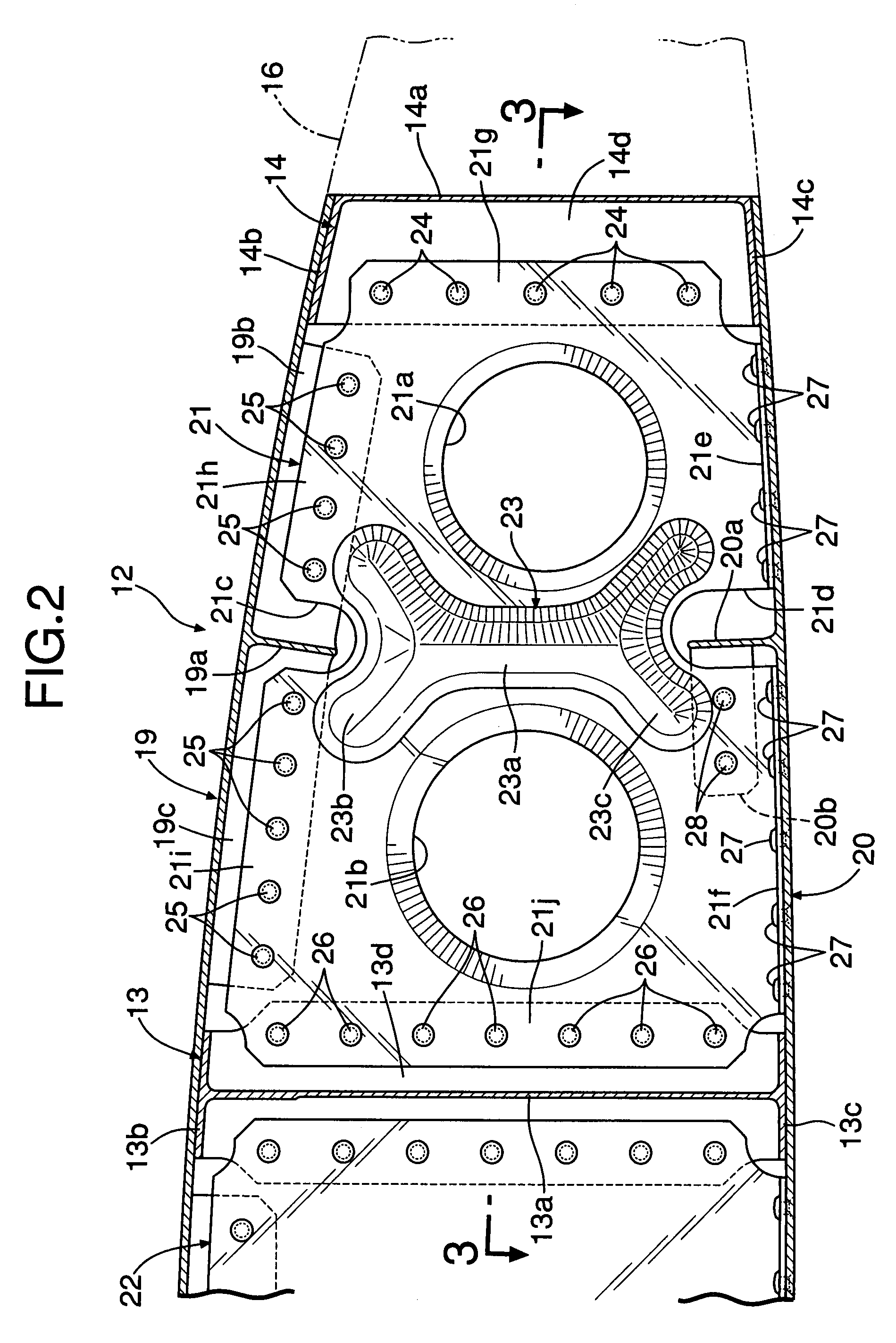

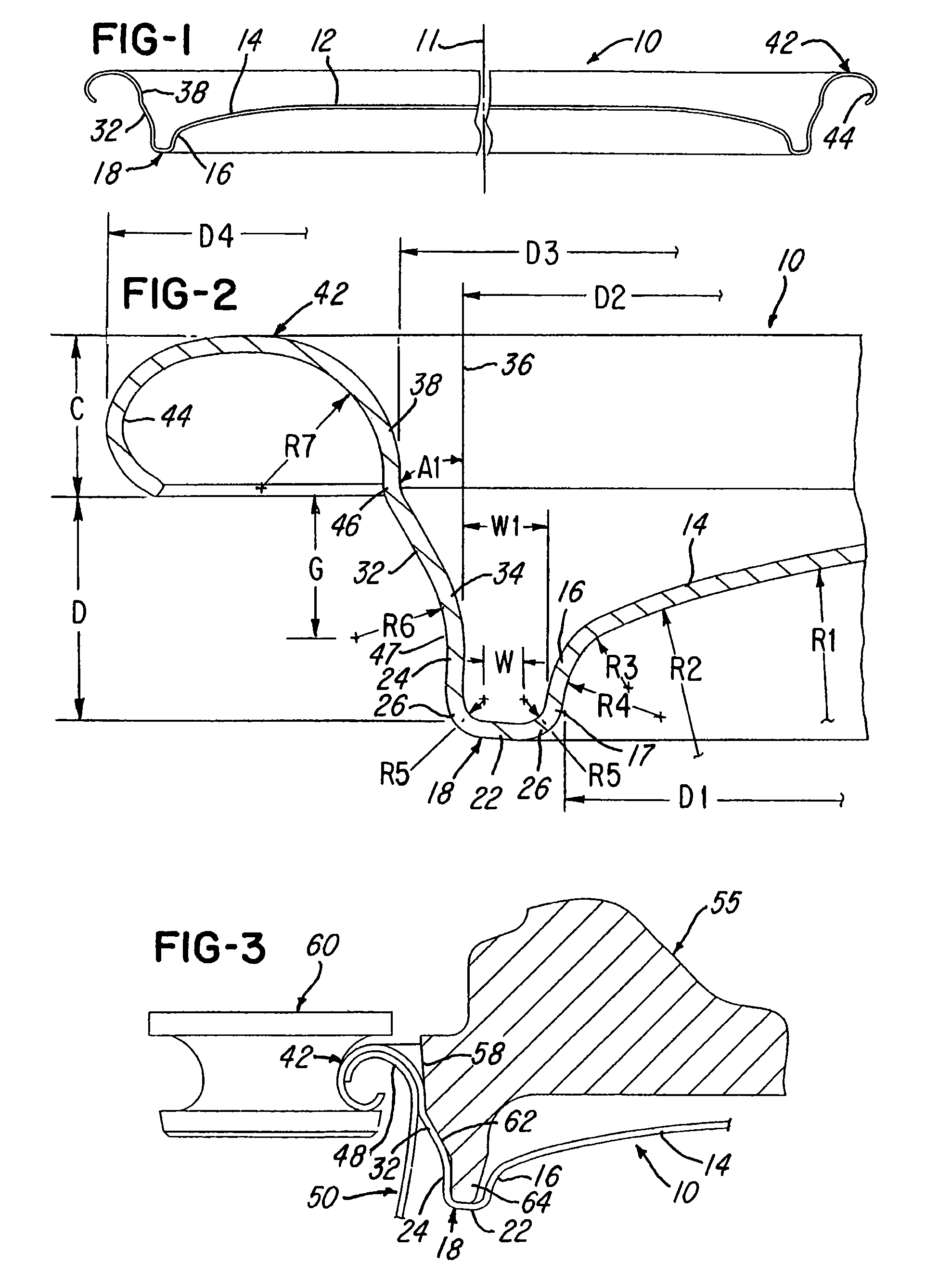

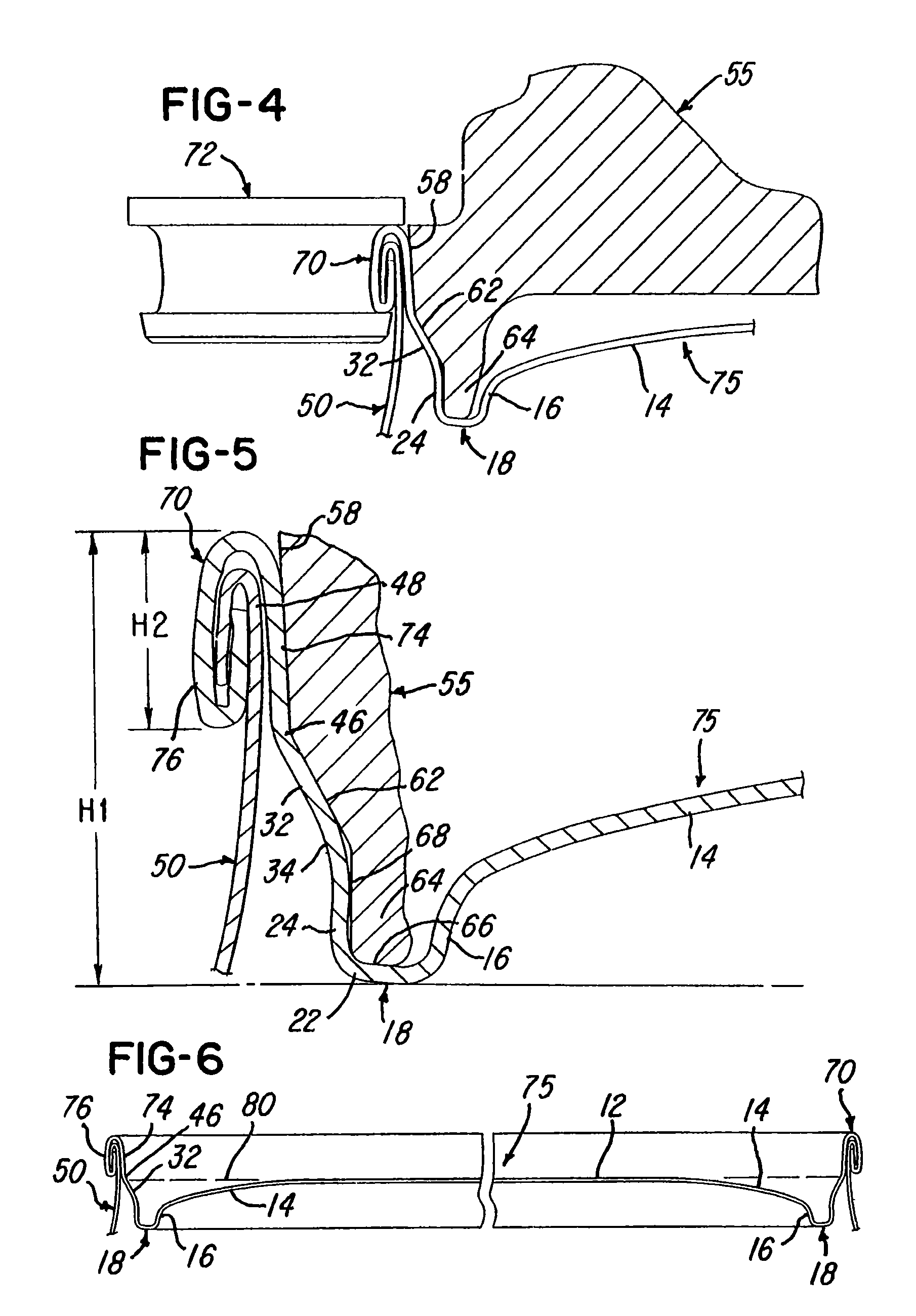

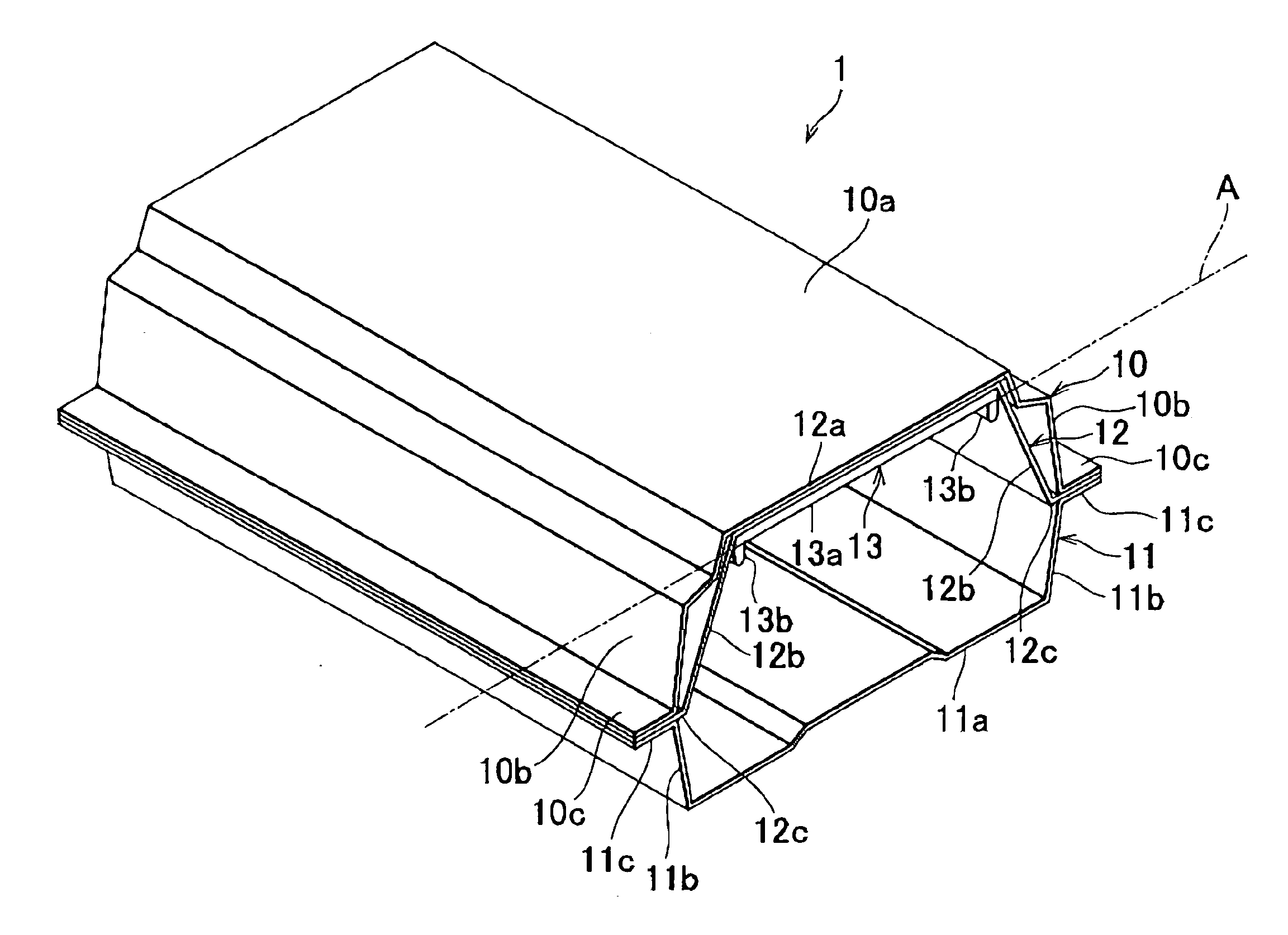

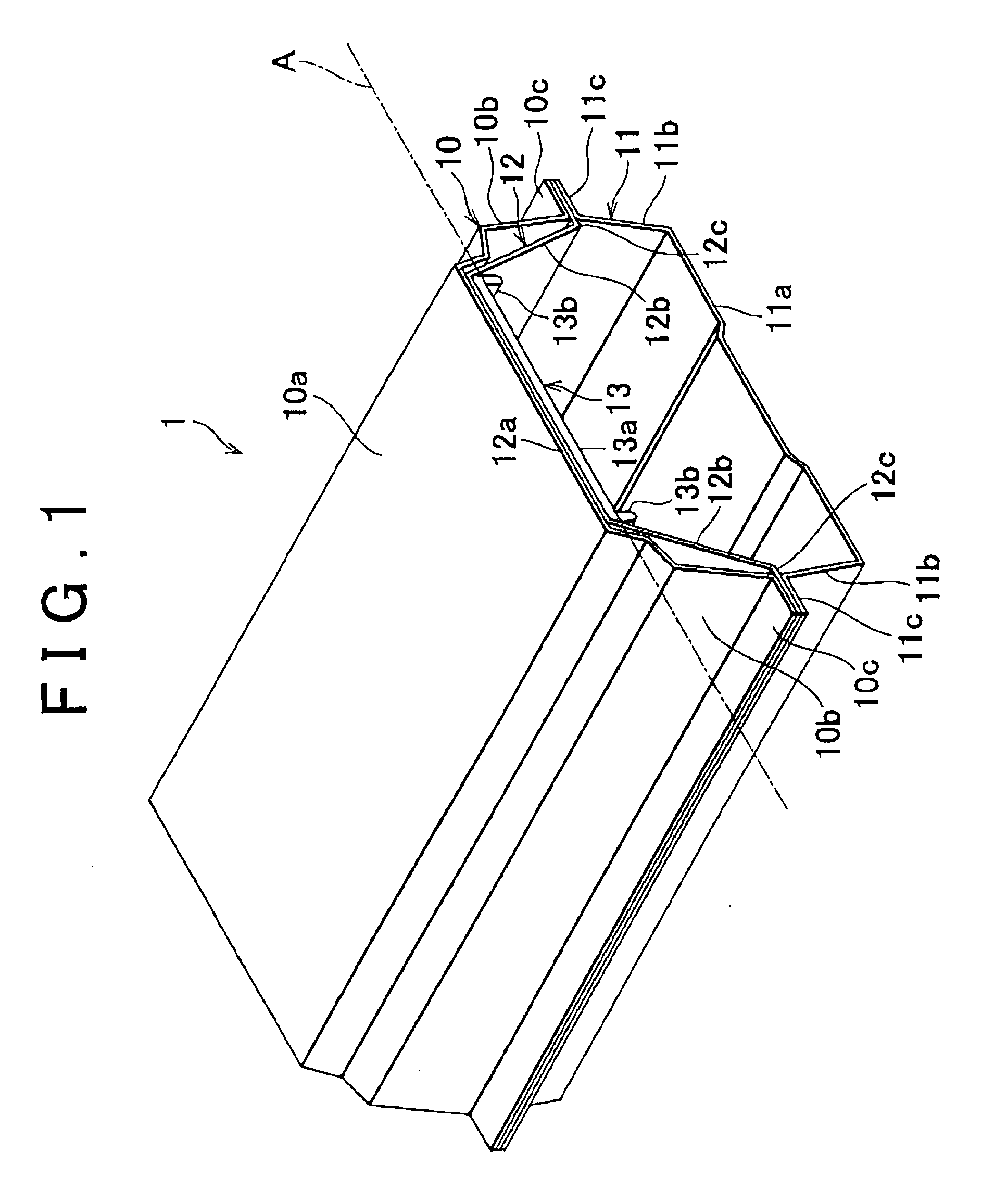

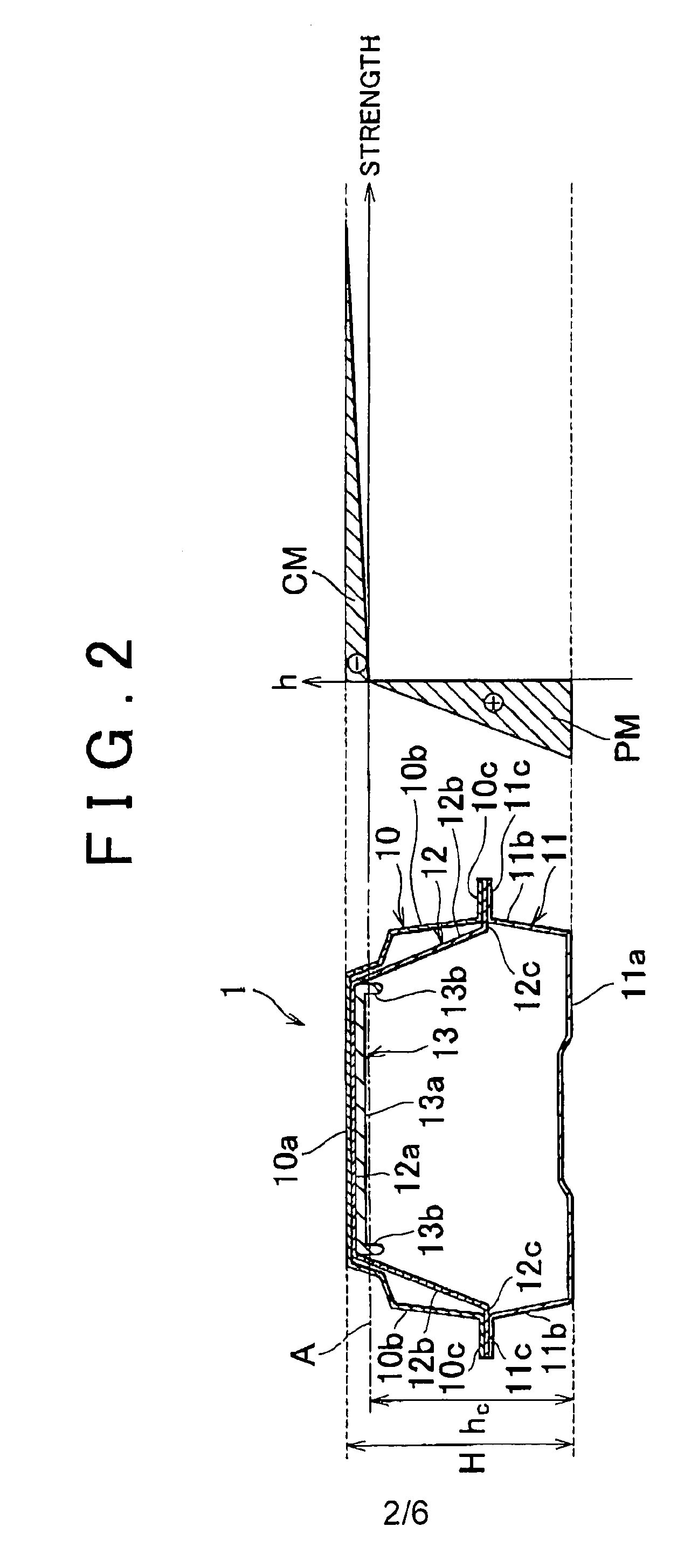

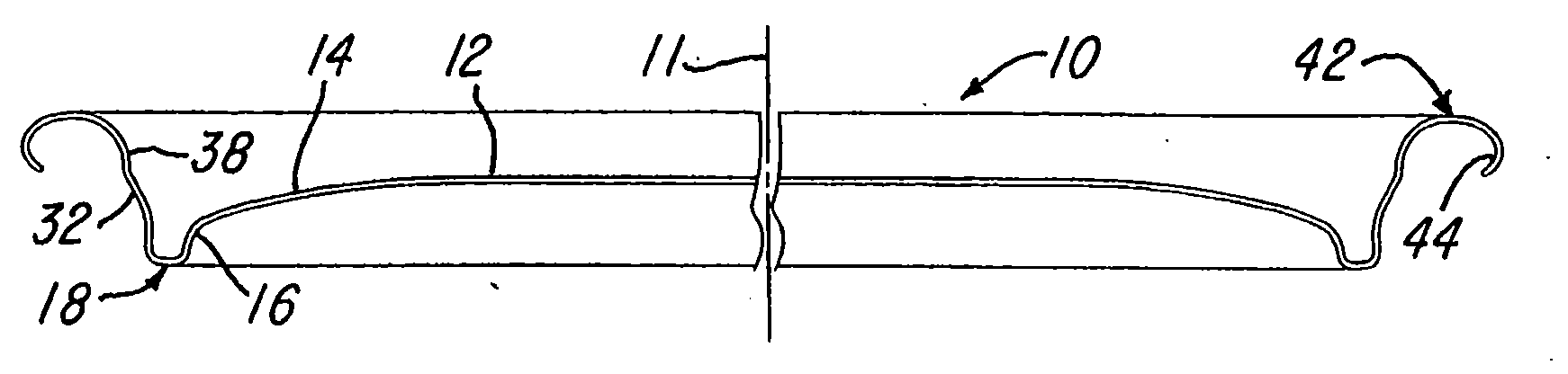

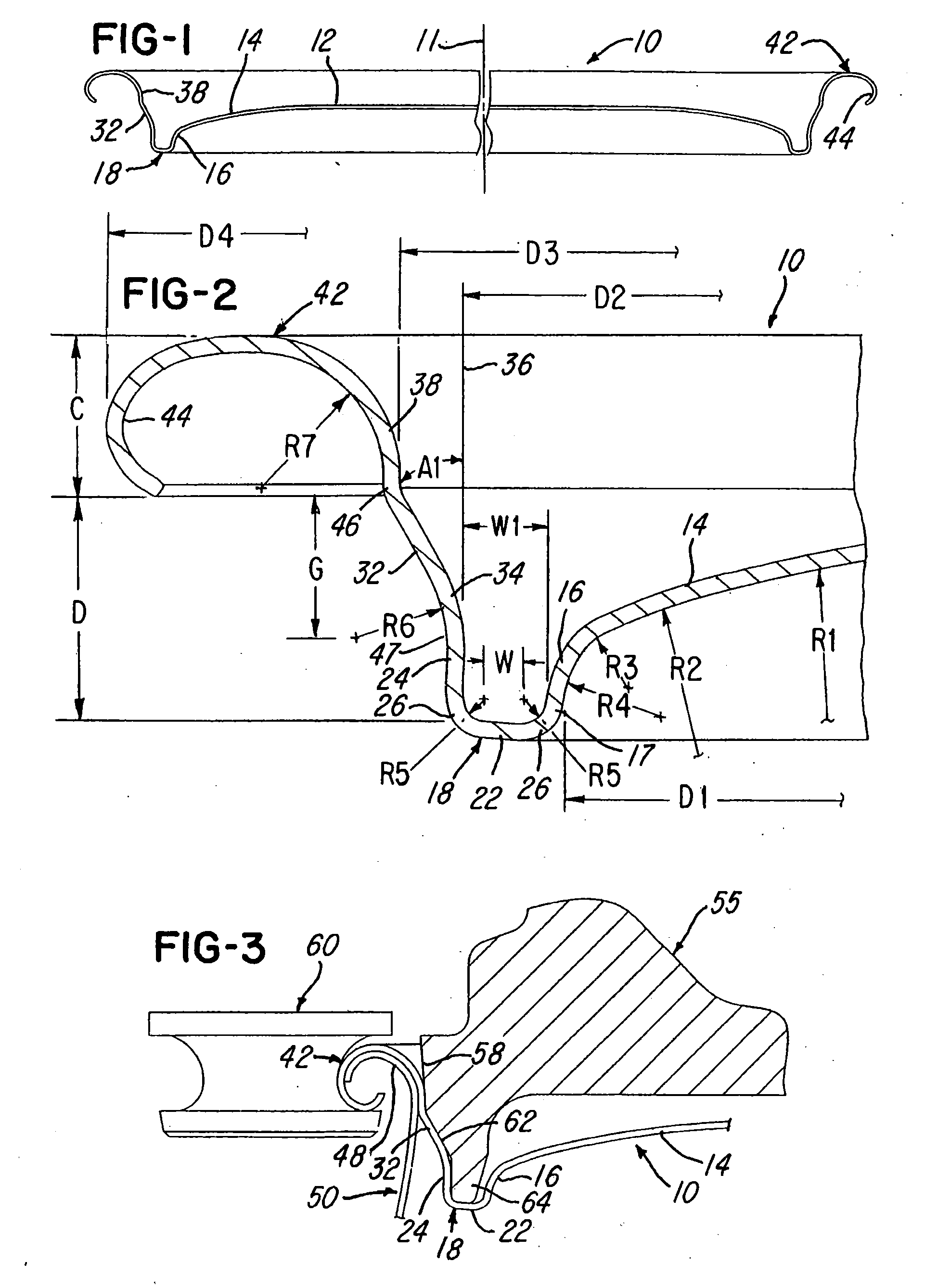

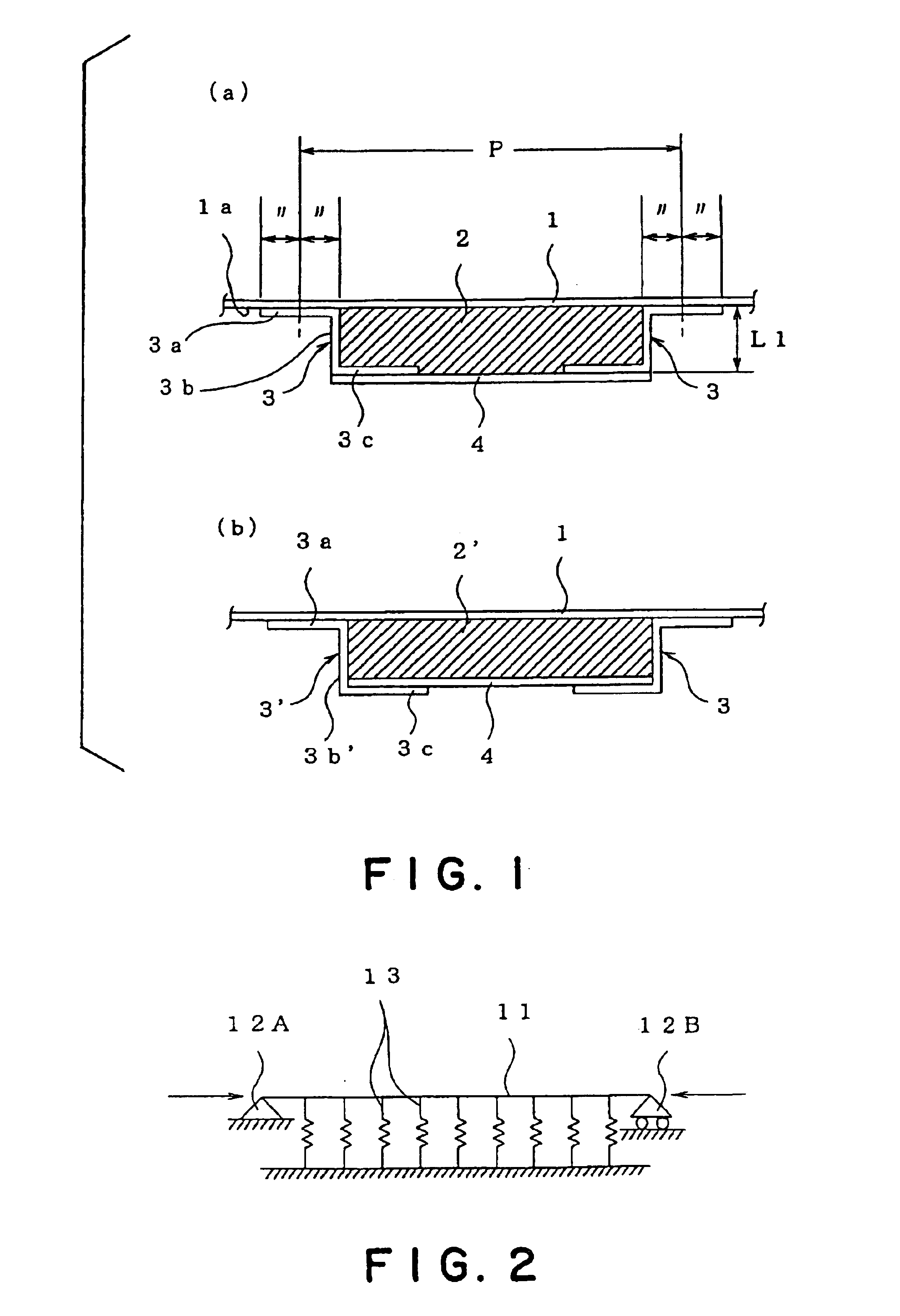

Can shell and double-seamed can end

InactiveUS7341163B2Reduction in blank diameterIncrease strength/weight ratioRigid containersHollow articlesAcute angleAluminum can

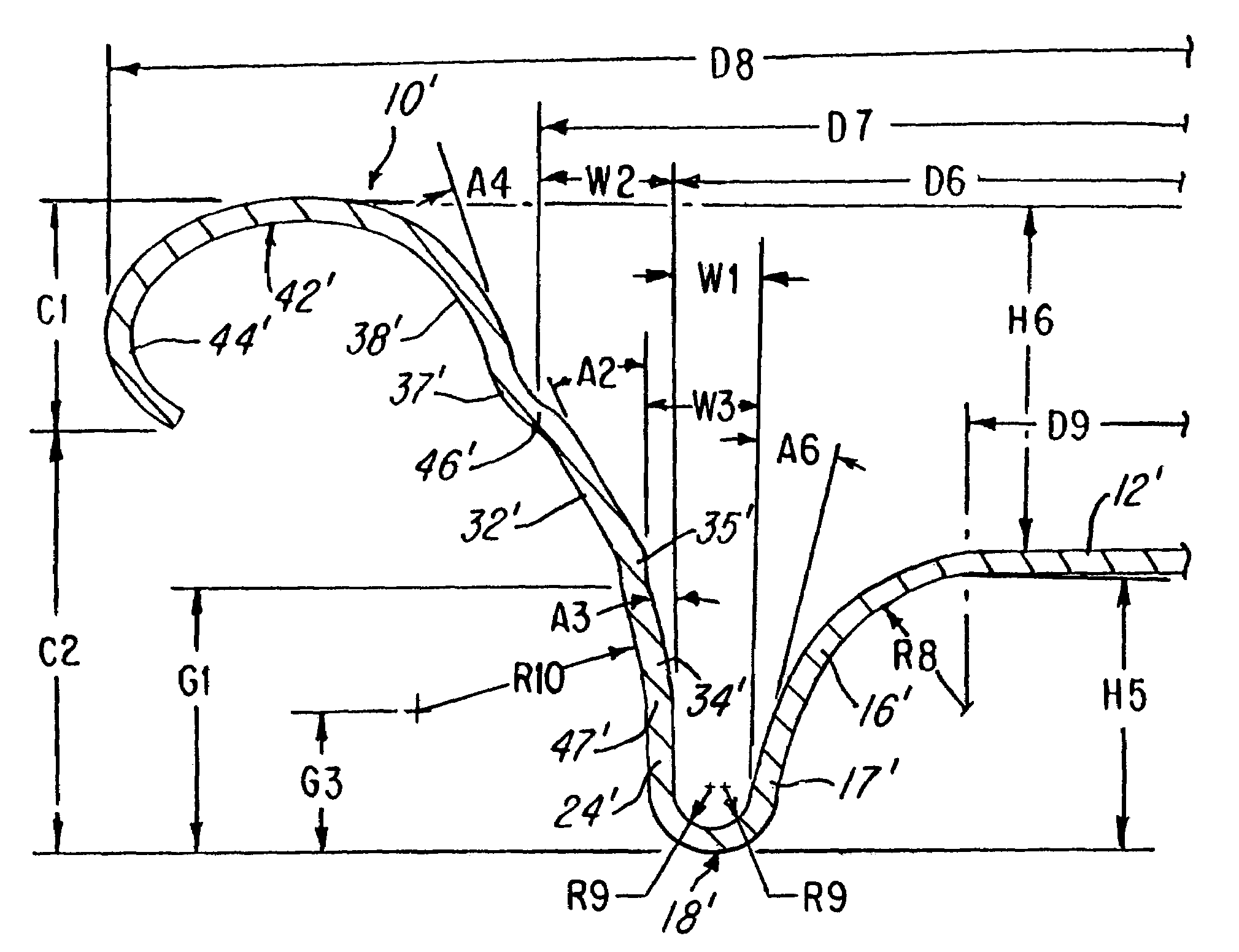

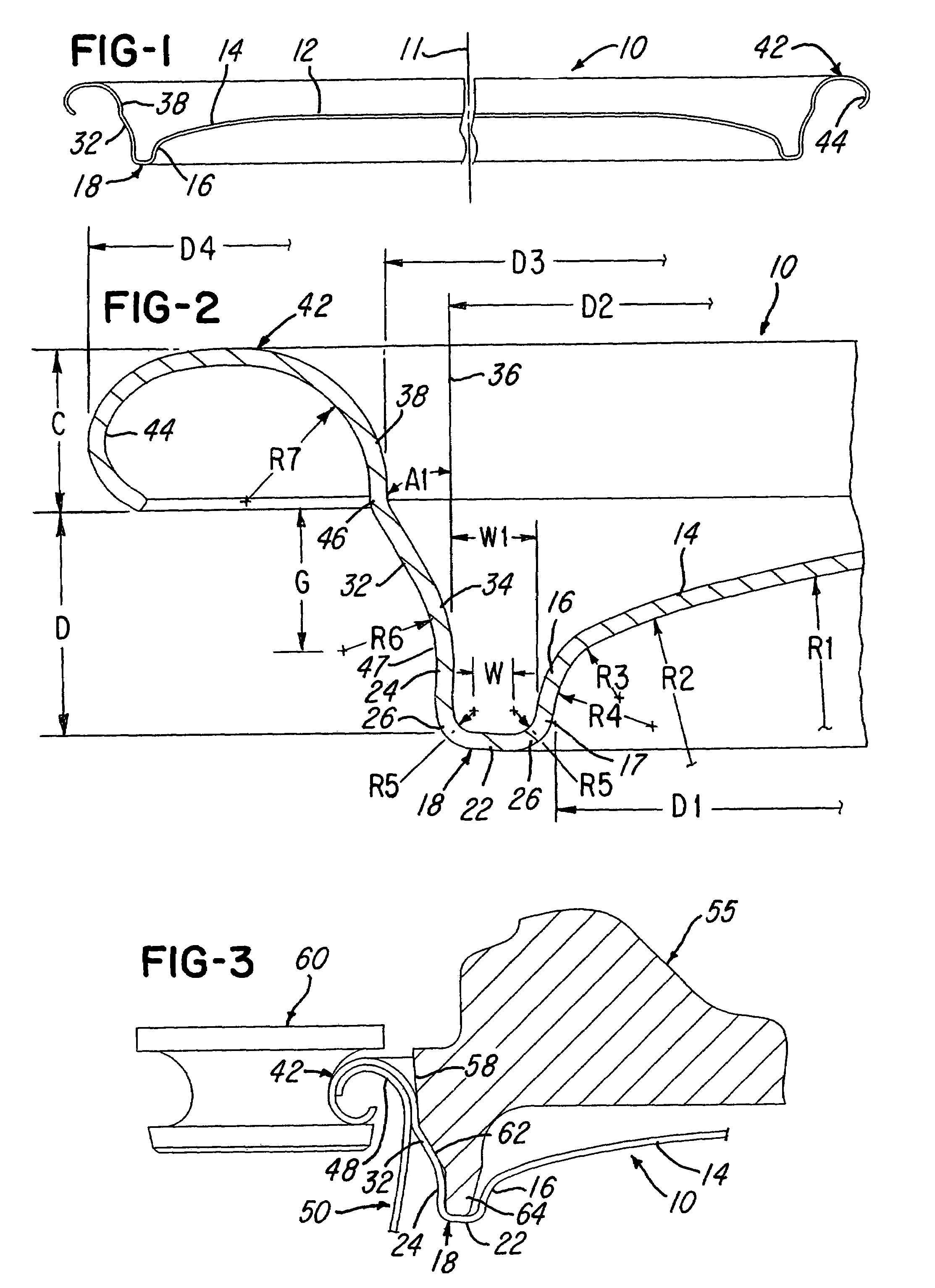

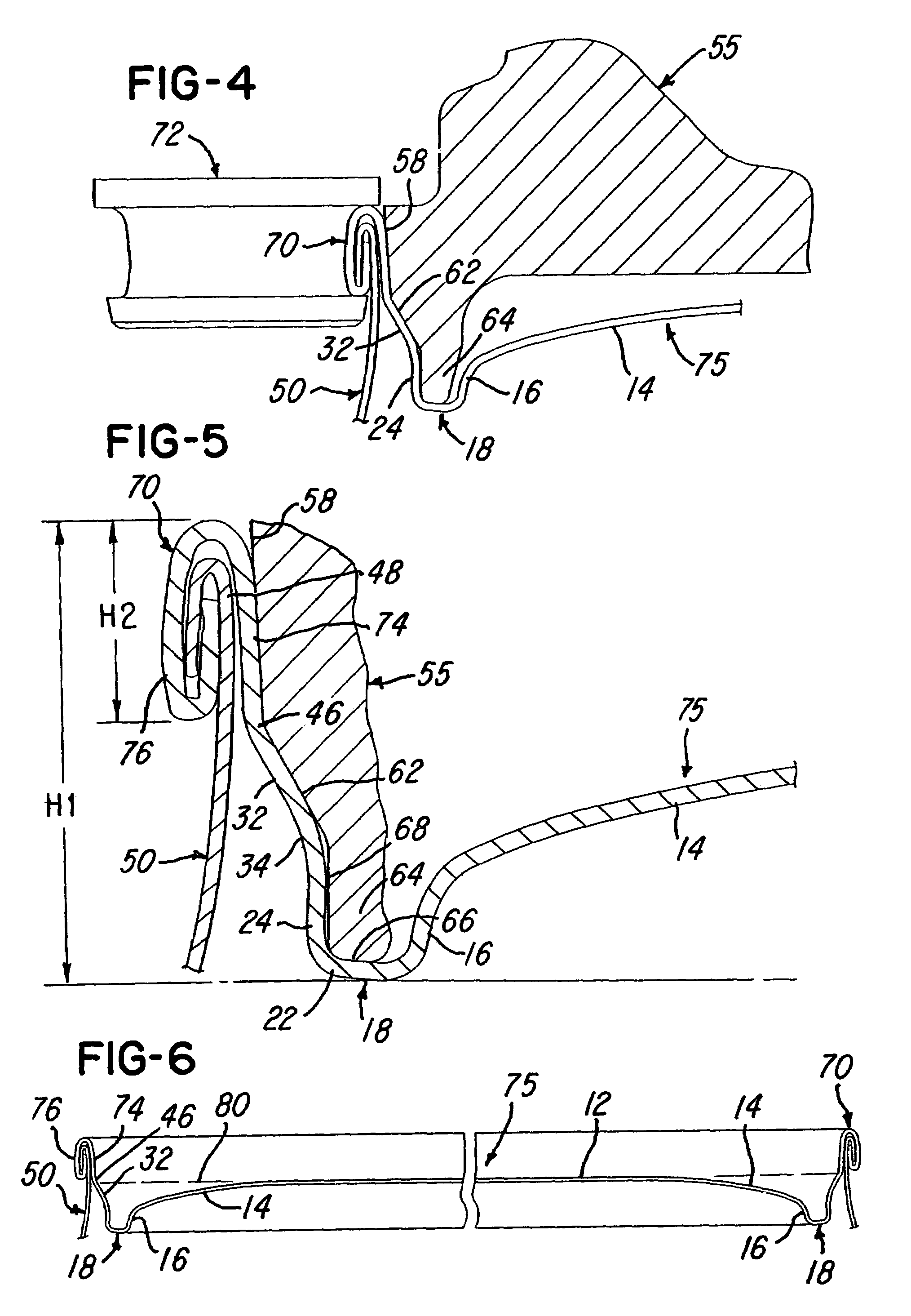

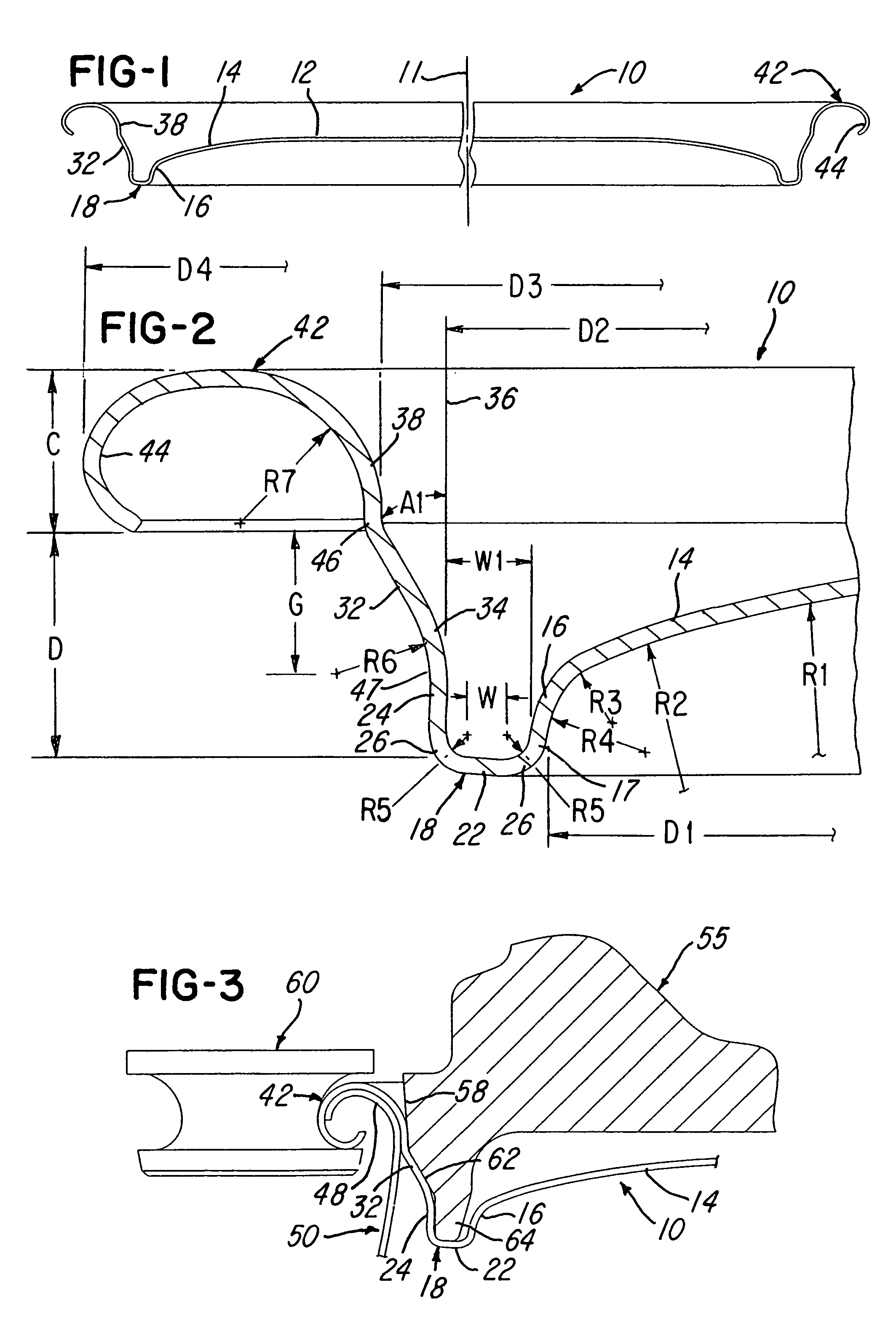

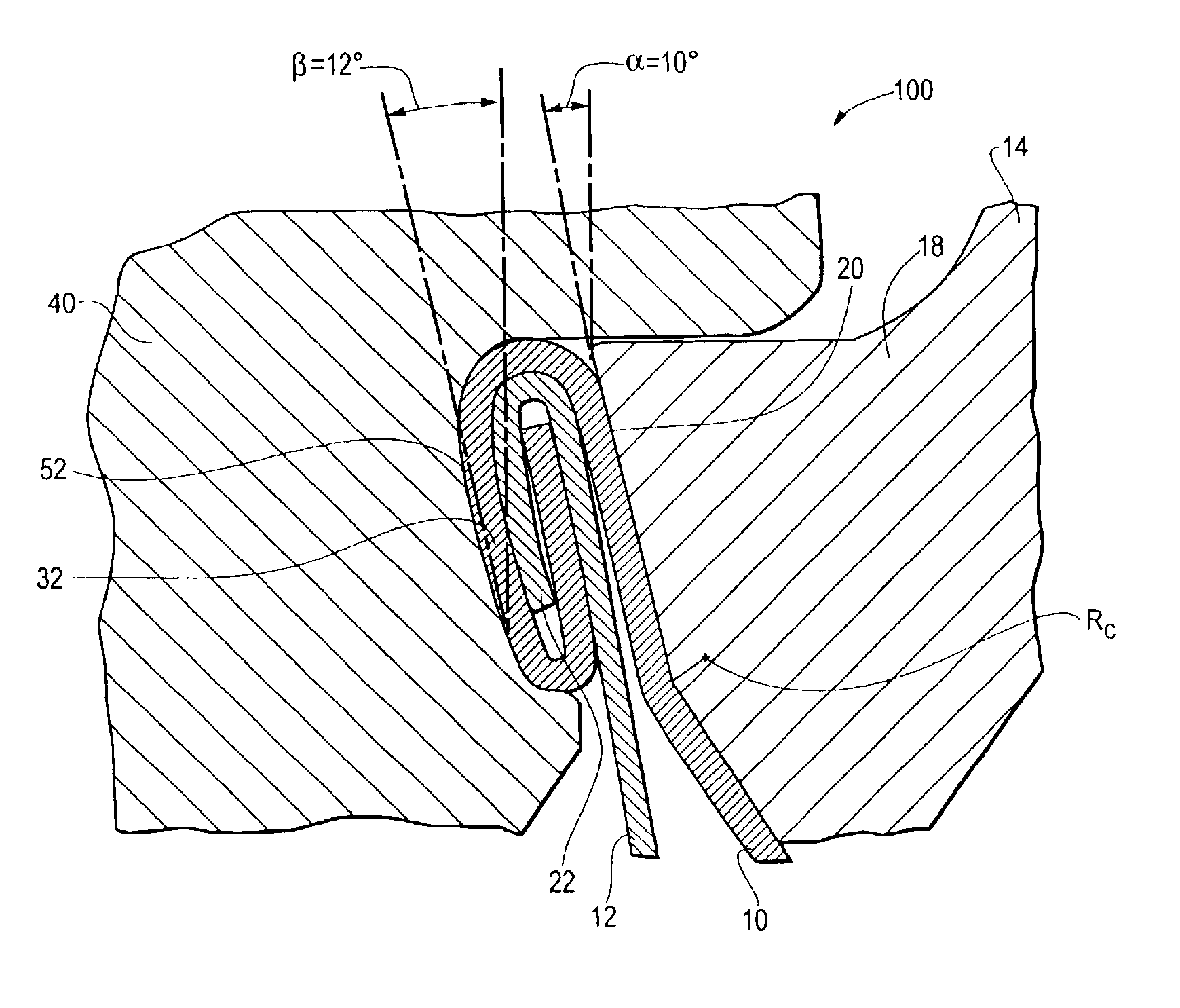

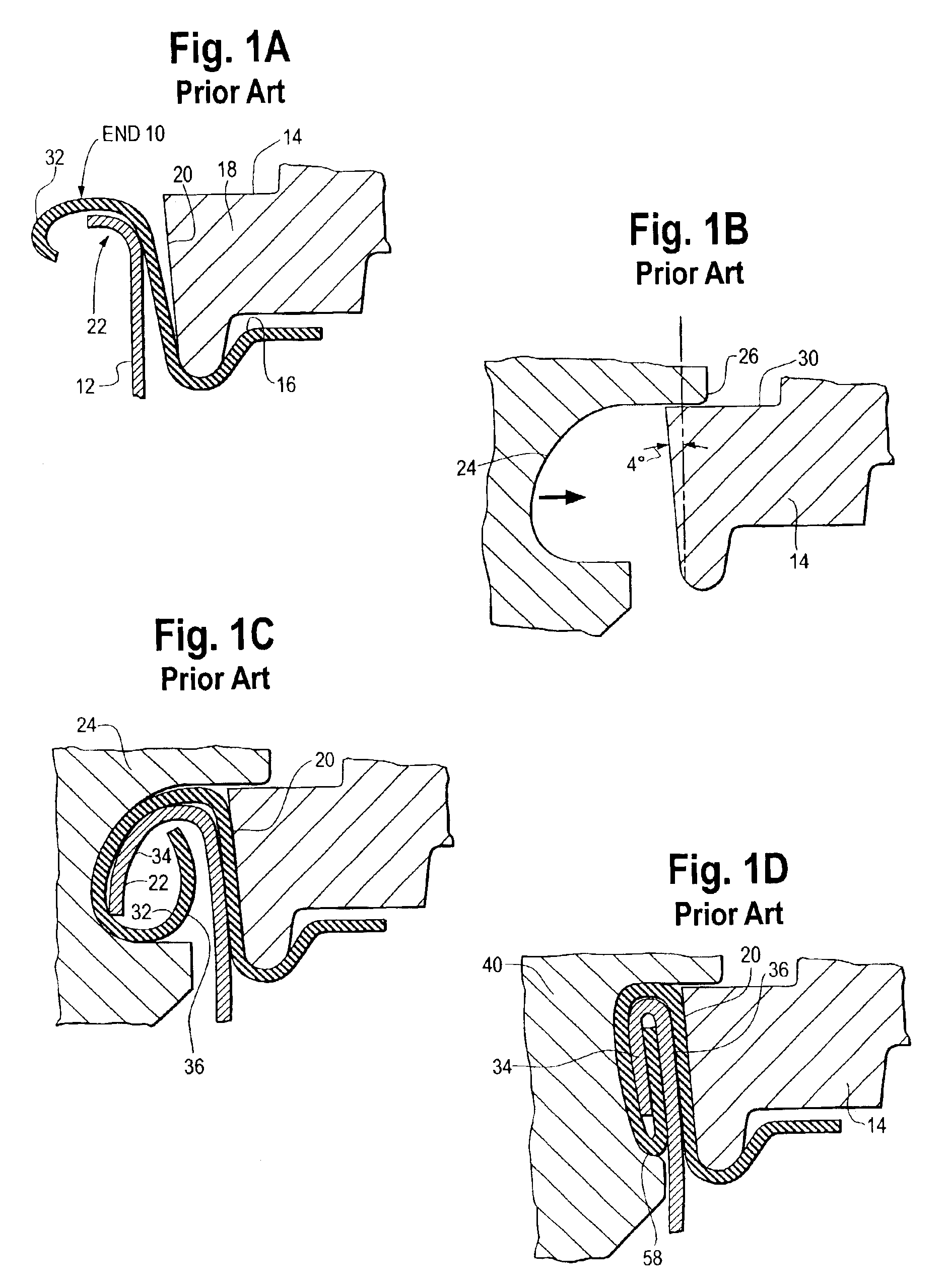

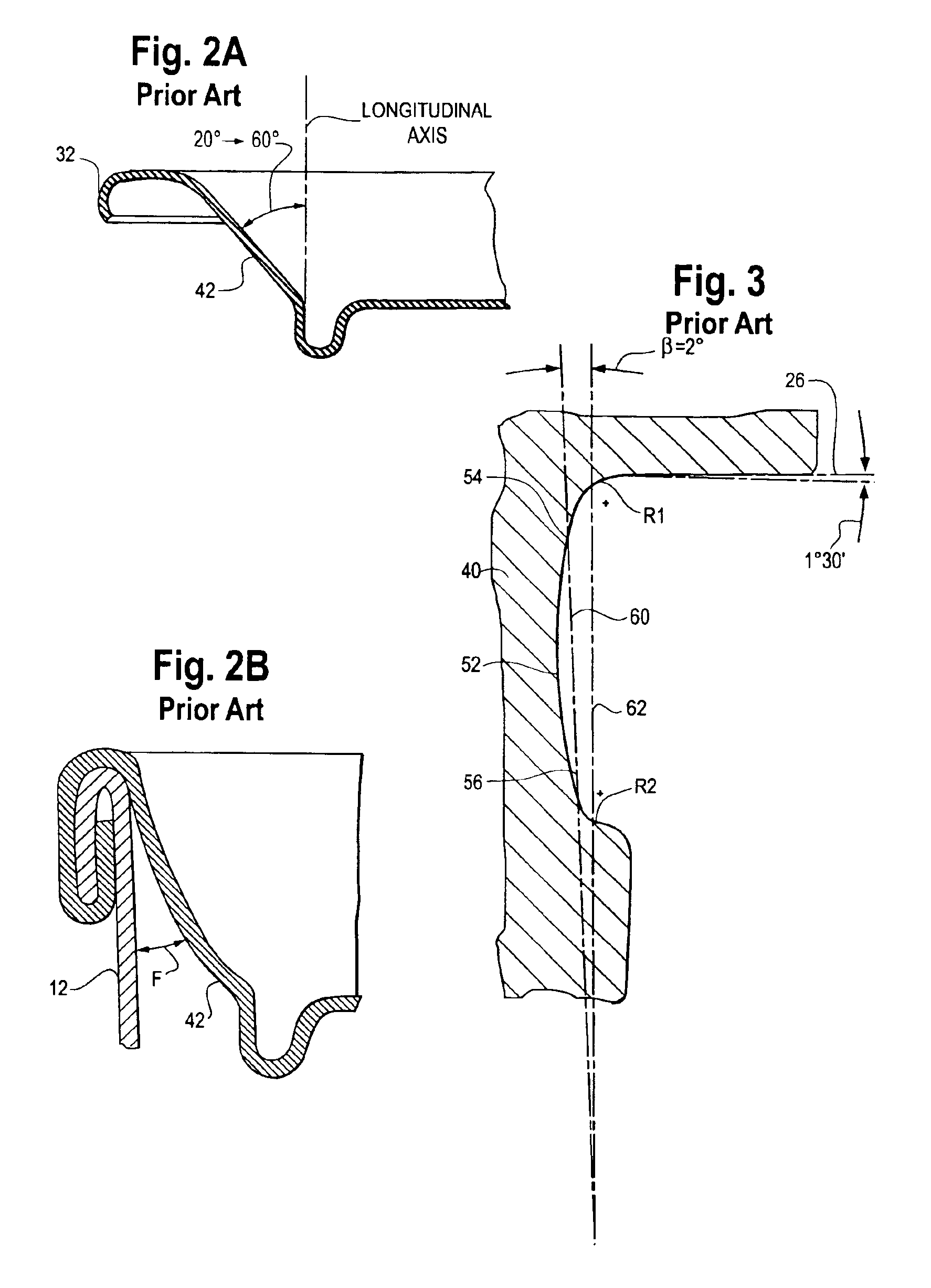

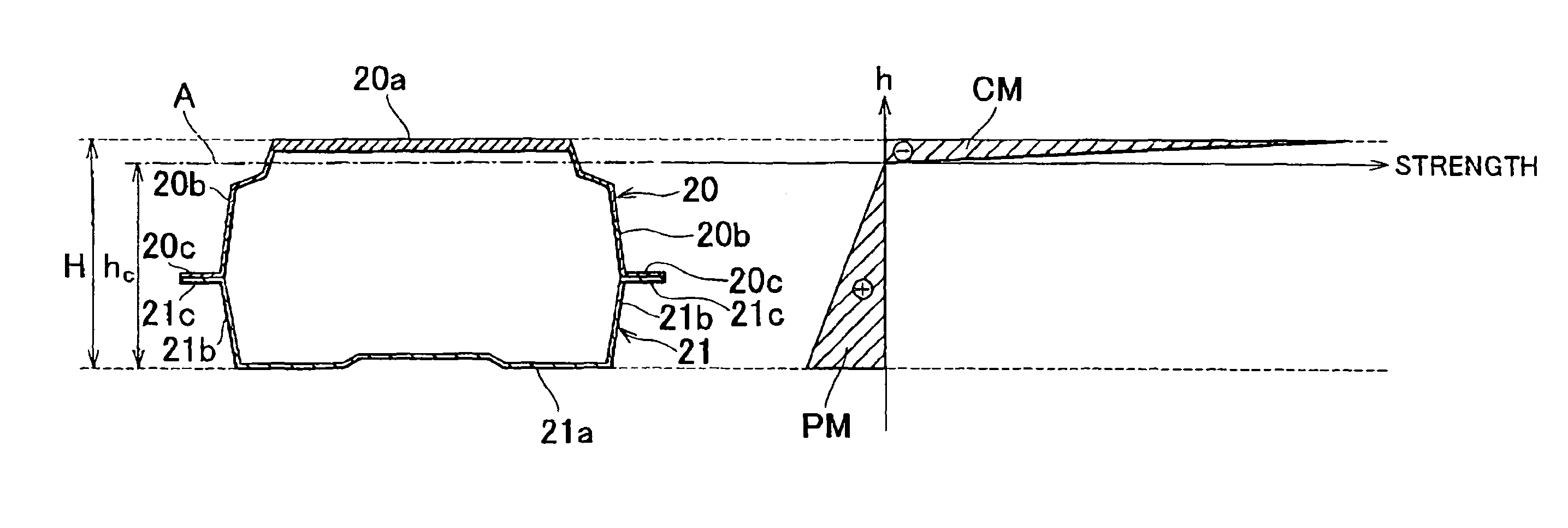

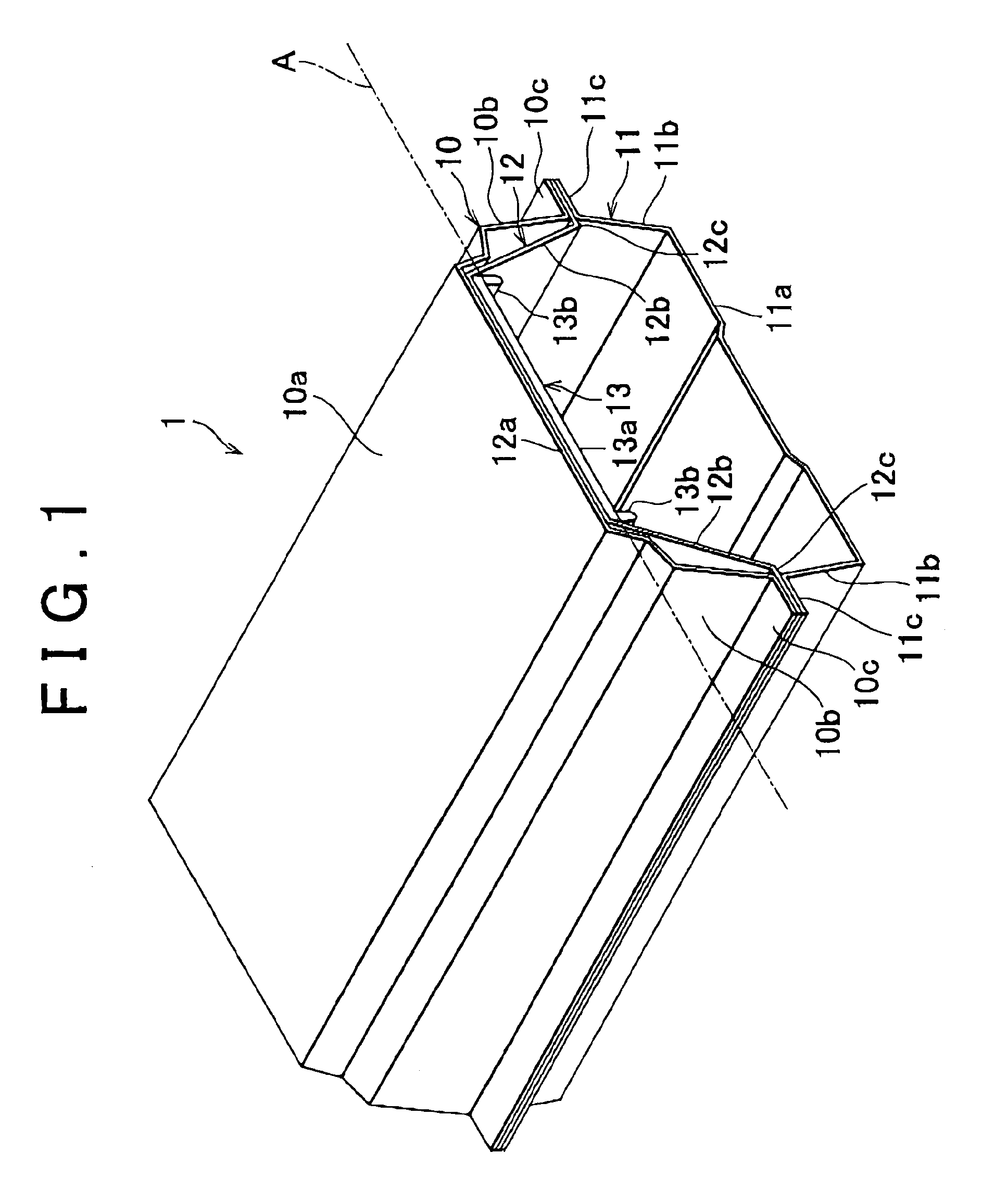

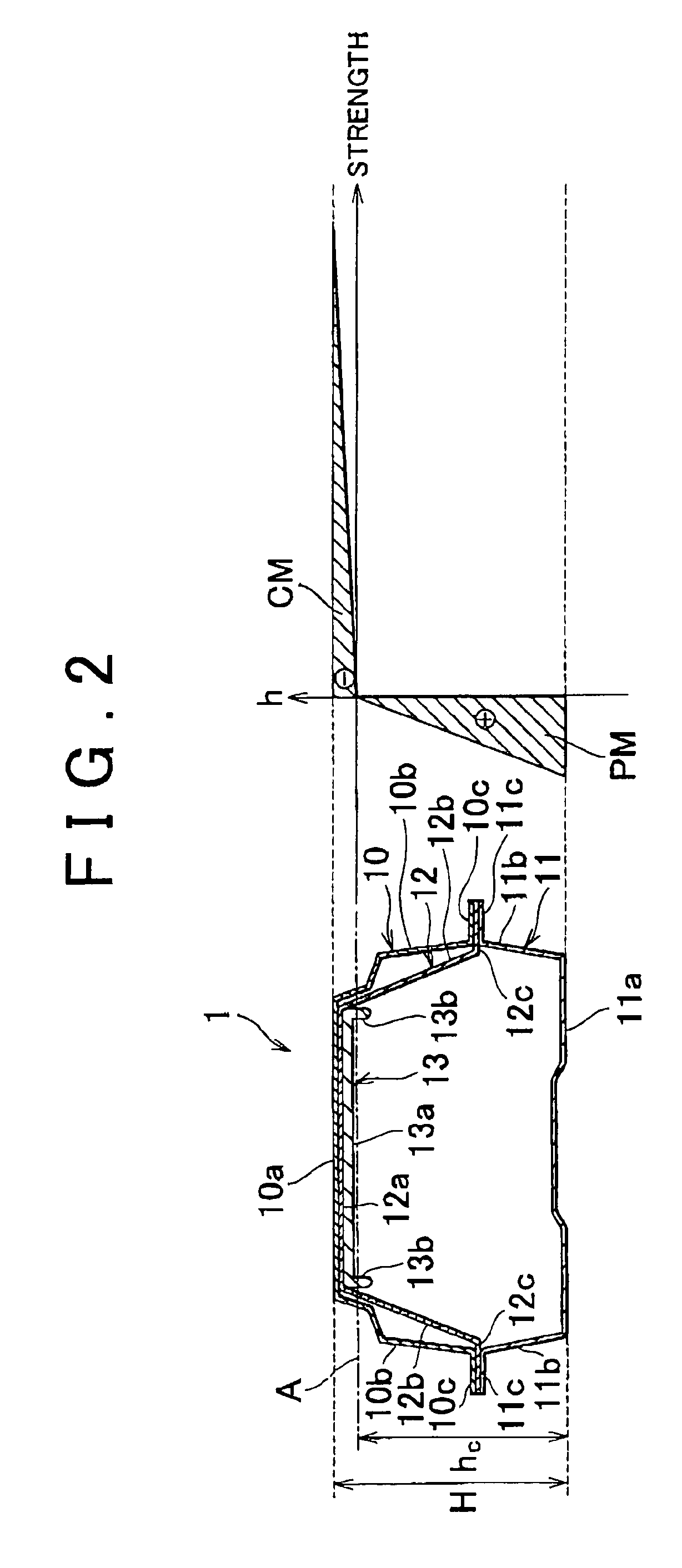

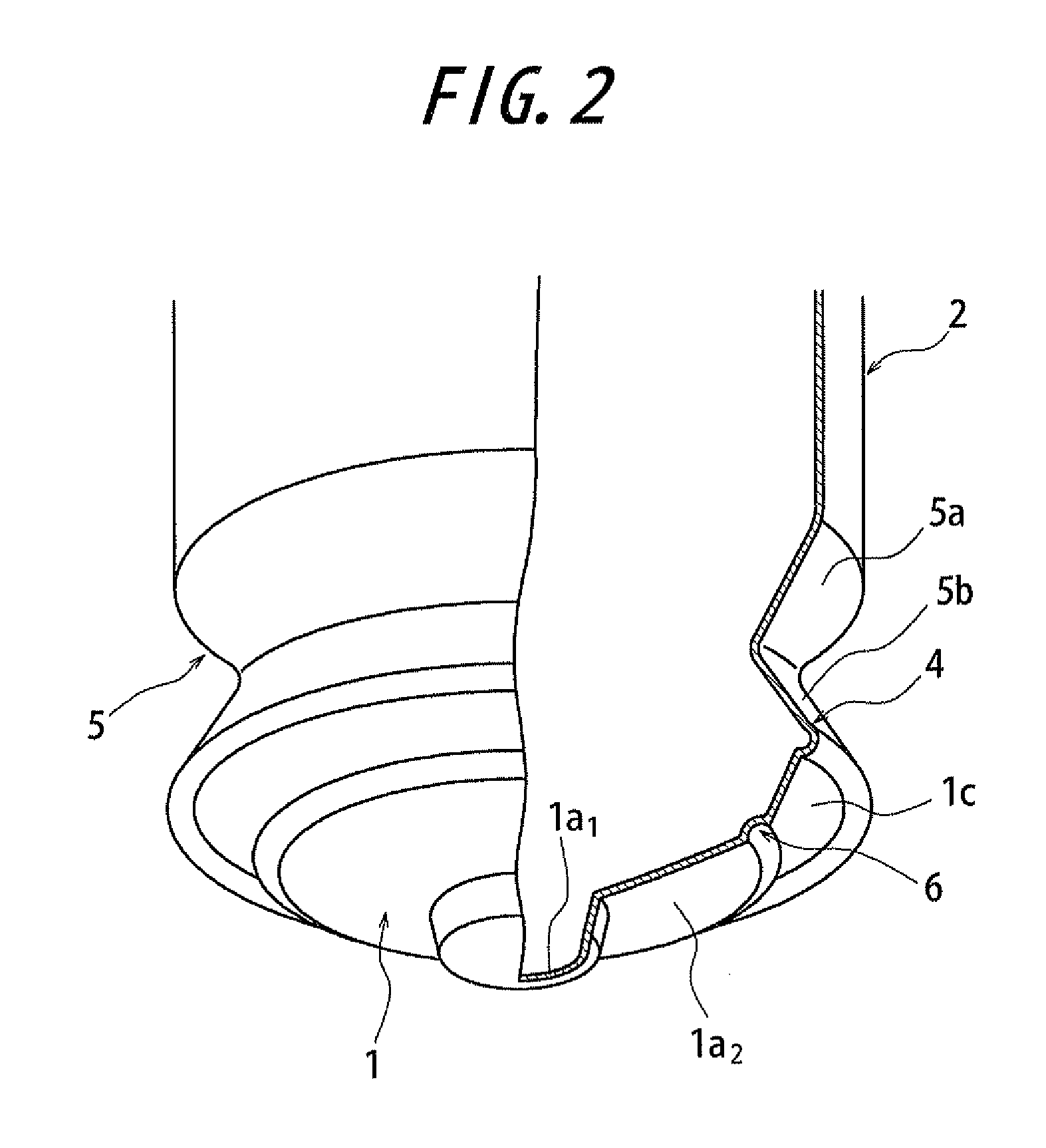

A drawn aluminum can shell has a peripheral crown which is double-seamed with an end portion of an aluminum can body to provide a can end having a generally flat center panel connected by a curved panel wall to an inner wall of an annular U-shaped countersink. The countersink has a generally cylindrical outer wall and an inner width less than the radius of the panel wall. The outer wall of the countersink connects with a frusto-conical chuckwall at a junction below the center panel, and the chuckwall extends to an inner wall of the crown at an angle of at least 16° with the center axis. The chuckwall has an S-curved intermediate configuration, the inner width of the countersink is less than the radius of the panel wall, and the inner wall of the countersink extends at an acute angle relative to the outer wall.

Owner:CONTAINER DEVELOPMENT LTD

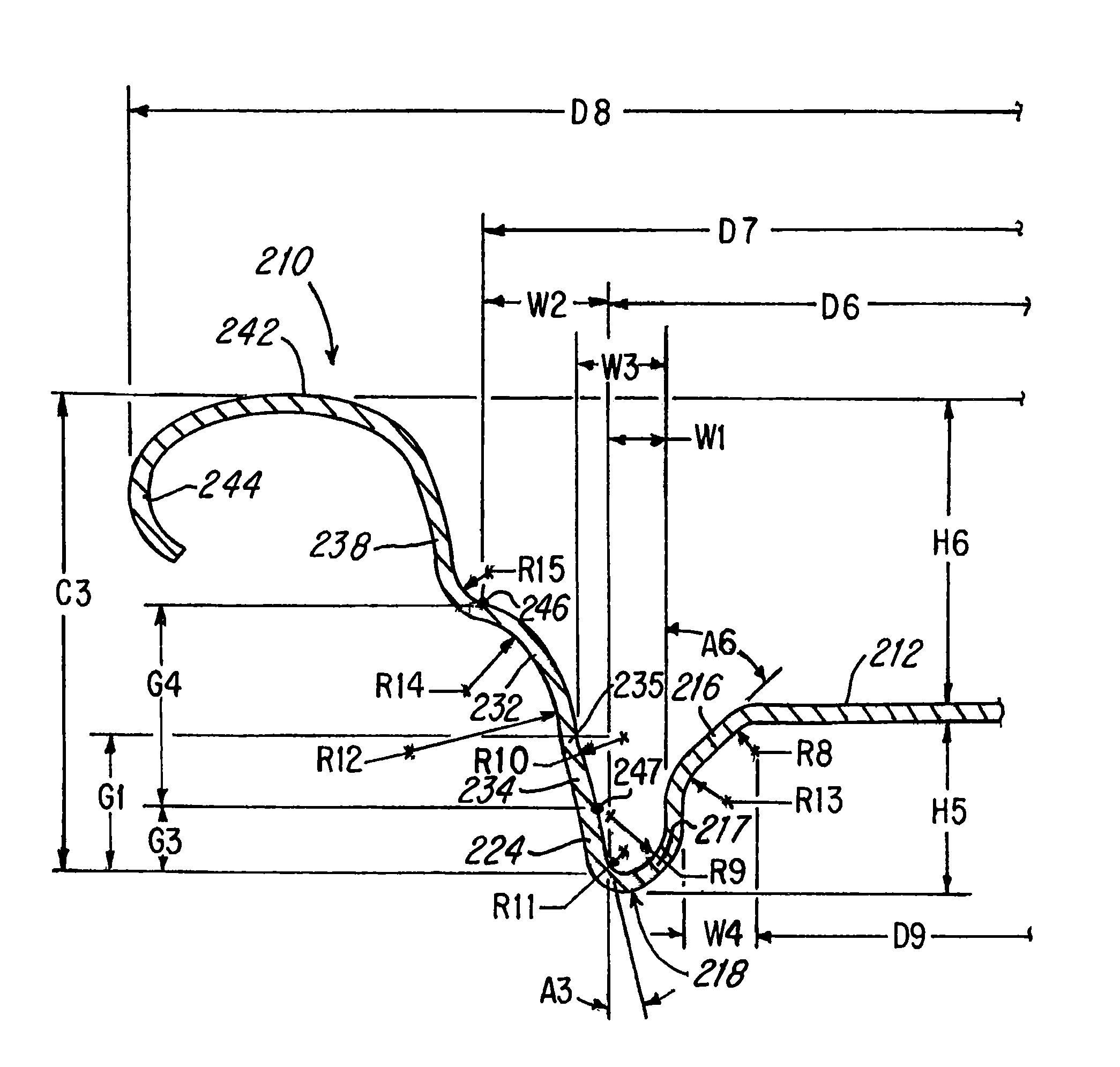

Can shell and double-seamed can end

InactiveUS7819275B2Reduce the overall diameterRaise the ratioRigid containersHollow articlesAluminum canEngineering

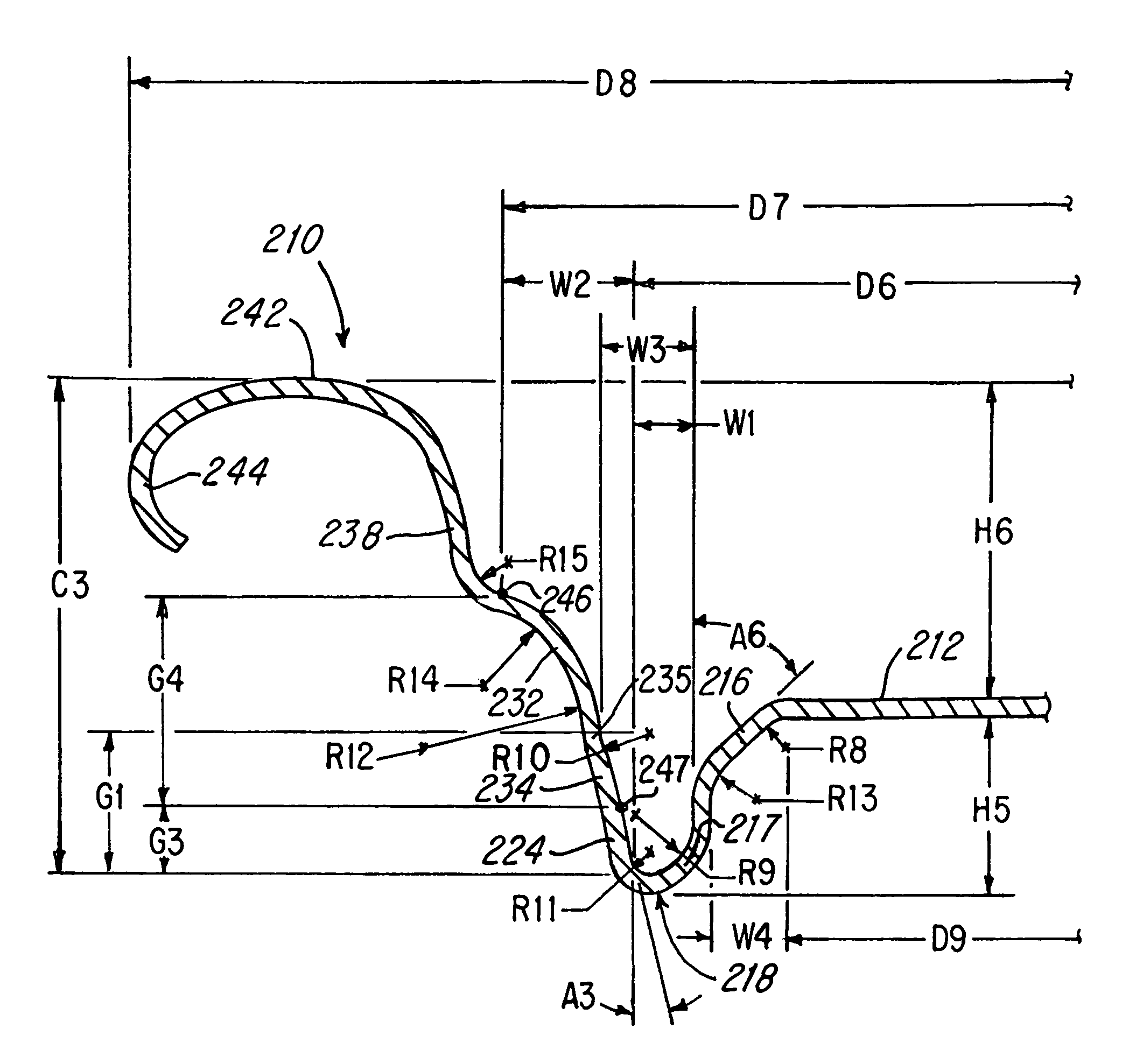

A drawn aluminum can shell has a peripheral crown which is double-seamed with an end portion of an aluminum can body to provide a can end having a generally flat center panel connected by an inclined curved or straight panel wall to an inclined inner wall of an annular U-shaped countersink. The countersink has an outer wall which connects with an inclined lower wall portion of a chuckwall at a junction below the center panel, and the chuckwall has a curved or inclined upper wall portion which connects with an inner wall of the crown. The chuckwall also has an intermediate wall portion forming a break, and the inner bottom width of the countersink is less than the radial width of the panel wall. The inclined upper wall portion of the chuckwall extends at an angle greater than the angle of the inclined lower wall portion of the chuckwall.

Owner:BALL CORP +1

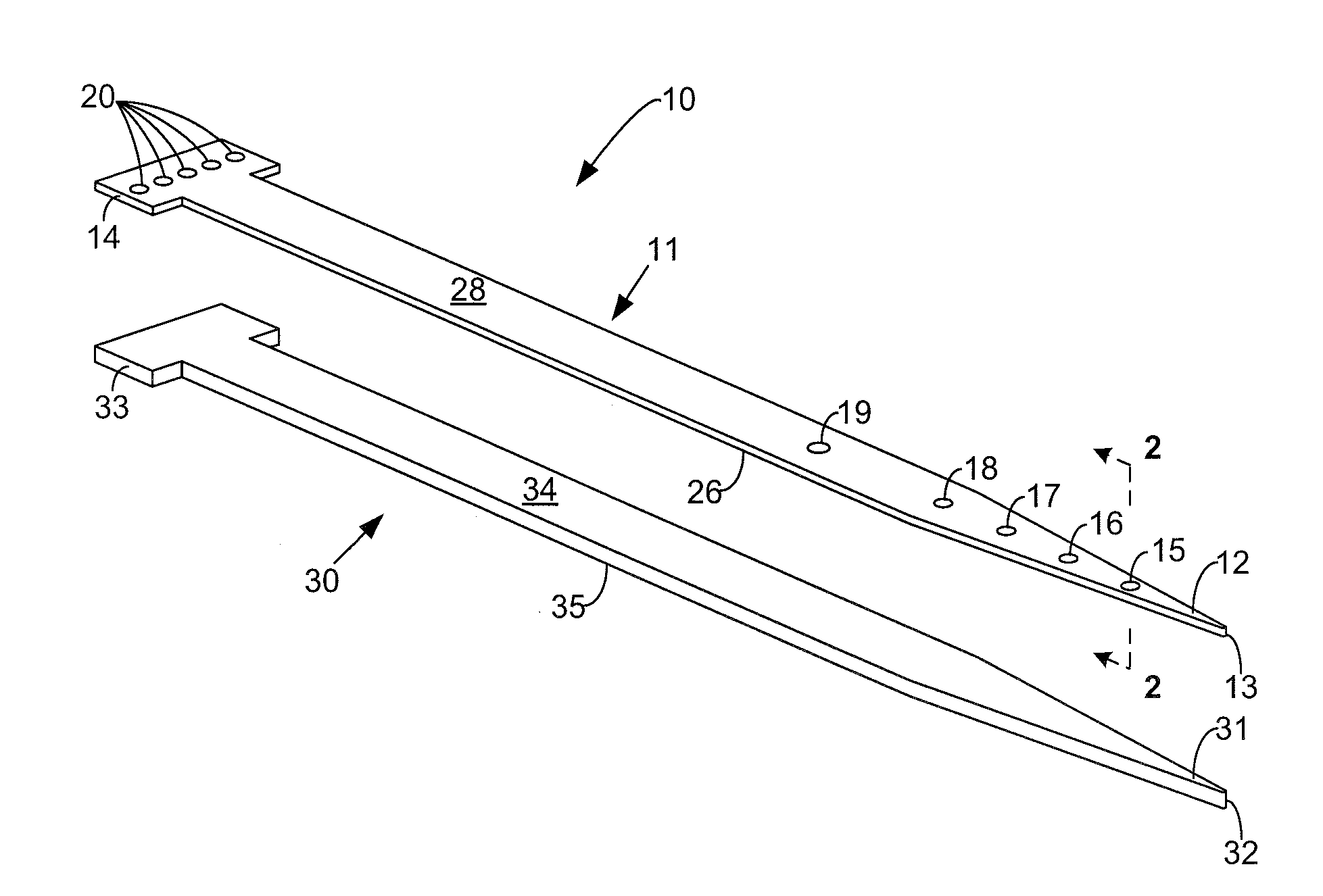

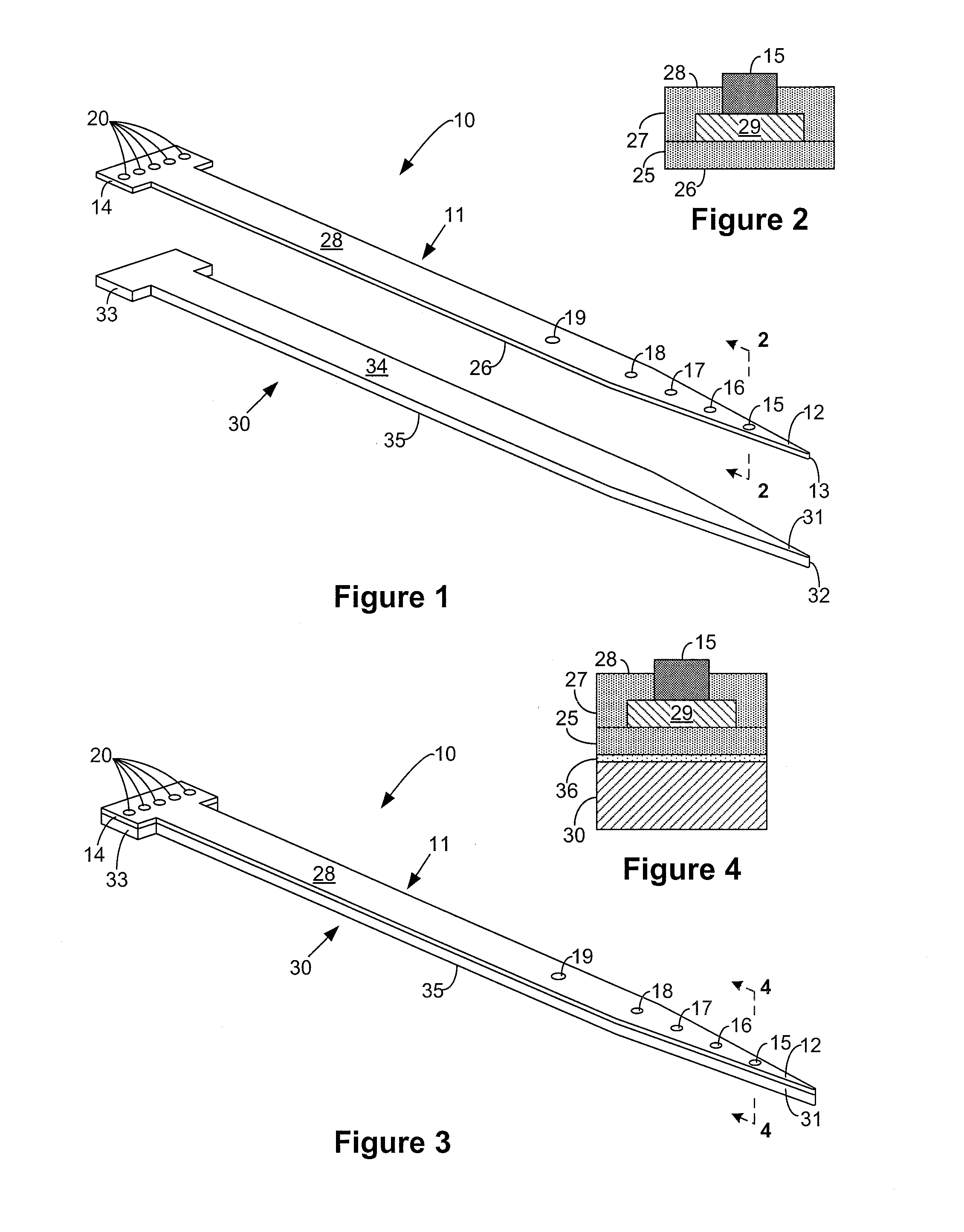

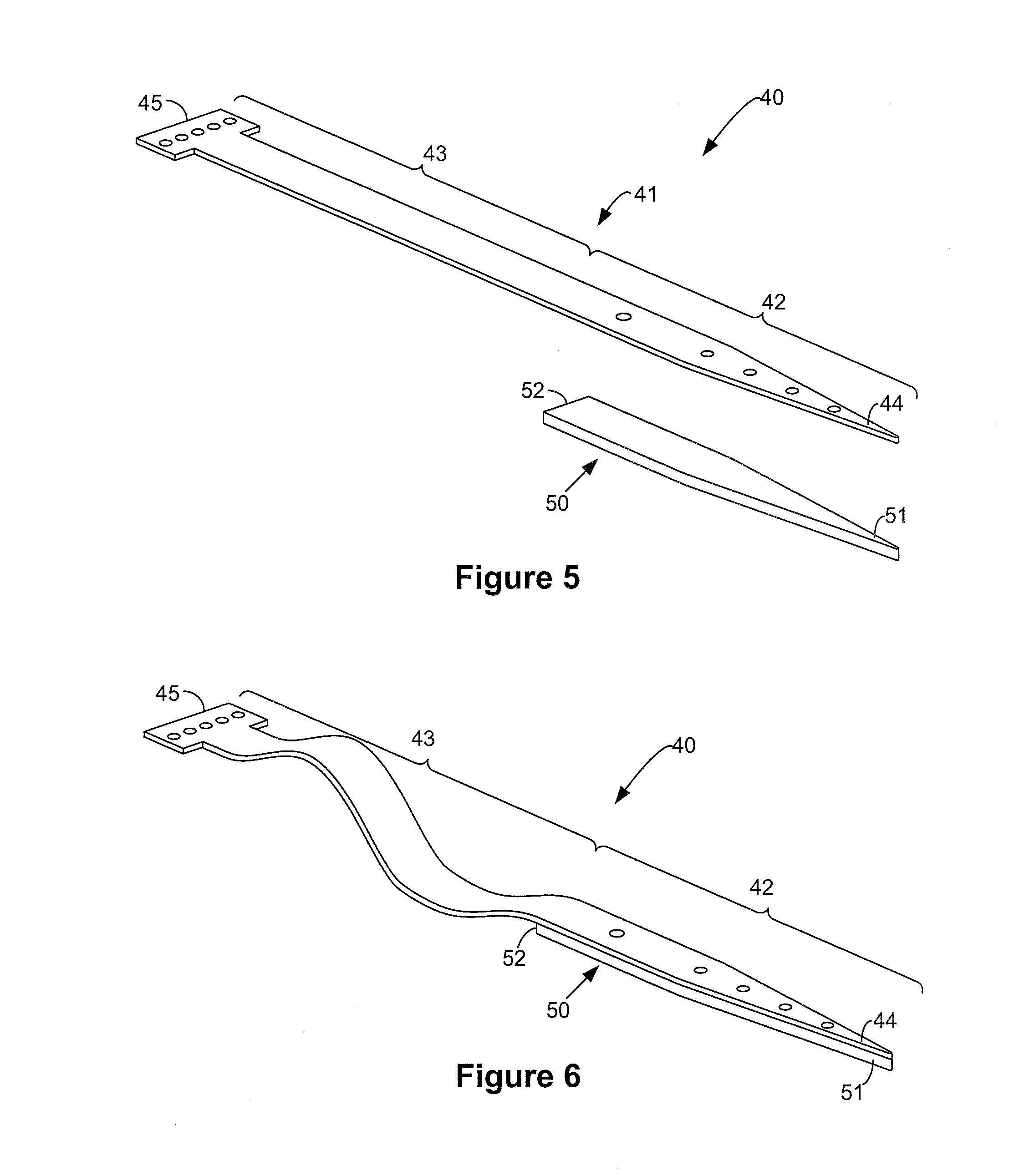

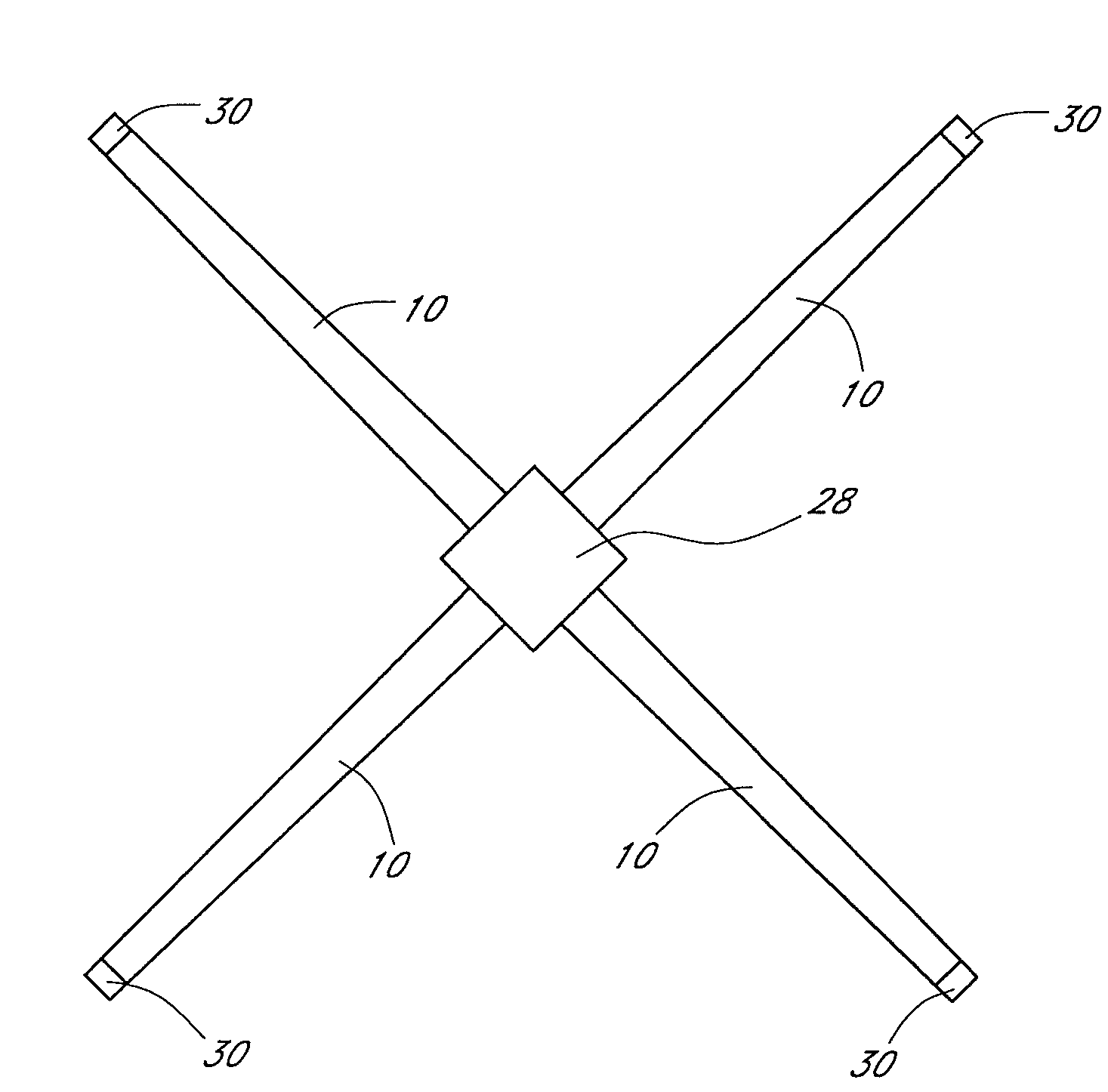

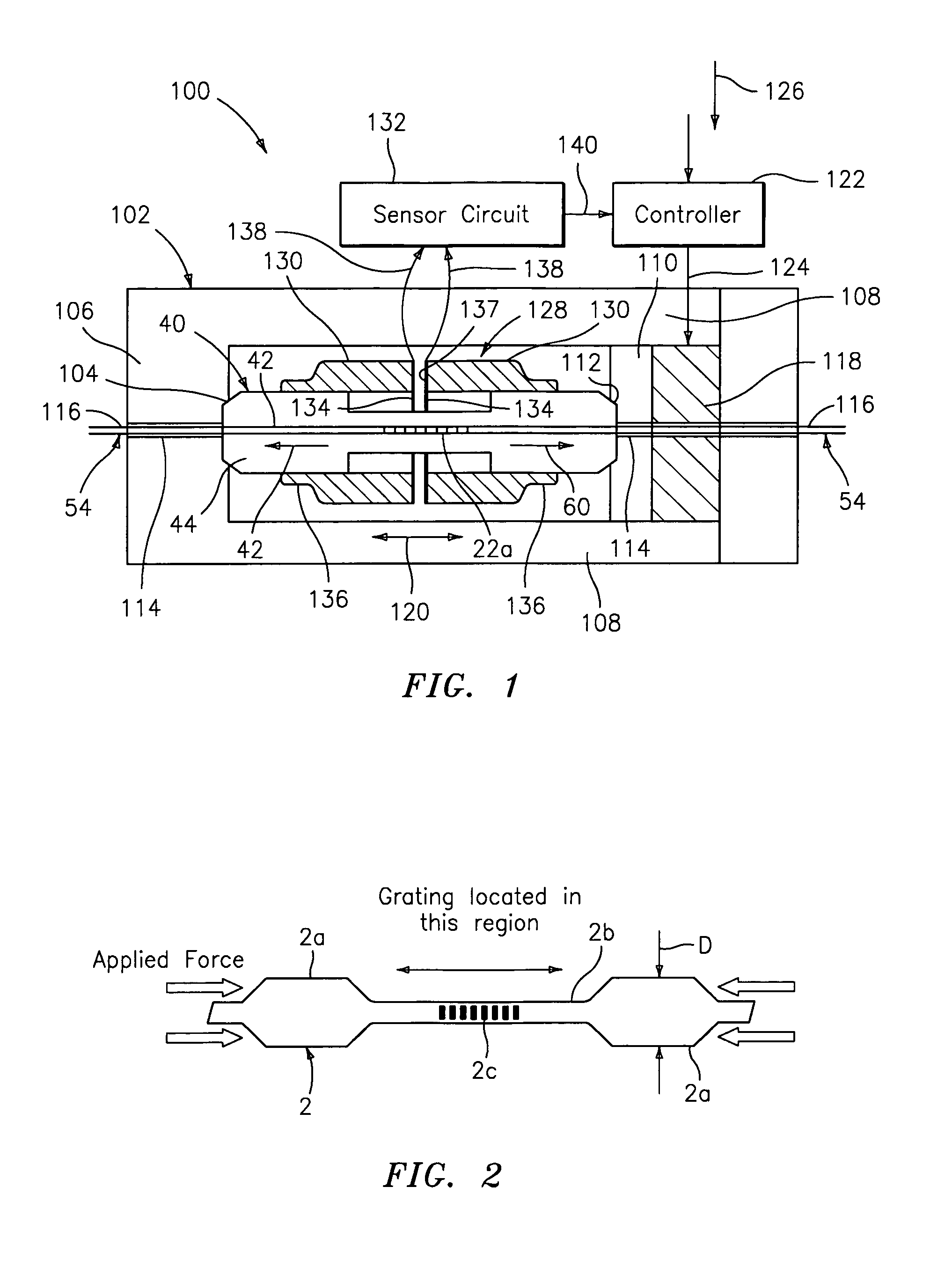

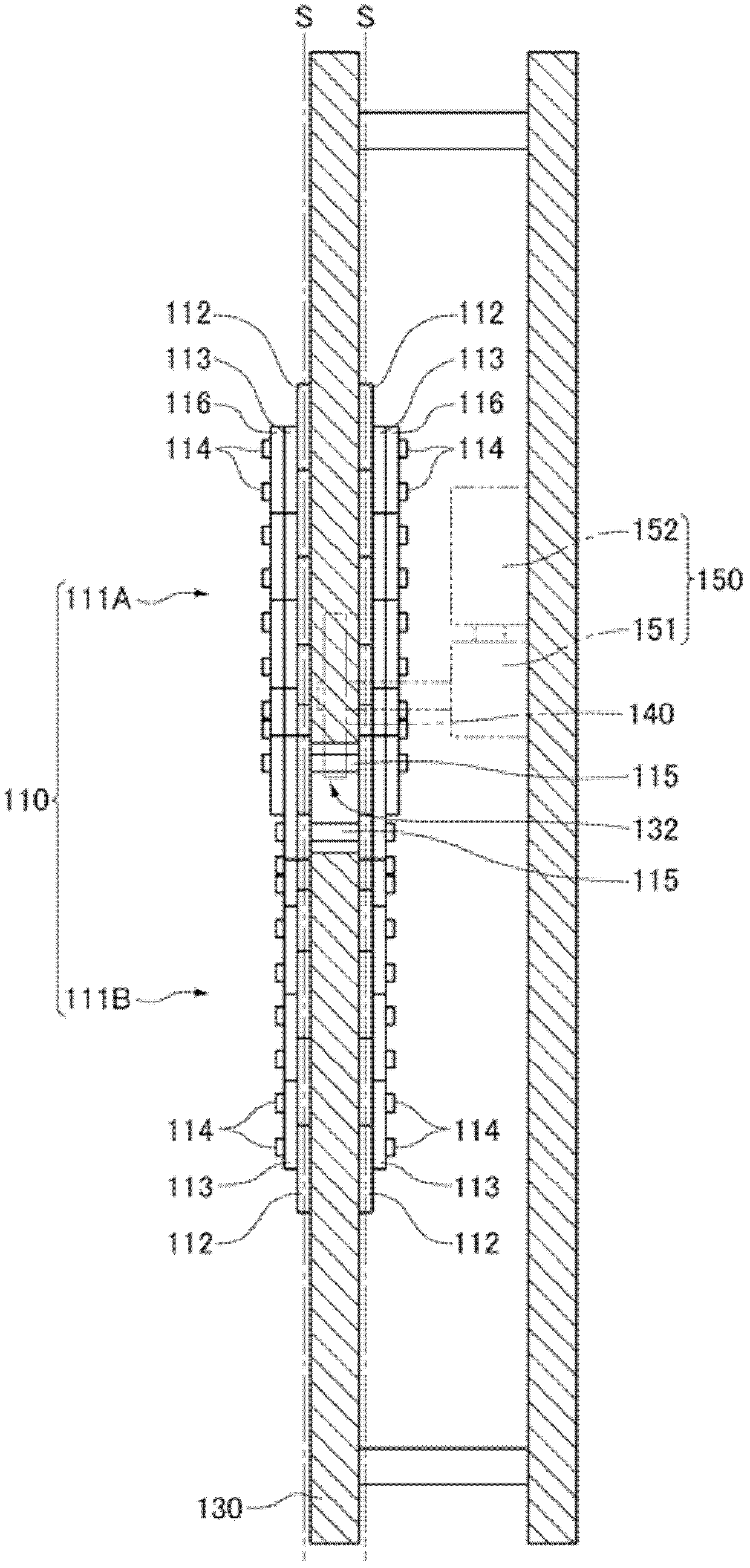

Rigid spine reinforced polymer microelectrode array probe and method of fabrication

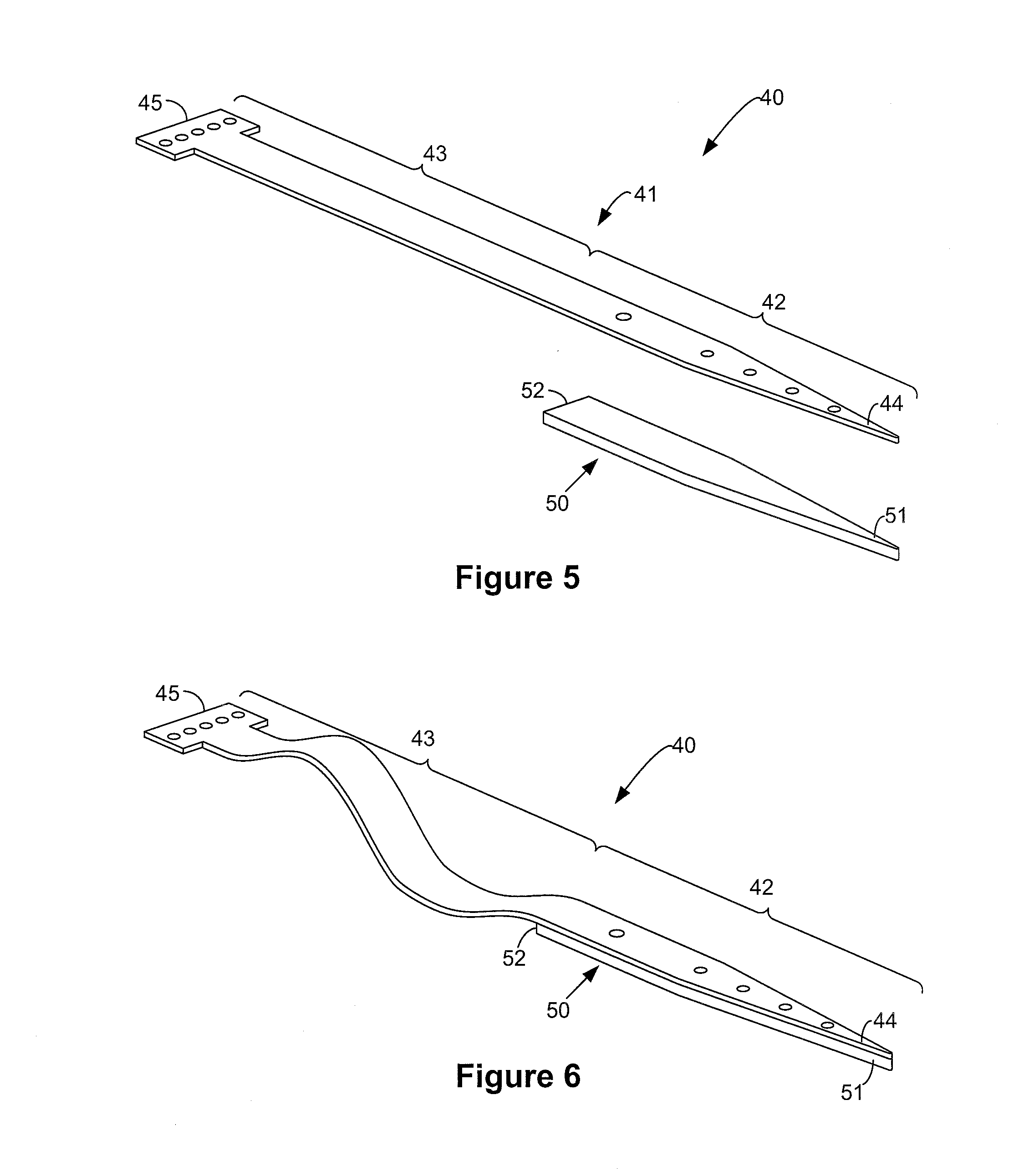

ActiveUS8738110B2Increased buckling strengthReduce riskLine/current collector detailsInternal electrodesTitaniumMicroelectrode

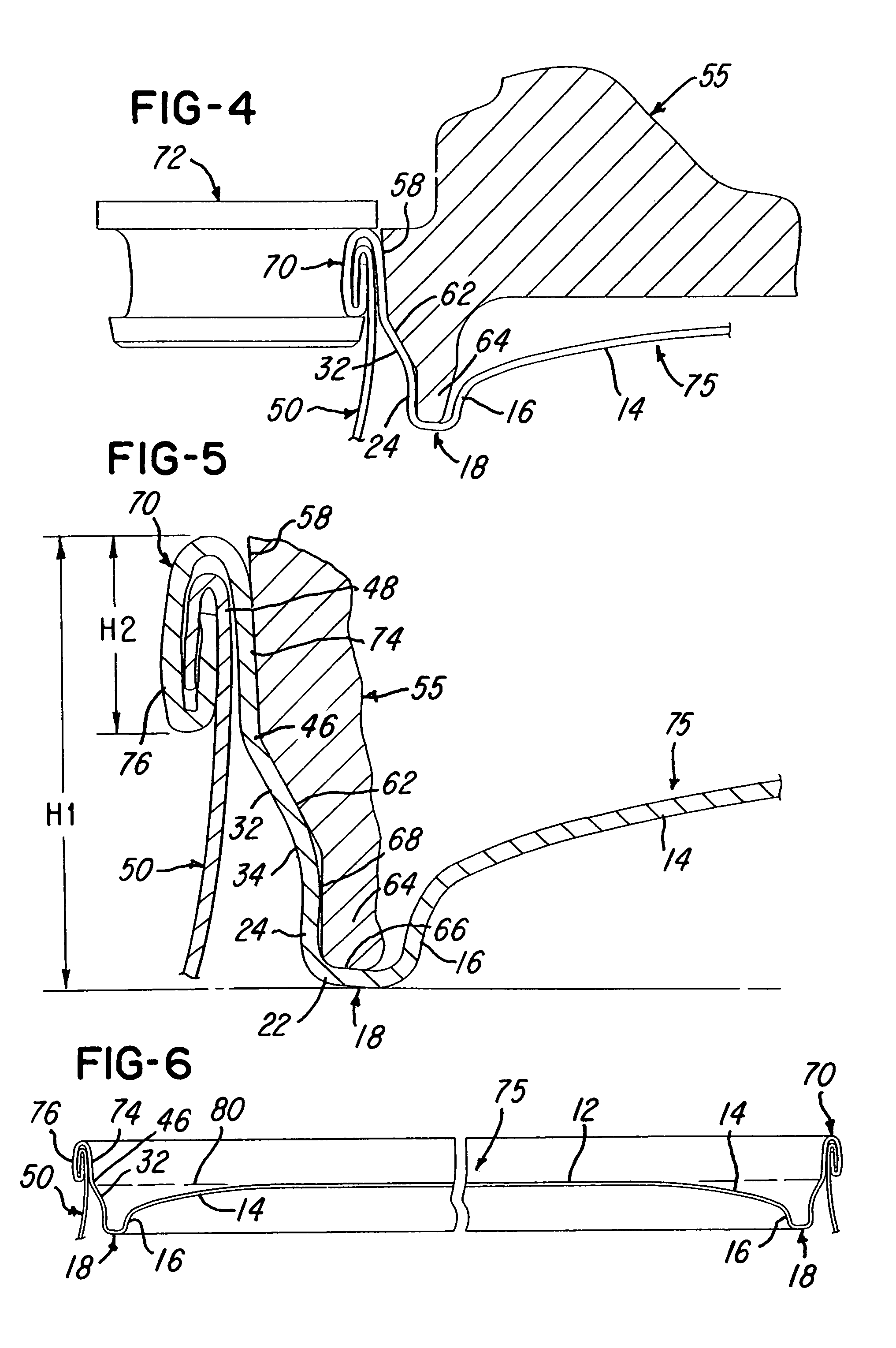

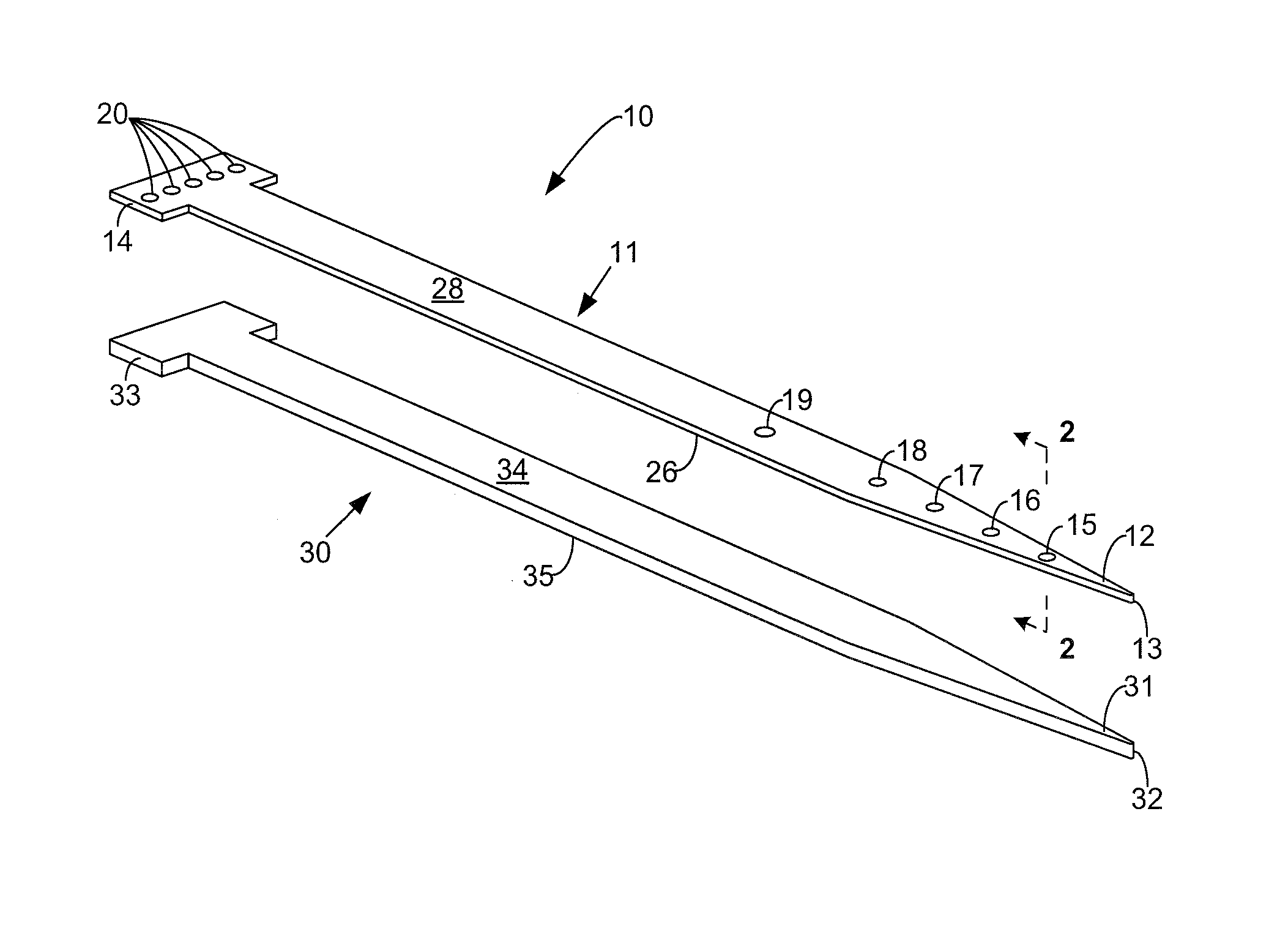

A rigid spine-reinforced microelectrode array probe and fabrication method. The probe includes a flexible elongated probe body with conductive lines enclosed within a polymeric material. The conductive lines connect microelectrodes found near an insertion end of the probe to respective leads at a connector end of the probe. The probe also includes a rigid spine, such as made from titanium, fixedly attached to the probe body to structurally reinforce the probe body and enable the typically flexible probe body to penetrate and be inserted into tissue, such as neural tissue. By attaching or otherwise fabricating the rigid spine to connect to only an insertion section of the probe body, an integrally connected cable section of the probe body may remain flexible.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

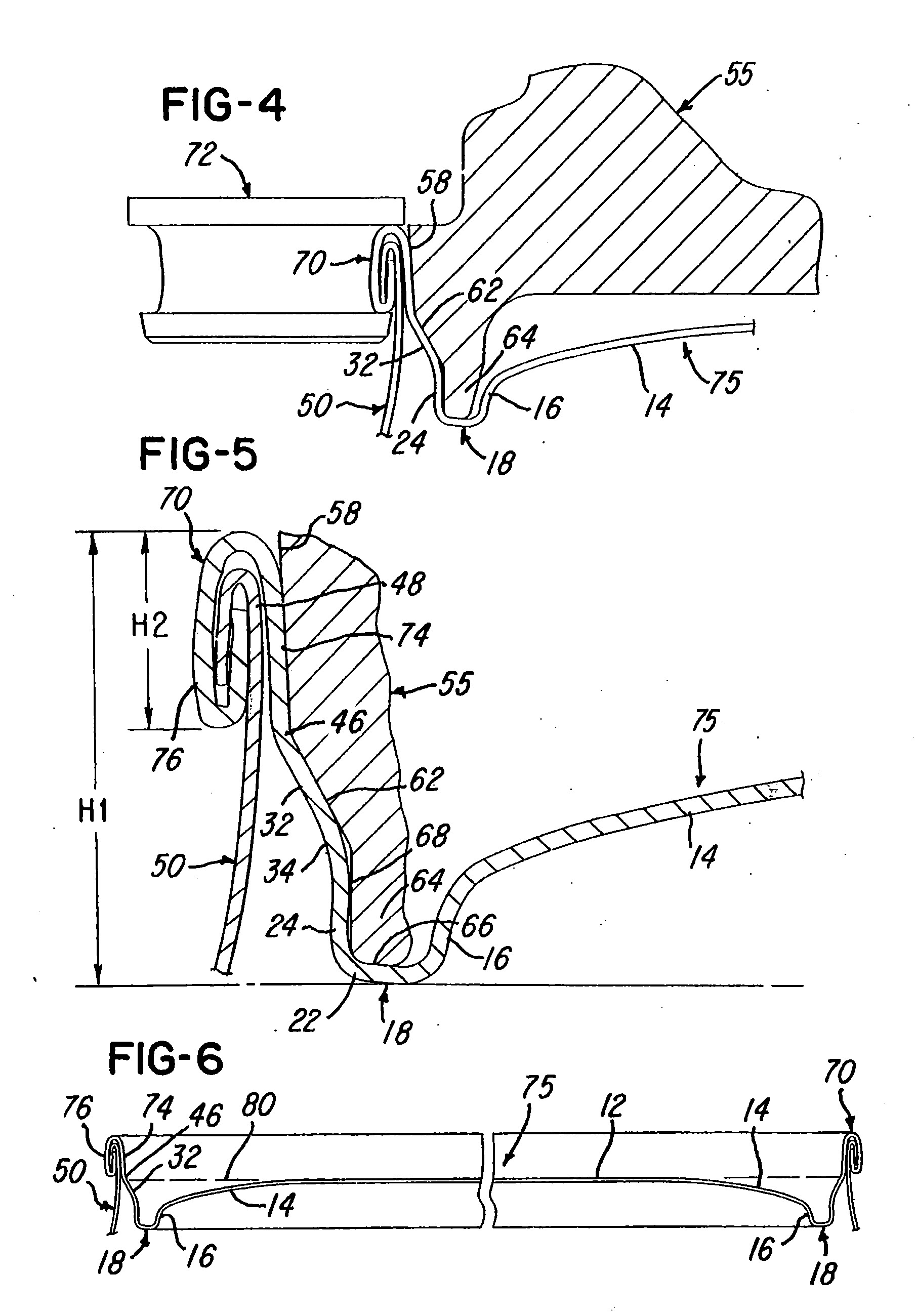

Seaming apparatus and method for cans

InactiveUS6915553B2Less bending of the chuck wallReduced strengthMetal working apparatusHollow articlesEngineeringFlange

Owner:REXAM BEVERAGE CAN

Rigid Spine Reinforced Polymer Microelectrode Array Probe and Method of Fabrication

ActiveUS20100331935A1Increased buckling strengthReduce riskLine/current collector detailsInternal electrodesMicroelectrodeTitanium

A rigid spine-reinforced microelectrode array probe and fabrication method. The probe includes a flexible elongated probe body with conductive lines enclosed within a polymeric material. The conductive lines connect microelectrodes found near an insertion end of the probe to respective leads at a connector end of the probe. The probe also includes a rigid spine, such as made from titanium, fixedly attached to the probe body to structurally reinforce the probe body and enable the typically flexible probe body to penetrate and be inserted into tissue, such as neural tissue. By attaching or otherwise fabricating the rigid spine to connect to only an insertion section of the probe body, an integrally connected cable section of the probe body may remain flexible.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

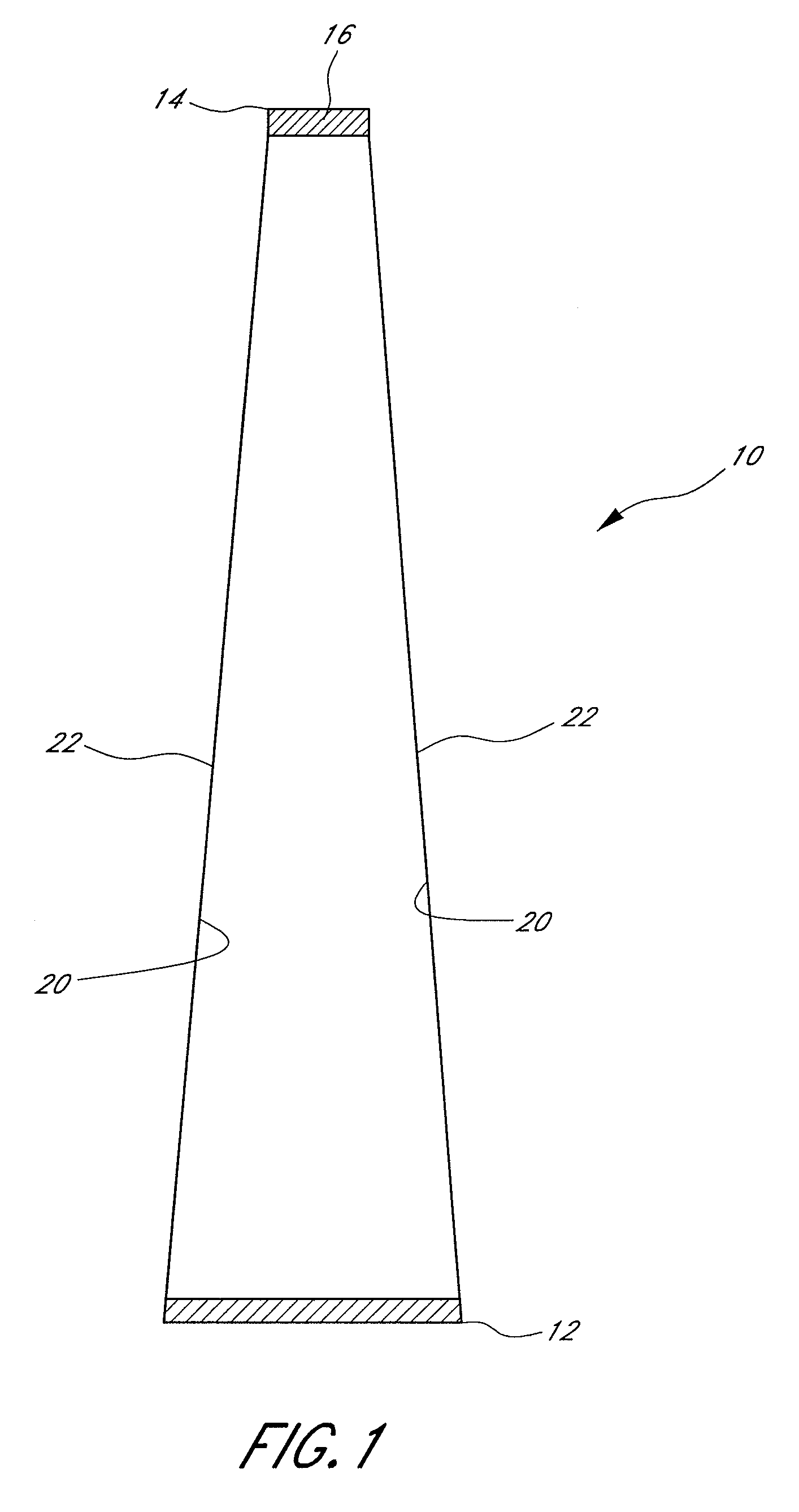

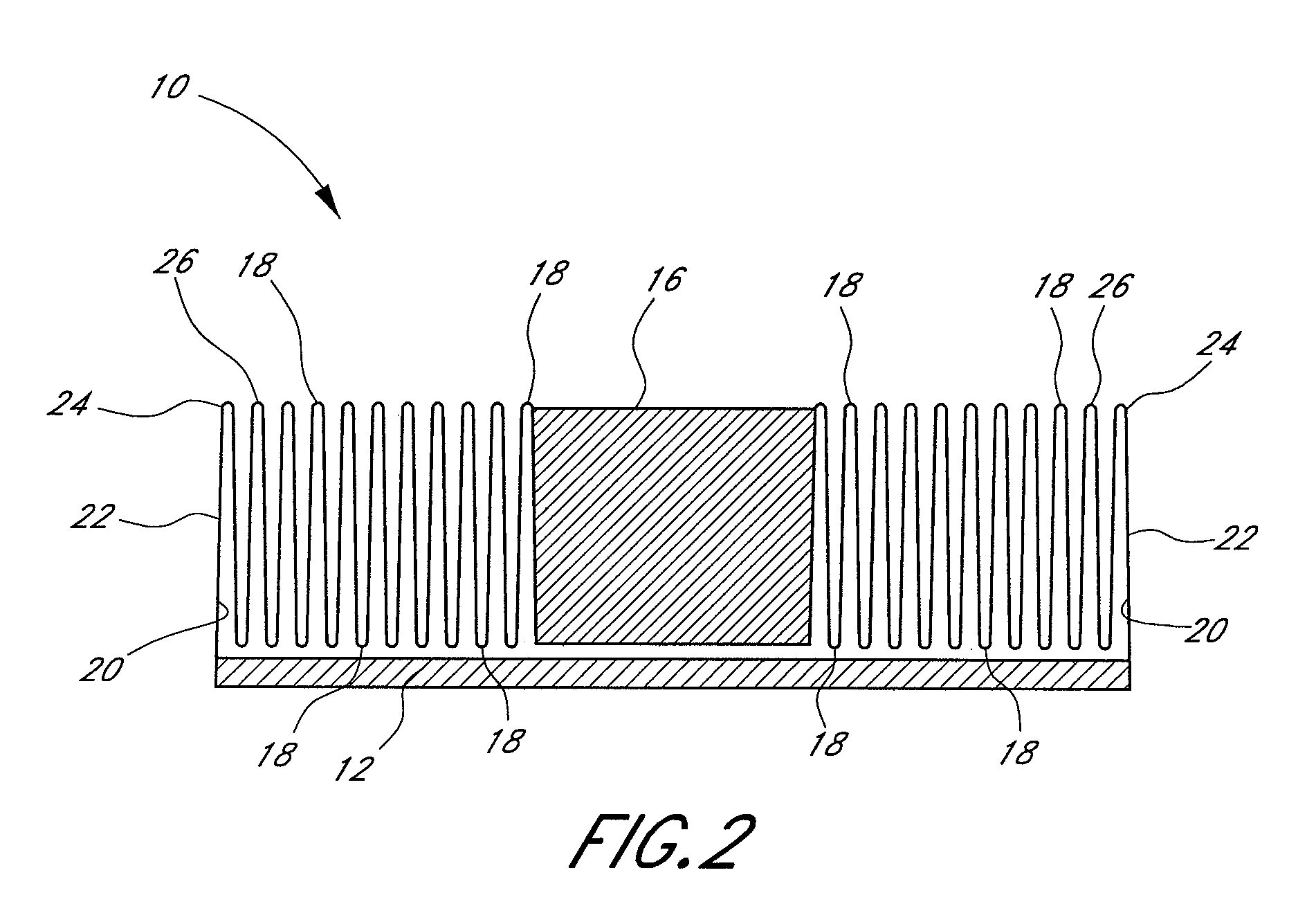

Deployable inflatable boom and methods for packaging and deploying a deployable inflatable boom

InactiveUS20040046085A1Good adhesionHigh bulk densityCosmonautic vehiclesInflatable space structuresEngineeringCantilever

Abstract of the Disclosure An inflatable boom for space applications, and a methods of folding and deploying a boom are disclosed. The boom comprises a membrane having a substantially tapered cylindrical shape. A wide end of the membrane is attached to a base, and a narrow end of the membrane is attached to a mandrel. The method of folding a boom comprises forming a plurality of ring-shaped folds in the boom membrane. The method of deploying a boom comprises increasing a gas pressure inside the boom and repeatedly unfolding the outer-most ring fold to increase the length of the boom.

Owner:LGARDE

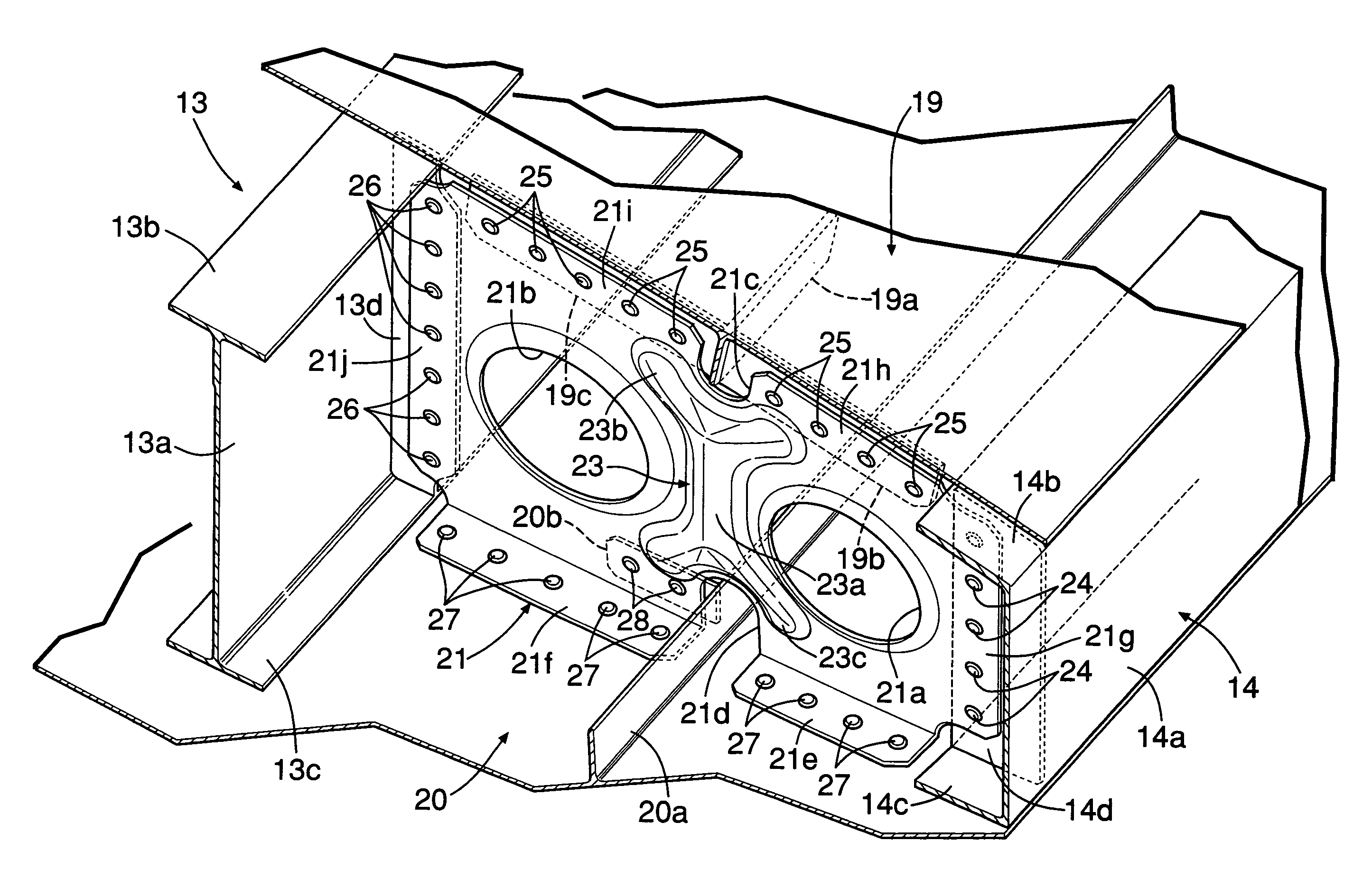

Wing structure for aircraft

ActiveUS7740202B2Increased buckling strengthAvoid deformationFuselage framesAircraft stabilisationArcuate shapeAirplane

In a wing structure for an aircraft, a rib extends in a chord direction for connecting spars to each other with upper and lower stringer through holes through which stringers of skins pass being formed in upper and lower edges of the rib. A bead is formed on the rib so as to extend between the upper and lower stringer through holes. Upper and lower ends of the bead are formed into arcuate shapes so as to surround the upper and lower stringer through holes, respectively. Thus, it is possible to enhance the buckling strength of the rib against a shear load acting on the wing of the aircraft.

Owner:AMERICAN HONDA MOTOR COMPANY

Can shell and double-seamed can end

InactiveUS8313004B2Reduce the overall diameterRaise the ratioRigid containersHollow articlesAluminum canEngineering

A drawn aluminum can shell has a peripheral crown which is double-seamed with an end portion of an aluminum can body to provide a can end having a generally flat center panel connected by an inclined curved or straight panel wall to an inclined inner wall of an annular U-shaped countersink. The countersink has an outer wall which connects with an inclined lower wall portion of a chuckwall at a junction below the center panel, and the chuckwall has a curved or inclined upper wall portion which connects with an inner wall of the crown. The chuckwall also has an intermediate wall portion forming a break, and the inner bottom width of the countersink is less than the radial width of the panel wall. The inclined upper wall portion of the chuckwall extends at an angle greater than the angle of the inclined lower wall portion of the chuckwall.

Owner:BALL CORP +1

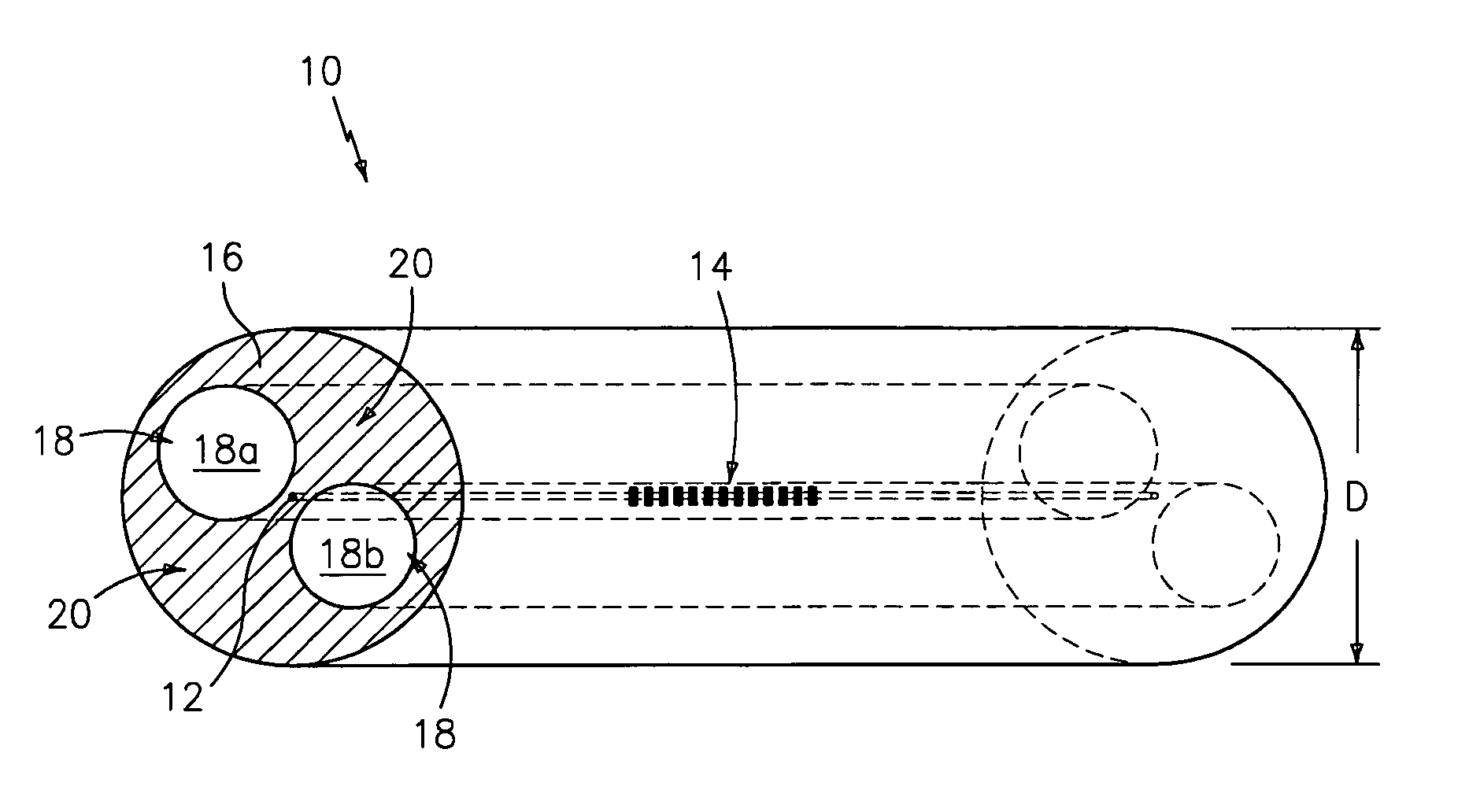

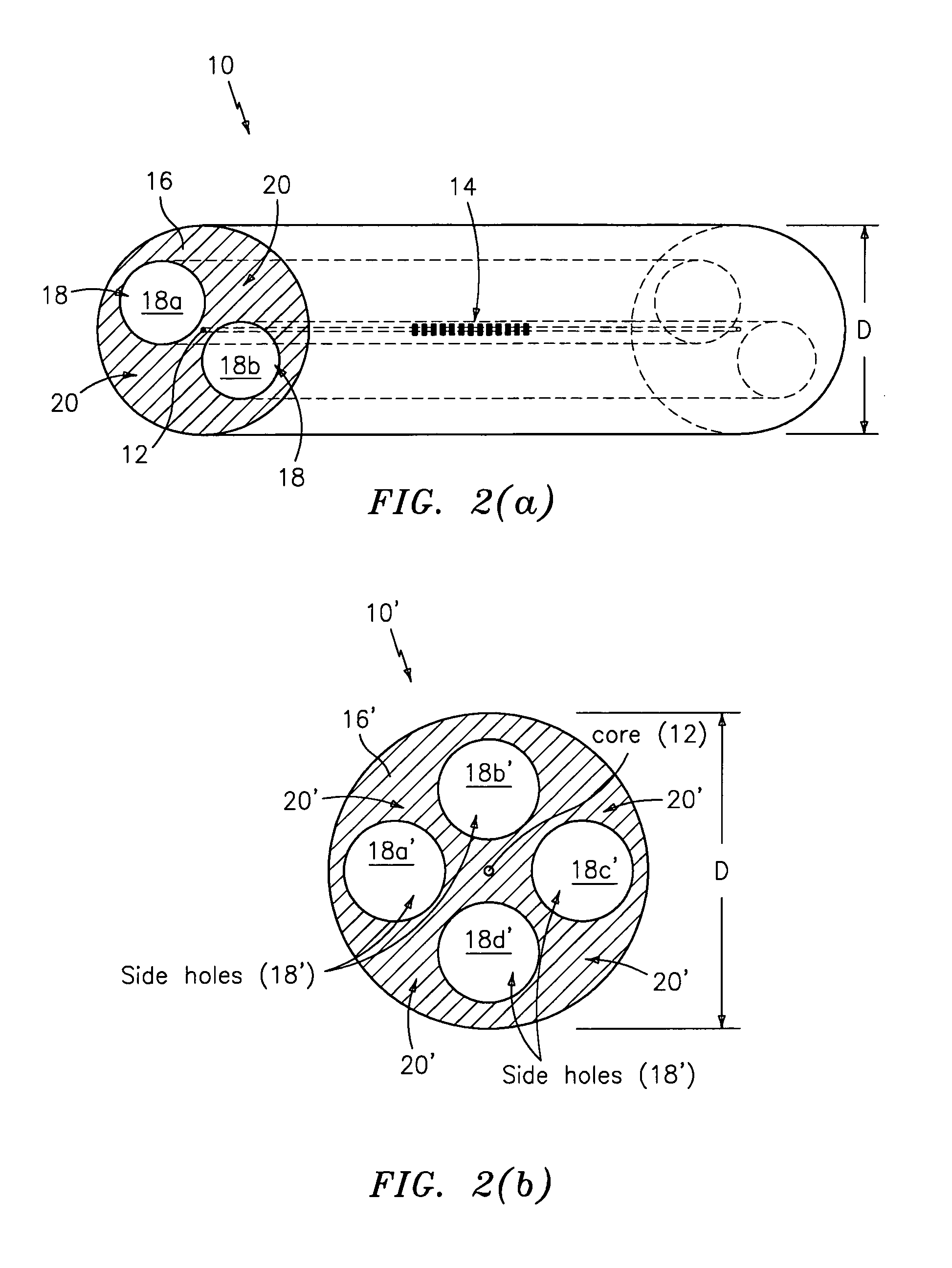

Tunable optical filter having large diameter optical waveguide with bragg grating and being configured for reducing the bulk modulus of compressibility thereof

InactiveUS7062126B2Reducing bulk modulusMaintaining anti-buckling strengthGlass making apparatusOptical fibre with polarisationGratingFiber Bragg grating

A tunable optical filter has a large diameter cane waveguide with “side-holes” in the cane cross-section that reduce the force required to compress the large diameter optical waveguide without overly compromising the buckling strength thereof. The large diameter optical waveguide has a cross-section of at least about 0.3 millimeters, including at least one inner core, a Bragg grating arranged therein, a cladding surrounding the inner core, and a structural configuration for providing a reduced bulk modulus of compressibility and maintaining the anti-buckling strength of the large diameter optical waveguide. The structural configuration reduces the cross-sectional area of the large diameter optical waveguide. These side holes reduce the amount of glass that needs to be compressed, but retains the large diameter.

Owner:II VI DELAWARE INC

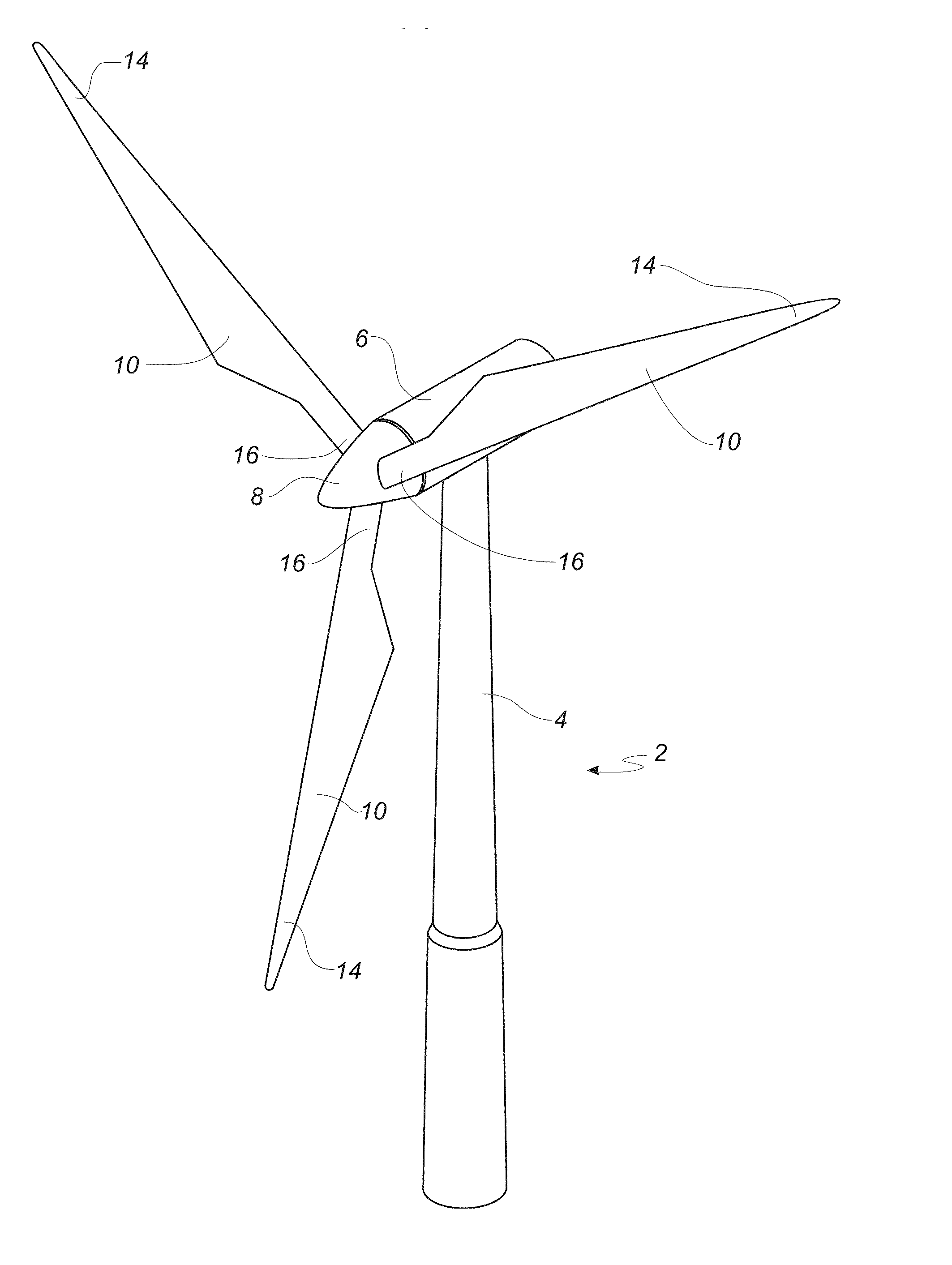

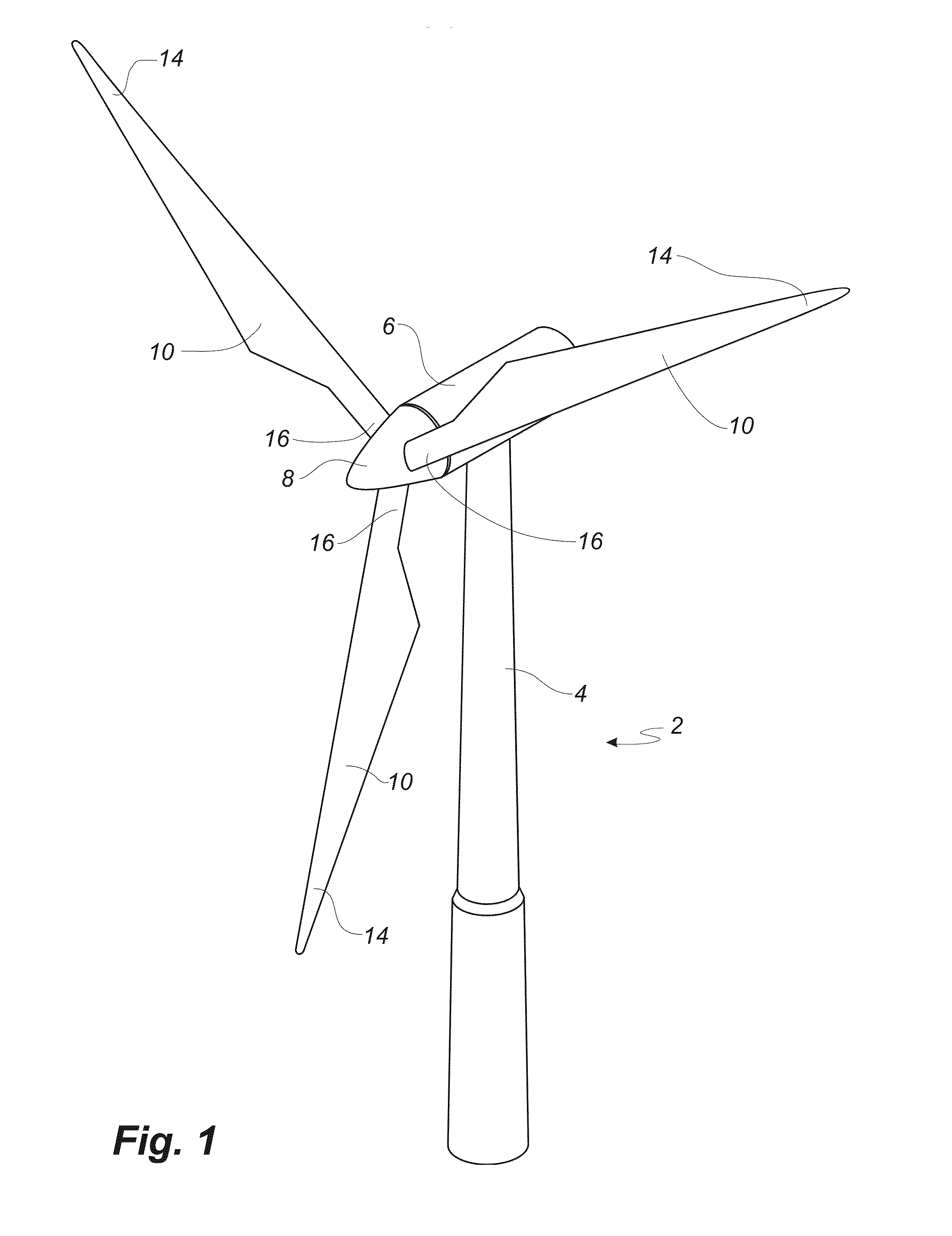

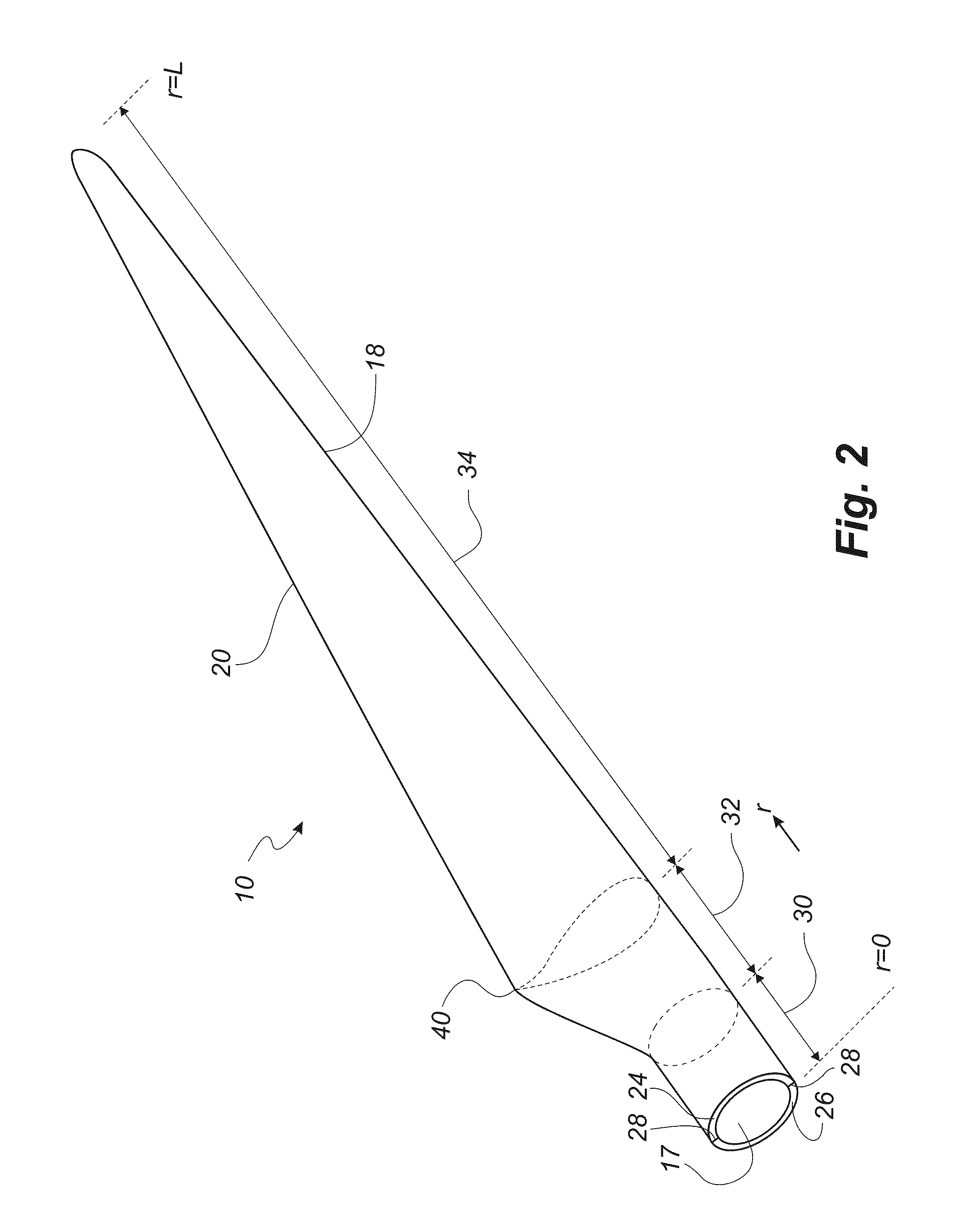

Wind turbine blade having a bond line adjacent a sandwich panel of the blade

ActiveUS20160168997A1Less adhesiveIncreased buckling strengthFinal product manufactureEngine fuctionsTurbine bladeTrailing edge

A wind turbine blade and an associated method of manufacture is described, wherein a structural bond line of the blade is positioned to be adjacent to a sandwich panel construction of the blade. By locating the structural bond line nest to a sandwich region of the blade, the buckling strength of the joint is improved and the risk of crack initiation in the adhesive joint is reduced considerably. This allows for a reduction in the amount of structural adhesive used in the blade, and / or a reduction in the amount of core material which is required in the sandwich panel to maintain the required blade stiffness. A particular advantage is provided in the region of the trailing edge of the blade, wherein the relocated structural joint considerably reduces the risk of buckling in the trailing edge side of the blade.

Owner:LM WP PATENT HLDG

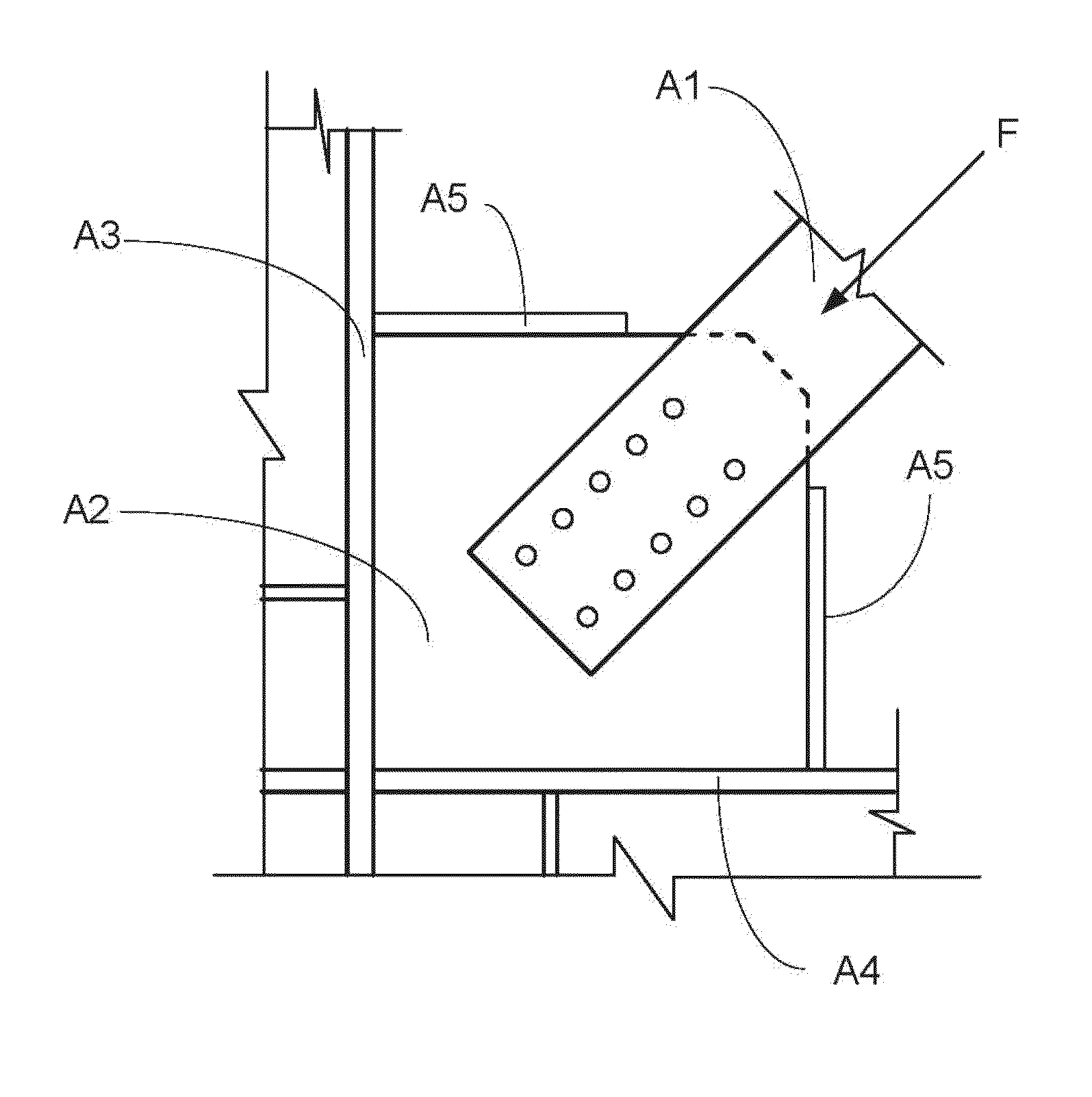

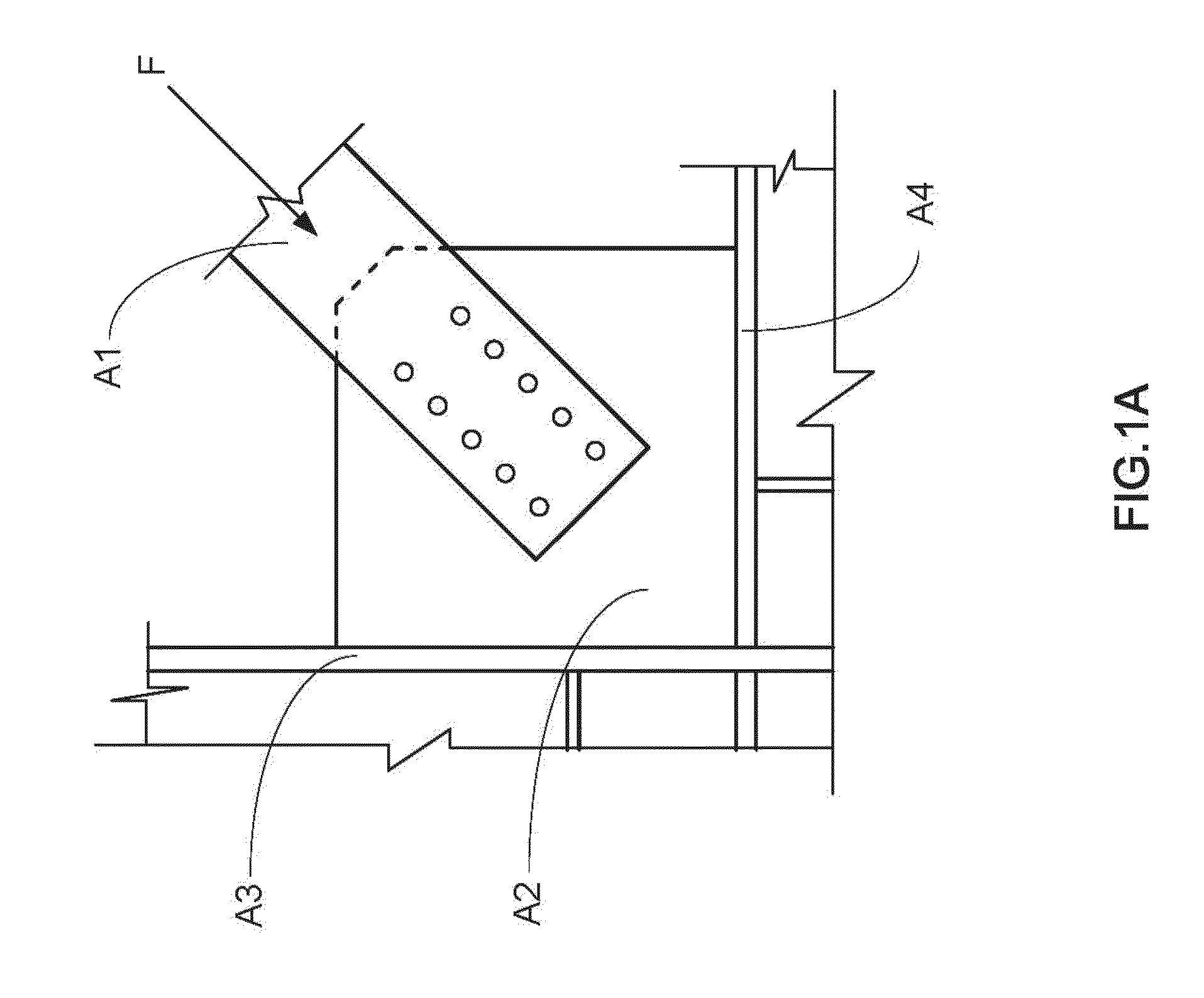

Laterally restrained joint structure

InactiveUS8505260B1Increased buckling strengthBuilding roofsProtective buildings/sheltersGusset plateEngineering

A laterally restrained joint structure including a structural member, a gusset plate and at least one restraining member is disclosed. The gusset plate is connected to the structural member, and a two-force member is disposed opposite to the structural member and connected to the gusset plate. The restraining member is disposed over side or at edges of the gusset plate and connected to the structure member, so that the lateral deformation of the gusset plate can be controlled and the buckling strength of the gusset plate can be enhanced by the restraining member, and the laterally restrained joint structure is capable of reinforcing a building.

Owner:NAT TAIWAN UNIV OF SCI & TECH

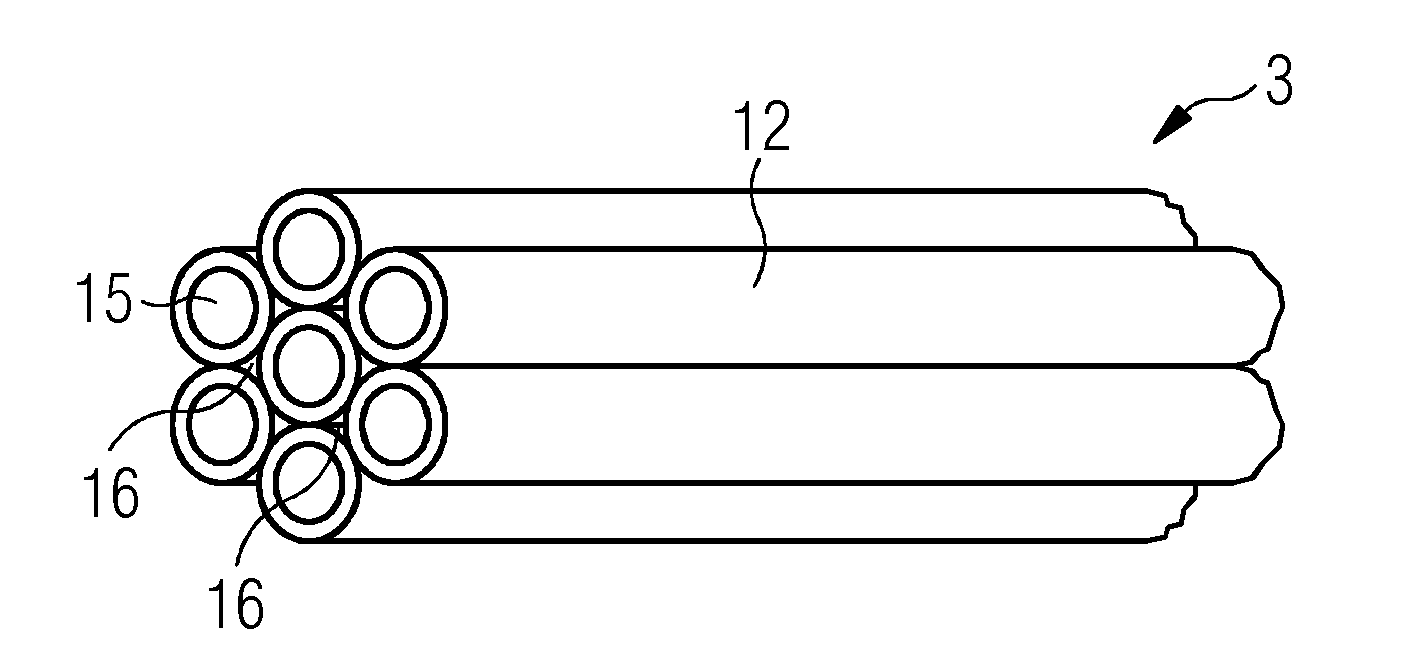

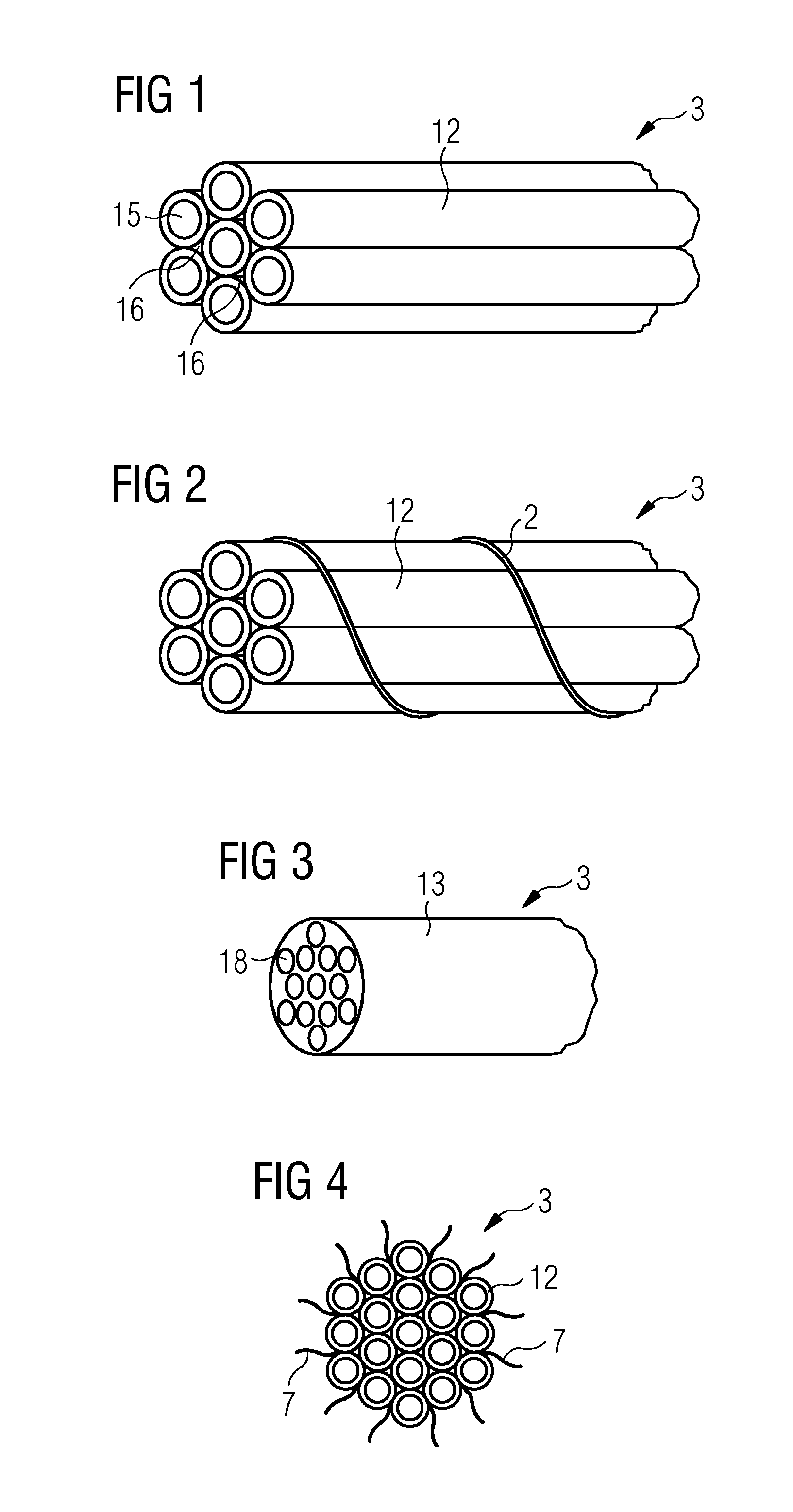

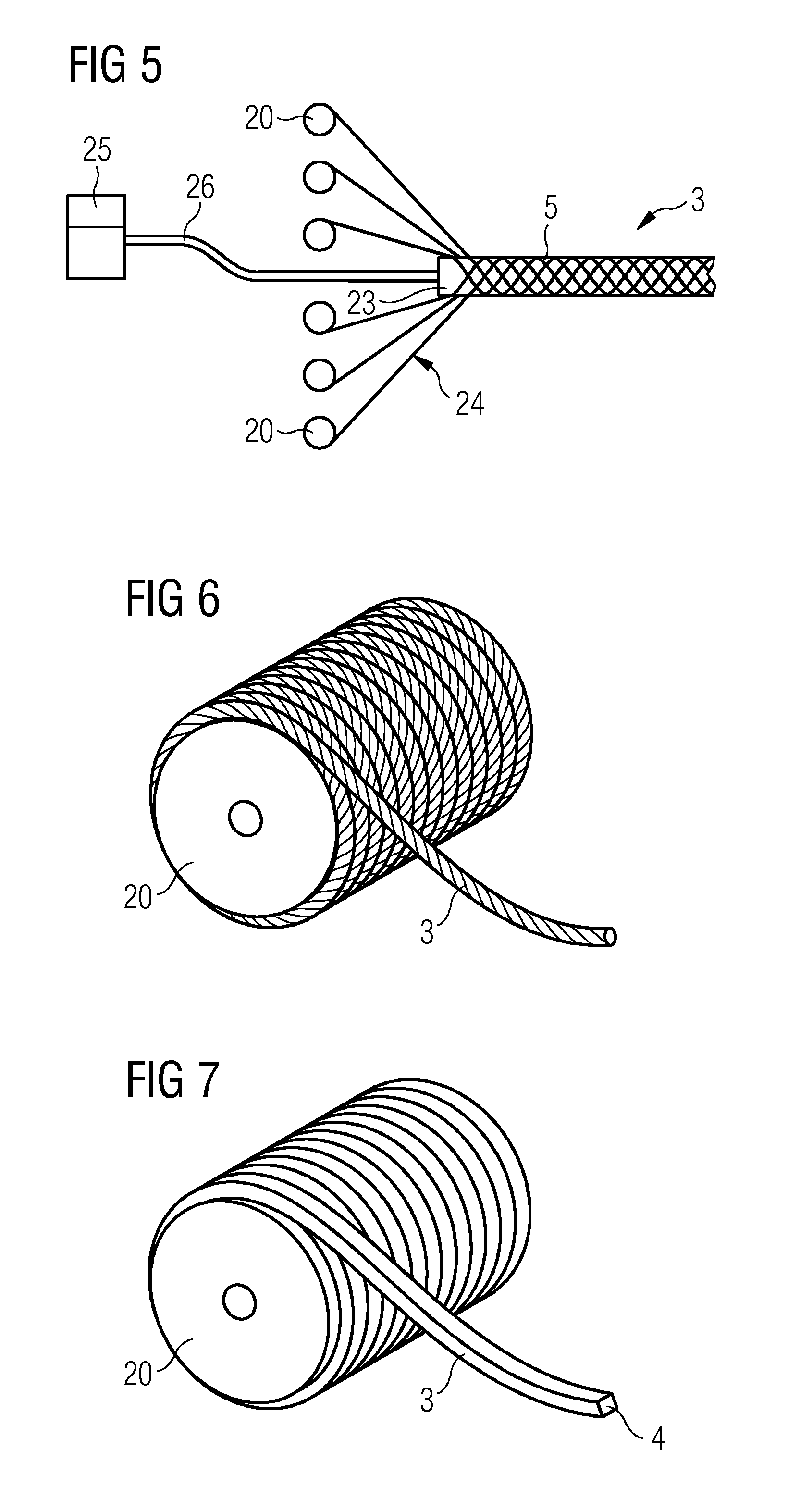

Sandwich core material

InactiveUS20130171381A1Reduce weightSpacePropellersFinal product manufactureTurbine bladeMechanical engineering

A sandwich core material for a sandwich laminate is disclosed. The sandwich core material includes a number of flexible core material elements having a longitudinal structure. A flexible core material for a sandwich core material, a sandwich laminate and a wind turbine blade including such a sandwich core material are provided. In addition, the present a method of manufacturing such a sandwich core material is provided.

Owner:SIEMENS AG

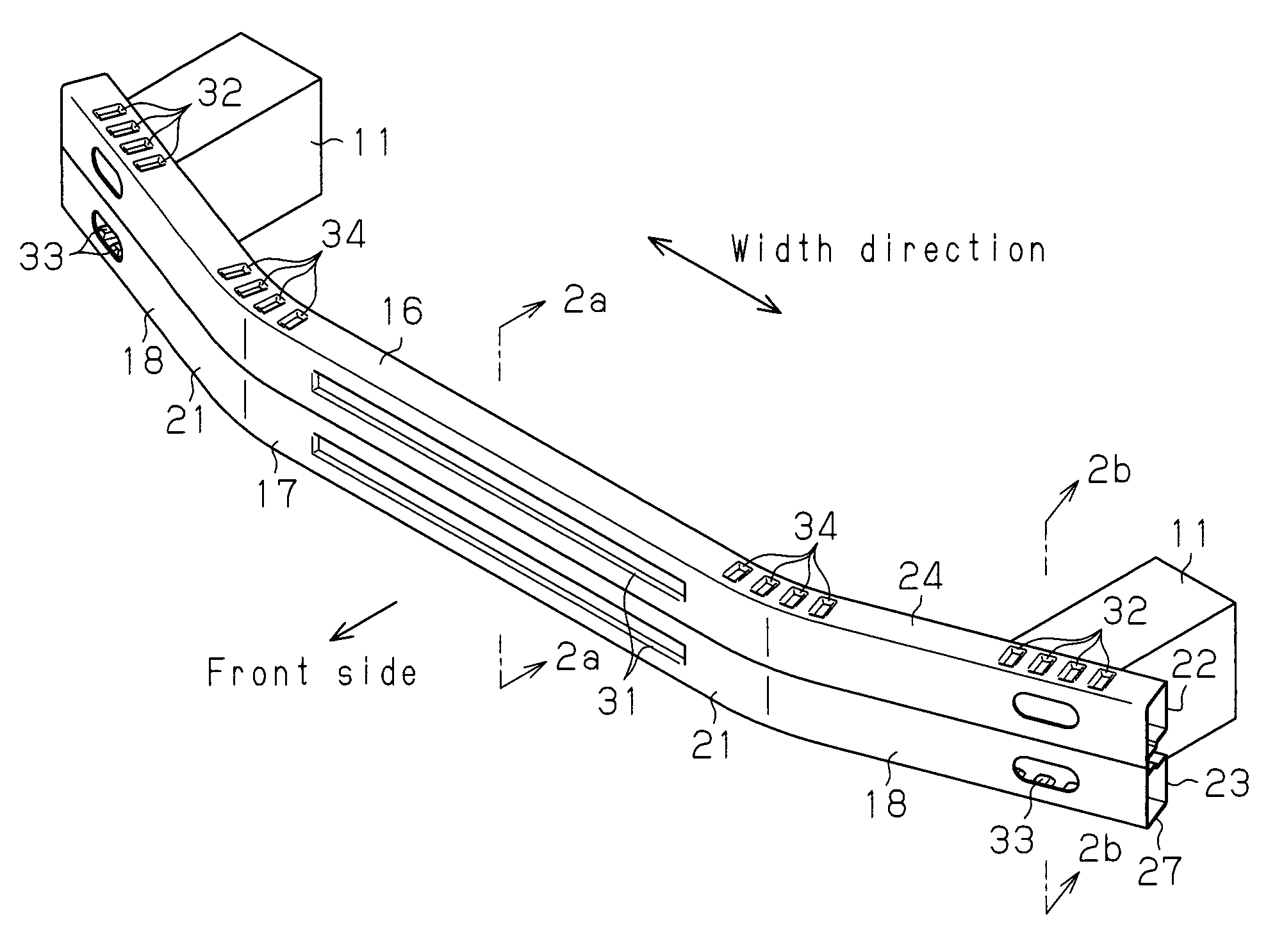

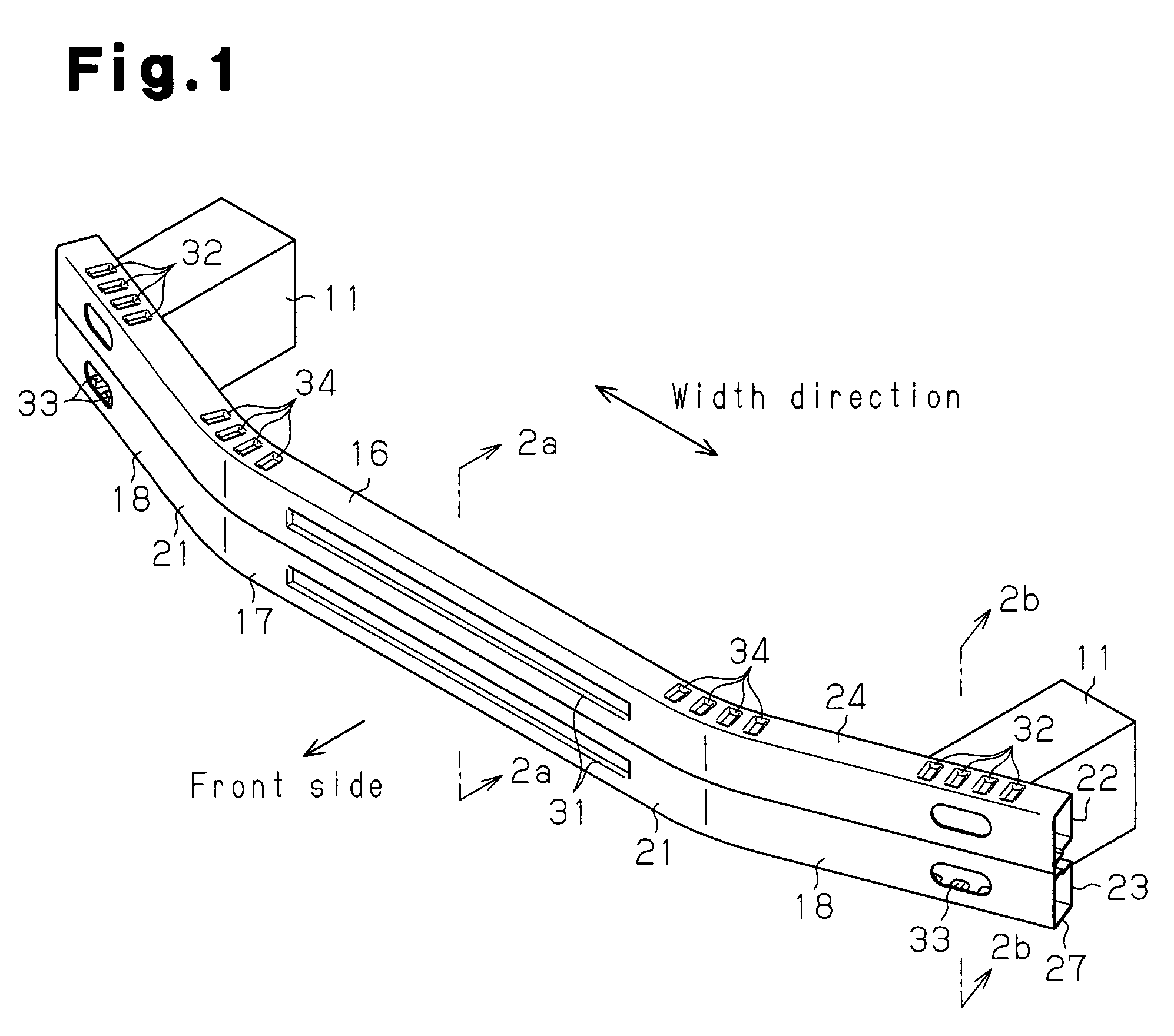

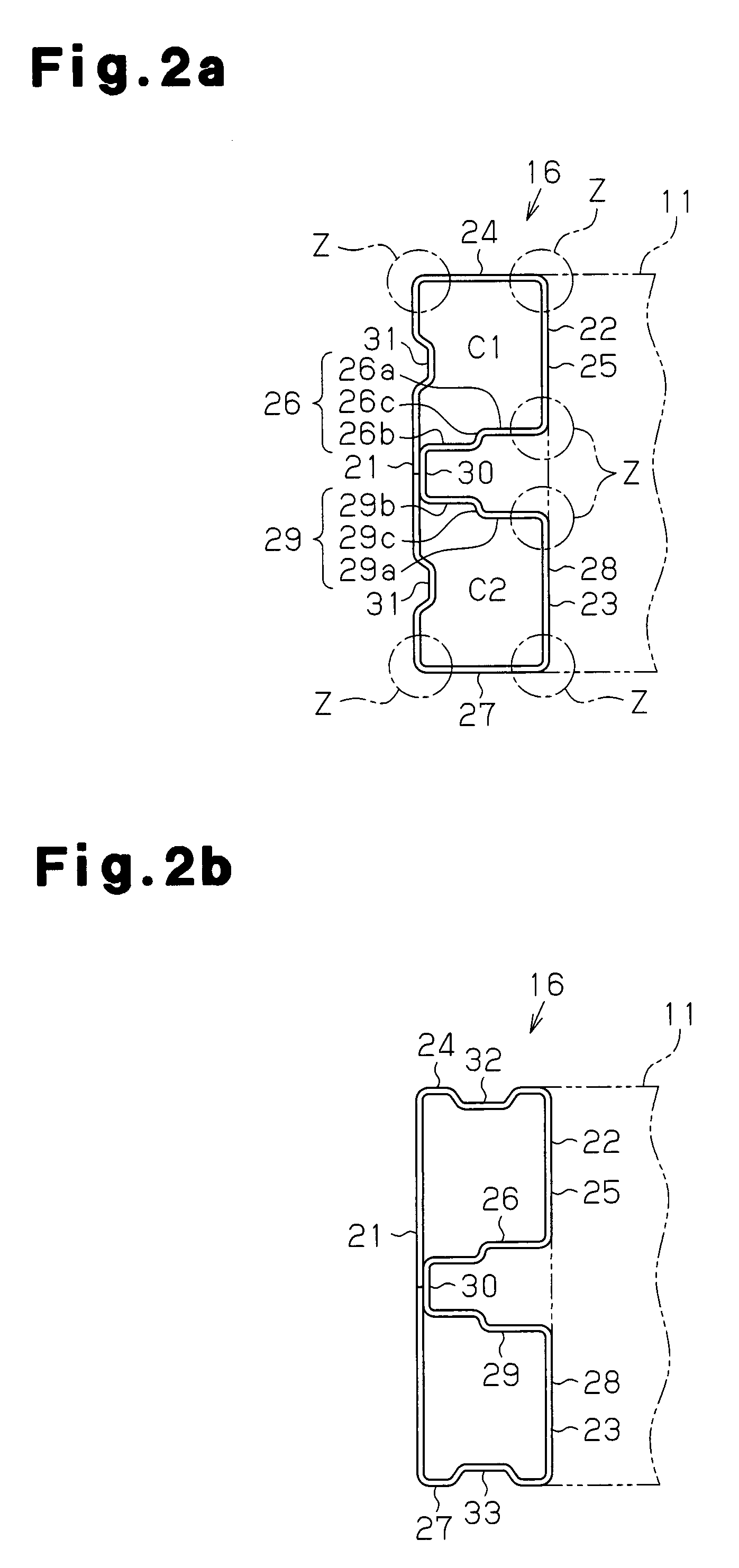

Vehicle bumper device

InactiveUS8746761B2Improve bending strengthQuality improvementBumpersStructural engineeringLower half

Owner:AISIN SEIKI KK +1

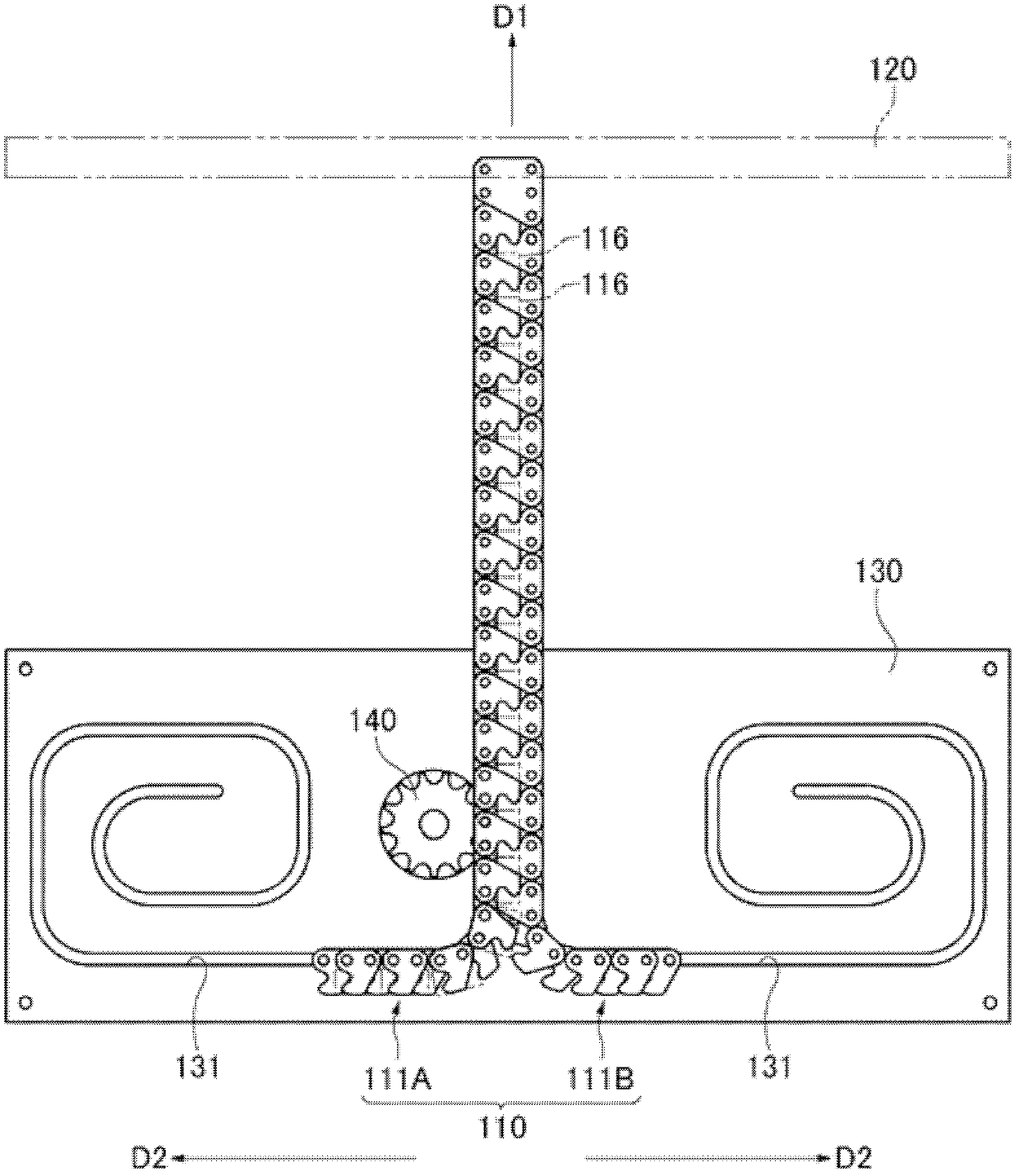

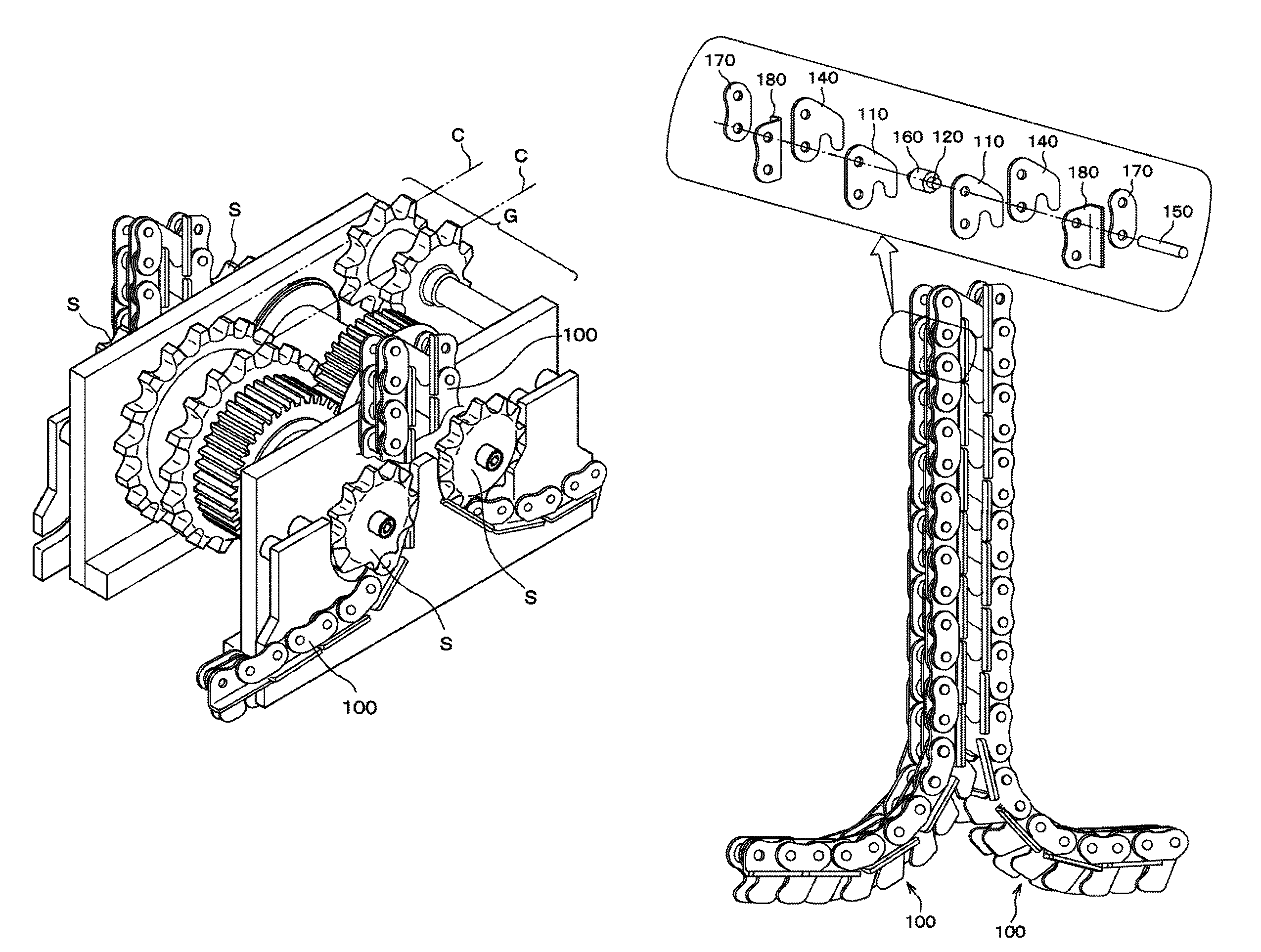

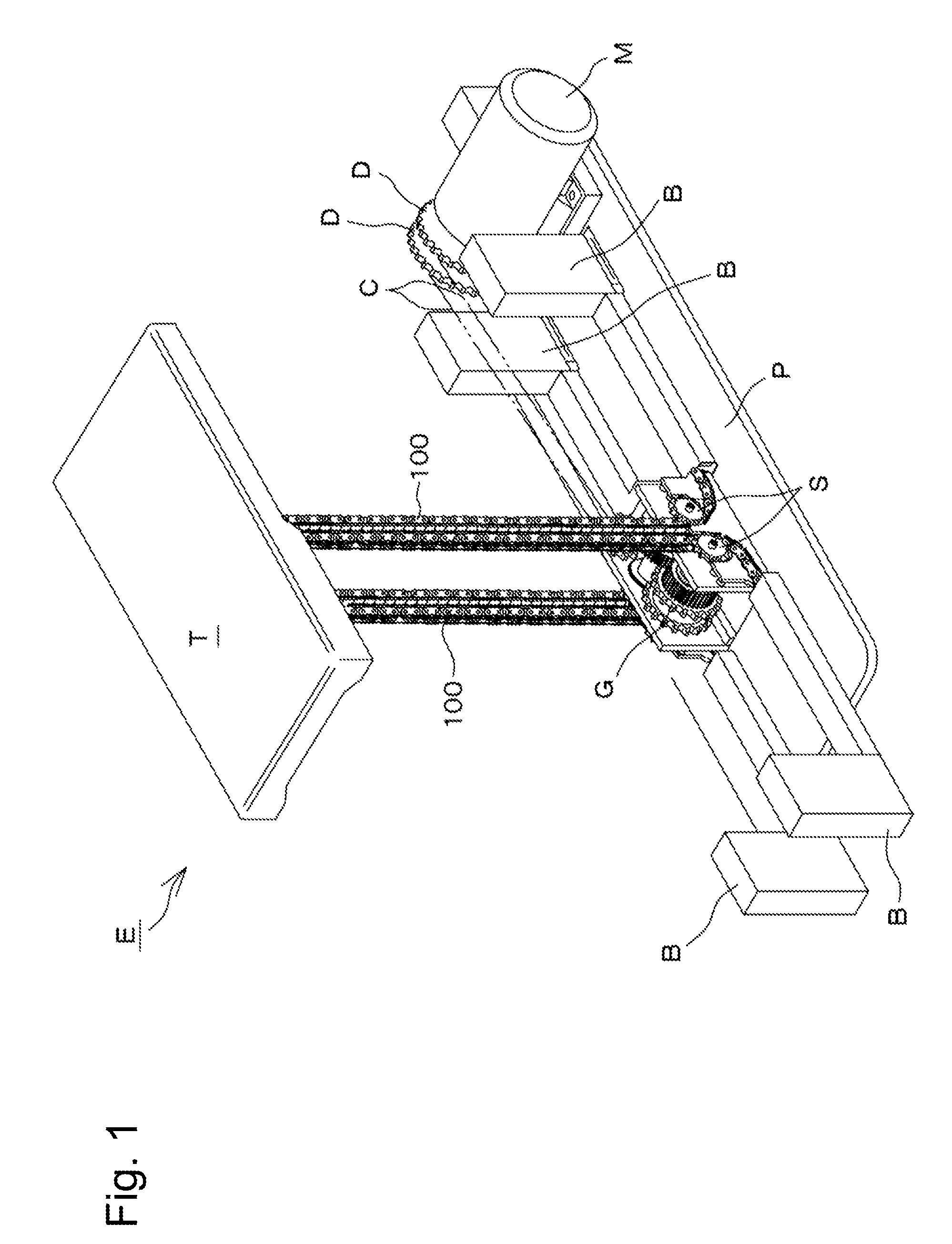

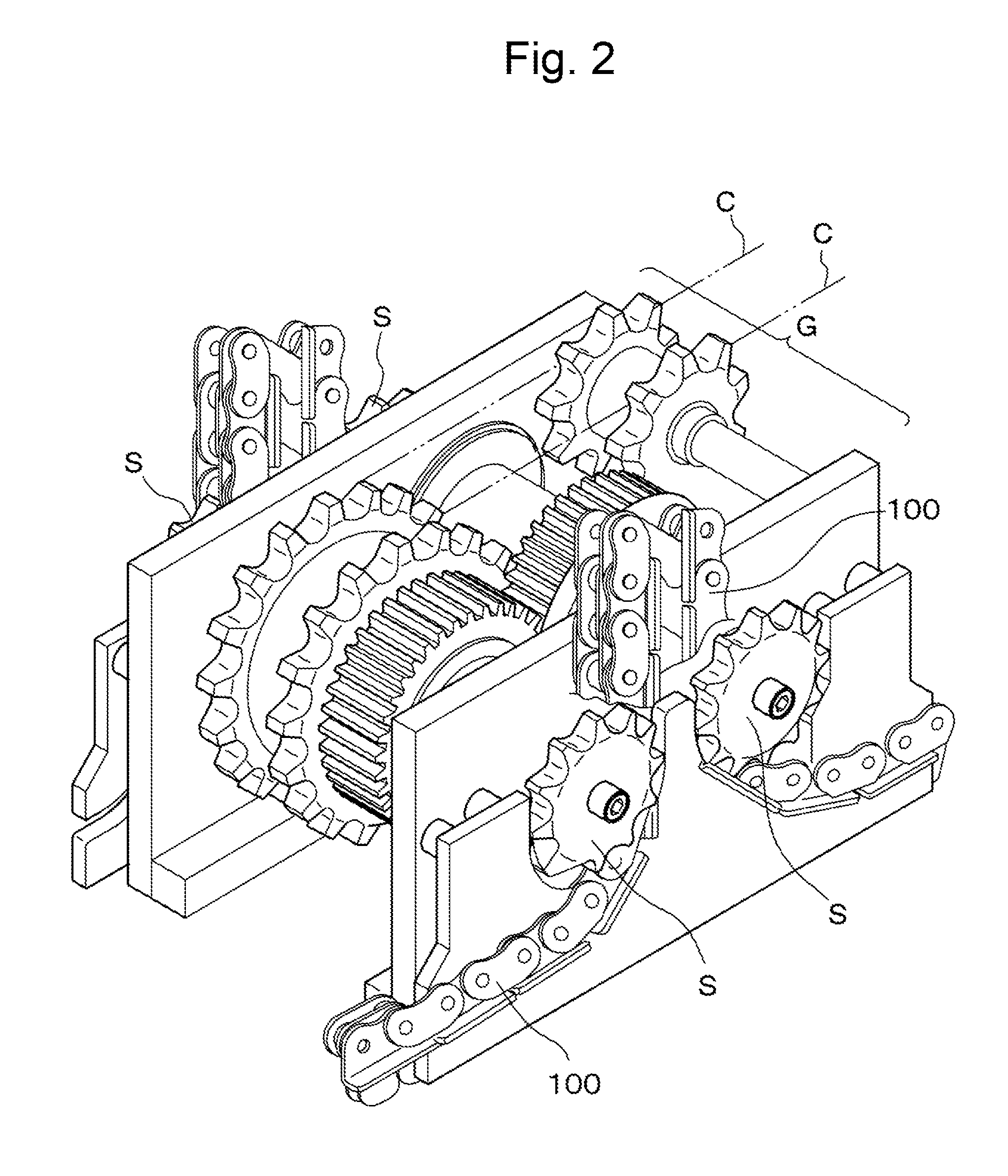

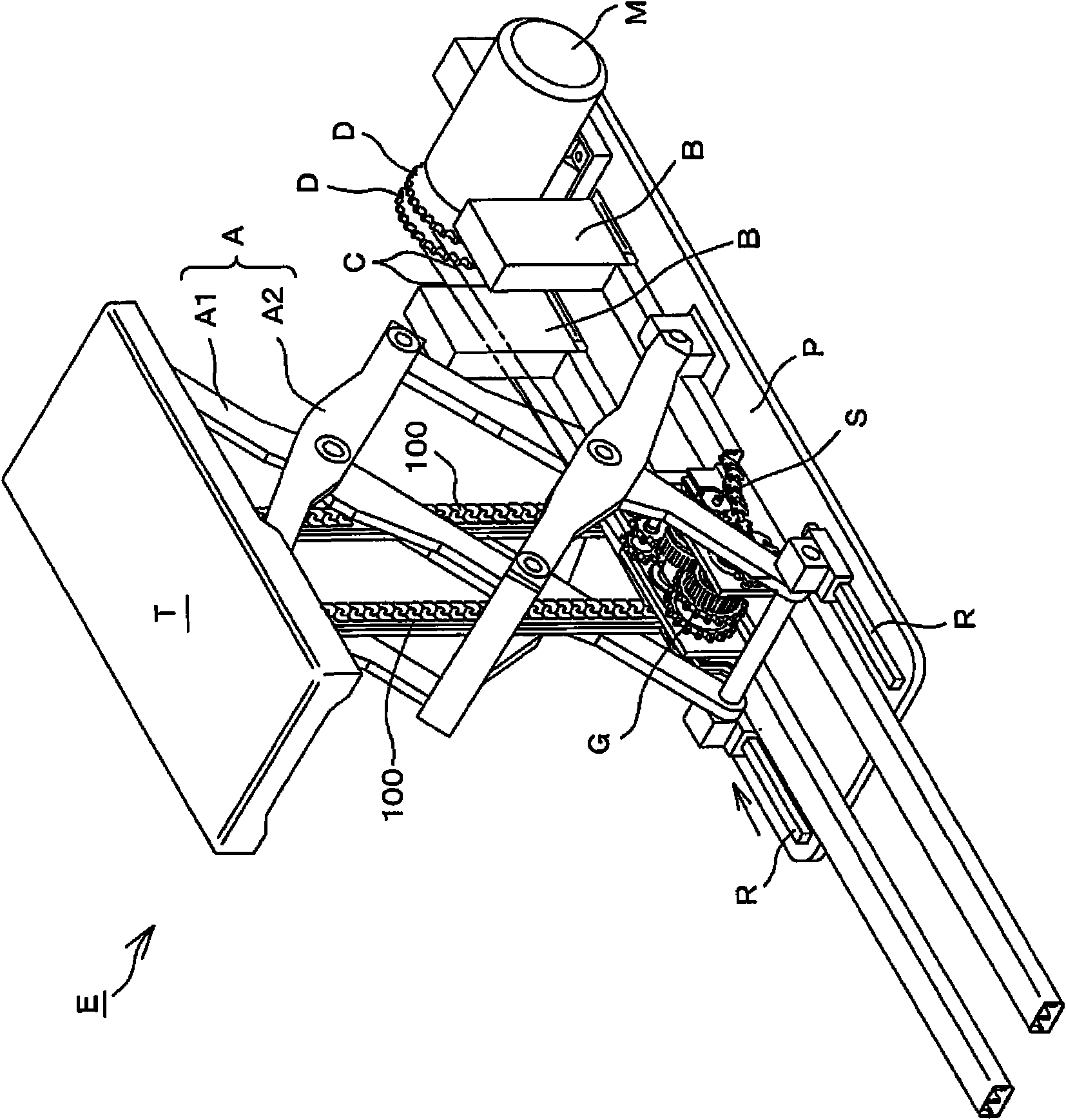

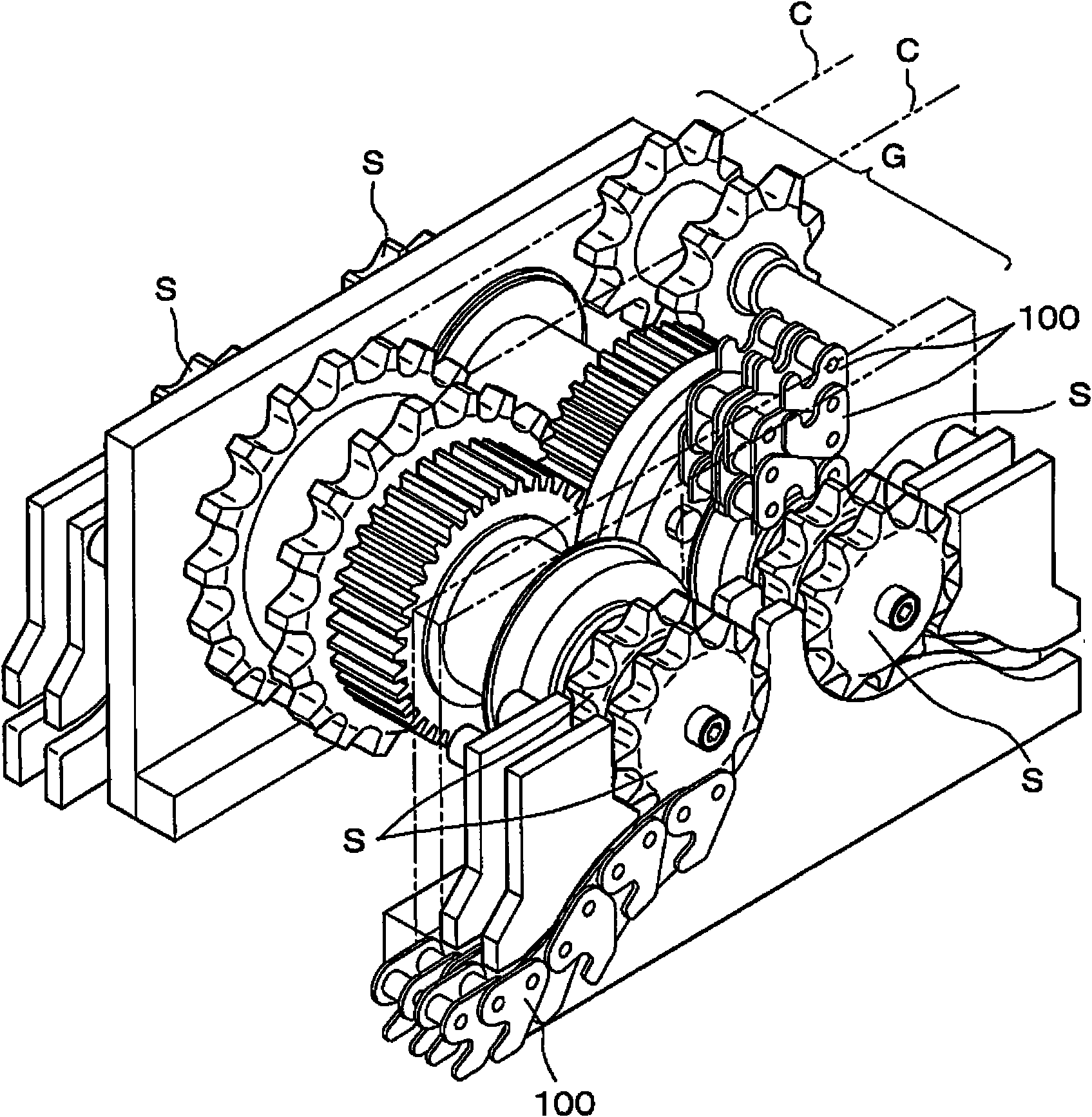

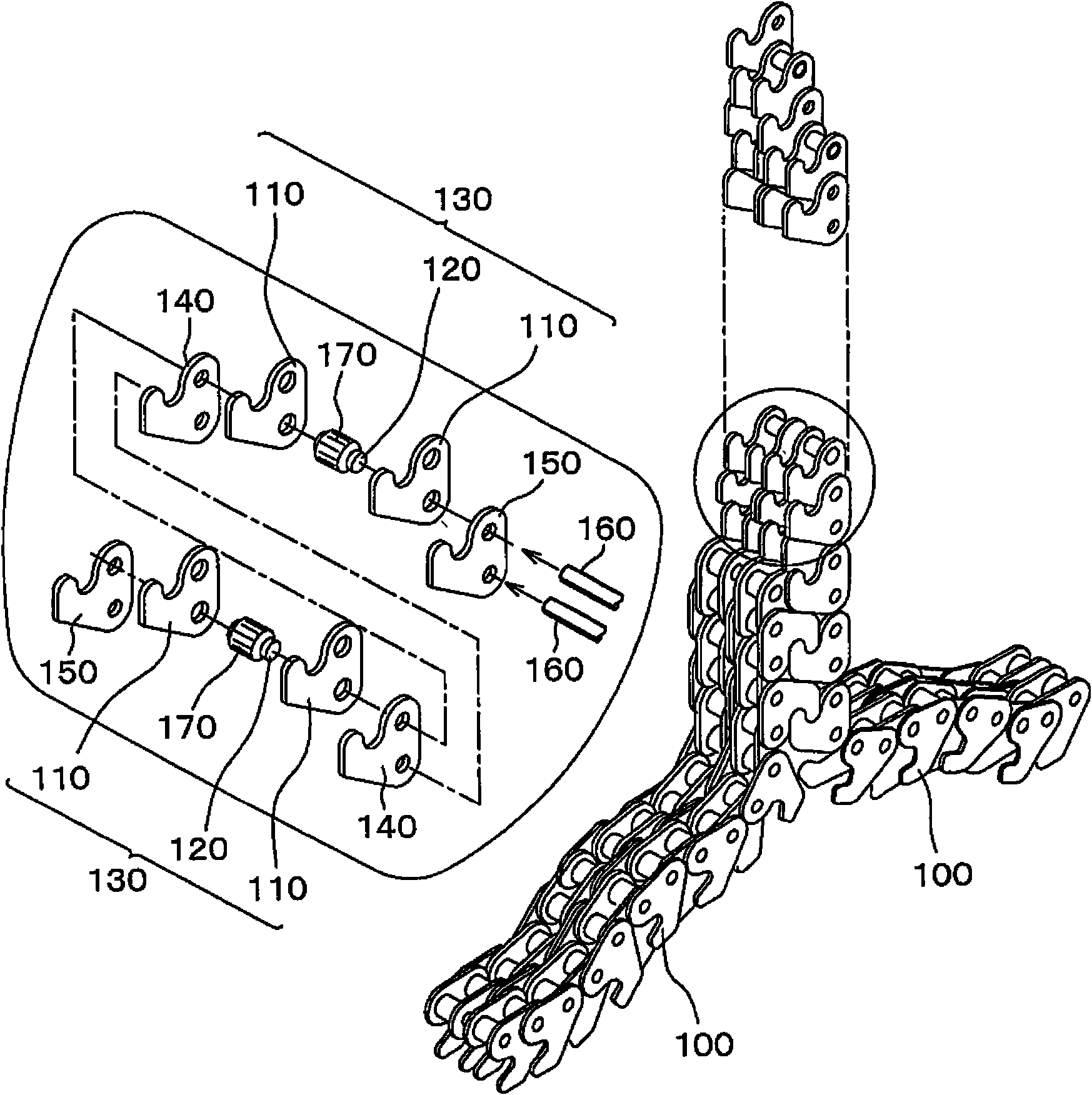

Lifting engagement chain unit

InactiveCN102588512AIncrease the cross-sectional areaAvoid mutual contactLifting framesChain elementsUltimate tensile strengthMechanical engineering

Owner:TSUBAKIMOTO CHAIN CO

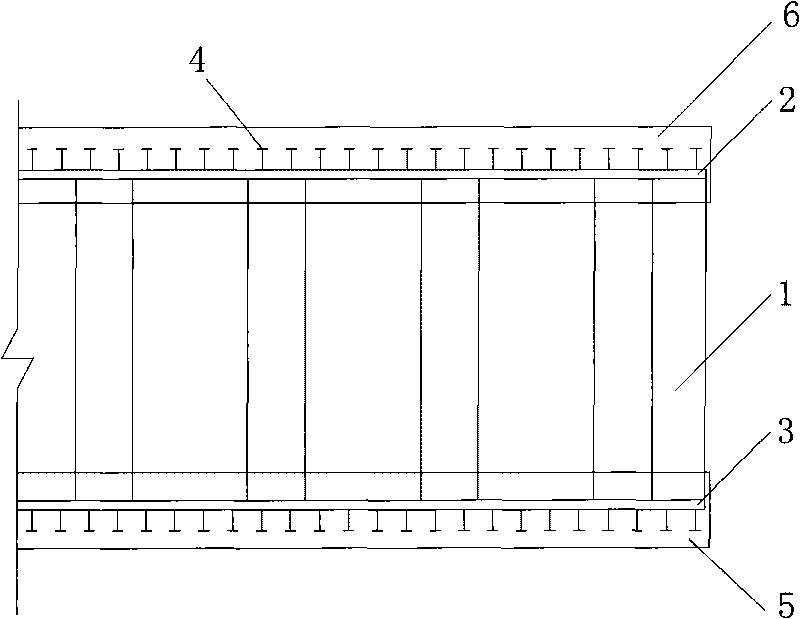

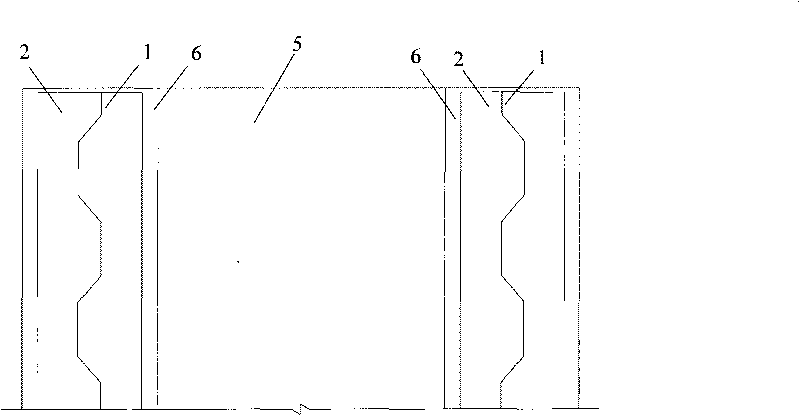

Corrugated steel web pre-flex assembled groove shape beam and manufacturing method thereof

InactiveCN101691737AEasy to manufactureIncreased complexityBridge erection/assemblyBridge materialsStress conditionsSheet steel

The invention discloses a corrugated steel web pre-flex assembled groove shape beam and a manufacturing method thereof. The assembled groove shape beam comprises a corrugated steel webs (1) located at two sides of the assembled groove shape beam, primary concrete bad plate (5) cast at the periphery of a lower flange steel plate (3), and a secondary concrete cast at the periphery of an upper flange steel plate (2) or connected with the upper flange steel plate (2) by a shear connecting piece (4), the upper parts of the corrugated steel webs (1) are connected with the upper flange steel plate (2), the lower parts of the corrugated steel webs (1) are connected with the lower flange steel plate (3), and the formed cross section is a groove shape structural beam. The assembled groove shape beam solves the problems of the complex stress condition of plate-beam joint position of common prestress concrete groove shape beam, the easy cracking of concrete, the complex structure of reinforcing bars of the plate-beam joint position and high construction difficulty, high requirements for construction technology and condition, the large occupied area of on-site casting construction, the long construction period, etc.

Owner:SOUTHEAST UNIV

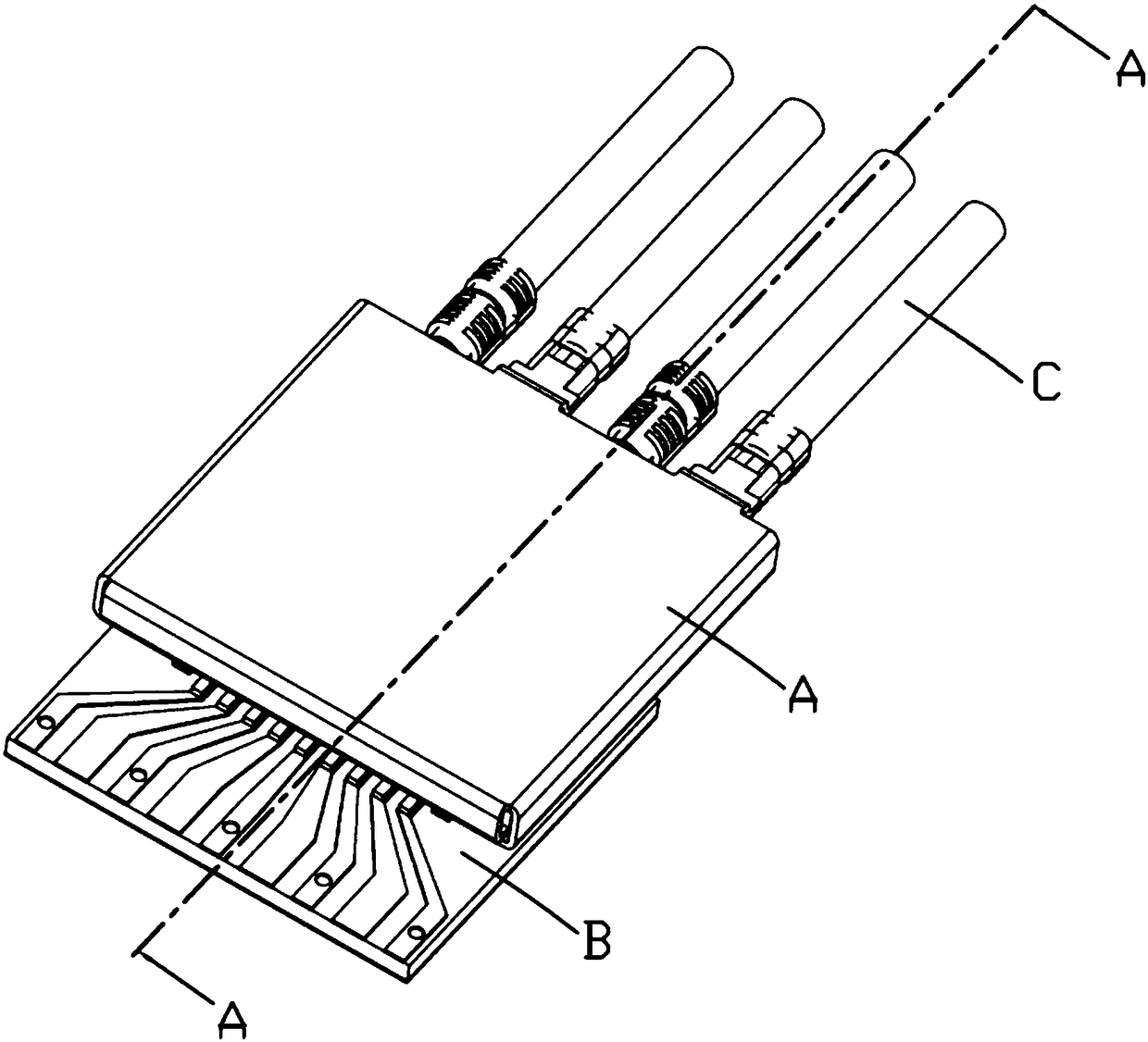

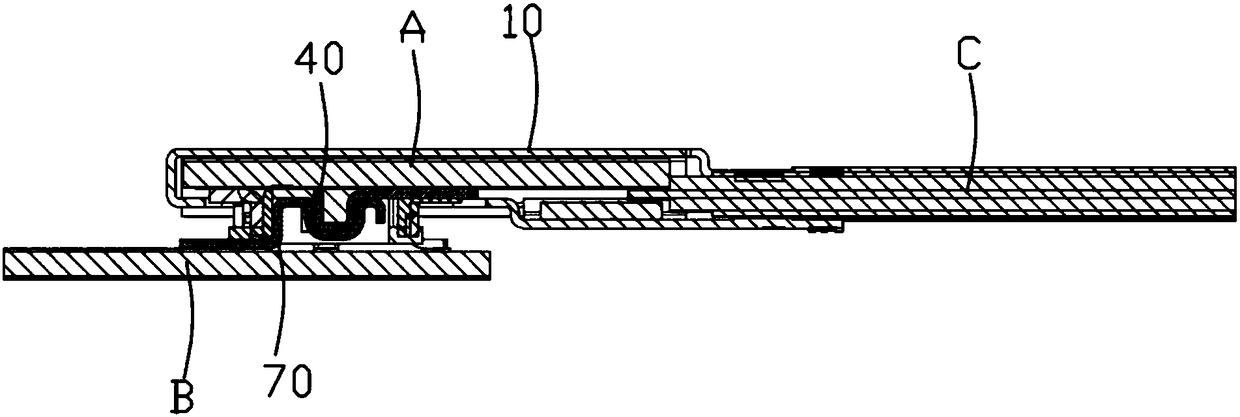

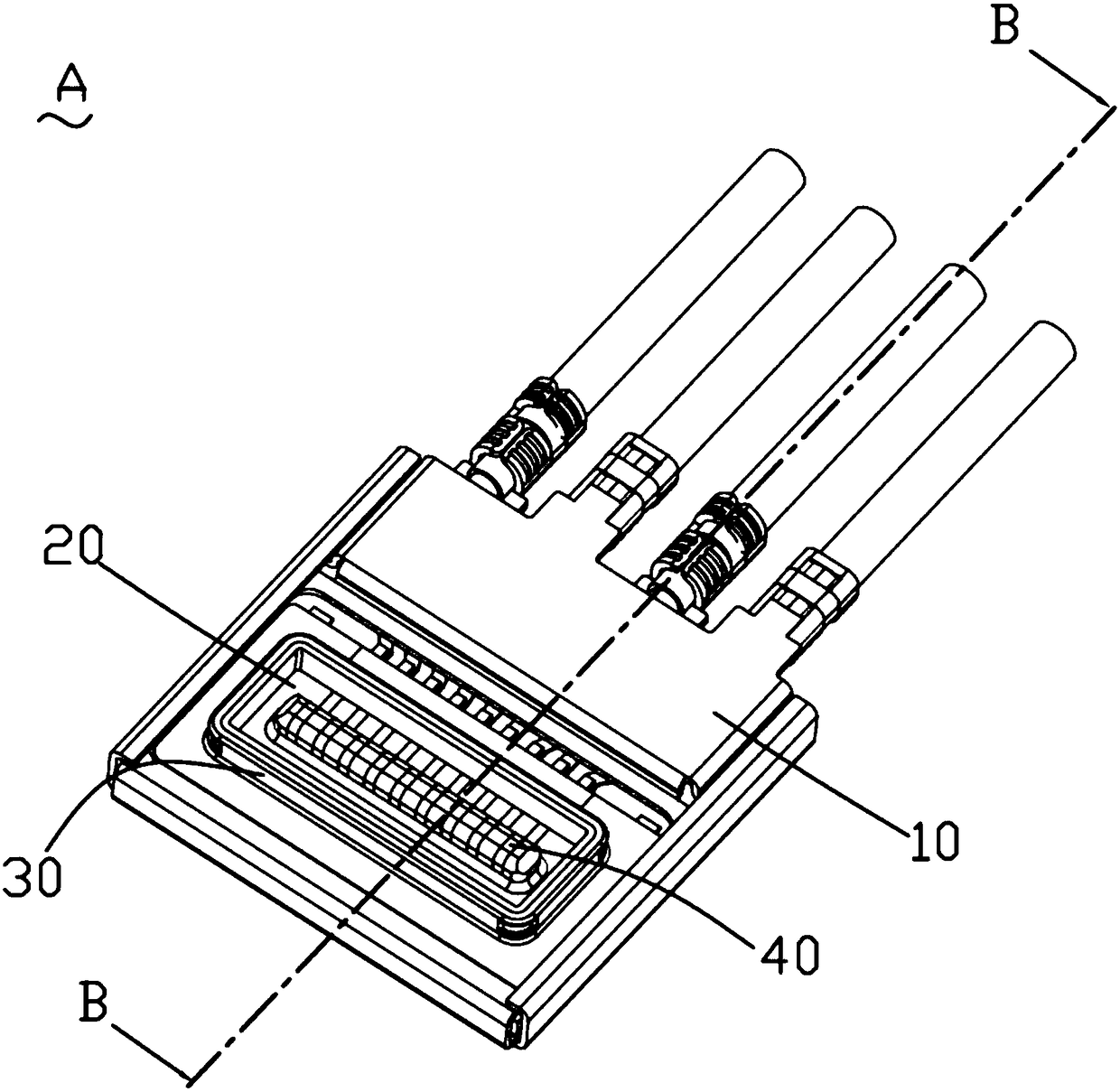

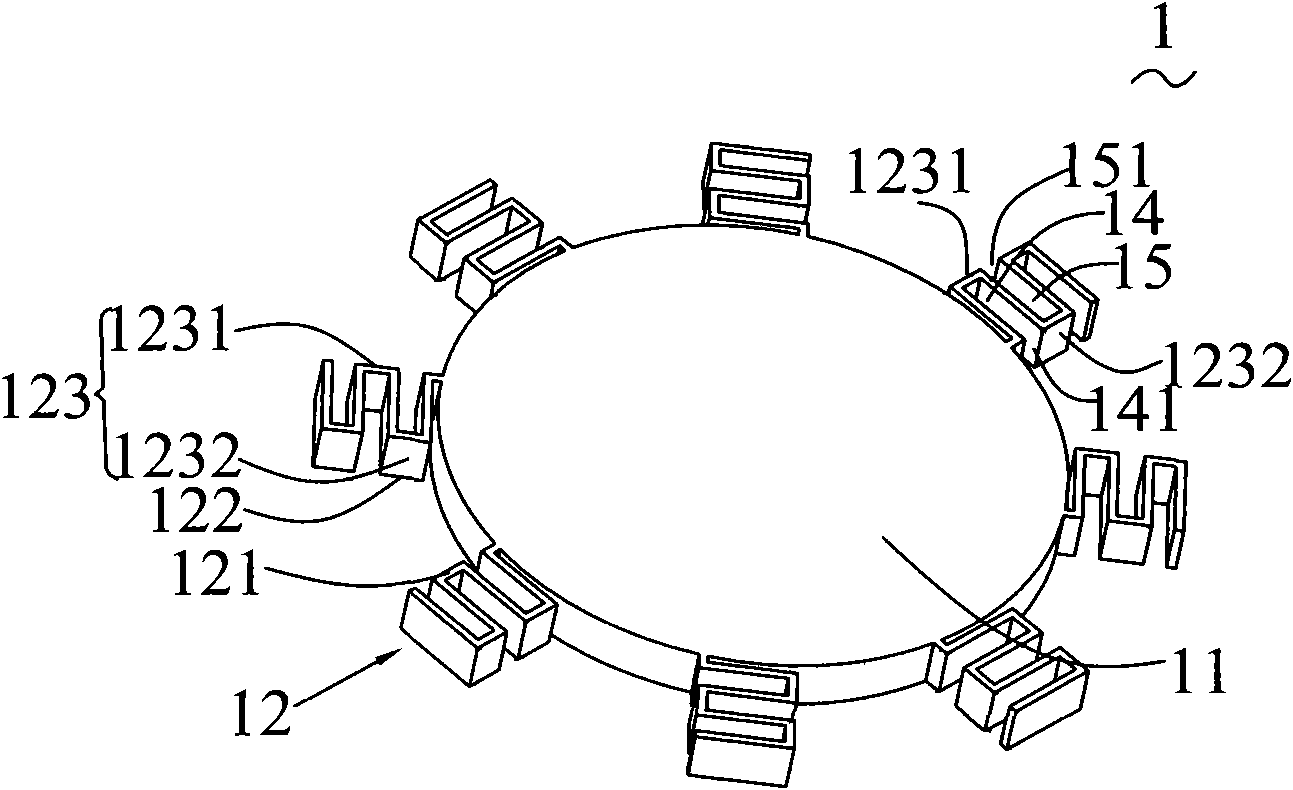

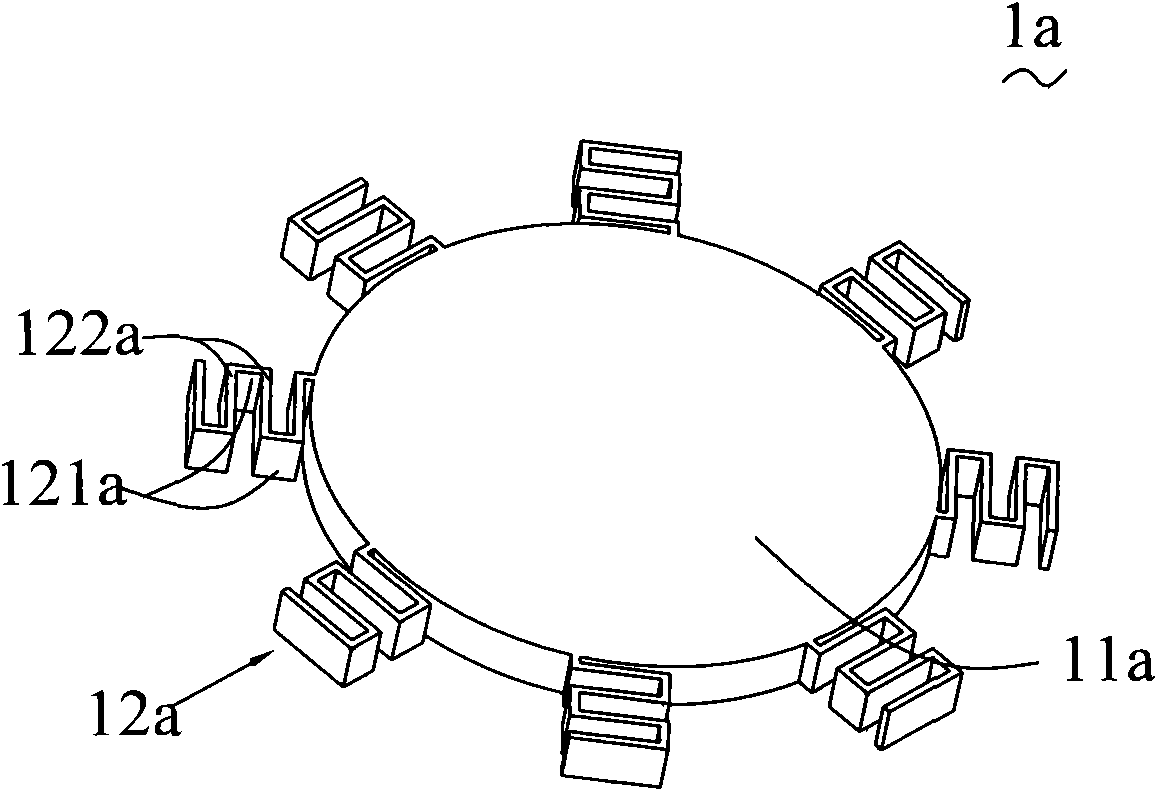

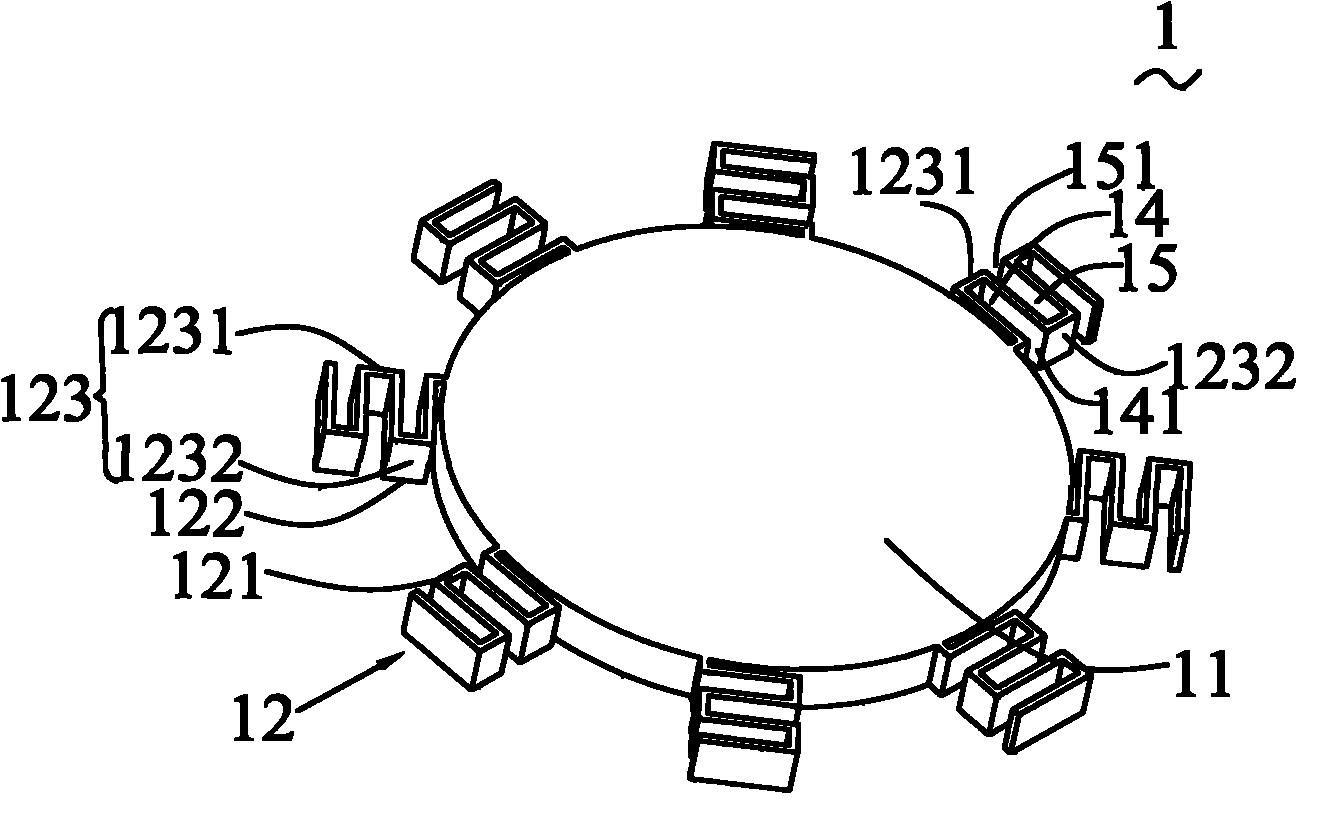

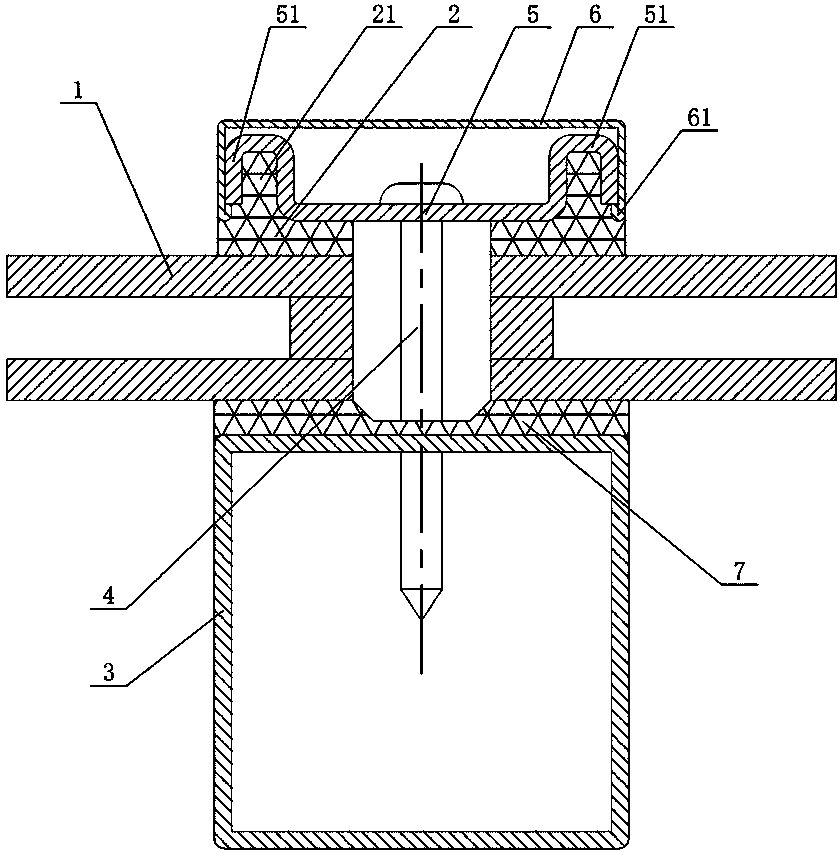

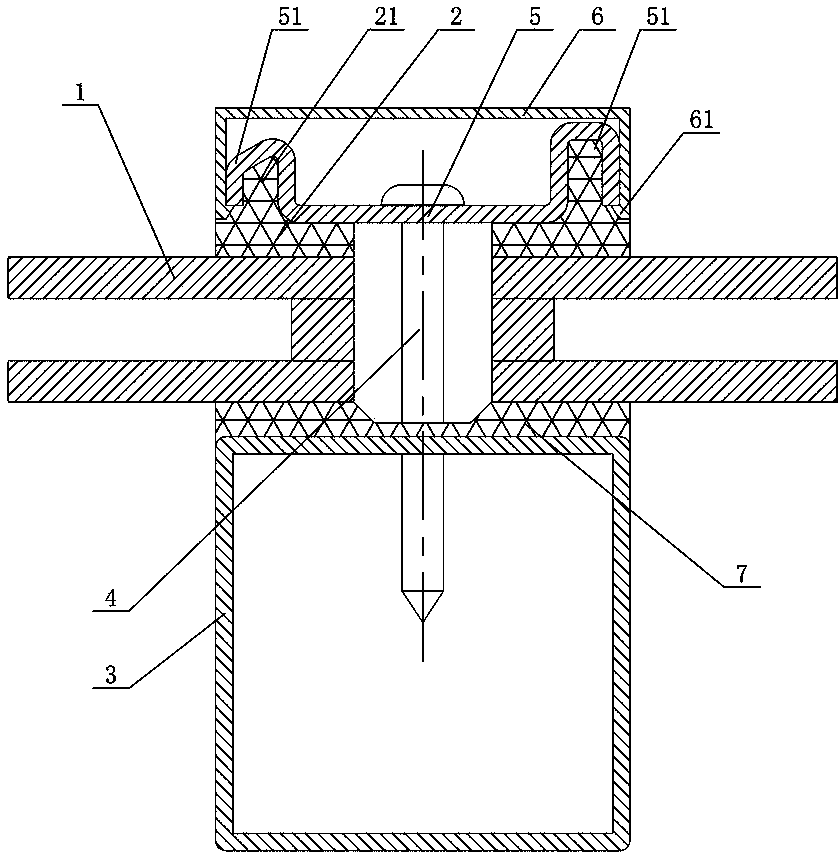

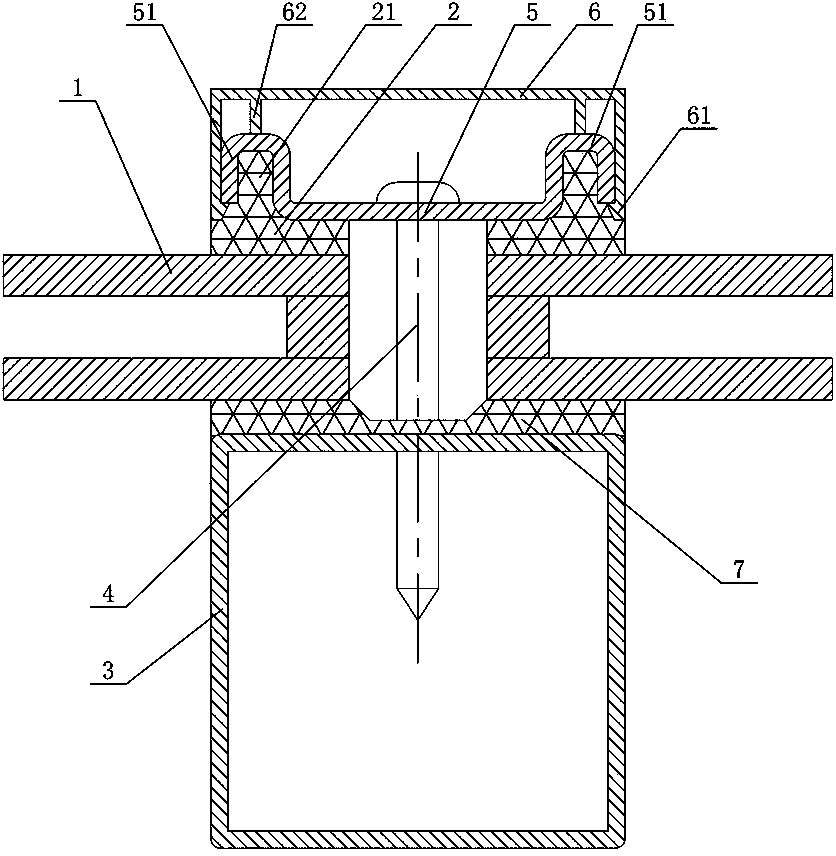

Board-to-board type RF plug, socket and connector assembly

ActiveCN108155499AHigh strengthIncreased buckling strengthCoupling contact membersTwo-part coupling devicesCoaxial lineEngineering

A board-to-board type RF plug comprises a plug body, plug terminals arranged in the plug body, a plug fixing piece surrounding the periphery of the plug body, a coaxial line, and a plug circuit boardconnecting the plug terminal and the coaxial line. The plug body comprises a body pedestal, a body outer wall, an island part and an insertion space, the periphery of the body pedestal extends upwardly to form the body outer wall in an integral way, the middle of the pedestal extends upwardly to form the island part in the integral way, the insertion space is formed between the body outer wall andthe island part, and the periphery of the body pedestal extends outwardly to form a platform part. The plug fixing piece comprises a fixing outer wall surrounding the periphery of the body outer walland a parallel bottom wall which is formed by extending vertically from the bottom of the fixing outer wall, and the parallel bottom wall is pasted to the platform part. The invention also provides aboard-to-board type RF socket and a board-to-board type connector assembly.

Owner:SHENZHEN EVERWIN PRECISION TECH +1

Structural member

InactiveUS20100133877A1High strengthHigh lightweightVehicle seatsUnderstructuresUltimate tensile strengthTension stress

A structural member includes: a compression-side wall part disposed in a compressive stress field of a bend; a tension-side wall part disposed in a tensile stress field of the bend; and a coupling wall part that couples the compression-side wall part and the tension-side wall part. The neutral axis of the bend is disposed in the vicinity of the compression-side wall part. For example, the compression-side wall part is higher in material strength, and / or larger in sheet thickness, than the tension-side wall part.

Owner:TOYOTA JIDOSHA KK

Engagement chain

InactiveUS8500101B2Suppression problemIncreased buckling strengthPortable liftingLifting framesEngineering

Owner:TSUBAKIMOTO CHAIN CO

Can Shell and Double-Seamed Can End

InactiveUS20110031256A1Reduction in blank diameterIncrease strength/weight ratioRigid containersHollow articlesEngineeringDouble seam

A drawn aluminum can shell has a peripheral crown which is double-seamed with an end portion of an aluminum can body to provide a can end having a generally flat center panel connected by an inclined curved or straight panel wall to an inclined inner wall of an annular U-shaped countersink. The countersink has an outer wall which connects with an inclined lower wall portion of a chuckwall at a junction below the center panel, and the chuckwall has a curved or inclined upper wall portion which connects with an inner wall of the crown. The chuckwall also has an intermediate wall portion forming a break, and the inner bottom width of the countersink is less than the radial width of the panel wall. The inclined upper wall portion of the chuckwall extends at an angle greater than the angle of the inclined lower wall portion of the chuckwall.

Owner:BALL CORP +1

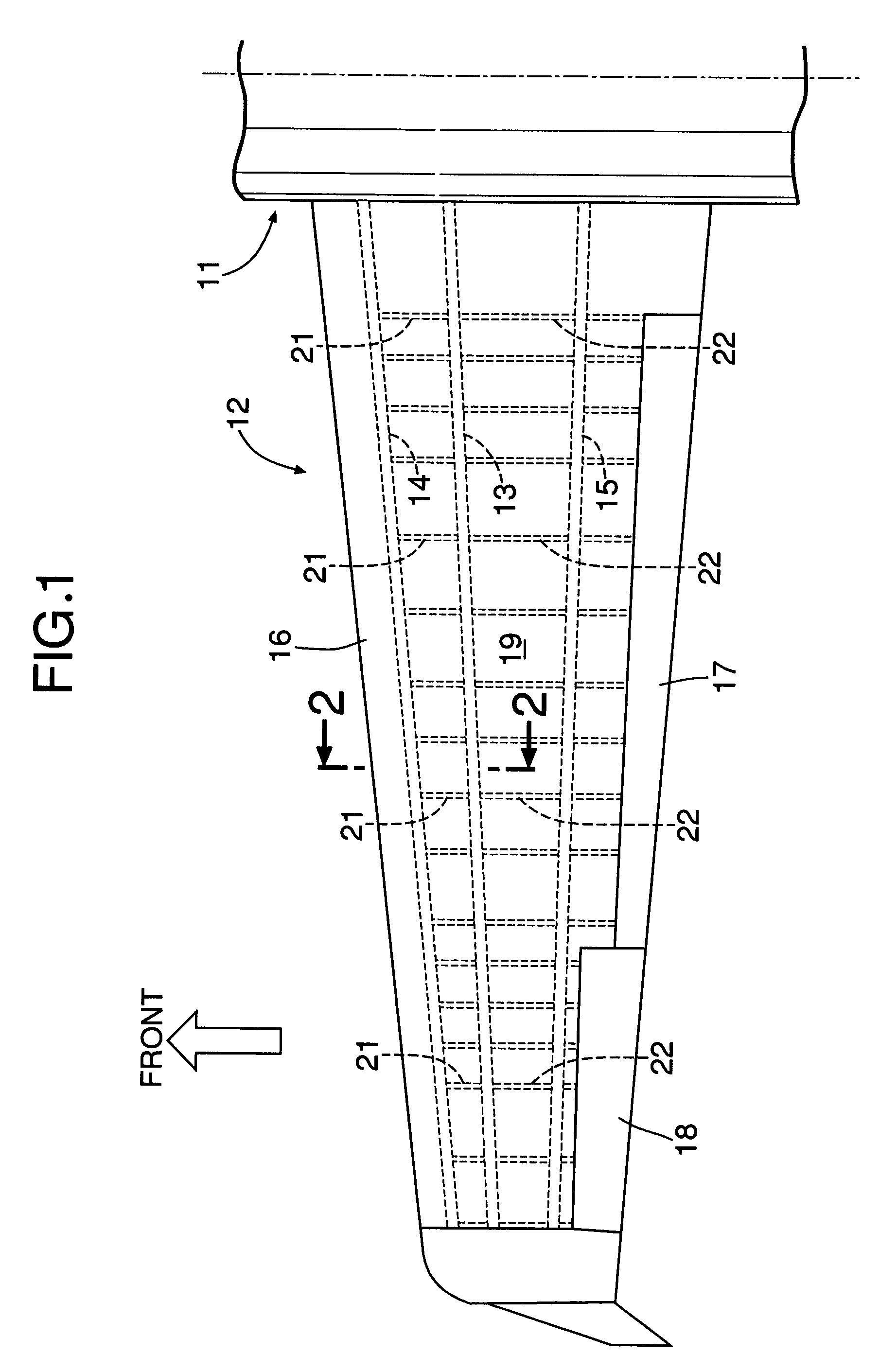

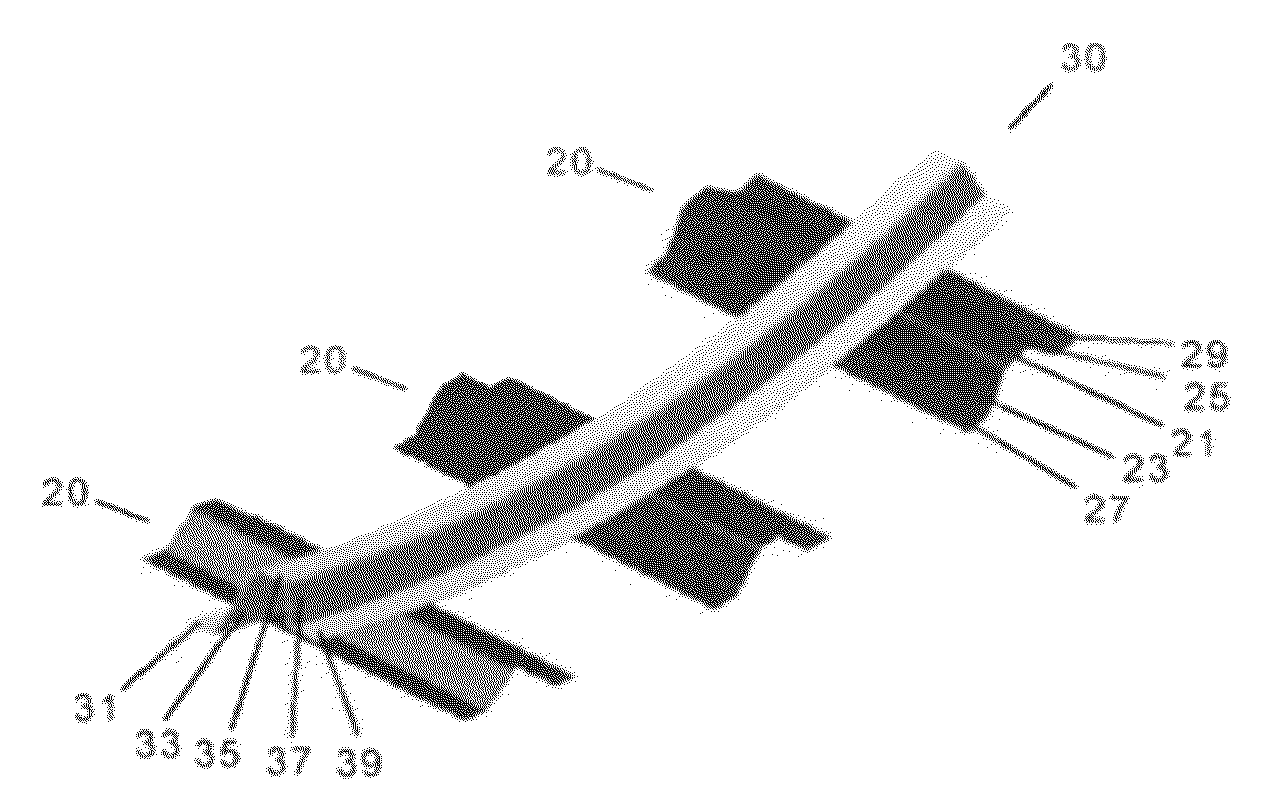

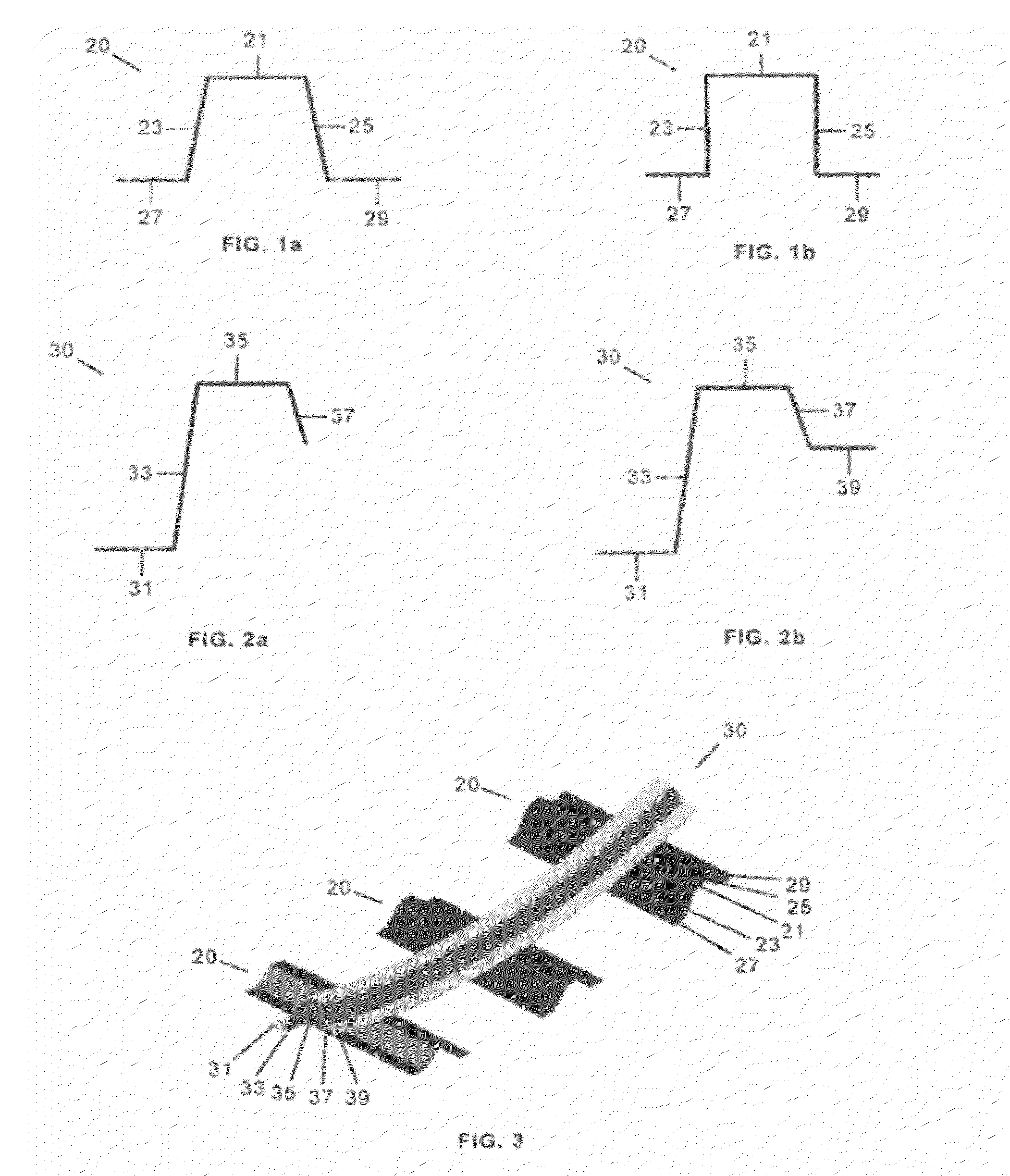

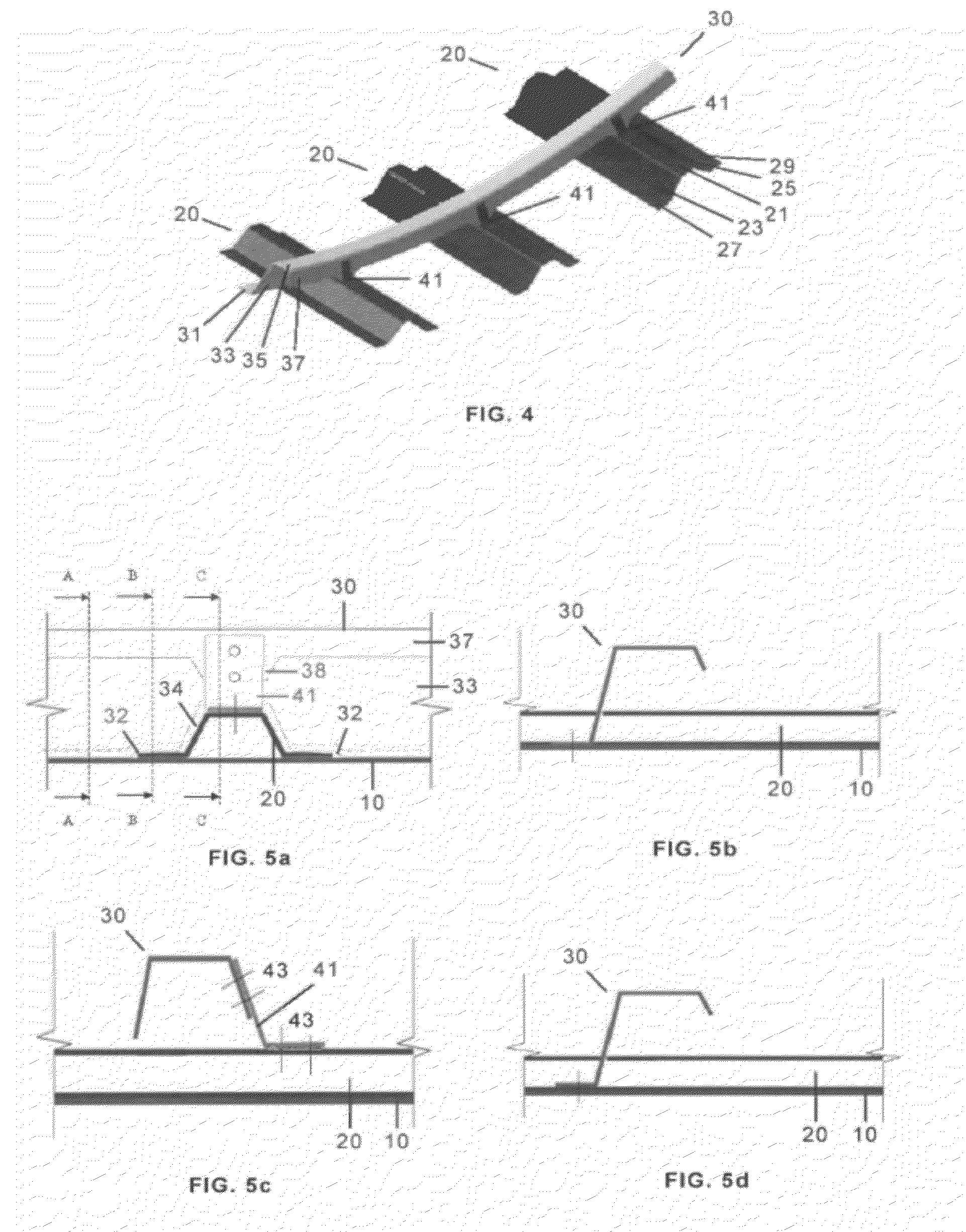

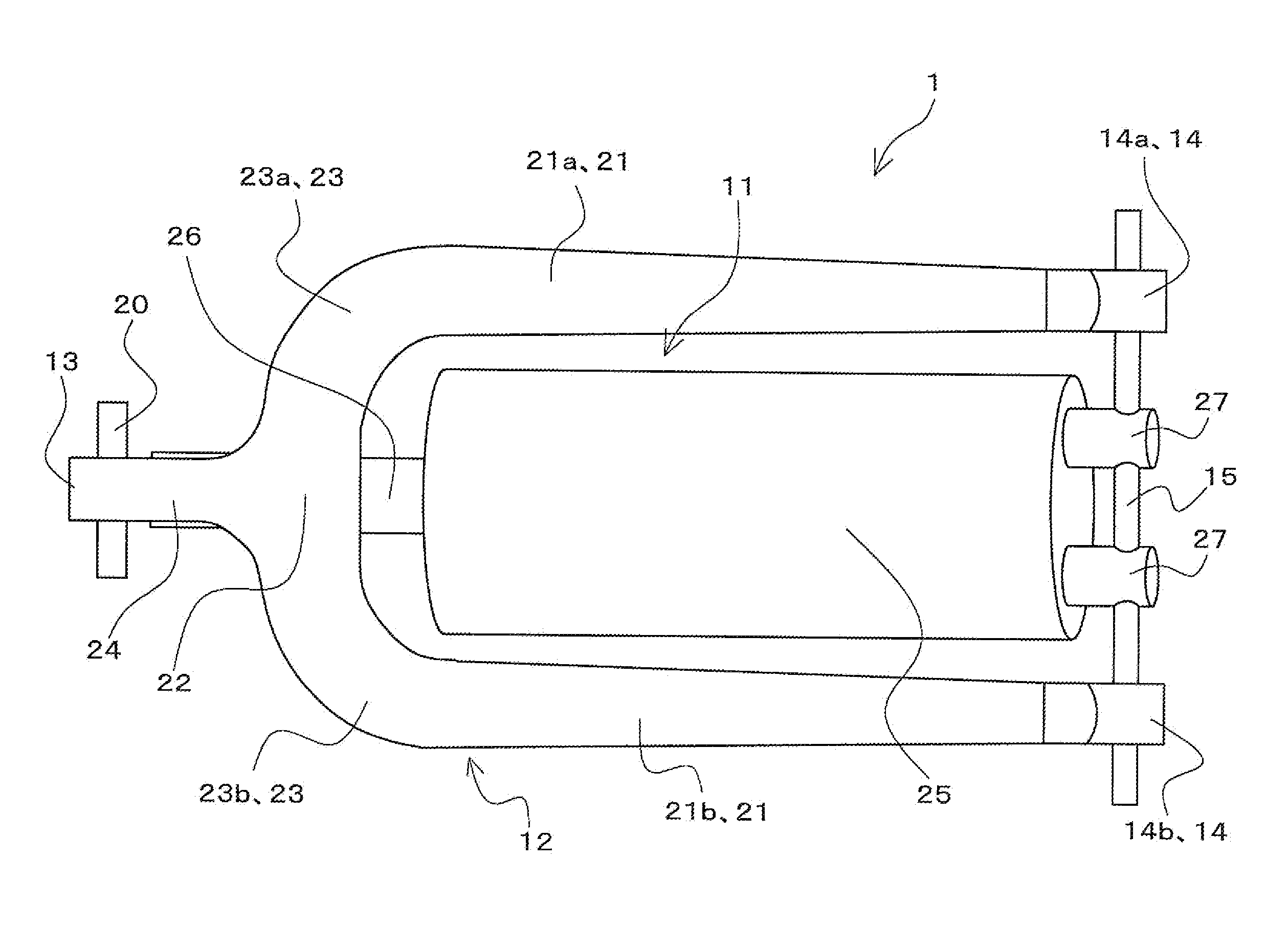

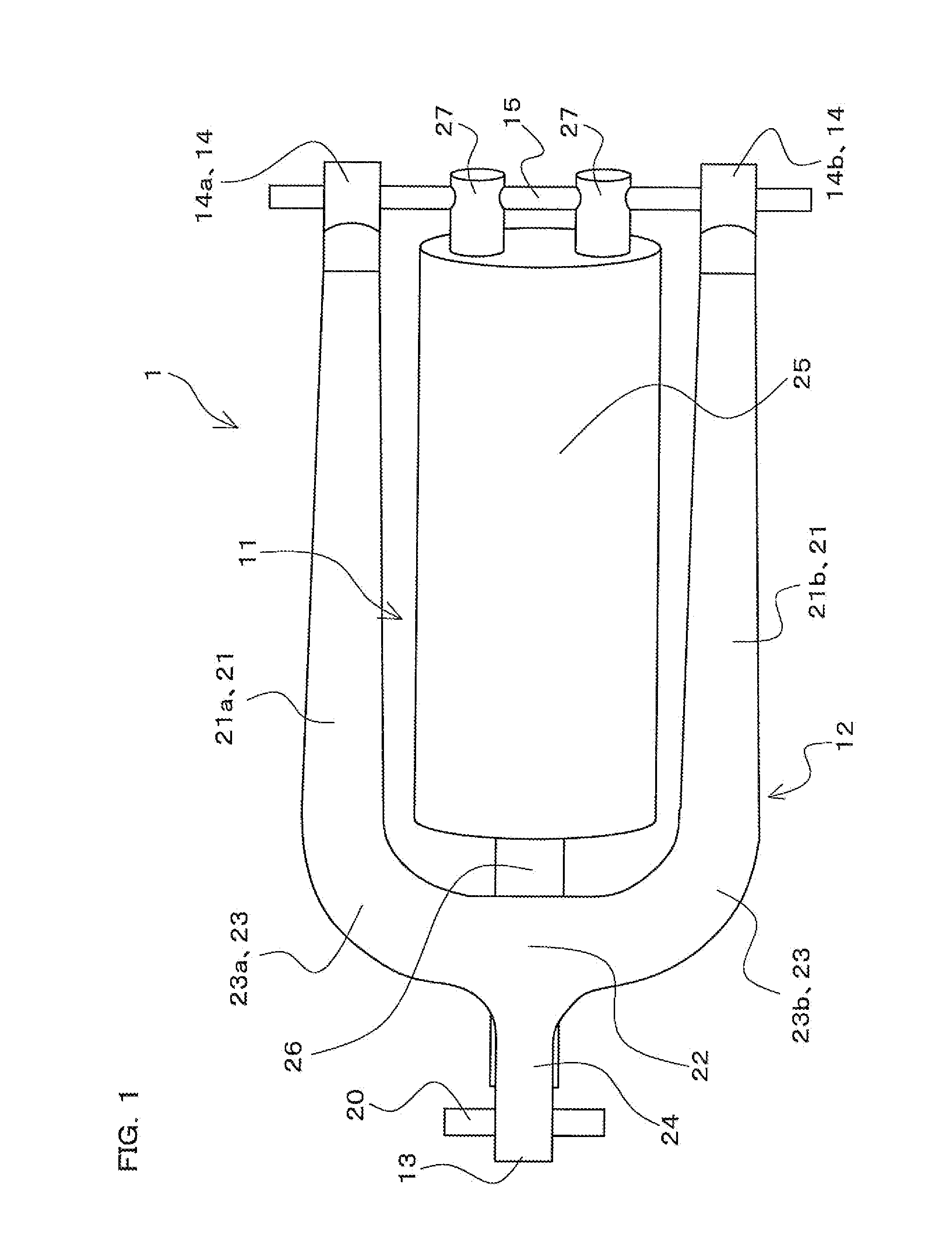

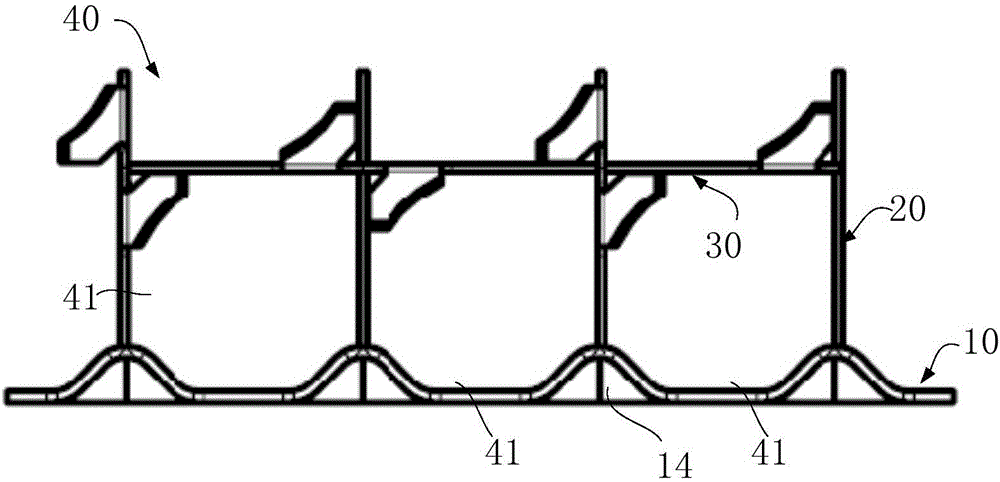

Aircraft fuselage with high strength frames

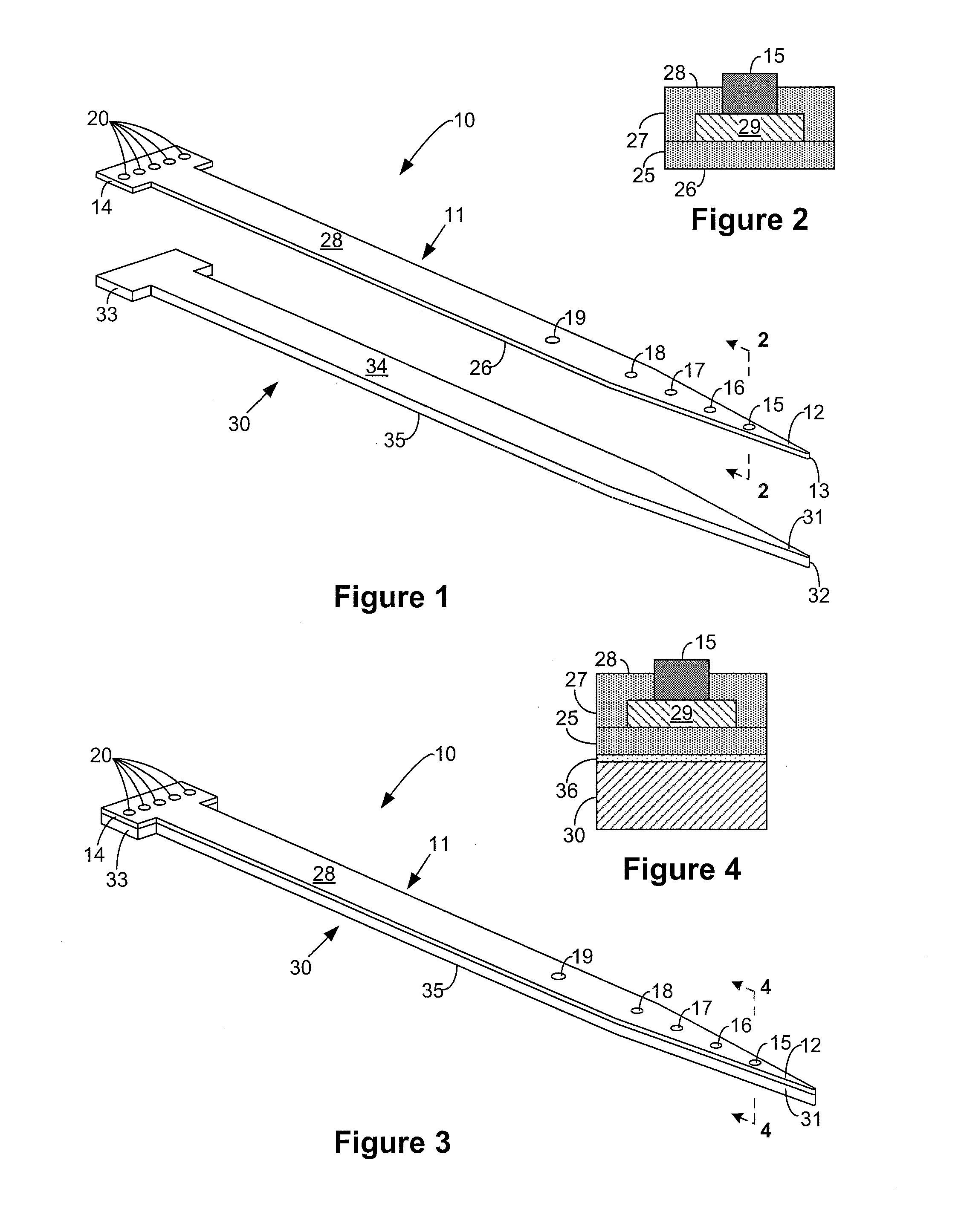

ActiveUS20120248247A1Improve the immunityIncrease resistanceFuselage framesFuselage bulkheadsEngineeringFuselage

Fuselage section of an aircraft whose structure comprises a skin (10), a plurality of frames (30) positioned transversely to the longitudinal axis of the fuselage and a plurality of longitudinal stringers (20); the stringers being configured with a closed transversal section comprising a hat (21), two webs (23, 25) and two feet (27, 29) joined to the skin (10); the frames (30) being configured in at least one its sectors with a foot (31) joined to the skin (10), a web (33) having holes at the crossing zones with said stringers (20), a cap (35) and a cap extension (37) which does not interfere with the stringers (20); the frames (30) being joined to, at least, the stringer hats (21) at their crossing zones.

Owner:AIRBUS OPERATIONS SL

Structural member

InactiveUS8393672B2High strengthHigh lightweightVehicle seatsUnderstructuresTension stressStructural element

A structural member includes: a compression-side wall part disposed in a compressive stress field of a bend; a tension-side wall part disposed in a tensile stress field of the bend; and a coupling wall part that couples the compression-side wall part and the tension-side wall part. The neutral axis of the bend is disposed in the vicinity of the compression-side wall part. For example, the compression-side wall part is higher in material strength, and / or larger in sheet thickness, than the tension-side wall part.

Owner:TOYOTA JIDOSHA KK

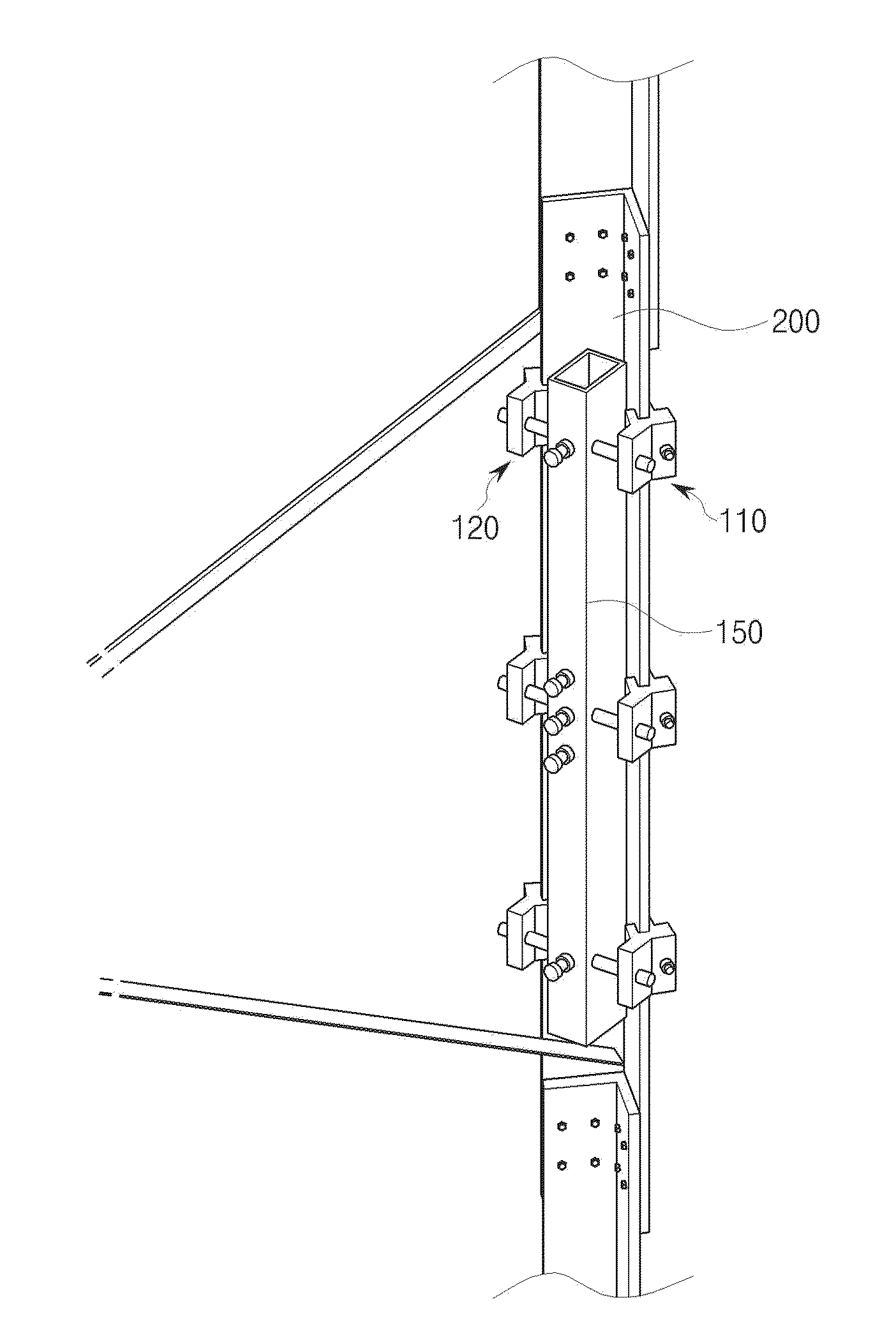

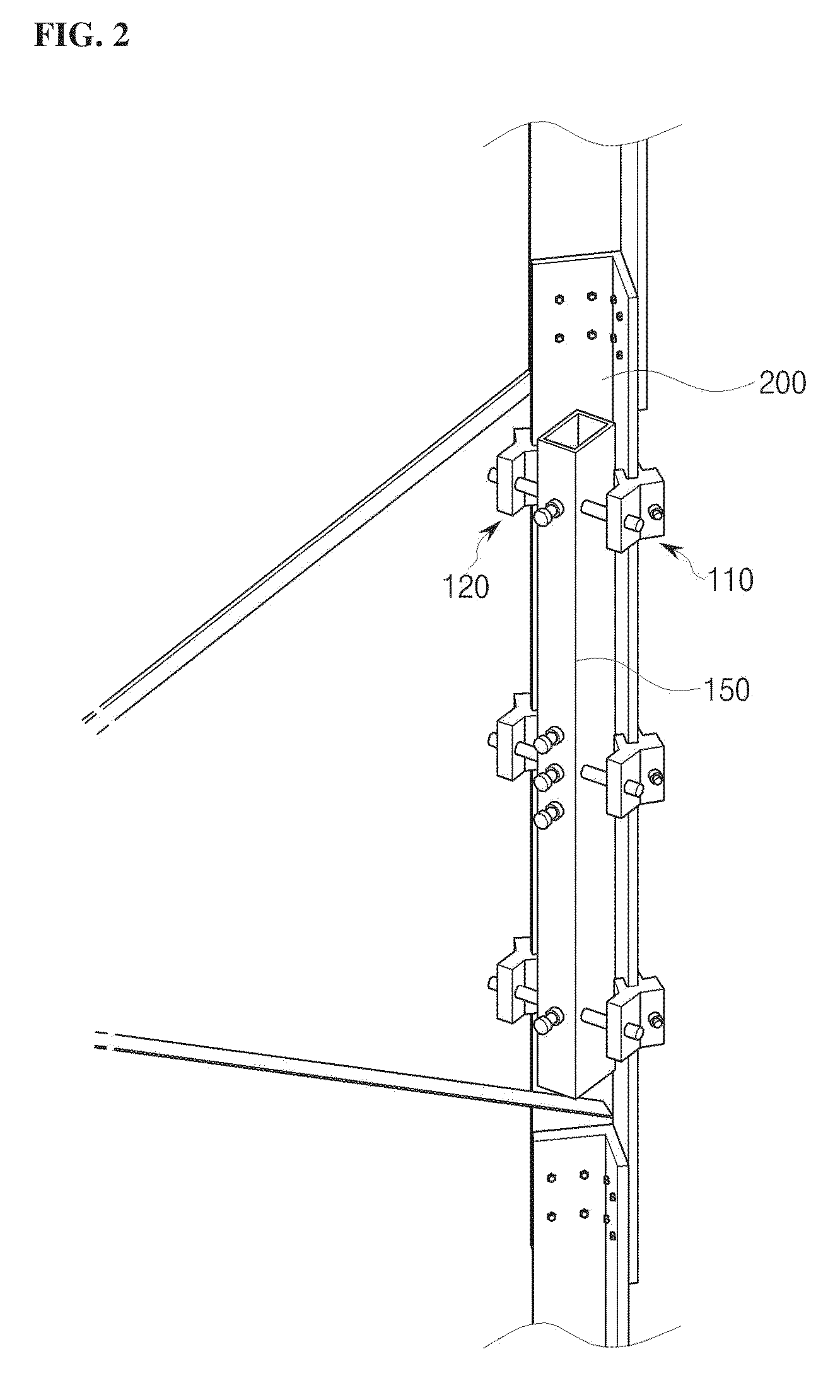

Reinforcement device for compression buckling strength and method of fastening the same

ActiveUS20100132300A1Improve compression buckling strengthAvoid compressionCandle holdersLighting support devicesSteel frameTower

A reinforcement device for compression buckling strength and a method of fastening the same are disclosed. The reinforcement device includes a member seating body surrounding an angle-type steel-frame member, first and second securing couplers securing opposite ends of the angle-type steel-frame member and opposite ends of the member seating body and adjustable to meet a standard of the angle-type steel-frame member, a horizontal engaging element connecting the first and second securing couplers with each other, a supporter positioned in a space where the angle-type steel-frame to member forms a right angle and supporting the angle-type steel-frame member, and a reinforcing bar connecting the supporter and the horizontal engaging element. The reinforcement device prevents an angle-type steel-frame member for a steel-frame structure or a steel power-transmission tower from undergoing compression buckling and accidental eccentricity, and improves compression buckling strength without power interruption of transmission lines, member disassembly, or field preparation.

Owner:KOREA ELECTRIC POWER CORP

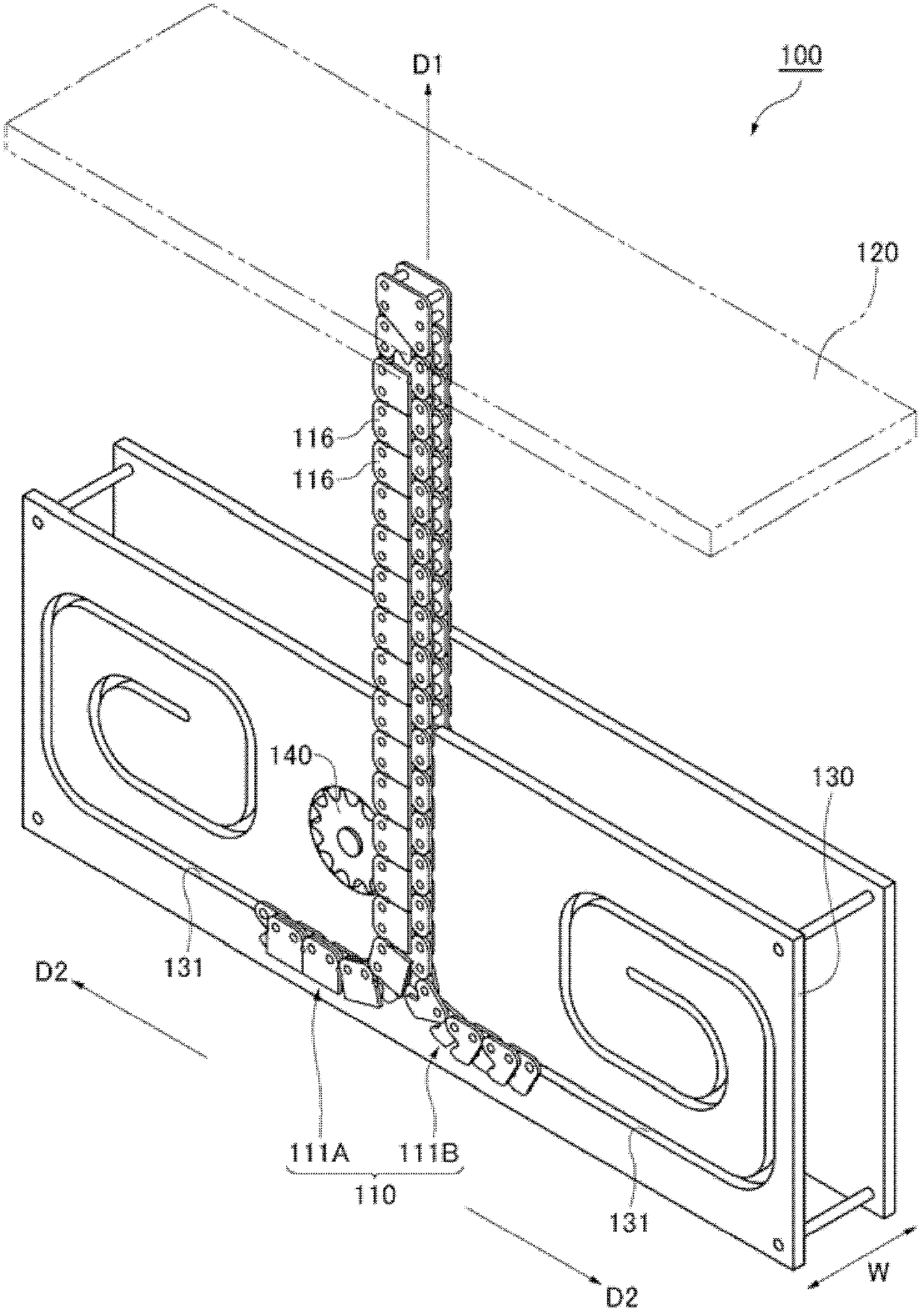

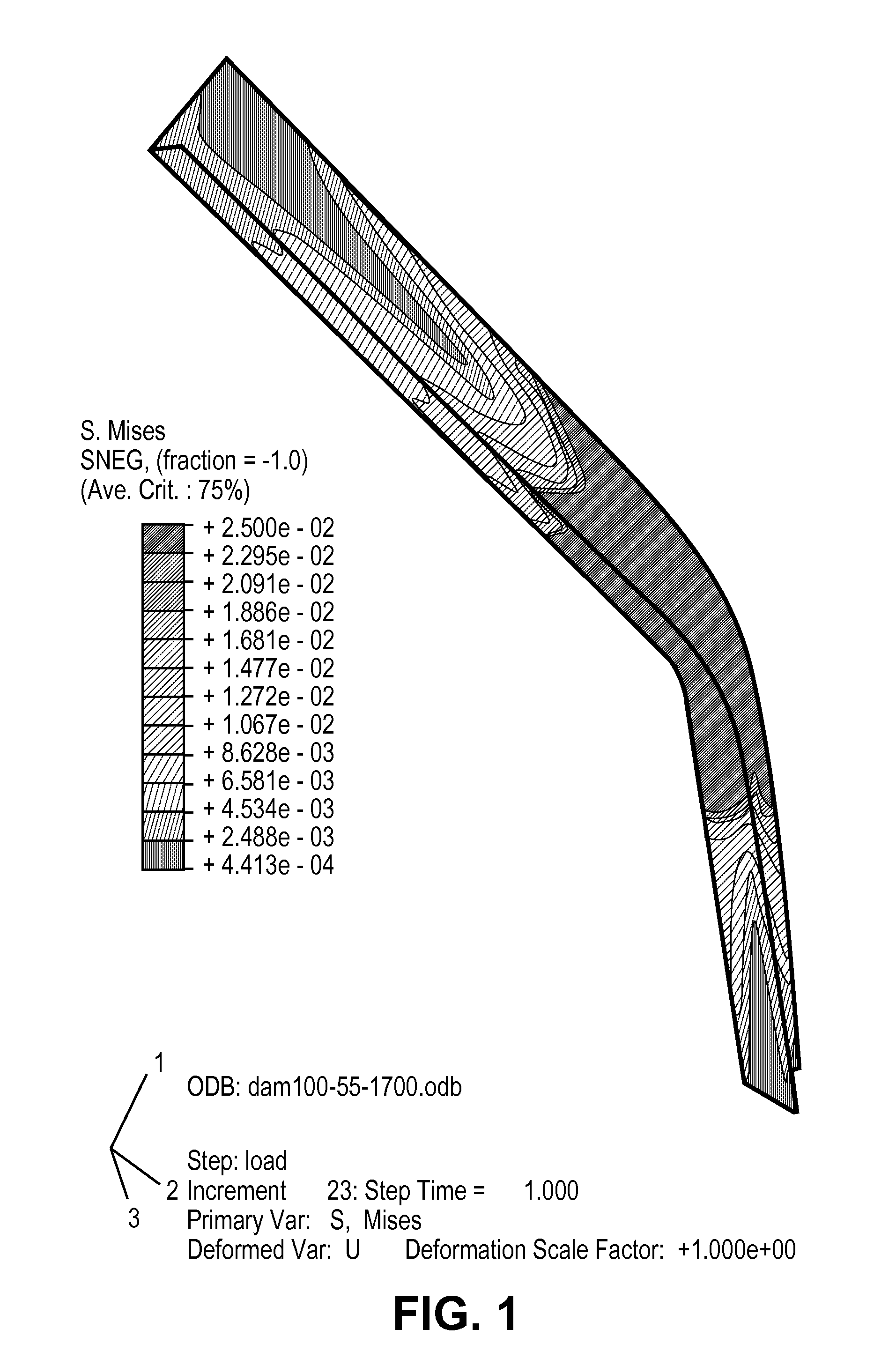

Aircraft actuator

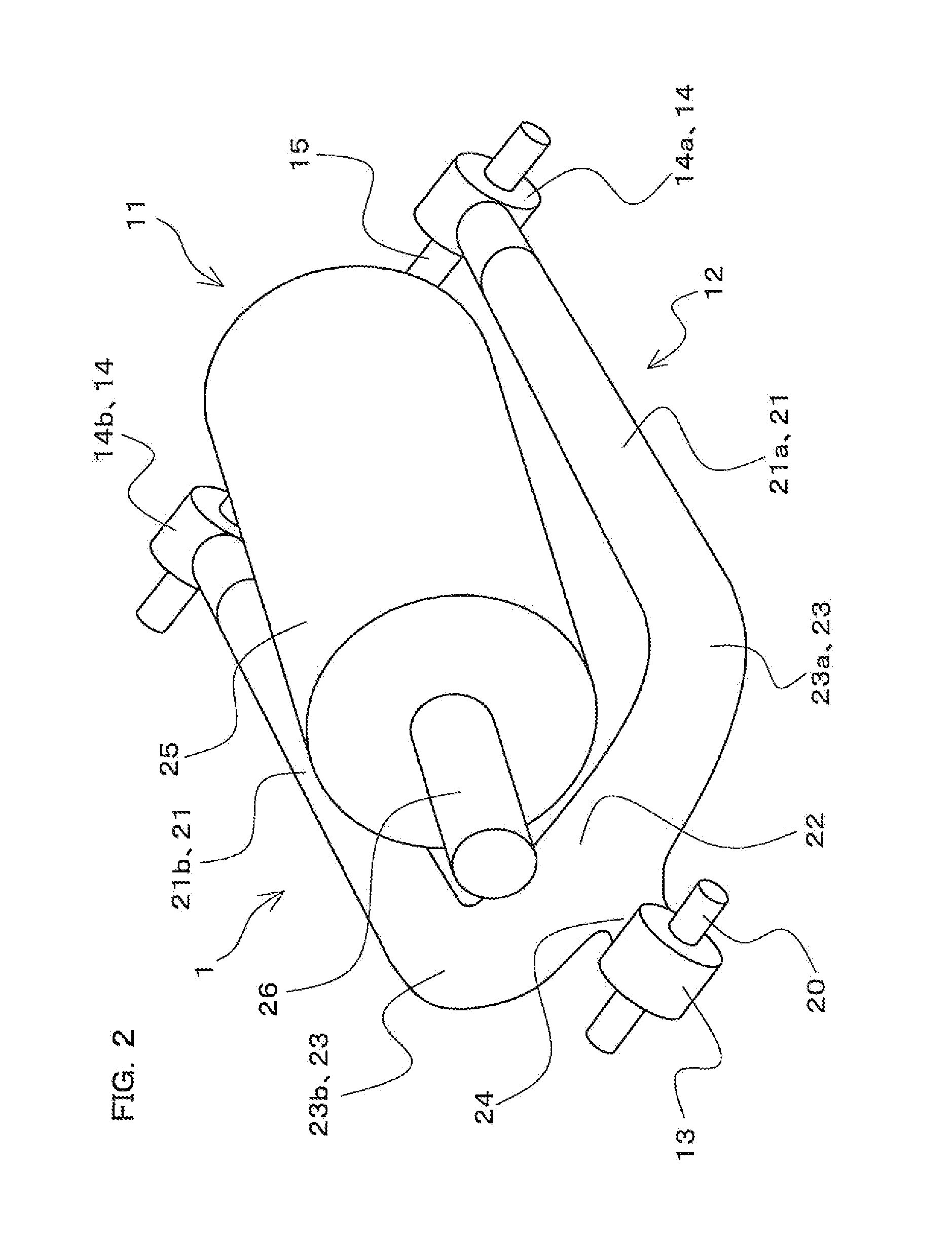

ActiveUS20100270426A1Increased buckling strengthLarge weightAircraft stabilisationWithout power ampliicationFiberCoupling

An aircraft actuator is provided that can achieve a significant weight reduction, while securing a sufficient tensile strength and a sufficient buckling strength, even if it is provided with a reaction link in which large bent portions are formed. A reaction link is made of fiber reinforced plastic, and includes a pair of linear portions, a coupling portion, and a pair of bent portions. The cross section at the pair of linear portions, the coupling portion, and the pair of bent portions is formed as a hollow cross section. The outer cross sectional area of the hollow cross section at each of the pair of bent portions is configured to be larger than the outer cross sectional area of the hollow cross section at each of the pair of linear portions.

Owner:NABLESCO CORP

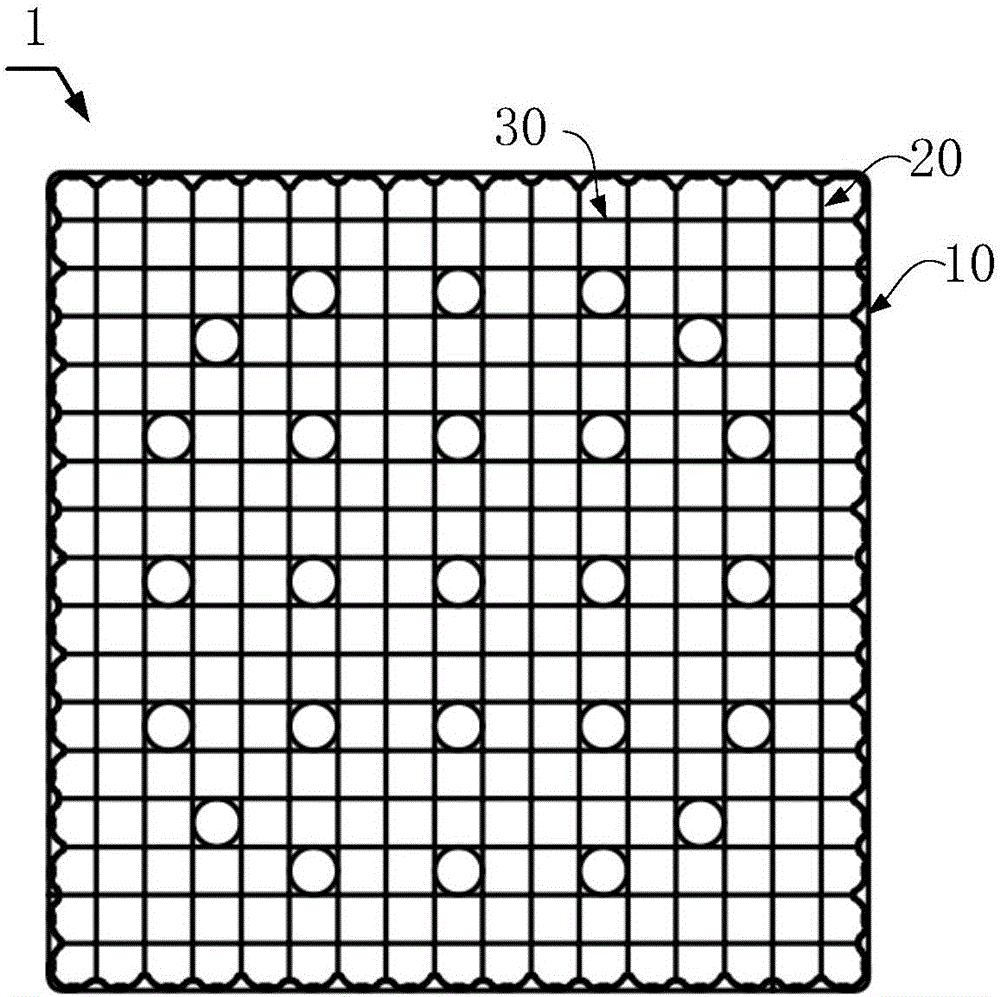

Outer strip, location grid of nuclear reactor fuel subassembly, and nuclear reactor fuel subassembly

ActiveCN106409346AIncreased buckling strengthIncrease safe operating marginNuclear energy generationFuel element assembliesNuclear reactorSafe operation

The invention discloses an outer strip, a location grid of a nuclear reactor fuel subassembly, and the nuclear reactor fuel subassembly. According to the outer strip, in the longitudinal direction, the outer strip comprises an upper edge part, a middle part, and a lower edge part which are connected; on the upper edge part and / or the lower edge part, a plurality of guiding parts are formed via protruding towards the same side of the plane of the middle part; the guiding parts are arranged at intervals along the length direction of the outer strip; the middle part is used for connecting the upper edge part and the lower edge part in a plate shaped manner; buckling of the middle part, shaping like a plate, of the outer strip is not caused, so that the buckling strength of the location grid entire body is increased, and safe operation surplus capacity of the nuclear reactor fuel subassembly under reactor accident conditions is increased; the gaps between the outer strips of the adjacent location grids are narrowed, so that it is ensured that more cooling agent flows into the interior of the location grids for blending, better cooling agent blending performance is achieved, and reactor thermal working condition safe operation surplus capacity is increased.

Owner:CHINA NUCLEAR POWER TECH RES INST CO LTD +2

Diaphragm and silicon capacitor microphone comprising same

InactiveCN102065354AReduce stress gradientReduce rigidityElectrostatic transducer microphonesTransducer diaphragmsCapacitanceHigh stress

Owner:AAC ACOUSTIC TECH (SHENZHEN) CO LTD +1

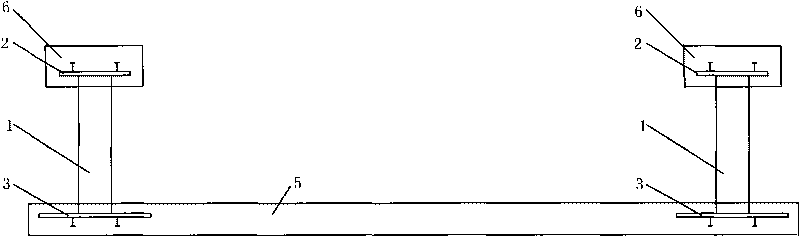

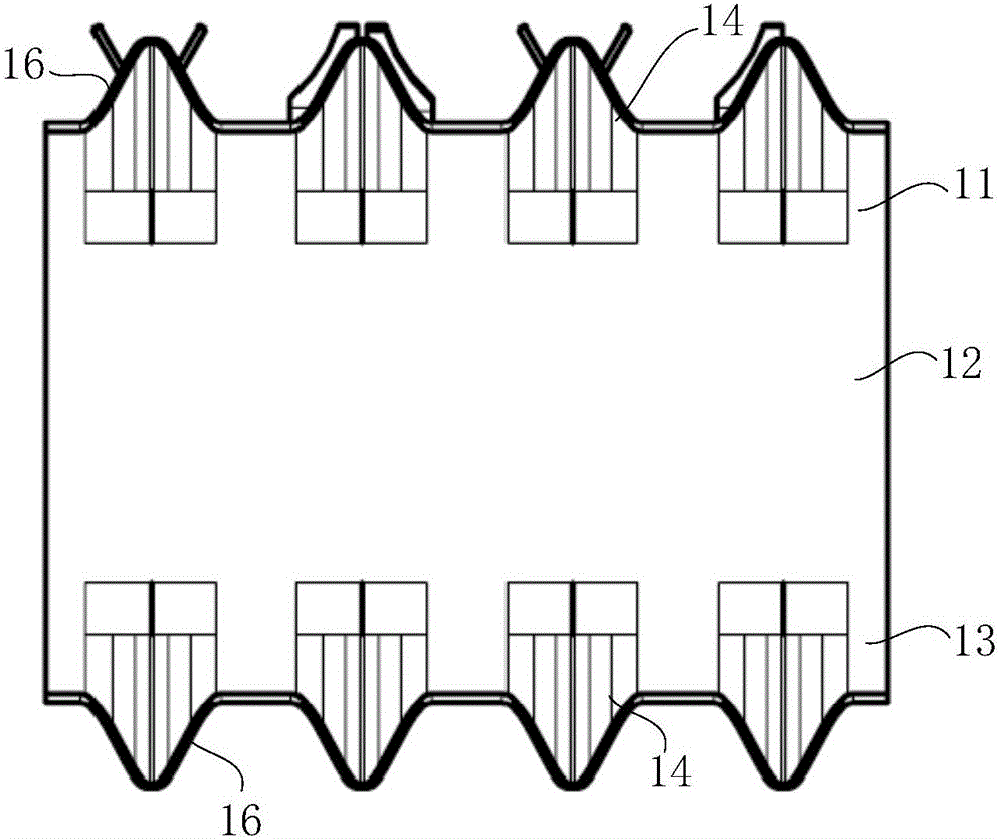

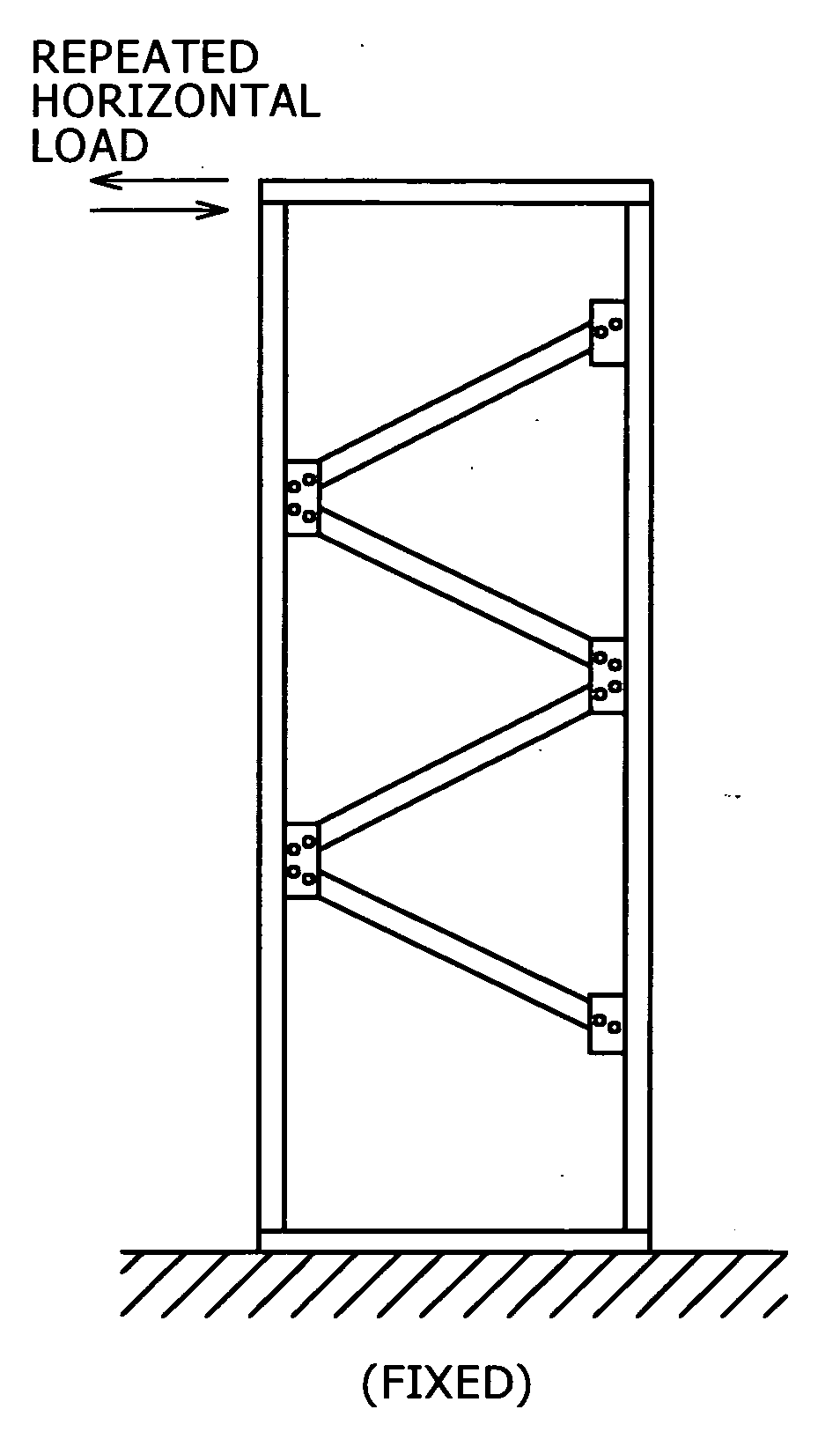

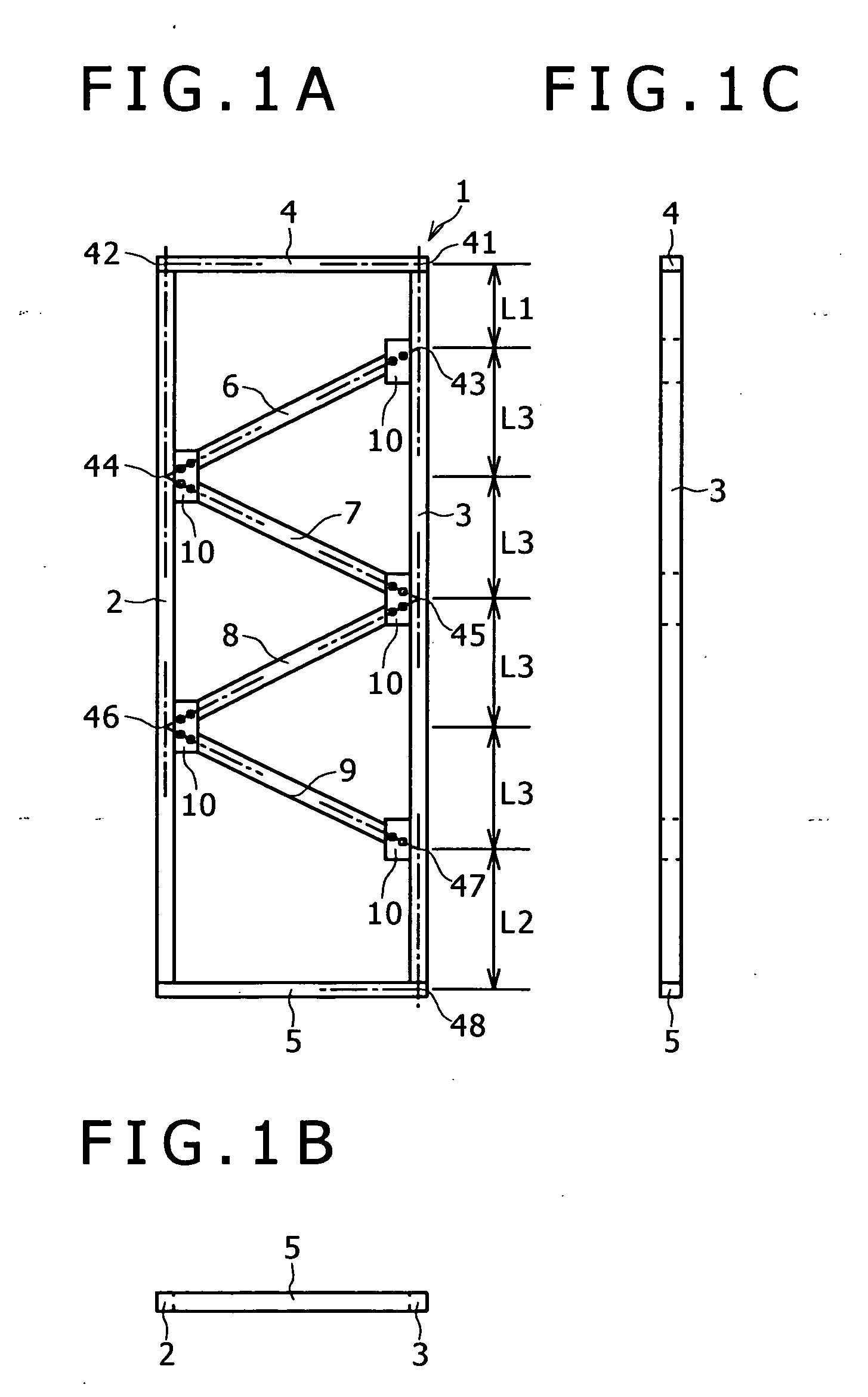

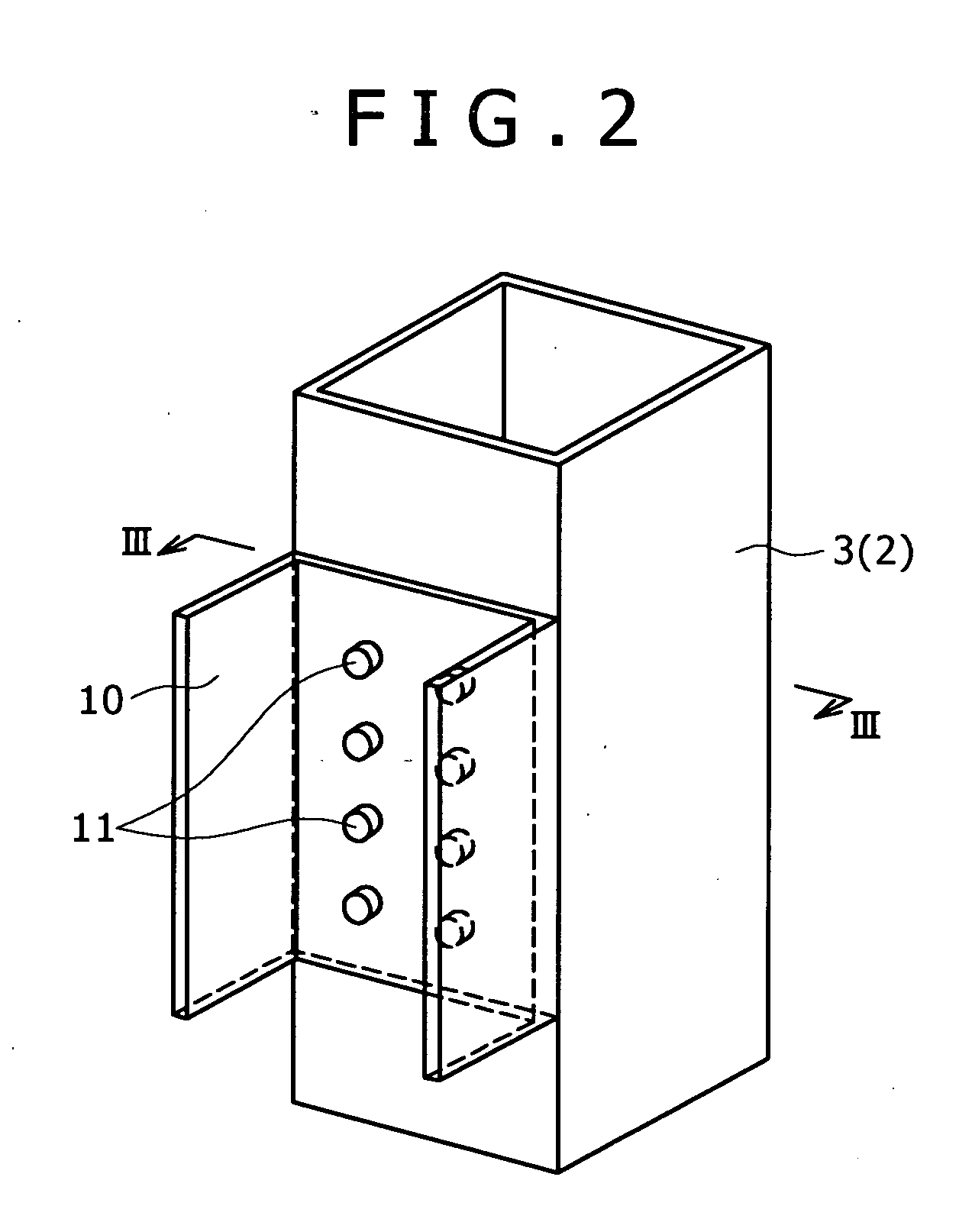

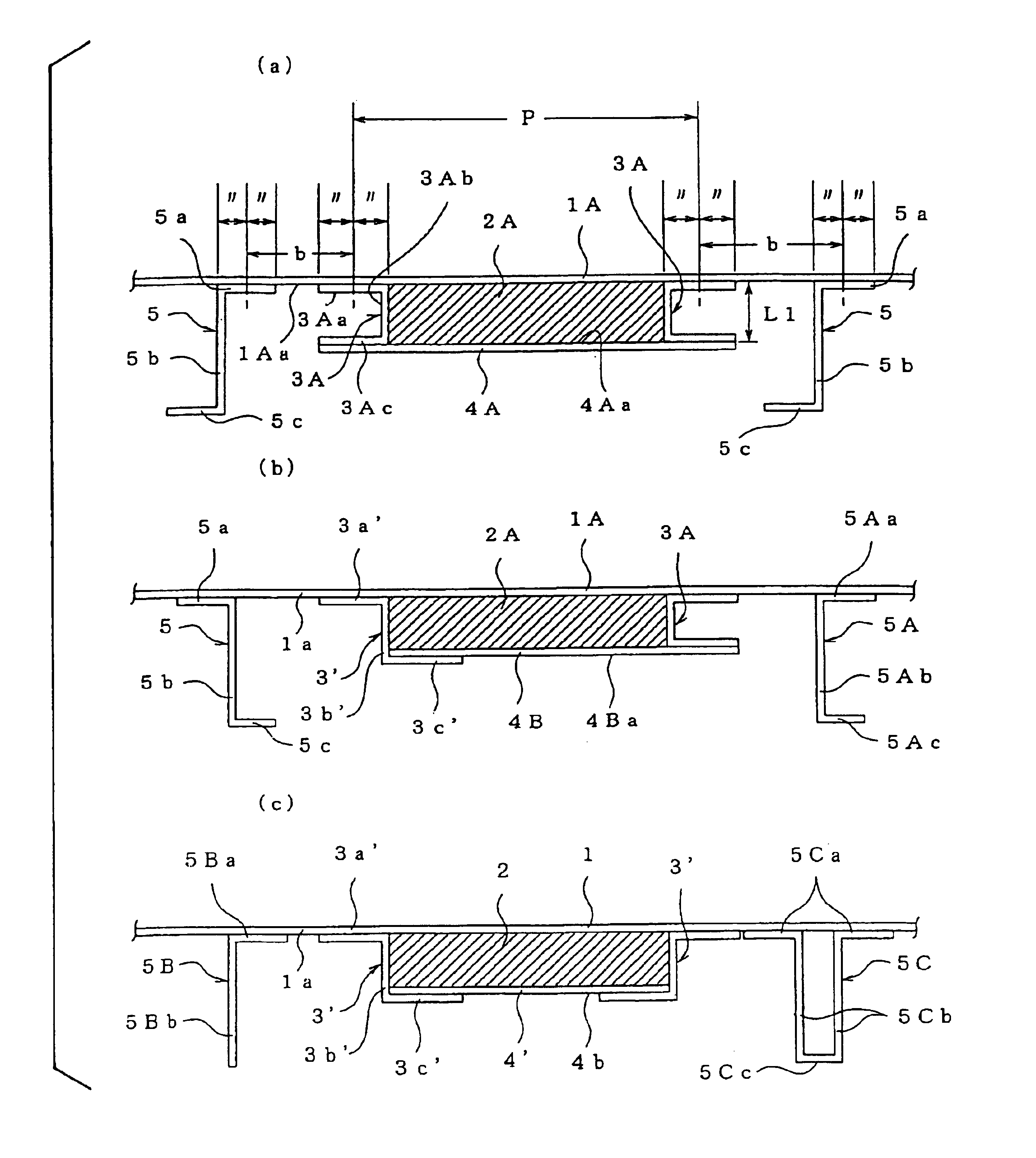

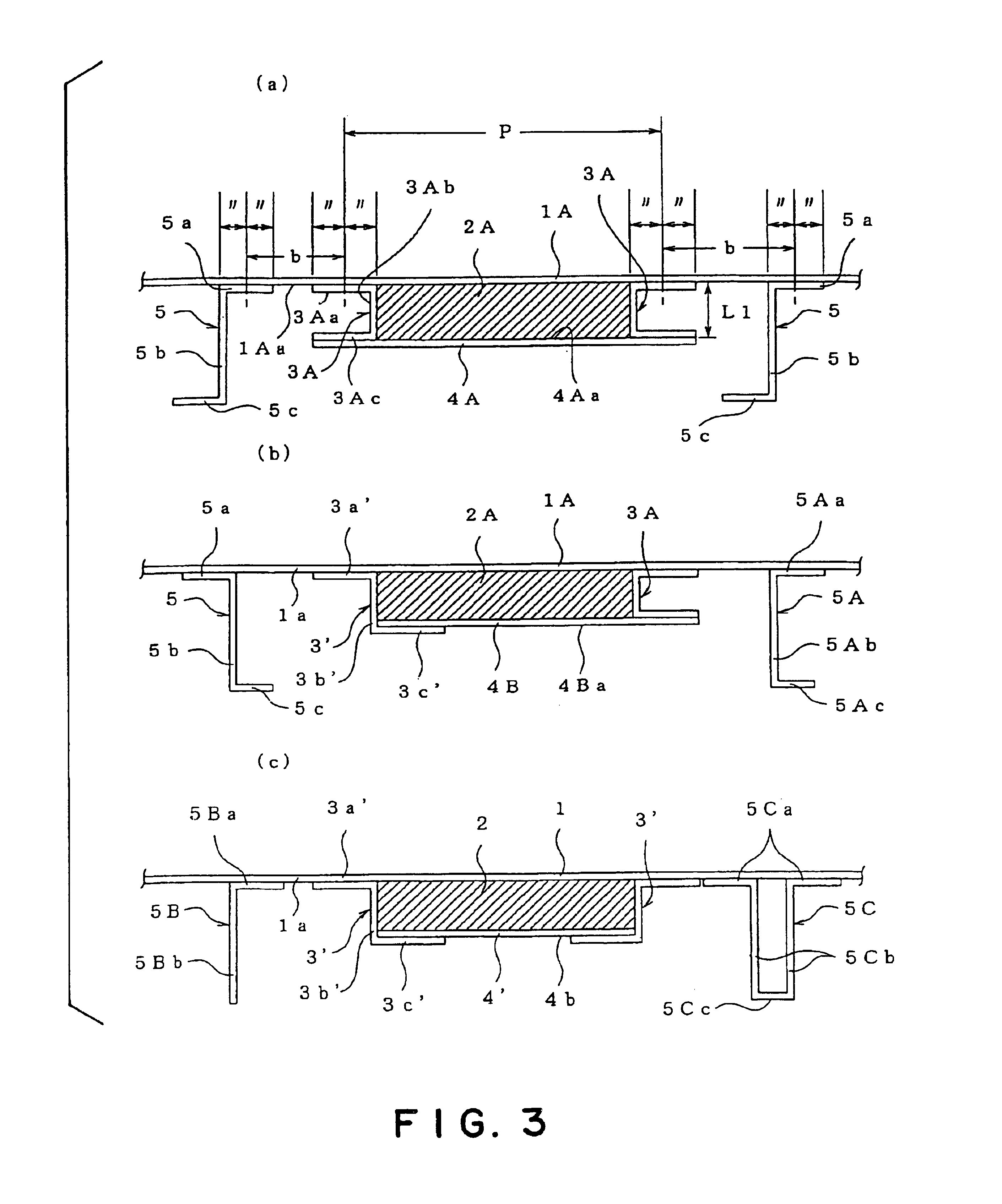

Load Bearing Frame

InactiveUS20100031600A1Improve carrying capacityBuckling suppressionWallsTowersEngineeringLoad bearing

The present invention is to provide a load bearing frame for suppressing generation of buckling of diagonal materials and breakage of connection parts and having high deformability.A load bearing frame 1 has two pillar materials 2 and 3, two frame materials 4 and 5 and four diagonal materials 6 to 9. A connection point 41 between the pillar material 3 and the frame material 4 is apart from a connection point 43 between the diagonal material 6 arranged on the uppermost side and the pillar material 3 by a distance L1. A connection point 48 between the pillar material 3 and the frame material 5 is apart from a connection point 47 between the diagonal material 9 arranged on the lowermost side and the pillar material 3 by a distance L2.

Owner:KOBE STEEL LTD

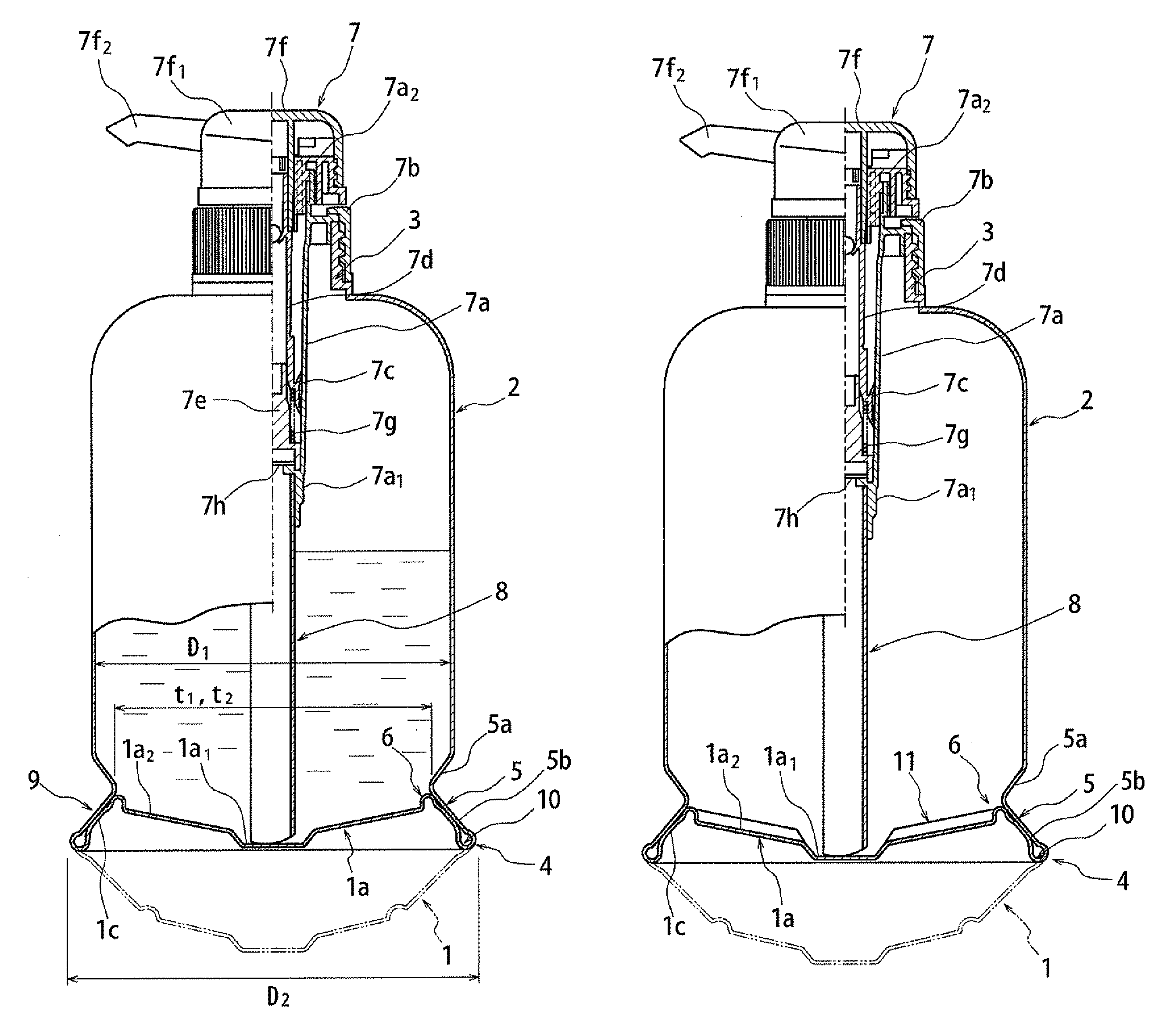

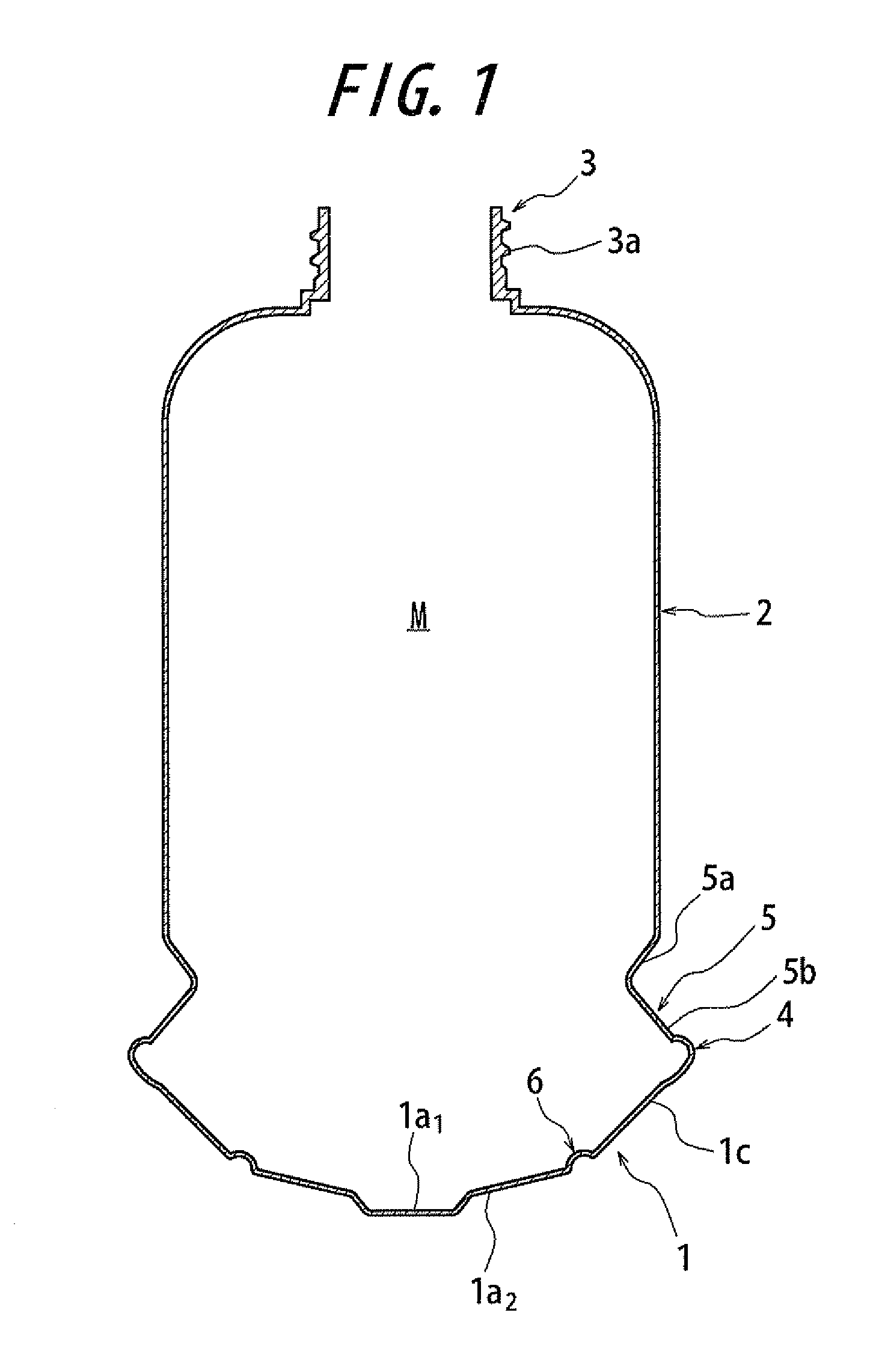

Synthetic resin container having inverted, folded back bottom wall

ActiveUS8505763B2Improve buffering effectIncreased buckling strengthPackage recyclingDispensing apparatusBlow moldingEngineering

Disclosed is a synthetic resin container provided with an inverting, foldback bottom wall that can maintain a stable, self-supporting position while being able to minimize the amount of residual contents, and that can be formed by blow-molding, etc., and maintain the favorable producibility or low cost of the past. The synthetic resin container is provided with a bottom wall that forms the bottom of the container, and a drum section that is united to the perimeter of the bottom wall and forms a filling space M for contents on the inside, and is a synthetic resin container wherein a raised bottom is formed by inverting and folding back said bottom wall toward said drum section. Said drum section has a lower peripheral wall that touches or approaches the outer wall part of said bottom wall and forms a self-supporting base by the inversion and folding back of said bottom wall.

Owner:YOSHINO KOGYOSHO CO LTD

Engagement chain

ActiveCN101659383AGuaranteed rigidityIncreased buckling strengthLifting framesDriving chainsSprocketEngineering

Owner:TSUBAKIMOTO CHAIN CO

Fireproof curtain wall system

ActiveCN104358335ANot easy to come outReduce the difficulty of fasteningWallsFire proofingKeelEngineering

The invention discloses a fireproof curtain wall system. The fireproof curtain wall system comprises a fireproof panel, a keel, a fastening bolt, a steel pressing plate and a decorative cover, wherein the fastening bolt penetrates through the steel pressing plate and is connected with the keel; the fireproof panel is pressed against the keel through the steel pressing plate; the decorative cover is buckled on the steel pressing plate; bending parts of which openings face the fireproof panel are arranged on two sides of the steel pressing plate; fastening parts which extend inwards are arranged on the two sides of the decorative cover and are buckled at the bottom ends of the outer side walls of the bending parts; the outer side walls of the bending parts are attached to the inner side wall of the decorative cover. The fireproof curtain wall system has the advantages of simple structure, simple formation, low cost and high buckling strength.

Owner:HUNAN GOLDWELL NEW MATERIALS TECH CO LTD

Structural element and body structure including the same

InactiveUS6871903B2Reduce weightReduce in quantitySuperstructure subunitsAxle-box lubricationWindow openingEngineering

A side structure included in a railroad car is provided with an window opening, and door openings formed on the longitudinally opposite sides of the window opening, respectively. The side structure excluding parts corresponding to the window opening and the door openings are divided into a plurality of sections. A first section extends vertically between the window opening and the door opening, a second section extends vertically between the window opening and the door opening, and a third section of a width substantially equal to that of the window opening extends under the window opening. Each of the sections has a core attached to the inner surface of an outer panel, and rim members having a substantially Z-shaped cross section and surround the core. An inner panel is attached to the core and the rim members so as to cover the inner surface of the core.

Owner:KAWASAKI HEAVY IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com