Fireproof curtain wall system

A technology of fire curtain and steel pressure plate, applied in the field of fireproof curtain wall system, can solve the problems such as the difficulty of forming, increase the difficulty of fastening the steel pressure plate and the external decorative cover, and push up the production cost of the steel pressure plate, so as to reduce the production cost and reduce the The effect of fastening difficulty and reducing molding difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

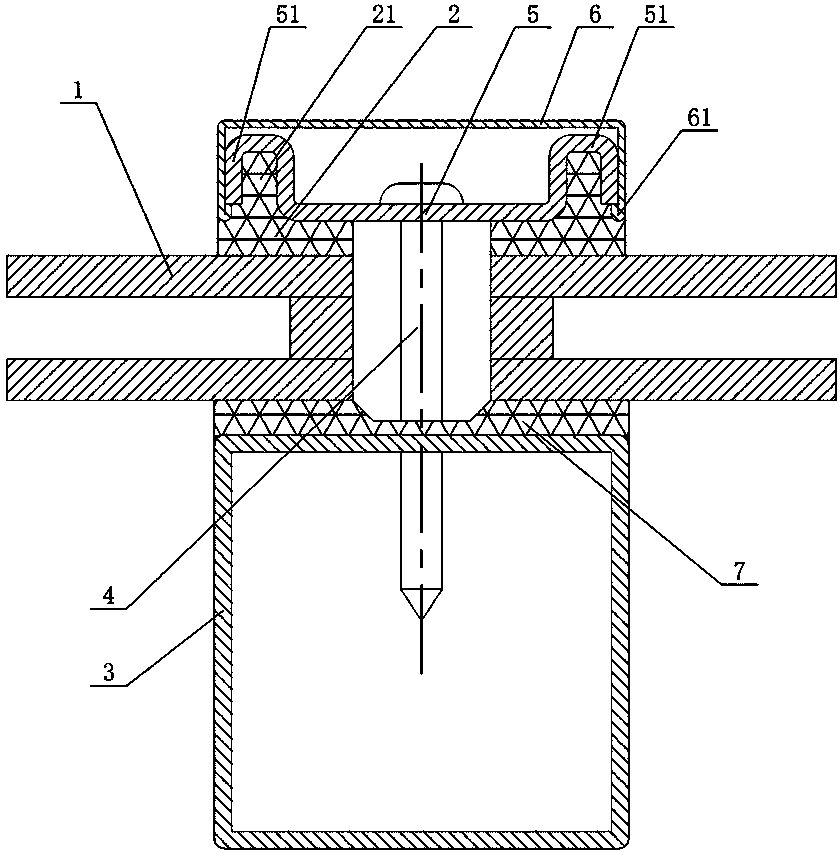

[0026] Such as figure 1 As shown, the first embodiment of the fireproof curtain wall system of the present invention, the curtain wall system includes a fireproof panel 1, a keel 3, fastening bolts 4, a steel pressure plate 5 and a decorative cover 6, and the fastening bolt 4 passes through the steel pressure plate 5 and the keel 3 connection, the fireproof panel 1 is pressed tightly on the keel 3 through the steel pressure plate 5, the decorative cover 6 is fastened on the steel pressure plate 5, the steel pressure plate 5 is provided on both sides with openings facing the bending part 51 of the fireproof panel 1, and the decorative cover 6 is two There is a fastening part 61 extending inward on the side. The fastening part 61 is fastened to the bottom end of the outer wall of the bending part 51, and the outer wall of the bending part 51 is close to the inner wall of the decorative cover 6. When installing, first Lay the fireproof panel 1 on the keel 3, so that the keel 3 fo...

Embodiment 2

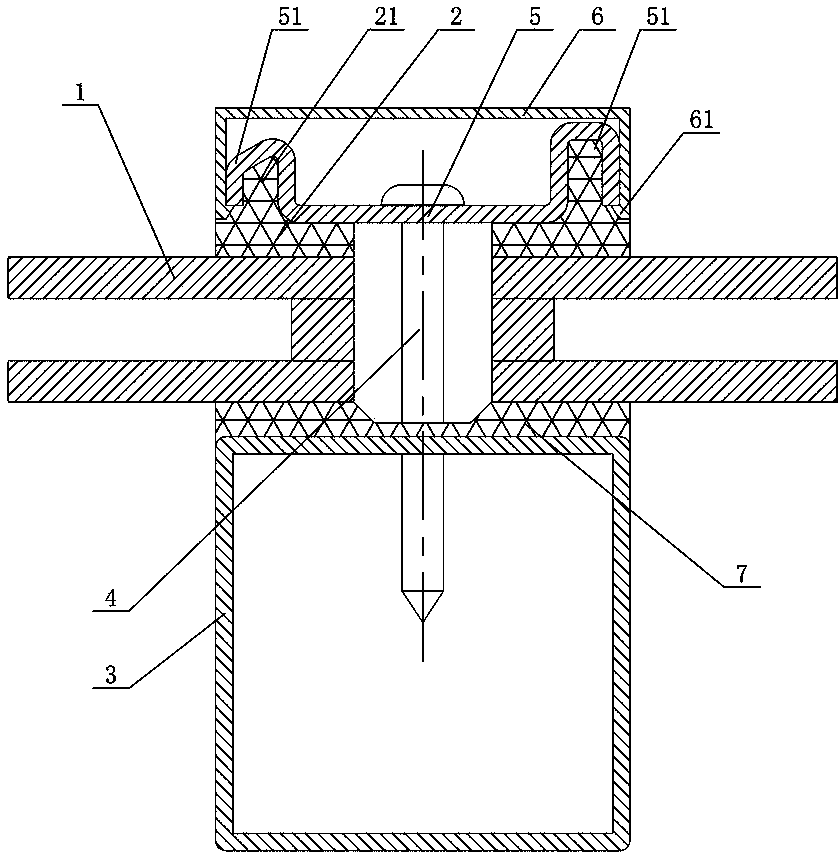

[0032] Such as figure 2 As shown, the second embodiment of the fireproof curtain wall system of the present invention, the curtain wall system is basically the same as Embodiment 1, the only difference is that the top edge of one of the U-shaped sides of the steel plate 5 is set as a hypotenuse, and the low position of the hypotenuse Located on the side close to the fastening portion 61, in this structure, by setting the top edge of the U-shaped side as a hypotenuse, and the low position of the hypotenuse is located on the side close to the fastening portion 61, so that when the decorative cover 6 is installed, it can First fasten a fastening part 61 of the decorative cover 6 with the other U-shaped side of the steel plate 5, and then slide the other fastening part 61 of the decorative cover 6 to the outer edge of the U-shaped side along the hypotenuse to form a buckled fit. Its structure is simple, which improves the convenience of installing the decorative cover 6 .

Embodiment 3

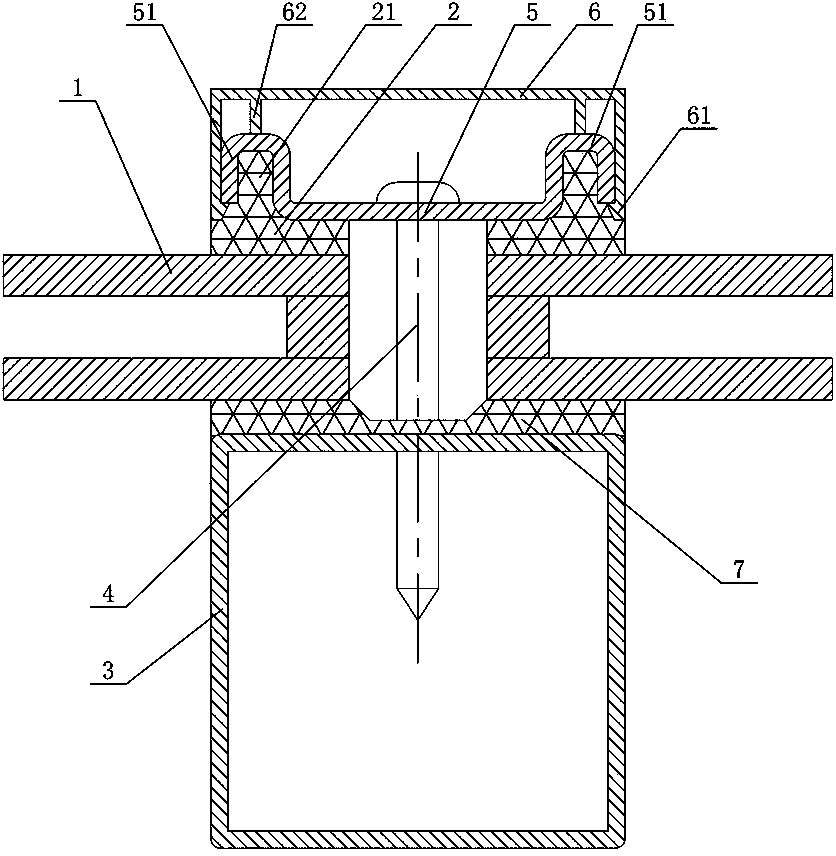

[0034] Such as image 3 As shown, the third embodiment of the fireproof curtain wall system of the present invention, the curtain wall system is basically the same as that of Embodiment 1, the only difference is that: the decorative cover 6 is provided with a limit reinforcement on the inner side of the top plate for abutting against the top of the bent portion 51 Rib 62 , the limiting reinforcing rib 62 is offset against the top of the bent portion 51 , on the one hand, it can prevent the steel plate 5 from moving upwards, and plays a role of limiting, on the other hand, it improves the strength of the decorative cover 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com