Aluminum radiator of improved riveting-embedding structure and riveting method

A radiator and riveting technology, which is applied in the field of aluminum radiators and riveting to improve the riveting structure, can solve the problems of accidental falling off, weak riveting pressure, and easy loosening of aluminum fins.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0091] The following are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

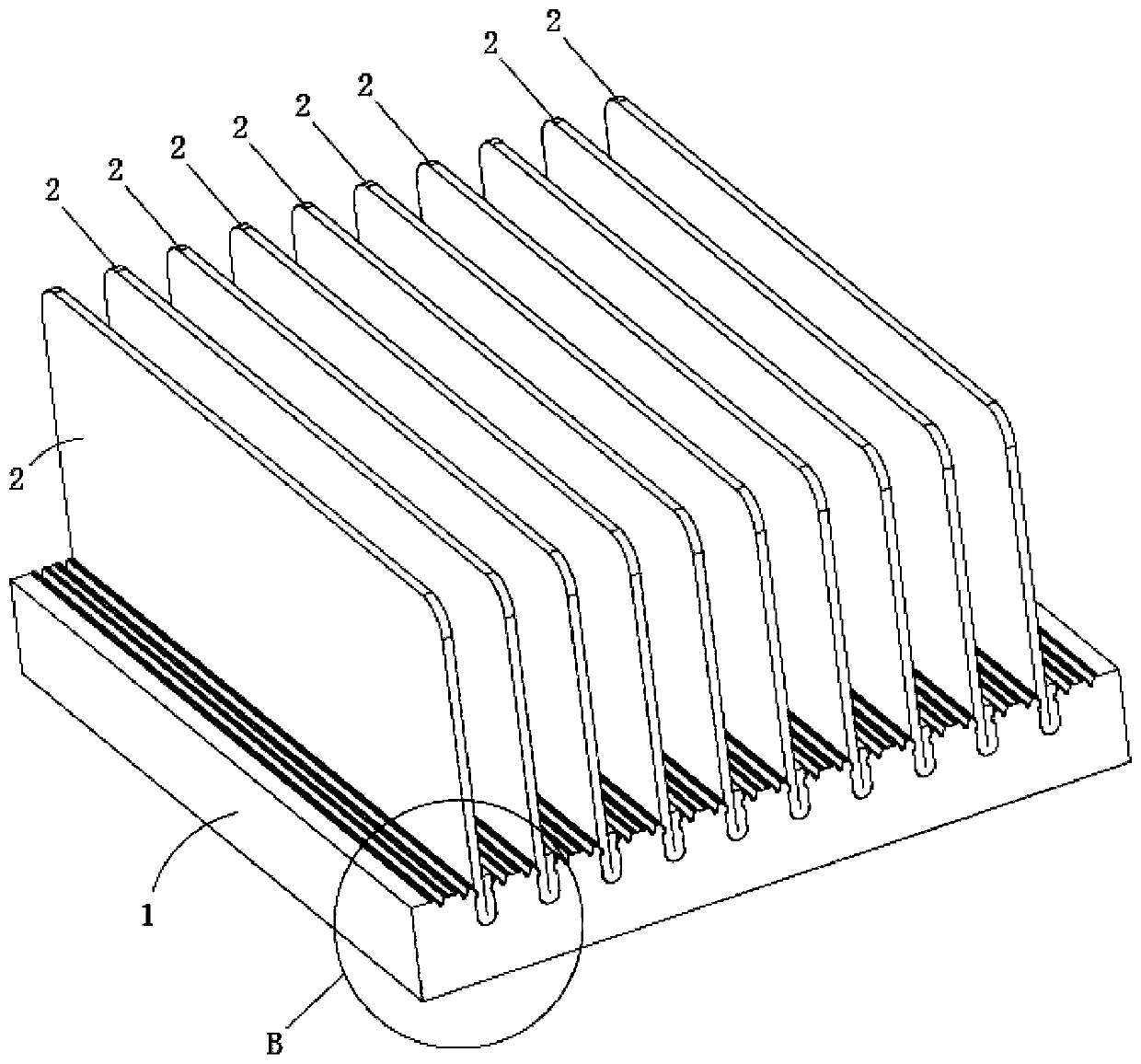

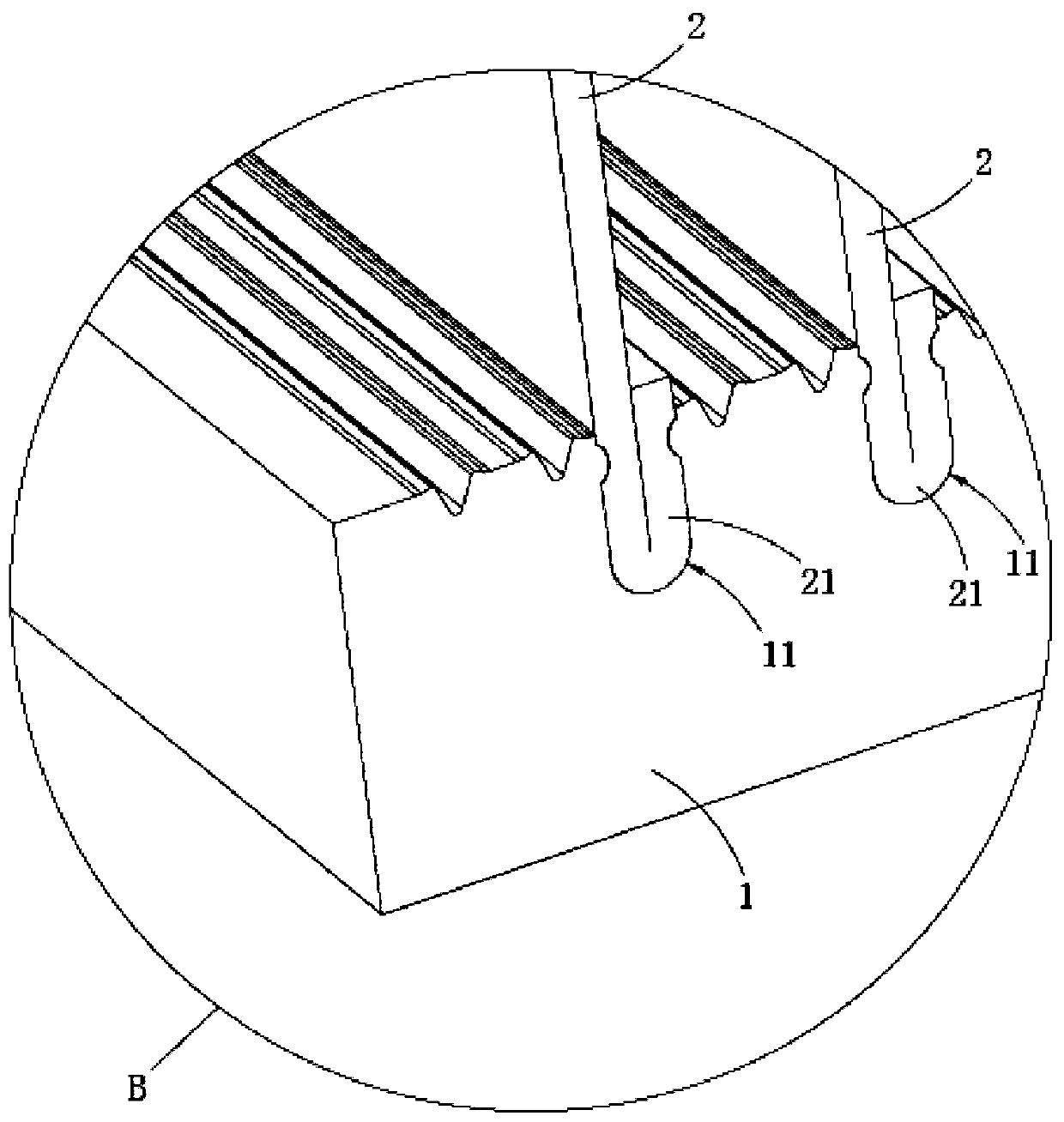

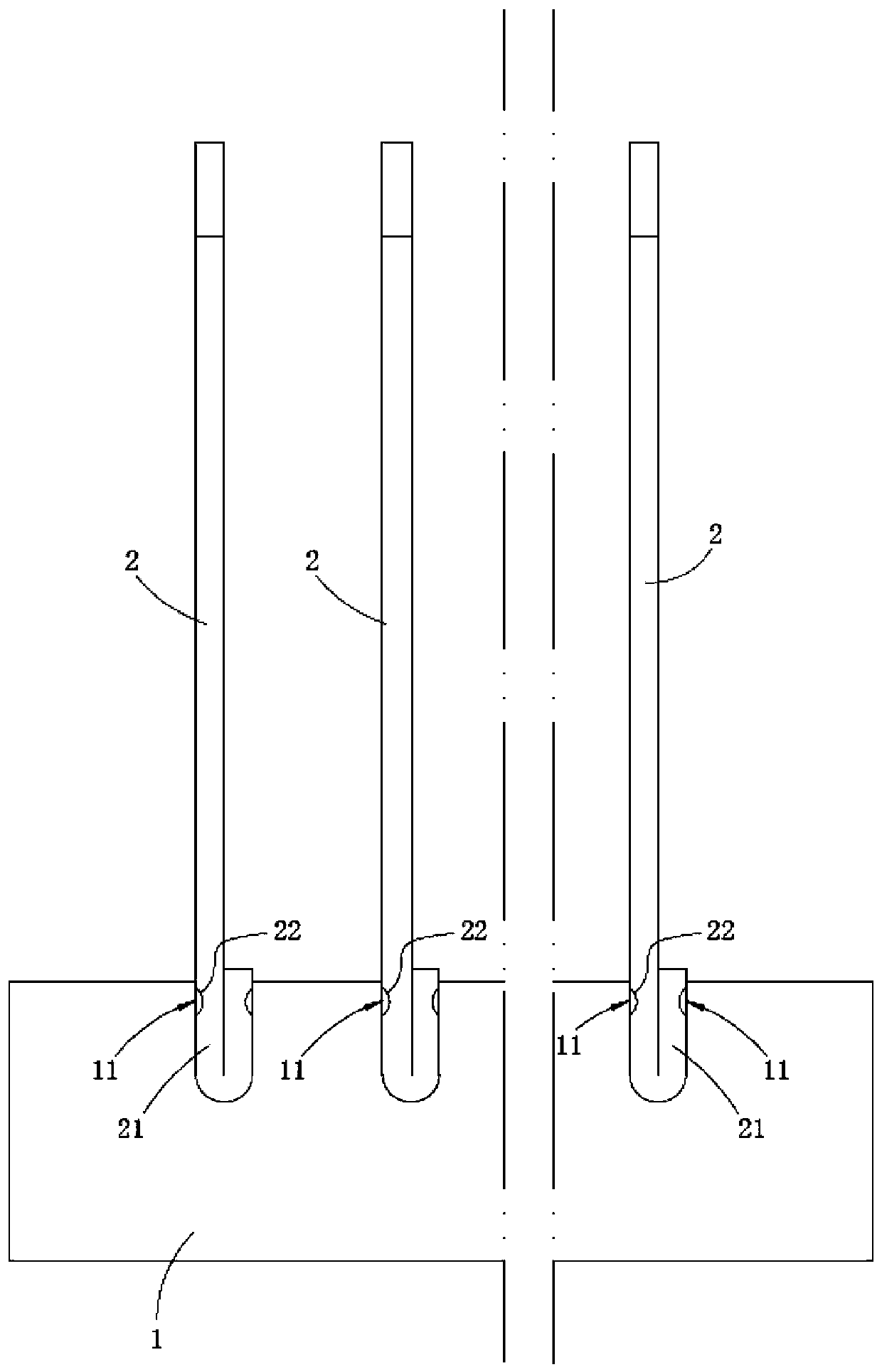

[0092] A method for riveting an aluminum heat sink, comprising a heat dissipation aluminum fin processing step, an aluminum base material processing step and a riveting processing step,

[0093] 1 heat dissipation aluminum fin processing steps, including the following sub-steps,

[0094] 1.1 The sub-step of machining heat-dissipating aluminum fins is to process aluminum materials to obtain a plurality of thin sheet-shaped heat-dissipating aluminum fins 2, and the lower parts of each heat-dissipating aluminum fins 2 are respectively provided with riveting parts 21; specifically, through machining Form the riveting part 21, bend the lower end of the heat dissipation aluminum fin 2 upwards and reversely and overlap and press it on the lower part of the heat dissipation aluminum fin 2, so as to form a U-shaped riveting at the low...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com