Patents

Literature

69results about How to "Strong riveting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

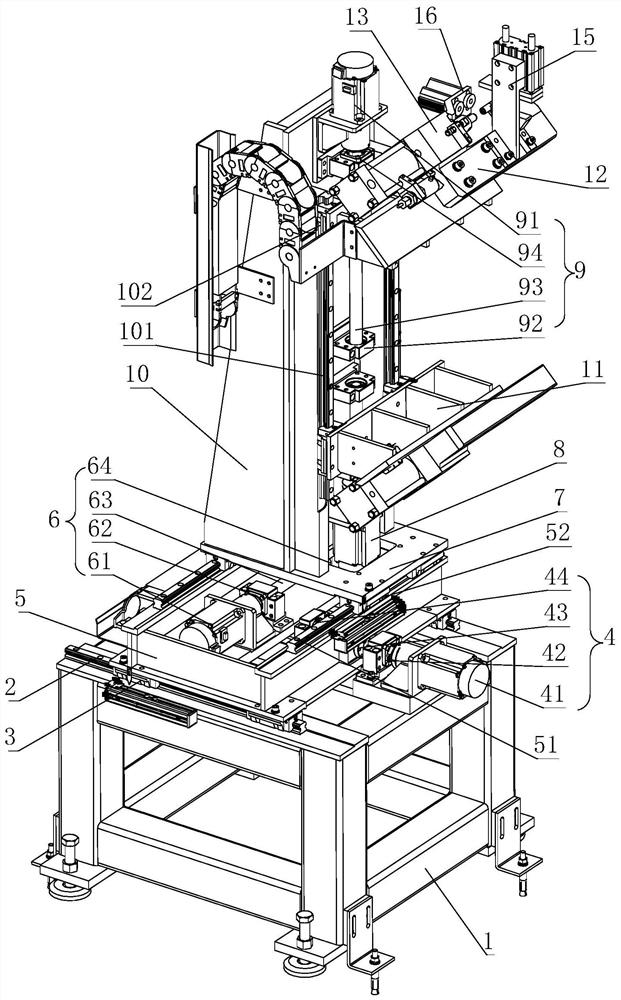

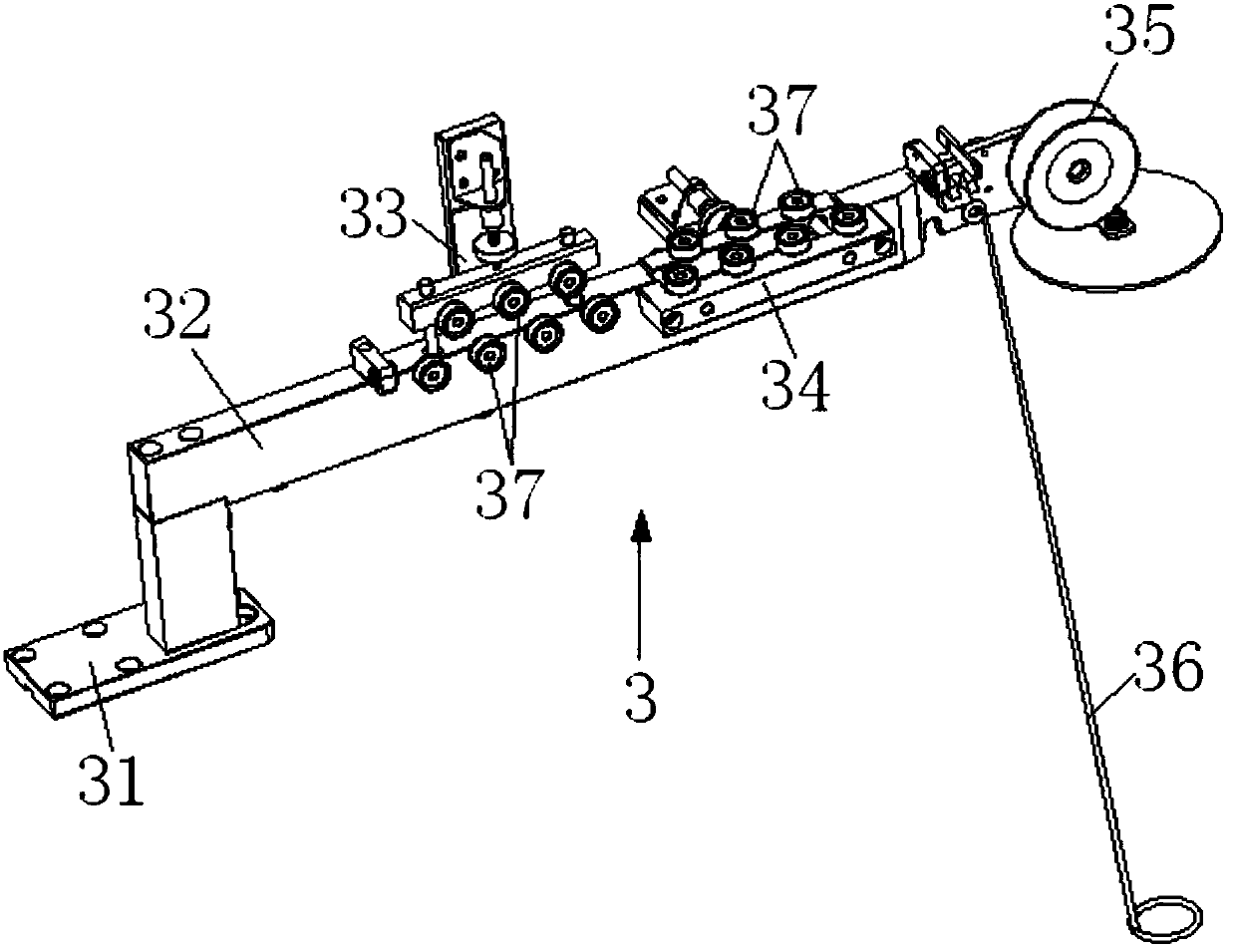

Full-automatic wire rod single-end terminal press fitting wetting machine

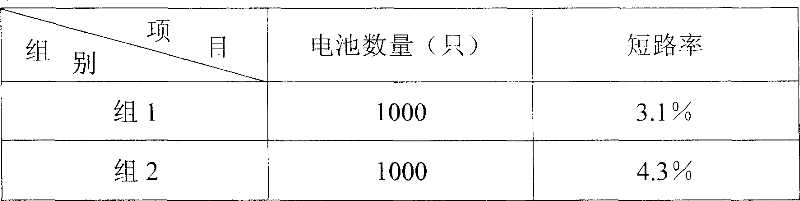

ActiveCN105790036AAccurate rivetingReduce error rateConnection formation by deformationPhysicsWire cutting

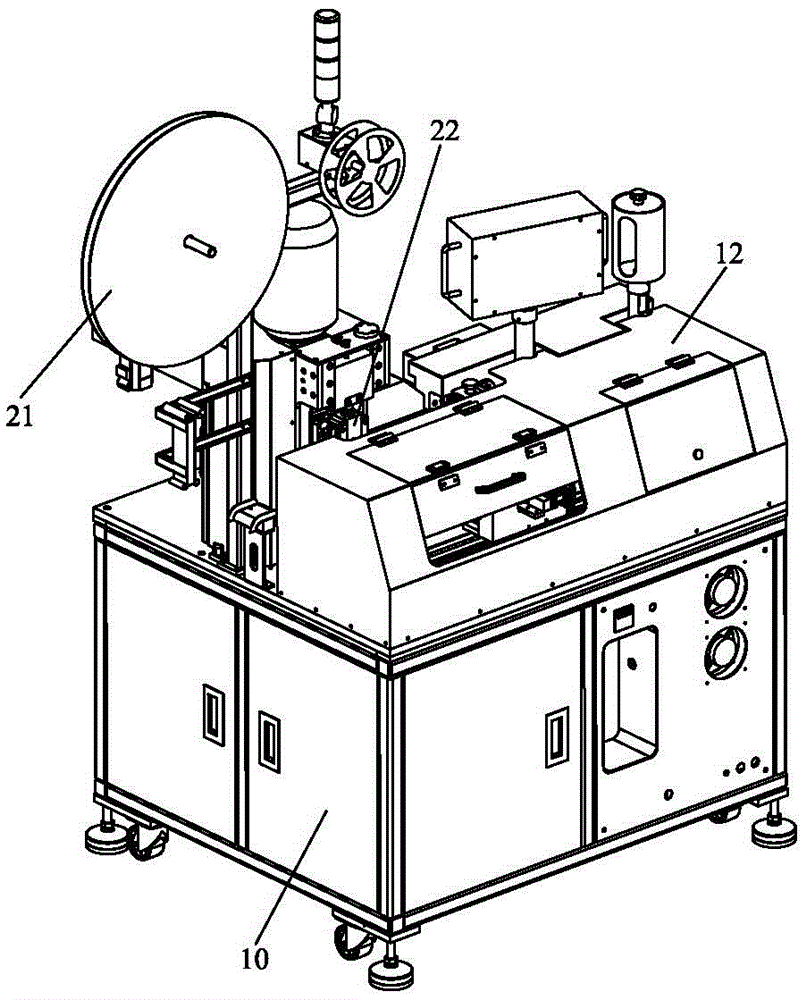

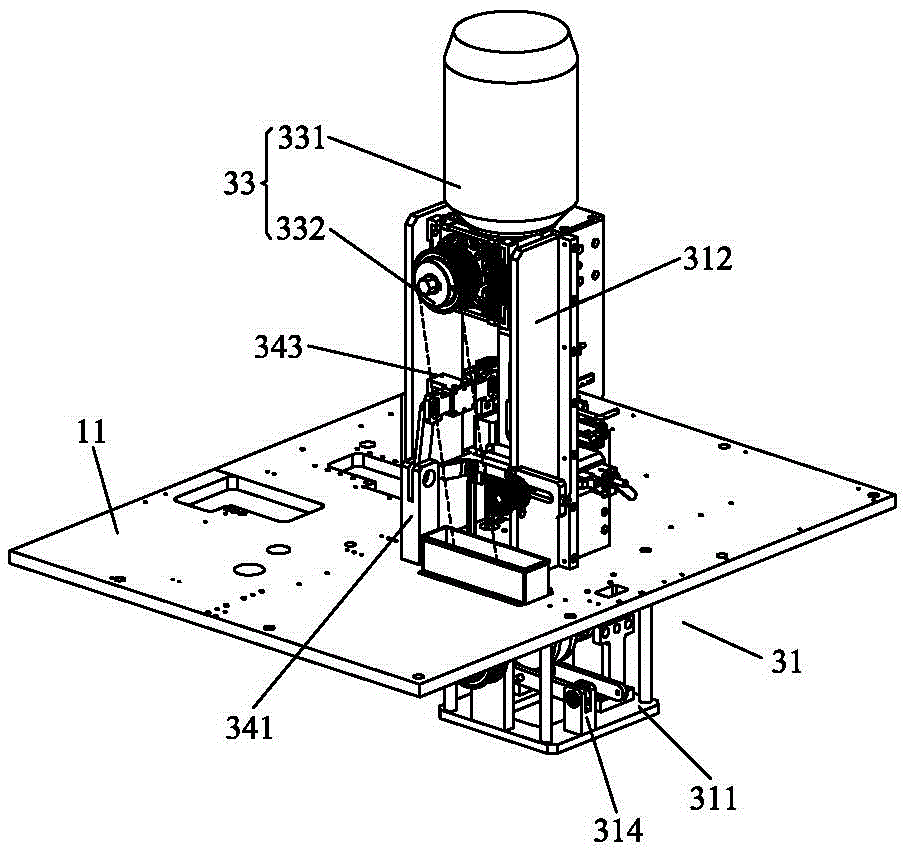

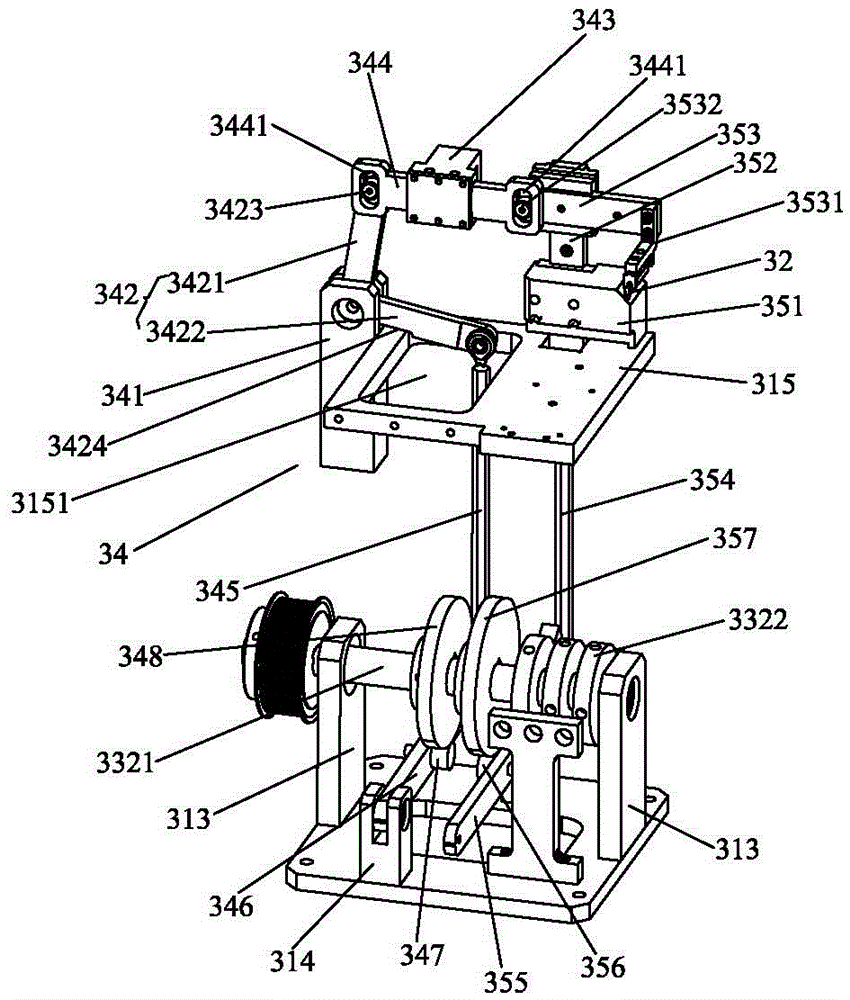

A full-automatic wire rod single-end terminal press fitting wetting machine disclosed by the present invention comprises a rack, a terminal conveying and press fitting mechanism, a branching mechanism, a wire rod moving mechanism, a wire cutting, peeling and twisting mechanism, a wire pulling and clamping mechanism and a wetting mechanism. The rack is equipped with a workbench, the wetting machine utilizes the wire rod moving mechanism to move the wire rods to the branching mechanism and the terminal conveying and press fitting mechanism to branch the wires and press fit the terminals, and then the wire rods are cut, peeled, twisted, wetted with the soldering flux and the tin, so that the above mechanisms are integrated on the rack, and all the wire rods can be separated and straightened before the terminals are press fitted, and accordingly, the terminals and the wire rods are riveted more accurately and firmly. The wire rods can be cut, peeled and twisted automatically, so that the wire rod processing efficiency is improved. Moreover, the wire rods are wetted with the soldering flux and the tin automatically, so that that the operations of branching, terminal press fitting, cutting, peeling, twisting, wetting with soldering flux and tin of the wire rods all can be finished automatically, the artificial workload and the production cost are reduced, and the production efficiency is improved.

Owner:东莞市超日自动化设备科技有限公司

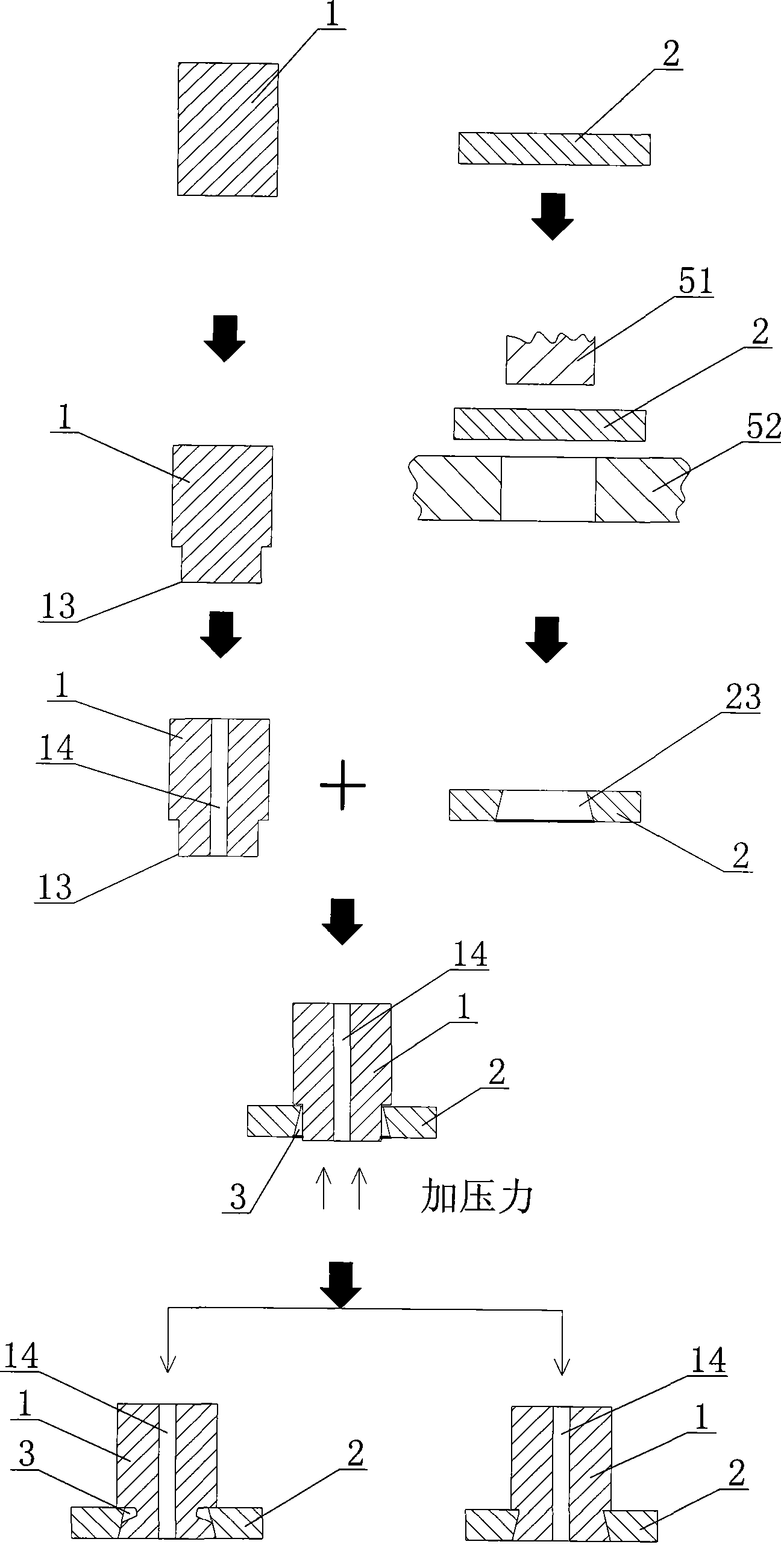

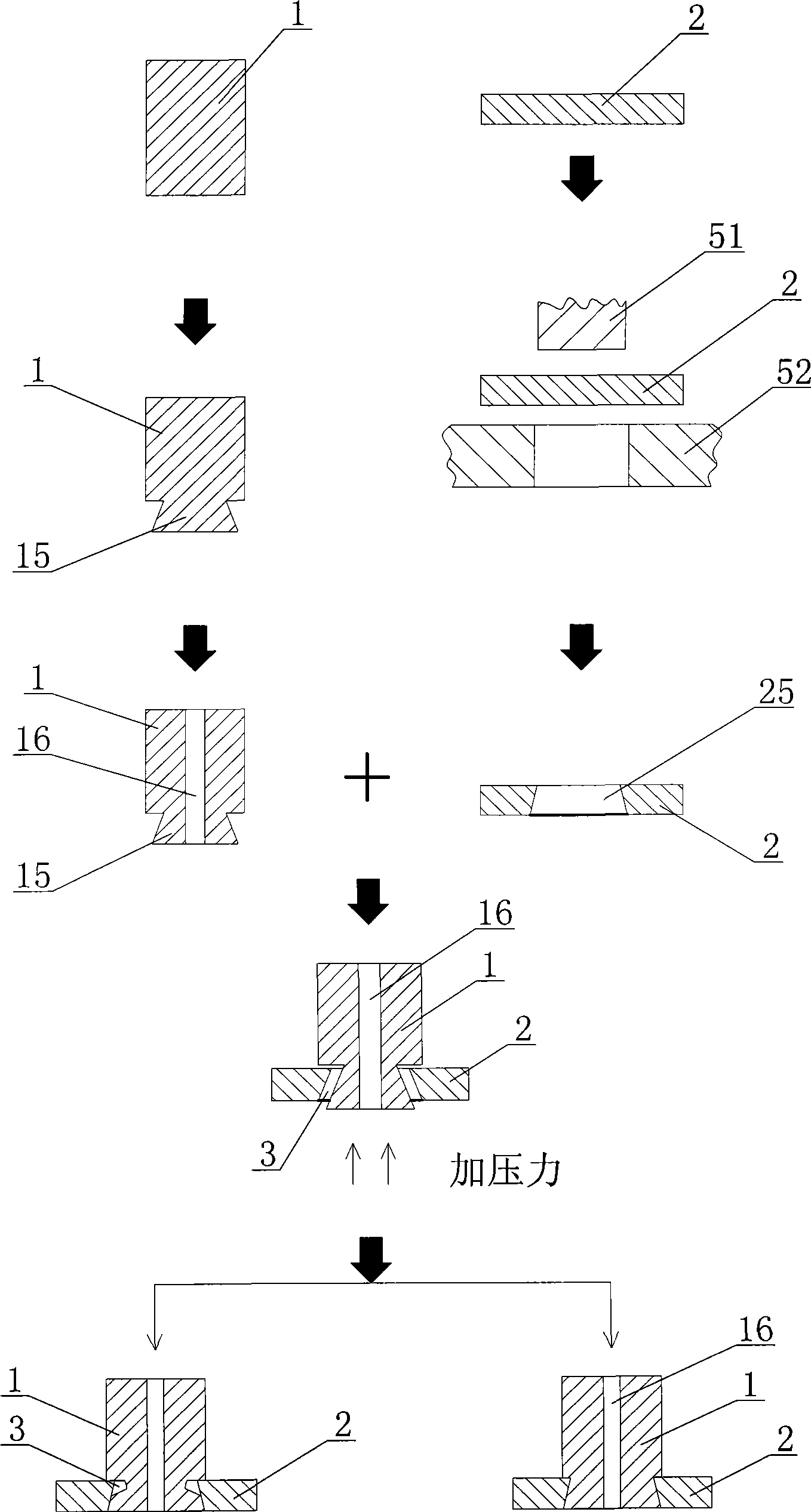

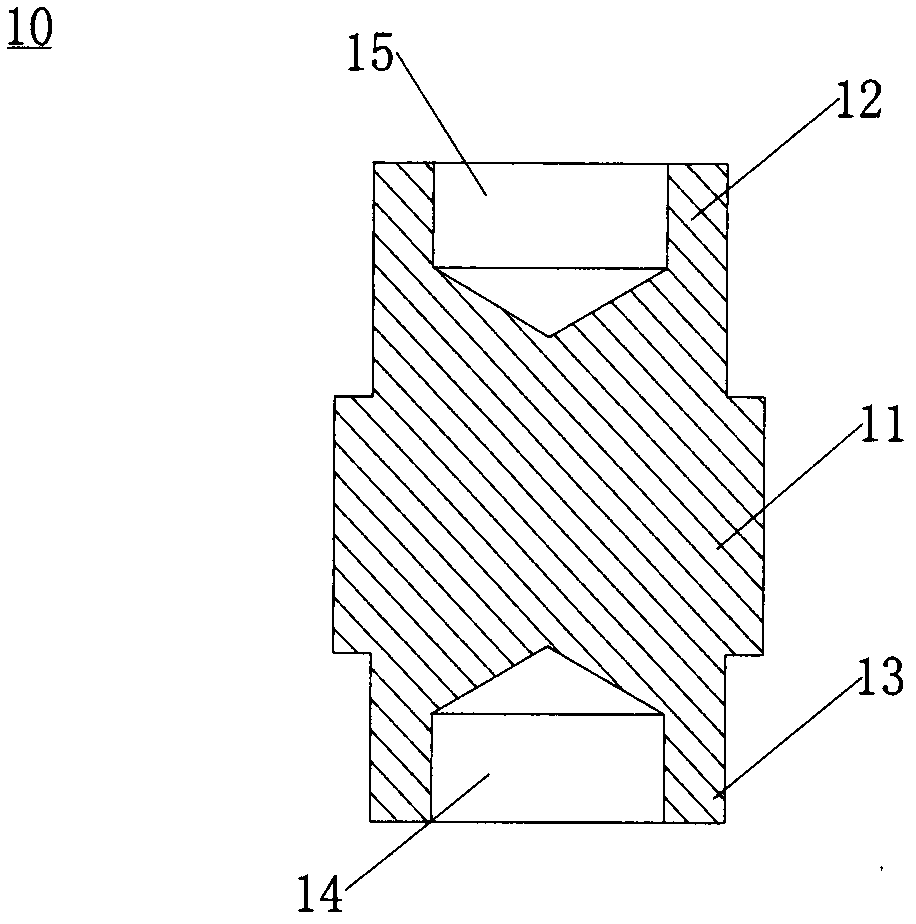

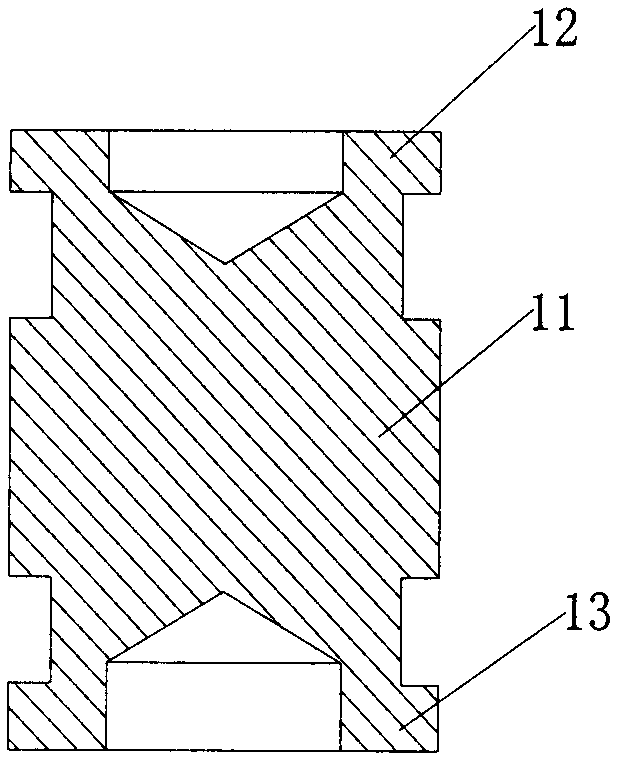

Riveting method

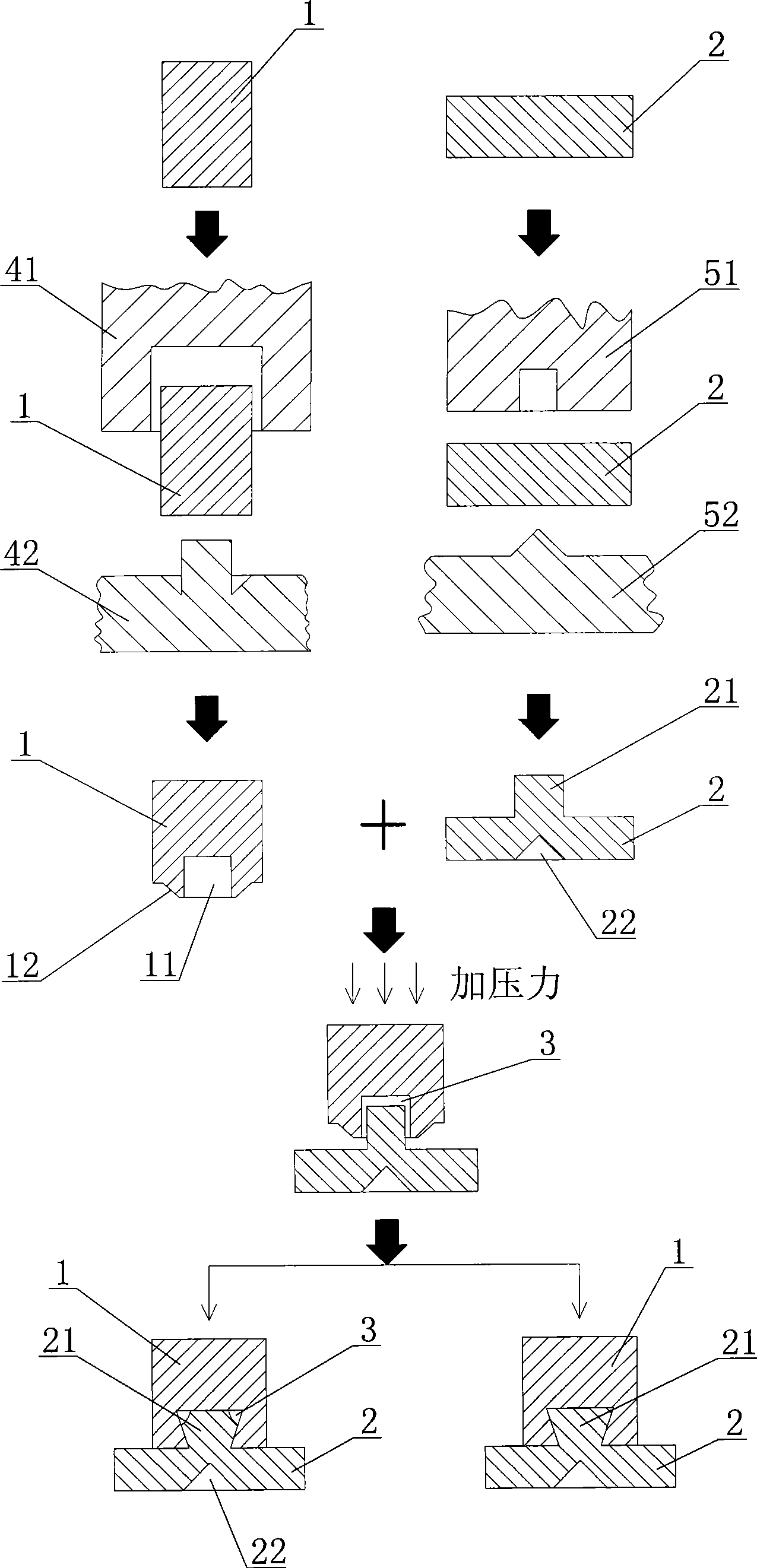

The invention relates to a riveting method, which comprises the following steps: firstly, two metal elements to be riveted are pretreated by utilizing the prior machining method of punching or lathe processing, and a gap is formed on a riveted point of the two metal elements to be riveted; and secondly, pressure is applied on the riveted point of the two metal elements to be riveted through combined punched riveting, so that the two metal elements mutually extrude and fill up the gap to form firm connection. The riveting method adopts the two-step method of combining pretreatment by the prior machining method and filling of hollow cavities and expanded angles, and performs the pretreatment of certain shape on the metal elements to be mutually riveted by utilizing the prior machining method of punching or lathe processing first; after the riveted point is formed, the combined punched riveting is used to make the two metal elements provided with the hollow cavities before combination mutually extrude influenced by punching and fill up the hollow cavities to form a reversely suspended locking mechanism which is partially filled or fully filled, so the aim of firm riveting is achieved.

Owner:李殷德

Double-end pressure riveting method, riveting pin and pressure riveting device

Owner:SUZHOU DONGFENG FINEBLANKING ENG

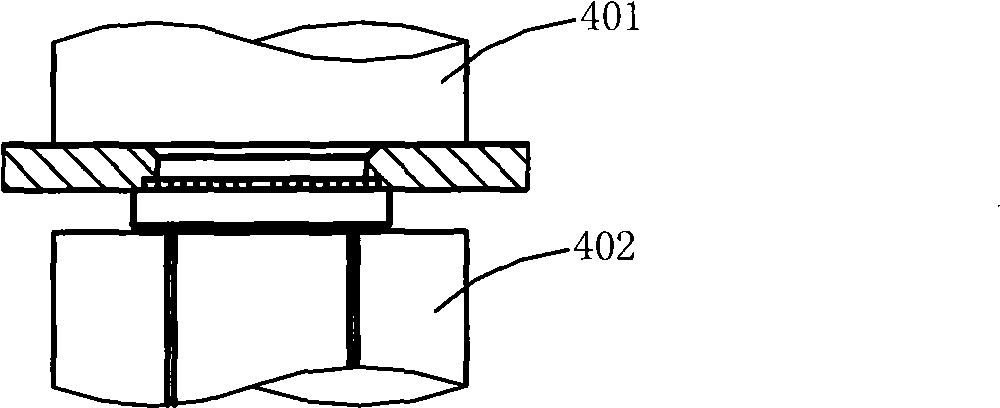

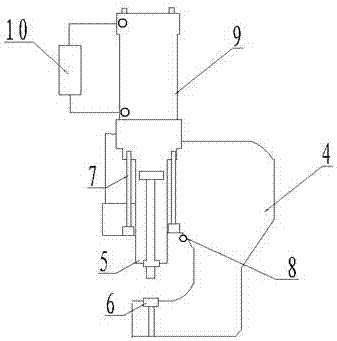

Riveting processing device of magnetron

The invention provides a riveting device of a magnetron, which comprises a machine body, a positioning seat which is used for fixing the magnetron and a riveting head which makes horizontal movement are arranged on the machine body, wherein the positioning seat is arranged on the surface of a lifting table, and the riveting head is arranged on worktables at both sides of the lifting table and always moves along the horizontal direction above the lifting table. The riveting head is provided with an outer riveting head and an inner riveting head, a gap is reserved between the two riveting heads, and a gap is also reserved between the outer riveting head and the inner edge of a mounting seat, and the size of each gap is slightly larger than the thickness of the magnetron outer shell. The riveting device uses a general structure filter box as a positioning object and a clearance is reserved between the riveting heads to make the device suitable for riveting magnetrons with various specifications. When the lifting table is lifted to a certain position and is delayed for a certain period, and cylinders at both sides push the riveting heads simultaneously during the delay to make an end cover buckle with the outer shell. The riveting device is simple and reasonable in the structure, stable and accurate in riveting, is low in rework and scrap.

Owner:GUANGDONG GALANZ GRP CO LTD

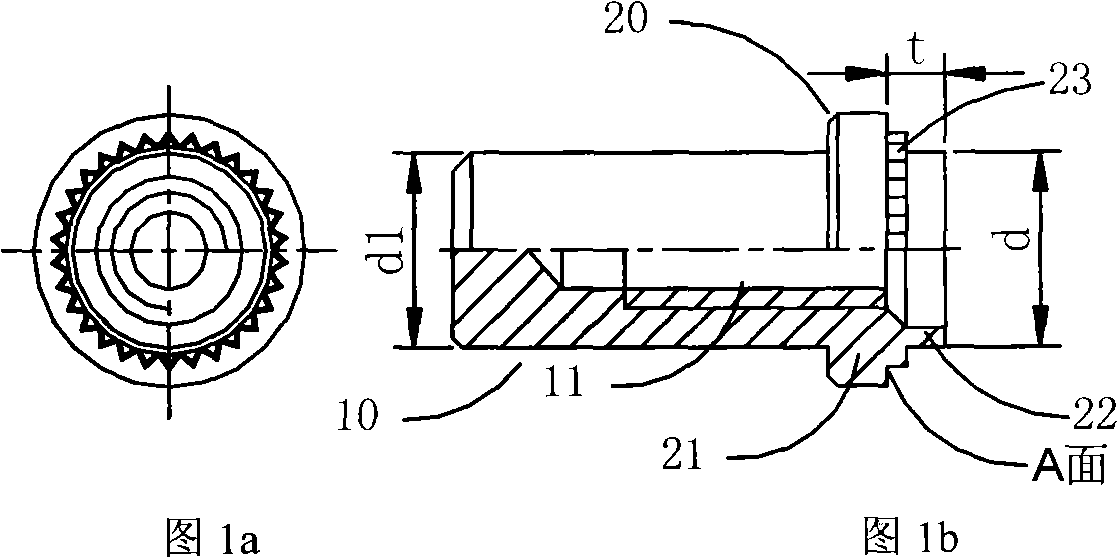

Riveting connector

InactiveCN101504023AImprove the axial bearing capacityLarge radial torque resistanceSheet joiningMetallic materialsEngineering

The invention discloses a riveting connecting piece, which comprises a connecting part and a riveting part, wherein a through threaded hole or a blind threaded hole is formed in the riveting connecting piece preferentially, and the inside diameter of the hole is smaller than that of the riveting part; naturally, the hole can be a through hole or a blind hole arranged in the riveting connecting piece so as to adopt other connecting modes; the connecting part is used for connecting other components, and the riveting part is used for riveting and tightening with a sheet material to be riveted; the riveting part is hollow inside and comprises a base part and a deformed riveting column; the deformed riveting column is of a short pipe shape, the bottom thereof is provided with annularly-distributed pointed teeth towards the outside to prevent rotation, one end face of the base part contacts with the sheet material to be riveted, the other end of the base part is connected with the connecting part, and the outside diameter of the pointed teeth is smaller than that of the base part; the material of the riveting connecting piece is a plastic deformation material of which the strength is higher than that of the sheet material to be riveted, and the material is preferably stainless steel, or other metallic materials or nonmetal materials. The riveting connecting piece not only has stronger axial bearing capacity, but also has stronger radial twisting resistance, thus the riveting is firmer.

Owner:ZTE CORP SHENZHEN CITY

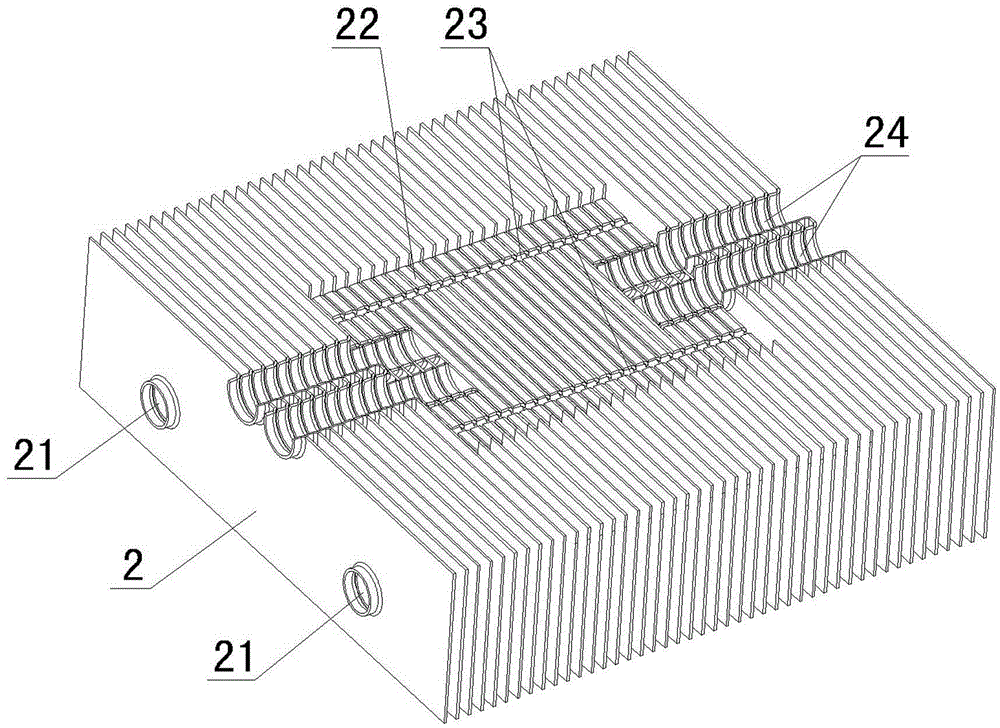

Aluminum radiator of improved riveting-embedding structure and riveting method

PendingCN110284142AFast heat conductionSimple processAnodisationMetallic material coating processesInterference fitAluminum substrate

The invention discloses an aluminum radiator of an improved riveting-embedding structure and a riveting method. After a riveting-embedding portion of each radiating aluminum fin is subjected to surface activation treatment, a nonporous solid blocking layer and a porous viscidity layer are attached to the surface of the riveting-embedding portion; after riveting-embedding grooves of an aluminum substrate are subjected to surface activation treatment, an aluminum oxide passivating film layer is attached to the surface of each riveting-embedding groove; and the riveting-embedding portions are in interference fit with the riveting-embedding grooves after riveting-pressing machining is conducted, clearances formed between the riveting-embedding portions and the riveting-embedding grooves are filled with the porous viscidity layers of the riveting-embedding portions after riveting-pressing deformation, and the porous viscidity layers of the riveting-embedding portions are in engaging fit with the aluminum oxide passivating film layers of the riveting-embedding grooves. According to the aluminum radiator of the improved riveting-embedding structure and the riveting method, the process is simple, riveting is firm, structure loosing or falling is not prone to occurring, and the heat conduction speed at the riveting joint is high.

Owner:DONGGUAN JIFU METALLIC PROD CO LTD

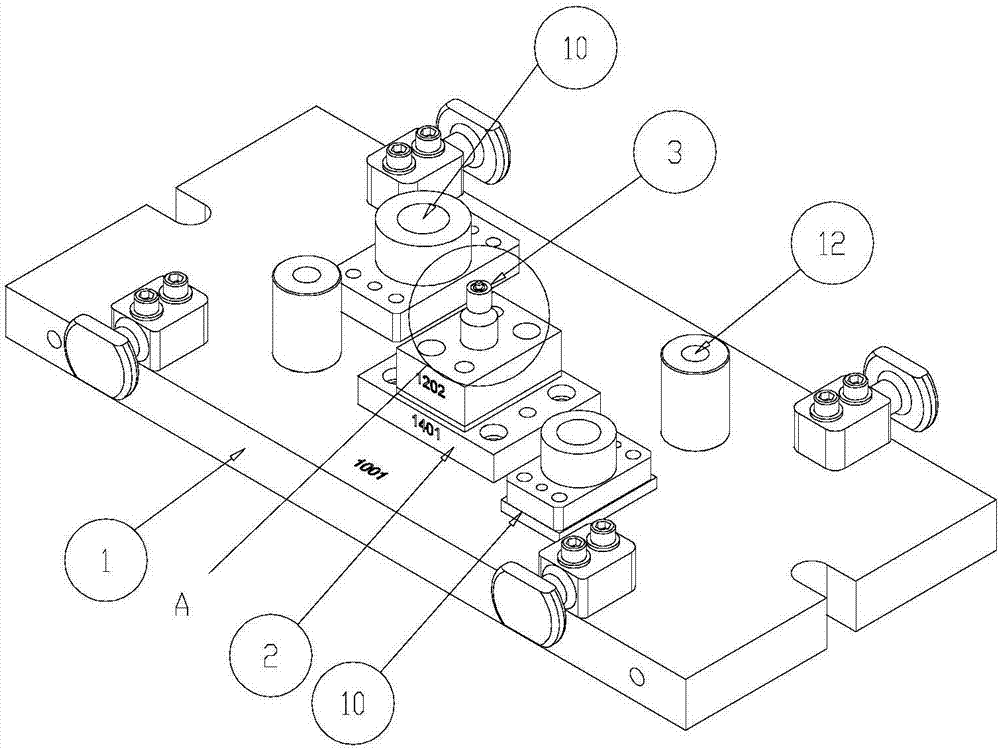

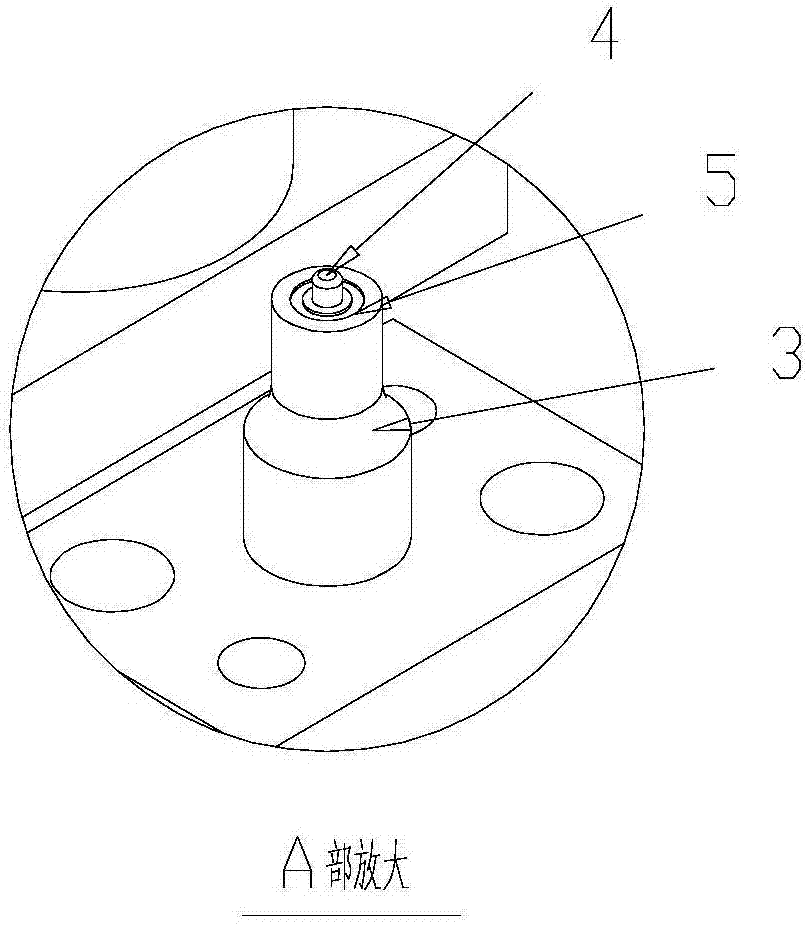

Airtight detection device

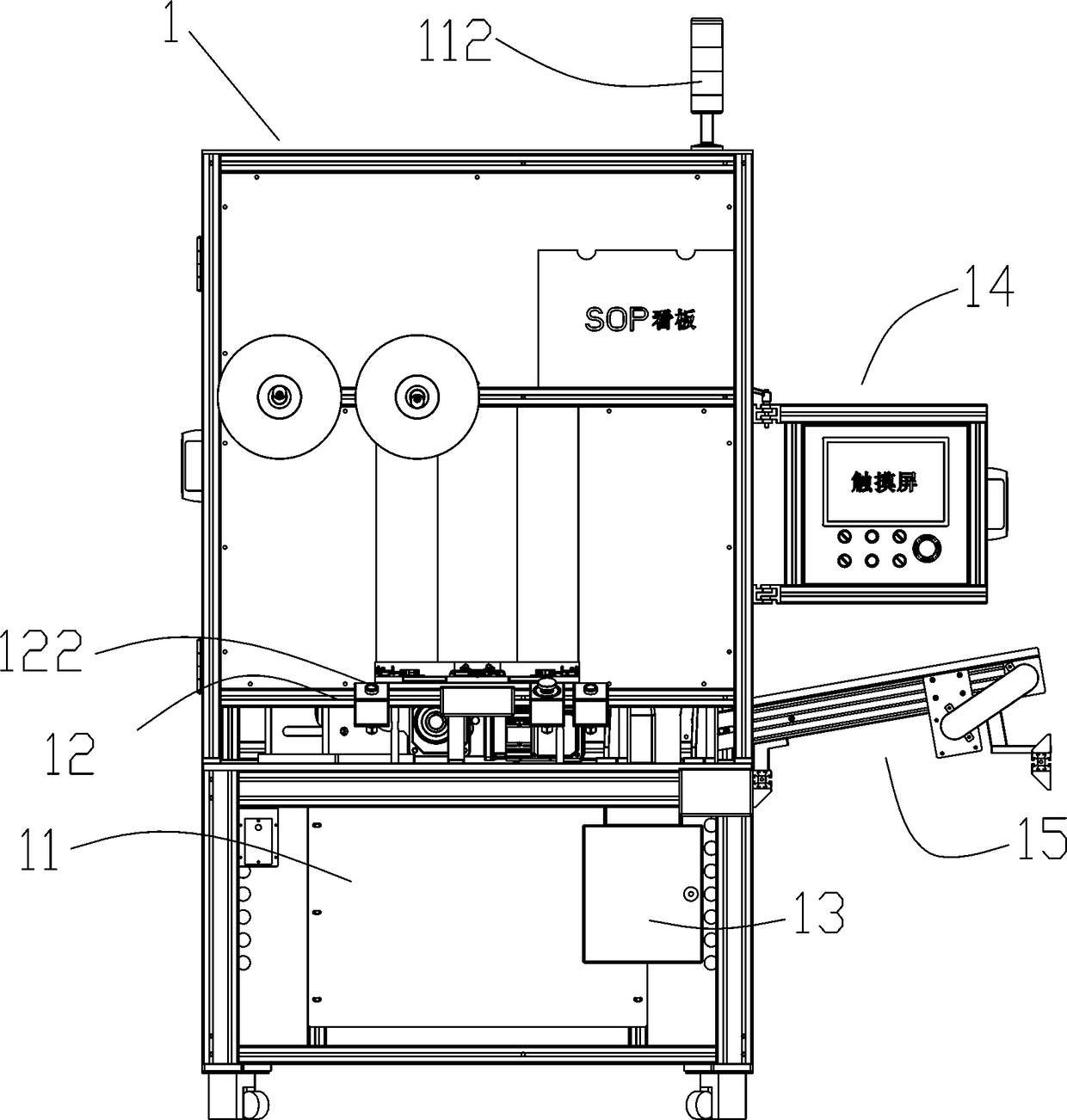

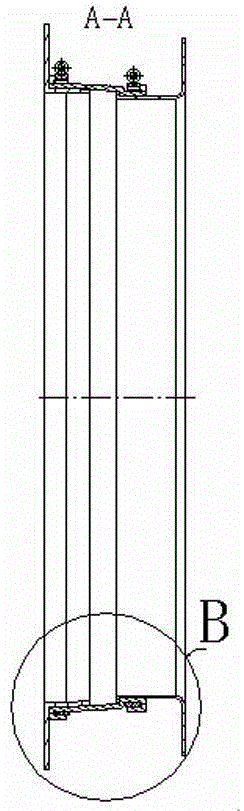

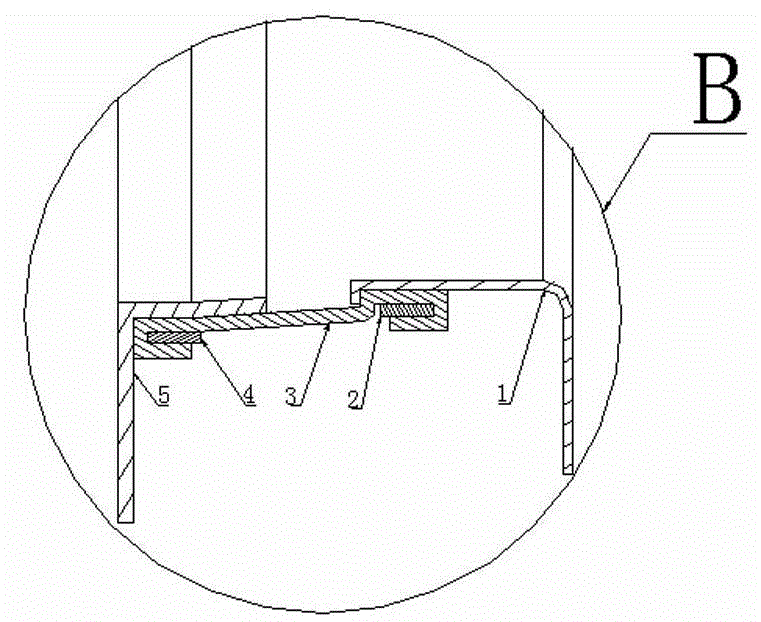

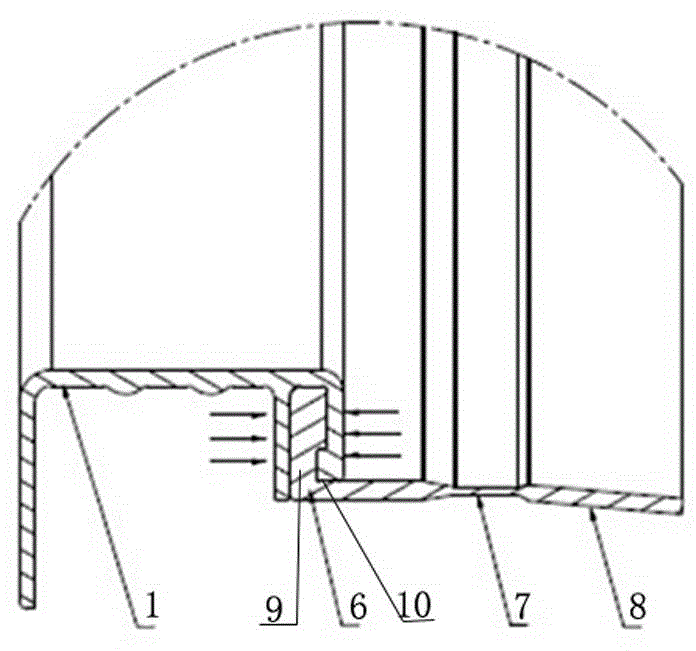

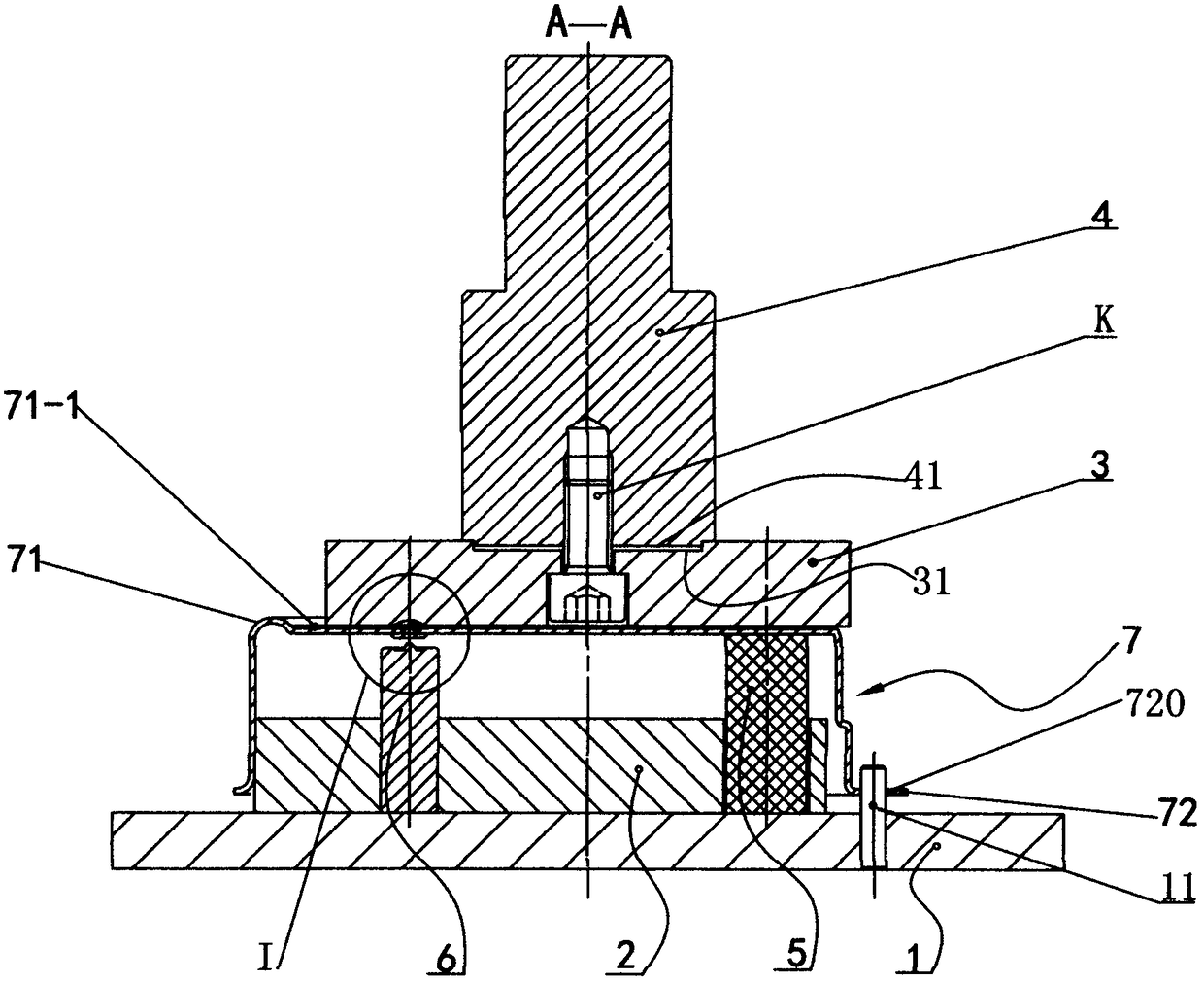

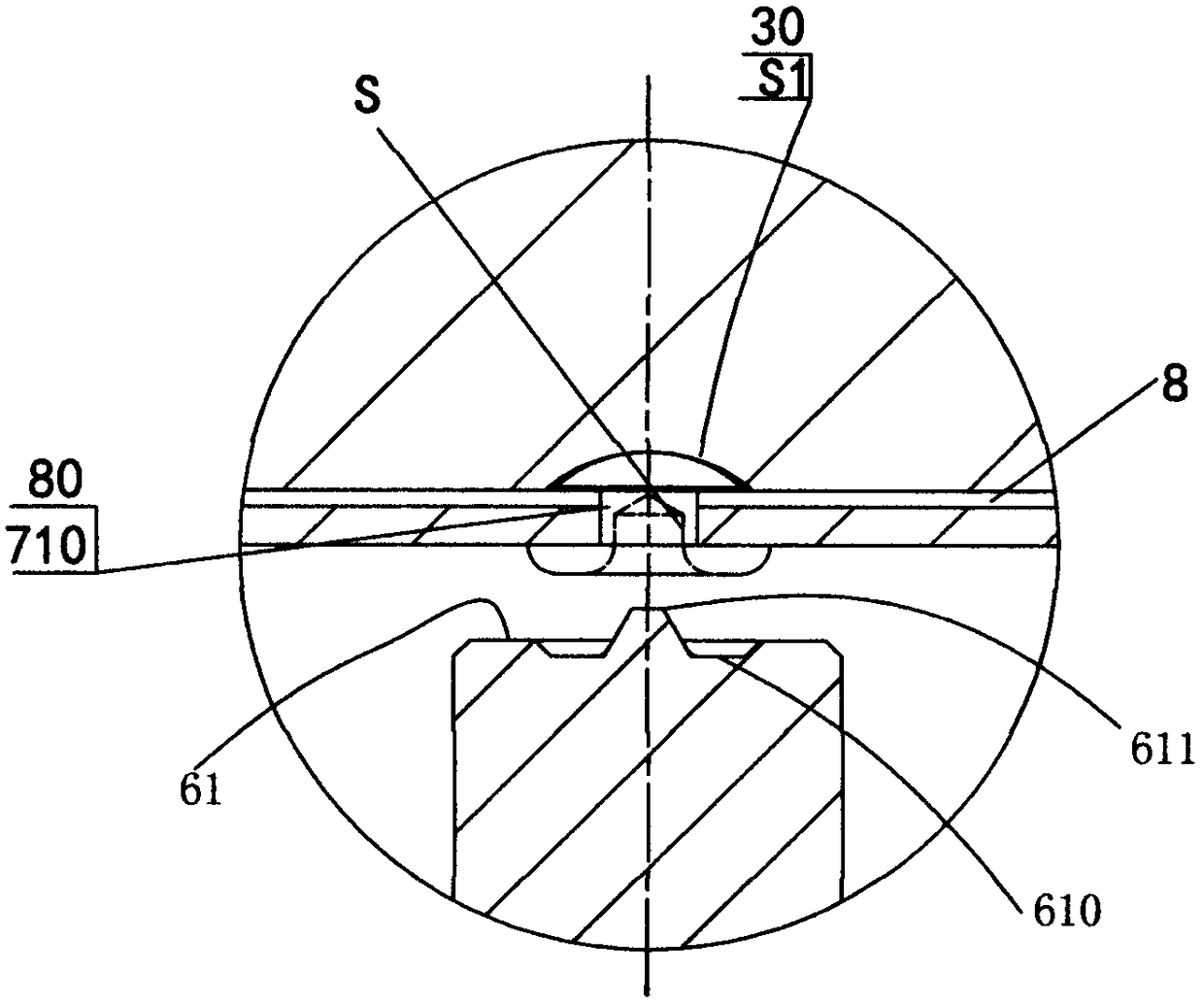

PendingCN109060269AAchieving height detectionReduce lossMeasurement of fluid loss/gain rateElectrical/magnetic thickness measurementsEngineeringManipulator

The invention discloses an airtight detection device, comprising an integral body frame. The integral body frame is provided with an airtight detection zone, an operation zone and an unqualified workpiece placement zone from top to bottom, wherein the operation zone is provided with a working platform; the working platform is provided with a rotary disc mechanism; the airtight detection zone is provided with an airtight detector; the unqualified workpiece placement zone is provided with a waste material box; the rotary disc mechanism is electrically connected with a control box; the working platform is provided with a feeding mounting device, an elastic sheet riveting device, an integral airtight detection device, a thin film airtight detection device, an elastic sheet height detection device and a mechanical arm material distributing device which are electrically connected with the control box in sequence along a material conveying direction; one side of the working platform is connected with a material conveying channel; and the outer portion of the integral body frame is provided with a touch screen and an SOP watch plate. According to the airtight detection device, mechanical automation can be achieved, detection efficiency can be improved, workpiece loss can be reduced and airtight detection accuracy can be improved.

Owner:SUZHOU INST OF INDAL TECH

Pressing rivet structure of automobile engine wind shielding ring assembly

InactiveCN106321223AConvenient riveting structureThe pressure riveting structure is firm and reliableMachines/enginesEngine cooling apparatusEngineeringOpen type

The invention provides a pressing rivet structure of an automobile engine wind shielding ring assembly. The open-type pressing rivet structure is arranged on the outer wall or the inner wall of a journal of a wind shielding ring. The pressing rivet structure is characterized in that the opening of the open-type pressing rivet structure faces outwards or inwards; the included angle between the opening direction of the open-type pressing rivet structure and the outer wall or the inner wall of the journal of the wind shielding ring ranges from 0-90 degrees; the number of the opening of the open-type pressing rivet structure is one or two, and a boss is arranged on the inner wall of the opening; and the side edge of the outer circumference or the inner circumference of the opening of the open-type pressing rivet structure is folded upwards so that the opening of the open-type pressing rivet structure can be in a half-surrounded structure. The pressing rivet structure is convenient to implement, and the pressing rivet force application direction is parallel to the axis direction of the wind shielding ring, that is, the force application direction ranges from 0-90 degrees. Thus, limitation of pressing rivet equipment and pressing rivet operation space on pressing rivet force application is small, the opening of the pressing rivet structure can shrink easily, proper elastic deformation of a rubber sealing ring is ensured, that is, the opening of the pressing rivet structure shrinks so that the rubber sealing ring can be deformed elastically, then the rubber sealing ring is tightly clamped, and the wind shielding ring is formed.

Owner:湖北晟正汽车零部件有限公司

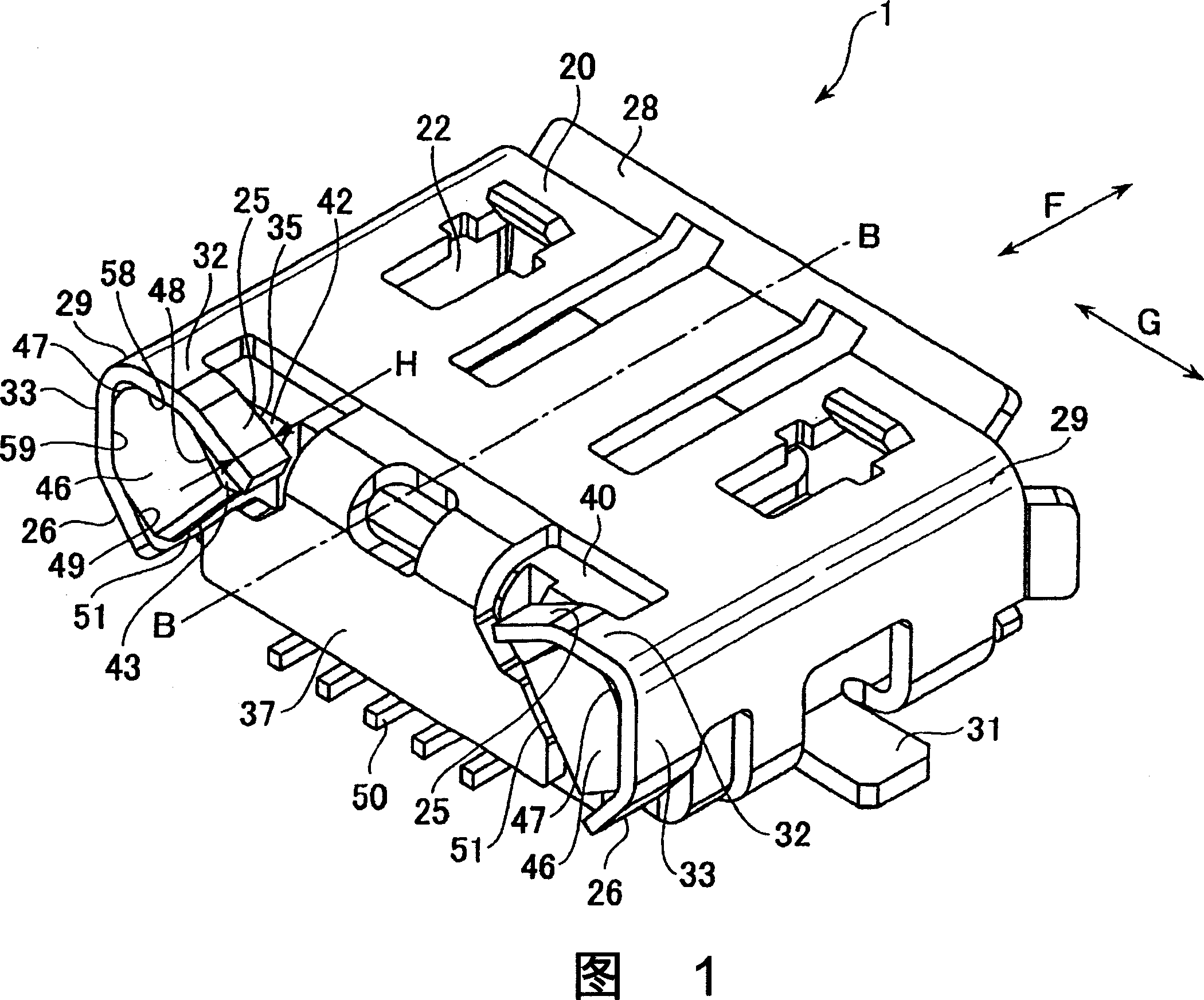

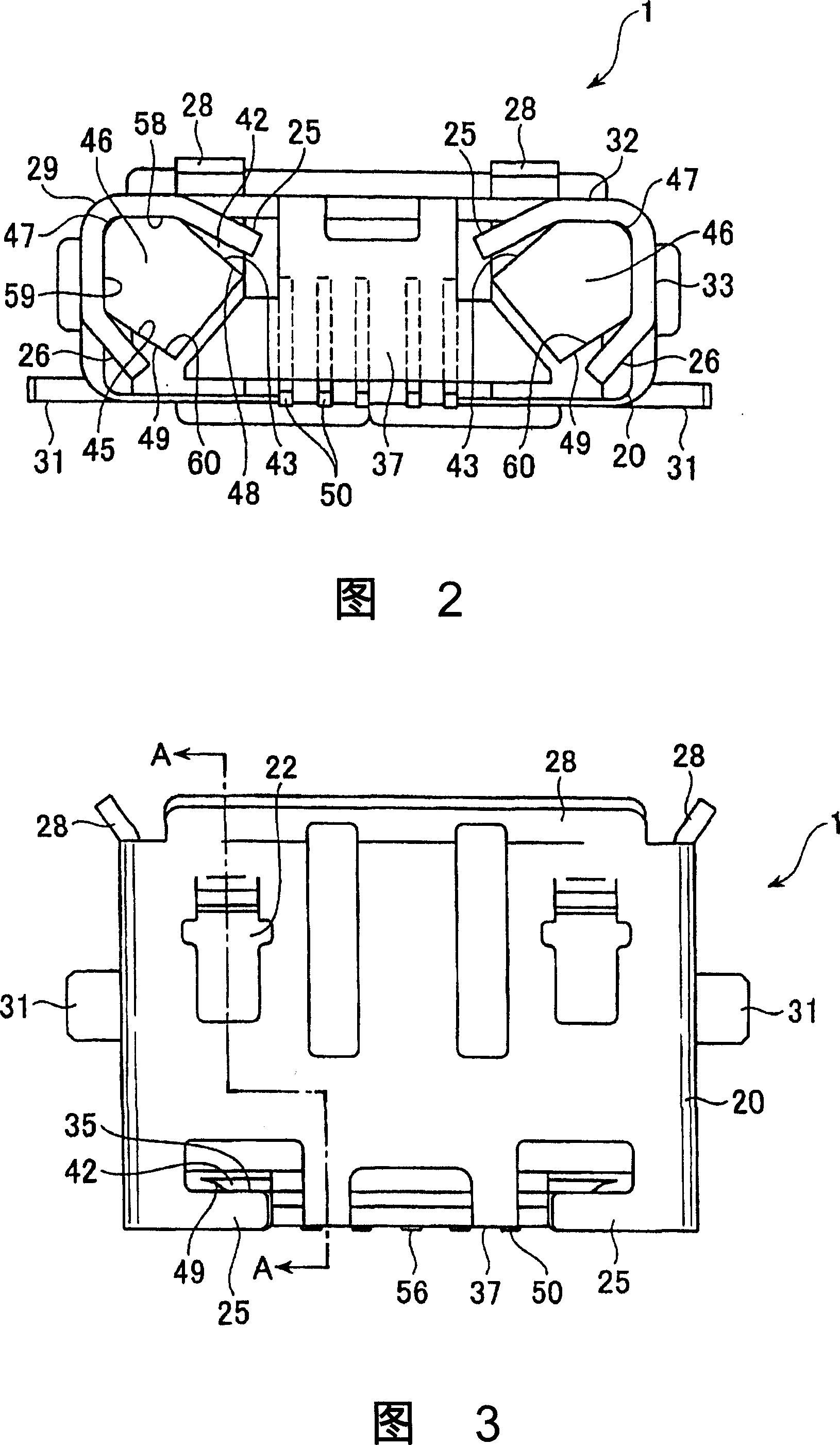

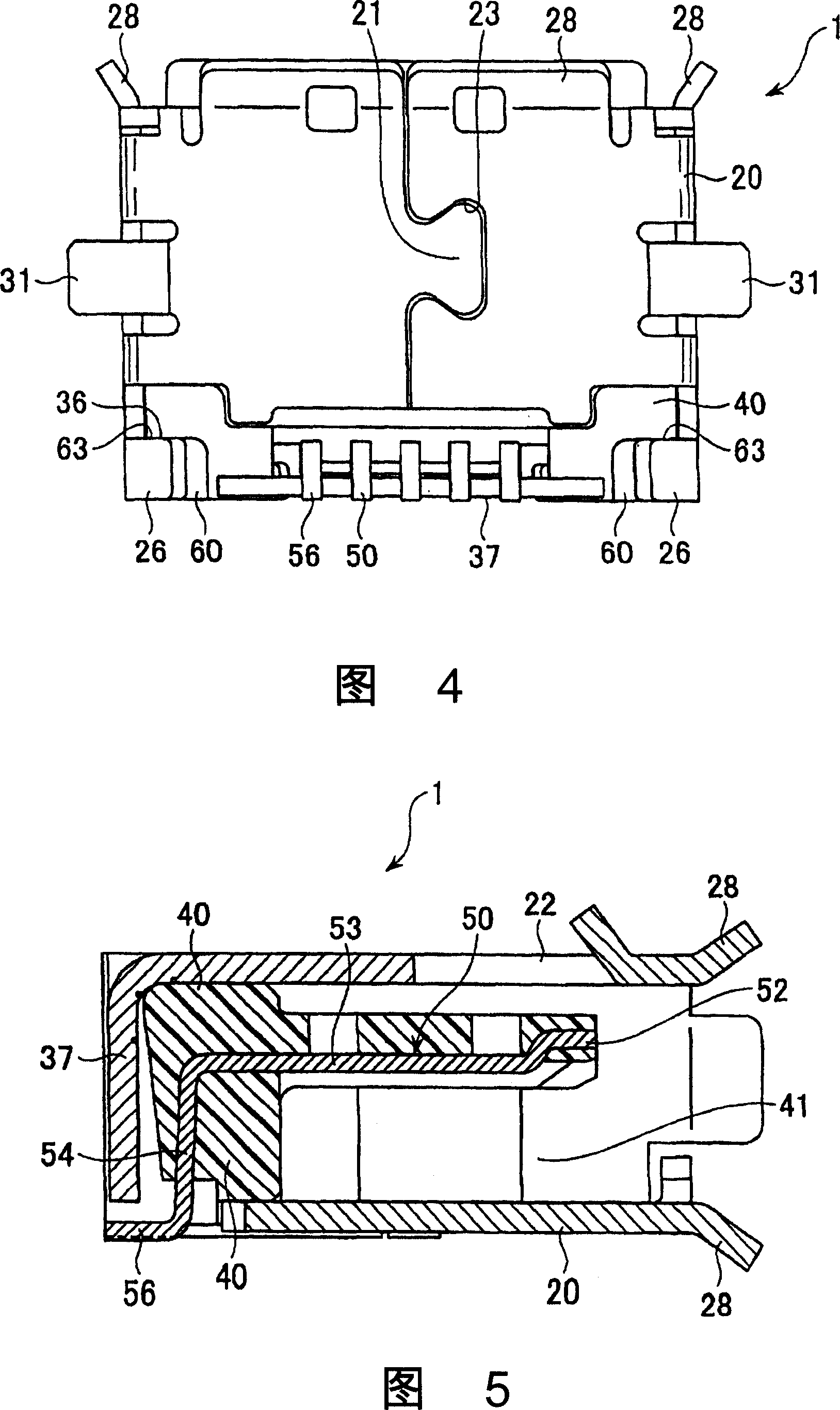

Connector

InactiveCN101017943AStrong rivetingCouplings bases/casesTwo-part coupling devicesEngineeringClose contact

A connector includes a housing, a housing cover for covering at least part of the housing, and a plurality of terminals arranged in the housing. The housing cover has a tongue portion extending in a direction perpendicular to the plugging direction. The side edge of the tongue portion is brought into close contact with the housing by means of cutting by the tongue portion. The invention provides a method of forcely riveting the housing cover such metal housing to the housing, in order to enforce the fastness between them.

Owner:HIROSE ELECTRIC GROUP

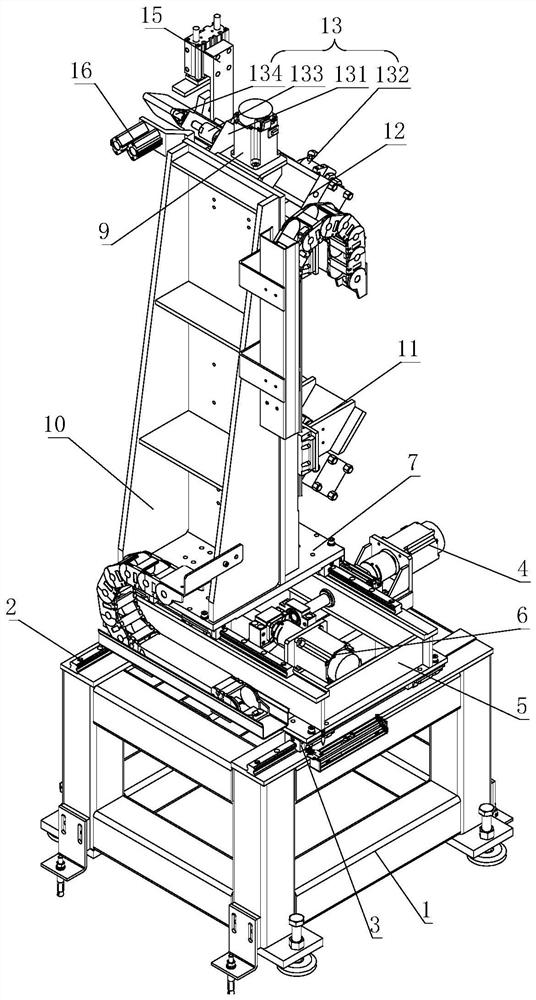

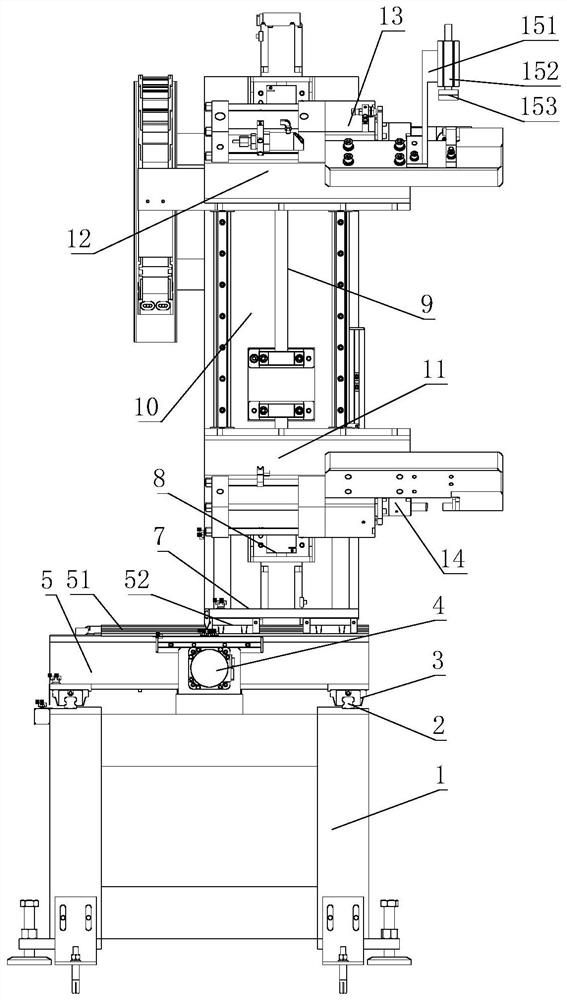

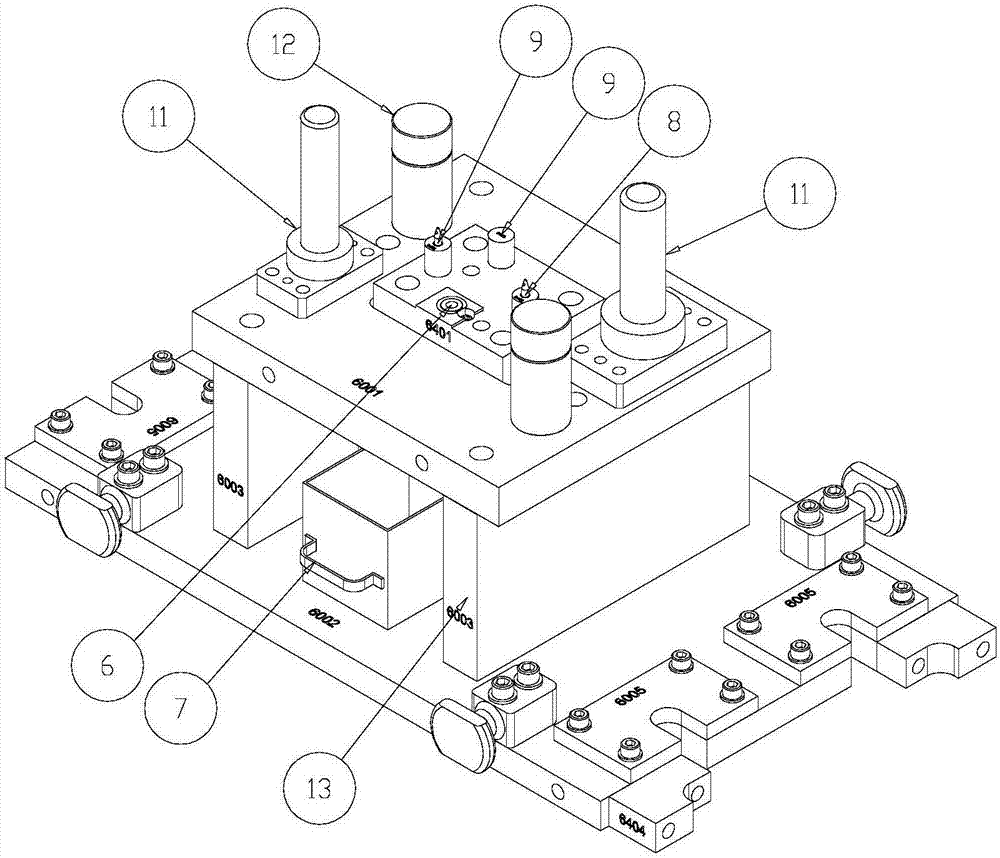

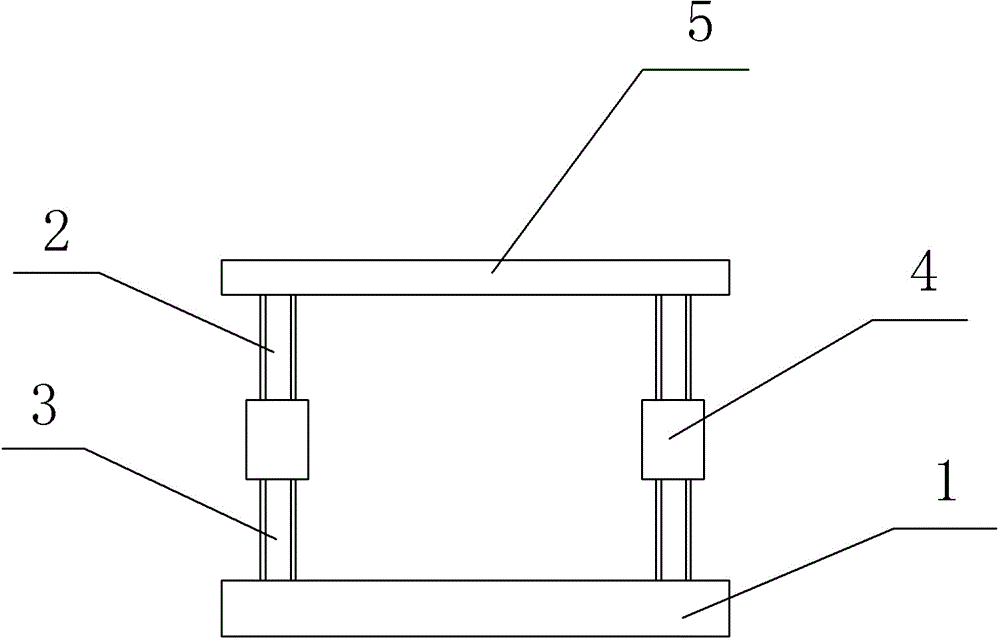

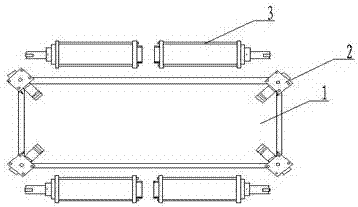

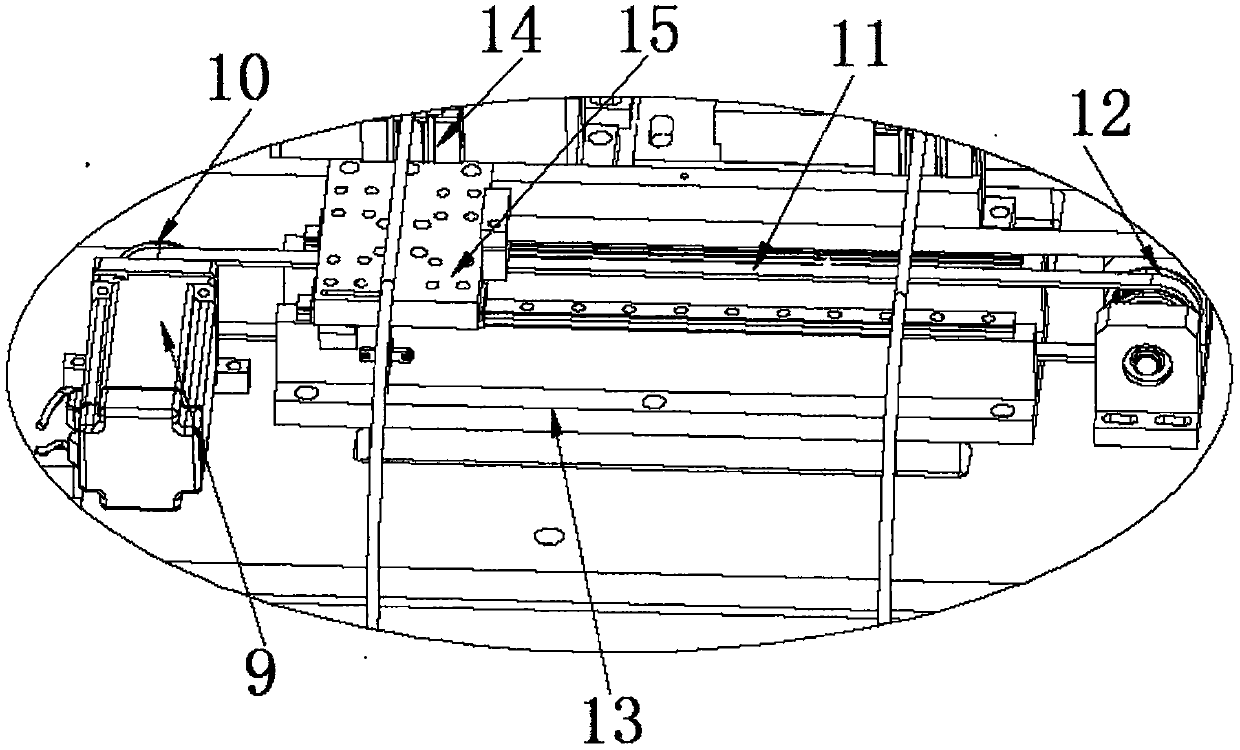

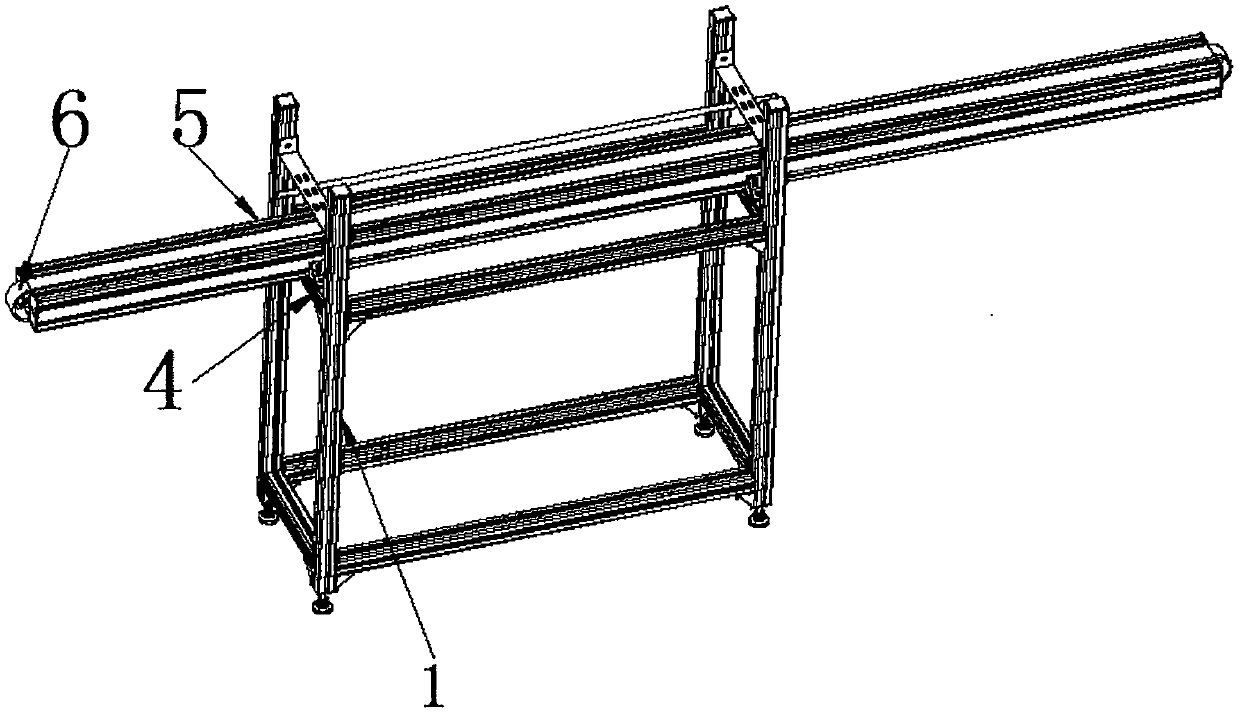

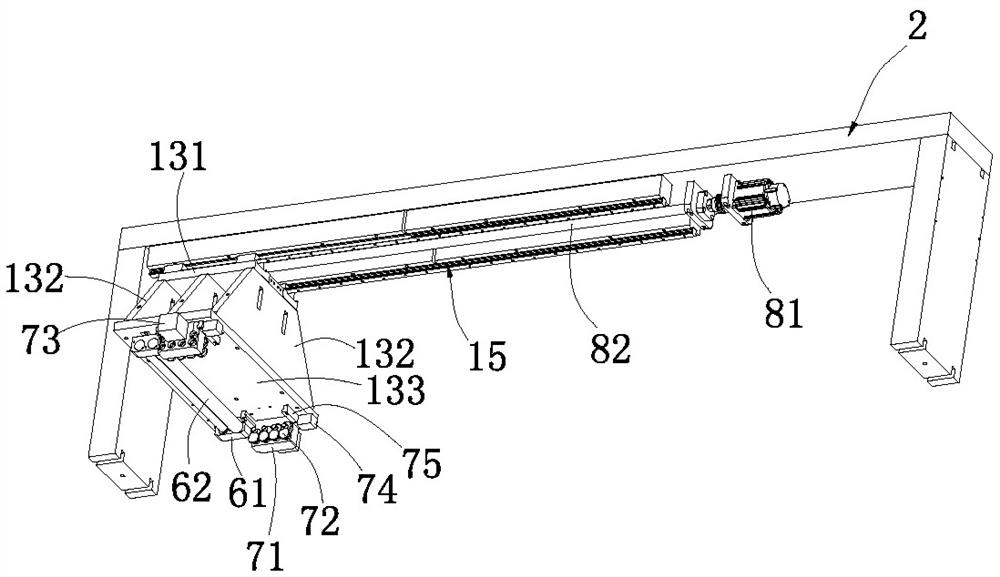

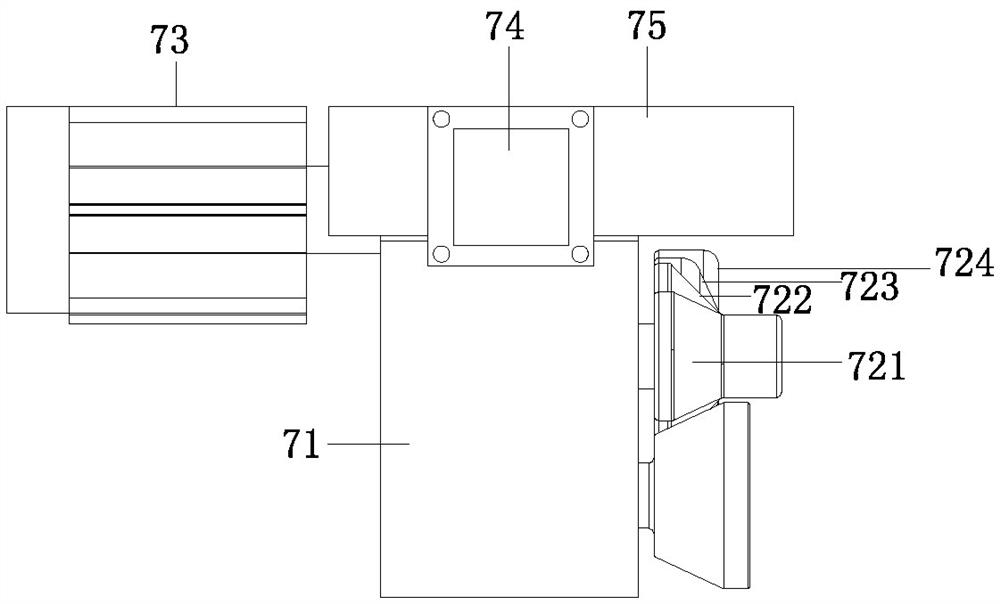

Automatic adjusting device for riveting clamp body of freezer liner

PendingCN113953393AReduce laborImprove processing efficiencyMetal-working feeding devicesPositioning devicesEngineeringMachining

The invention discloses an automatic adjusting device for a riveting clamp body of a freezer liner, which comprises a main body rack, and a first driving assembly used for driving a lower support to move horizontally is installed at the upper end of the main body rack; the lower support is provided with a second driving assembly used for driving a horizontal support to move transversely; a vertical support is fixedly installed on the horizontal support, and a third driving assembly used for driving a lower riveting frame in a lifting mode and a fourth driving assembly used for driving an upper riveting frame in a lifting mode are installed on the vertical support; the lower riveting frame is provided with a lower riveting assembly used for riveting the freezer liner; and an upper riveting assembly used for riveting the freezer liner is installed on the upper riveting frame. The positions of two groups of riveting assemblies in the X-axis direction, the Y-axis direction and the Z-axis direction are adjusted by arranging the four groups of driving assemblies, so that riveting machining is conducted on different positions of the freezer liner, and meanwhile riveting machining of products of different specifications can be met.

Owner:ANHUI KINGPOWER EQUIP & MOLD MFR

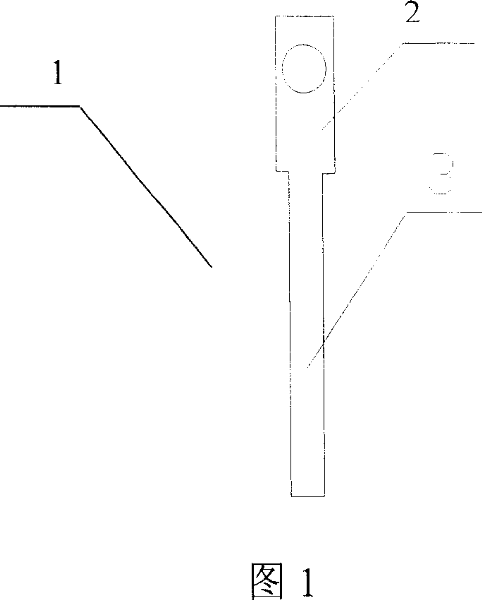

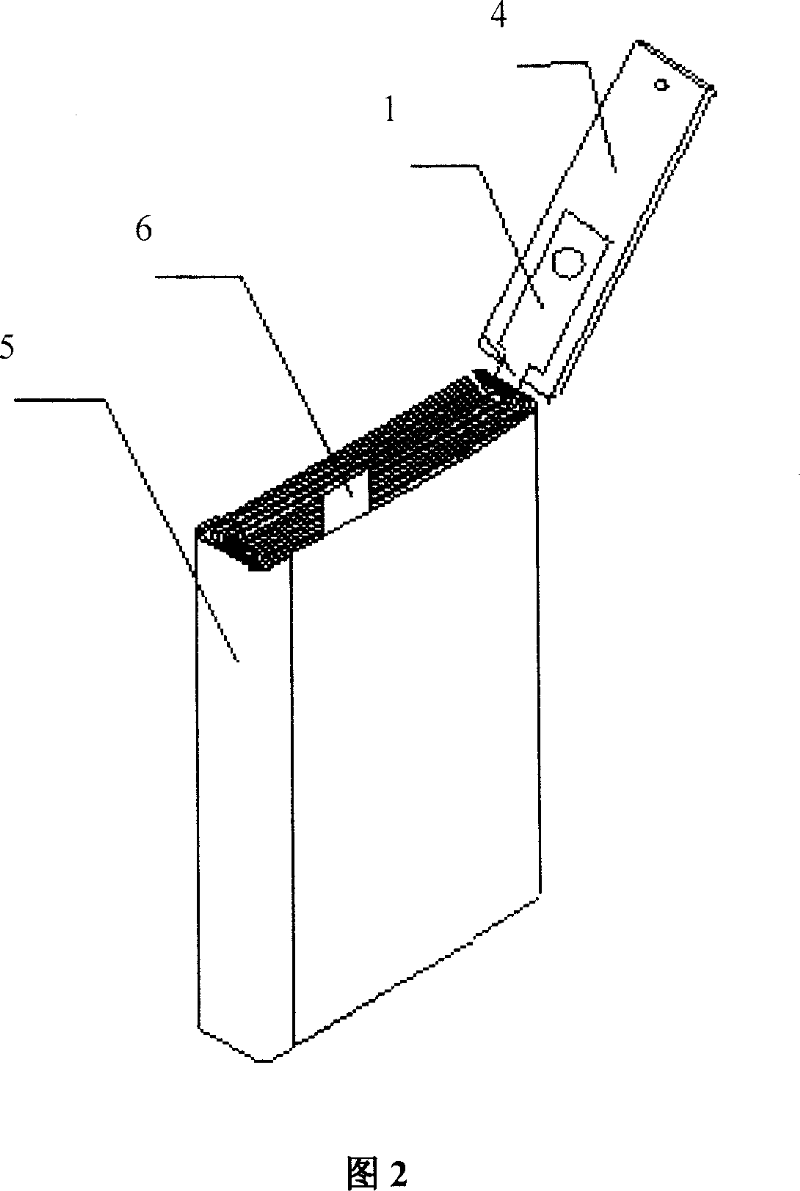

Rectangular lithium ion battery ear-pole and its making method, battery

ActiveCN100337346CFirmly connectedNot easy to fall offSecondary cellsCell component detailsPaper sheetEngineering

This invention discloses one rectangle lithium ion battery ear and its process method, wherein, the ear is of bar electrode ear with different width, one is wider nearly and the other is thinner. The process method comprises the following steps: processing one end of electrode ear wide enough connected to cover board to be connected to cover board easily; processing the other end thin enough of ear to avoid pore through isolation film in process. This invention discloses one rectangle lithium ion battery comprising electrode slices, bar electrode ear and cover board with one end wider and the other end thinner.

Owner:ZHENGZHOU BAK BATTERY CO LTD

Friction plate hollow rivet

InactiveCN108119469ADoes not affect strengthDoes not affect the shapeRivetsEngineeringUltimate tensile strength

The invention belongs to the technical field of rivets, and provides a friction plate hollow rivet. One end of a hollow cylinder extends outwards to form a base. The outer surface of the hollow cylinder is provided with an annular outer boss from the upper plane of the base, and the external diameter of the annular outer boss is larger than that of the hollow cylinder. The inner surface of the hollow cylinder is provided with an annular inner boss from the bottom plane of the base, and the internal diameter of the annular inner boss is smaller than that of the hollow cylinder. Chamfers are arranged at the inner border between the annular inner boss and the base. The friction plate hollow rivet has the advantages that the height of the annular outer boss is identical to the thickness of a connected part with lower strength, due to the fact that the annular inner boss and the annular outer boss are thickened, the strength of the junction position is improved, when the connected part is riveted to a connecting base, the effect that the connected part is riveted firmly and reliably can be guaranteed, the strength and the service life of the connected part are not affected, and the riveting quality is good. The friction plate hollow rivet is suitable for riveting of vehicle friction plates.

Owner:刘义稳

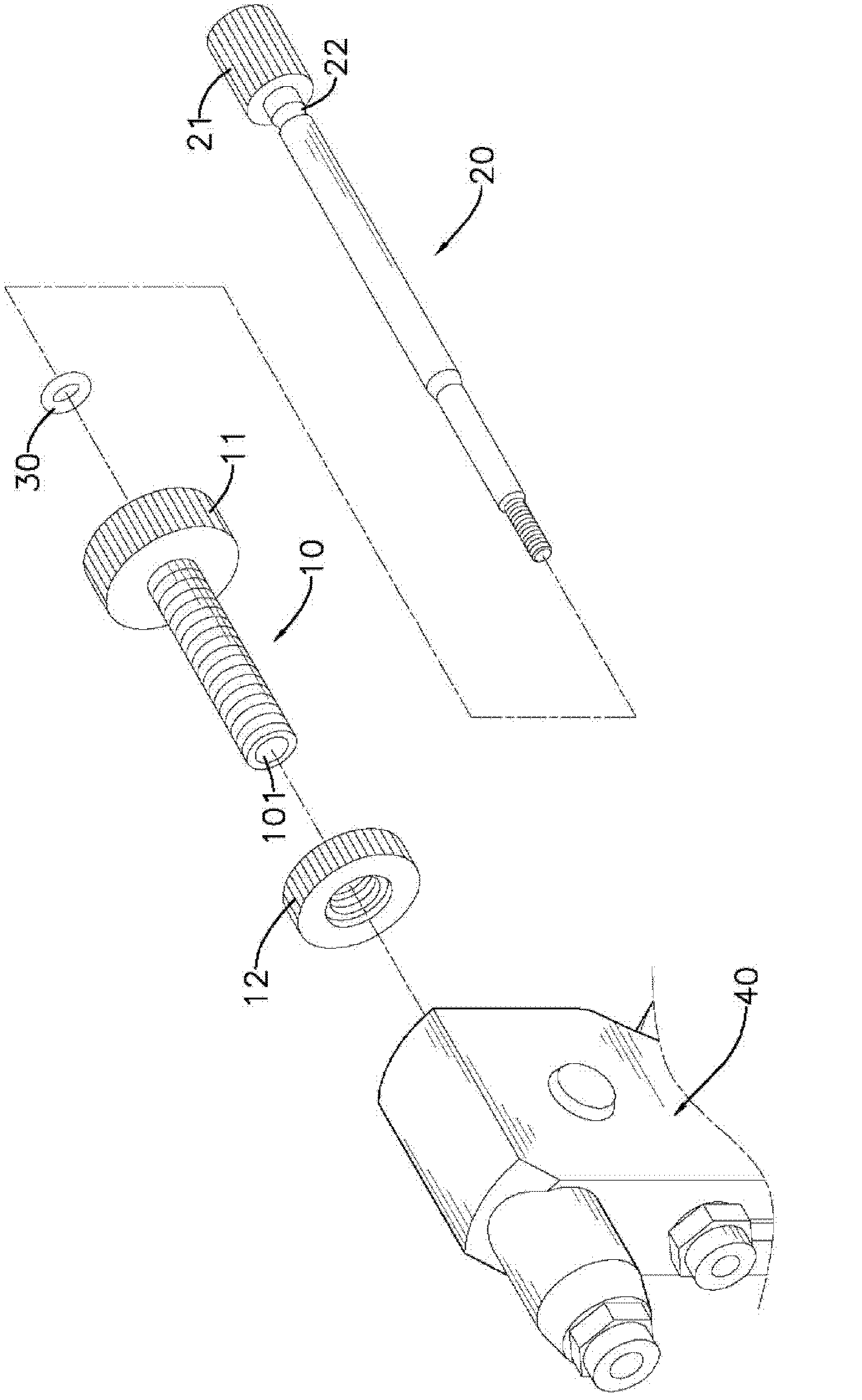

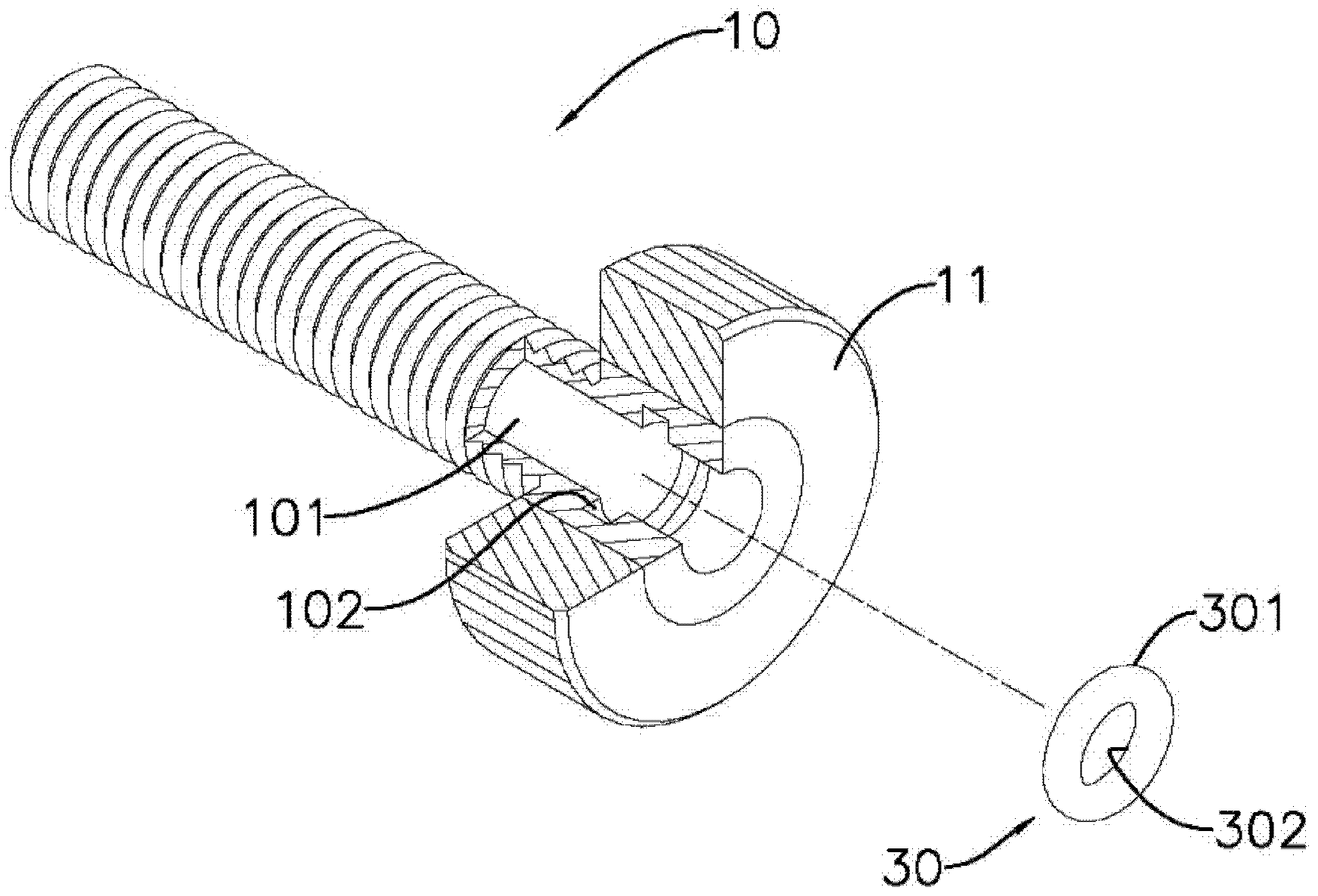

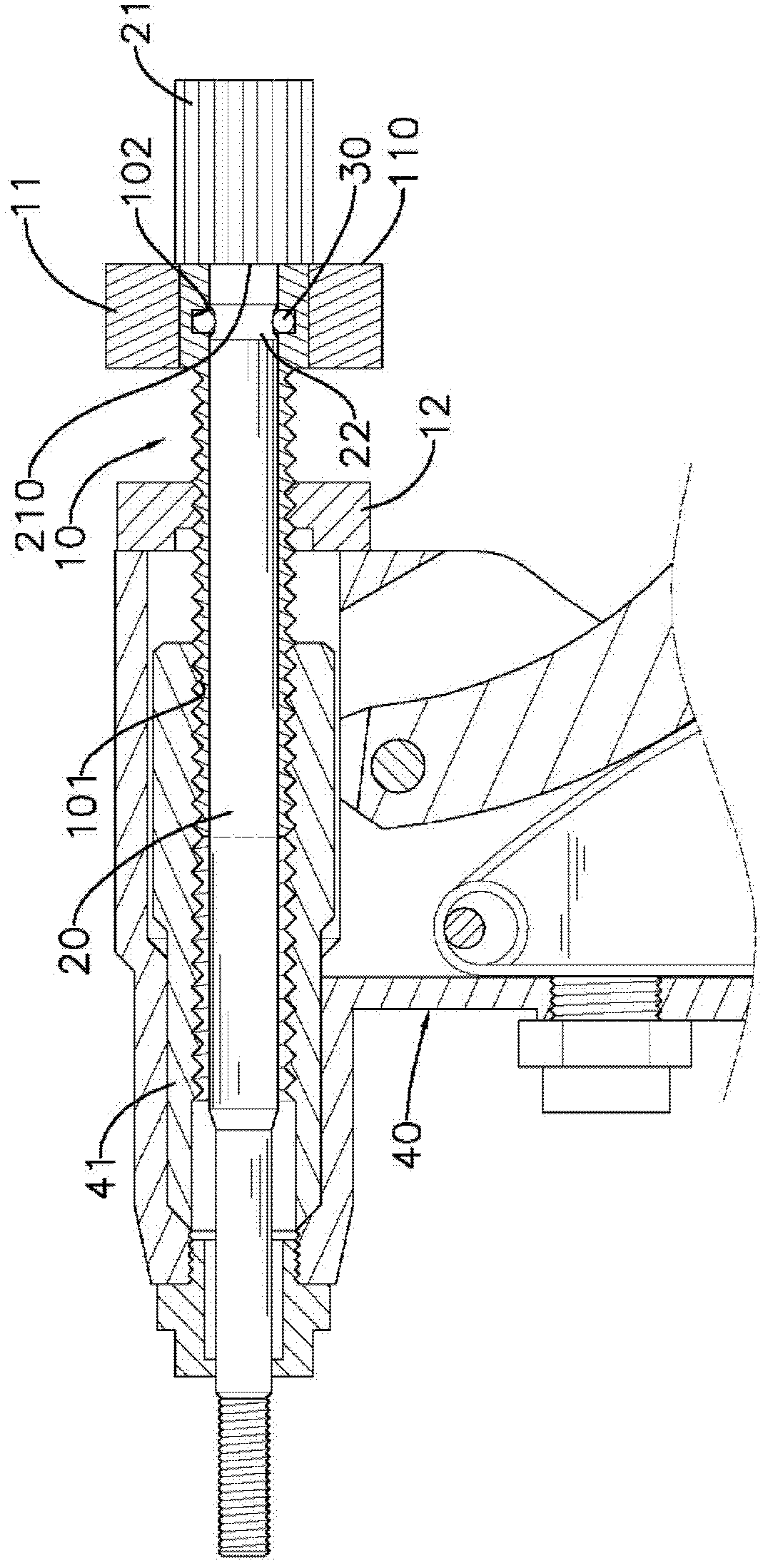

Positioning device for blind nut hand tool

The invention relates to a positioning device for a blind nut hand tool, which comprises a rotating sleeve, a pull rod and a positioning ring. An installation groove is formed inside a through hole at the position of a rotating head of the rotating sleeve; the positioning ring is arranged in the installation groove by an outer lateral ring surface; the pull rod is provided with a positioning groove corresponding to the positioning ring, and thus, when the pull rod moves to be inserted into the through hole, an inner lateral ring surface of the positioning ring is elastically sleeved on the positioning groove and a pull rod head can be surely positioned at a fixed position without shaking, so that the blind nut hand tool can stably rivet a blind nut on a workpiece. According to the device, by the technical means, a positioning device in the prior art is simplified, assembly labor hours and cost can be reduced and a better positioning effect is provided.

Owner:KARAT INDAL CORP

Riveting method for front and back plates used for package of high-voltage cable disc

The invention discloses a riveting method for front and back plates used for package of a high-voltage cable disc. The method comprises the following steps: package plates are subjected to hole forming; a first package plate is grabbed by a grabbing device, a wire disc is approached according to a calculation path, and an automatic riveting device is controlled to drill and rivet the connection position between the first package plate and a plate edge; the wire disc rotates under effect of a disc side circumference driving mechanism while the grabbing device grabs a second package plate; the wire disc is approached according to a calculating path so that the upper side of the second package plate presses the tail side of the first package plate; and the automatic riveting device is controlled to carry out riveting connection and finishing riveting connection with the disc side after the first package plate and the second package plate are folded. After the grabbing device is used for positioning, a disc side compaction mechanism is directly used for compaction and attachment prior to riveting such that package plates are closely attached to the side wall of the wire disc. After riveting, firmer attachment is achieved. Meanwhile, the position between the two connected package plates is partially overlapped. Two sides and the middle part of an overlapped part are in rivet joint at the same time such that the combination part of the package plates is more firmly fixed.

Owner:合肥神马电气有限公司

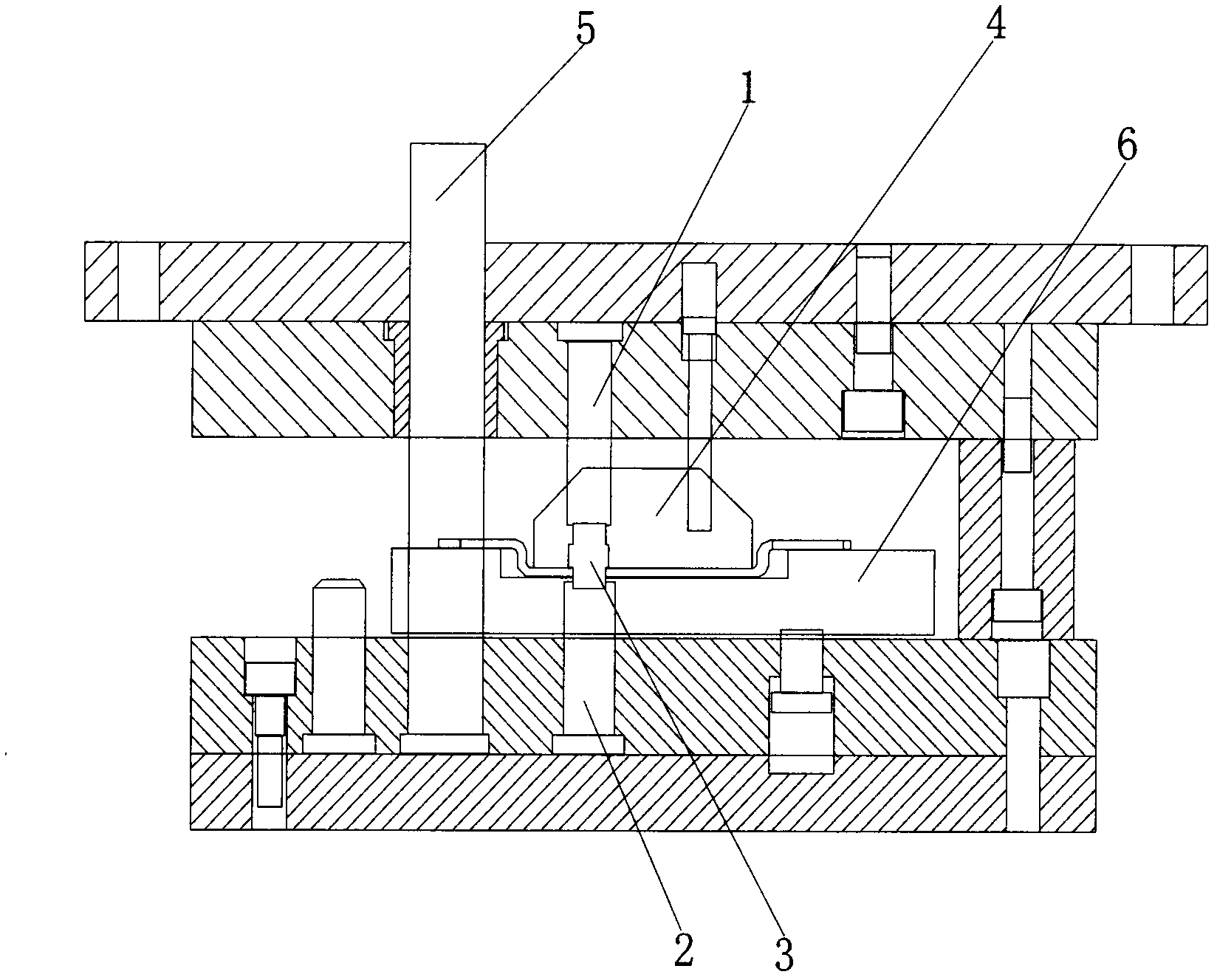

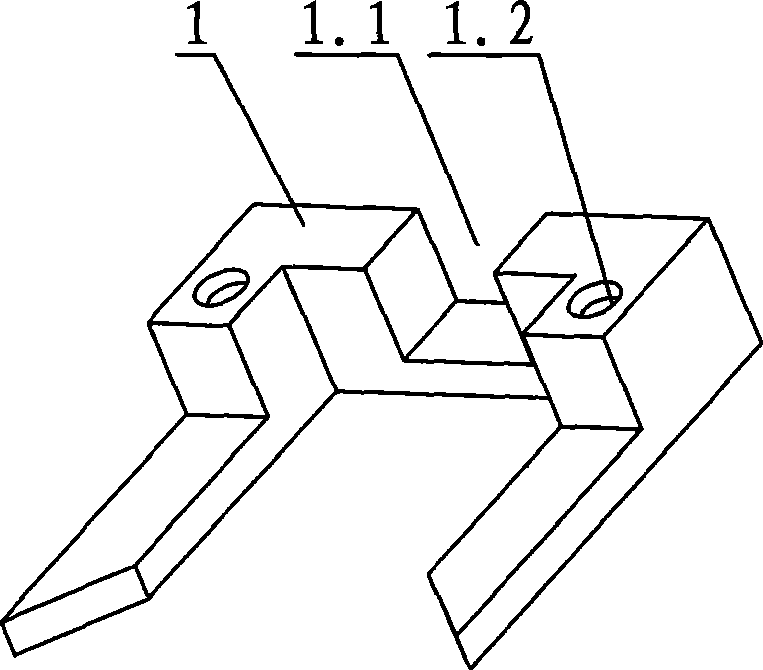

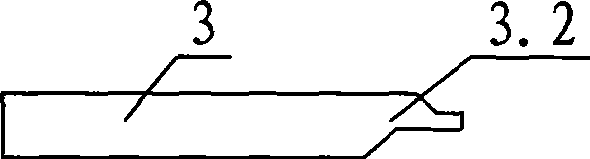

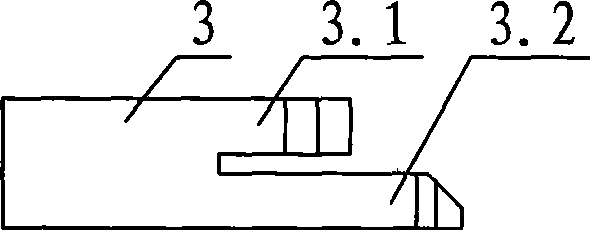

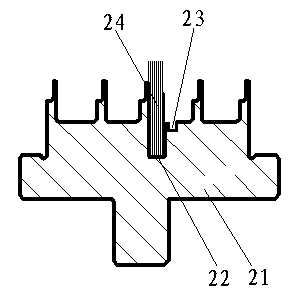

Nut punching riveting die

The invention discloses a nut punching and riveting mold with high stamping efficiency and good riveting effect. There is a stepped through hole with a large upper part and a smaller one at the lower part. A stepped shaft-shaped ejector pin is pierced through the stepped through hole. A nitrogen spring for pushing the ejector pin is provided in the upper mounting seat, and an adsorption nut is provided at the bottom of the riveting punch. The ring magnet is provided with a riveting die set in the lower die base, a waste material discharge hole is arranged in the riveting die set, and at least two positioning pins for positioning workpieces are arranged on the lower die base.

Owner:福州金鸿顺汽车部件有限公司

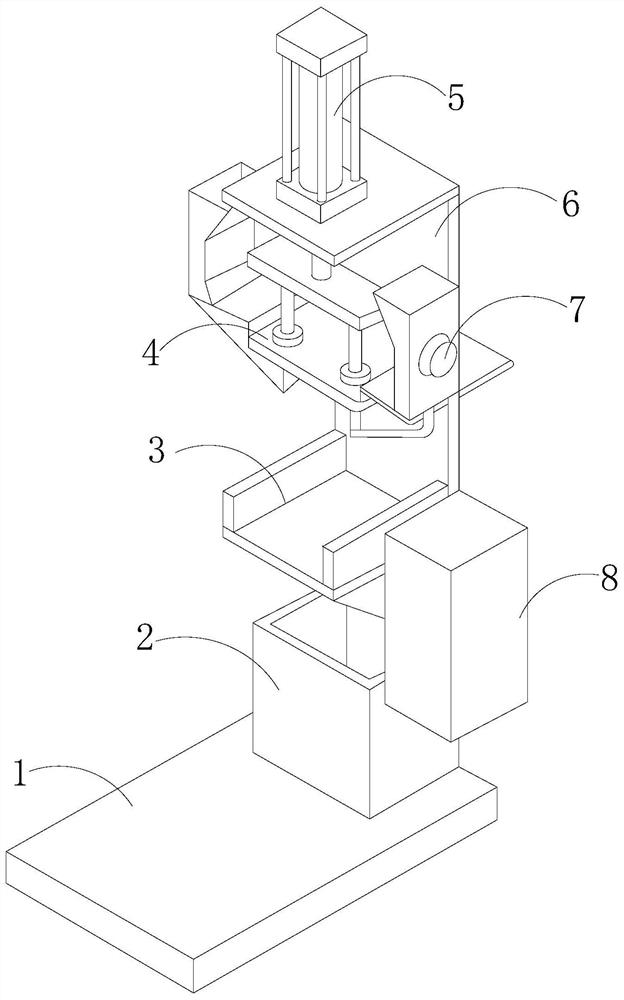

Riveting machine for riveting of circuit boards

InactiveCN112091157ANo slidingNo wear and tearNon-rotating vibration suppressionElectric controlElastic rods

The invention discloses a riveting machine for riveting of circuit boards. The riveting machine structurally comprises a base, a supporting column, a clamping device, a riveting head, an air cylinder,a machine body, a protective cover and an electric control box. When the riveting machine is used after improvement, a clamping cavity and a pulling piece can be expanded outwards under the extrusionforce of a circuit board, then the position of the clamping cavity is limited by a limiting block, the opening angle of the clamping cavity is prevented from being too large, and the circuit board can be stably clamped on a clamping arm; and when the riveting head impacts a rivet on the circuit board, the clamping arm can shake due to the impact force, a movable elastic rod and a buffer piece arematched with each other to eliminate the shaking force generated by the clamping arm in the riveting process, the riveting head can stably rivet the rivet on the circuit board, it is guaranteed thatthe rivet can be stably and accurately riveted on a riveting hole of the circuit board, the rivet and the circuit board can be stably riveted together, and the riveting efficiency of the circuit boardis improved.

Owner:杨清云

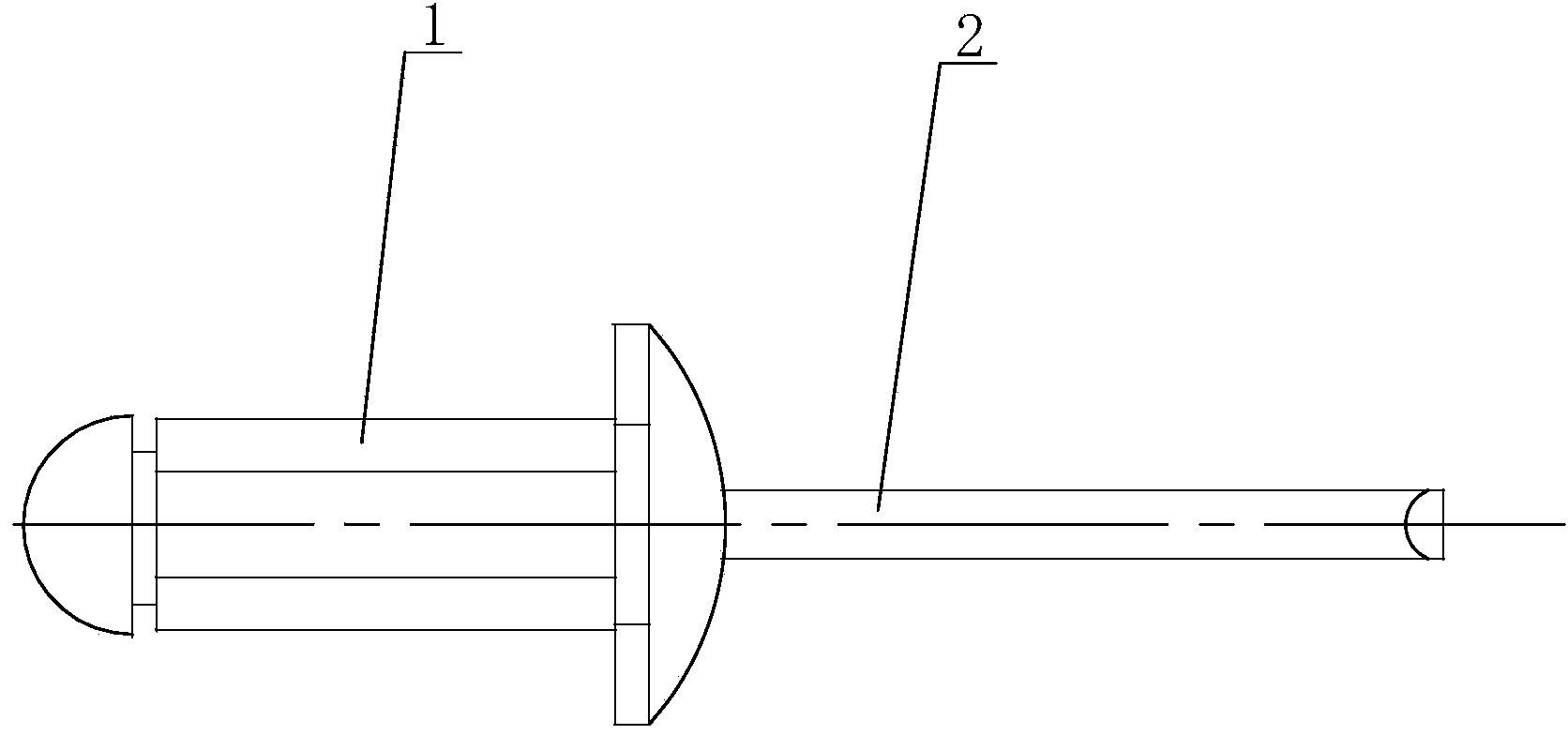

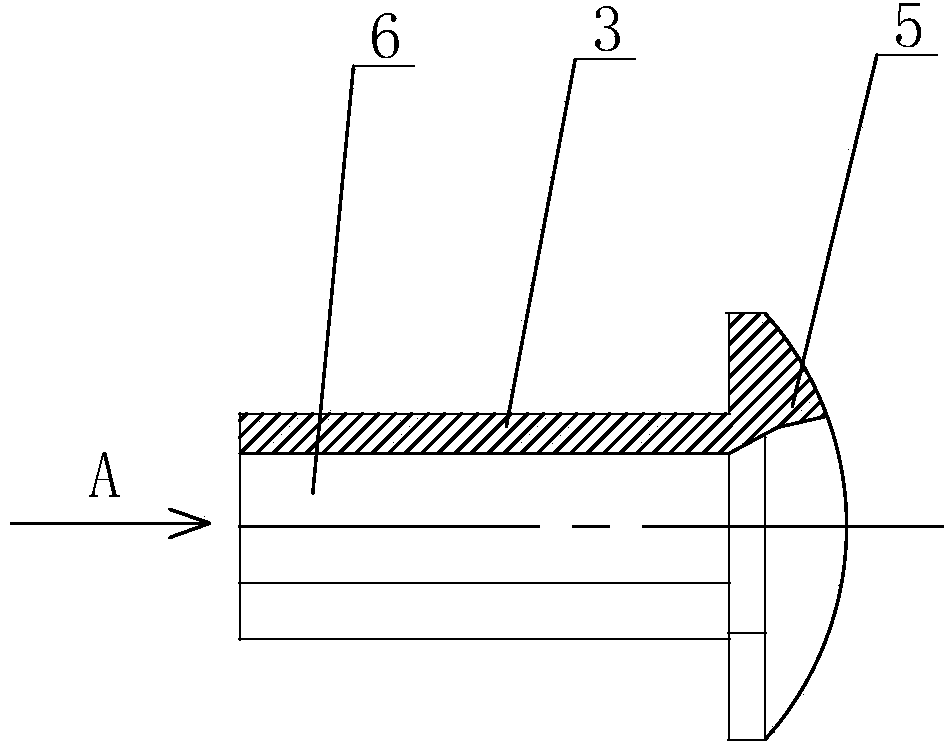

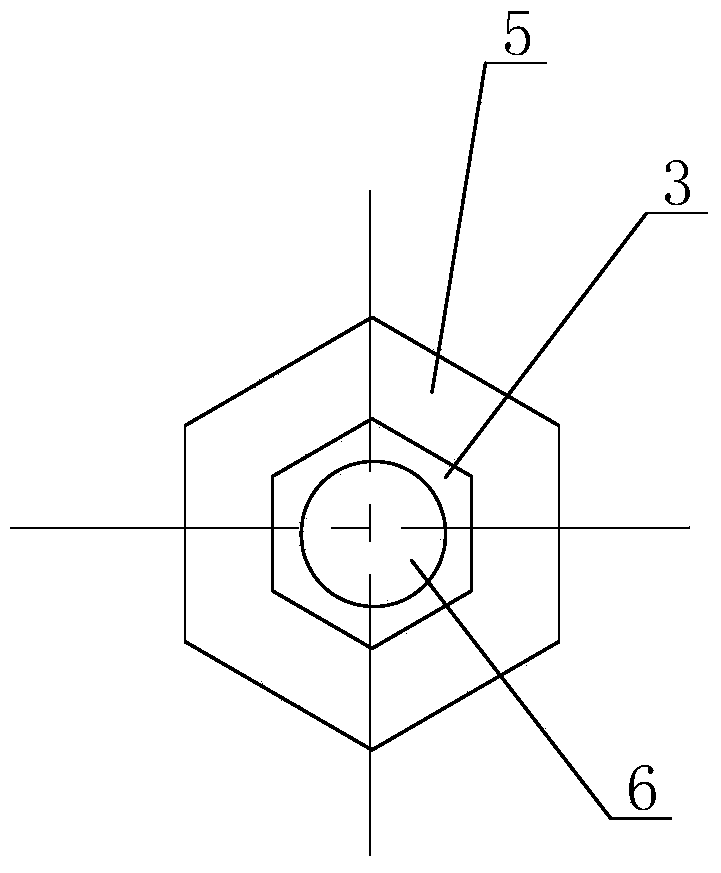

Auxiliary tool for self-plugging rivet and use method thereof

The invention discloses an auxiliary tool for a self-plugging rivet. The auxiliary tool comprises a base, a regulating rod and a fixed ring, wherein the regulating rod mainly consists of a first screw rod, a second screw rod and a sleeve, the sleeve is in threaded connection with one ends of the first screw rod and the second screw rod respectively, the other end of the first screw rod is connected to the base, and the other end of the second screw rod is connected to the back surface or the outer edge of the fixed ring; the inner diameter of the fixed ring is smaller than the diameter of a deformable section of the self-plugging rivet. According to the auxiliary tool disclosed by the invention, the fixed ring is used for being abutted to the deformable section of the self-plugging rivet when a nail core is drawn out, so that the downward expansion of the deformable section is limited; the nail core and the deformable section extend to two sides as much as possible, areas of expansion parts on the two sides are enlarged, and a rivet body is not liable to drop out of a mounting hole, so that the rivet connection is steadier; the regulating rod adopts a structure with a regulable length, the other end of the second screw rod is connected to the fixed ring, and the height of the fixed ring can be regulated through the length of the regulating rod, so that the fixed ring is convenient to mount and take out.

Owner:CHONGQING JIANGLU LASER TECH

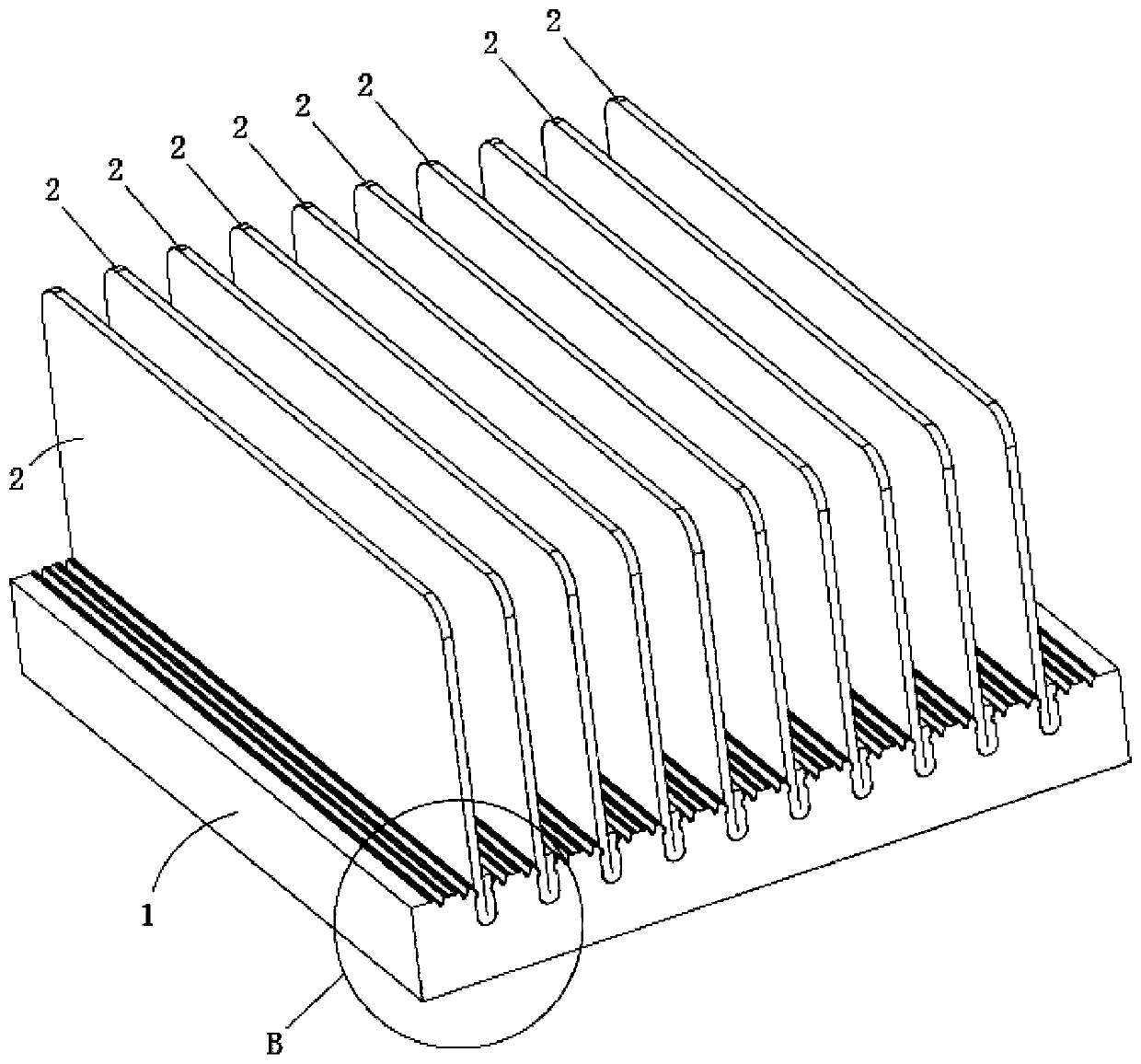

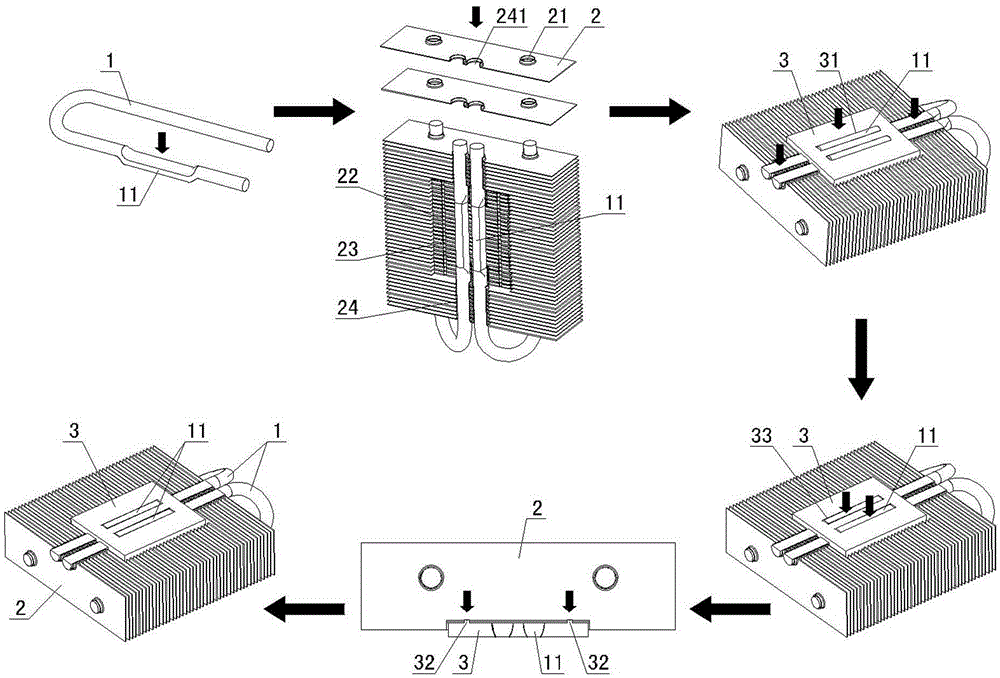

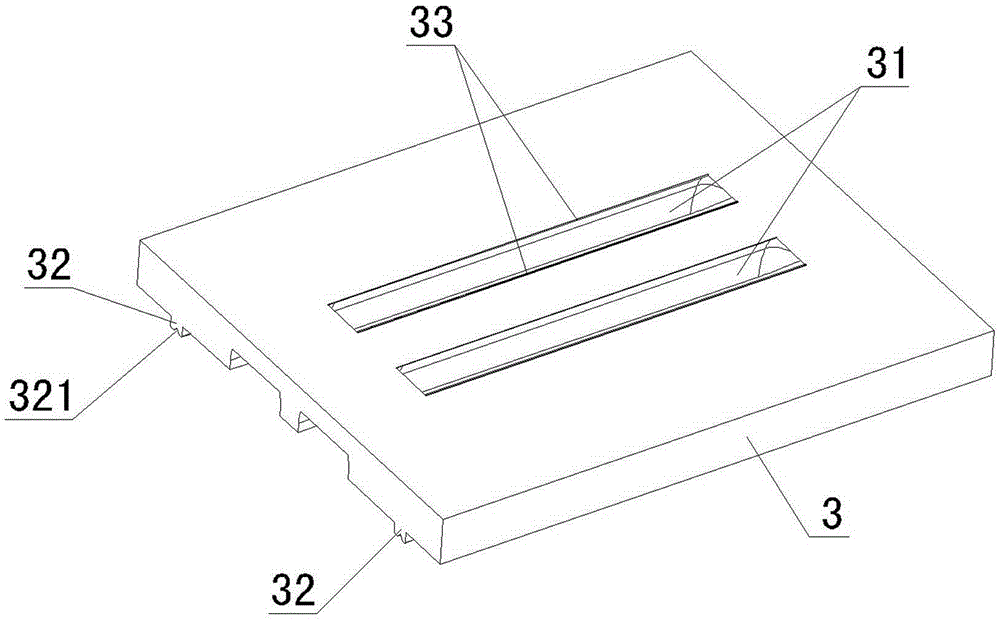

Manufacturing method of cooler

InactiveCN105382124ASimple processIncrease productivityHeat exchange apparatusHeat resistanceCooling effect

The invention provides a manufacturing method of a cooler. The method includes the steps that one strut of each U-shaped heat conductive pipe is pressed on a boss; cooling fins are riveted to the other strut of each U-shaped heat conductive pipe one by one; a bottom board and the boss are preliminarily riveted and fixed and meanwhile the two ends of each strut with the corresponding boss are riveted and fixed to the cooling fins; the boss is riveted, so that the boss is flush with the bottom board; and finally the bottom board and the cooling fins are riveted and fixed. The riveting process is adopted for manufacturing the cooler, no electroplating or welding process is needed, the process is simple, production efficiency is improved, production cost is reduced, energy is saved, and environmental friendliness is achieved. Meanwhile, the heat conductive pipes are flattened and then embedded in the bottom board, one side of each heat conductive pipe can make direct contact with a heat source, the other side of each heat conductive pipe makes direct contact with the cooling fins, heat resistance of an aluminum board is reduced, the heat conductive performance is effectively improved, a cooling path is shortened, heat generated by the heat source can be rapidly conducted and dissipated out, the cooling effect is improved, and the service life of the heat source is effectively prolonged.

Owner:SIHUI HONGYI ELECTRONICS TECH CO LTD

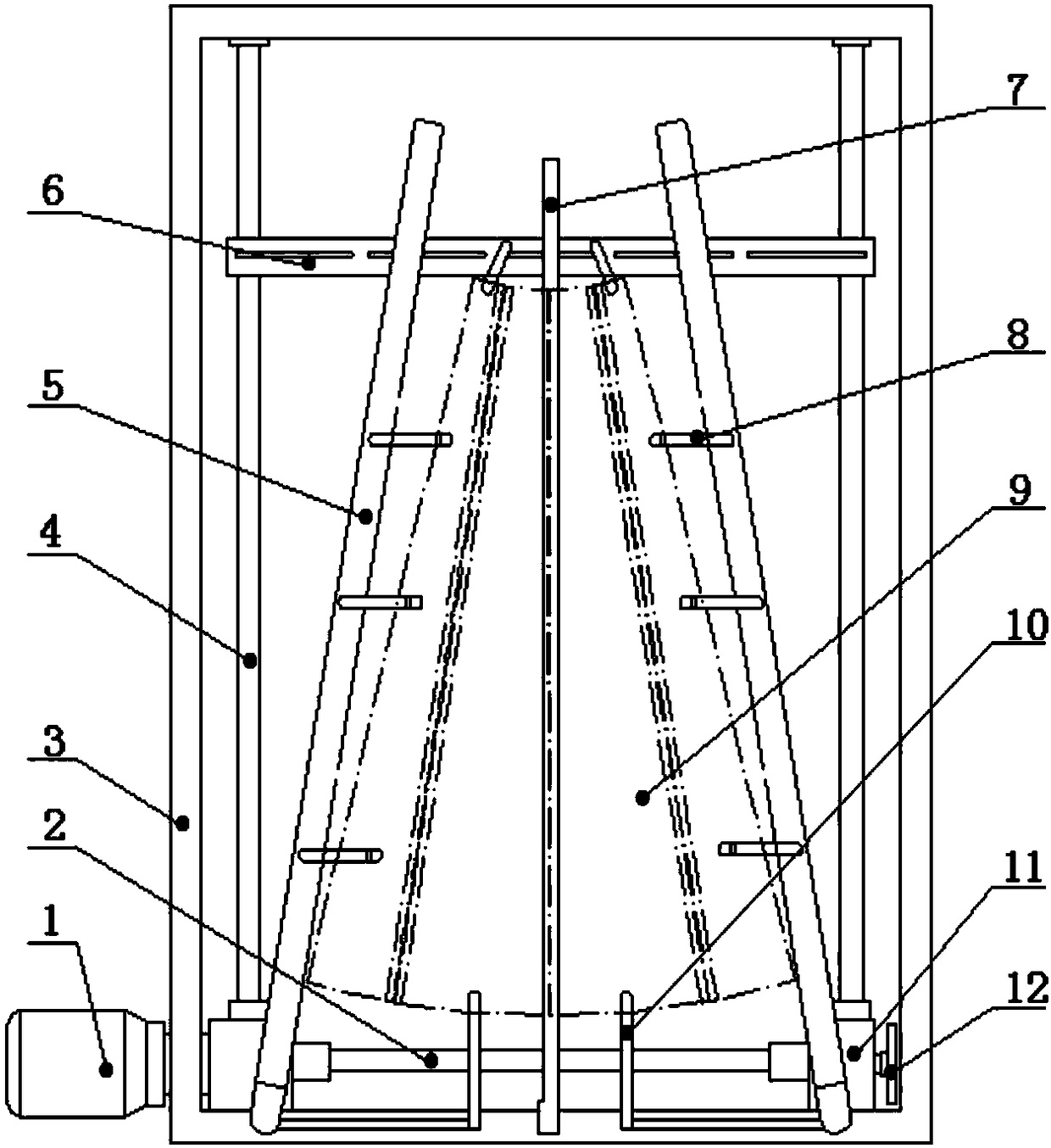

Riveting caliper body equipment for elevator landing door

The invention discloses a riveting pliers device for an elevator hall door, which comprises four pliers and four pliers superchargers, each pliers includes a base, a bracket is fixedly arranged on the base, and a bracket is respectively arranged on the bracket. The structure of the upper beam and the lower beam is equipped with a gas-hydraulic booster cylinder at the uppermost end of the upper beam, and a piston spindle is set in the gas-hydraulic booster cylinder. A stamping rod that moves up and down is connected to the lower end of the piston spindle. A punching head is provided, and the present invention is a riveting pliers device for an elevator hall door, which has compact design, stable workpiece processing, firm riveting, and high quality.

Owner:TAICANG YOJET MACHINERY CO LTD

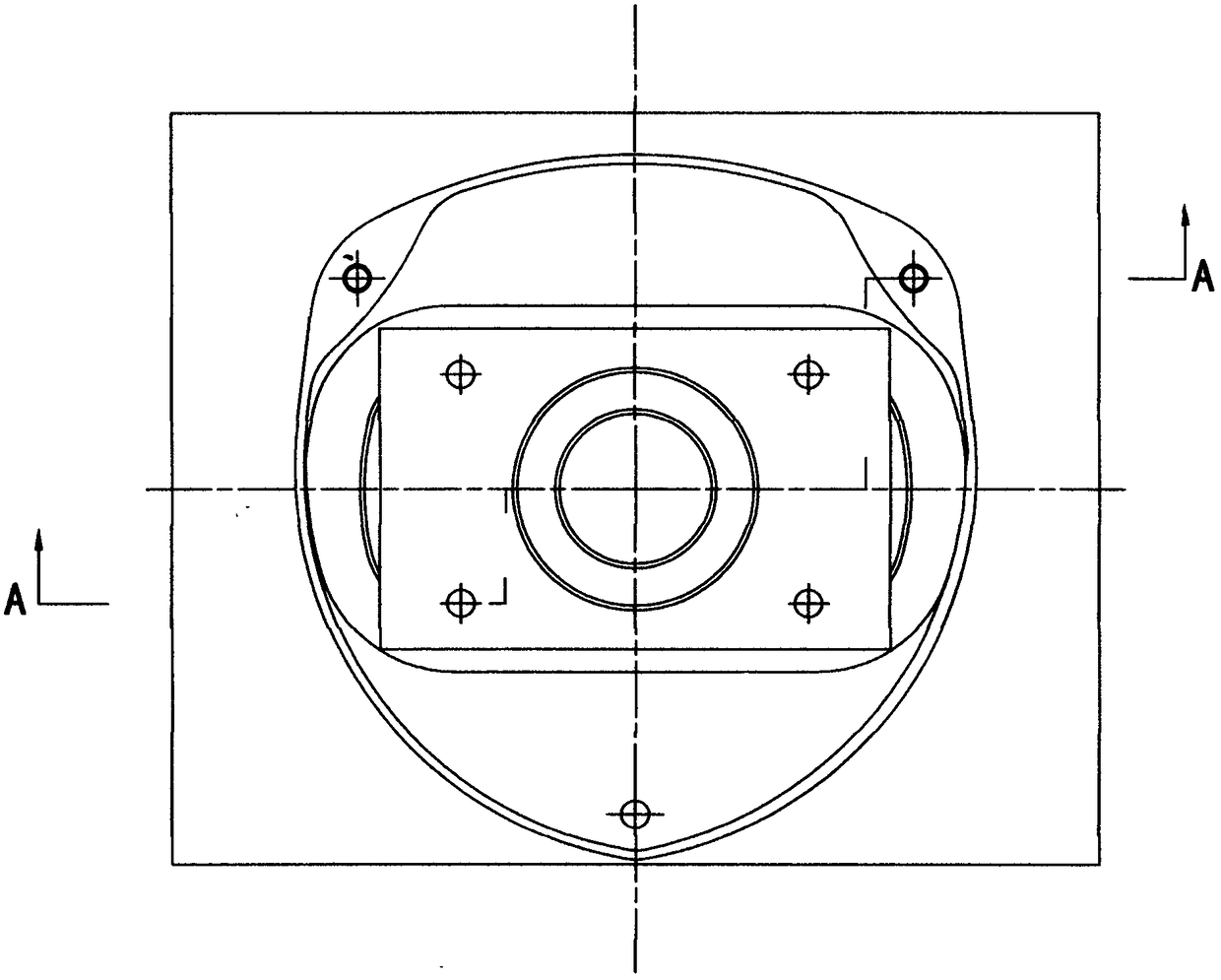

Pressing rivet die for hoist nameplate

The invention discloses a pressing rivet die for a hoist nameplate and belongs to the technical field of hoist nameplate pressing rivet dies. The pressing rivet die comprises a bottom plate, a positioning plate fixed to the bottom plate, an upper die body arranged on the upper portion of the positioning plate, and a die shank fixedly connected with the upper die body. A hoist casing is provided with a casing end face and a casing brim provided with a pin hole. The casing end face is provided with a nameplate groove for accommodating the hoist nameplate. A positioning pin for positioning of thepin hole is arranged on the bottom plate. Two elastic ejection rods are symmetrically arranged on the positioning plate. At least two riveting rods are symmetrically arranged on the positioning plate. The riveting rods are lower than the two elastic ejection rods. The top end face of each riveting rod extends axially to form a small conical riveting head and a shallow groove surrounding the rootof the small conical riveting head. The small conical riveting heads are used for stretching a semi-hollow riveting body part. A complete and consistent riveting flange is formed at the end port of the semi-hollow riveting body part through the shallow grooves. Multiple positions of the nameplate can be simultaneously pressed and riveted by the die, the hoist nameplate and the hoist casing are riveted firmly, and the riveting quality coherence is high.

Owner:ZHEJIANG SHUANGNIAO MACHINERY

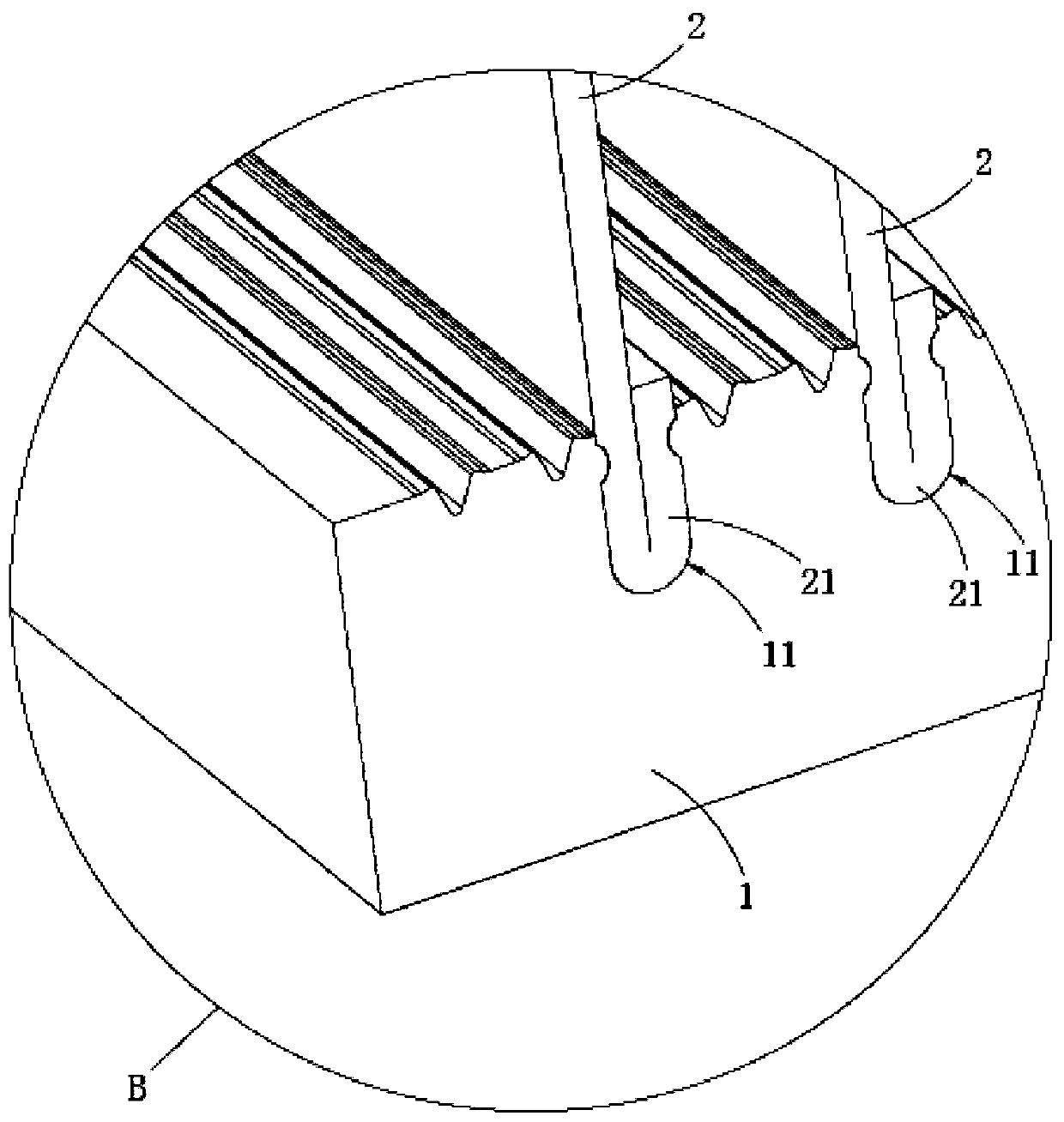

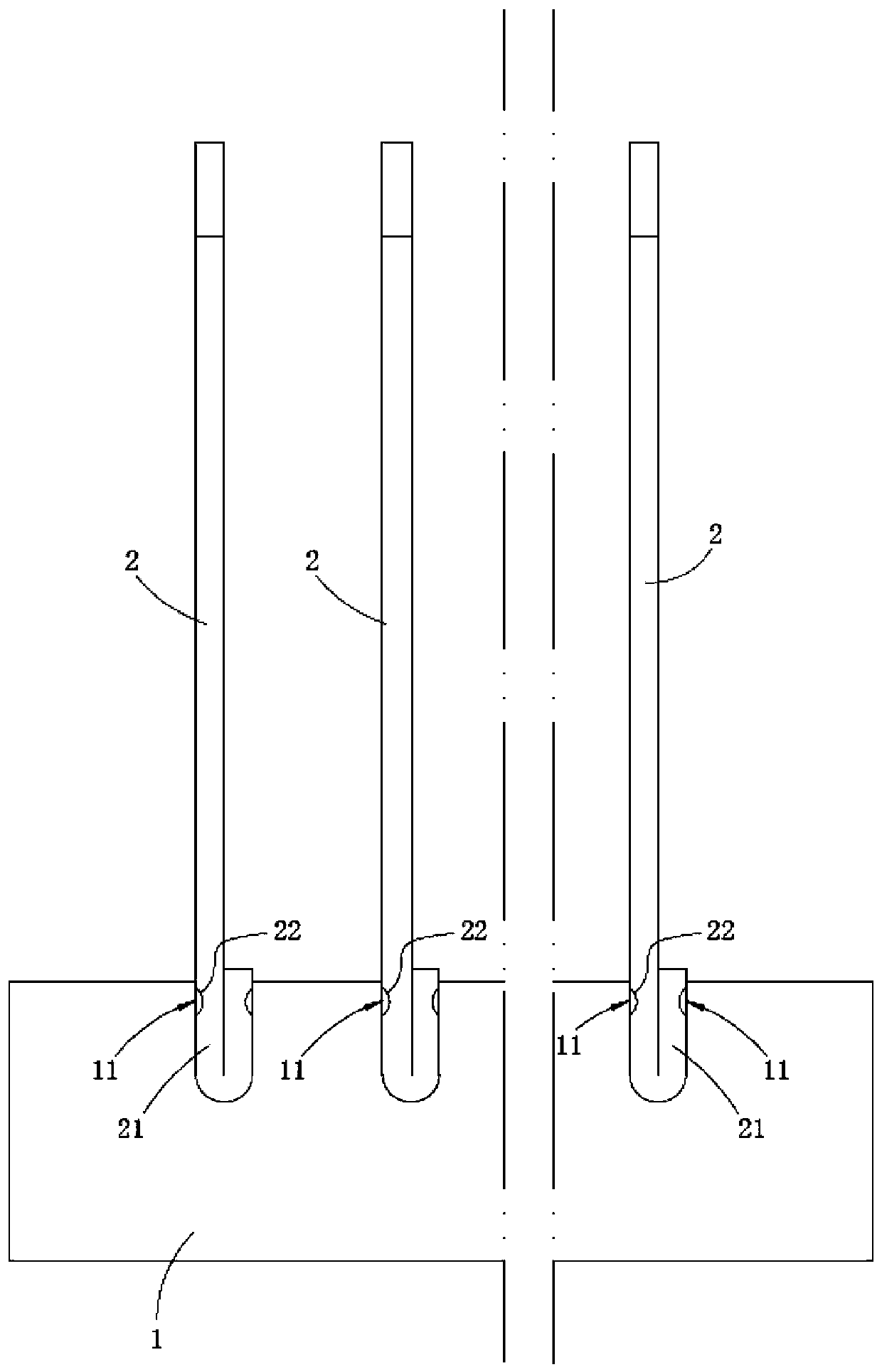

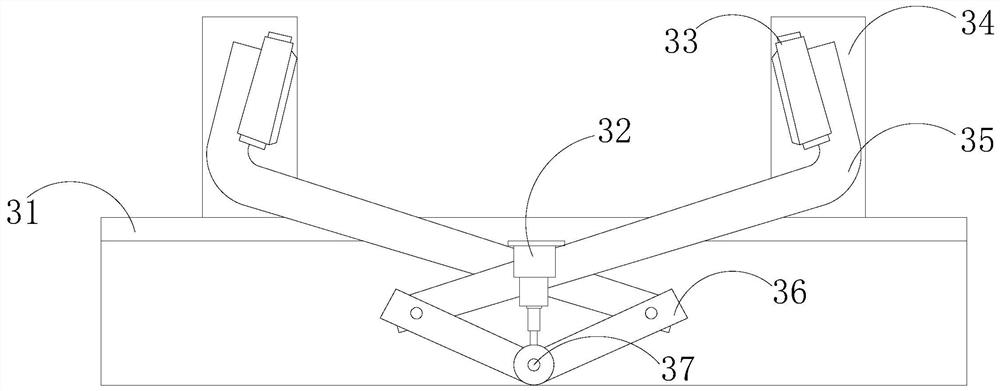

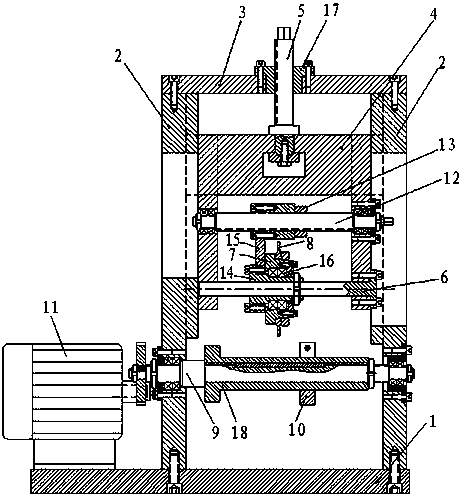

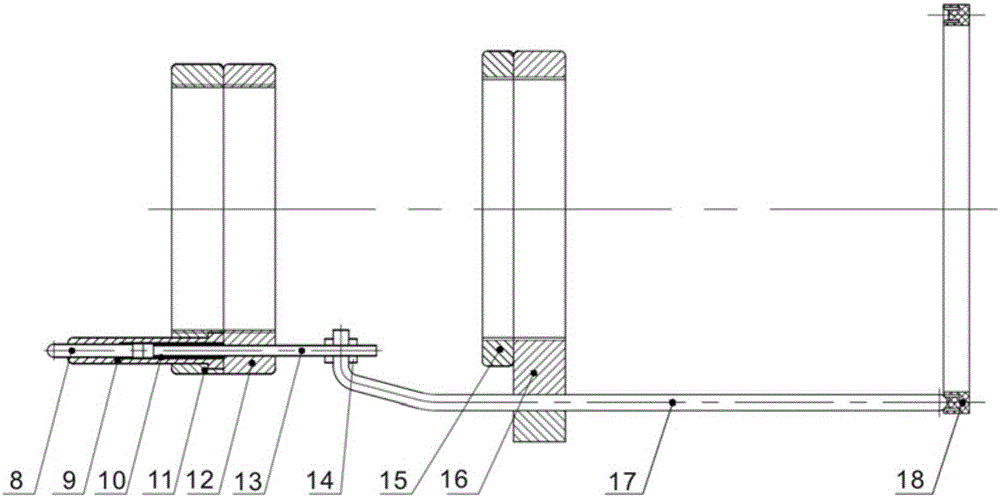

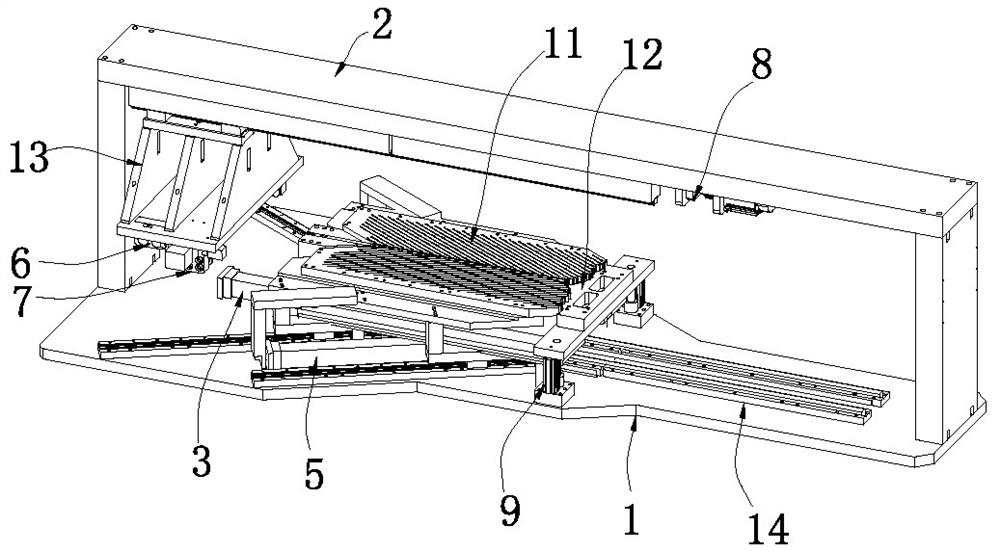

Brush ring hobbing and riveting machine for brush-type steam seals

The invention discloses a brush ring hobbing and riveting machine for brush-type steam seals. The brush ring hobbing and riveting machine comprises a frame which is composed of a base, a left stand column, a right stand column and an upper crossbeam plate, 'n'-shaped sliders are slidably connected between the left stand column and the right stand column, an upper adjusting rod and a lower adjusting rod are connected at the tops of the sliders and are movably connected with the upper crossbeam plate, a transverse fixed shaft is arranged between the lower portions of the sliders, a hob seat and a hob are movably sleeved on the fixed shaft, a driving shaft is arranged below the fixed shaft, two ends of the driving shaft are rotatably connected to the left stand column and the right stand column, a limiting sleeve is fixedly sleeved on the driving shaft, and one end of the driving shaft is in transmission connection with a driving device. By the aid of the brush ring hobbing and riveting machine, a brush ring can be fixedly hobbed and riveted on a steam seal to form a brush-type steam seal, manual riveting is replaced by equipment processing, manpower is saved, efficiency is improved, and riveting is firm.

Owner:江苏鑫信润科技股份有限公司

Special-shaped polygonal self-plugging rivet

The invention discloses a special-shaped polygonal self-plugging rivet which is especially suitable for the field with special requirements, such as aerospace and servo antennas. The special-shaped polygonal self-plugging rivet comprises a rivet body and a rivet mandrel, the rivet body comprises a body of the rivet body, the body of the rivet body is provided with a middle round hole and is in a tube shape, the section of the body of the rivet body is of a polygonal structure, the rivet mandrel comprises a solid rivet mandrel rod, the rivet mandrel rod is inserted into the middle round hole of the rivet body, and a rivet body head portion with the outer diameter larger than that of the body of the rivet body is arranged at one end of the body of the rivet body. A rivet mandrel head portion with the outer diameter larger than that of the rivet mandrel rod is arranged at one end of the rivet mandrel rod, a breakage portion with the cross section area smaller than that of the rivet mandrel rod is arranged on the rivet mandrel rod, and at least two annular grooves are formed in the position, between the breakage portion and the rivet mandrel head portion, on the rivet mandrel rod. The section of the body of the rivet body is polygonal. In the riveting process, after a polygonal hole matched with the section of the body of the rivet body is punched in a riveted plate, riveting is carried out, rotation never occurs after riveting, and riveting is firm.

Owner:WUXI ANSHIDA HARDWARE

Harness box body assembling machine for split junction boxes

PendingCN110336174AControl lengthSmall footprintLine/current collector detailsPhotovoltaic energy generationWire cuttingEngineering

The invention discloses a harness box body assembling machine for split junction boxes, which comprises a support frame, support feet and a working box. The bottom of the support frame is rotationallyconnected with the support feet. One side of the inner surface of the support frame is fixedly connected with a stabilization plate. The top of the stabilization plate is fixedly connected with a transfer frame. The left side of the top of the working box is fixedly connected with a pay-off folding plate. One side of the pay-off folding plate is fixedly connected with a guide groove block. The invention relates to the technical field of harness box body assembling machines. According to the harness box body assembling machine for split junction boxes, through the joint setting of a wire cutting cylinder and a connecting block, a cylinder clamping a wire harness sends the wire harness to a stripping knife, a large-diameter cylinder pushes a gear to move relative to another gear meshed withthe gear so as to drive two cutting knives to advance relative to each other to complete wire cutting, the depth of wire cutting is controlled by adjusting the buffer stroke of the cylinder, and thelength of wire stripping is controlled by adjusting the position of the cylinder clamping the wire harness.

Owner:宁波禹泰自动化科技有限公司

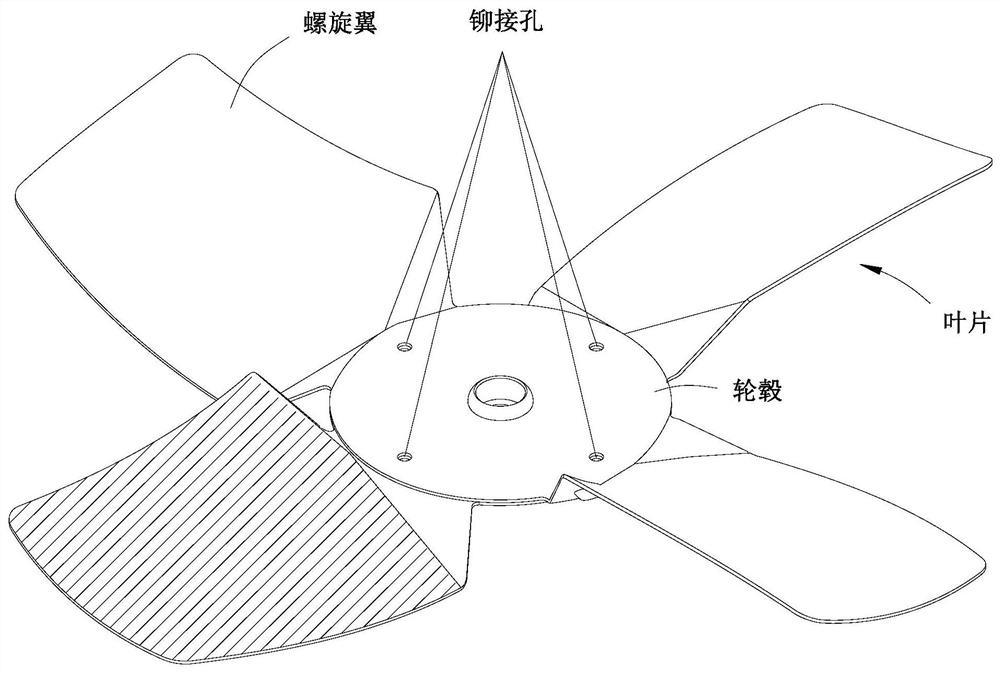

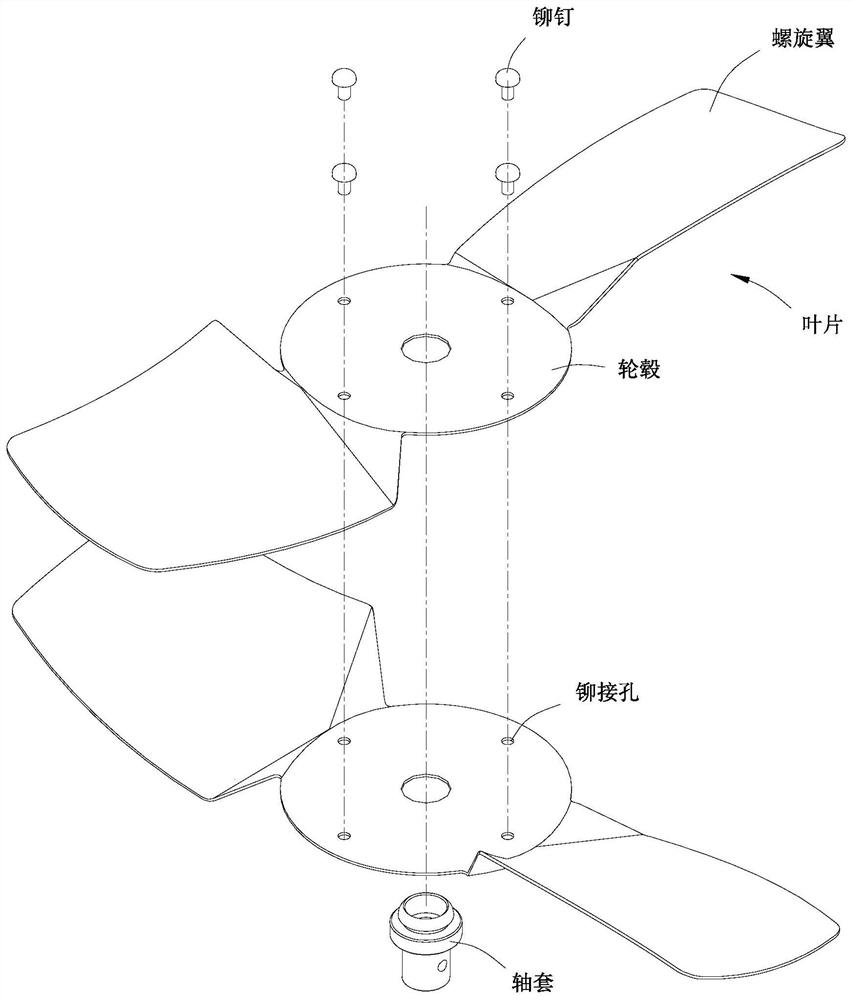

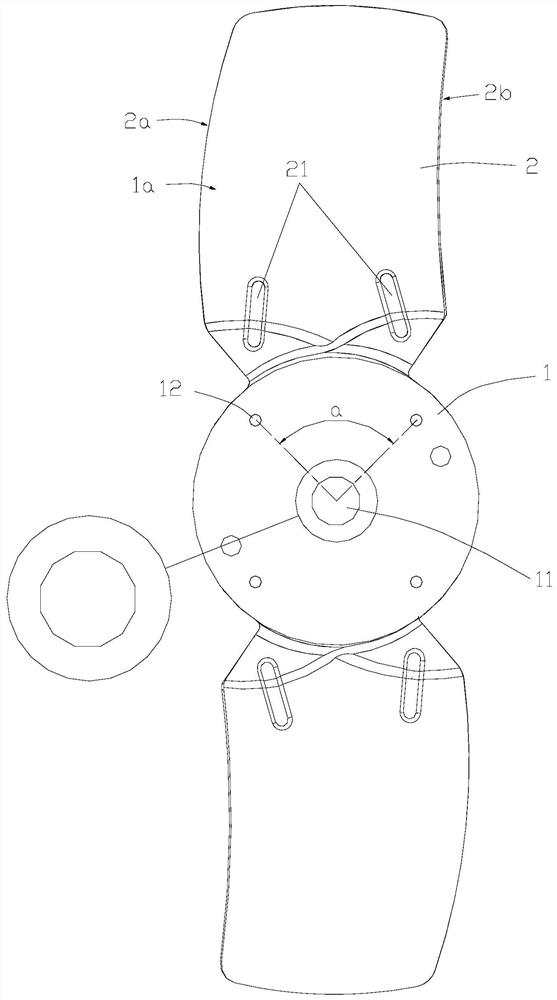

Blade and fan blade applying same

The invention belongs to the technical field of ventilation equipment, and particularly relates to a blade and a fan blade applying the same. The blade comprises a hub and at least two spiral wings arranged on the periphery of the hub. A shaft hole is formed in the middle of the hub, the root parts of the spiral wings are connected with the hub, and at least riveting holes are formed in the portions, close to the edges of the two sides of the root part of each spiral wing, of the hub. Compared with the prior art, the blade has the advantages that the positions of the riveting holes in the hubare reset, the riveting holes are formed in the portions, corresponding to the edges of the two sides of each spiral wing, of the hub, so that the rigidity of the spiral wings and the hub is improved,the riveting of the fan blade applying the blade is more stable, the spiral wings can effectively avoid the influence caused by positive pressure and torsion, the vibration amplitude of the spiral wings is reduced, and the wind noise is reduced.

Owner:叶剑明

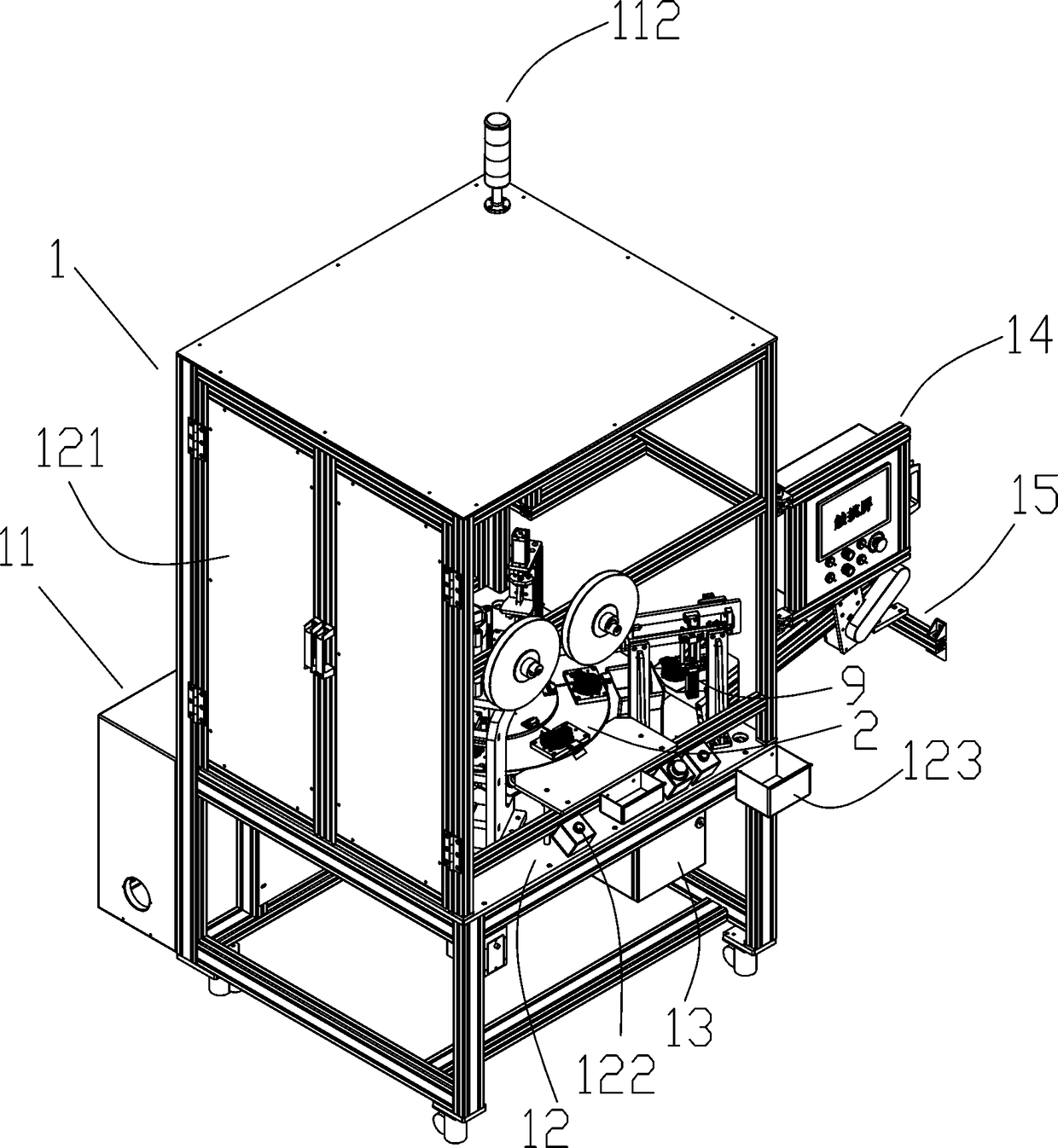

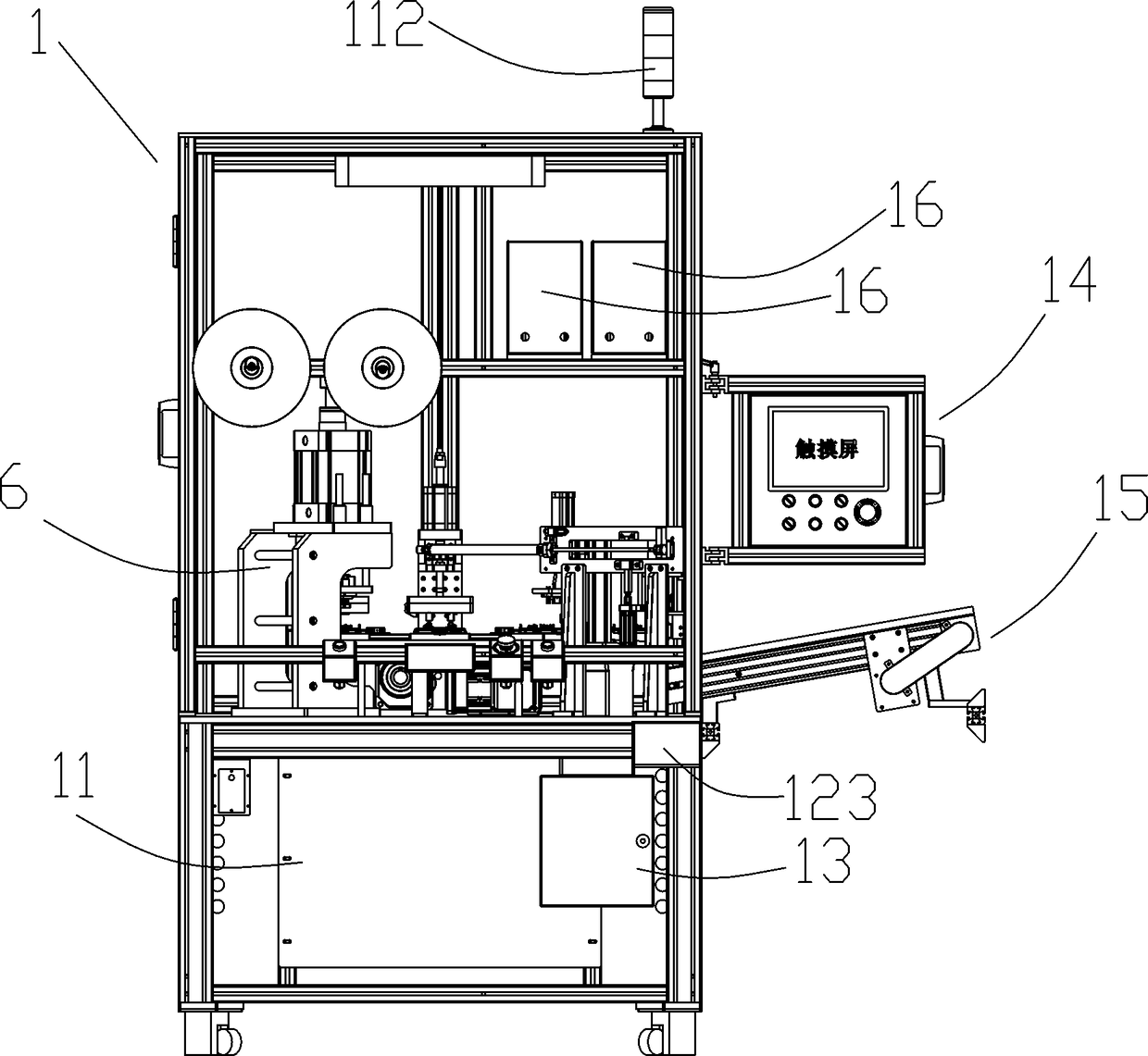

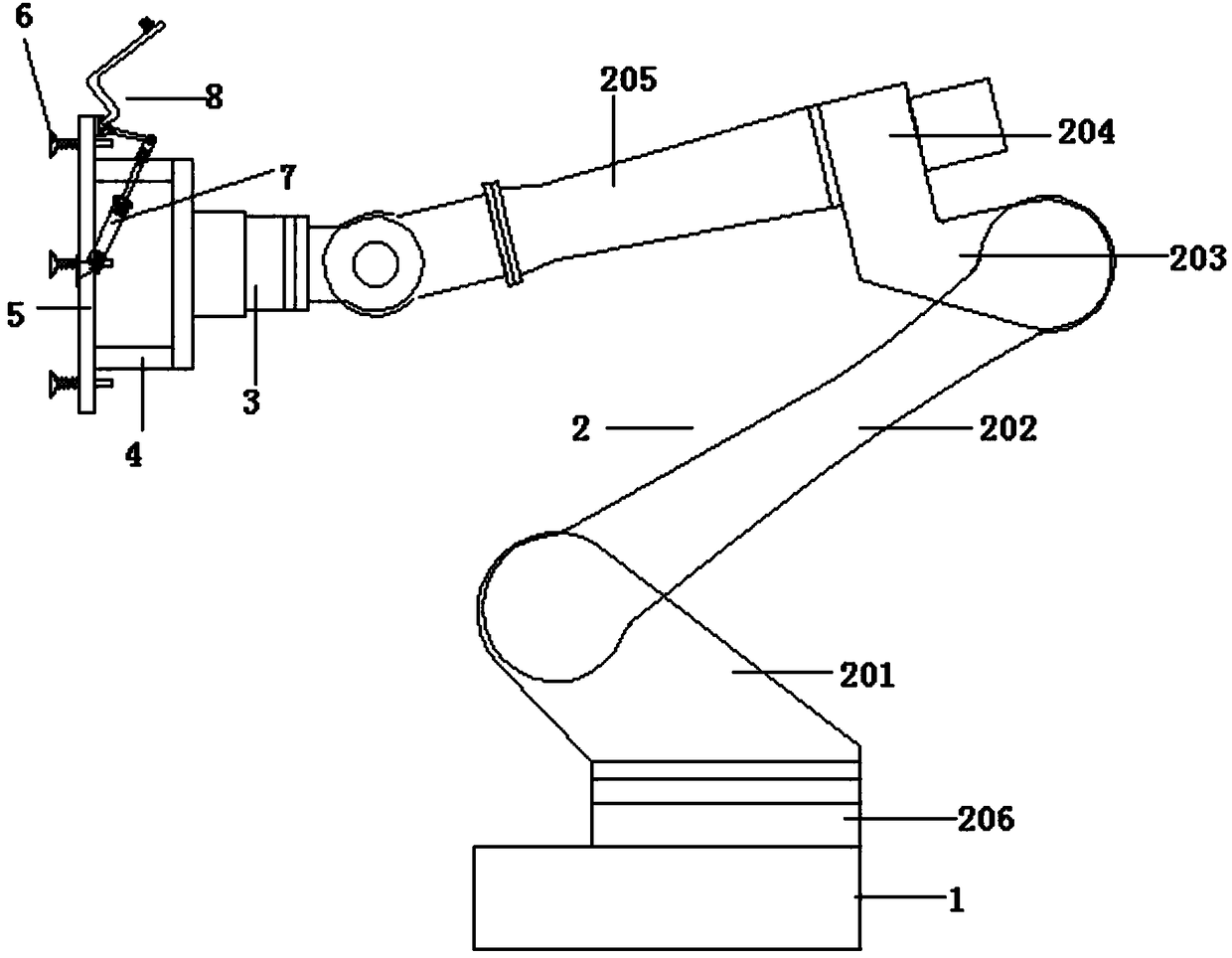

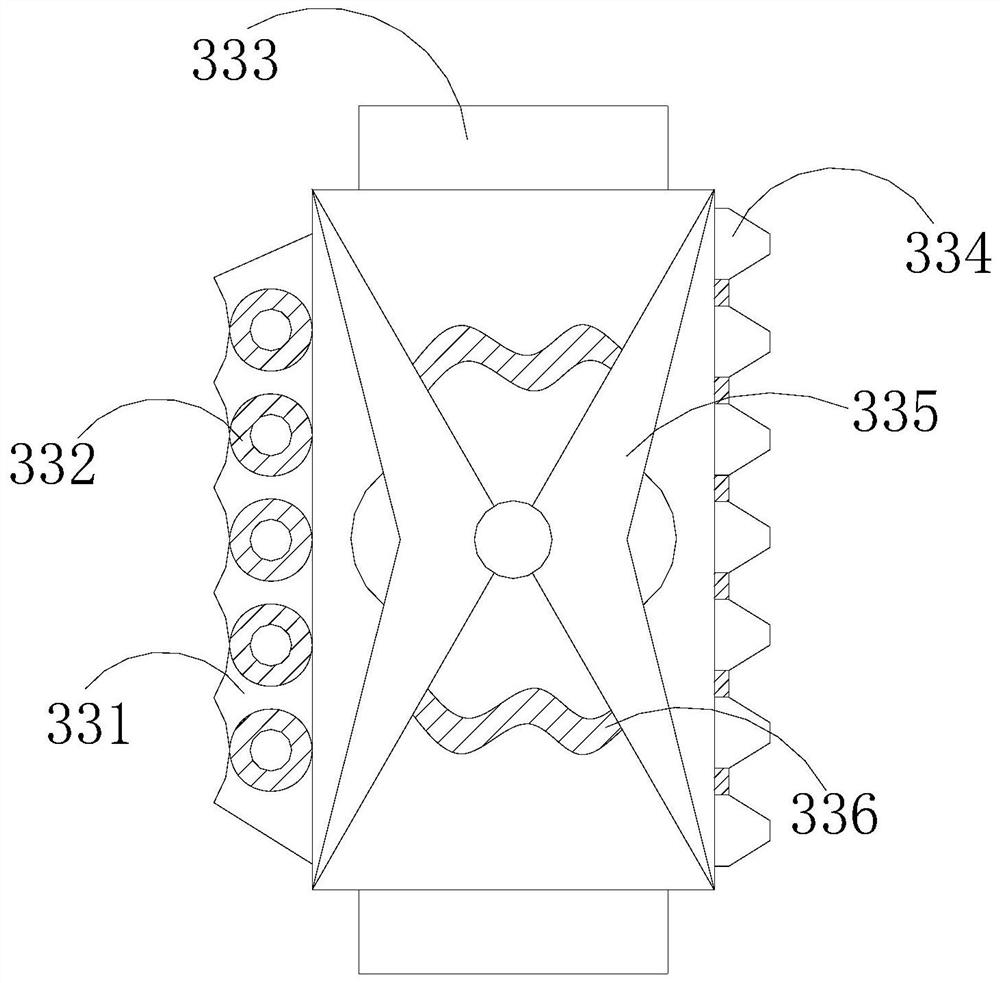

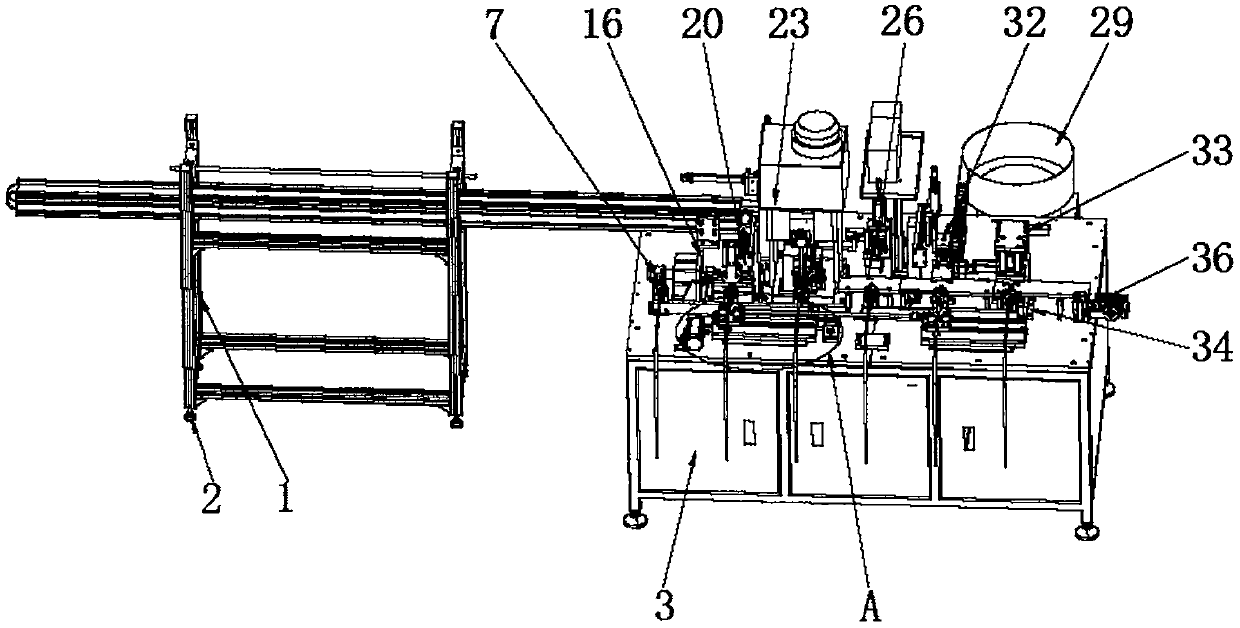

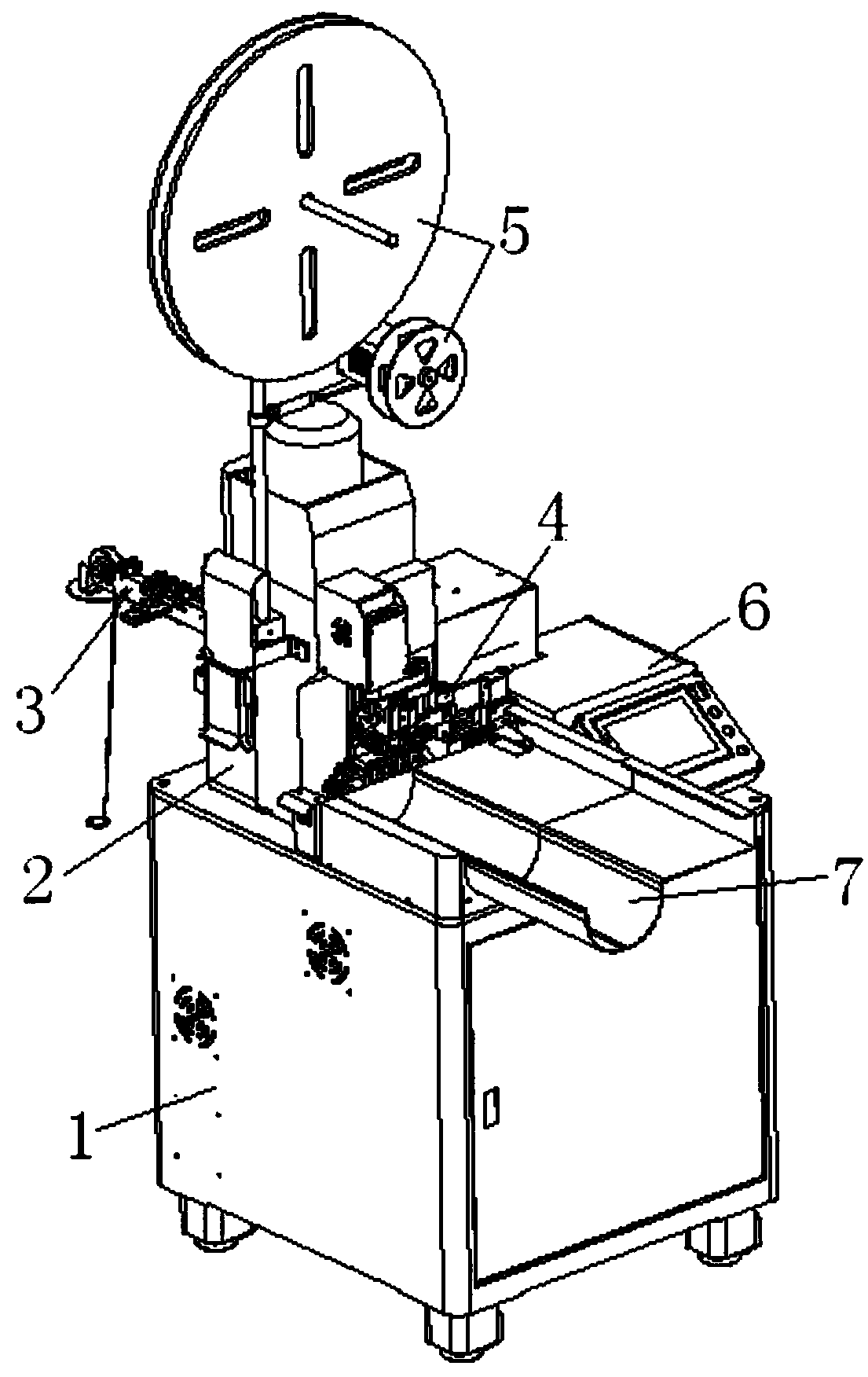

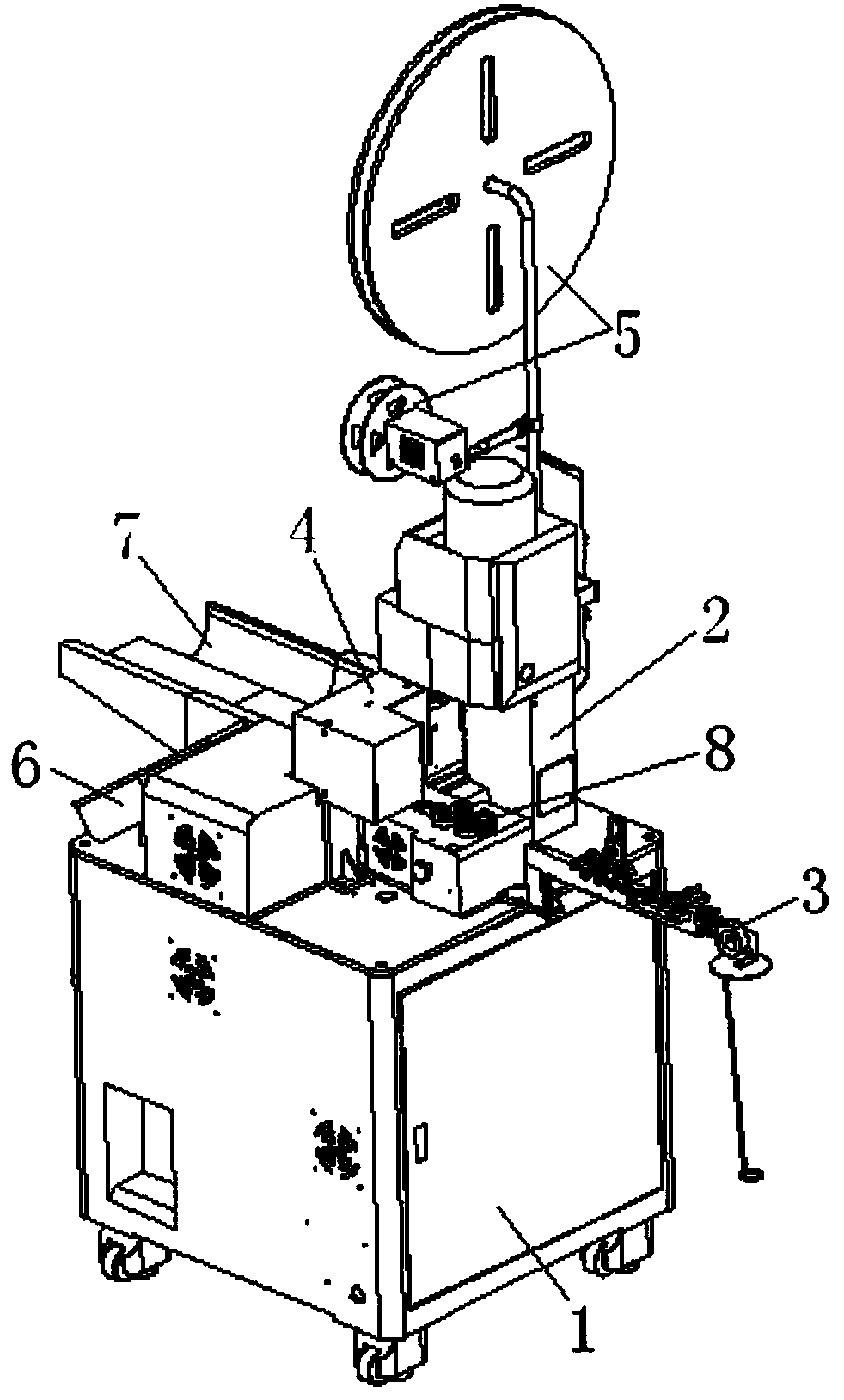

Dual-head and full-automatic terminal machine for harness

PendingCN107681408AImprove processing efficiencyStrong rivetingLine/current collector detailsElectronic waste recyclingMan machineEngineering

A dual-head and full-automatic terminal machine for a harness comprises a case and a fixed bottom rack, wherein the fixed bottom rack is fixedly arranged at the top of the case, a rotation round discis arranged at the top of the fixed bottom rack, a transmission device is arranged on an end surface of one side of the fixed bottom rack, a line cutting and terminal punching mechanism is fixedly arranged at the top of the transmission device, a loading device is arranged on an end surface of an outer side of the transmission device, a receiving device is arranged on an end surface of one side ofthe line cutting and terminal punching mechanism, and a human-machine interaction device is arranged on an end surface of the other side of the line cutting and terminal punching mechanism. Under control of the human-machine interaction device, the loading device, the transmission device and the line cutting and terminal punching mechanism are jointly coordinated and matched to work, so that twoends of the harness are separated and straightened at an extruded terminal, the terminal and the hardness are more stably and accurately riveted, and the finished rate is improved; and meanwhile, operation such as line cutting and line twisting can be automatically completed by the harness, the processing efficiency of the harness is improved, the labor capacity of a worker is reduced, the production efficiency is improved, and the production cost is reduced.

Owner:苏州正兆机械有限公司

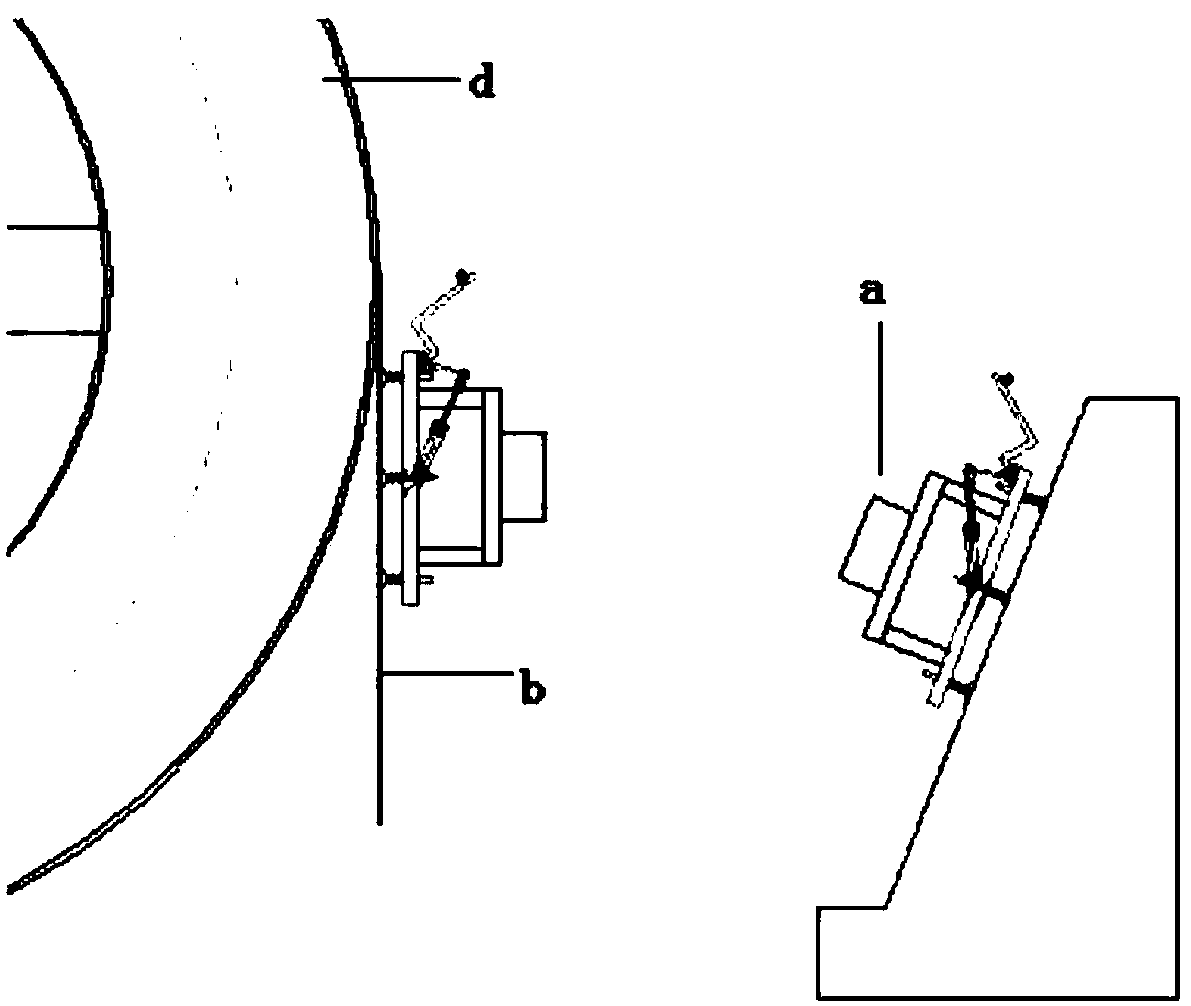

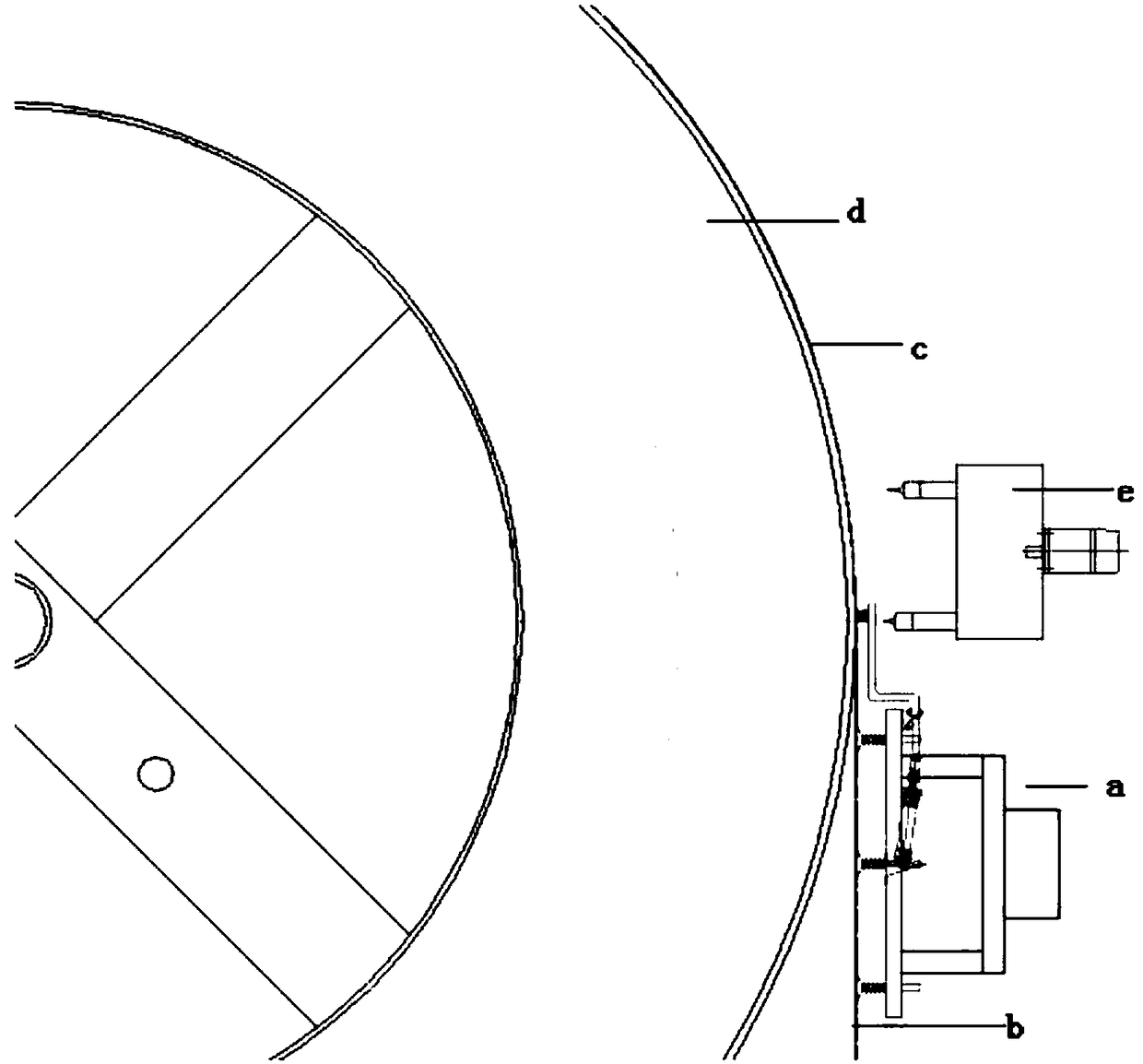

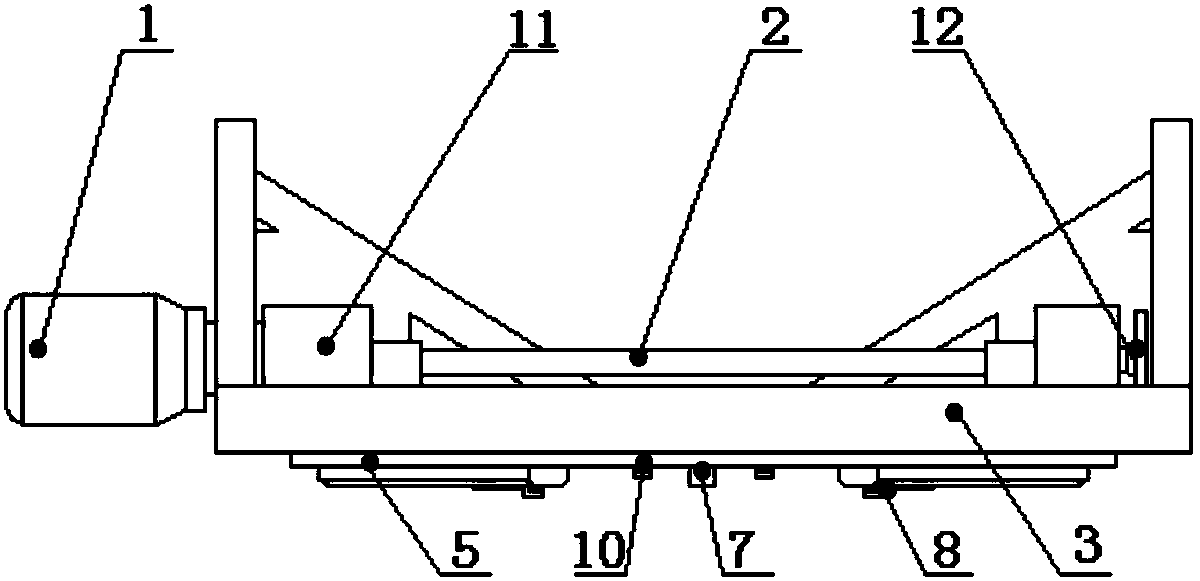

Flexible locating device for riveting cone shell segment wall plate products

The invention provides a flexible locating device for riveting cone shell segment wall plate products. The device comprises a fixed type enclosing frame, a variable swing fixture, a transmission structure and a support clamping part. The fixed type enclosing frame comprises a frame-shaped bracket body and a vertical locating plate. The vertical locating plate is fixed to the center of the bracketbody and is perpendicular to the bottom of the bracket body. The transmission structure comprises a motor, a horizontal transmission shaft, vertical transmission shafts, transmission assemblies and ahand wheel. The variable swing fixture is arranged in the bracket body and comprises a sliding connection plate and swing assemblies. By means of the flexible locating device, the assembling state canbe adjusted according to variation of structural boundary dimensions of the cone shell segment wall plates product so that the flexible locating device can be adapted to the wall plate products of different diameters, heights and taper degrees, and rapid locating and flexible assembling of the cone shell segment wall plate products are achieved.

Owner:CAPITAL AEROSPACE MACHINERY +1

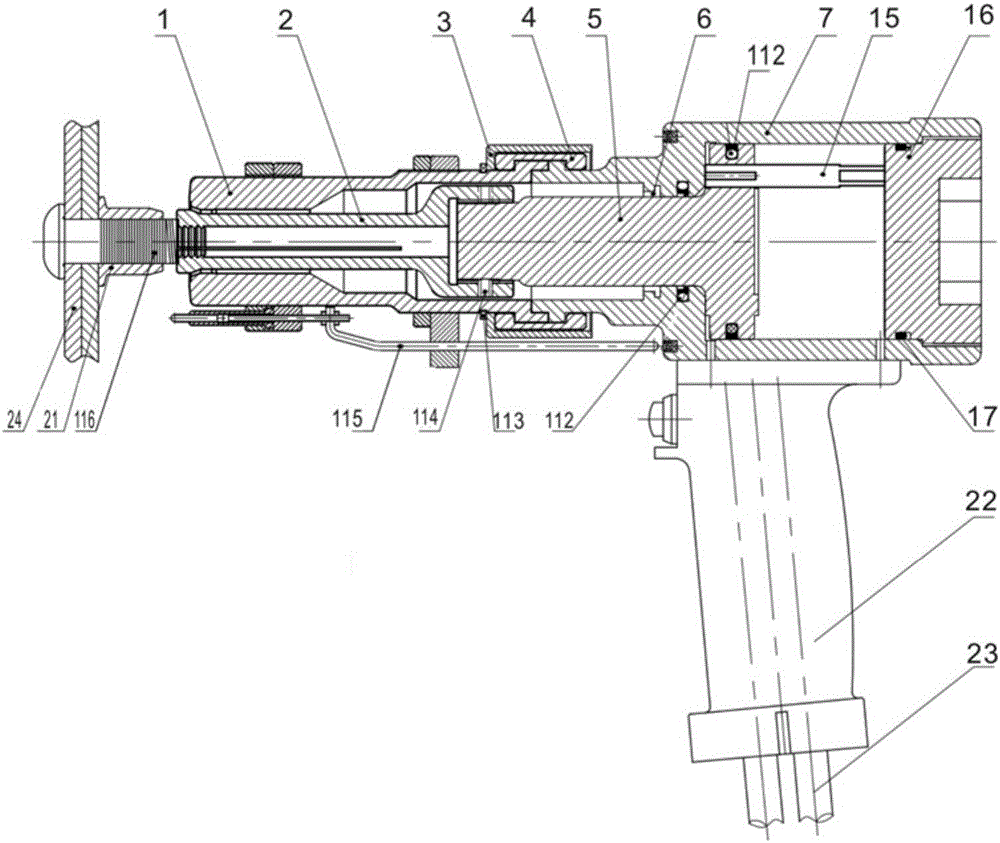

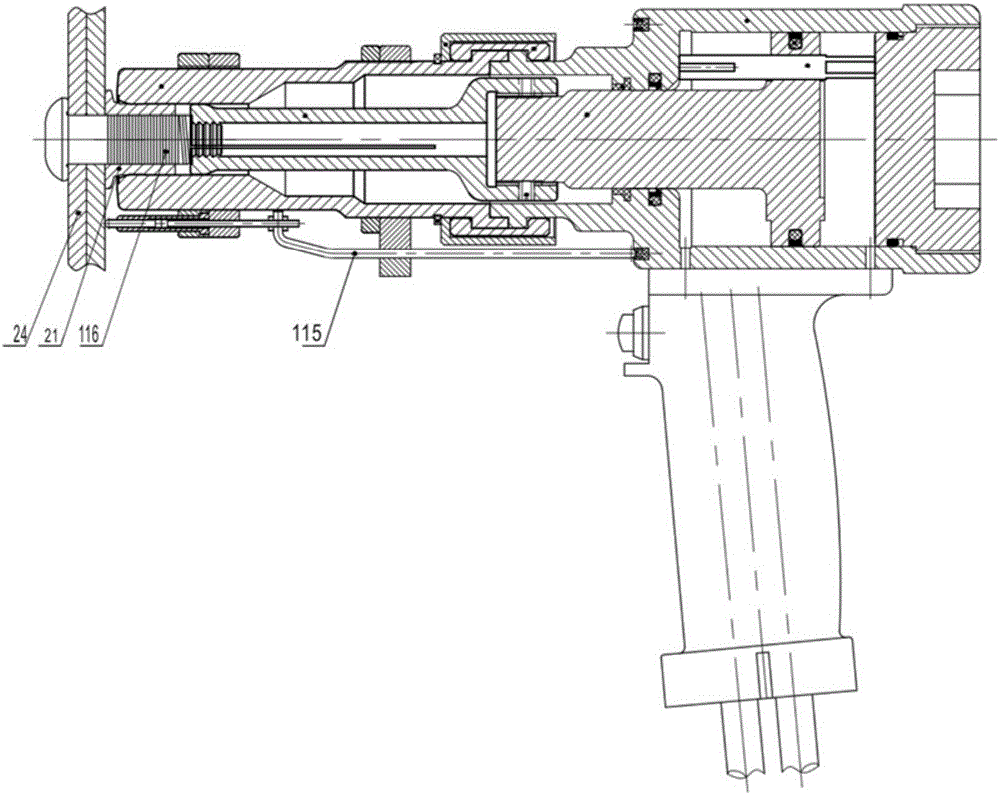

Reusable rivet intelligent riveting machine

The invention discloses an intelligent riveting machine. The intelligent riveting machine comprises a cover, a rivet grabber, an automatic positioning device and a hydraulic system; the back end of the river grabber coats the front end of a piston, and the two are connected as a whole by a thread and locked through a screw; an oil cylinder and the cover are at the outer periphery of the piston; the cover is connected with the oil cylinder through a connecting clamping part, a connecting sleeve and a retainer ring; meanwhile, the oil cylinder is connected with a back cover through a thread; an unloading rod is arranged in a large-head end surface of the piston; the piston slides on the unloading rod; a compensation seal is mounted at the back end of the piston, and a radial seal is mounted at the front end of the back cover; a dustproof ring and a rod seal are mounted in the front end of the oil cylinder; the automatic positioning device is connected with the cover through a thread, and a signal ring thereof is inlaid in the outer front end surface of the oil cylinder; a handle is mounted at the lower part of the oil cylinder; the internal of the handle passes through a high-pressure oil pipe; and the oil cylinder is connected with a hydraulic station through the high-pressure oil pipe. The intelligent riveting machine has the advantages of fast riveting speed, good riveting molding, stable riveting process, accurate riveting effect judgment and convenience for automatic control and recording.

Owner:GUANGDONG NACRE HYDRAULIC CO LTD

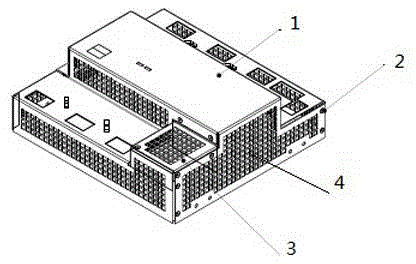

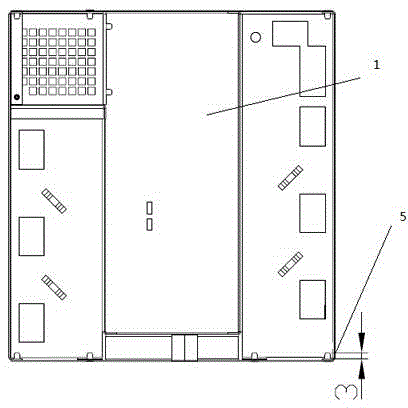

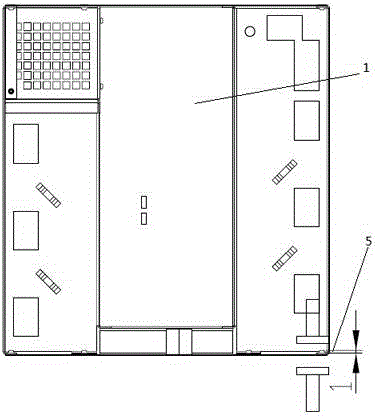

High-heat-dissipation control box and production method

ActiveCN104812218AImprove corrosion resistanceImprove heat resistanceCooling/ventilation/heating modificationsEngineeringElectronic component

The invention discloses a high-heat-dissipation control box. The high-heat-dissipation control box comprises a control box body, a control box bottom cover plate fixed on the control box body, air vents formed in surfaces of the control box body and fixing pieces used for fixing the control box body, wherein the air vents are in linear array arrangement and spaced at intervals of 2mm, and the distance between each air vent and a bending edge is larger than or equal to 7mm. The high-heat-dissipation control box has the advantages of capability of quickly radiating heat generated by an electronic component, firmness in riveting, stable quality, stability in fixing, resistance to extrusion, acid and heat, attractive appearance and no-discoloration.

Owner:昆山荣科钣金科技有限公司

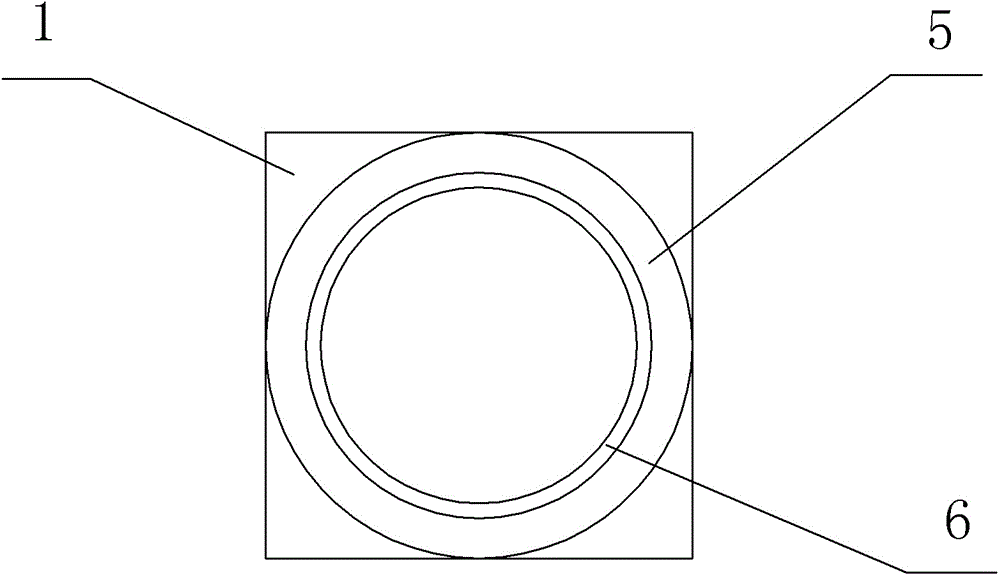

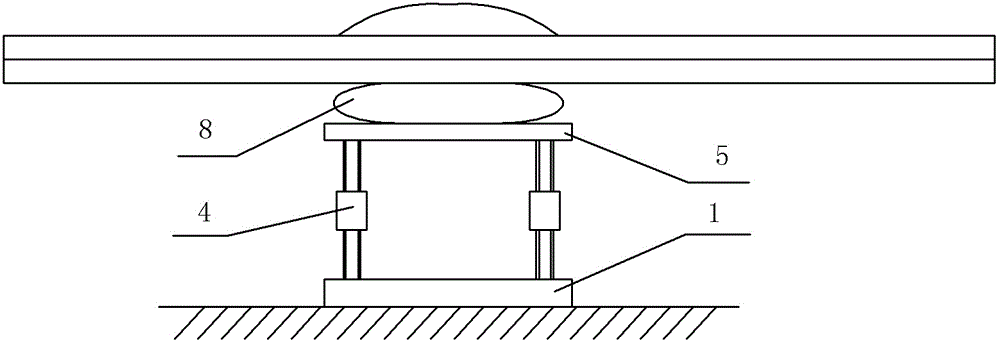

Immobilisation element with profile provided with protrusions

PendingCN111629698AReliable anchoringNot affected by environmental factors such as humidityRestraining devicesNon-surgical orthopedic devicesEngineeringBody region

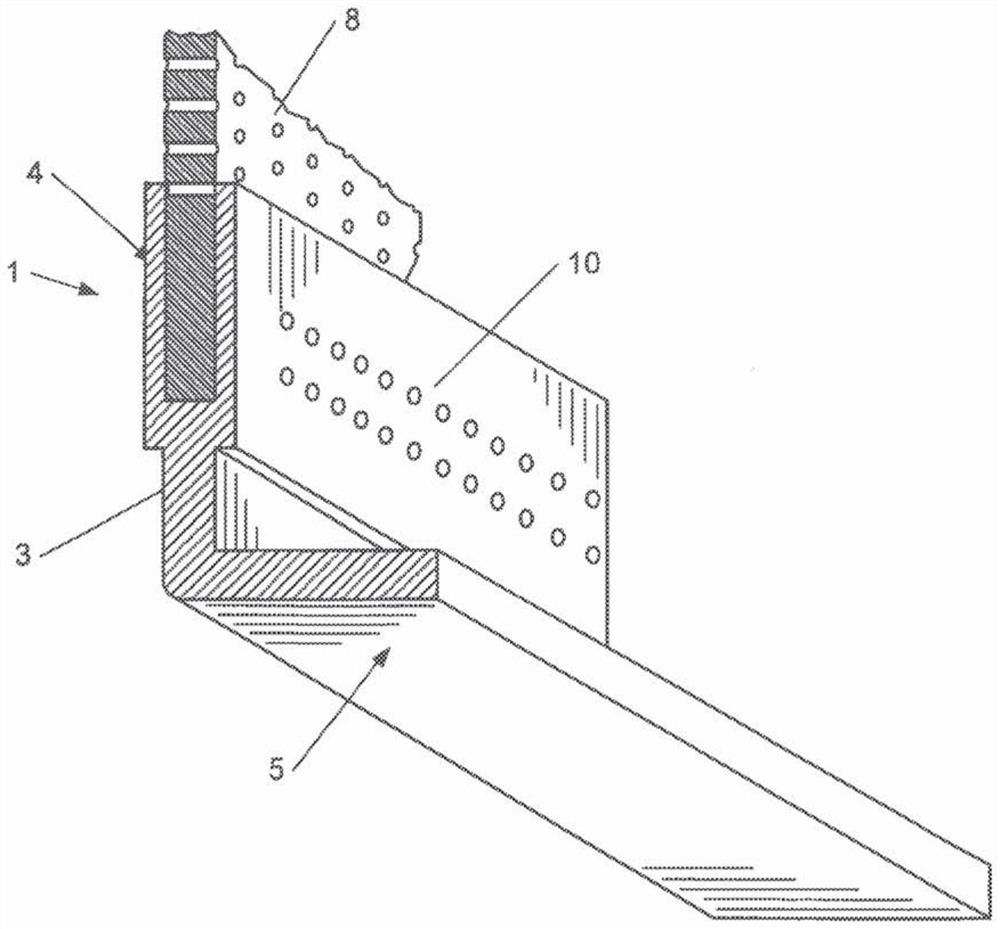

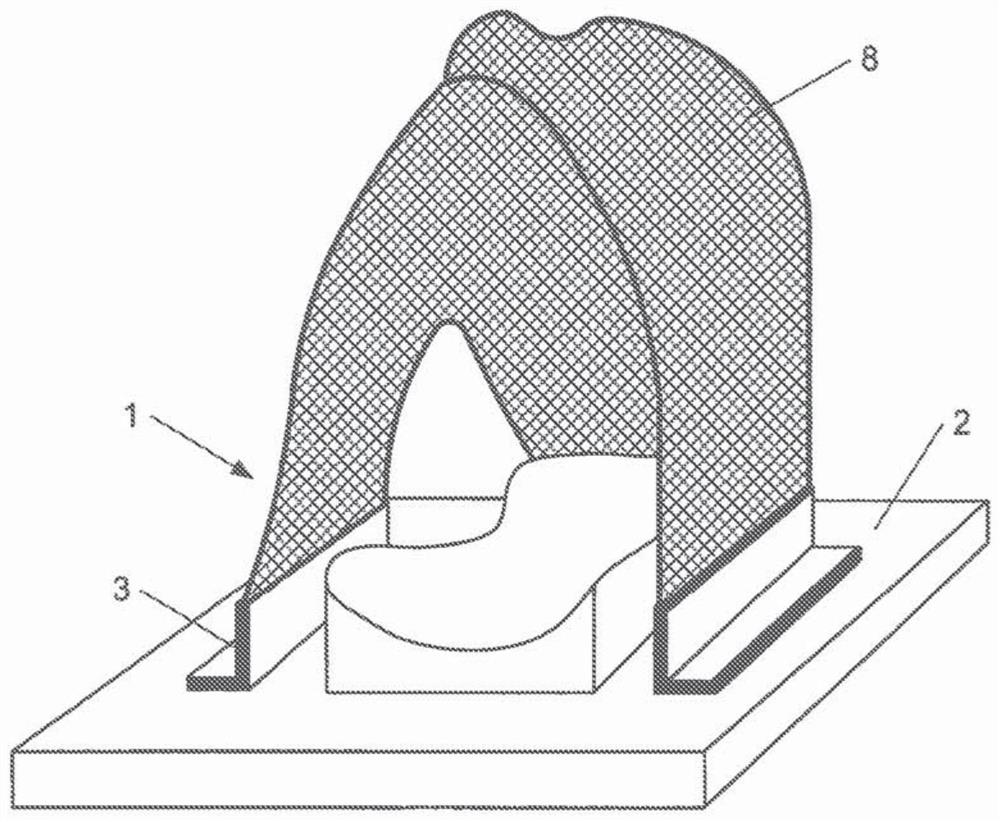

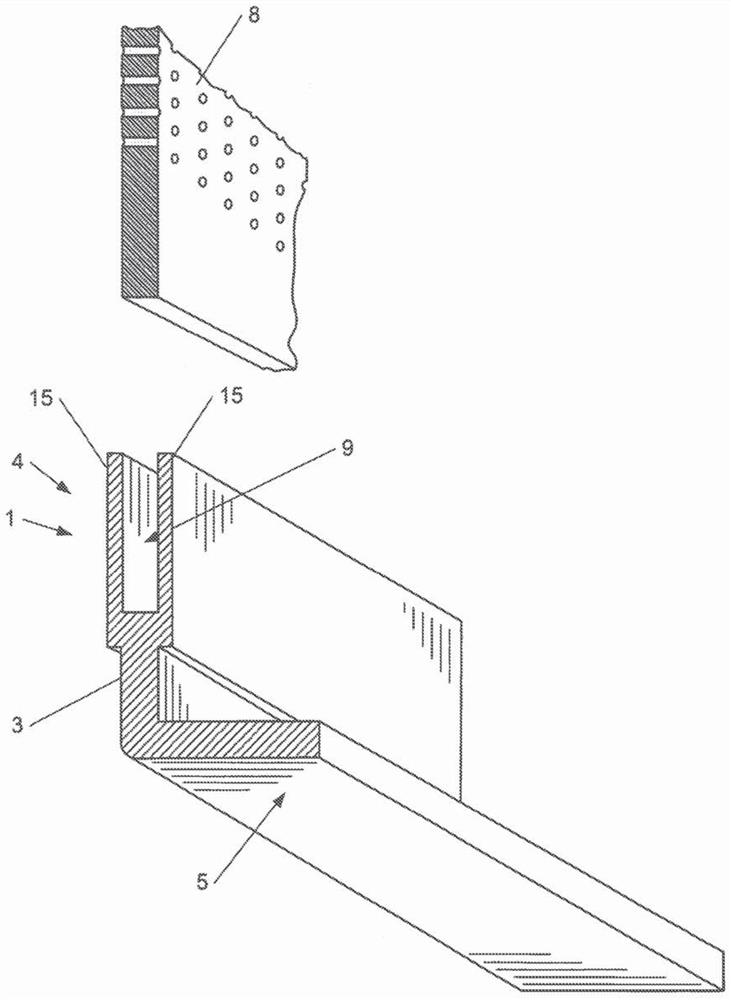

Method for producing an immobilisation element (1) for immobilising a body part of a patient on a supporting surface, wherein the immobilisation element (1) comprises a sheet (8) of thermoplastic material for receiving the body part to be immobilised, and at least one profile (3) for fixing the immobilisation element (1) to the supporting surface, wherein the profile (3) comprises a first fixing means for fixing the profile (3) to the sheet (8), wherein the fixing means comprises a groove (9) delimited by a first contact surface (6) and a second contact surface (7) opposite the first contact surface (6), wherein the groove (9) receives the sheet (8) so that the first and the second contact surfaces (6, 7) lie along the sheet (8), and wherein at least one of the first contact surface (6) and the second contact surface (7) is provided with at least one protrusion (10), wherein the protrusion (10) penetrates the sheet (8) of thermoplastic material in the thickness direction of the sheet (8) in order to anchor the sheet (8) of thermoplastic material in the groove (9).

Owner:ORFIT IND

Fast assembly, rolling riveting and bending integrated forming method and device

PendingCN111715808ASimple stepsEasy to implementShaping toolsMetal-working feeding devicesStructural engineeringIndustrial engineering

The invention discloses a fast assembly, rolling riveting and bending integrated forming method and a riveting device. The method comprises the following steps that an inclined pushing device pushes an inclined comb plate to move to comb and centralize cooling fins, so that when a cover plate covers the cooling fins, riveting convex points on the cooling fins can be aligned with and matched with riveting holes in the cover plate one by one; then, a riveting and bending screw rod driving mechanism drives a rolling riveting device and a bending device to move simultaneously, during pushing out,the rolling riveting device carries out riveting pressing on the riveting convex points on the cooling fins, and thus the purpose of rolling riveting is achieved; and during pulling pack, the bendingdevice is used for bending the edge position of the cover plate, so that the bending purpose is achieved. Therefore, the centralizing function, rolling riveting function and bending function can be rapidly achieved through one-time clamping, the operation process is effectively simplified, the operation is easy and convenient, time and labor are saved, the working efficiency is improved, meanwhile, the consistency of the riveting effect and bending effect is guaranteed, and finally, the yield is improved.

Owner:东莞市毅帆五金模具有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com