Riveting connector

A connecting piece and riveting technology, applied in the direction of connecting components, thin plate connection, mechanical equipment, etc., can solve the problems of nut falling off, weak axial tensile force, etc., and achieve firm riveting, large axial bearing capacity, large radial Anti-torsion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

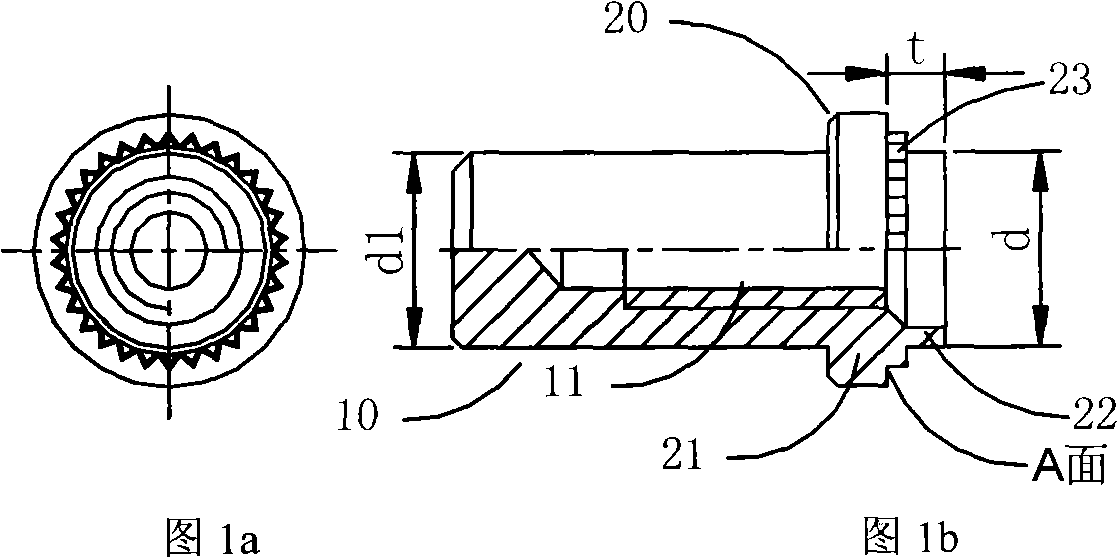

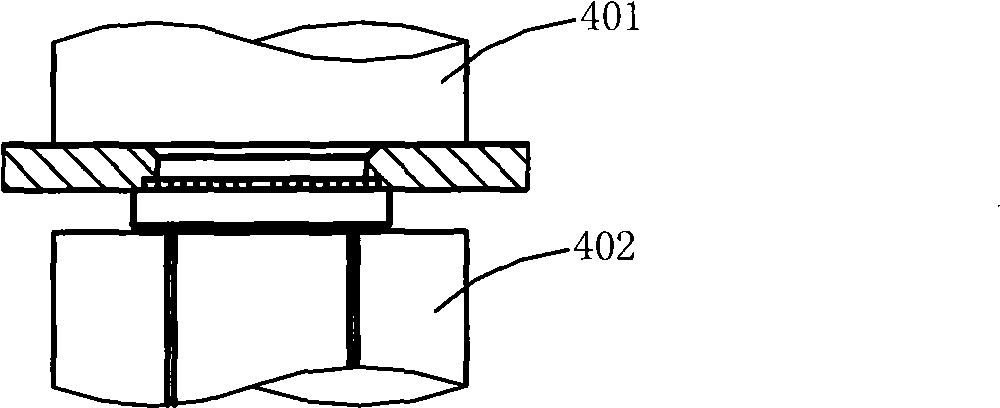

[0018] As shown in Figure 1a, Figure 1b As shown, the present embodiment takes a nut as an example for illustration. The riveted connector includes a connecting part 10 and a riveted part 20. The connecting part 10 is provided with a threaded hole 11 for connecting with other parts. The riveted part 20 is used for For riveting fastening with the plate to be riveted, it is hollow inside, the inner diameter of the blind threaded hole 11 is smaller than the inner diameter of the inner hole of the riveting part 20, and the transition between the blind threaded hole 11 and the inner hole of the riveting part 20 is a conical surface, and the riveting The part 20 includes a base 21 and a deformed riveting column 22. The deformed riveting column 22 is in the shape of a short tube, the height t is greater than the thickness of the sheet to be riveted, and the bottom is provided with ring-shaped distribution tines 23 to prevent rotation. It is in contact with the plate to be riveted, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com