Patents

Literature

60results about How to "Improve the axial bearing capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

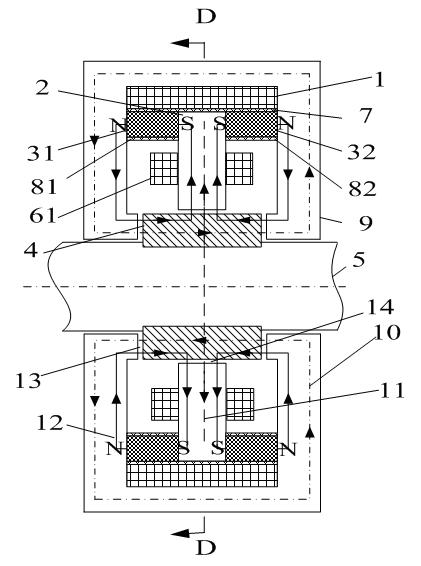

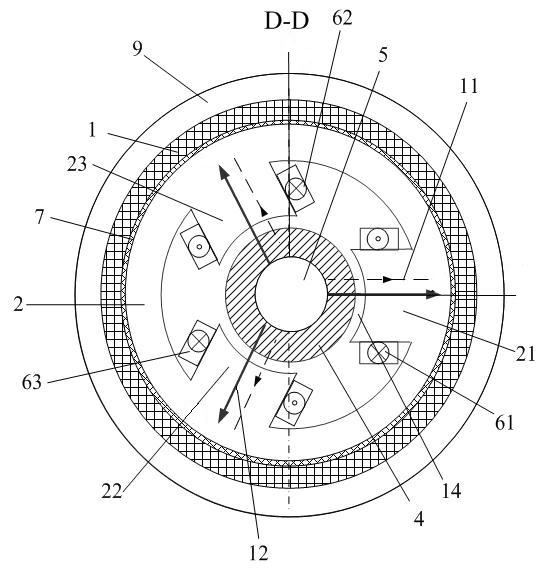

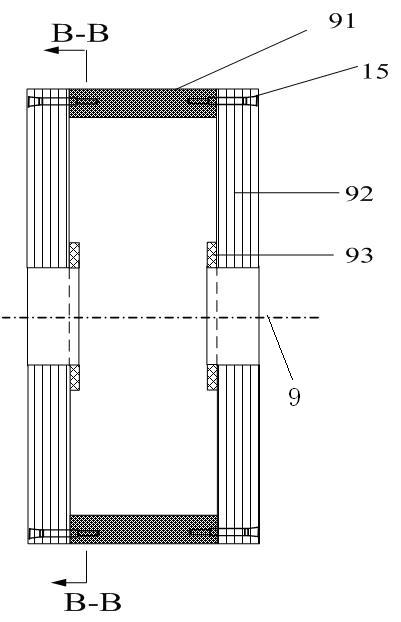

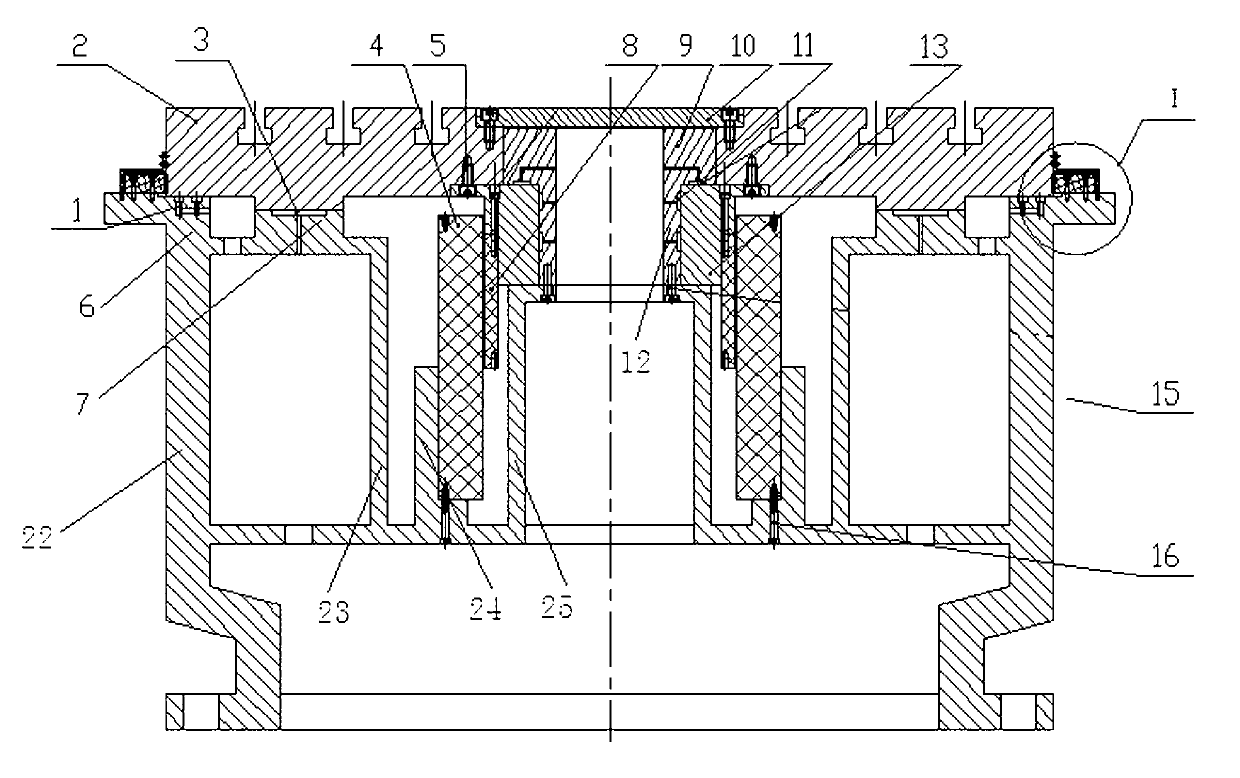

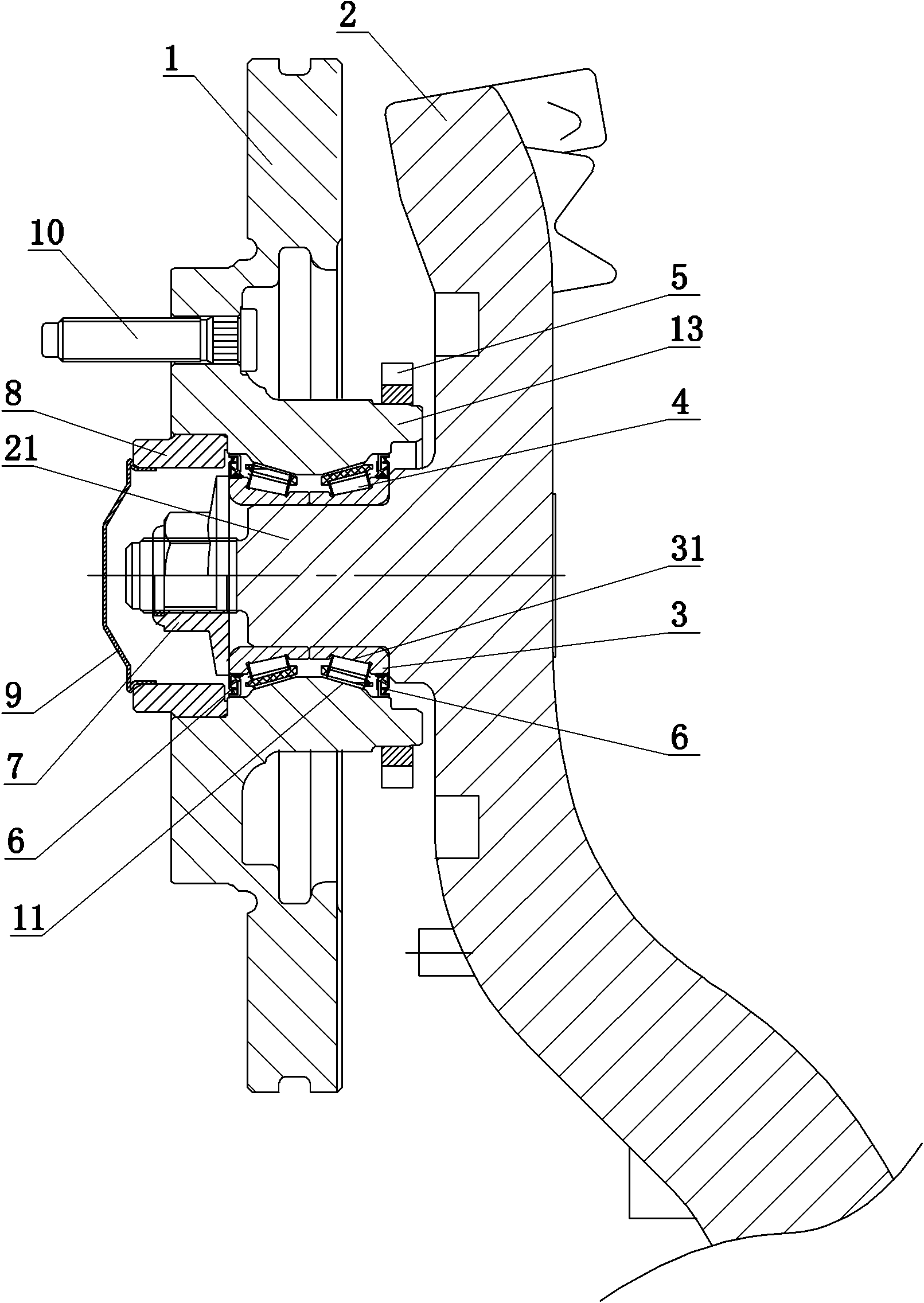

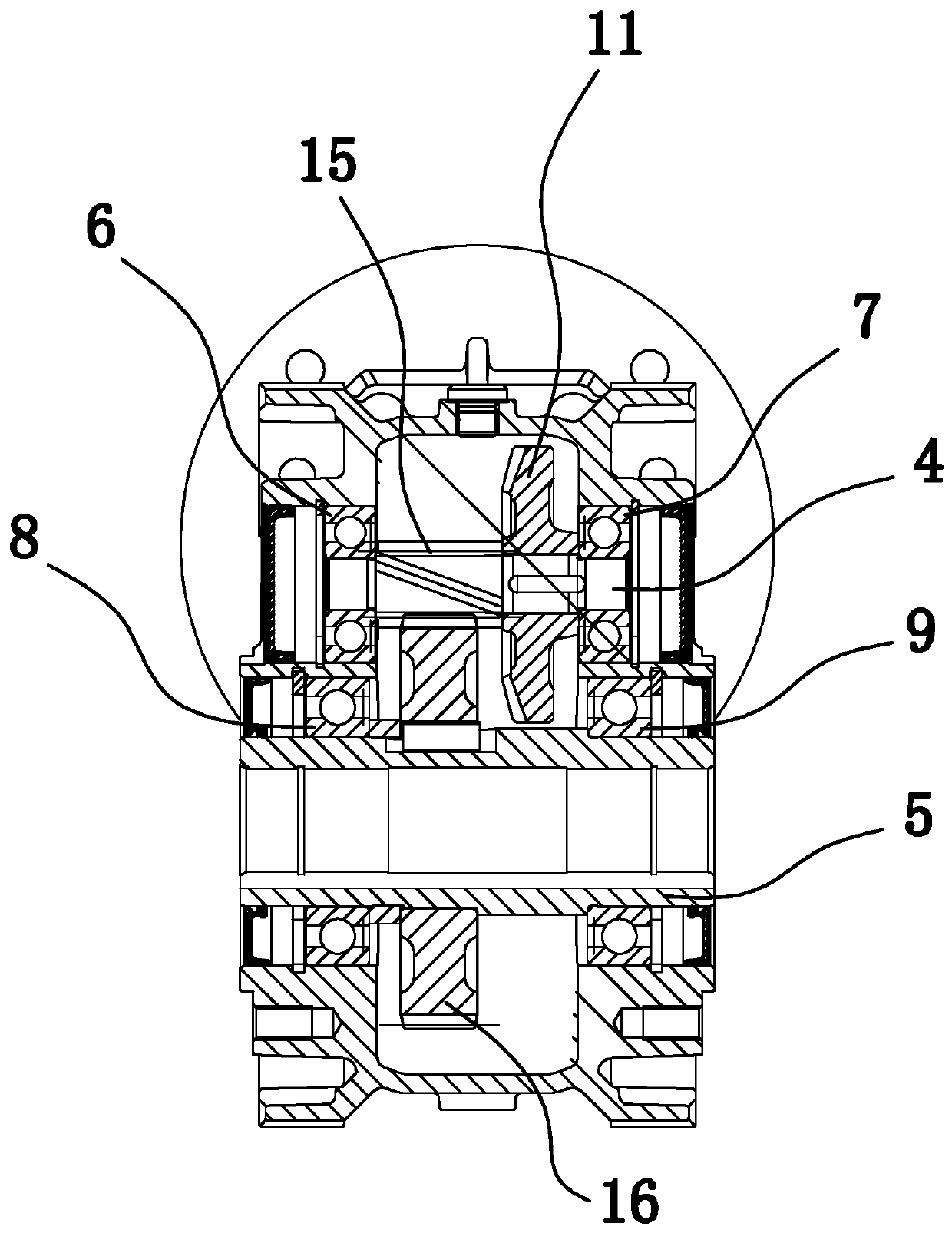

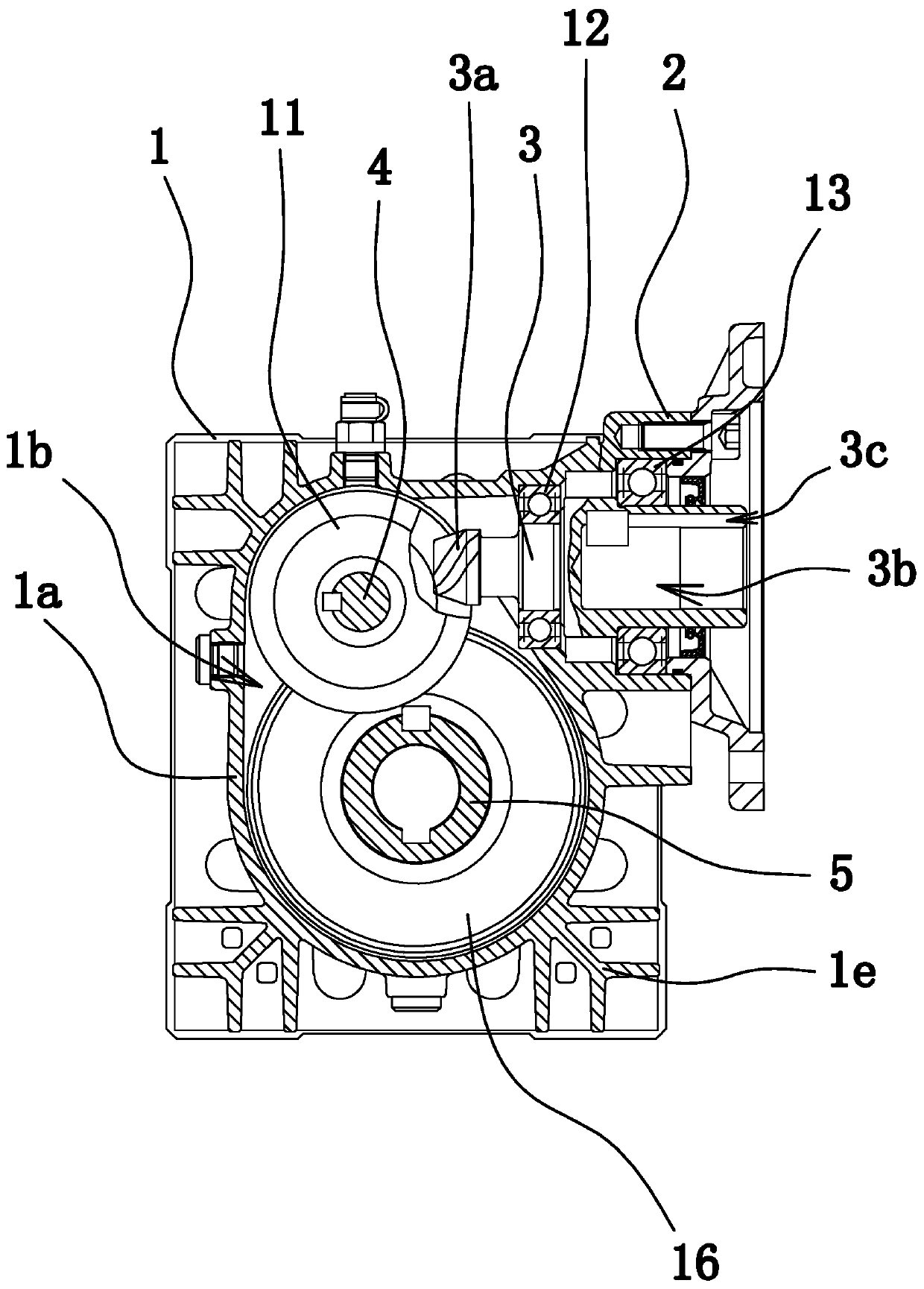

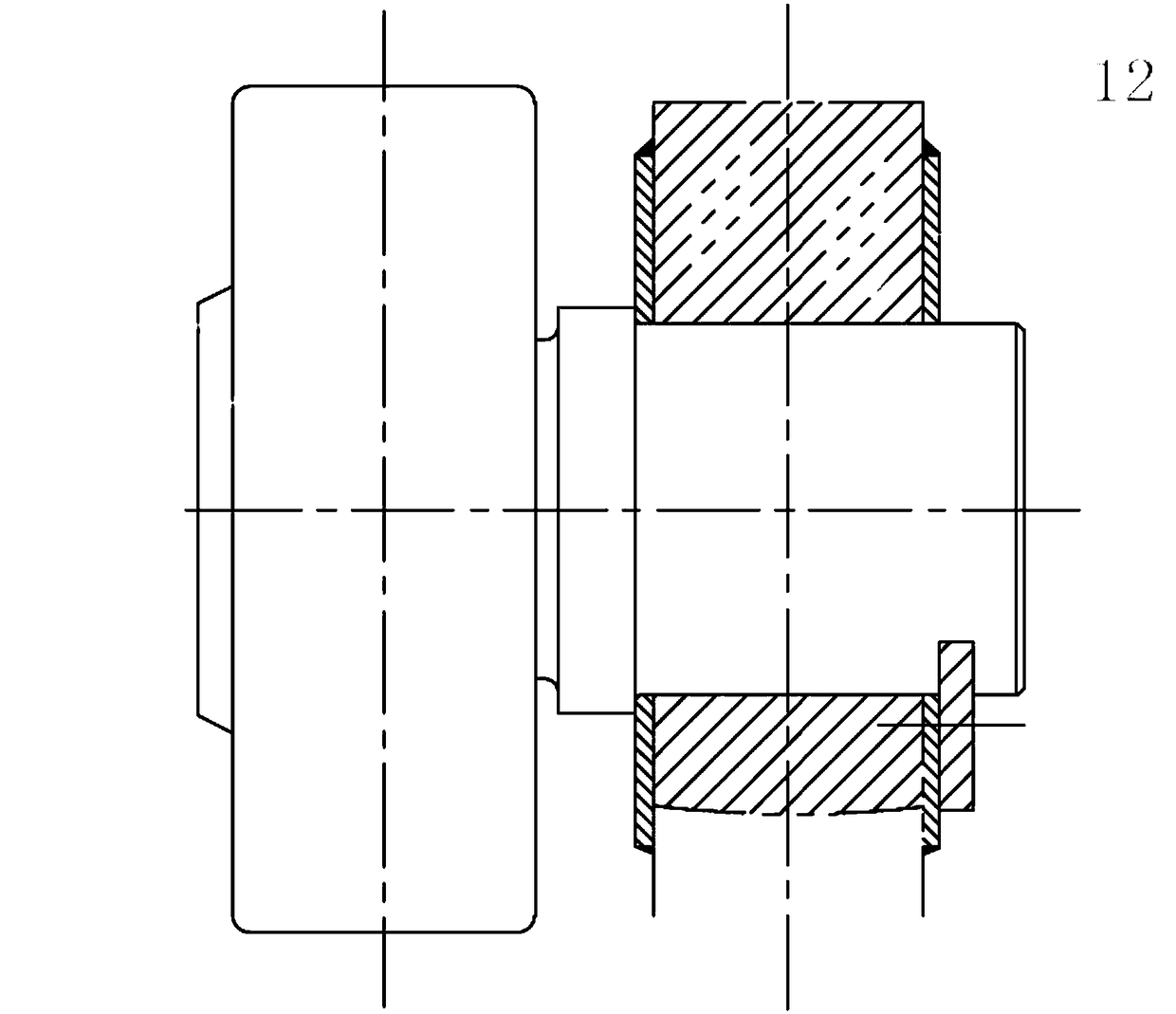

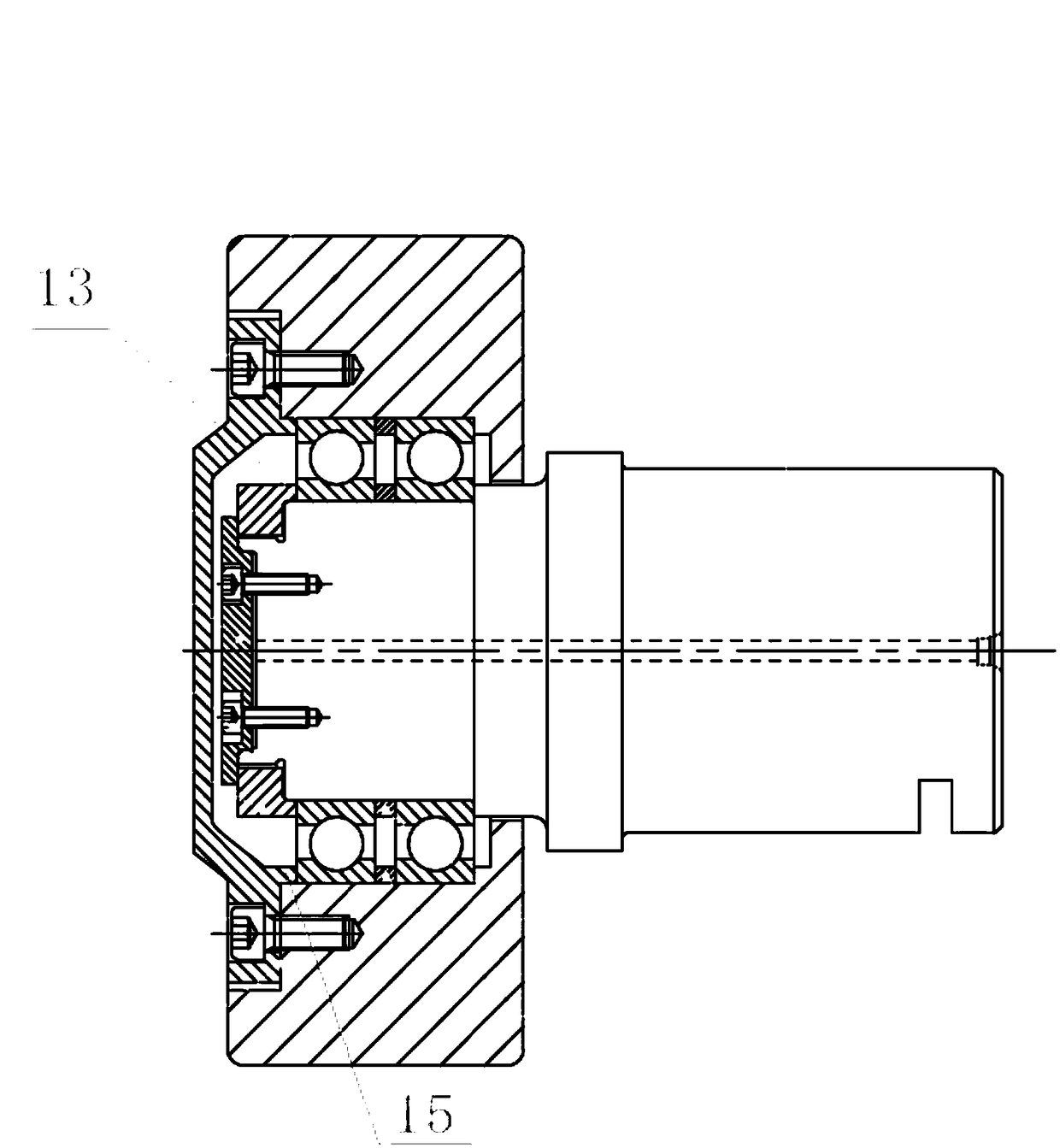

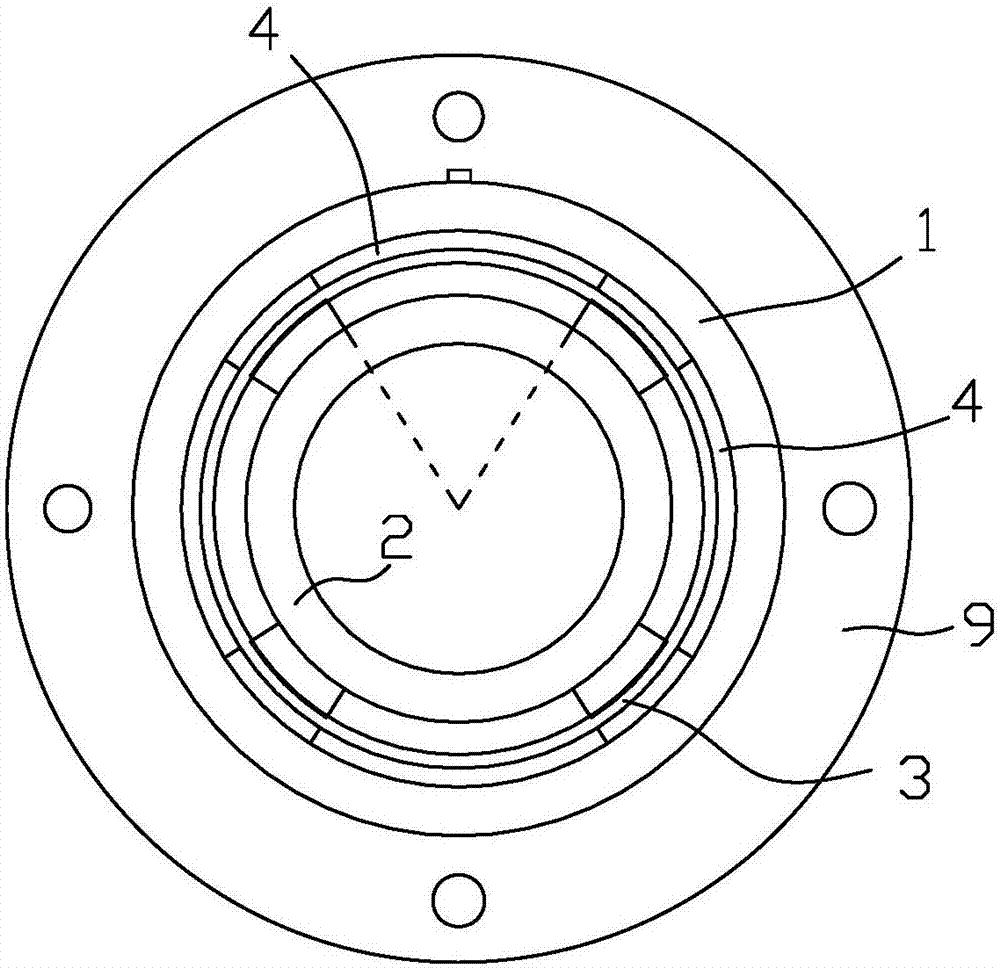

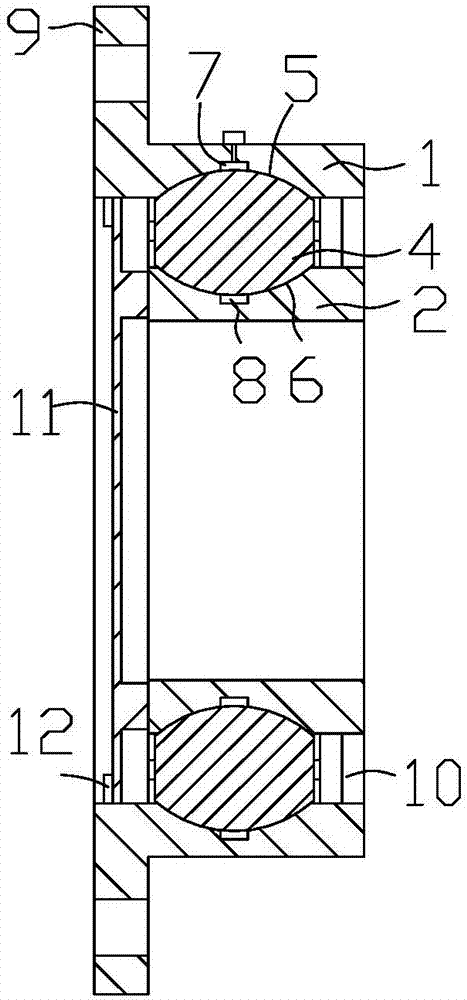

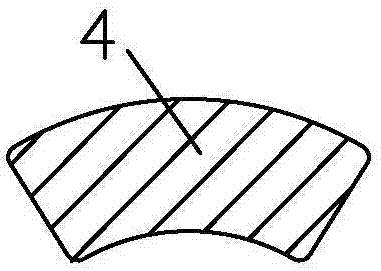

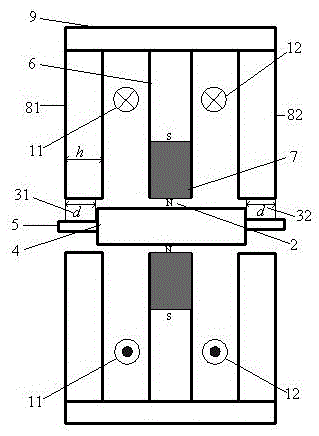

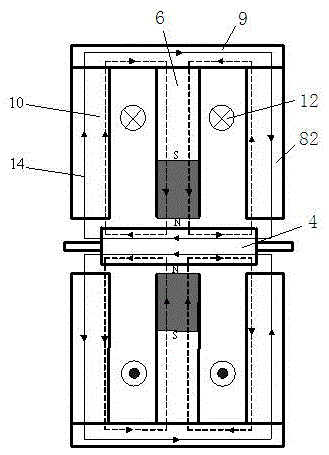

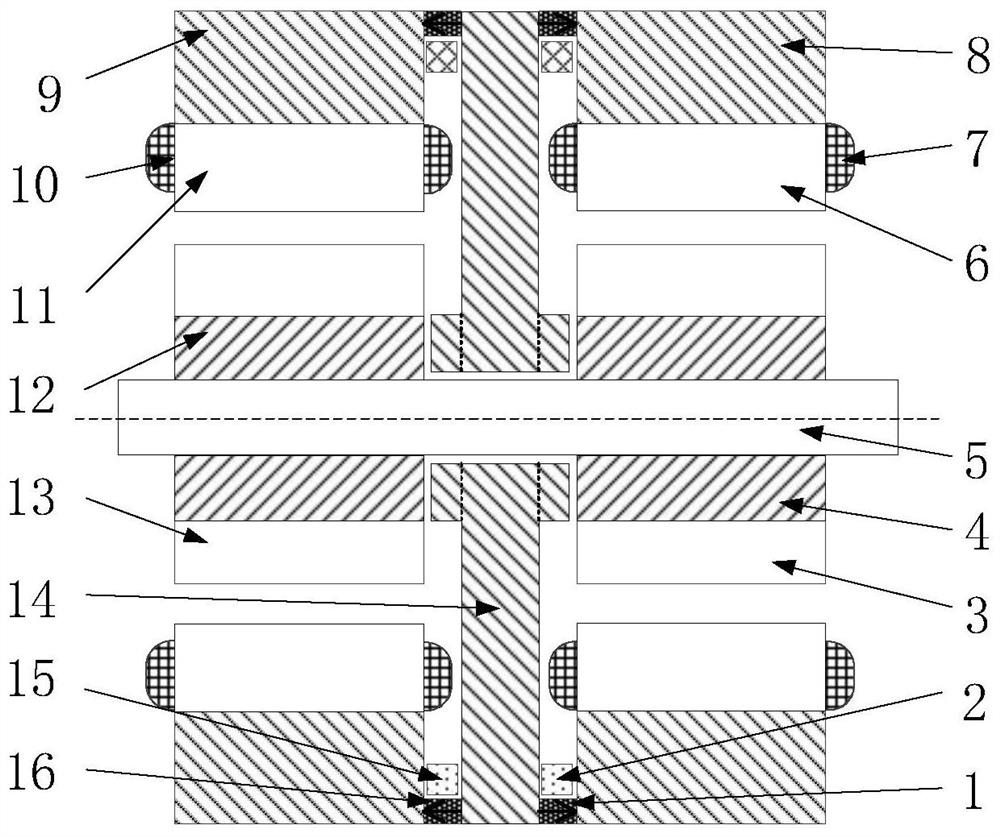

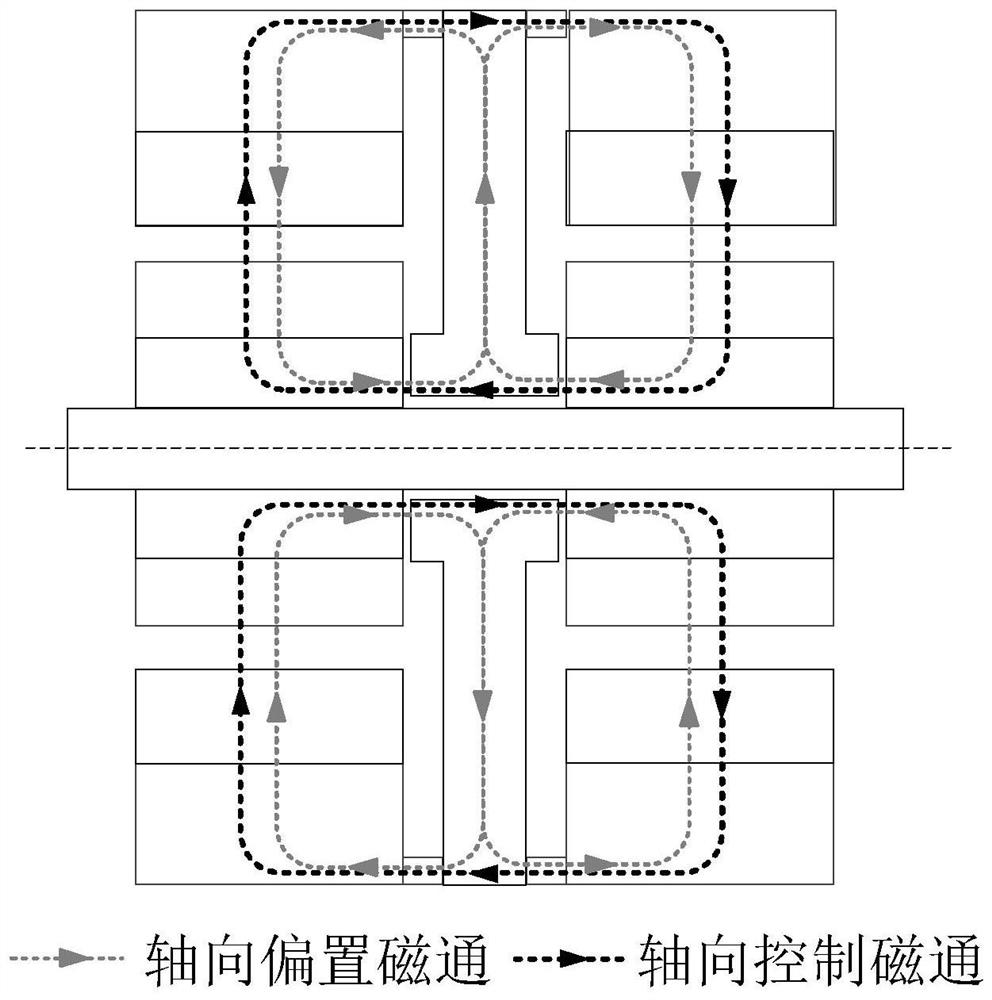

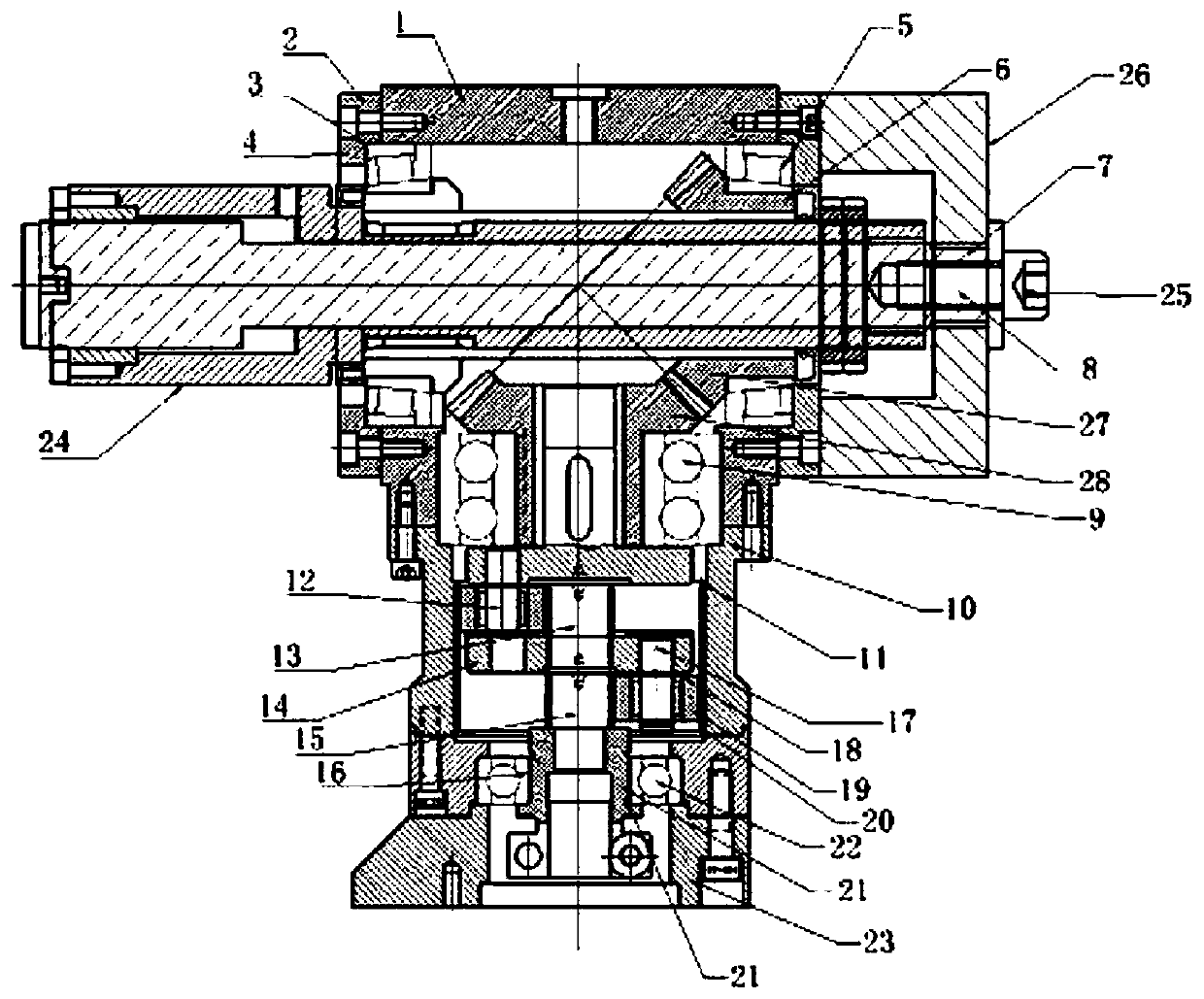

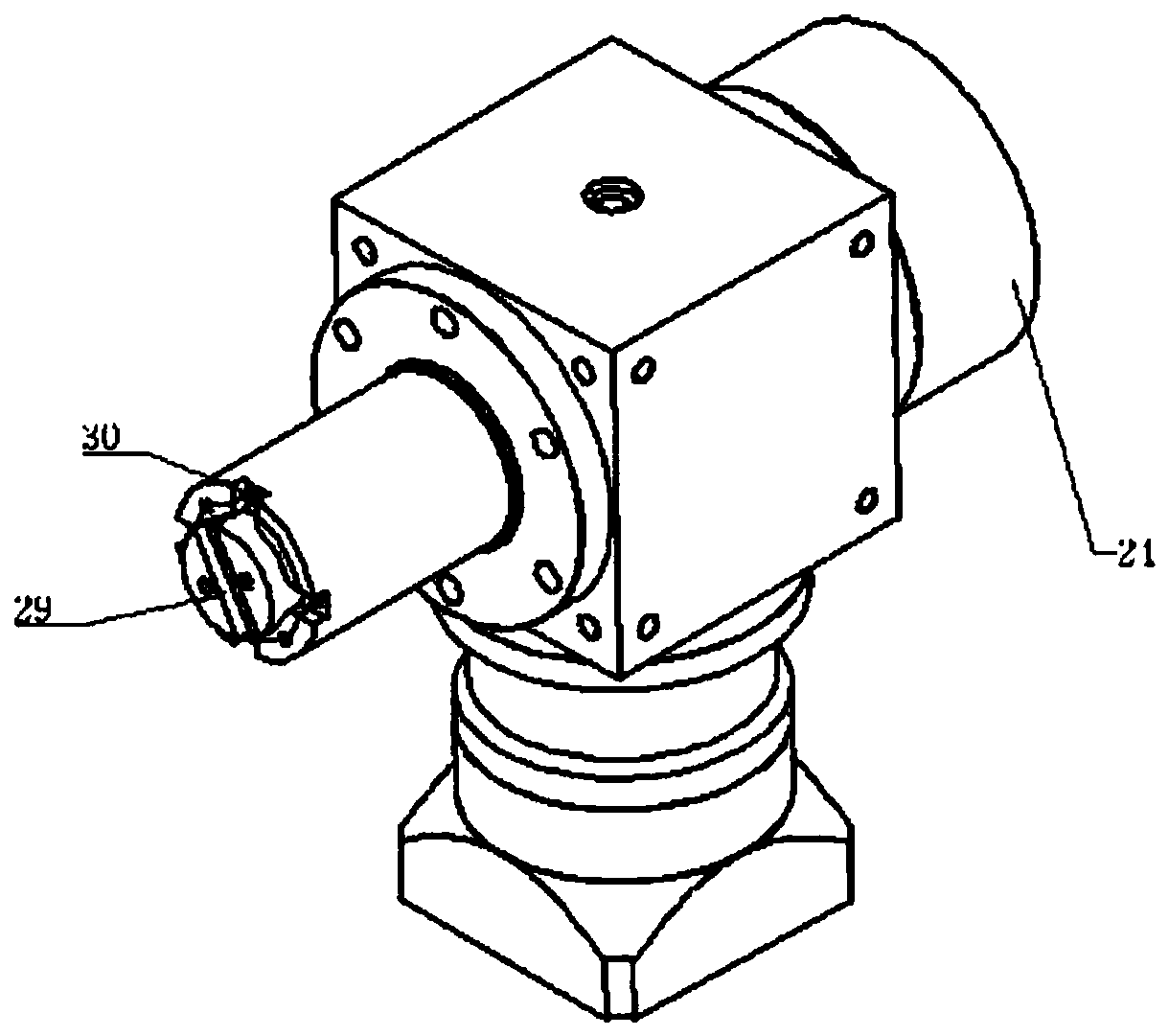

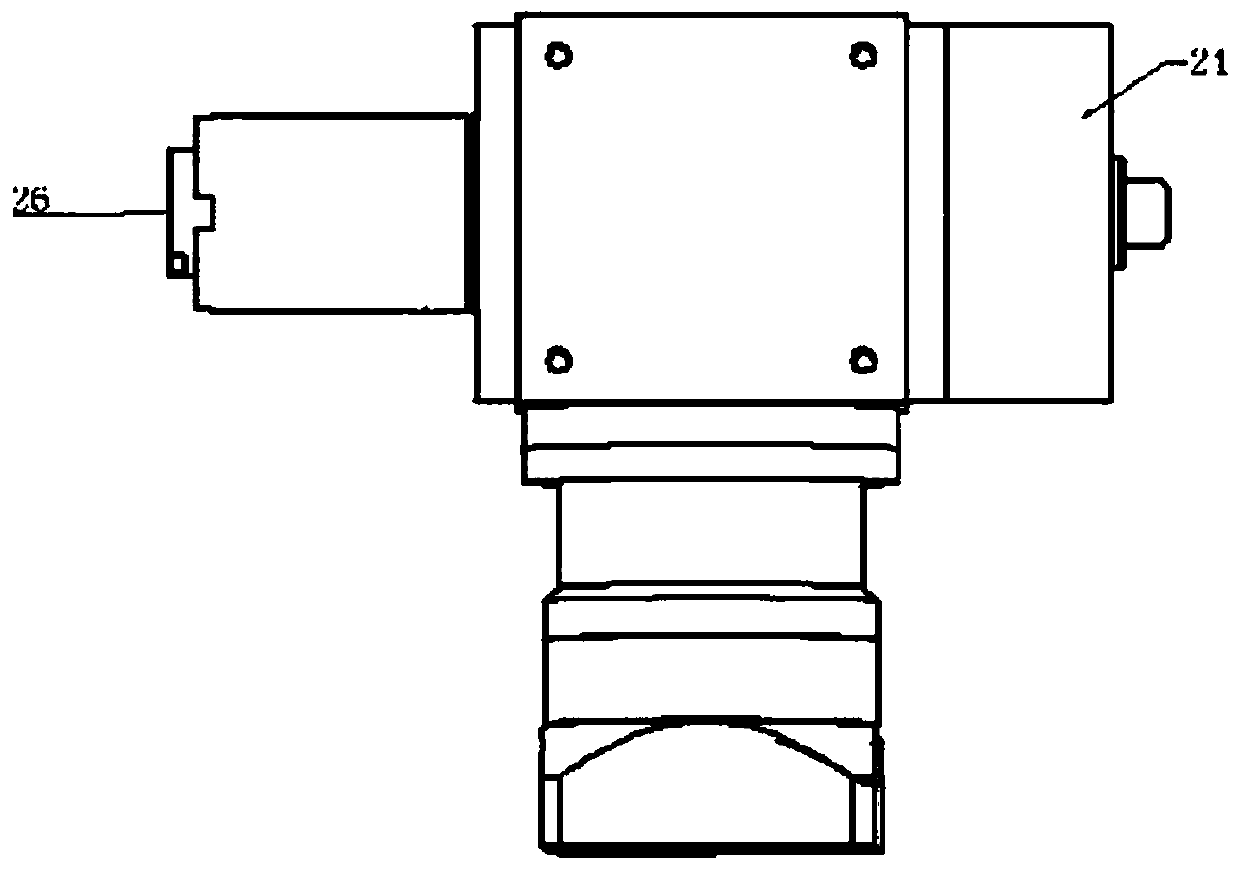

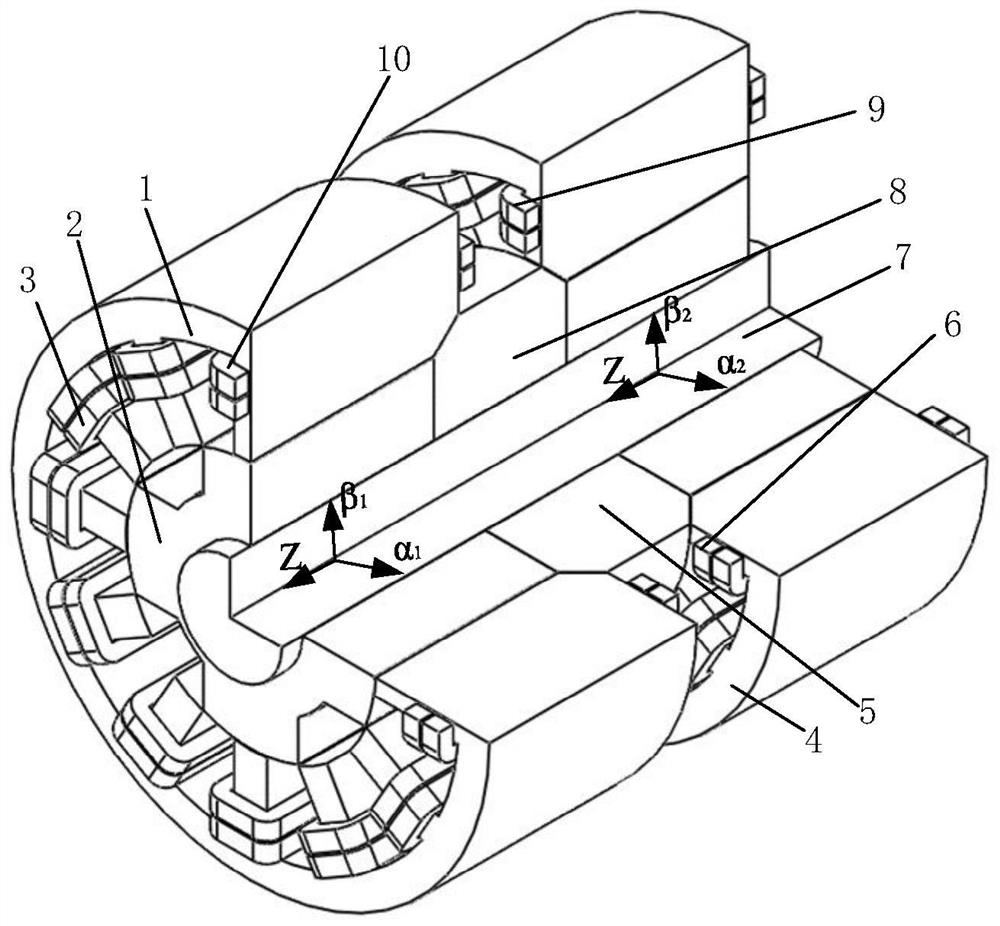

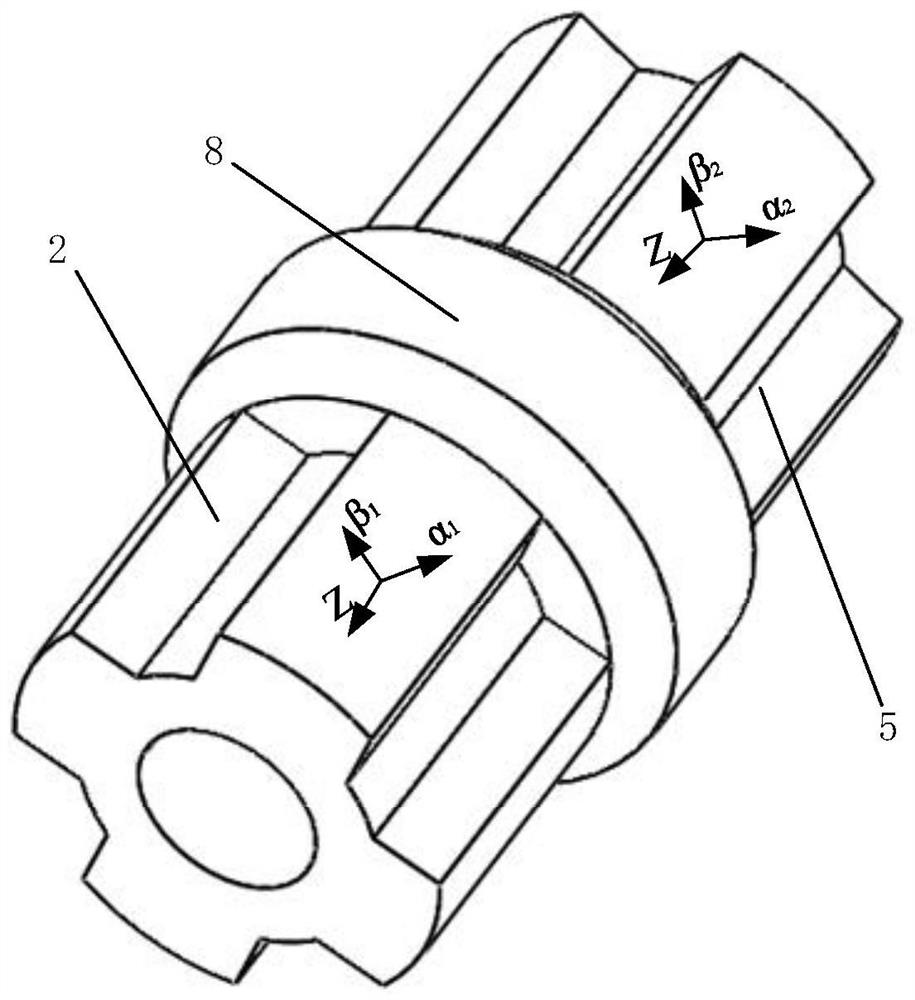

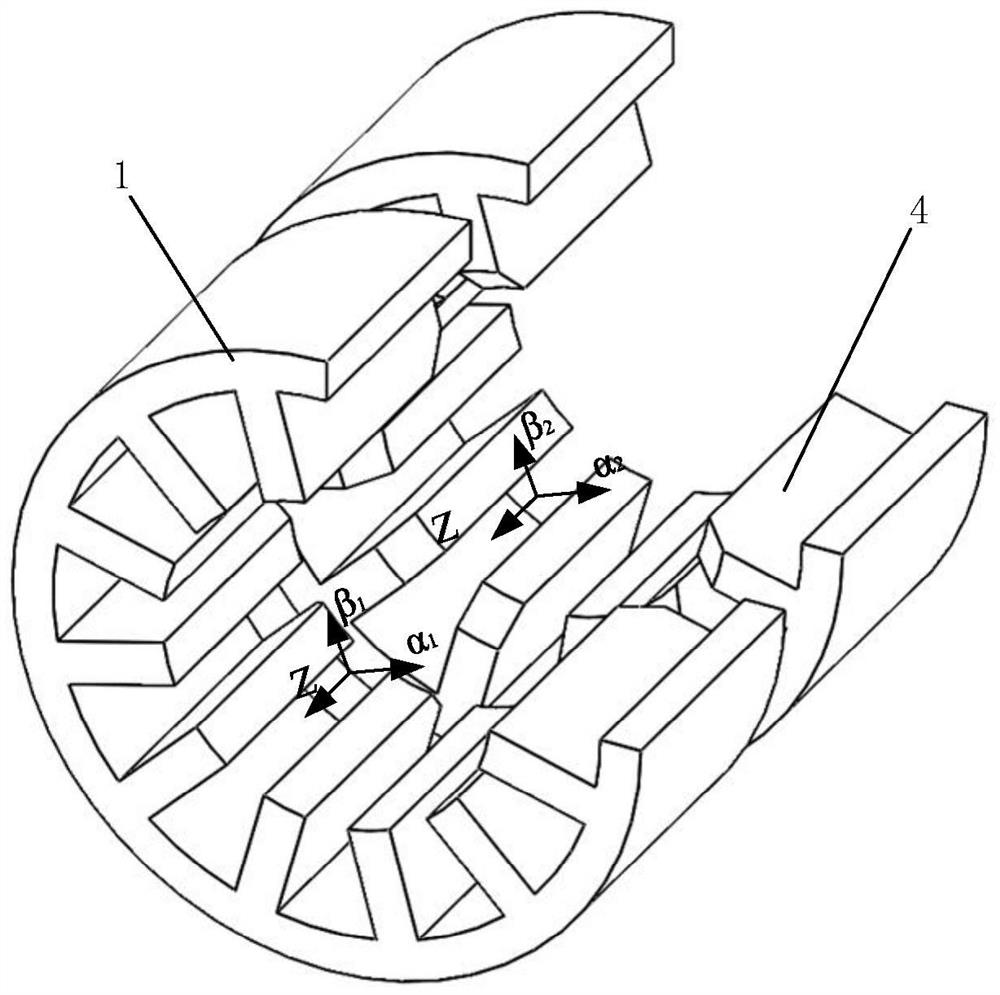

Radial-axial three-degree-of-freedom alternating current-direct current hybrid magnetic bearing

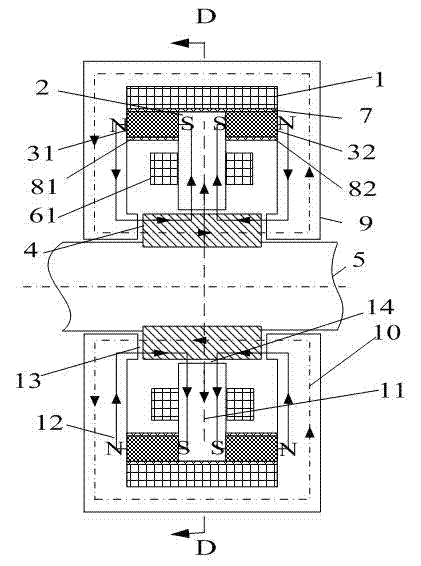

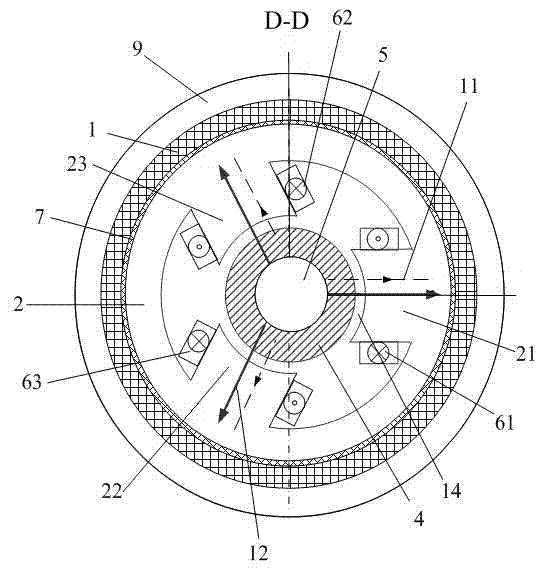

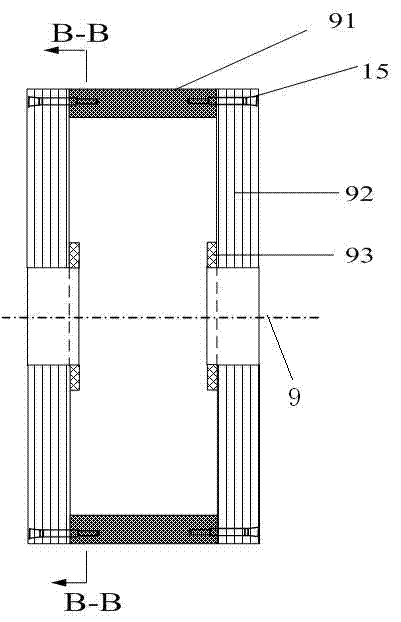

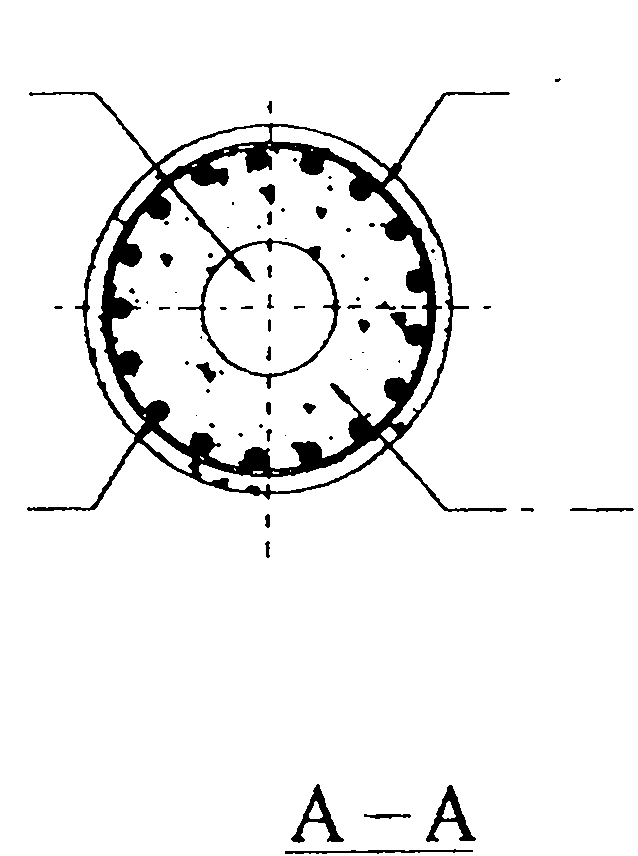

The invention discloses a radial-axial three-degree-of-freedom alternating current-direct current hybrid magnetic bearing used for non-contact suspension bearing. An axial control coil is arranged between a radial stator core and an axial stator core; an axial air gap is formed between the axial stator core and the end face of a rotor in the axial direction; three same stator core magnetic poles uniformly distributed in the circumferential direction extend from the wall of an inner cavity of the radial stator core to the axle center; same radial control coils are wound on the three stator core magnetic poles, and radial air gaps are formed between the stator core magnetic poles and the outer wall of the rotor in the radial direction; same axially magnetized annular permanent magnets are arranged between two axial sides of the radial stator core and the axial stator core; and S poles of the permanent magnets face the radial stator core, and N poles of the permanent magnets face the axial stator core. The radial-axial three-degree-of-freedom alternating current-direct current hybrid magnetic bearing integrates axial and radial functions, is only driven by a three-phase alternating current power inverter, is provided with two axially magnetized annular permanent magnets, controls the magnetic flux not to pass magnetic poles where the permanent magnets are positioned, and has the advantages of low power consumption, small volume, light weight and high bearing capacity.

Owner:JIANGSU UNIV

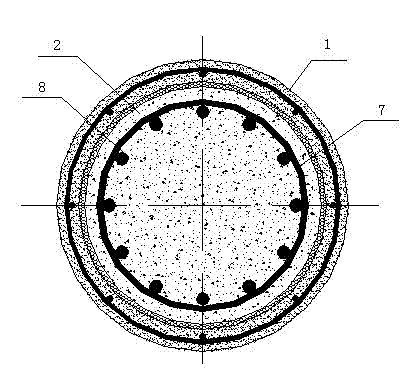

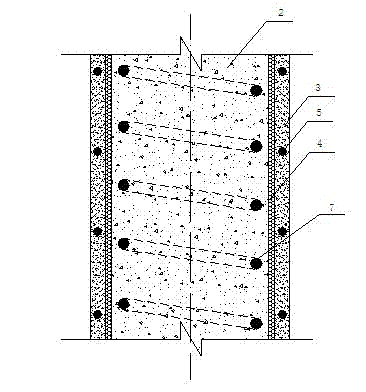

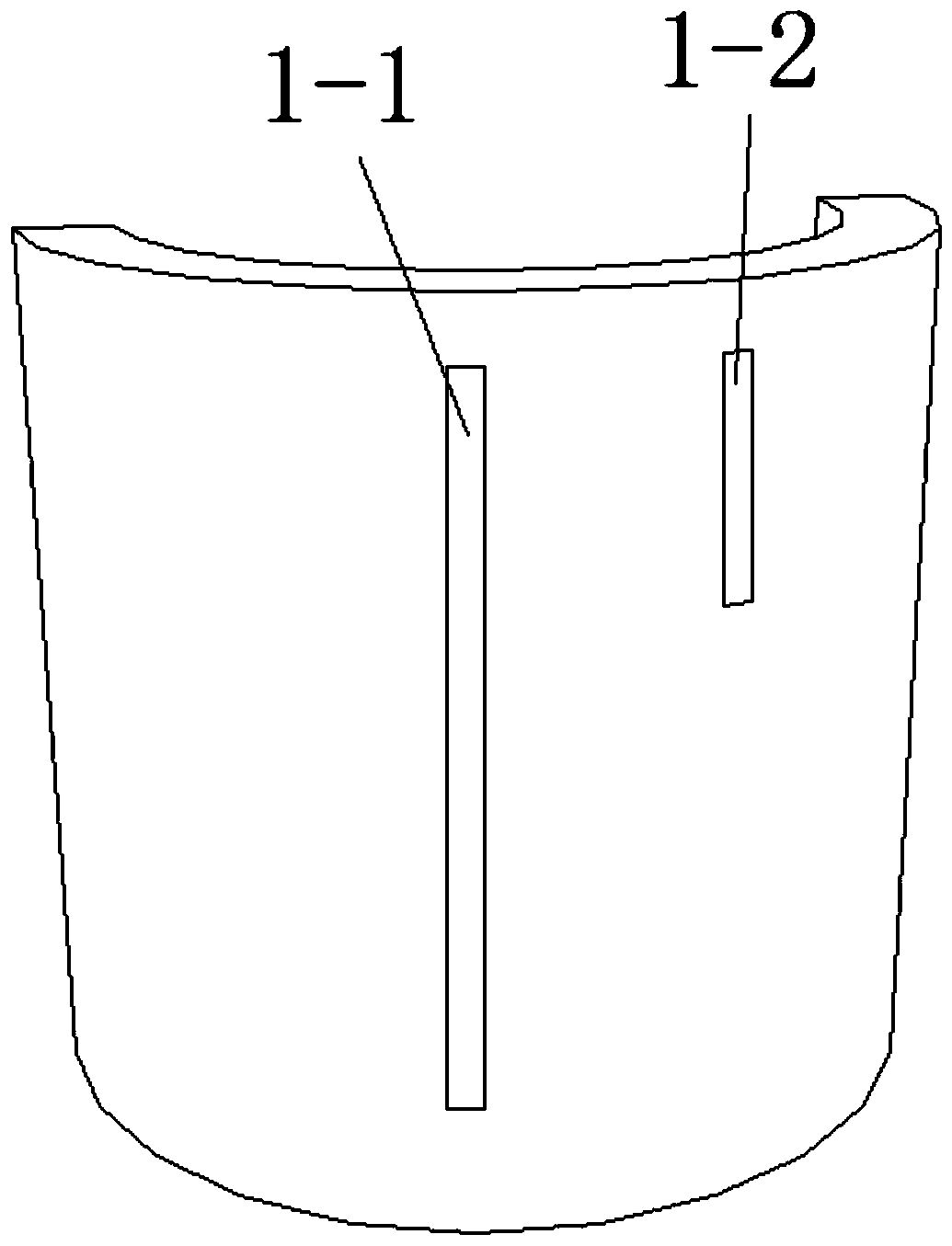

Sleeve reinforced concrete column

InactiveCN102102423AGive full play to the material performanceEasy constructionStrutsPillarsReinforced concrete columnShock resistance

The invention discloses a sleeve reinforced concrete column. The sleeve reinforced concrete column is characterized in that: a sleeve (1) of a reinforced concrete column (2) is a prefabricated active powder concrete sleeve. The sleeve reinforced concrete column has the advantages of convenience for construction, low cost, high axial bearing capacity, good shock resistance, predominant fireproof performance, excellent durability and the like, meanwhile, saves more resources and energy, and accords with the requirements of sustainable development.

Owner:HUNAN UNIV

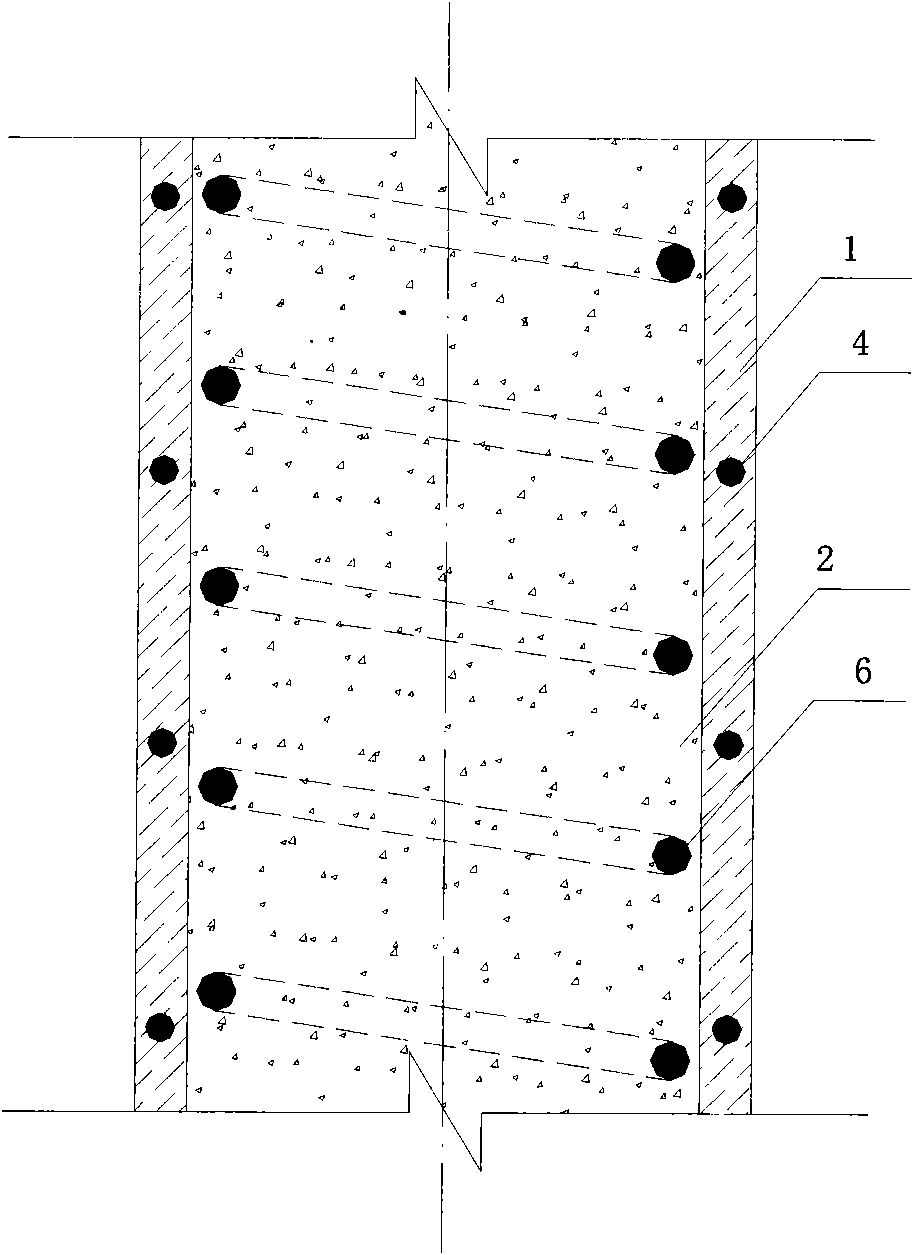

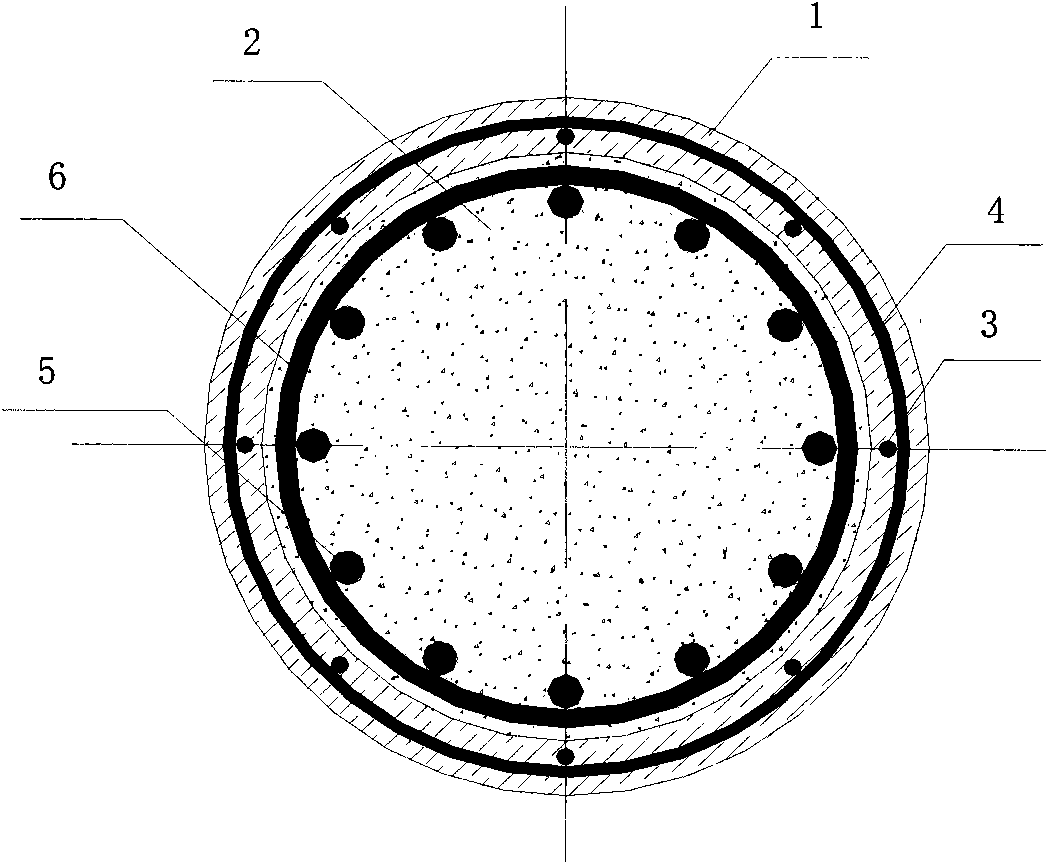

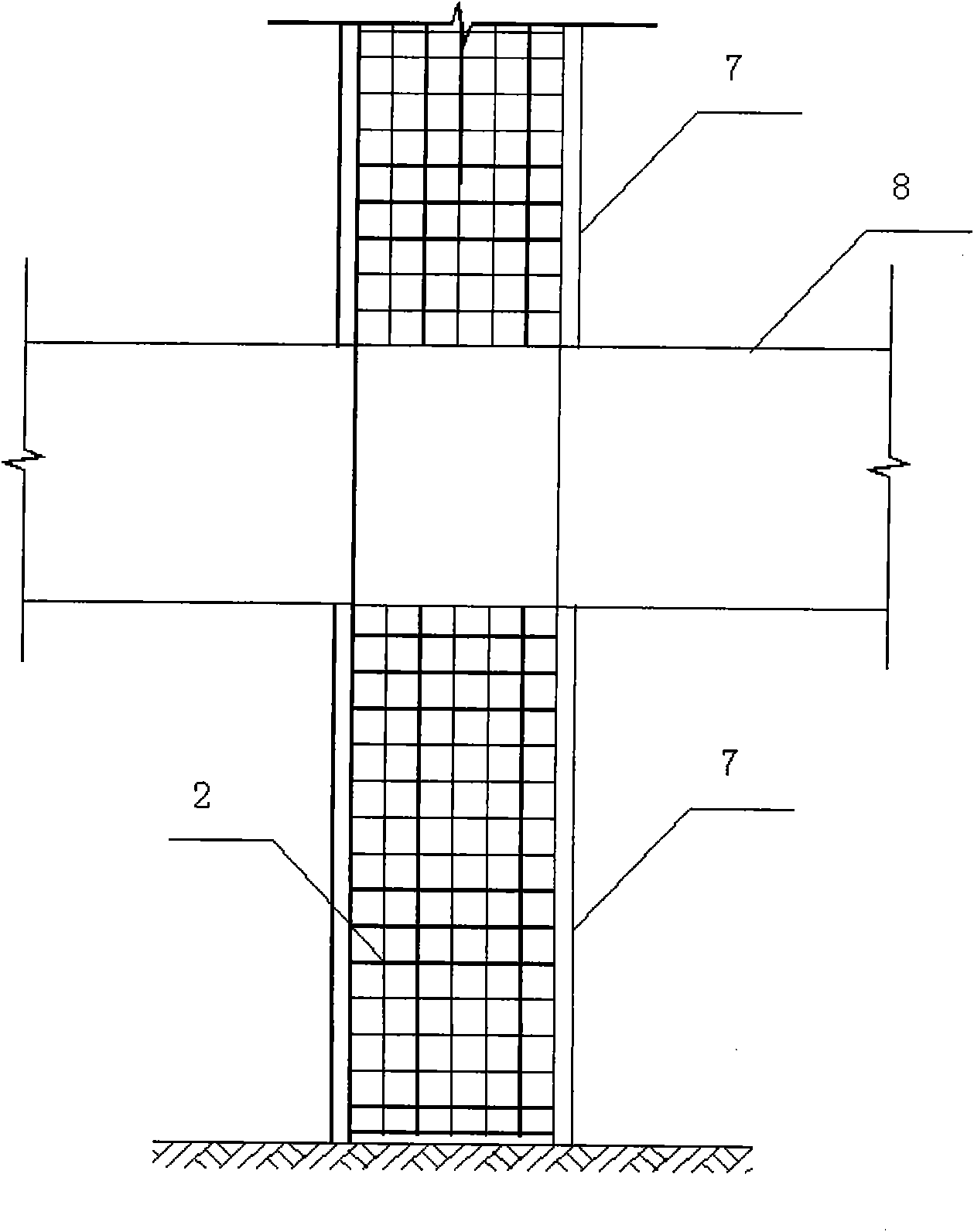

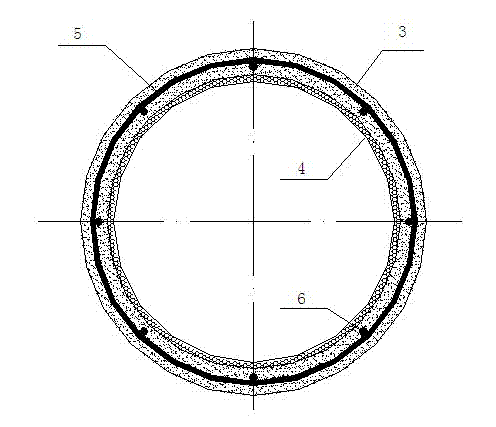

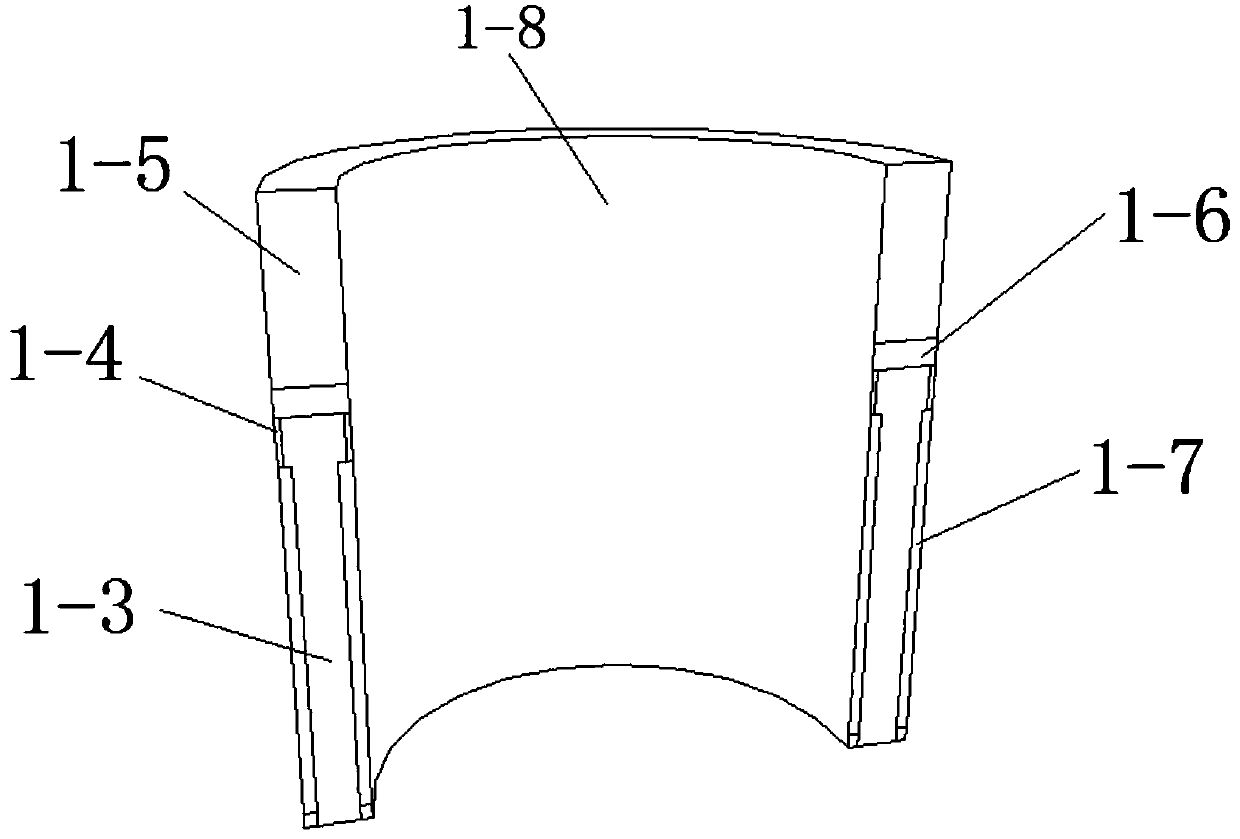

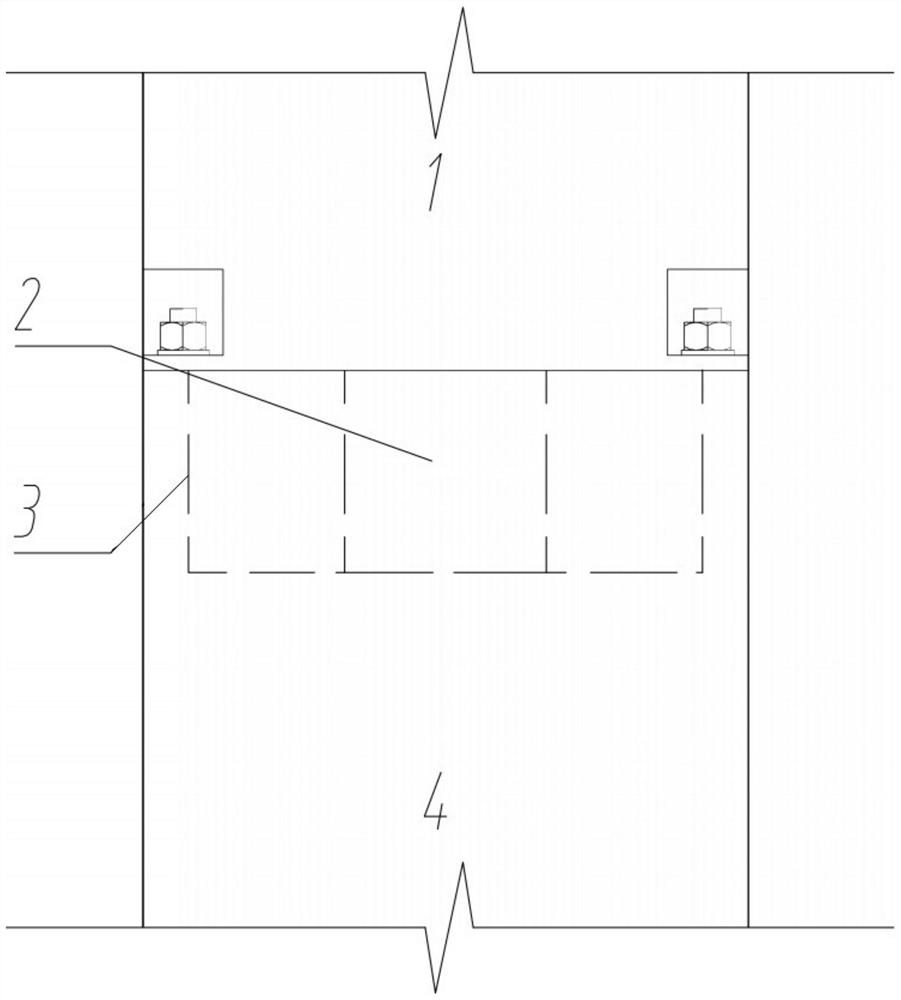

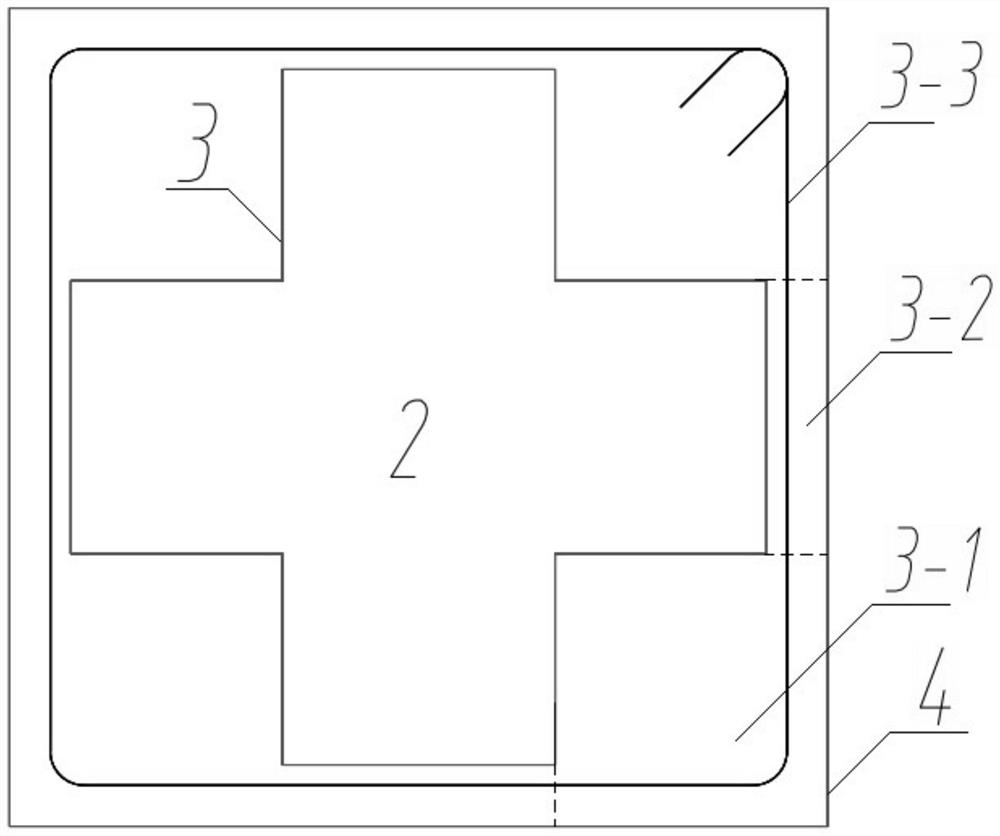

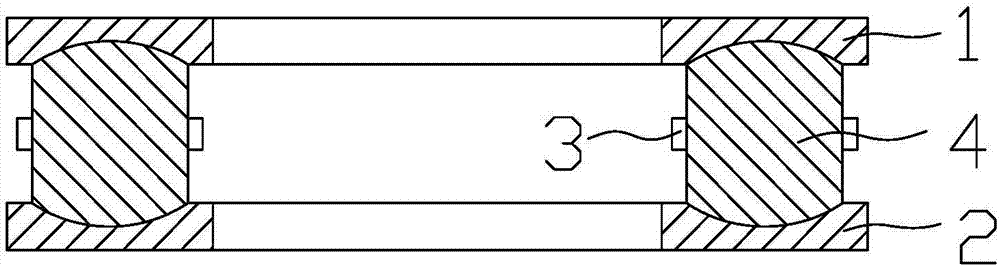

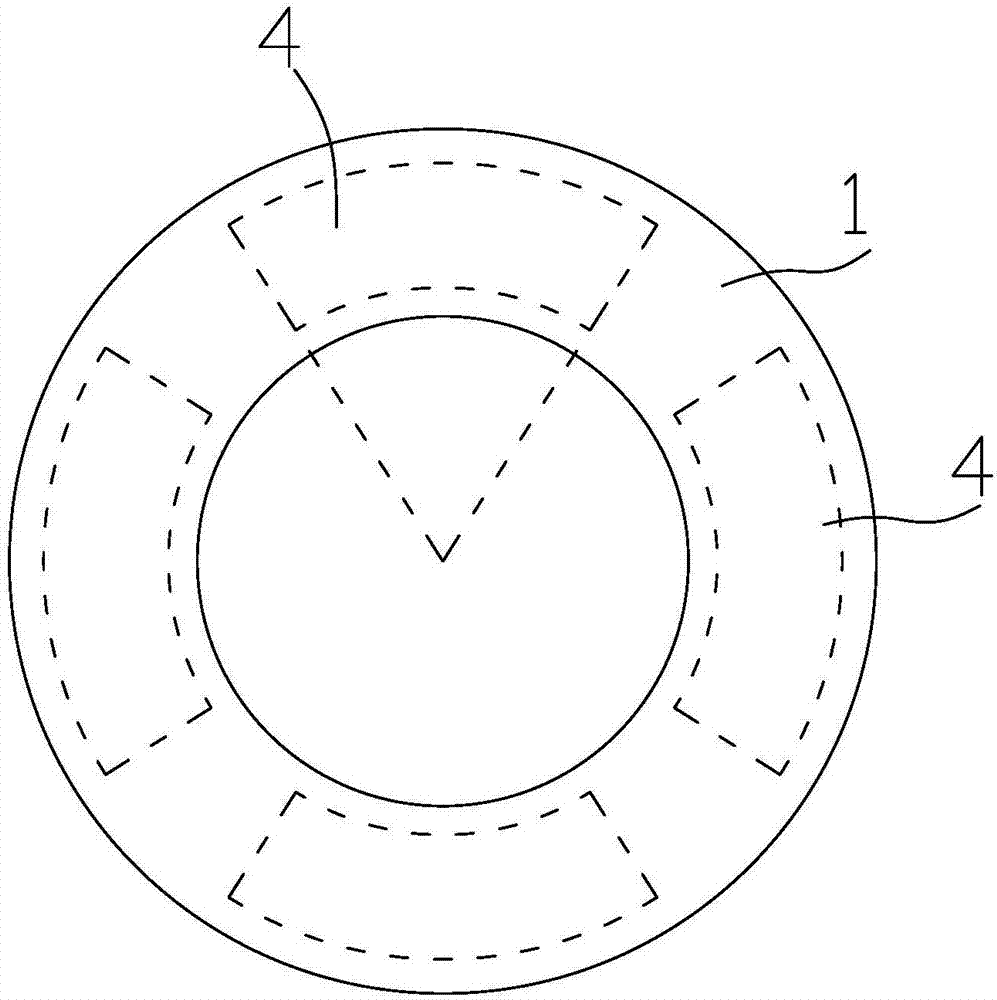

Composite casing pipe restrained reinforced concrete column

InactiveCN102776985AImprove the axial bearing capacityImprove bearing capacityStrutsBuilding reinforcementsReinforced concrete columnRebar

The invention discloses a composite casing pipe restrained reinforced concrete column which is characterized in that a composite casing pipe of the reinforced concrete column (2) is a combined body of a precast active power concrete outer casing pipe (3) and a precast active power concrete inner casing pipe (4). The composite casing pipe restrained reinforced concrete column provided by the invention has the characteristics of convenience in construction, low cost, high bearing force, shock-resistant property, obvious fireproof performance, excellent durability and the like, meanwhile, the composite casing pipe restrained reinforced concrete column can be used for saving resources and energy sources, and conforms to the sustainable development requirement.

Owner:HUNAN UNIV

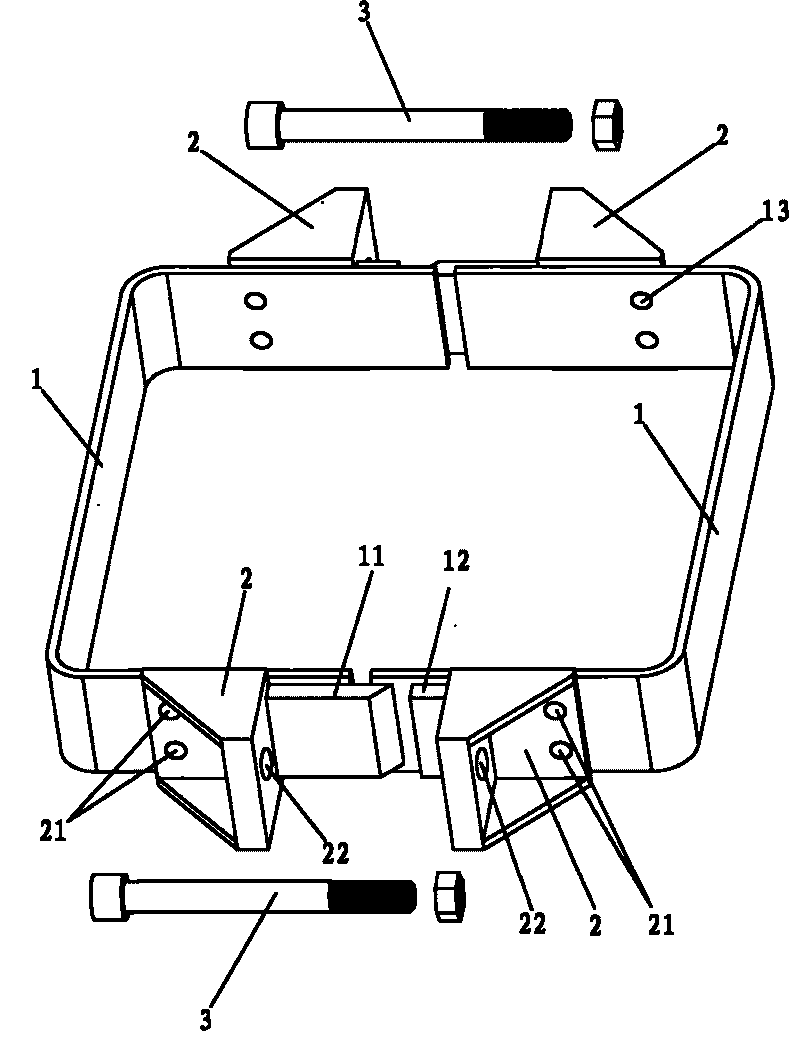

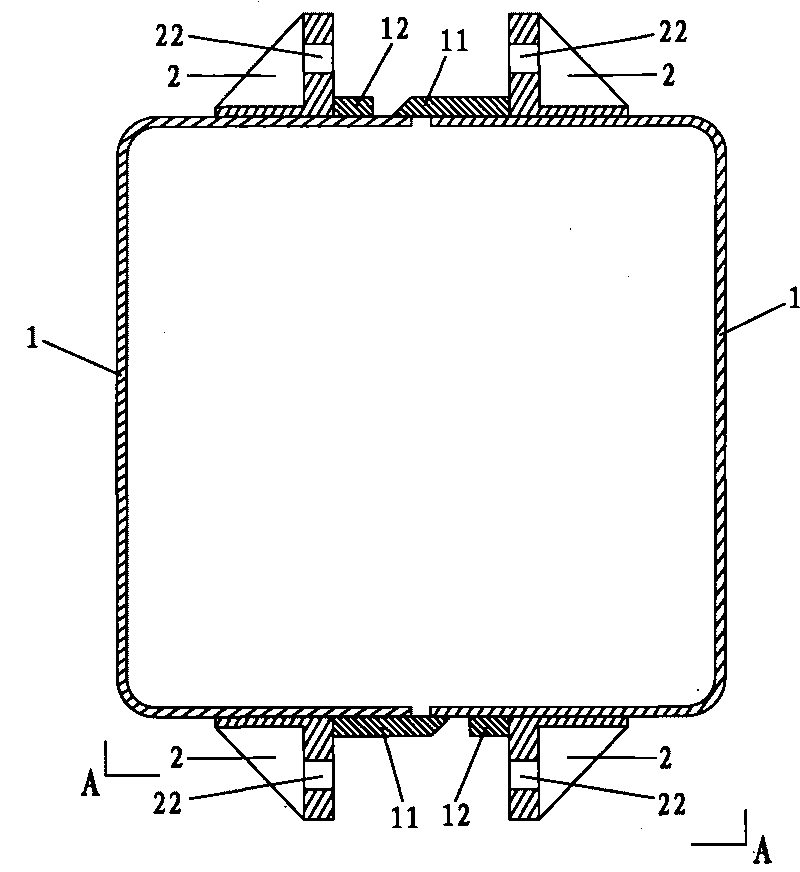

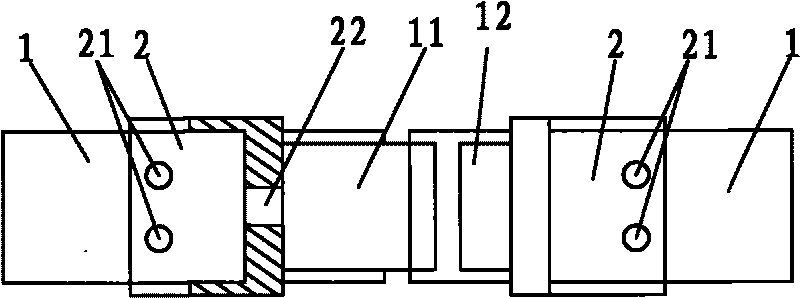

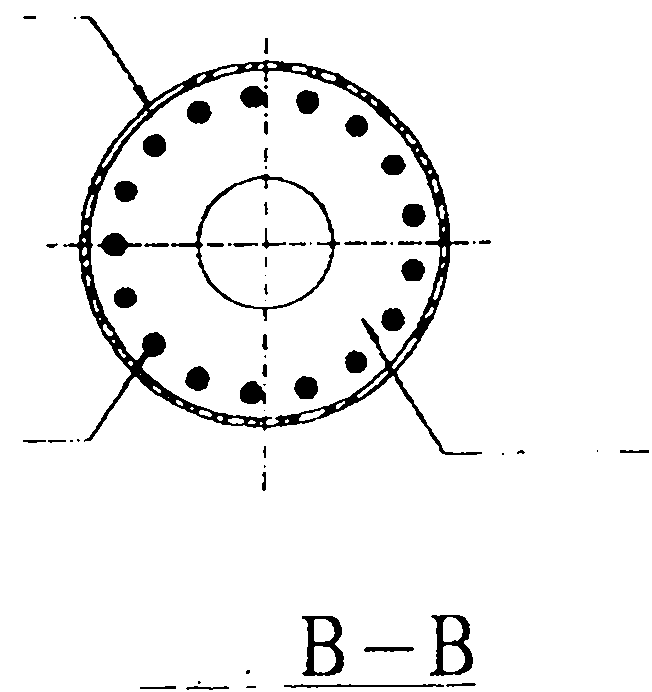

Novel pre-stressed steel plate hoop device and installation method thereof

InactiveCN101705662AIncreased shear capacityImprove the axial bearing capacityBridge structural detailsBridge erection/assemblySheet steelPre stress

The invention discloses a novel pre-stressed steel plate hoop device and an installation method thereof. The structure of the device comprises two U-shaped steel hoop plates that can compose a whole hoop, two suites of tensioning plates and tensioning bolts that can prestress the steel hoop. The device and the method have good technical reinforcement effect, and the structure has simple structure, convenient operation, low cost and has the advantages of environment protection and energy conservation.

Owner:HUAQIAO UNIVERSITY

Static-pressure direct drive rotating table

InactiveCN103128561AImprove axial stiffnessReduce processing difficultyLarge fixed membersEngineeringMechanical engineering

The invention relates to a static-pressure direct drive rotating table which comprises a base seat and a rotating plate, wherein the rotating plate is assembled on the base seat in a rolling mode through a static-pressure bearing, and the axial line of the rotating plate extends along an up-and-down direction. The static-pressure bearing is arranged in the middle part of the rotating plate. At least one circle of static-pressure bearing guide rail pair is arranged in the periphery of the static-pressure bearing between the base seat and the rotating plate. The static-pressure direct drive rotating table is small in processing amount of the rotating plate and large in axial bearing capacity.

Owner:HENAN UNIV OF SCI & TECH

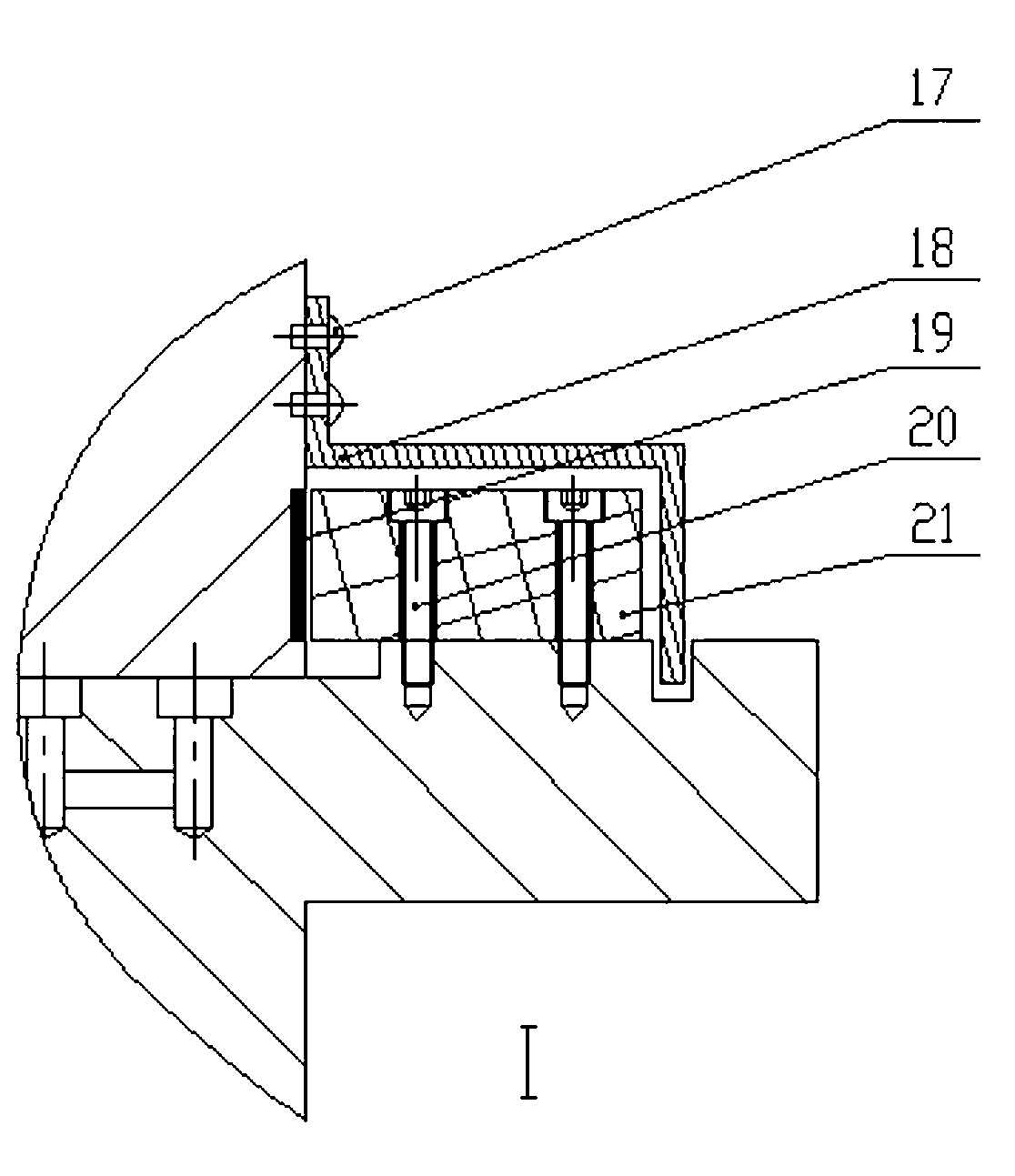

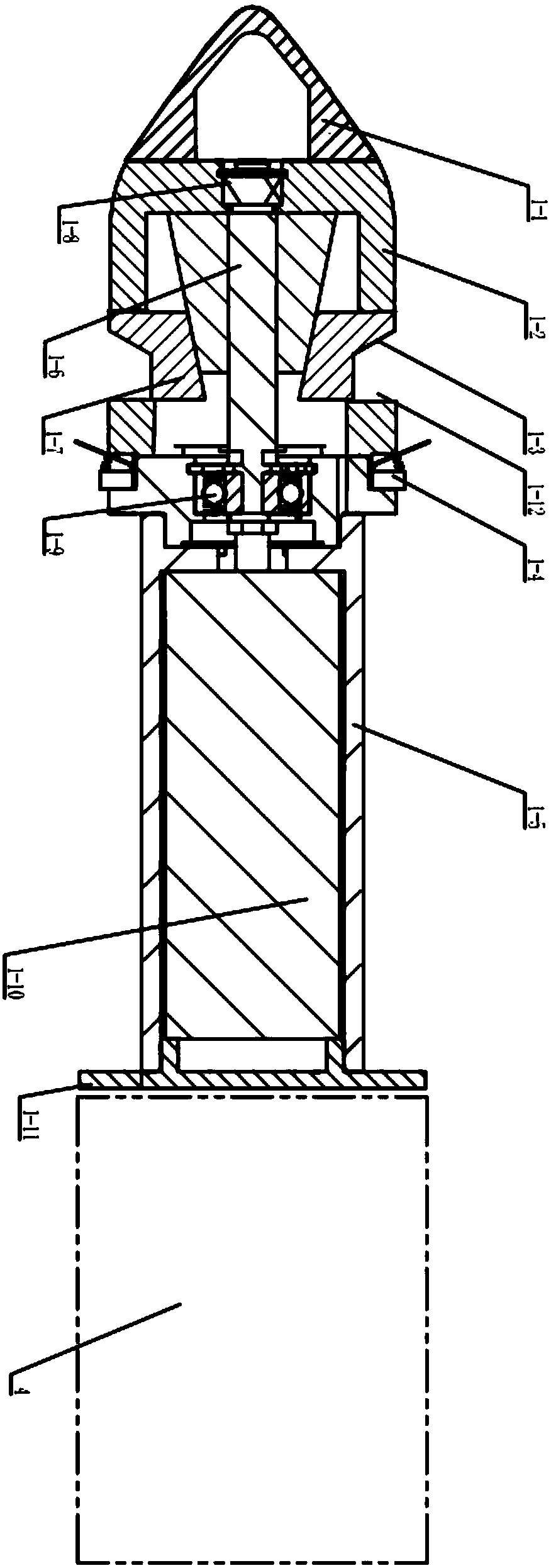

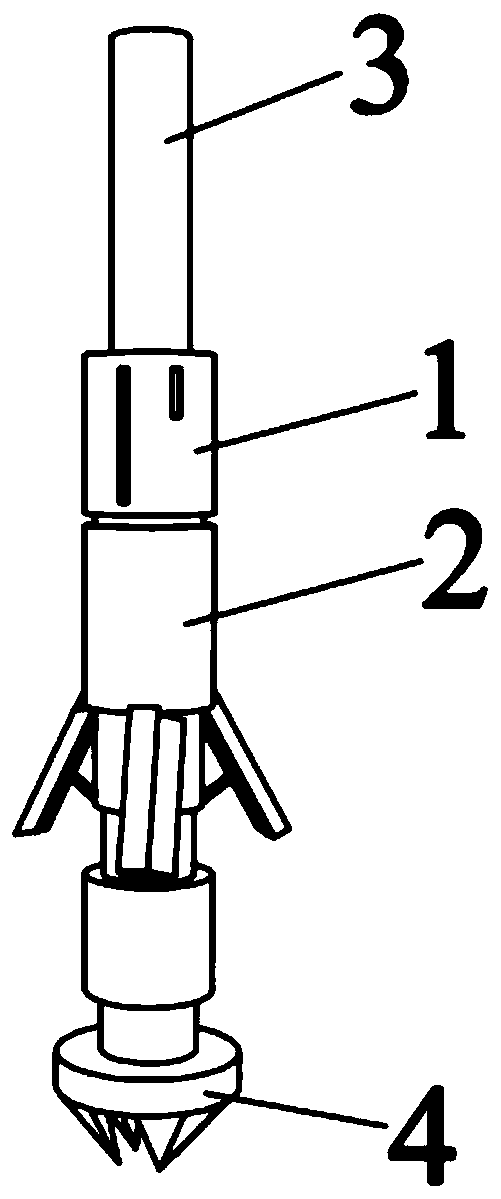

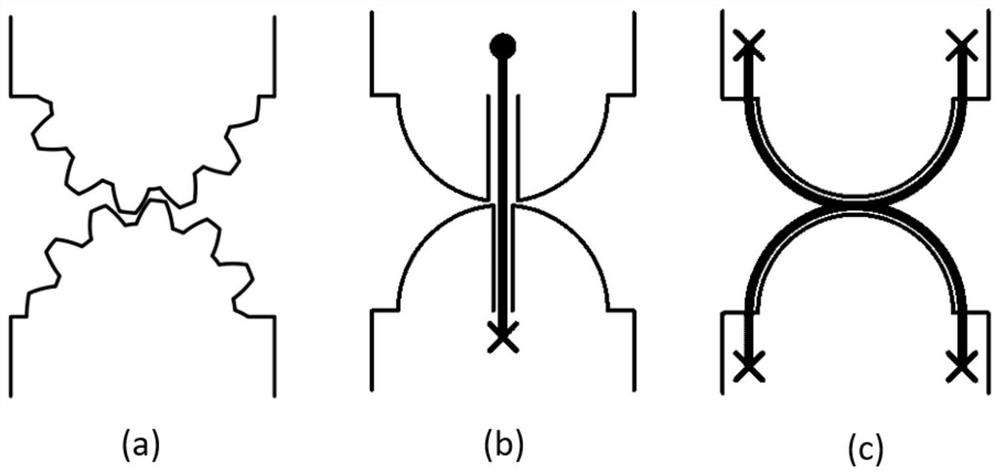

Radial snap-on capture locks for spacecraft and methods of operation

ActiveCN109050991ASelf-locking and reliableImprove flight safetyCosmonautic vehiclesCosmonautic component separationLinear motionReciprocating motion

A radial snap-on capture lock for a spacecraft and a working method thereof are provided, the capture lock includes an active end mounted on the active aircraft and a passive end mounted on the passive aircraft, the passive end is of a conical structure, the active end includes a housing assembly, Drive Assembly, Drive assembly and latch assembly, the housing assembly is used for supporting, connecting the drive assembly, Drive assembly and latch assembly, The drive assembly drives the drive assembly to convert the rotary motion into linear motion, the drive assembly controls the radial reciprocating motion of the latch assembly, the latch assembly clamps the passive end when the latch assembly radially extends out of the housing assembly, and the latch assembly releases the passive end when the latch assembly radially retracts the housing assembly. The invention solves the problems of complex system, large quality, poor universality and the like of the prior docking mechanism technology, and realizes the capture, locking and release of low disturbance in the docking process of the aircraft.

Owner:HARBIN INST OF TECH

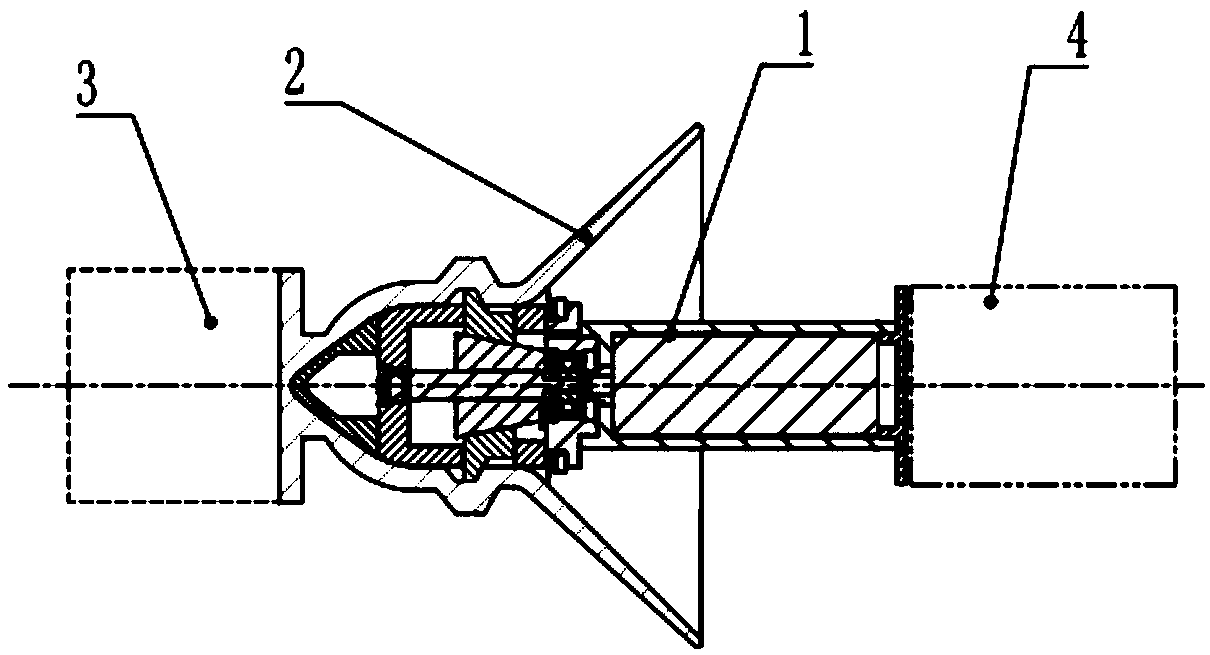

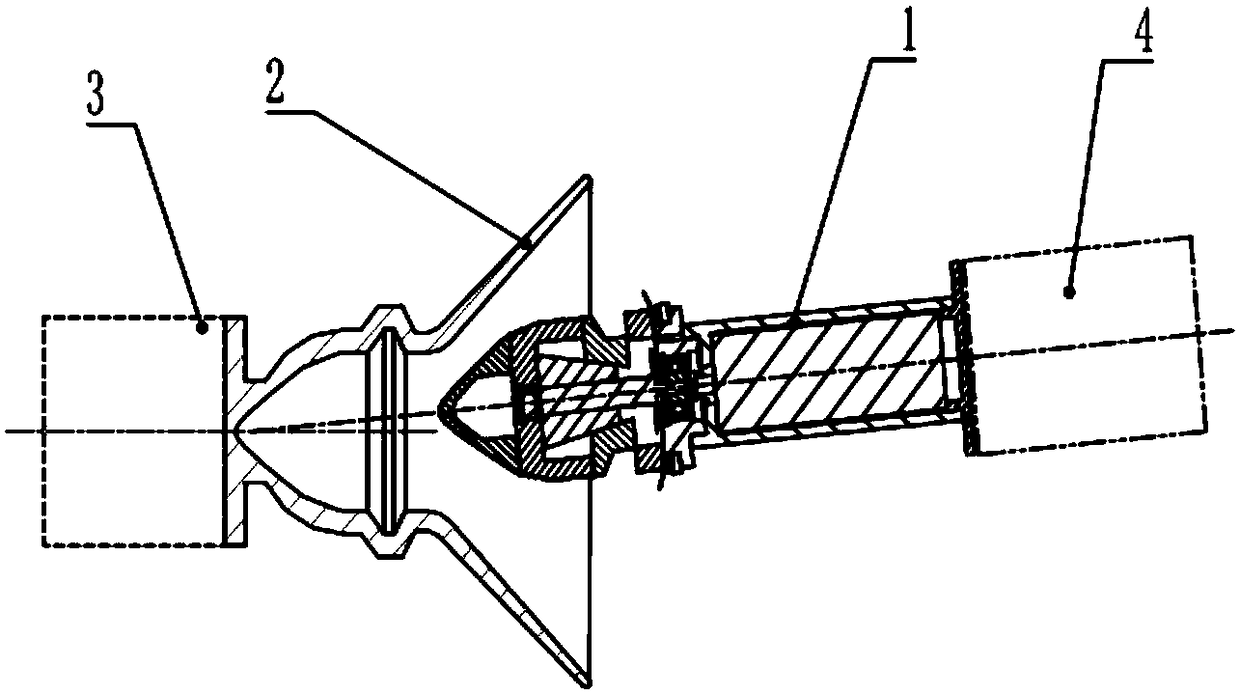

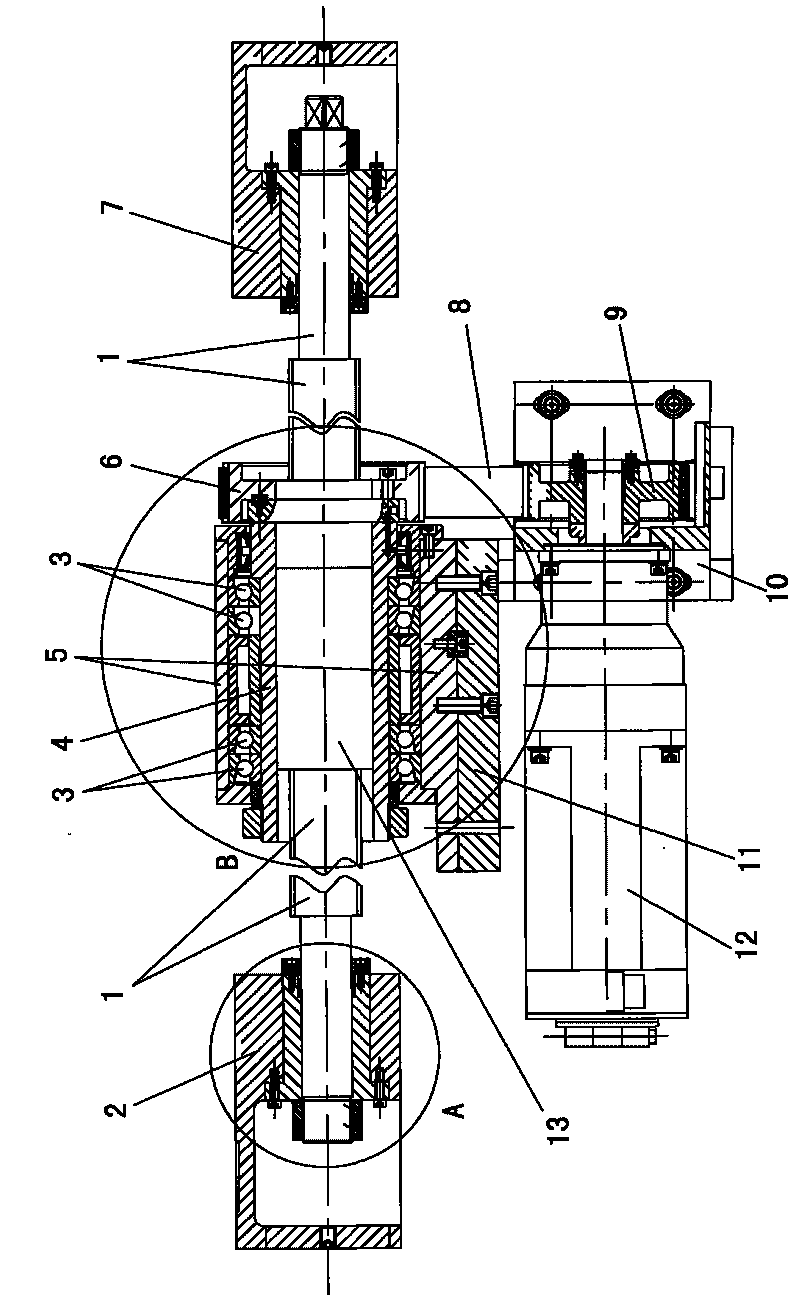

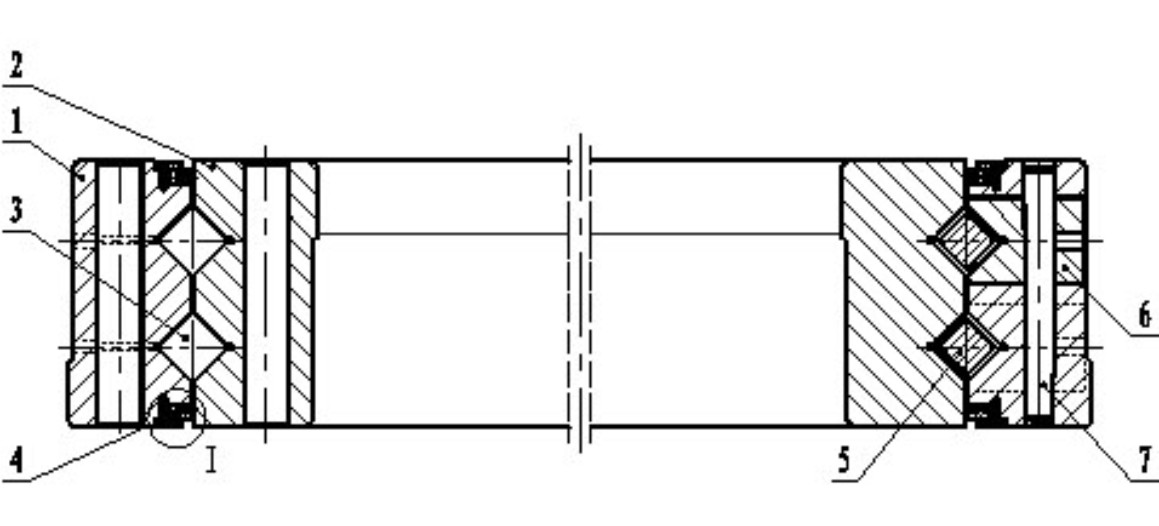

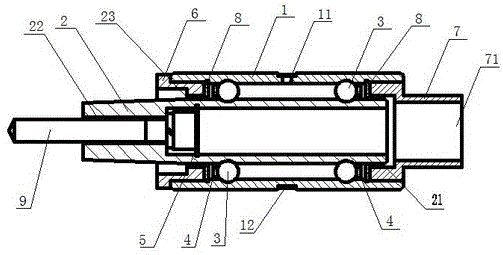

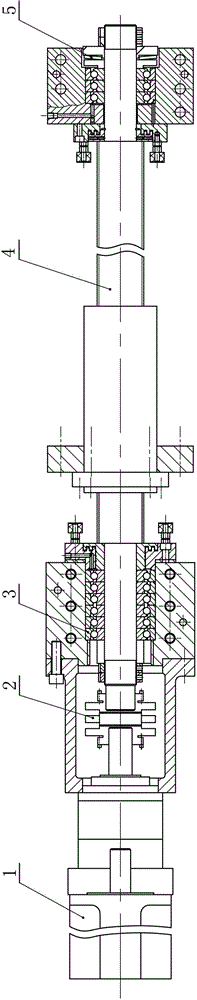

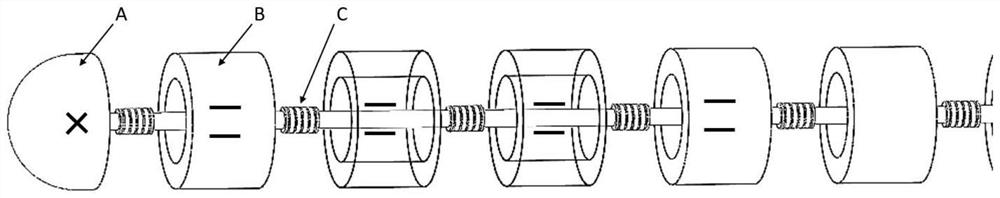

Driving mechanism for nut rotary type long lead screw

InactiveCN101722436AAvoid large deflection problemsAvoid unfavorable factors such as the limitation of critical speedFeeding apparatusBall screwEngineering

The invention discloses a driving mechanism, particularly a driving mechanism for a nut rotary type long lead screw, which comprises a long lead screw and a nut with a thread. The two ends of the long lead screw is fixedly supported on a support; the nut with the thread which is matched with the long lead screw is connected with a rotary driving mechanism; the outer side of the nut with the thread is provided with a fixed sleeve which is connected with a connecting plate; a bearing is arranged between the fixed sleeve and the nut with the thread; and the rotary driving mechanism is arranged on the support which is connected with the fixed sleeve or the connecting plate. During use, the long lead screw does not rotate, the nut with the thread is driven to rotate by a power plant to enable the nut with the thread to move relative to the long lead screw, so that the nut with the thread drives other components to move, the problem of large deflection caused by the rotation of a long ball screw is solved, and the adverse factors such as the restriction on the critical rotational speed of the ball screw are avoided. Thus, when the length of the lead screw is longer and the movement speed is higher, oscillation phenomenon cannot occur and the lead screw can move steadily without influencing other components, which improves the running accuracy of the equipment.

Owner:大连机床(数控)股份有限公司

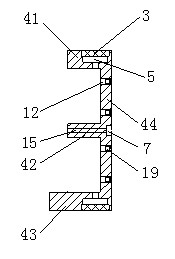

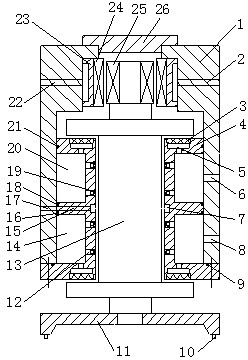

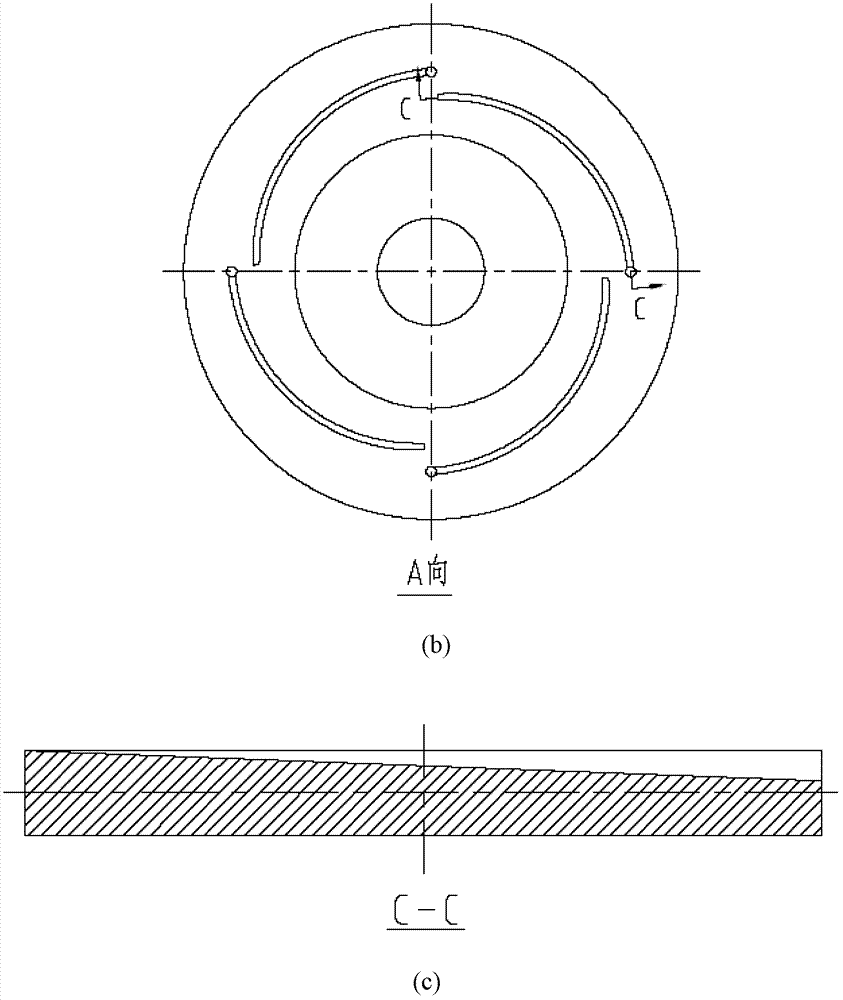

Radial-axial three-degree-of-freedom alternating current-direct current hybrid magnetic bearing

The invention discloses a radial-axial three-degree-of-freedom alternating current-direct current hybrid magnetic bearing used for non-contact suspension bearing. An axial control coil is arranged between a radial stator core and an axial stator core; an axial air gap is formed between the axial stator core and the end face of a rotor in the axial direction; three same stator core magnetic poles uniformly distributed in the circumferential direction extend from the wall of an inner cavity of the radial stator core to the axle center; same radial control coils are wound on the three stator core magnetic poles, and radial air gaps are formed between the stator core magnetic poles and the outer wall of the rotor in the radial direction; same axially magnetized annular permanent magnets are arranged between two axial sides of the radial stator core and the axial stator core; and S poles of the permanent magnets face the radial stator core, and N poles of the permanent magnets face the axial stator core. The radial-axial three-degree-of-freedom alternating current-direct current hybrid magnetic bearing integrates axial and radial functions, is only driven by a three-phase alternating current power inverter, is provided with two axially magnetized annular permanent magnets, controls the magnetic flux not to pass magnetic poles where the permanent magnets are positioned, and has the advantages of low power consumption, small volume, light weight and high bearing capacity.

Owner:JIANGSU UNIV

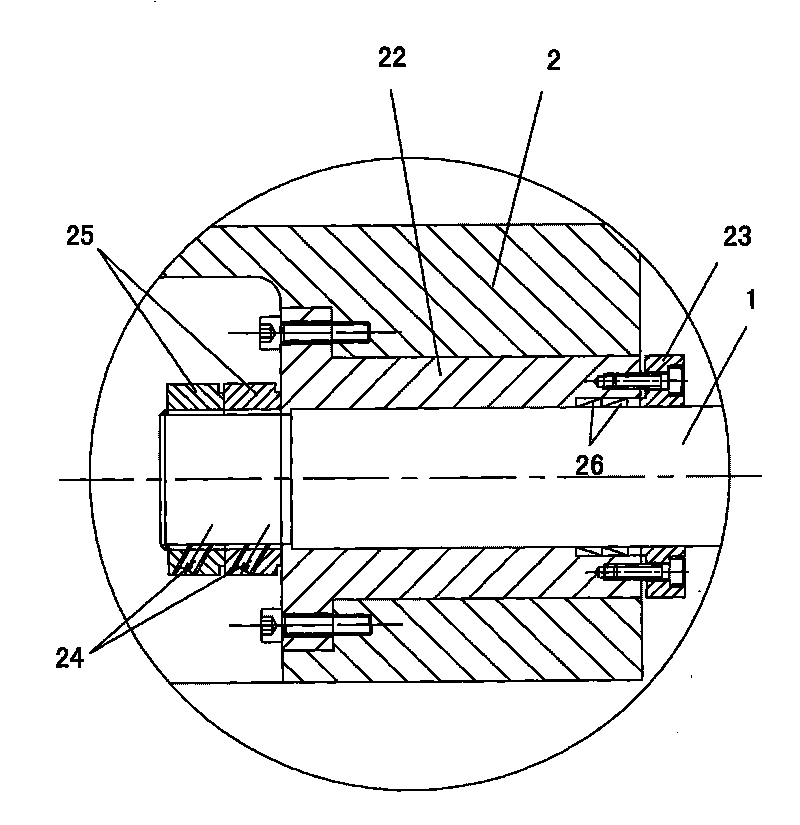

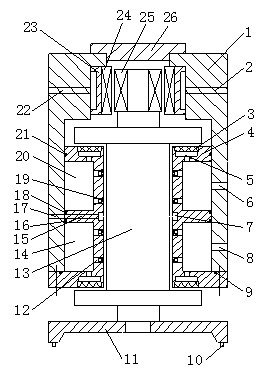

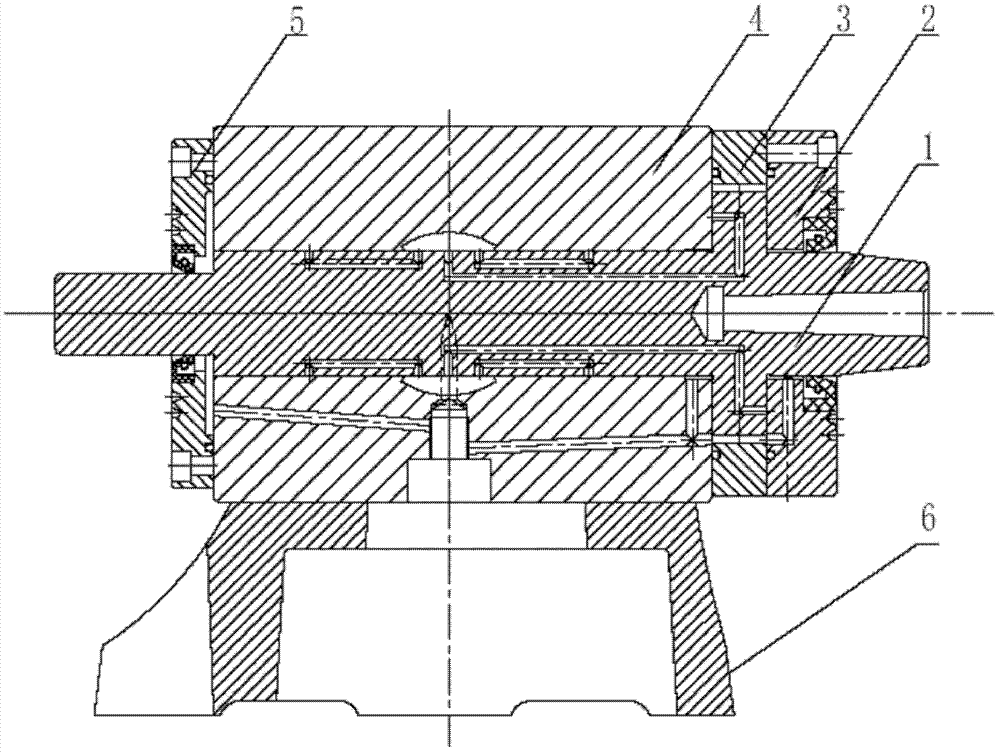

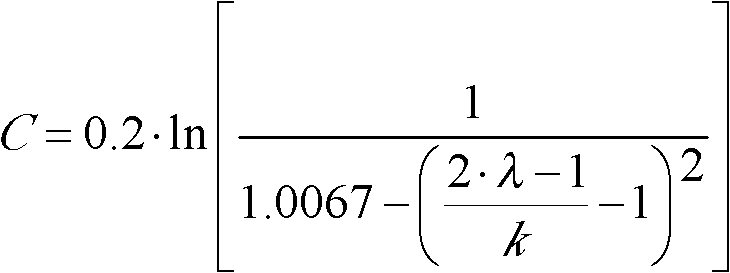

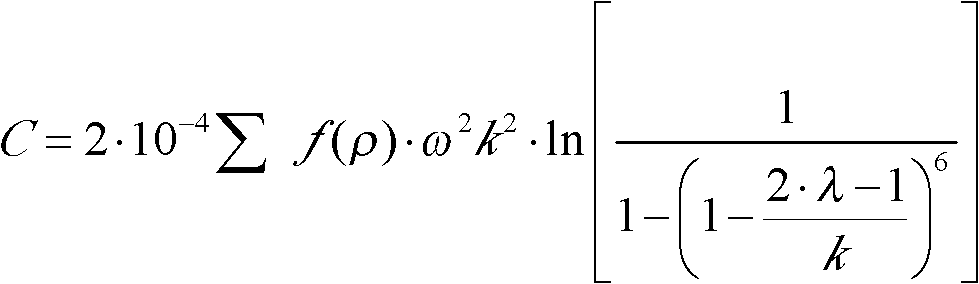

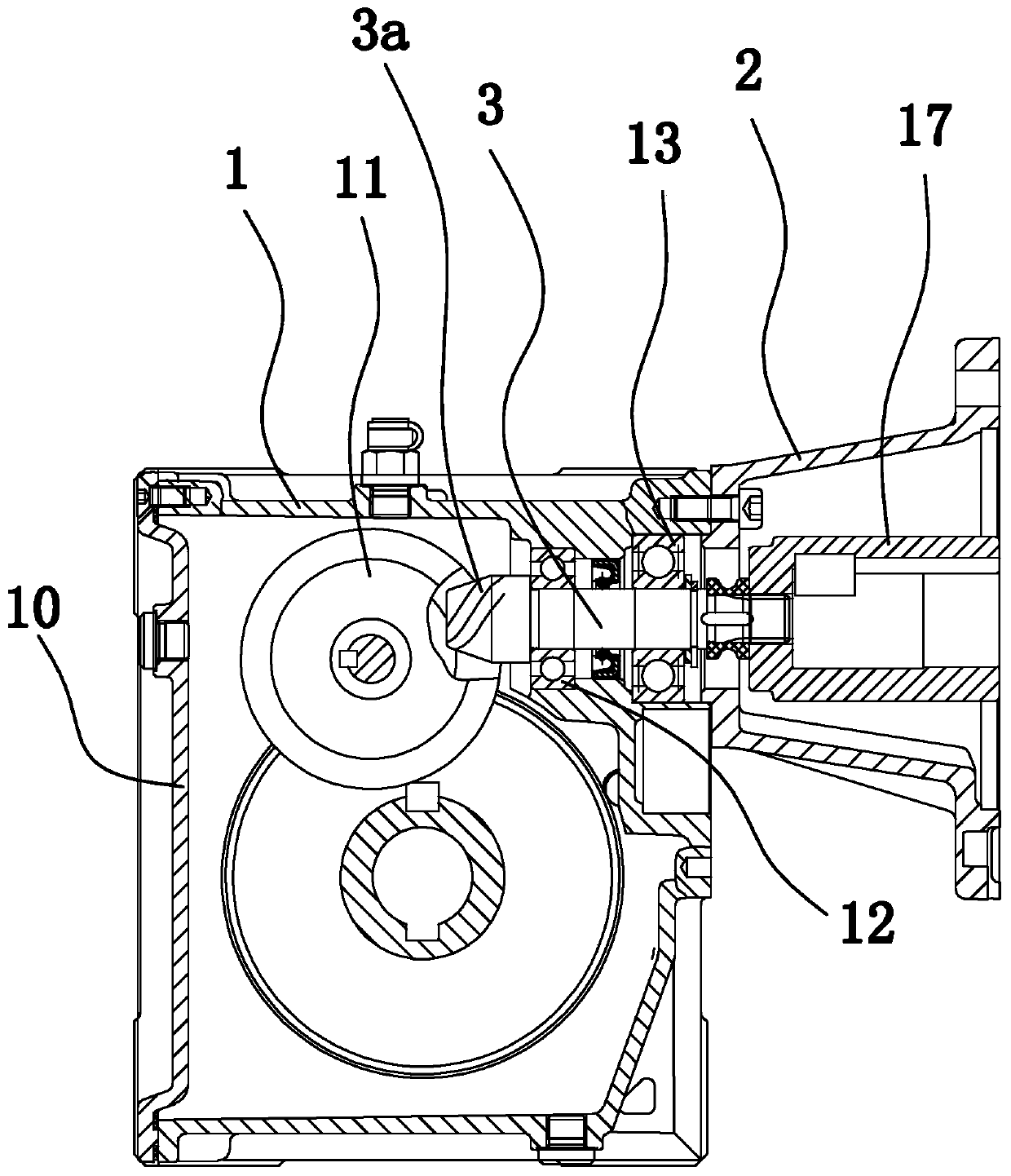

Grinding device for high-precision ultrathin wafer

InactiveCN102172877AImprove the axial bearing capacityImprove axial stiffnessPolishing machinesGrinding machine componentsEngineeringWater jacket

The invention discloses a grinding device for a high-precision ultrathin wafer, comprising a bearing, a shell, a grinding wheel, a grinding wheel disk, a spindle, a cooling water jacket, a motor stator, a motor rotator and a seal ring, wherein the bearing is a gas bearing composed of an upper ring sheet, a middle ring sheet, a lower ring sheet and a hollow pipe; the upper ring sheet and the lowerring sheet are respectively provided with an air inflow through hole, and a porous material layer is arranged in the air inflow through hole; the hollow pipe is provided with throttling through holes; each throttling through hole is provided with a choke; the inner wall of the middle of the hollow pipe is provided with a vent slot; a vent hole is arranged in the middle ring sheet; the shell is provided with an air outlet; and the vent slot is communicated with the outer environment via the vent hole and the air outlet. The bearing in the grinding device of the structure has the advantages of high axial bearing force and rigidity, low bearing abrasion loss and high precision and can satisfy the technical requirements of the high-precision ultrathin wafer.

Owner:SOUTHEAST UNIV

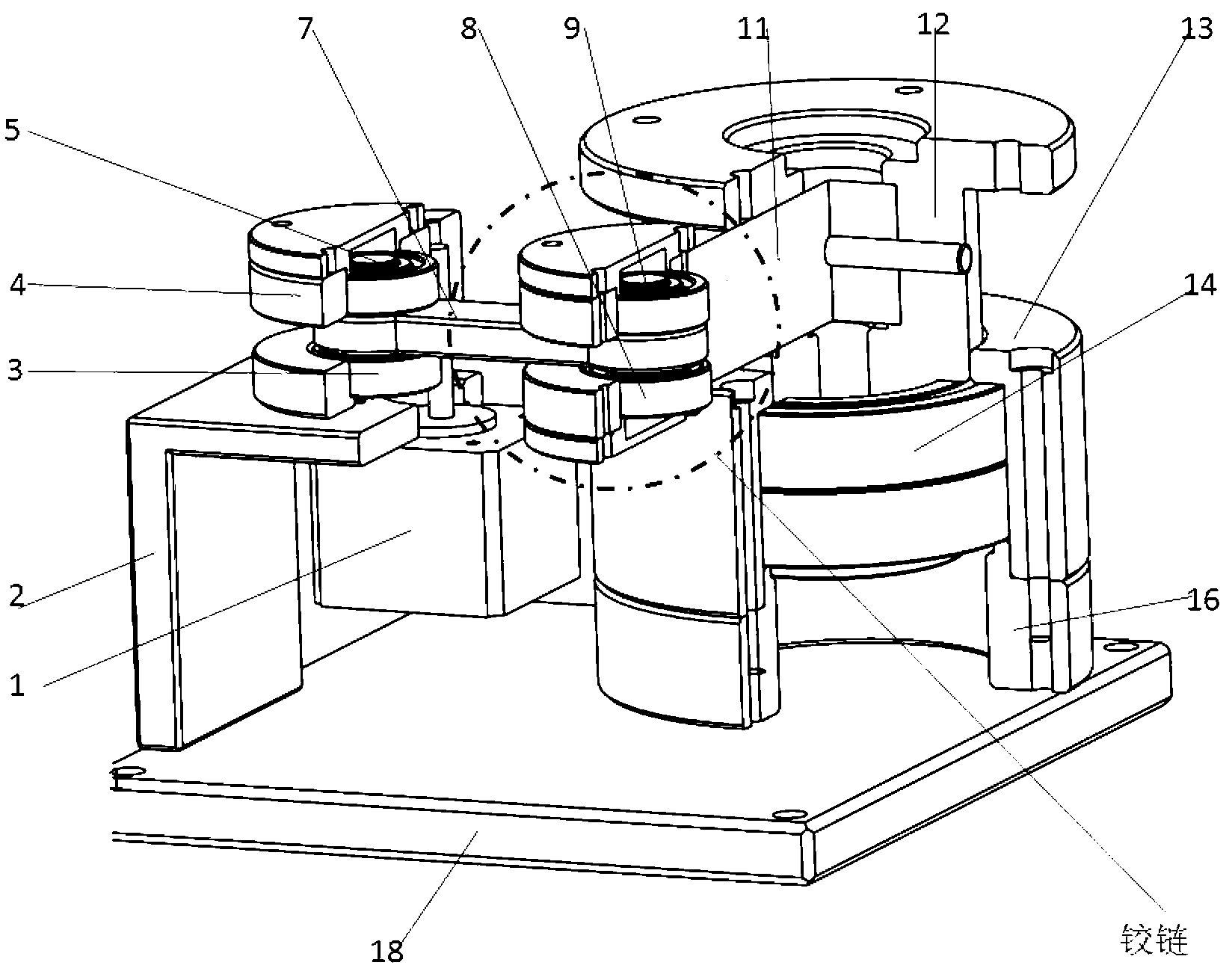

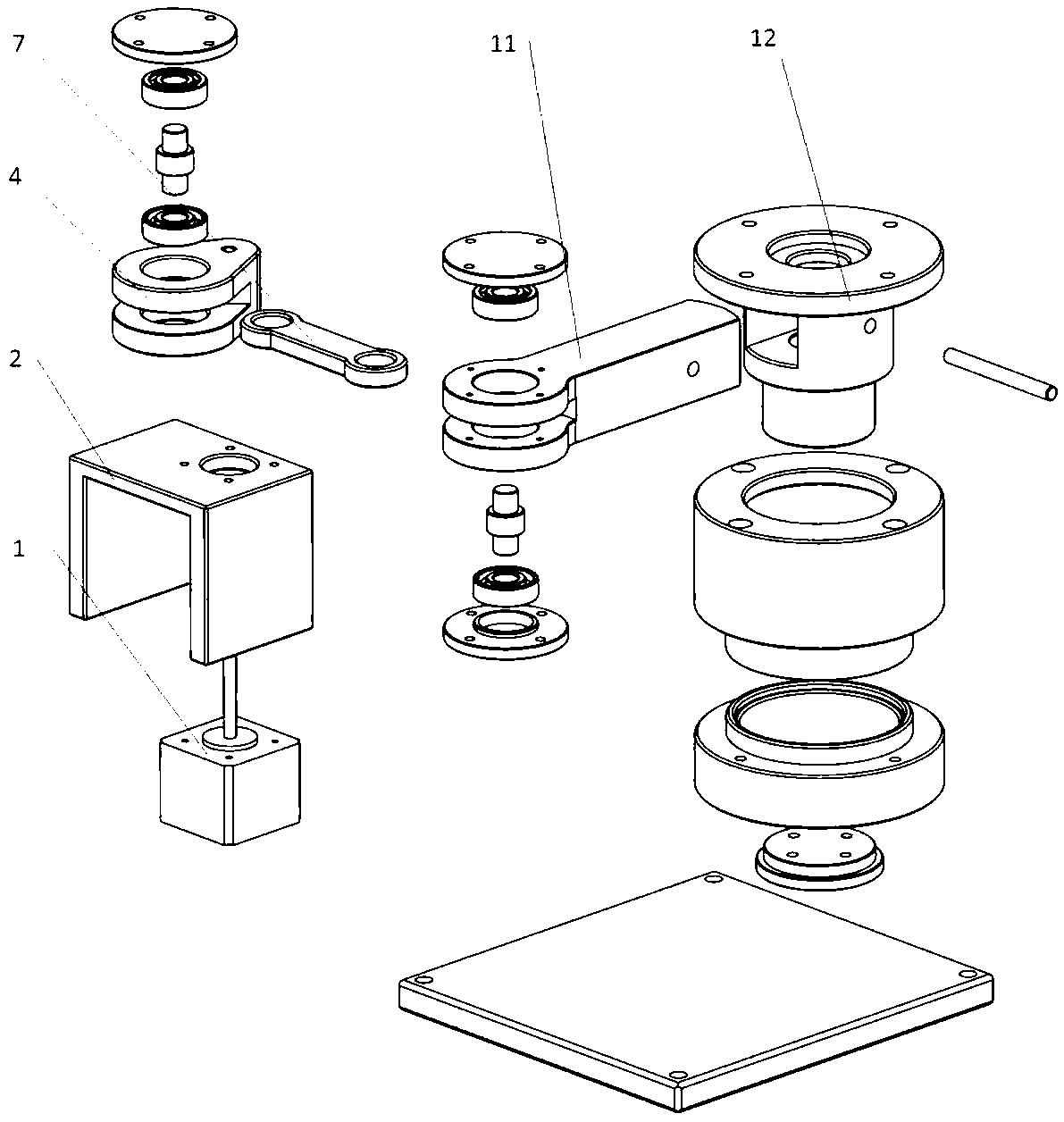

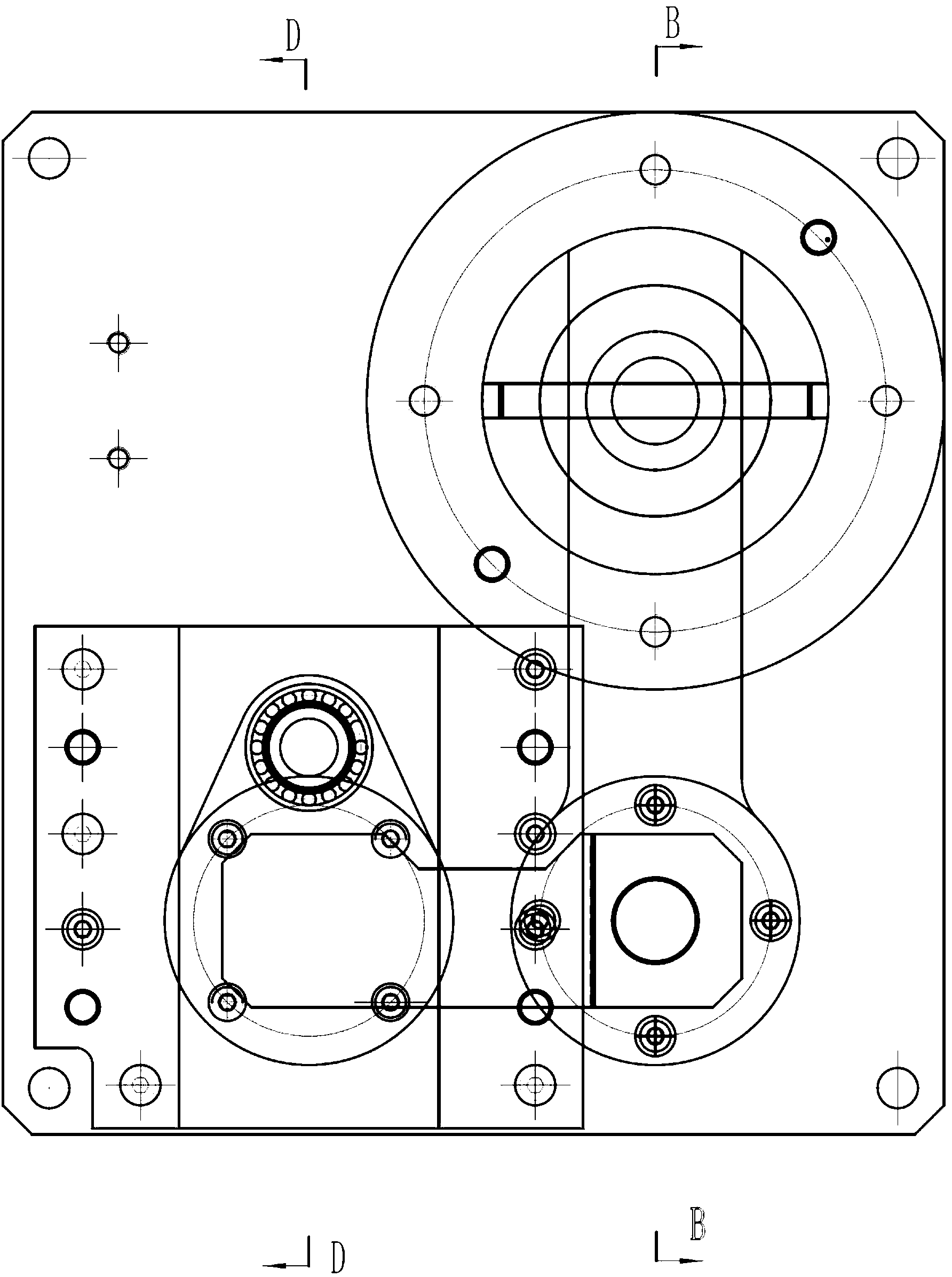

High-precision rotary table of gapless connecting rod mechanism and capable of moving slightly

The invention provides a high-precision rotary table of a gapless connecting rod mechanism and capable of moving slightly. The high-precision rotary table of the gapless connecting rod mechanism and capable of moving slightly comprises a driving motor, a motor supporting base, a rotary table body, a rotary table base, a base plate and the connecting rod mechanism, wherein the connecting rod mechanism comprises a bearing a, a crank, a connecting shaft a, a connecting rod, a bearing b, a connecting shaft b, an oscillating bar and a bearing c, the output torque of the motor is used as power for the rotation of the rotary table, the output shaft of the driving motor drives the crank to rotate, the crank drives the connecting shaft a installed on the crank and then the connecting rod is driven to swing, the connecting shaft b is driven to rotate through the swinging of the connecting rod, the oscillating bar is driven to swing through the rotation of the connecting shaft b, and then the rotary table body is driven to rotate, namely the torque of the motor is transmitted to the rotary table body through the crank, the connecting shaft a, the connecting rod, the connecting shaft b and the oscillating bar, and the rotary table body is driven to rotate within the range of a certain angle through the swinging of the oscillating. According to the high-precision rotary table of the gapless connecting rod mechanism and capable of moving slightly, due to the fact that a proper transmission ratio is configured and a high-precision angular contact ball bearing is pre-tightened, bearing clearance is eliminated and accuracy is improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Rotary cut-expanded branch pile machine and construction method of cut-expanded branch pile

PendingCN111042738APrevent slipping outGuaranteed stabilityDrill bitsDirectional drillingDrill bitHydraulic pressure

The invention discloses a rotary cut-expanded branch pile machine and a construction method of a cut-expanded branch pile. The cut-expanded branch pile comprises a drill rod, and a rotary cut-expanding assembly is fixed to the drill rod. The rotary cut-expanding assembly comprises a first force transferring barrel, and a plurality of soil cutting steel plates are hinged to the lower end of the first force transferring barrel. First sliding grooves are formed in the inner walls of the soil cutting steel plates. The lower end of a second force transferring barrel stretches inwards to form a pressing block, and a buckle seat is fixed to a connecting barrel. A spring is mounted on the side wall of the buckle seat, the lower end of the spring and the lower end of a mounting groove are fixed, and the upper end of the spring seat and a buckle are fixedly connected. One end of each connecting rod is fixed into the corresponding first sliding groove, and the other ends of the connecting rods are mounted on the buckle. When the drill bit reaches a target position, the soil cutting steel plates work under the action of a hydraulic component, the rotary speed and angles of the soil cutting steel plates achieve stepless speed change, and finally a tree-shaped branch plate cavity is formed in the same position. Compared with a common branch pile, the formed tree-shaped branch pile has the advantages that the size is larger, and the vertical and transverse axial bearing capacity of a pile foundation is remarkably improved.

Owner:CHANGAN UNIV

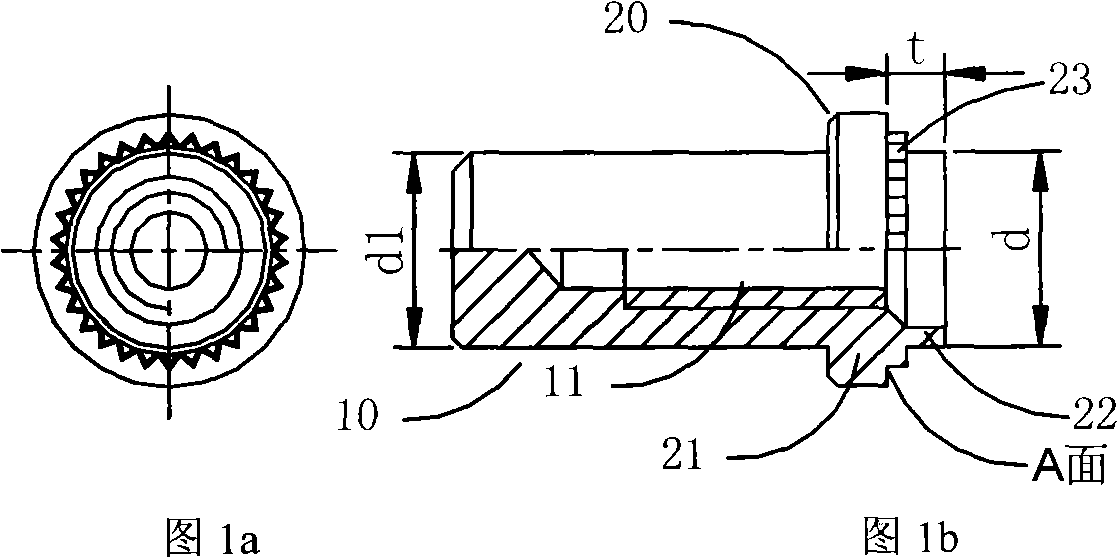

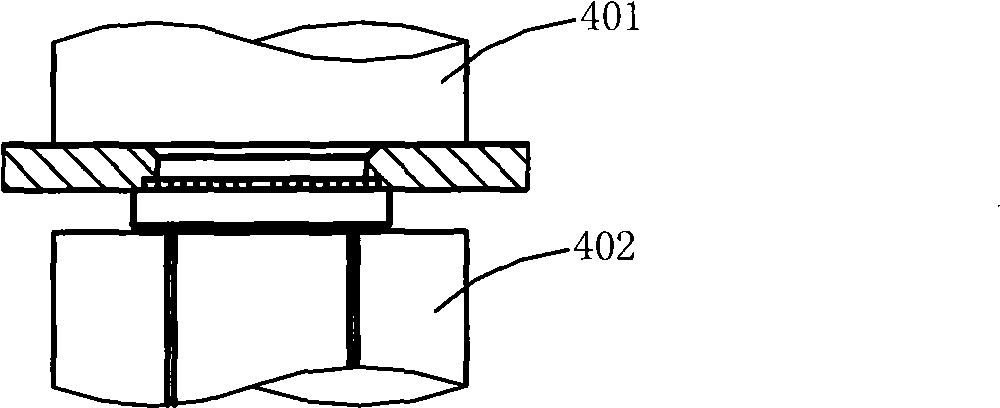

Riveting connector

InactiveCN101504023AImprove the axial bearing capacityLarge radial torque resistanceSheet joiningMetallic materialsEngineering

The invention discloses a riveting connecting piece, which comprises a connecting part and a riveting part, wherein a through threaded hole or a blind threaded hole is formed in the riveting connecting piece preferentially, and the inside diameter of the hole is smaller than that of the riveting part; naturally, the hole can be a through hole or a blind hole arranged in the riveting connecting piece so as to adopt other connecting modes; the connecting part is used for connecting other components, and the riveting part is used for riveting and tightening with a sheet material to be riveted; the riveting part is hollow inside and comprises a base part and a deformed riveting column; the deformed riveting column is of a short pipe shape, the bottom thereof is provided with annularly-distributed pointed teeth towards the outside to prevent rotation, one end face of the base part contacts with the sheet material to be riveted, the other end of the base part is connected with the connecting part, and the outside diameter of the pointed teeth is smaller than that of the base part; the material of the riveting connecting piece is a plastic deformation material of which the strength is higher than that of the sheet material to be riveted, and the material is preferably stainless steel, or other metallic materials or nonmetal materials. The riveting connecting piece not only has stronger axial bearing capacity, but also has stronger radial twisting resistance, thus the riveting is firmer.

Owner:ZTE CORP SHENZHEN CITY

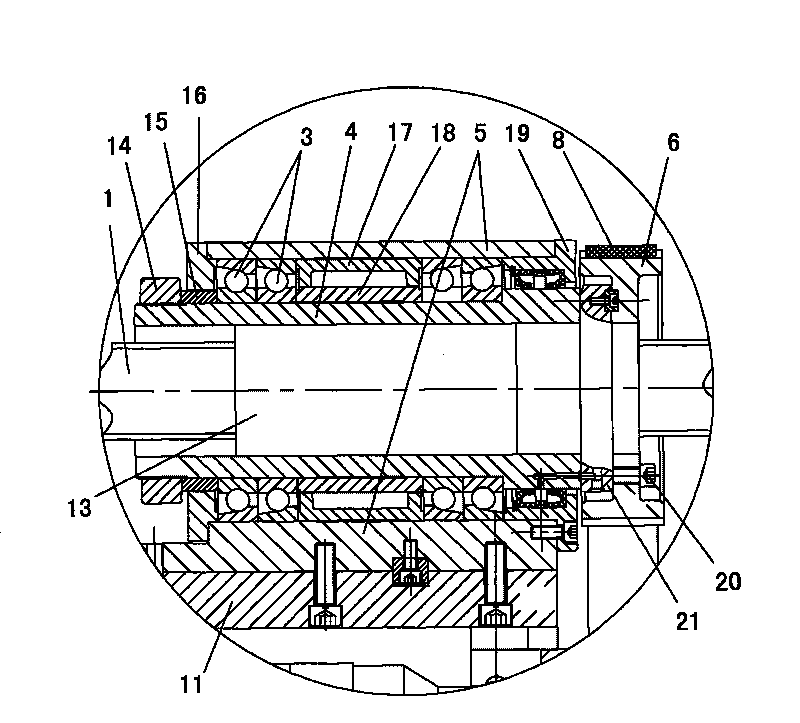

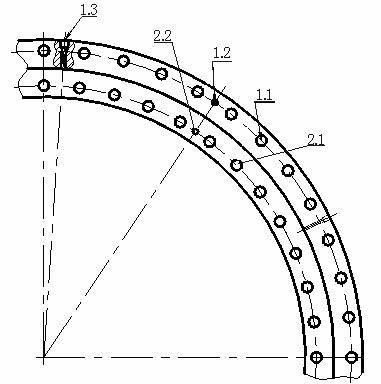

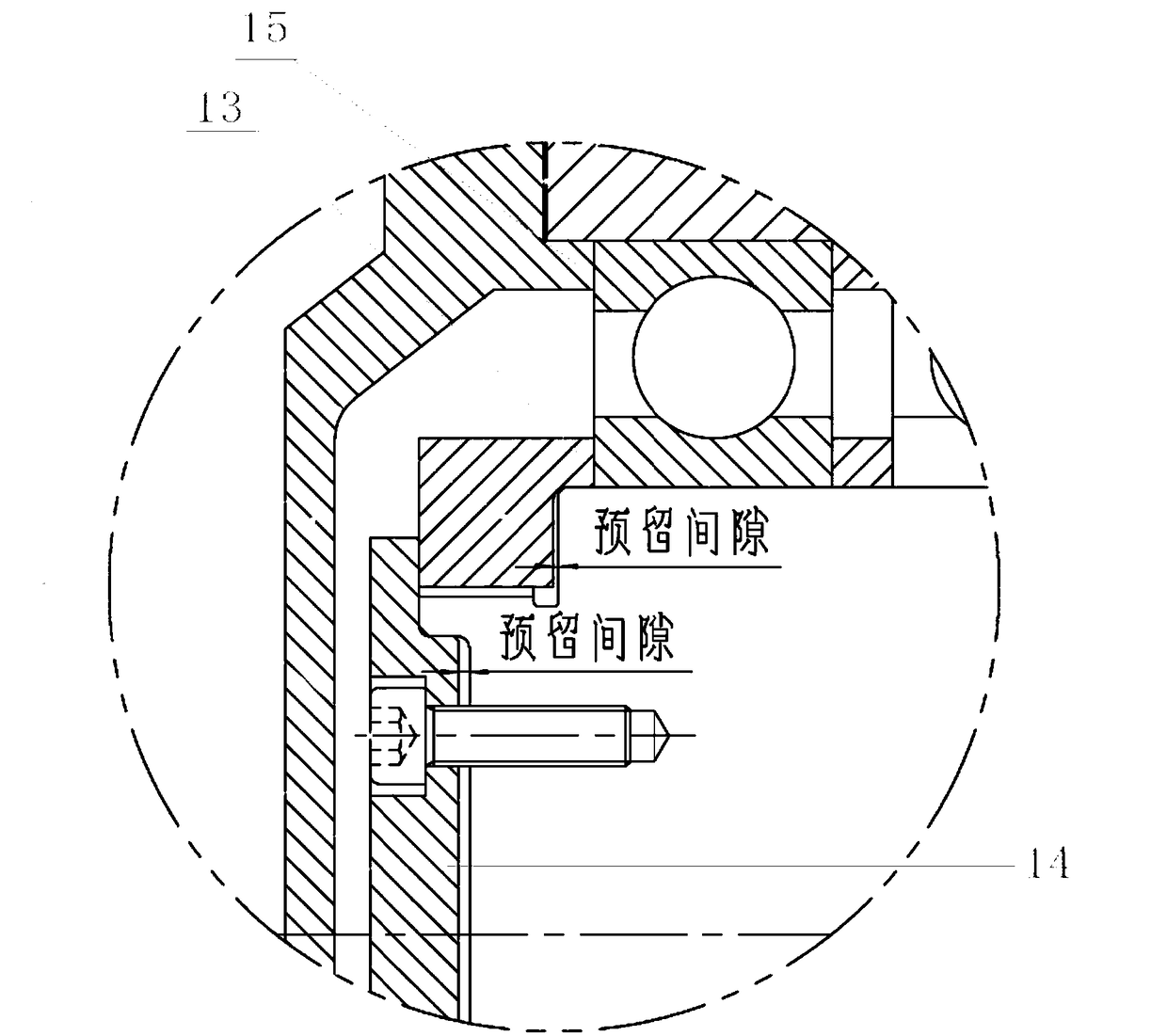

Design method of cross cylindrical roller bearing with two right-angle roller paths

ActiveCN102606621AImprove the radial bearing capacityIncreased axial capacity and overturning momentRoller bearingsBearing componentsLubricationMachining process

The invention provides a design method of a cross cylindrical roller bearing with two right-angle roller paths. An outer ring (1) is designed in an integral structure by a split type dual-half structure. The outer ring comprises two right-angle roller paths, an outer mounting hole (1.1), an outer hoisting thread hole (1.2), a lubricating oil hole (1.3), a plunger (6) and a conical pin (7). An inner ring comprises two right-angle roller paths, an inner mounting hole (2.1) and an inner hoisting thread hole (2.2). A cylinder roller (3) and an isolation block (5) are configured in the corresponding roller paths of the inner ring and the outer ring. Sealing is carried out through a sealing assembly (4), so that the problems of a plurality of machining processes, poor mounting condition, poor sealing, no lubrication and the like in a cross cylindrical roller bearing with a single roller path can be solved. Therefore, the axial bearing force and the overturn moment can be ensured, and simultaneously the radial bearing force is greatly improved.

Owner:洛阳轴研科技有限公司

Oil static pressure main shaft main shaft for shaft oil supply

InactiveCN102788086AImprove the axial bearing capacityImprove the radial bearing capacityEngine sealsBearingsMechanical engineering technologyHigh pressure

The invention relates to an oil static pressure main shaft for shaft oil supply, which belongs to the mechanical engineering technical field. The invention is characterized in that the oil static pressure main shaft for shaft oil supply is composed for the main shaft, a front end cover, a regulating ring, a bearing bush, a rear end cover and a bush seat. The high pressure oil is directly entered into an oil chamber of the bearing bush through an oil nozzle, an oil orifice is drilled on the main shaft, therefore the high pressure oil is supplied to the radial oil chamber through the oil orifice of the main shaft for thrusting the oil chamber. The main shaft is suspended in the bearing bush by an oil membrane, the hydraulic oil flowed out of the oil chamber is returned back to a hydraulic station through an oil return hole of the bearing bush. The oil static pressure main shaft has the effect and performance that a restrictor and a bush sleeve are removed, the shaft but the bush sleeve is used for oil supply, and the structure is simplified. The oil static pressure main shaft solves the obstruction problem of the restrictor and reduces the complex degree of mechanical treatment and assembly process.

Owner:秦嗣伟

Automobile hub bearing unit

ActiveCN102135134AImprove the axial bearing capacityEasy to processBraking element arrangementsRoller bearingsEngineeringMachining

The invention discloses an automobile hub bearing unit which comprises a braking disc and a rotating drum, wherein a convex shaft is arranged at the middle part of the rotating drum; two inner rings are sleeved on the convex shaft; conical-surface outer raceways are arranged on the inner rings; two rows of parallel conical-surface inner raceways are arranged inside the center hole of the braking disc; a conical roller is arranged between each conical-surface inner raceway and each conical-surface outer raceway; nuts are arranged at the end part of the convex shaft; and the nuts are in contactwith the outer side surfaces of the inner rings. In the invention, because the technical scheme is adopted, after the outer ring of a conical hub bearing and the braking disc are integrated into a whole, the machining of the raceways and the assembly of finished products are realized.

Owner:ZHEJIANG ZHAOFENG MECHANICAL & ELECTRONICS CO LTD

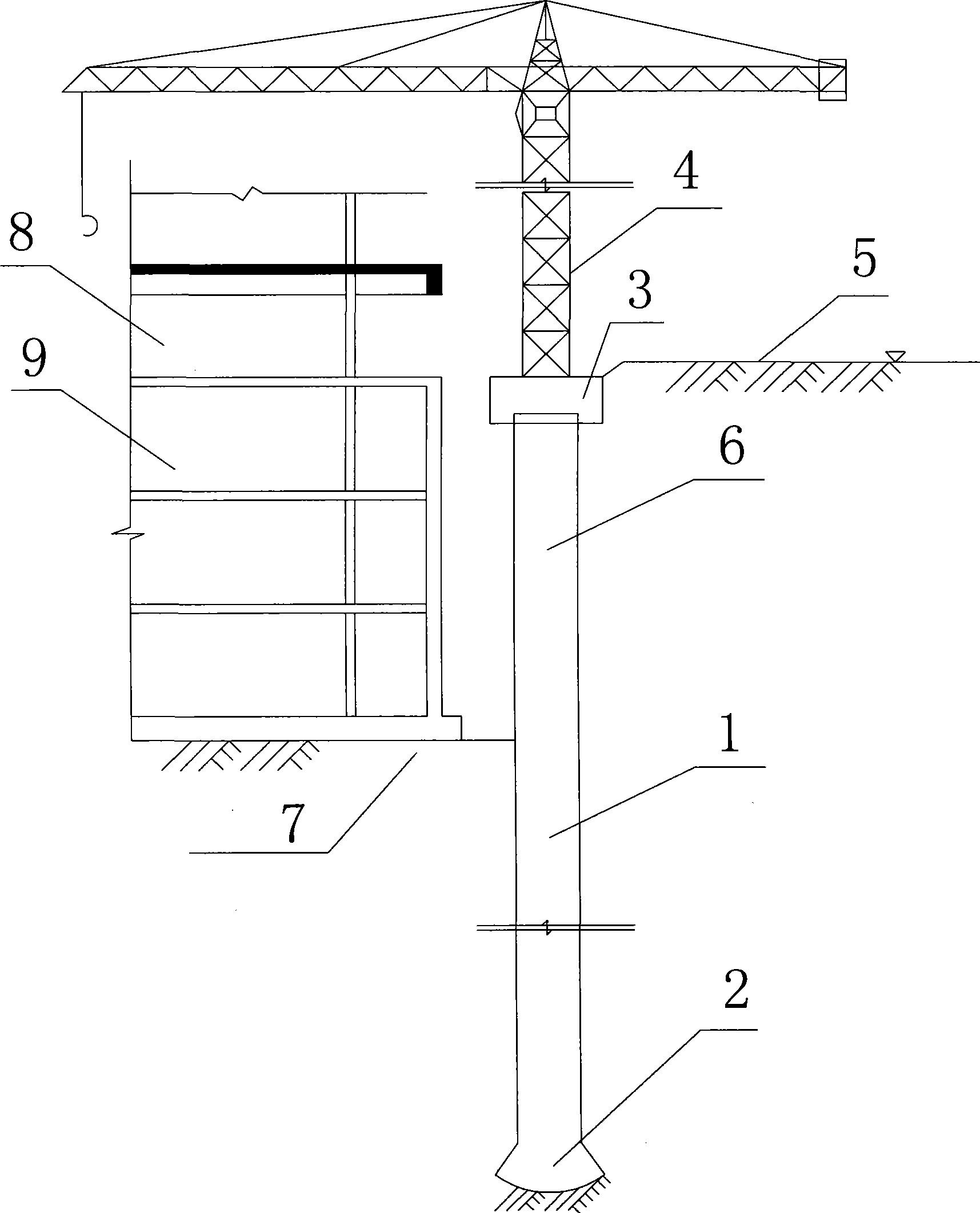

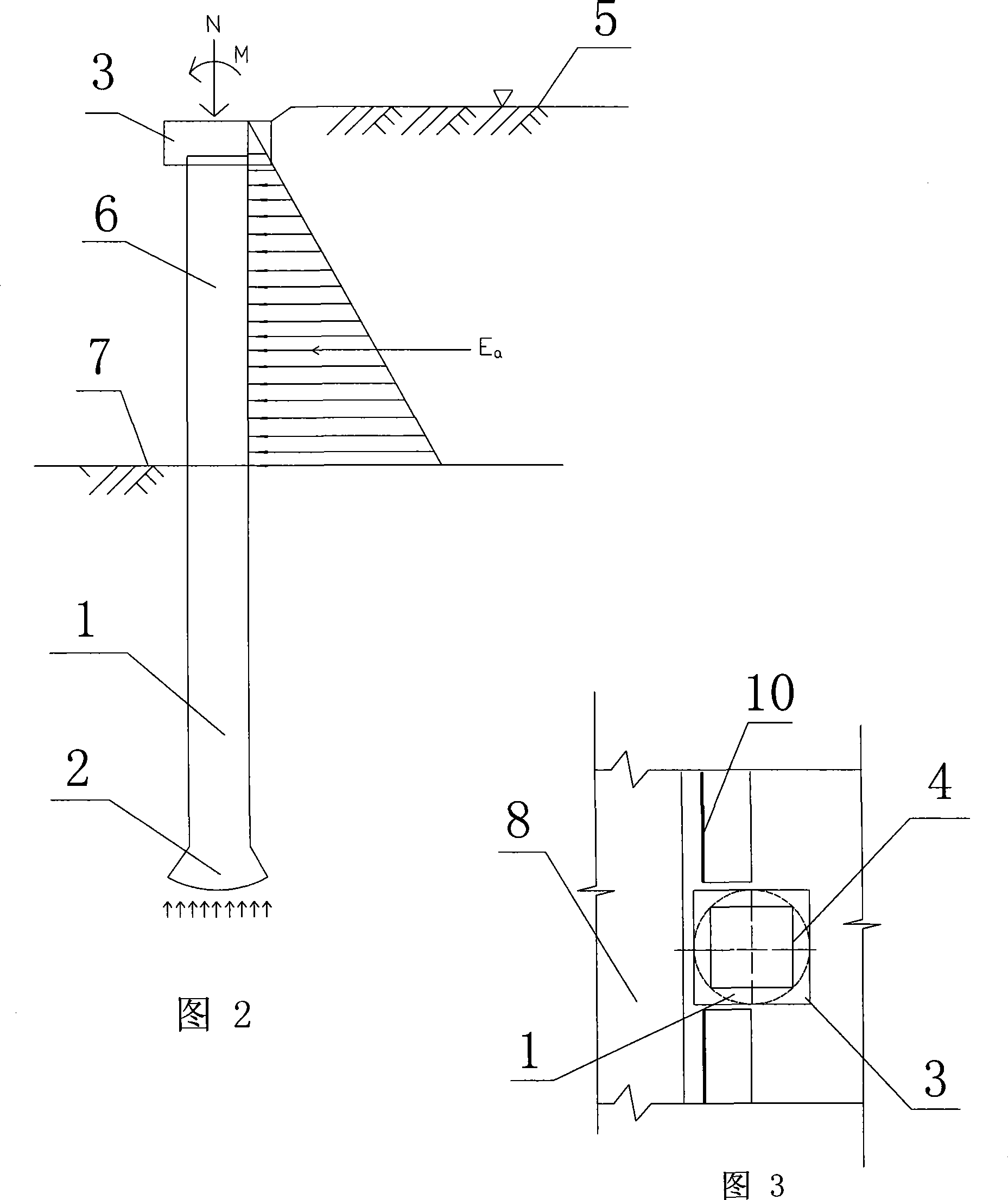

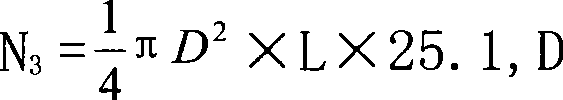

Construction method of foundation pit slope supported independent pile tower crane foundation

The invention discloses a method for constructing an independent pile tower crane foundation supported on an excavation slope. The steps are as follows: geologic drilling analysis is carried out on the excavation slope to draw up a construction scheme; according to the scheme, holes are dug on the excavation slope, water is pumped during the operation of digging the holes, retaining wall moulding boards are supported, and concrete retaining walls are cast. The diameter of each hole bottom is enlarged, and backing concrete is cast to form an expansion head. Independent supporting piles and the tower crane bearing foundation are cast by the concrete, the diameter of the independent supporting pile is equal to or larger than 1.42 times of the side length of each standard knot of a tower body, the depth of the independent supporting pile is equal to or larger than 1.5 times of the height of a pile foundation suspension arm, and the top face of the tower crane bearing foundation is lower than a natural terrace. The construction method has the advantages of low production cost, reliable quality, simple machines and equipment, convenient construction and operation and higher single-pile bearing force, thereby meeting the requirement of casting the tower crane bearing platform foundation; and the construction method has no noise during construction, no discharge of mud solution, little effect on ambient environment and buildings and small space occupation.

Owner:JIANGSU HUAJIAN CONSTR

Speed reducer structure

PendingCN111075908AHigh transmission precisionExtended service lifeGearboxesGearing detailsReduction driveDrive shaft

The invention provides a speed reducer structure, which belongs to the technical field of machinery, and solves the problems that an existing speed reducer is poor in transmission precision and is short in service life. The speed reducer structure comprises a housing, a flange, an input shaft, a transmission shaft and an output shaft, wherein the two ends of the transmission shaft are separately connected in the housing through a bearing I and a bearing II; the two ends of the output shaft are separately connected in the housing through a bearing III and a bearing IV; a coaming is arranged inthe housing, and a mounting cavity is enclosed in the housing; an opening is formed in the end surface of the housing, and the edge of the opening is detachably connected with an end cover; both the bearing I and the bearing III are arranged on the end cover; both the transmission shaft and the output shaft are positioned in the mounting cavity; a hypoid gear is arranged on the input shaft; a bevel gear which is engaged with the hypoid gear is arranged on the transmission shaft; and the dimension of the bearing II is greater than that of the bearing I. The bearing II can bear greater axial bearing force relative to the bearing I, so that stable and consistent transmission efficiency can be kept, and therefore, the speed reducer structure has relatively high transmission precision, and theservice life of the speed reducer structure is prolonged.

Owner:浙江通宇变速机械股份有限公司

Walking wheel mechanism of suspended cover manipulator

PendingCN109458402AIncrease axial forceReduce processing difficultyHubsShaftsRemote manipulatorEngineering

The invention discloses a walking wheel mechanism of a suspended cover manipulator. Wheel shafts are step shafts; wheels are mounted on the wheel shafts; bearings are arranged between the wheel shaftsand hubs of the wheels; the end parts of the wheel shafts penetrate through the bearings; threads are arranged on the peripheral surfaces, near the end parts, of the wheel shafts; nuts are connectedto the threads of the wheel shafts for pressing one ends of inner rings of the bearings; step end surfaces of the wheel shafts are pressed by the other end surfaces of the inner rings of the bearings;one ends of the wheels are connected with stifles; one end surfaces of outer rings of the bearings are pressed by the stifles; and the other end surfaces of the outer rings of the bearings are tightly pressed on the hubs. The nuts are used for axially positioning one ends of the inner rings of the bearings; the step end surfaces of the step shafts are used for axially positioning the other ends of the inner rings of the bearings; and the nuts and the wheel shafts are in threaded fit connection, so that the axial acting force of the bearings is increased, the axial bearing capacity of the wheels is improved, the deflection falling of walking wheels caused by looseness of the walking wheels is prevented, and the machining and assembly difficulty of the wheels is reduced.

Owner:SINOSTEEL XIAN MACHINERY

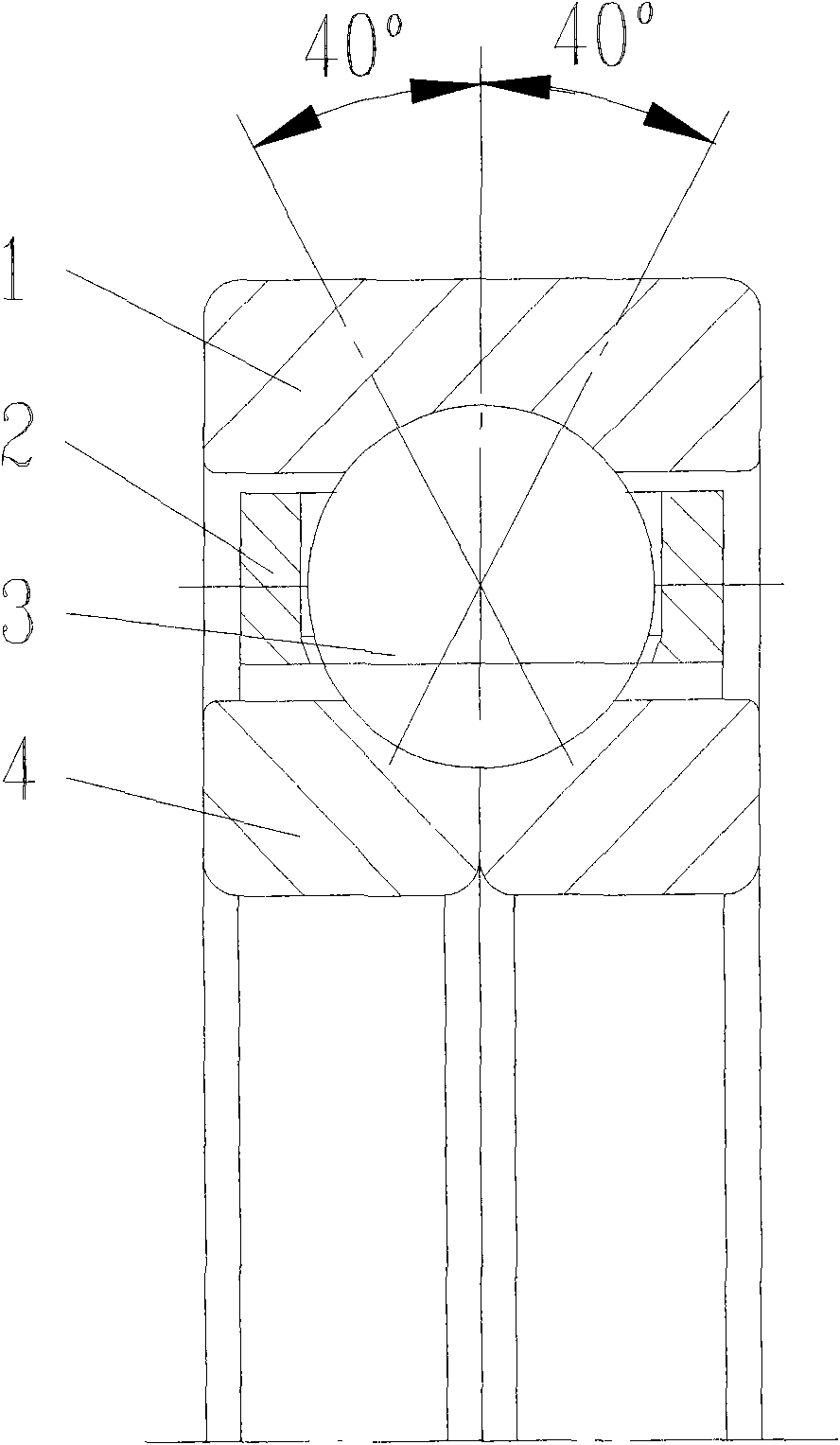

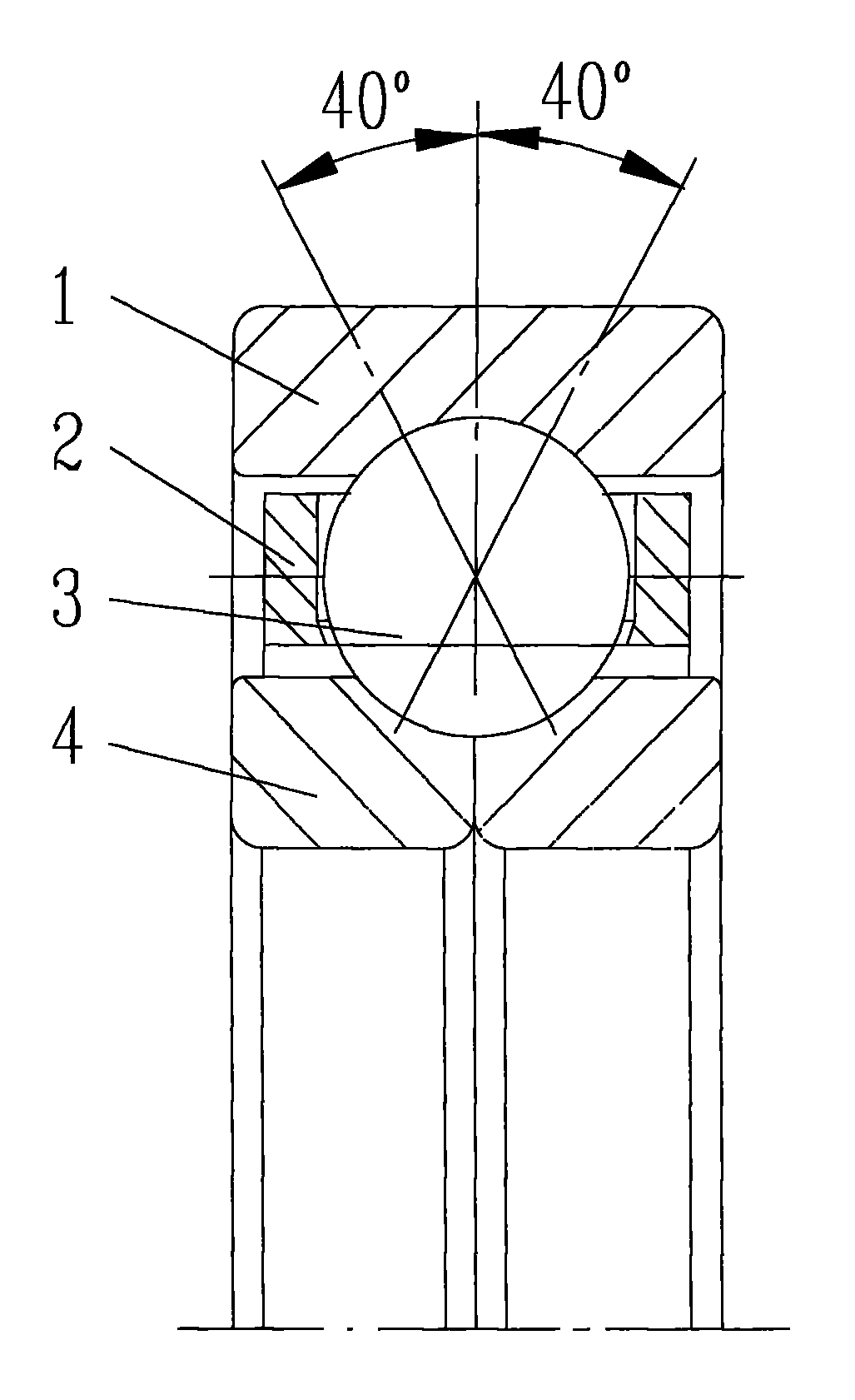

New four-point contact ball bearing

InactiveCN101788017AImprove the axial bearing capacityPrevent cage deformationBall bearingsBearing componentsLight railSelf locking

The invention provides a new four-point contact ball bearing, comprising an outer ring, inner rings, a steel ball and retainers. The contact angle of the bearing is increased to 40 degrees so as to improve the axial bearing capacity of the bearing. The retainers are integrated self-locking retainers and the steel ball can be effectively locked by inner counter bores of the retainers, thus effectively preventing the retainers from deformation caused by chiseling and printing and the ball from falling caused by uneven lock amount. The bearing is suitable for subway and light rail gear boxes and other similar special conditions.

Owner:WAFANGDIAN BEARING GRP CO LTD

Drawing leather roller sleeve bearing

InactiveCN106015319ASolve the heatImprove axial clearance accuracyRolling contact bearingsTextile treatmentEngineeringMechanical engineering

Owner:CHENGDU KECHUANG JIASI TECH

Hub module of mining equipment

InactiveCN107035774AImprove bearing capacitySatisfy the working conditions with large changes in bearing capacityBearing unit rigid supportInterference fitHeavy load

The invention discloses a hub module of mining equipment, and belongs to the technical field of bearing structures. The hub module comprises an outer ring and an inner ring for oppositely rotating; the inner ring is sleeved in the outer ring, and is coaxially arranged with the outer ring; a cage is arranged between the outer ring and the inner ring; a flange with a mounting hole is arranged at one end of the outer ring; the other end of the outer ring is leveled with the axial end surface of the inner ring; an annular inner slide way is peripherally formed in the inner side of the outer ring; an annular outer slide way is peripherally formed in the outer side of the inner ring; a slide body is arranged between the inner slide way and the outer slide way; the slide body comprises multiple slide blocks with arc structures; the slide blocks are provided with upper curved surface parts bonded corresponding to the outer slide way, and lower curved surface parts bonded corresponding to the inner slide way; a baffle plate is arranged in a shaft hole, at one end of the flange, of the outer ring; the baffle plate is extruded and pressed with the outer ring through a stop retainer ring; and the baffle plate is provided with an annular projection in interference fit with the axial end surface of the inner ring. The hub module adopts a full-contact surface rolling body, and can satisfy the use demands of a rotating part with low speed, heavy load and high load change in the process.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

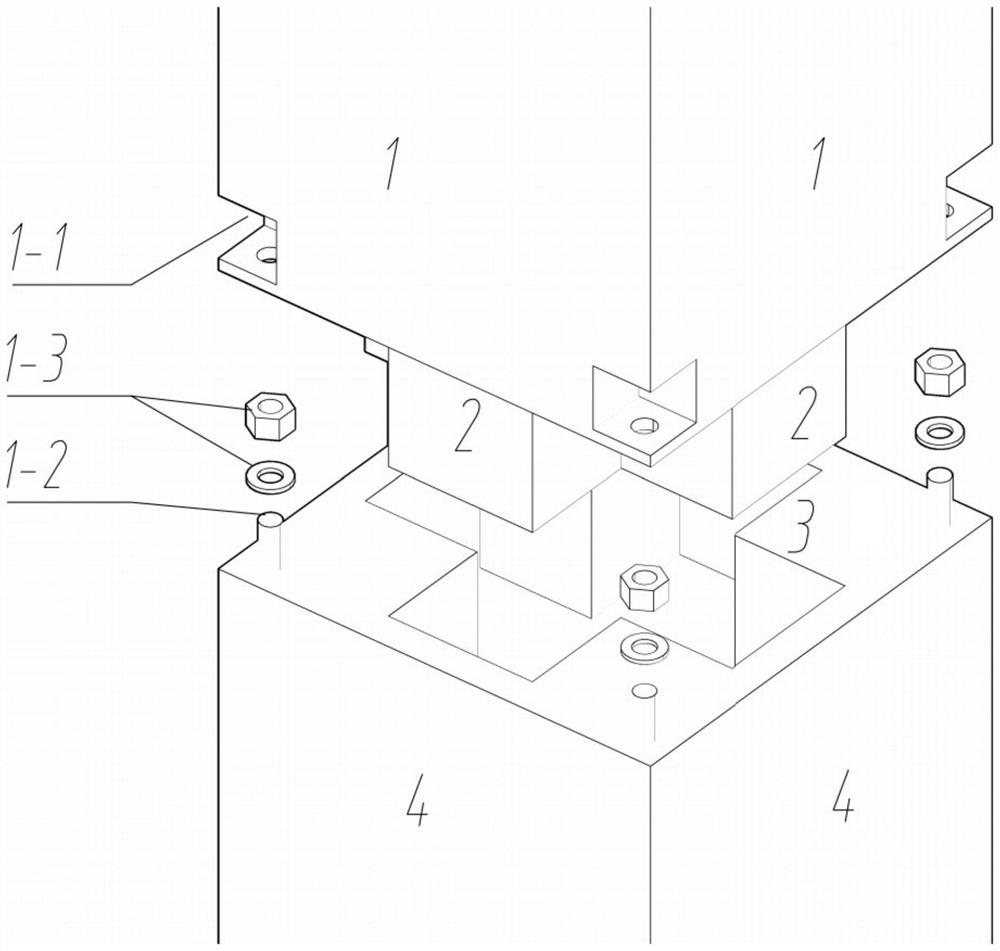

Cross tenon type vertical bolt connecting joint of fabricated concrete frame structure

PendingCN113047430AImprove assembly efficiencyImprove the standardization of constructionStrutsPillarsDuctilityMortise and tenon

The invention provides a cross tenon type vertical bolt connecting joint of a fabricated concrete frame structure. The cross tenon type vertical bolt connecting joint comprises an upper concrete column and a lower concrete column; a cross tenon is arranged at the bottom of the upper concrete column and is in matched inserted connection with a cross mortise formed in the top of the lower concrete column; bolt connecting grooves are formed in the four corners of the upper concrete column and above the cross tenon. Bolts vertically penetrate the four corners of the bottom of the upper concrete column from the four corners of the lower concrete column, stretch into the bolt connecting grooves and are fastened through nuts; the vertical bearing force of the upper concrete column and the lower concrete column is transmitted through cross mortise and tenon joint, and the force transmission section is the same as the section area of the concrete columns; meanwhile, integral stirrups are arranged at the joint so as to enhance the axial bearing force, the core position of the joint is in a three-direction pressed state under the axial pressure state exceeding the bearing force, ductility damage is generated, and the vertical bearing force is guaranteed; and bolt connection only bears the vertical loads of the columns, bears part of axial force in the normal state, bears pull force under the earthquake action and is clear in stress. The cross tenon type vertical bolt connecting joint has the beneficial effects of being simple in structure, convenient to construct, efficient in assembly and high in shear bearing capacity.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

A single degree of freedom magnetic bearing

Owner:江阴智产汇知识产权运营有限公司

Axial flux five-degree-of-freedom magnetic levitation motor

ActiveCN112436616AHighly integratedStrong fault toleranceMagnetic circuit rotating partsMagnetic circuit stationary partsCircular discMagnetic bearing

The invention discloses an axial flux five-degree-of-freedom magnetic levitation motor which comprises two bearingless switched reluctance motors, an axial disc, two permanent magnet rings and two sets of axial control windings. Rotors of the first bearingless switched reluctance motor and the second bearingless switched reluctance motor and the axial disc share one rotating shaft. The first bearingless switched reluctance motor and the second bearingless switched reluctance motor provide torque to drive the motors to rotate; radial suspension force is provided, and the radial four-degree-of-freedom suspension is guaranteed. The axial disc, the first permanent magnet ring, the second permanent magnet ring, a first stator tooth yoke, a second stator tooth yoke, a first rotor tooth yoke anda second rotor tooth yoke jointly form an axial bias magnetic flux, an axial control magnetic flux is generated by adjusting the first axial control winding and the second axial control winding, the axial suspension of the rotor is guaranteed, and finally the five-degree-of-freedom suspension of the system is achieved. According to the invention, the bearingless switched reluctance motors and an axial magnetic bearing are integrated, so that the high reliability and simplicity of a system can be embodied, and the advantages of no wear, long service life and the like of the magnetic bearing canbe exerted.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Multifunctional planetary reducer

PendingCN110242725AReduce lossImprove transmission efficiencyGearingGearing detailsElectric machineryReducer

The invention discloses a multifunctional planetary reducer, and belongs to the technical field of reducers. The multifunctional planetary reducer comprises a reducer box body and a transition flange, the transition flange is positioned at the bottom end of the speed reducer box body, an input shaft is arranged in the middle of the inner bottom end of the speed reducer box body, an output inner shaft and an output outer shaft are in transmission connection above the input shaft, an input sun gear is in transmission connection with the upper portion of the input shaft, one side of the input sun gear is in transmission connection with a planetary gear in a double-shaft transmission mode, and a clamping pin shaft is inserted in the middle of the interior of the planetary gear. The speed reducer is changed into a horizontal double-axis for use, the movement in the vertical direction is changed into movement in the horizontal direction, the output direction is provided with an inner double-shaft function and an outer double-axis function, the input end is connected with a servo motor for use, is connected with a planetary gear set so as to increase the transmission efficiency, and can be used for bending various angles, so that all directions and angles of the turning, milling and grinding are very convenient to process, the use of high precision is brought by indexing, and the energy loss is reduced.

Owner:东莞市卓蓝自动化设备有限公司

A Frustoconical Solid Cylindrical Bearingless Switched Reluctance Motor

ActiveCN111277091BLow costImprove reliabilityMagnetic circuit rotating partsMagnetic circuit stationary partsPull forceElectric machine

The invention discloses a truncated conical solid cylinder bearingless switched reluctance motor, which comprises a first stator and a rotor, a second stator and a rotor, a truncated conical solid cylinder; each tooth pole of the first and second stators There are first and second radial excitation windings on the top, these windings are independently controlled, and the axial excitation windings are connected in series on each tooth pole of the first and second stators; there is a conical outer chamfer on the axial inner side of the two stators Structure; the tooth poles of the first and second rotors have a 15° rotation mechanical angle difference; the first and second rotors share a rotating shaft with the truncated conical solid cylinder, and the outer chamfers of the truncated conical solid cylinder and the two stators There is an air gap length between them, when the first and second radial field windings conduct current, the first and second rotors provide radial levitation force, and at the same time the axial field windings conduct to control the magnetic flux in the stator teeth Density, so that the solid cylinder obtains a set of magnetic pulling force, and extracts the axial component of this set of magnetic pulling force to realize axial levitation control, and finally realizes five-degree-of-freedom levitation.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

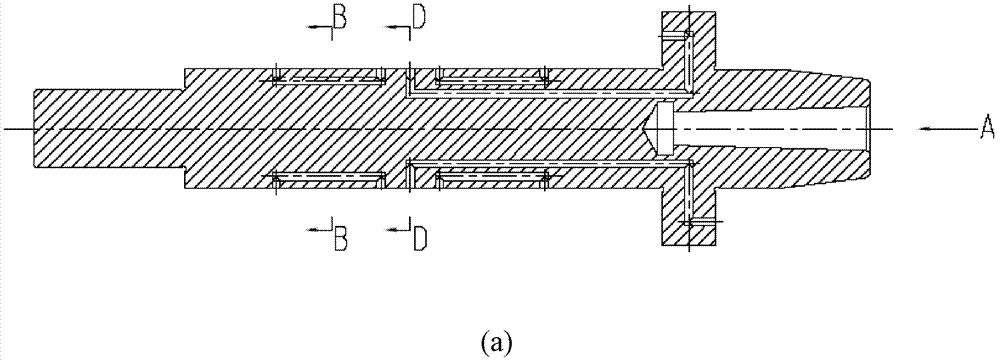

Ball screw end support bearing arranging structure of high-speed feed shaft

InactiveCN104526435AImprove performanceImprove machining accuracyGearingFeeding apparatusNumerical controlBall screw drive

The invention relates to a bearing arranging structure of a feed shaft of a numerical control machine tool, in particular to a ball screw end support bearing arranging structure of a high-speed feed shaft. The ball screw end support bearing arranging structure is mainly used for transmission of a high-speed machine tool linear feed shaft driven by a ball screw. Four plus two or more sets of precise thrust angular contact ball bearing combinations are adopted in the support of a power input end, and three or more sets of precise thrust angular contact ball bearing combinations are adopted in the support of a non-power end. Special precise thrust angular contact ball bearings for the screw and with the nominal contact angle alpha being 60 degrees are adopted as precise thrust angular contact ball bearings. A high-strength disc spring preload is installed at the non-power end of the screw. The special precise thrust angular contact ball bearings for the screw and with the nominal contact angle alpha being 60 degrees are adopted, the larger the number of bearing steel balls is, the higher the axial rigidity becomes compared with ordinary angular contact bearings, the starting torque is small, and the low-driving-force and high-precision running is achieved. The axial bearing force of the bearings is greatly improved, and the service life of the bearings is greatly prolonged. The machining precision and stability of a high-speed machine tool are improved.

Owner:JIER MACHINE TOOL GROUP

Bearing assembly

InactiveCN107165931AImprove bearing capacitySatisfy the working conditions with large changes in bearing capacityShaftsBearing componentsEngineeringMechanical engineering

The invention discloses a bearing assembly, and belongs to the technical field of bearing structures. The bearing assembly comprises an upper ring, a lower ring and cages, wherein the cages are located between an outer ring and an inner ring, and the upper ring and the lower ring correspond to each other in size and are arranged in a vertical coaxial mode. The bearing assembly is characterized in that an annular upper slide way is arranged on the lower end surface of the upper ring in the circumferential direction of the upper ring; an annular lower slide way is arranged on the upper end surface of the lower ring in the circumferential direction of the lower ring; a sliding body is arranged between the upper slide way and the lower slide way and comprises a plurality of sliding blocks which are of arc-shaped structures; upper curved surface parts which are correspondingly attached to the upper slide way surface and lower curved surface parts which are correspondingly attached to the lower slide way surface are arranged on the sliding blocks; and the cages are provided with placement positions for sleeving of the corresponding sliding blocks, and a lubricating chamber is arranged between every two adjacent sliding blocks. According to the bearing assembly, the sliding body capable of sliding is arranged and replaces a rolling body in the prior art, so that the bearing capacity of a bearing adopting the sliding body is large, and the bearing is suitable for slow running and capable of meeting the working condition with large bearing capacity change.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

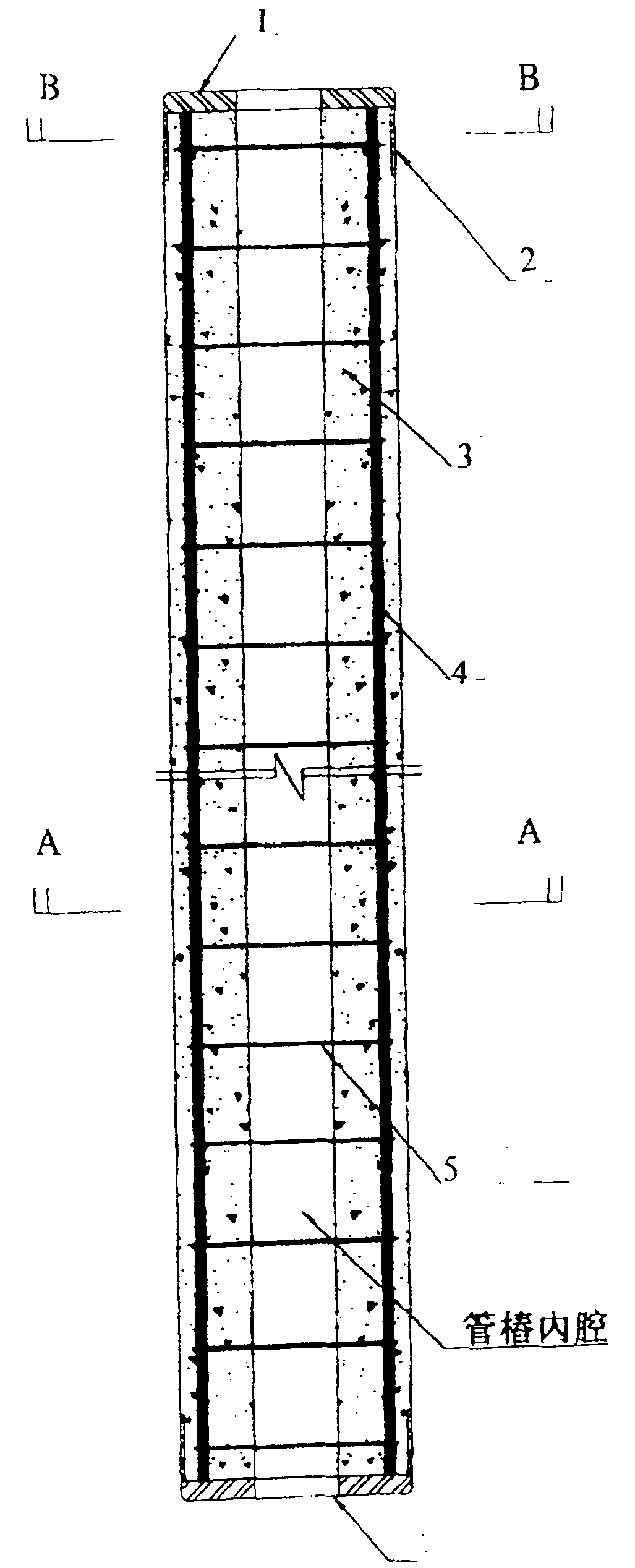

Precast reinforced concrete tubular pile

InactiveCN1560380BReduce dosageNo reduction in pile qualityCeramic shaping apparatusBulkheads/pilesHoopingReinforced concrete

The invention is a preprocessed steel bar concrete pipe structure. The structure includes concrete, primary steel bar of steel bar cage, ring or spiral type steel bard cage hooping, the pile head metal connection component at two ends of the pile and other constructing components, the steel cage primary bar is the one with non pretensioned prestressing. The method is: the steel bar cage made up of non pretensioned prestressing steel bar and hooping is produced according to the design; the steel bar cage is connected with the pile head metal components, arranges with each kind of embedded component; the steel bar cage is put into the steel model, pours the concrete in the model, completes the pile perform; the steel model assembled with a pile perform rotates around the spindle, the concrete is centrifugated and compacted and formed; maintenance and demolding. The structure and producing method does not uses pretensioned prestressing and restrain the process with special prestressing steel bar, but with normal steel bar or other additive material, the demands is low, the material is enough.

Owner:胡柏英

Rigid-flexible coupling joint based on complex rolling contact curved surface

ActiveCN112809732AImprove the axial bearing capacitySimple structureJointsCouplingClassical mechanics

The invention provides a rigid-flexible coupling joint based on a complex rolling contact curved surface. The joint comprises two rolling contact joint bodies of the same structure, connecting bodies fixed to the outer sides of the rolling contact joint bodies respectively and two flexible rods fixed to the outer sides of the rolling contact joint bodies through the connecting bodies, wherein each rolling contact joint body comprises four convex lugs fixedly connected through the corresponding connecting bodies, the four convex lugs of each rolling contact joint body form two sets and are arranged at the two ends of the corresponding rolling contact joint body respectively, rolling contact surfaces are formed between the two convex lugs at one end of one rolling contact joint body and the two convex lugs at one end of the other rolling contact joint body respectively, and each rolling contact surface is envelope lines formed by tangent lines which pass by the central point of the corresponding flexible rod and are perpendicular to the slope of the central point of the corresponding flexible rod. In the rolling contact process, the joint has the excellent characteristic that the length of the central axis is kept unchanged, and the problem of coupling between rigid structure supporting and flexible force interaction in a continuum robot is solved.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com