Driving mechanism for nut rotary type long lead screw

A technology of rotary drive mechanism and drive mechanism, which is applied to metal processing machinery parts, metal processing equipment, feeding devices, etc., can solve the problems that the screw drive mechanism is not suitable for moving distance, affects the positioning accuracy of the carriage, and affects the longitudinal speed. Achieve the effect of avoiding large deflection problems, avoiding critical speed limitations, and running smoothly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

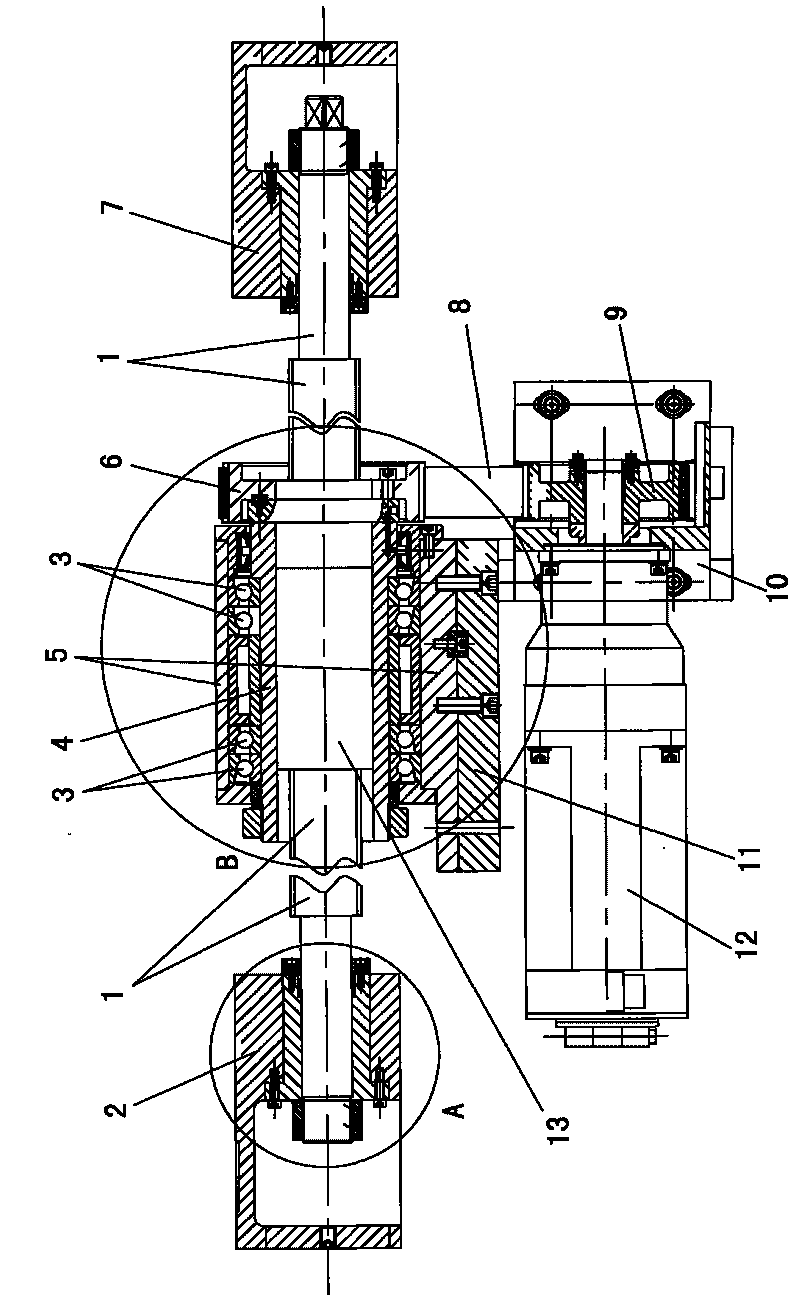

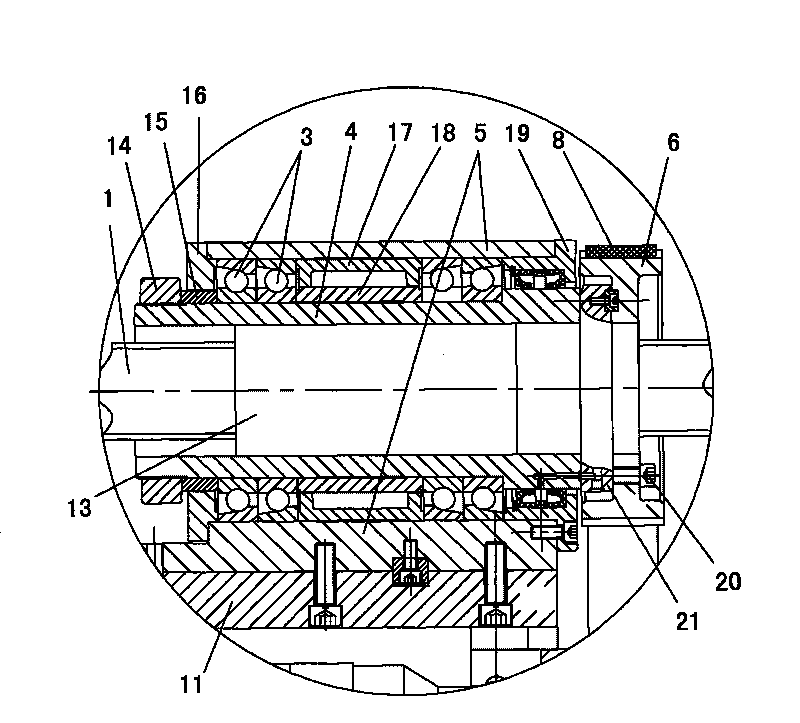

[0013] Such as figure 1 , 2 Shown: 1 is screw, can be the screw of ball screw or other structures. 13 is the nut that matches with leading screw 1.

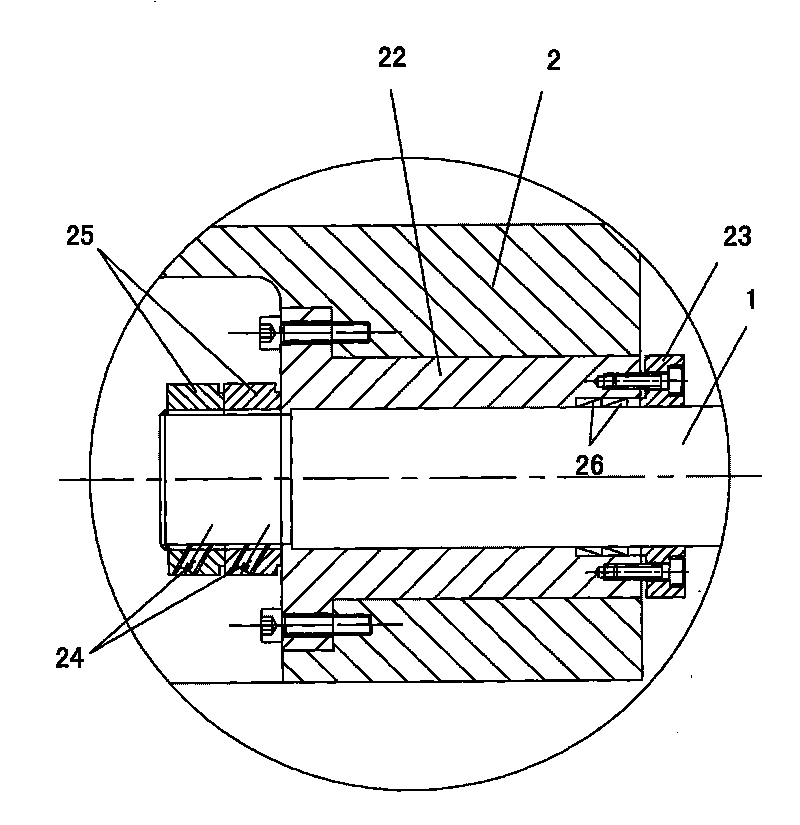

[0014] Such as image 3 As shown: the left end of the lead screw 1 is fixed and supported by the left support 2. The specific structure is: a support sleeve 22 is fixed with a bolt at the inner hole of the left support 2, and the left end of the long lead screw 1 is inserted into the support sleeve 22. An end cap 25 is threadedly connected to the outside of the inner hole for axial positioning, that is, the two nuts are back-tightened and fixed to each other. The right end of the support sleeve 22 is bolted with a gland 23 for compressing the fastening collar 26 between the support sleeve 22 and the long lead screw 1 . The support structure of the right support 7 at the right end of the long lead screw 1 is the same as that of the left support 2 at the left end and is arranged symmetrically.

[0015] Such as figure 1 , 2 S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com