Leveling method based on four-point support and electromechanical automatic leveling system

A four-point support, automatic leveling technology, applied in attitude control and other directions, can solve the problems of being easily affected by ambient temperature, troublesome maintenance and maintenance, low stability, etc., to achieve high leveling reliability, fast leveling speed, and improved The effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

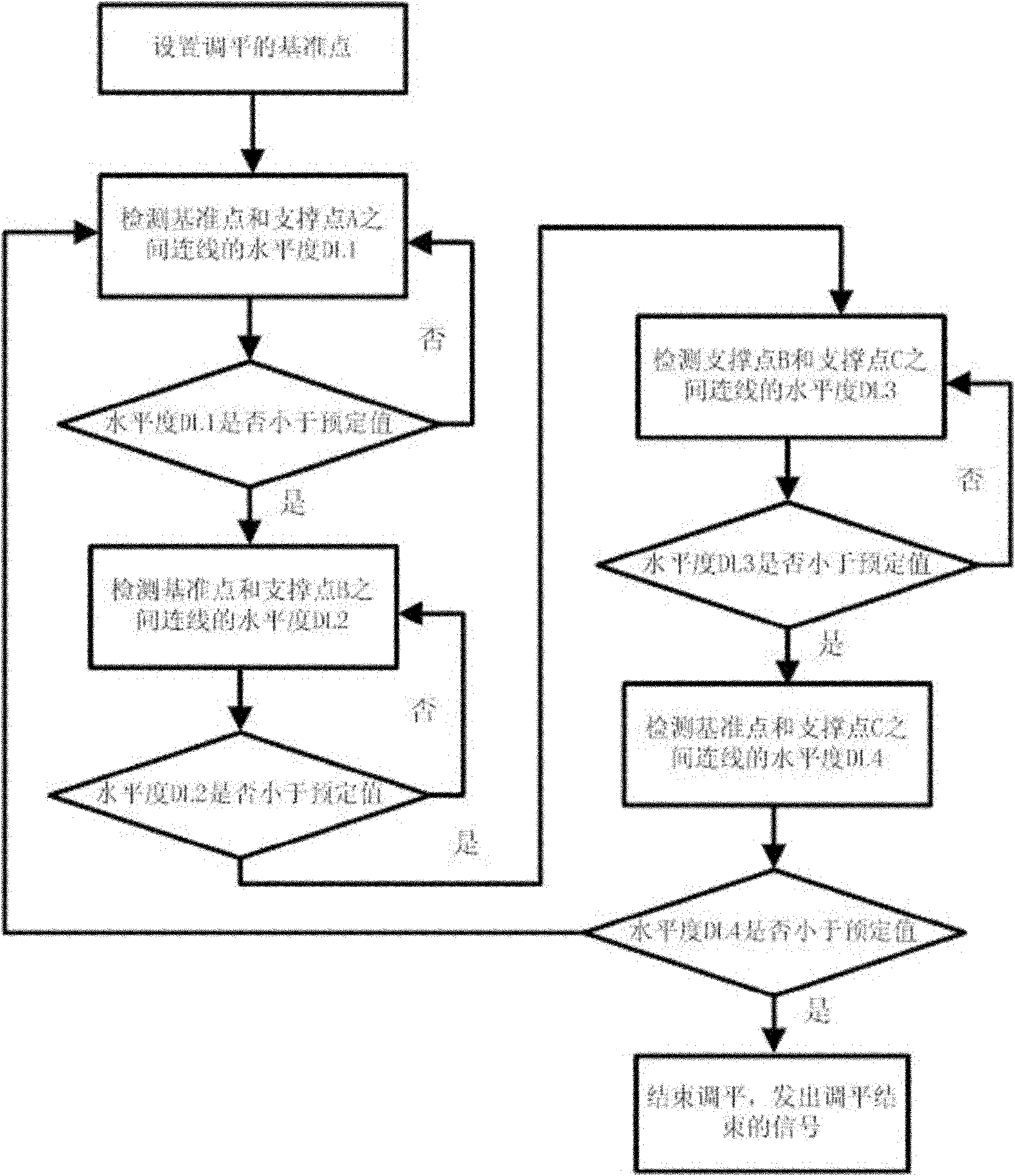

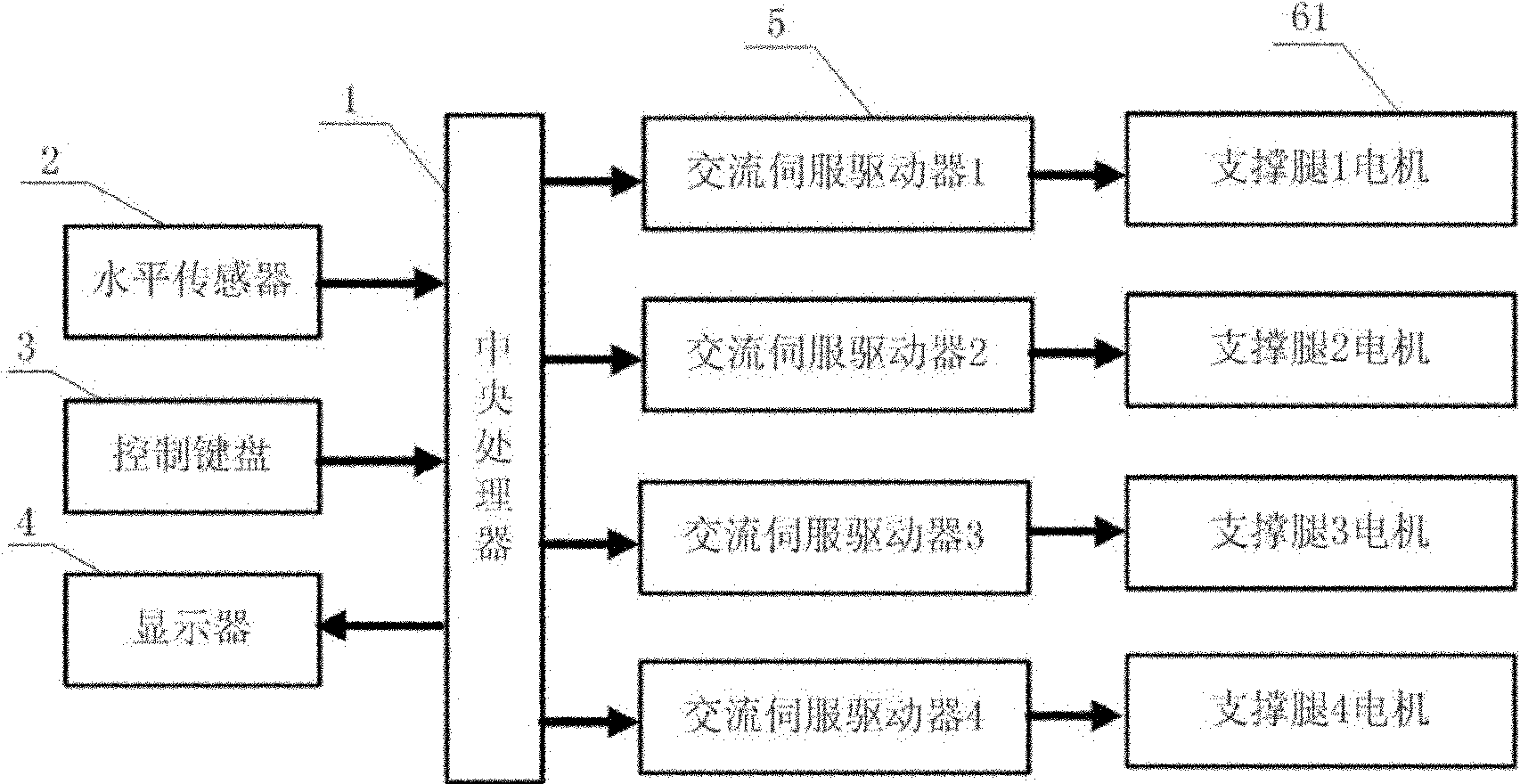

[0039] see figure 1 , figure 2 , the leveling method based on four-point support, including the following steps:

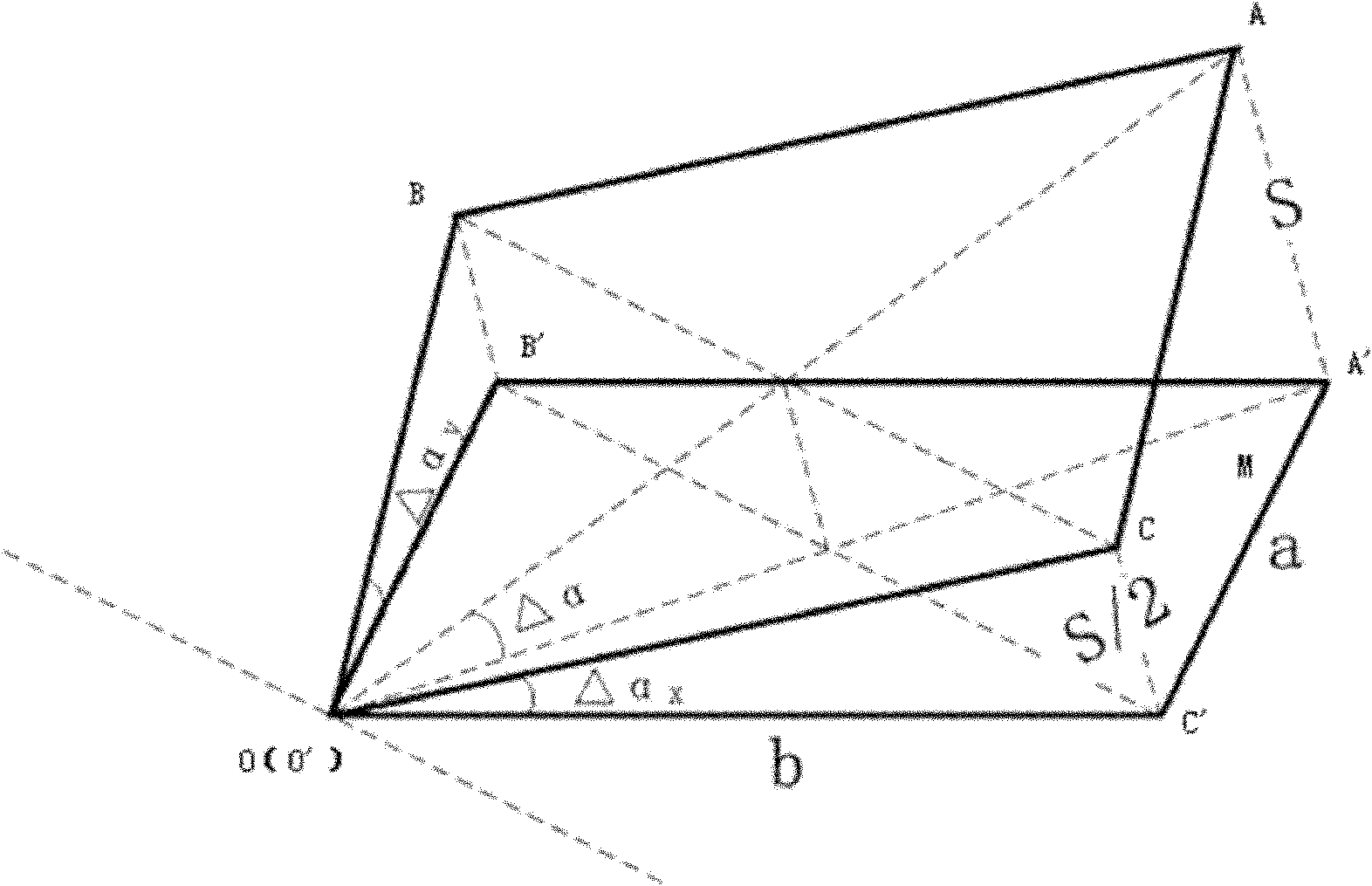

[0040]a. The projection points of the four support points on the horizontal plane are connected to each other to form a horizontal projection rectangle M, with one of the support points O as the reference point; the support point O is located on the horizontal projection rectangle M, that is, the support point O and its projection on the horizontal plane The projected points O' on the rectangle M coincide with each other, see figure 2 b. Detect the levelness DL1 of the connecting line between the reference point and the support point A, wherein the projection point A' of the support point A' and the projection point O' of the reference point are located on a diagonal line of the horizontal projection rectangle M; Check whether the degree DL1 is less than the predetermined value, if so, continue to the next step; if not, adjust the support point A until the lev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com