Equipment capable of automatically testing moisture of bituminous coal

An automatic test equipment, moisture technology, applied in the direction of removing a certain component and weighing, etc., can solve the problems of inability to meet the requirements of industrial modernization, labor-intensive moisture testing, and human errors in testing, and improve the efficiency of moisture testing. and precision, no human intervention, smooth motion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

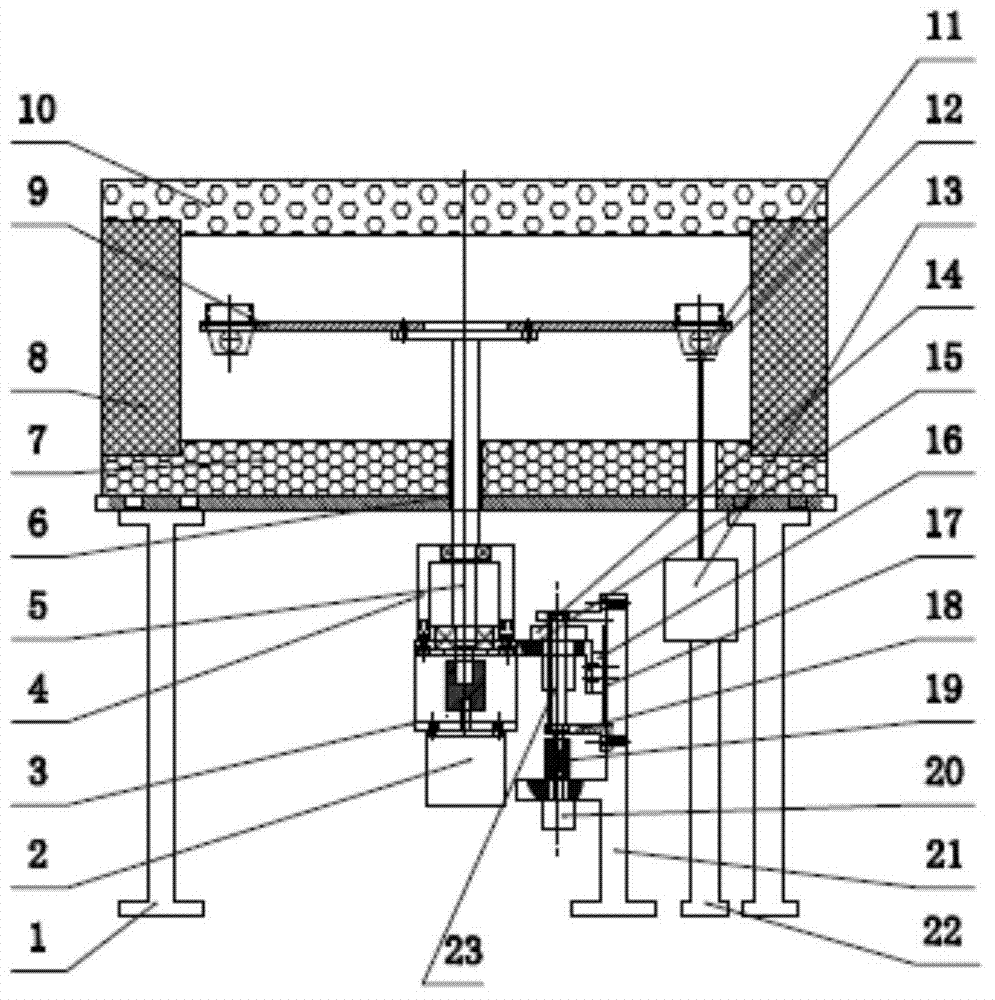

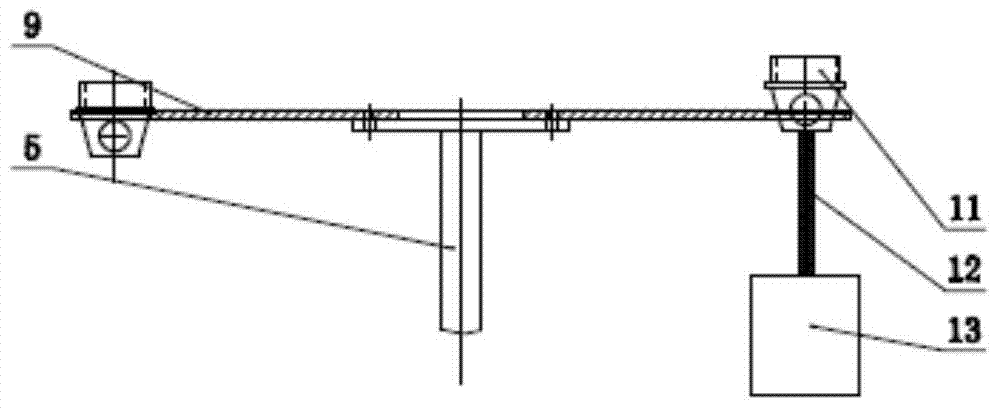

[0012] see figure 1 As shown, the moisture automatic testing equipment for bituminous coal of the present invention comprises a lower fiberboard 7, a furnace 8 installed on the lower fiberboard 7, an upper fiberboard 10 installed on the furnace 8; a lower fiberboard 7, a furnace 8 Together with the upper fiberboard 10, it constitutes a 1050C incubator for moisture experiments; the lower end of the rotating shaft 5 is connected with the rotating motor 2 through the coupling 19, and the upper end of the rotating shaft 5 is equipped with a turntable 9, and the rotating motor 2 can drive the turntable 9 through the rotating shaft 5 Rotation, and each rotation has a crucible 11 just above the weighing rod 12; the ball screw 23 installed inside the two bearing frames 18 can drive the lifting frame 15 under the guidance of the slider 16 , t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com