Method and device for automatic detection of composite errors of ball screw spiral raceway

A spiral raceway, automatic detection technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problem that it is difficult to meet the requirements of high-precision detection of the comprehensive error of the spiral raceway of the ball screw pair, and achieve good market prospects, The effect of accurate and reliable data values and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

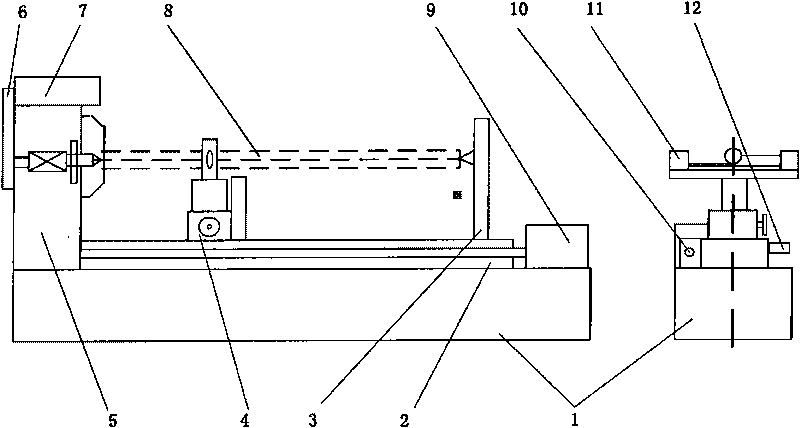

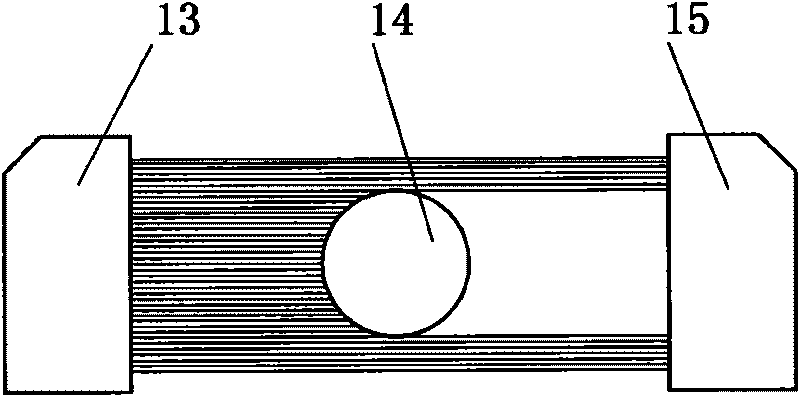

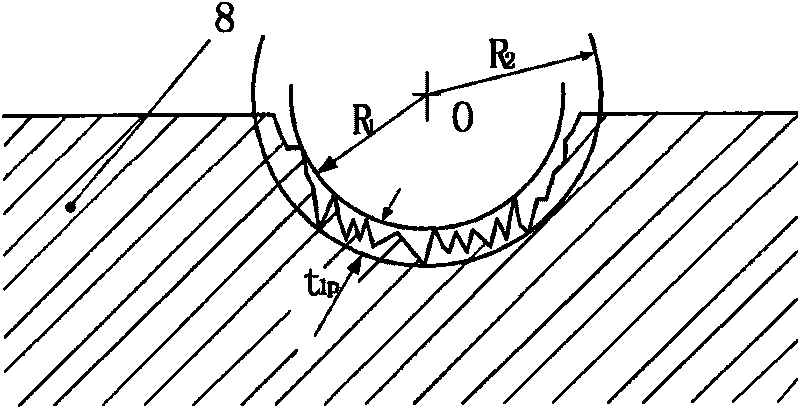

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0015] The invention discloses a method for automatically detecting comprehensive errors of a ball screw helical raceway. The method includes the following steps:

[0016] First, the preparatory work before sampling is carried out, the initial parameters of the detection device are set, and the initial rotation angle position of the ball screw to be tested is determined;

[0017] Secondly, use a grating ruler and a light curtain displacement sensor to sample the axial position and radial position on the normal truncation curve of each point of the ball screw spiral raceway to be measured, and the number of sampling points per millimeter in the axial direction is greater than or equal to 200 indivual;

[0018] Then, the aforementioned sampled data are processed, that is, the adjacent data points are sequentially connected according to the sampled data, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com