Intelligent mechanical arm of punch press

A technology of intelligent manipulators and punching machines, which is applied in the direction of manipulators, program-controlled manipulators, and metal processing equipment. Effects of work-related disability accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

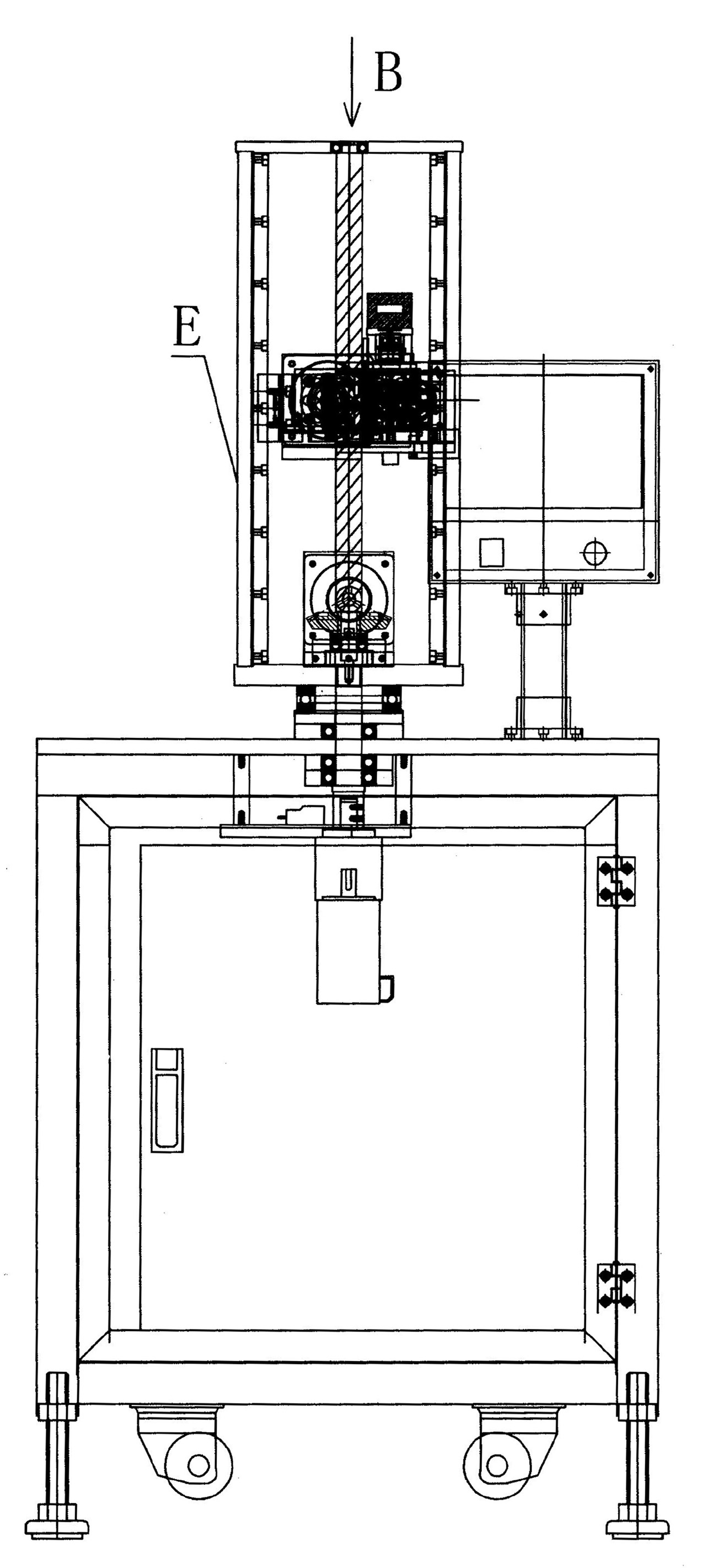

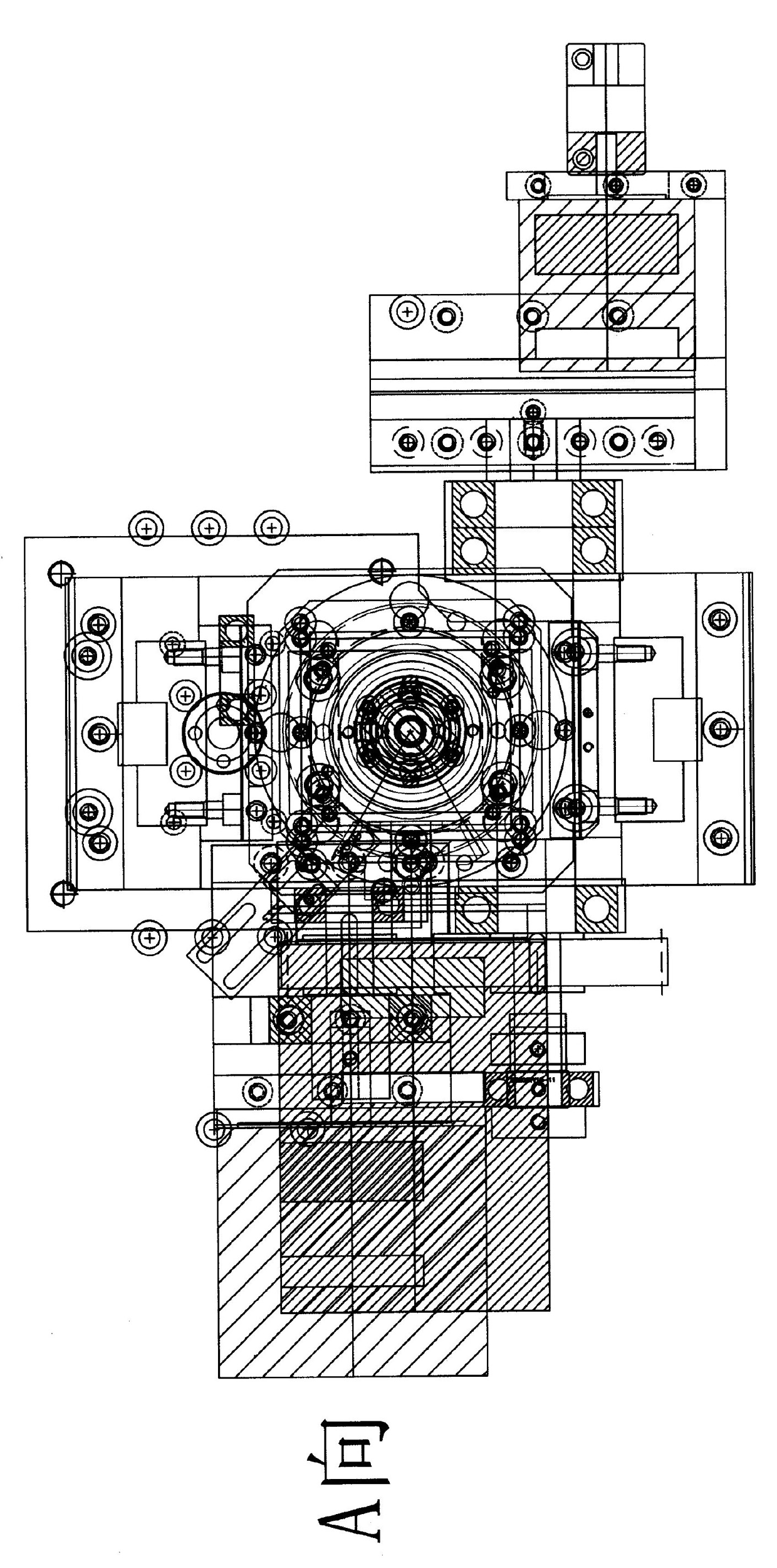

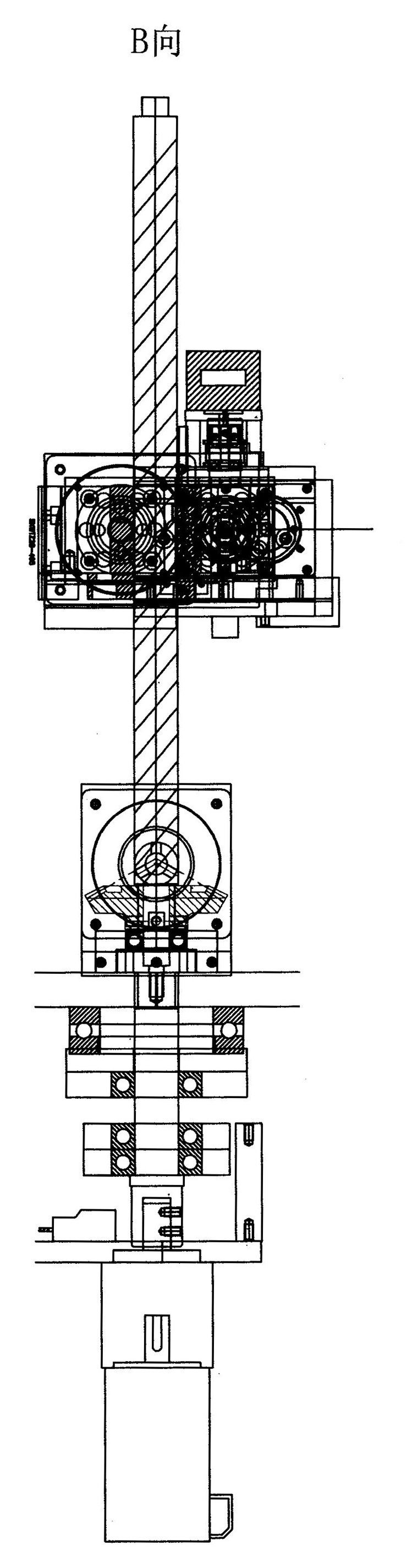

[0017] Depend on Figures 1 to 5 It can be seen that the present invention consists of a cabinet, a distribution box, a man-machine interface control box, a servo motor, a stepping motor, a gear, a screw and a female sleeve to form a horizontal motion mechanism A, a turning motion mechanism B, a swing arm motion mechanism C, and an execution end The rotary motion mechanism D and the vertical motion mechanism E are characterized in that:

[0018] The horizontal movement mechanism A of the manipulator is driven by a stepper motor 12 and a linear ball screw 15, and the actuator is set on the linear ball screw female sleeve 25 for moving back and forth in the horizontal direction;

[0019] Described manipulator turning motion mechanism B adopts stepper motor 8 and gear 9 transmission, is connected and driven arm 22 to turn over by turning main shaft 7, and arm 22 is provided with manipulator horizontal movement mechanism A to turn over together;

[0020] The swing arm movement st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com