Composite casing pipe restrained reinforced concrete column

A technology of reinforced concrete columns and composite sleeves, which is applied in the direction of columns, pier columns, pillars, etc., can solve the problems of hollowing out between steel pipes and concrete, large differences in material properties, and increased use costs, so as to improve bearing capacity and ductility. The effect of high axial bearing capacity and good bearing capacity ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

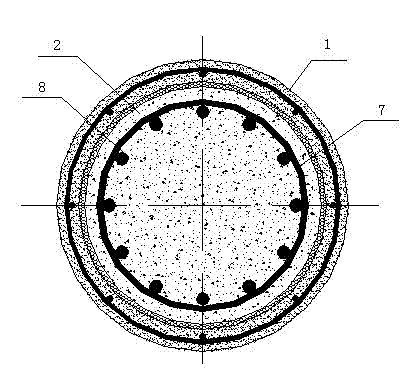

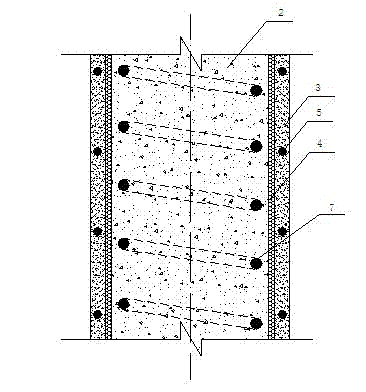

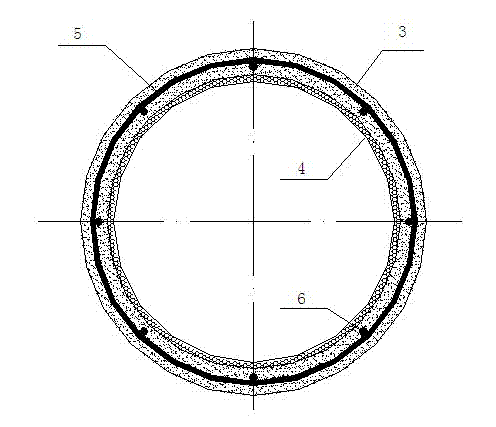

[0033] A composite casing-confined reinforced concrete column such as figure 1 , figure 2 , image 3 As shown, it is characterized in that the composite casing (1) of the reinforced concrete column (2) is a combination of a prefabricated active powder concrete outer casing (3) and an inner casing (4).

[0034] The inner casing (4) is a fiber reinforced plastic (FRP) pipe or steel pipe.

[0035] Fiber reinforced plastic (FRP) inner casing (4) is carbon fiber reinforced plastic (CFRP) pipe, glass fiber reinforced plastic (GFRP) pipe, aramid fiber reinforced plastic (AFRP) pipe, basalt fiber reinforced plastic (BFRP) pipe or hybrid Fiber reinforced plastic (HFRP) pipe.

[0036] The reinforcing bars arranged in the active powder concrete outer casing (3) are closed stirrups (5) and longitudinal reinforcing bars (6).

[0037] The reinforcing bars arranged in the reinforced concrete column (2) are closed stirrups (7) and longitudinal reinforcing bars (8).

Embodiment approach

[0039] First of all, bind the reinforcement cage composed of the longitudinal reinforcement 6 and the closed stirrup 5 in the active powder concrete outer casing, and place it in the mold composed of the outer mold and the inner casing 4 for making the prefabricated active powder concrete outer casing 2; pour the prepared Reactive powder concrete is made into a composite casing 1; the formwork is removed after one day of pouring, and the composite casing 1 is placed in hot water at 90°C for 48 hours of curing; the prefabricated composite casing 1 is transported to the construction site, and Hoisting in place; binding the longitudinal reinforcement 8 and the closed stirrup 7 of the reinforced concrete column 2 in the composite casing 1; supporting the formwork of the reinforced concrete beam 10 and the floor (not shown), binding the steel bars of the beam and the floor, and then Concrete is poured, so that the reinforced concrete column 9 constrained by composite sleeves is form...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com