Precast reinforced concrete tubular pile

A reinforced concrete pipe and concrete technology, which is applied in high-strength concrete pile structure, high bearing capacity pile structure, and non-prestressed fields, can solve the problems of providing bearing capacity, low steel bar content, high price, etc., and achieve axial bearing capacity Large, high modulus of elasticity, greatly increasing productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

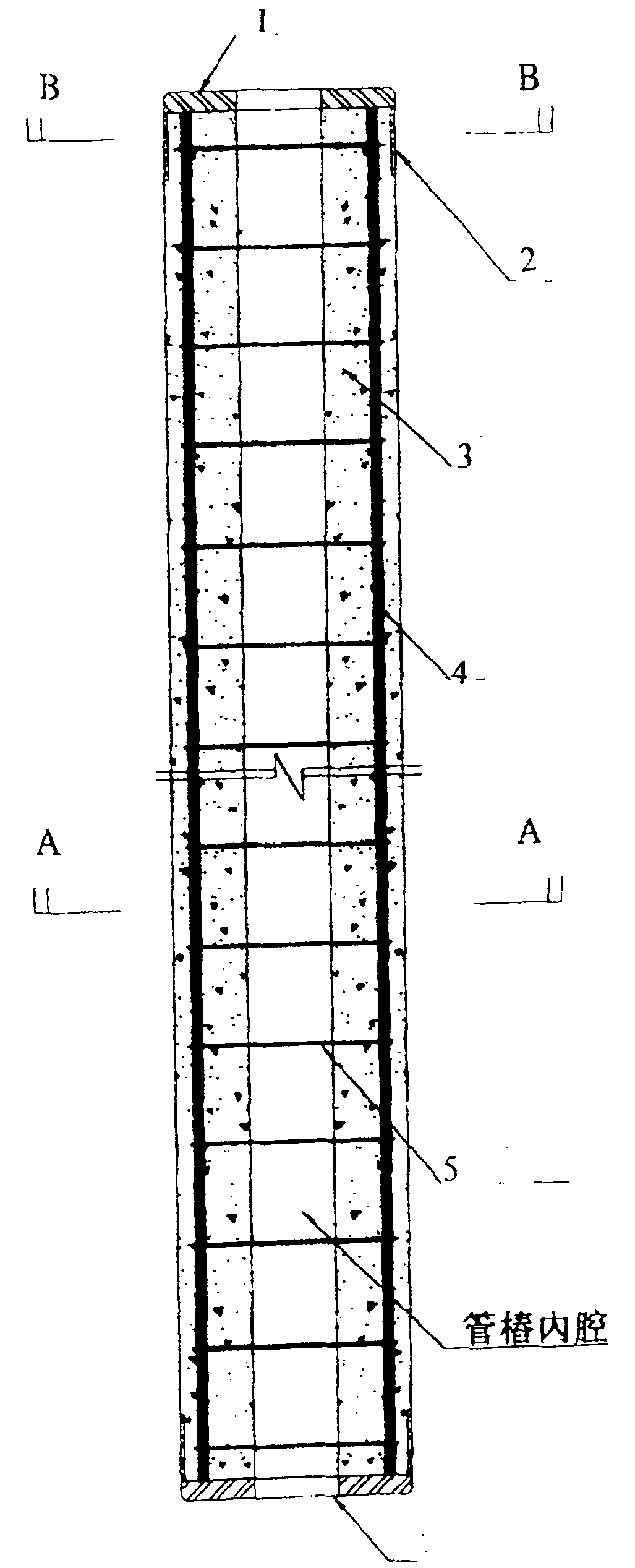

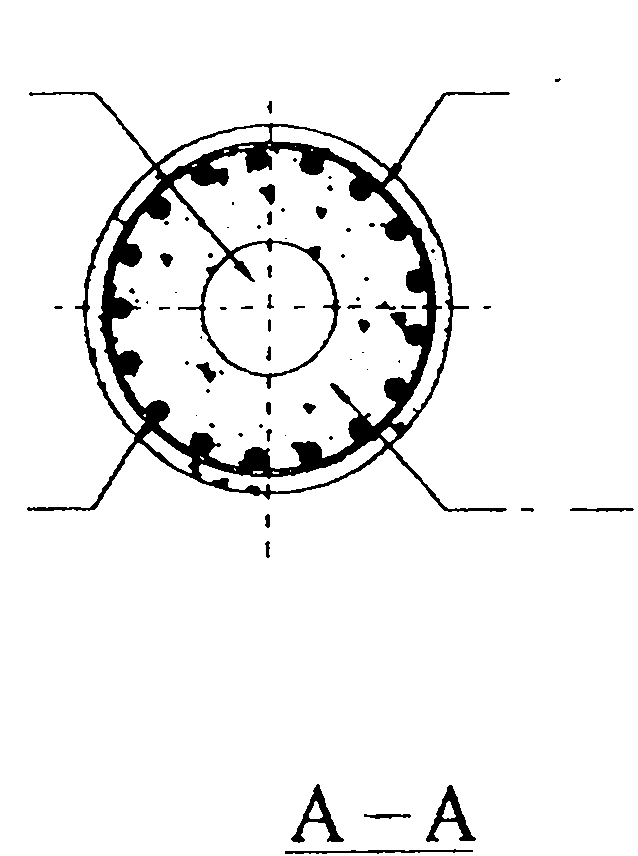

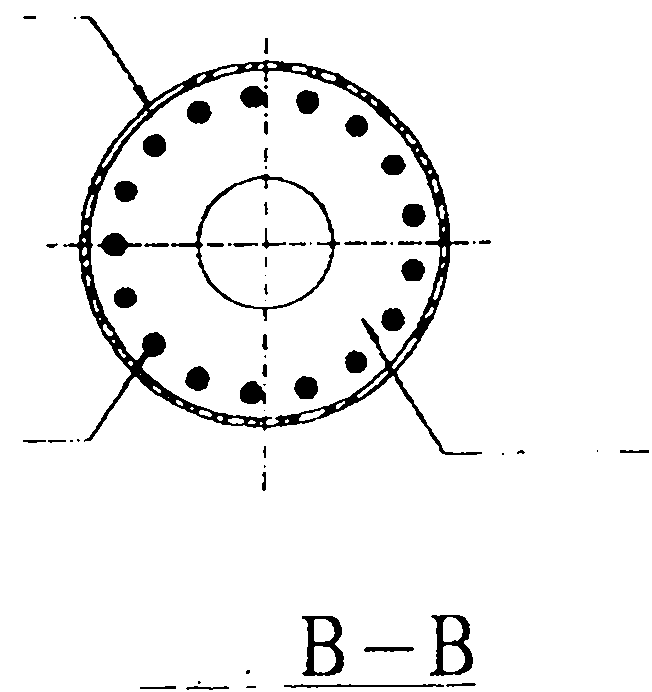

[0050] figure 1 It is a structural schematic diagram of the reinforced concrete pipe pile section of the present invention. The pipe pile can be formed by connecting one or more pipe pile sections by known methods. Each pipe section has the following materials and components: concrete and concrete additive materials 3, main steel bars of the steel cage 4, ring or spiral steel cage stirrups 5, pile head metal connectors 1 and 2 at both ends of the pile section and other structural accessories, The main reinforcement 4 of the reinforcement cage does not include the pretensioned prestressed reinforcement. Therefore, it can save costs and reduce processes compared with prestressed steel pipe piles. figure 2 , image 3 respectively figure 1 The A-A and B-B cross-sectional diagrams in , they jointly show the concrete 3, the main steel bar of the steel cage 4, the circular or spiral steel cage stirrup 5, the pile head metal connectors 1 and 2 at both ends of the pile section a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com