Design method of cross cylindrical roller bearing with two right-angle roller paths

A technology of crossed cylindrical rollers and cylindrical rollers, applied in the field of bearing design, can solve the problems of large radial bearing capacity, difficult machining, and many machining passes, and achieve the improvement of axial bearing capacity and overturning moment, Improving the radial bearing capacity and the effect of improving the radial bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

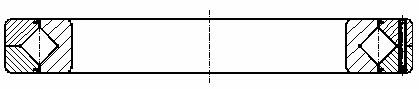

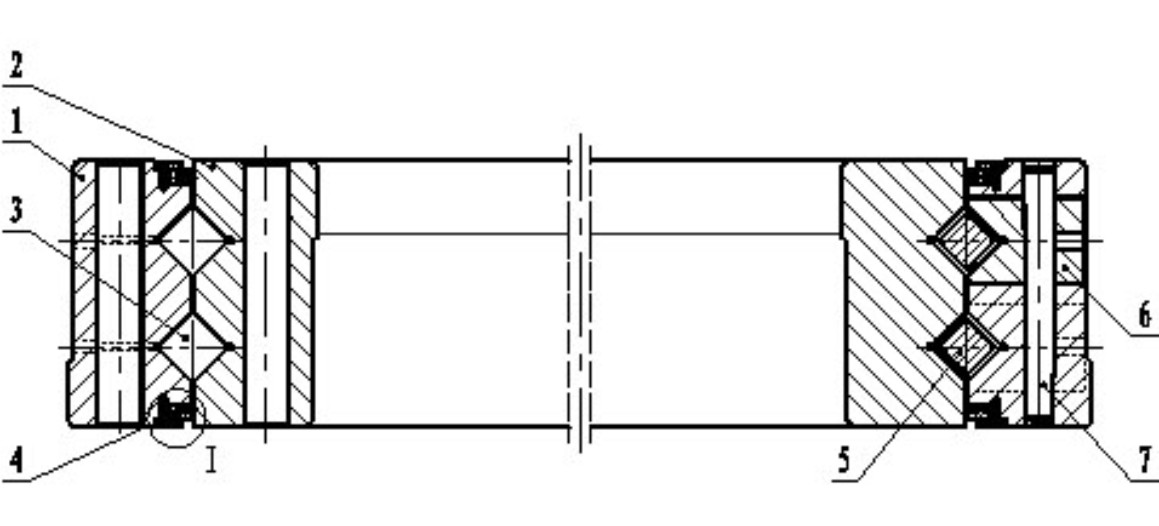

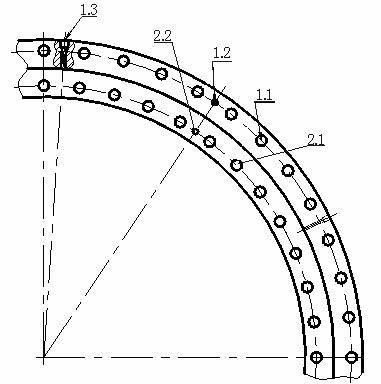

[0043] The present invention relates to a design method of crossed cylindrical roller bearings with two right angle raceways. Compared with single raceway crossed cylindrical roller bearings, the crossed cylindrical roller bearings with two right angled raceways are called double raceway crossed cylindrical roller bearings. sub bearings.

[0044] Double raceway crossed cylindrical roller bearings include outer ring, inner ring, cylindrical rollers and spacers, which is similar to the basic structure of single raceway crossed cylindrical roller bearings. The inner diameter end surface of the two-half structure of the outer ring has a right-angle raceway, and the outer diameter end surface of the inner ring is also a right-angle raceway. The right-angle raceway of the outer ring and the right-angle raceway of the inner ring have the same structural shape and correspond to each other to form a square raceway. The square raceway is equipped with an odd number of cylindrical roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com