One-dimensional micrometric displacement device

A micro-displacement, No. 1 technology, applied to the parts of the instrument, instruments, etc., can solve the problems of small radial stiffness of the flexible hinge, difficulty in accurately controlling the output, and small radial bearing capacity, and achieve precise displacement control output, diameter The effect of large radial bearing capacity and improved radial stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

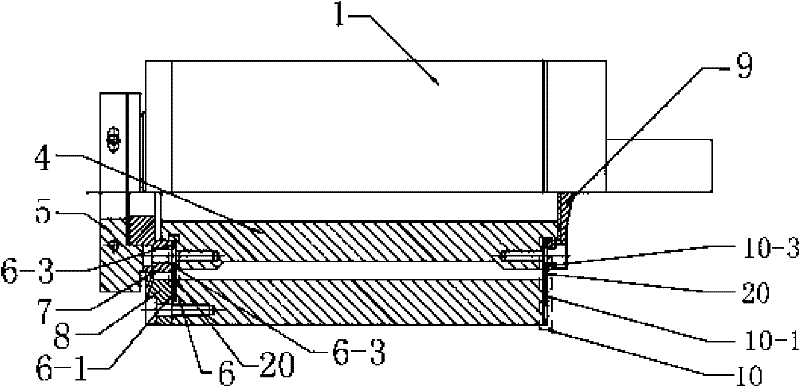

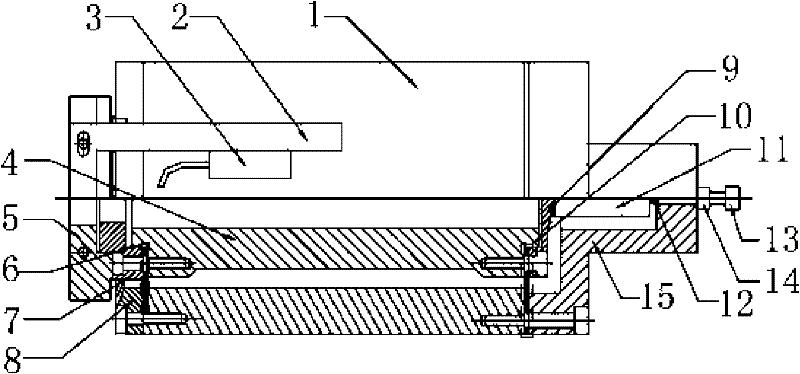

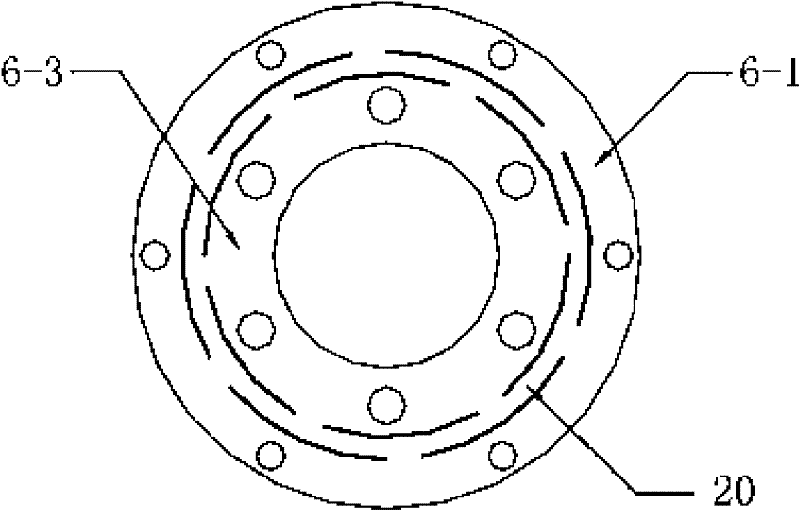

[0013] Specific implementation mode 1. Combination figure 1 , image 3 and Figure 4 Illustrate this specific embodiment, one-dimensional micro-displacement device, it comprises base 1, front end cover 7 and rear end cover 9, and it also comprises workbench 5, front strain gauge 6 and rear strain gauge 10 and connecting shaft 4, described The connecting shaft 4 is located in the working hole of the base 1, and the front strain gauge 6 is composed of a No. 1 outer ring 6-1, a strain ring 20 and a No. 1 inner ring 6-3; the No. 1 inner ring 6-3, the strain ring 20 is coaxial with the No. 1 outer ring 6-1, and the strain ring 20 is flexibly connected between the No. 1 outer ring 6-1 and the No. 1 inner ring 6-3; the rear strain gauge 10 is composed of the No. 2 outer ring 10-1, The strain ring 20 is composed of the rear strain inner ring 10-3, the No. 2 inner ring 10-3, the strain ring 20 and the No. 2 outer ring 10-1 are coaxial, and the strain ring 20 is flexibly connected to ...

specific Embodiment approach 2

[0016] Embodiment 2. The difference between this embodiment and the one-dimensional micro-displacement device described in Embodiment 1 is that it also includes a piezoelectric ceramic sheet 11 and a piezoelectric ceramic sheet holder 15, and the piezoelectric ceramic sheet holder The seat 15 is a table body with a T-shaped groove in the center of the left end. The piezoelectric ceramic sheet 11 is located in the groove of the piezoelectric ceramic sheet holder 15. The left end surface of the piezoelectric ceramic sheet 11 is connected to the rear The end cover 9 is in close contact, and the right end face of the piezoelectric ceramic sheet 11 is in close contact with the groove bottom of the piezoelectric ceramic sheet holder 15; the left end surface of the piezoelectric ceramic sheet holder 15 is fixed on the on base 1.

[0017] In this embodiment, by applying a certain amount of voltage to the piezoelectric ceramic 11, the piezoelectric ceramic is stretched, and the rear en...

specific Embodiment approach 3

[0018] Embodiment 3. The difference between this embodiment and the one-dimensional micro-displacement device described in Embodiment 2 is that it also includes a steel ball 12, which is located on the right end surface of the piezoelectric ceramic sheet 11 and the piezoelectric ceramic Between the groove bottoms of the card holder 15.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com