Grinding device for high-precision ultrathin wafer

A high-precision, ultra-thin technology, used in grinding machine parts, grinding/polishing equipment, shafts and bearings, etc., can solve problems such as unfavorable high-precision and ultra-thin processing of semiconductor wafers, and achieve small gaps and precision. High and low friction loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

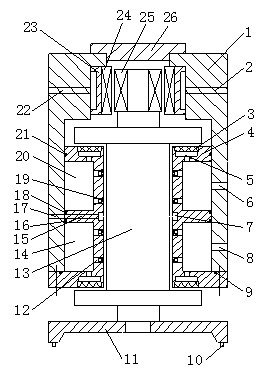

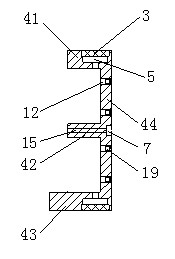

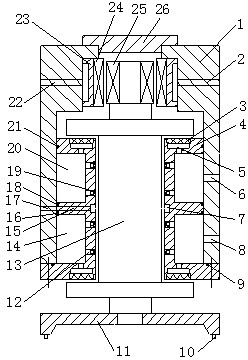

[0010] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0011] like figure 1 and figure 2 As shown, a grinding device for high-precision and ultra-thin wafers of the present invention includes a bearing, a housing 1, a grinding wheel 10, a grinding wheel disc 11, a main shaft 13, a cooling water jacket 23, a motor stator 24 and a motor rotor 25 . Bearing, shell 1, emery wheel disc 11, main shaft 13, cooling water jacket 23, motor stator 24 and motor rotor 25 are coaxial. The shell 1 is a cylindrical body with coaxial through holes at the top and bottom. The housing 1 is provided with a cooling water inlet 22 and a cooling water outlet 2 . A cooling water jacket 23 is embedded in the upper inner wall of the casing 1 , and the cooling water inlet 22 and the cooling water outlet 2 communicate with the cooling water jacket 23 respectively. The cooling water jacket 23 is sleeved on the circumfer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com