Novel pre-stressed steel plate hoop device and installation method thereof

An installation method and prestressing technology, which can be used in the erection/assembly of bridges, construction, and the processing of building materials, etc., can solve the problems of local anchorage difficulty on the side of concrete columns, poor confinement effect of concrete columns, high reinforcement costs, etc., and achieve simple structure , Improve the shear bearing capacity and save material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

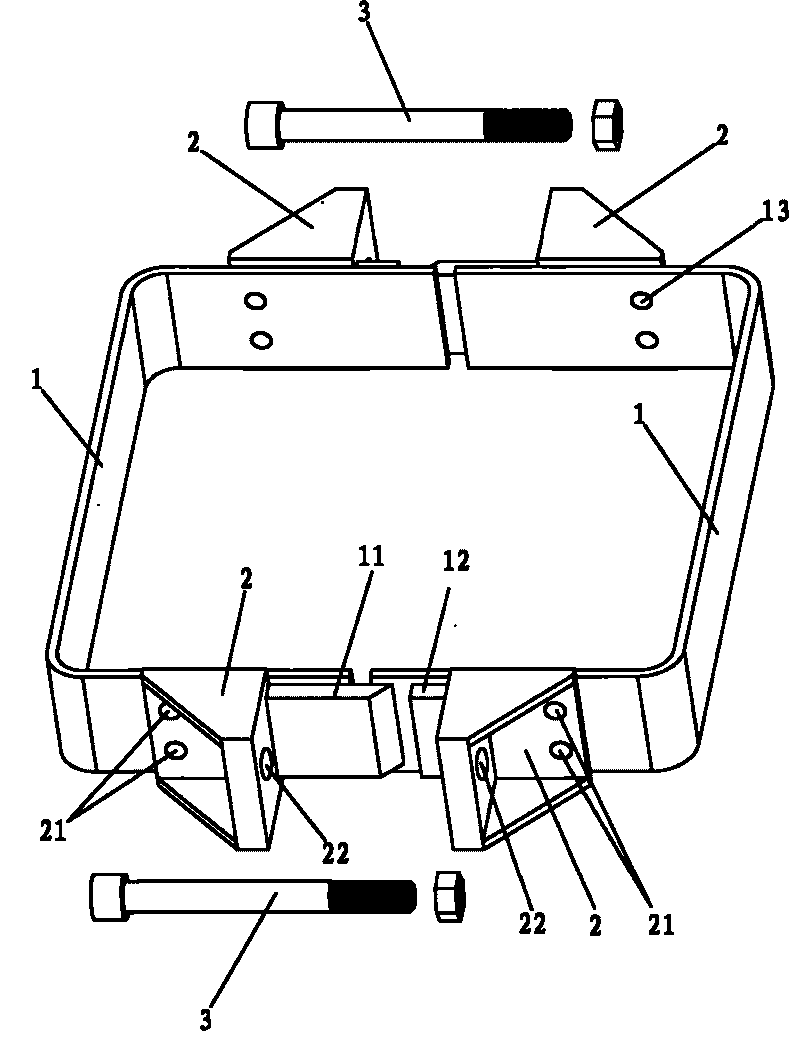

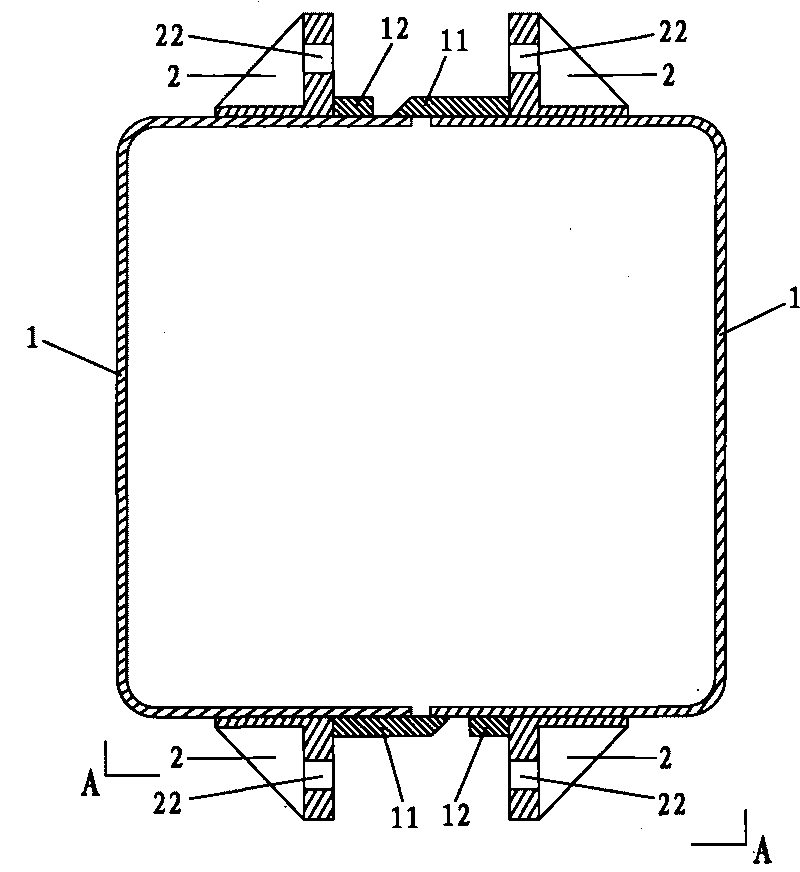

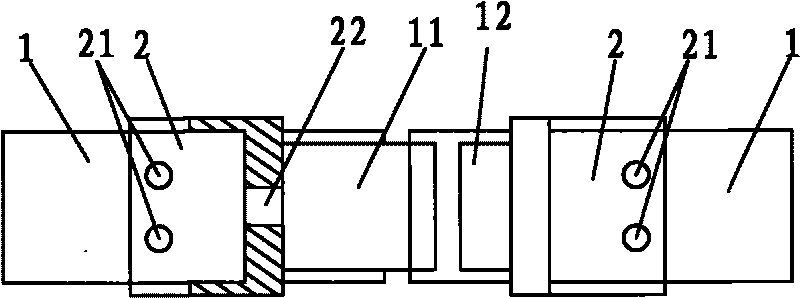

[0022] Novel prestressed steel plate hoop device of the present invention, as Figure 1-3 As shown, it includes two U-shaped steel hoops 1 that can be buckled correspondingly. After the two U-shaped steel hoops 1 are buckled together, they can form a closed-loop hoop that is suitable for the cross-section of the object to be reinforced. The corners of the U-shaped steel hoop 1 are rounded to optimize the force transmission during the tensioning process and avoid stress concentration in the corner force transmission process. The two ends of each U-shaped steel hoop 1 are welded with joints plate 11 and baffle 12.

[0023] It is also equipped with a force plate 2 and a tension screw 3 for applying prestress to the U-shaped steel hoop plate 1. There are four force plates 2, and the corresponding parts of each force plate 2 and U-shaped steel hoop plate 1 Bolt holes 21, 13 are respectively opened, and the four reinforcing plates 2 are respectively fixed on the two arms of the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com