High-precision rotary table of gapless connecting rod mechanism and capable of moving slightly

A link-type, gap-free technology, used in worktables, manufacturing tools, etc., can solve the problems of low precision, slow motion response, and high cost of turntables, achieve rigidity, good motion stability, good acceleration and deceleration performance, and eliminate bearings. gap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

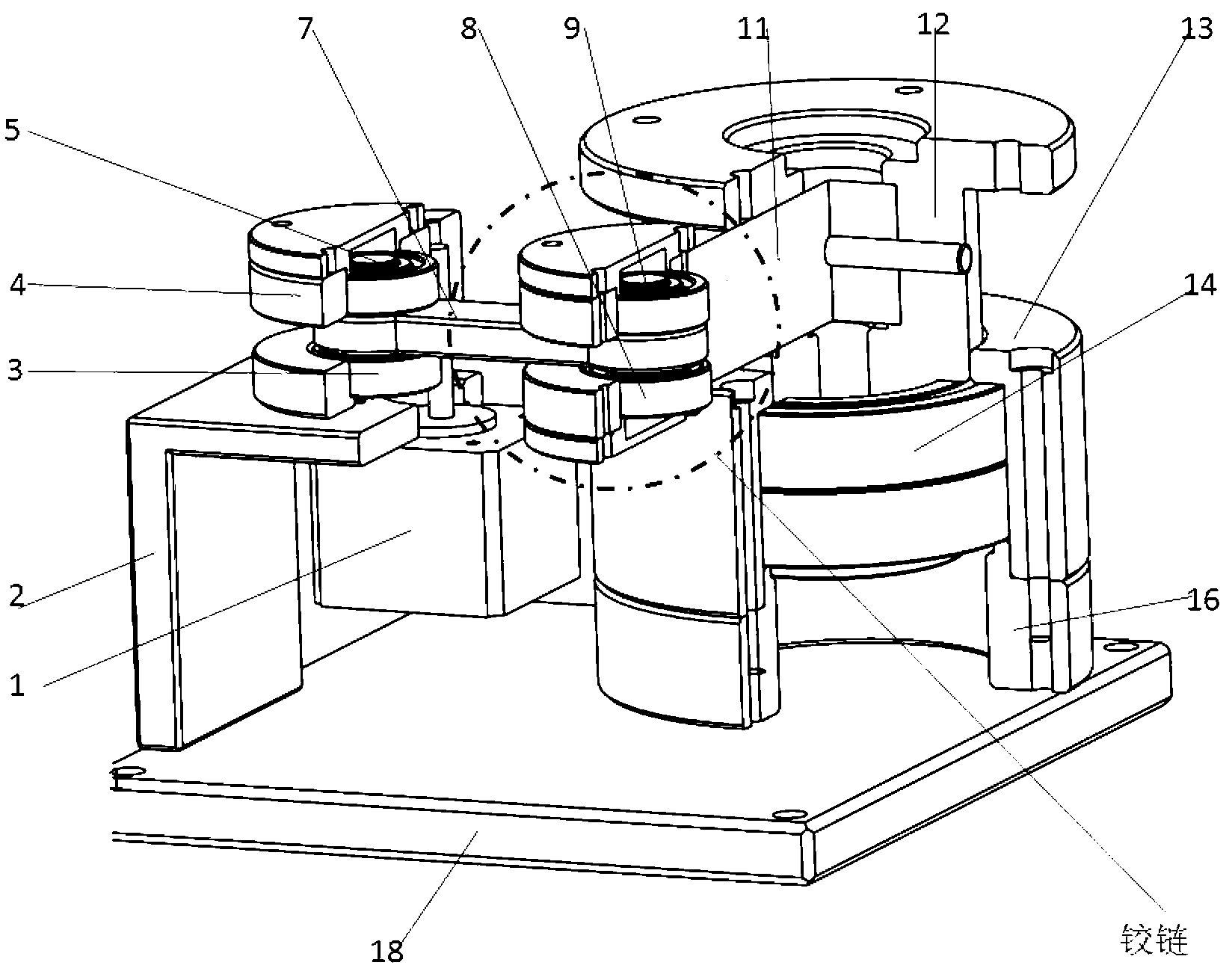

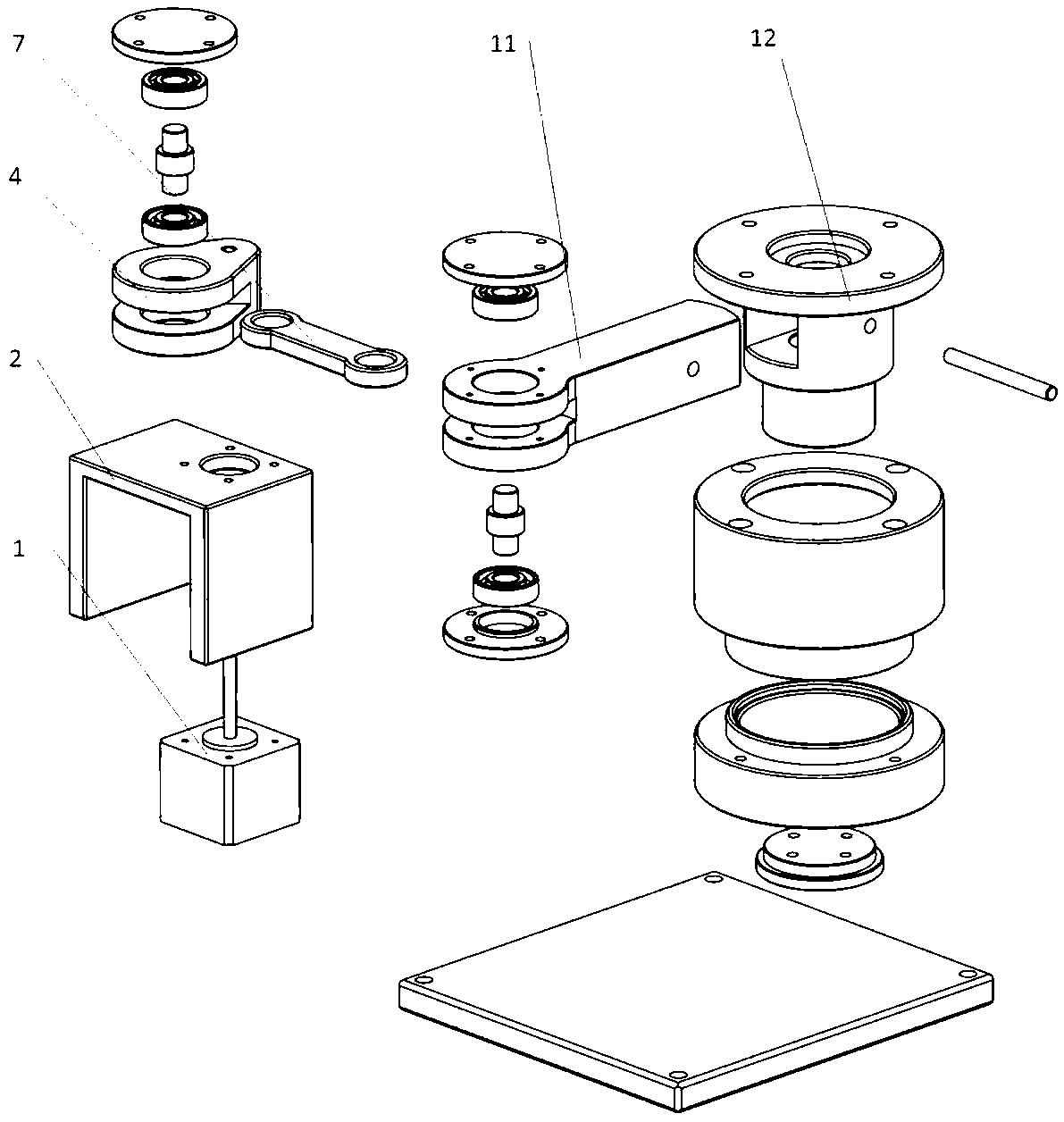

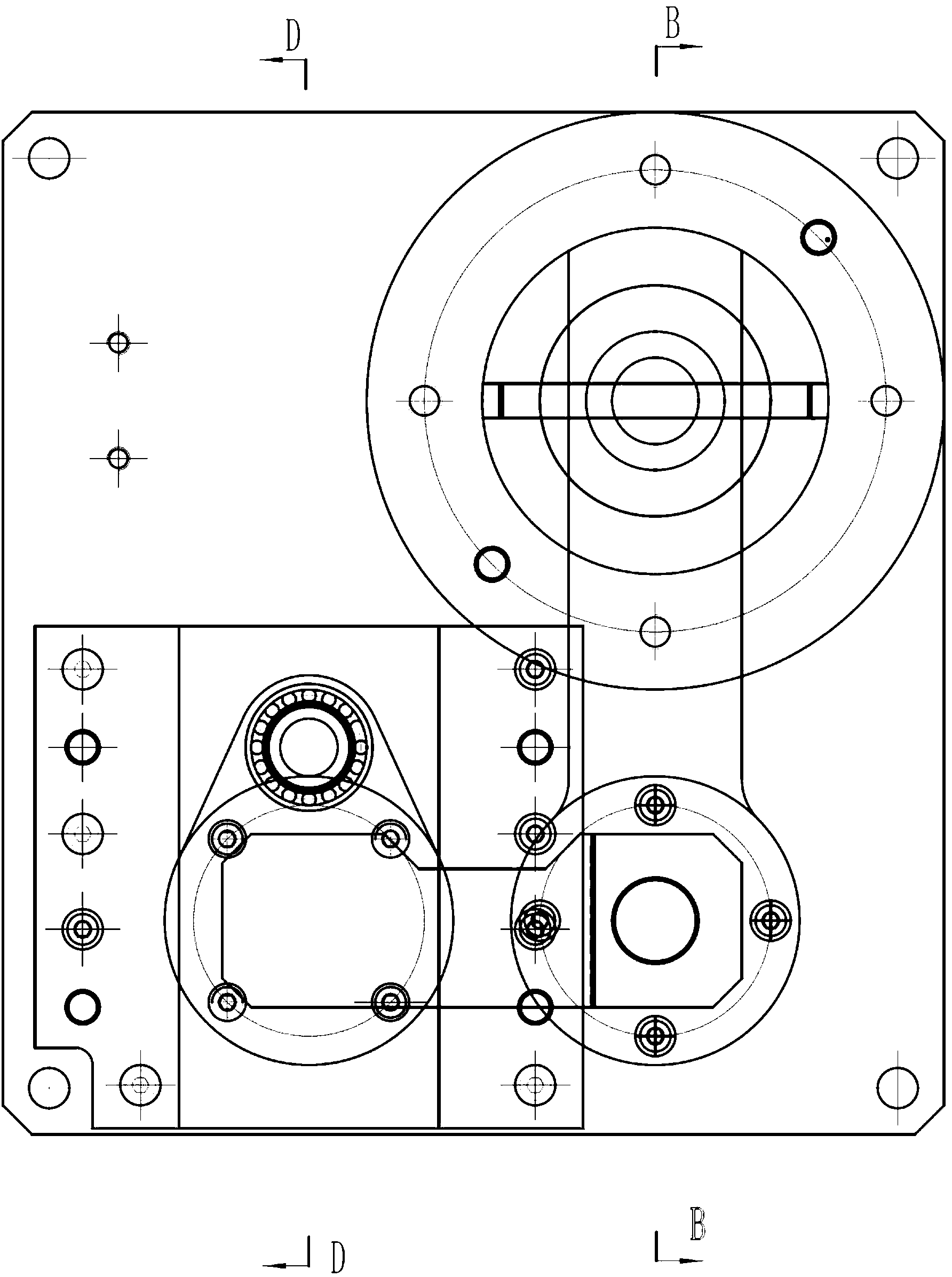

[0023] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0024] as attached figure 1 , figure 2 , image 3 As shown, the present invention provides a high-precision micro-movement turntable with a gapless linkage mechanism, which includes a drive motor 1, a motor support seat 2, a turntable main body 12, a turntable base 16, a bottom plate 18 and a link mechanism , wherein the connecting rod mechanism includes bearing a3, crank 4, connecting shaft a5, connecting rod 7, bearing b8, connecting shaft b9, swing rod 11 and bearing c14, the bearing a3 and bearing b8 adopt precision angular contact ball bearings, and the bearing c14 adopts double row angular contact ball bearings.

[0025] Installation relationship:

[0026] The turntable main body 12 is connected with the motor 1 through a link mechanism. The motor support base 2, the turntable base 16 and the base plate 18 are connected by positioning pins to e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com