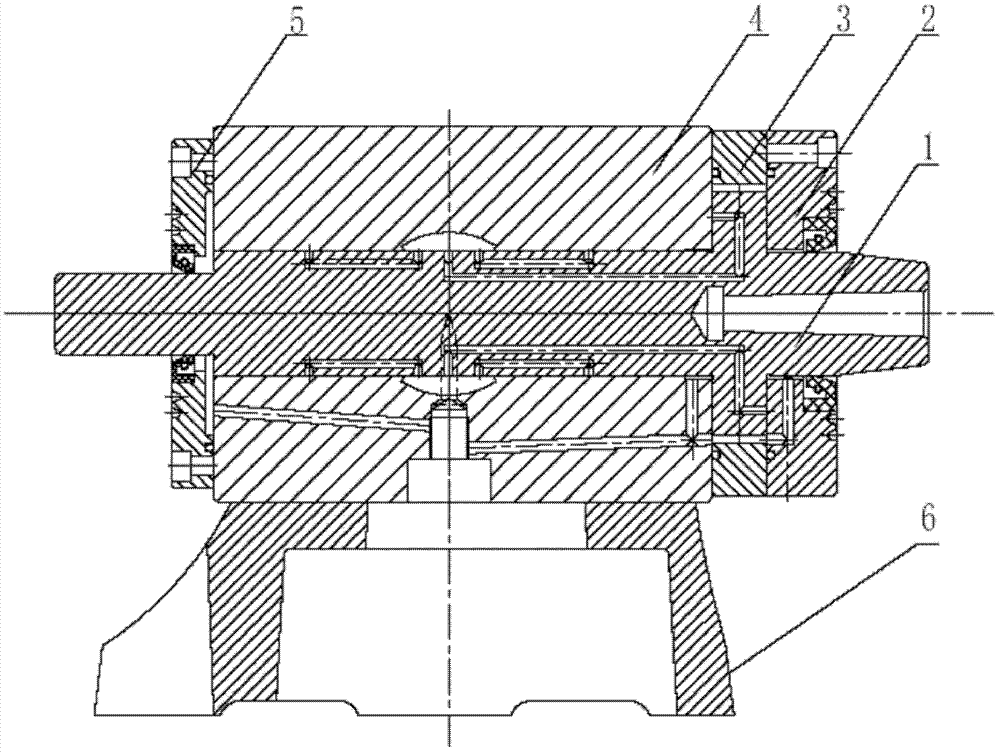

Oil static pressure main shaft main shaft for shaft oil supply

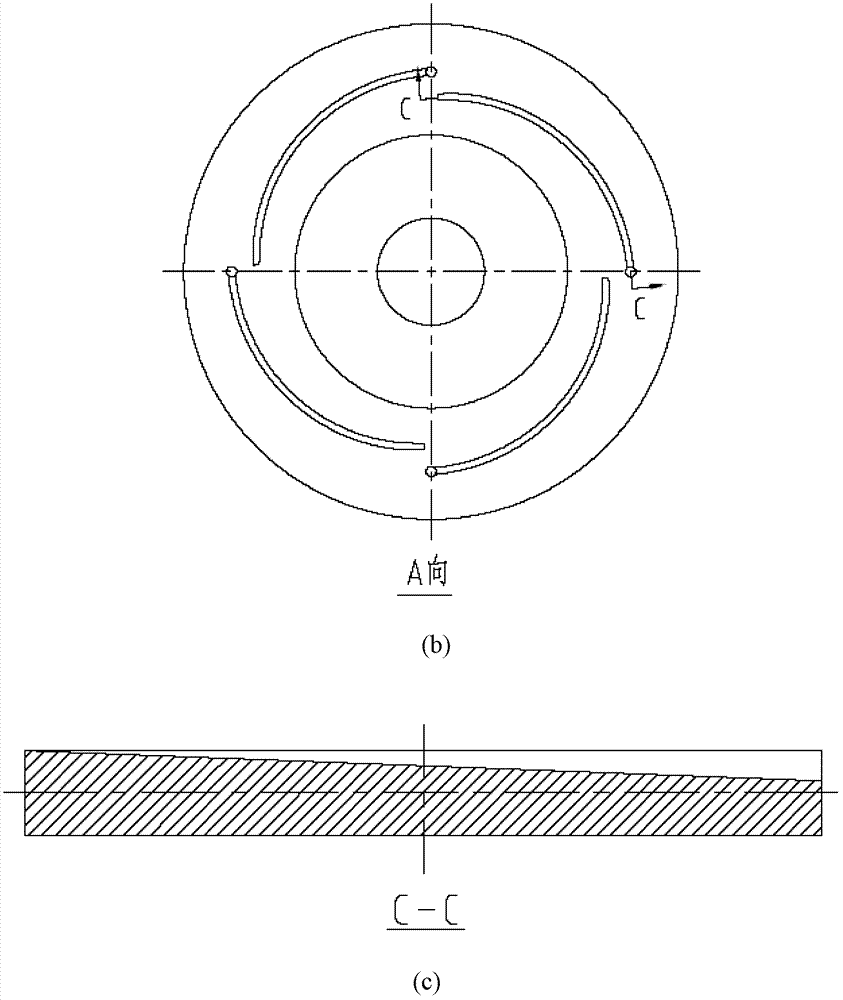

A hydrostatic spindle and oil supply technology, which is applied to shafts and bearings, rigid brackets of bearing components, bearings, etc., can solve the problems of choke blockage in machining process and complicated assembly process, and achieve large bearing capacity and reduce complexity. degree, the effect of increasing the amount of oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

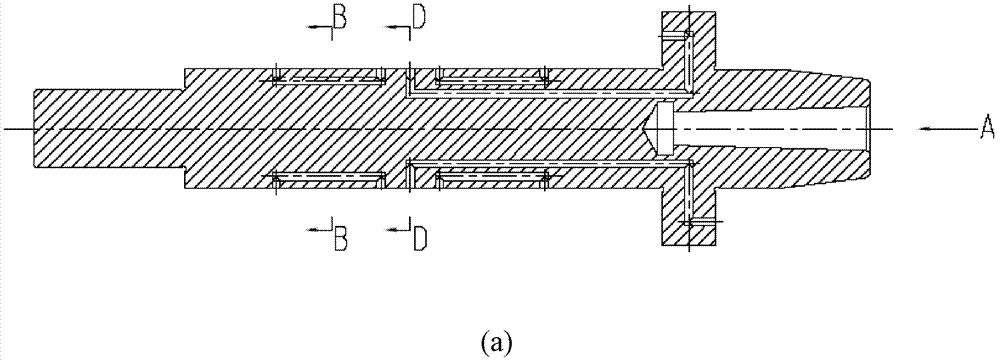

[0021] Example: The shaft oil supply hydrostatic spindle is applied to the bearing testing instrument to test the bearing. The specific implementation steps are as follows:

[0022] step 1.

[0023] Clean the white steel oil tank of the hydraulic station, and inject filtered 20# clean hydraulic oil. The main components of the hydraulic station: oil pump, filter, accumulator, heater, radiator, liquid level thermometer, connect the oil inlet pipe and oil return pipe, open the hydraulic station to suspend the main shaft in a static state.

[0024] Step 2.

[0025] Install the shaft oil hydrostatic spindle on the test platform, and install the pulley or coupling, and connect to the motor. Install sensors related to bearing detection and axial and radial force devices, and insert the mandrel into the series of Morse taper holes of the main shaft or on the outer Morse taper.

[0026] Step 3.

[0027] When the hydraulic station is turned on, turn on the motor to drive the main sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com