Patents

Literature

30results about How to "Increase oil intake" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for smearing wood wax oil on surface of wood product

InactiveCN103182725AIncrease exerciseIncrease oil intakeCoating impregnationCoatingsWaxEnvironmentally friendly

The invention relates to a method for smearing wood wax oil on the surface of a wood product, which comprises the following steps: 1, smoothening; 2, smearing the wood wax oil; 3, kneading a wax oil coating on the surface; 4, wiping floating oil; 5, drying; 6, repeating the steps 2-5 for one or two times; 7, polishing till the hand feeling is smooth; and 8, spraying polishing wax, polishing and entering a next assembly process. By using the method, the crack of the wood product can be effectively prevented, and the service life is prolonged; the operation is simple, and materials, labors and oil are saved; the wood wax oil is a green and environmentally-friendly coating and a low-carbon environmentally-friendly product; and by using the method, the wide application of the wood wax oil can be promoted, and an important significance on environment friendliness is realized.

Owner:张克广

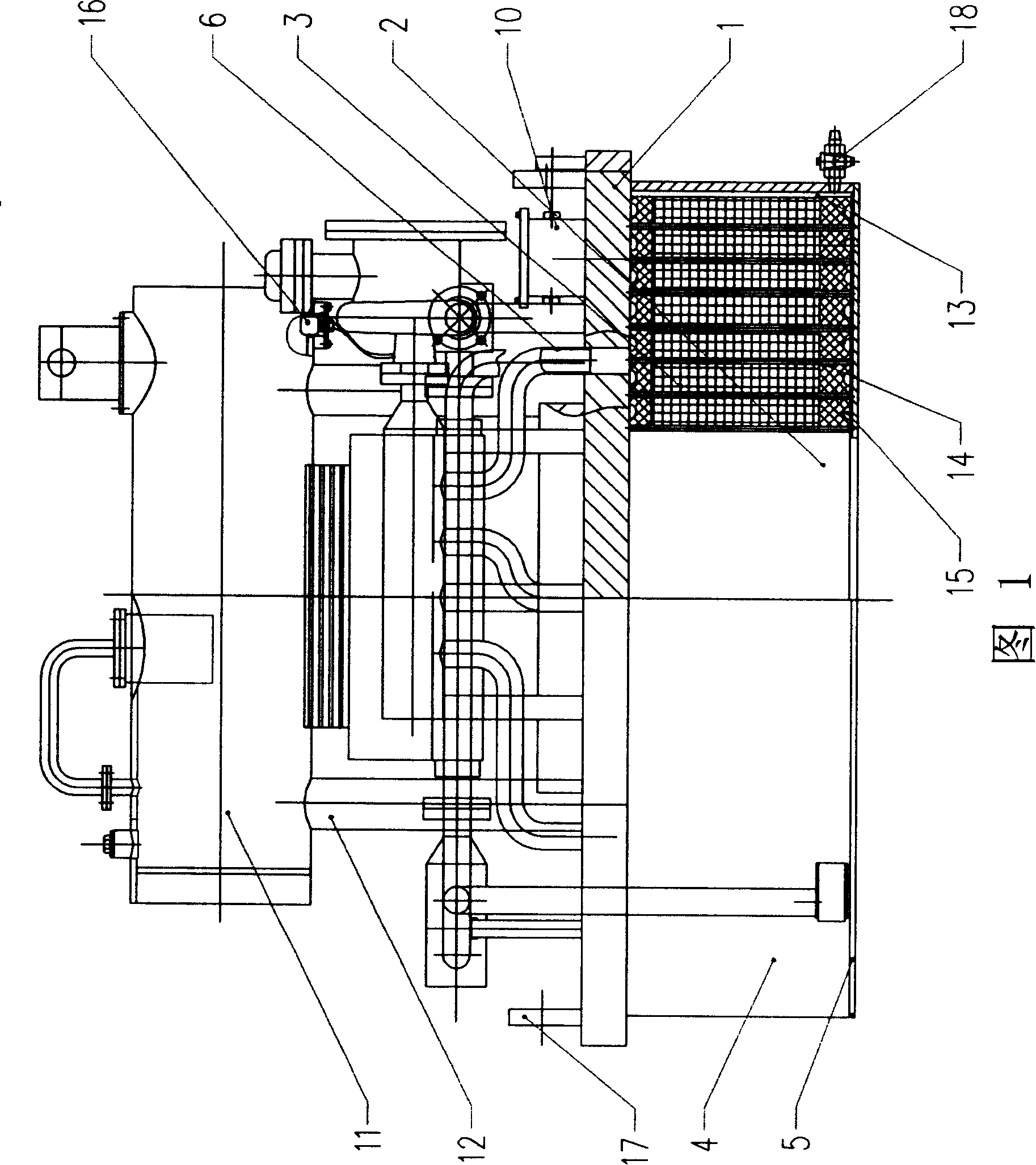

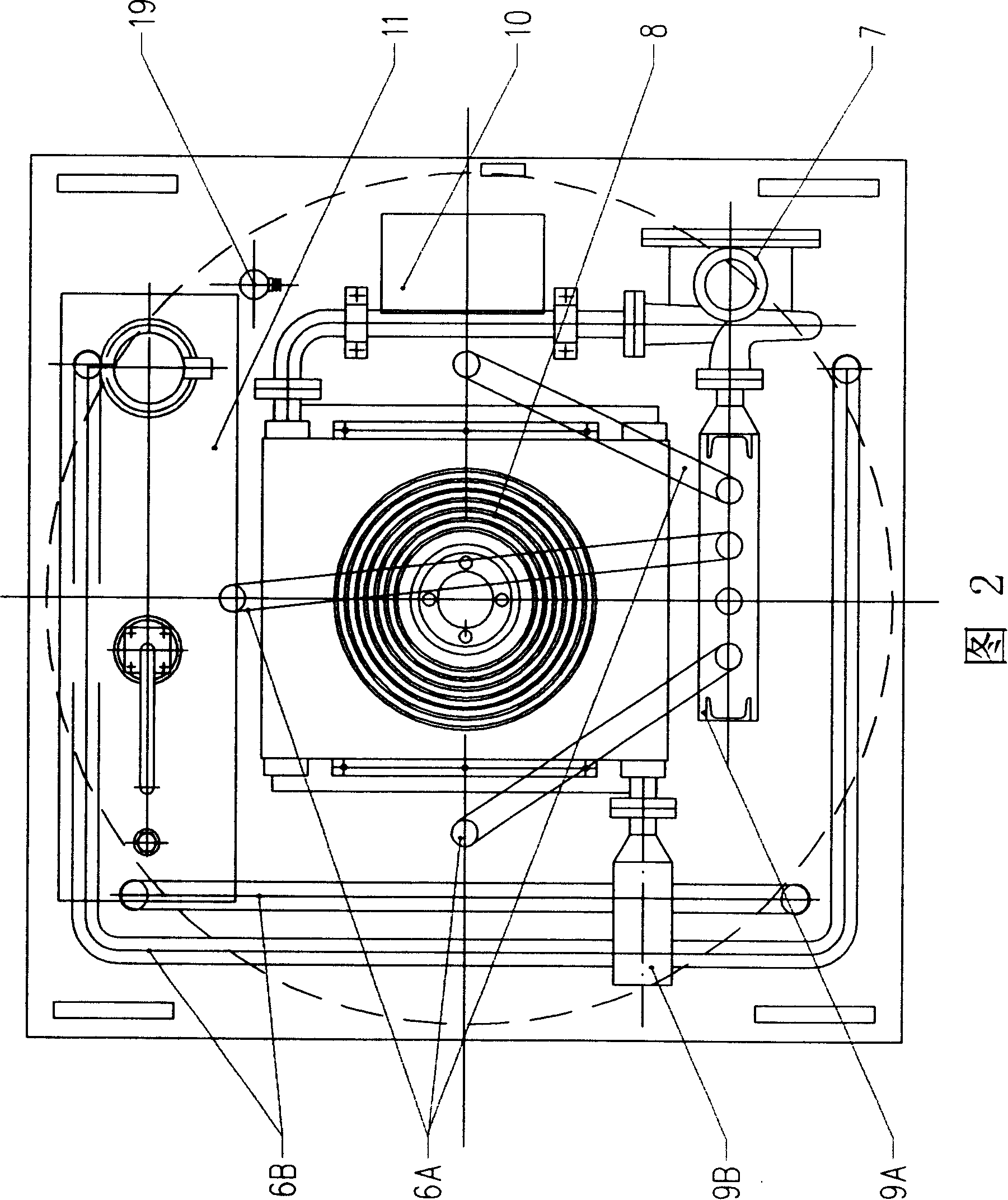

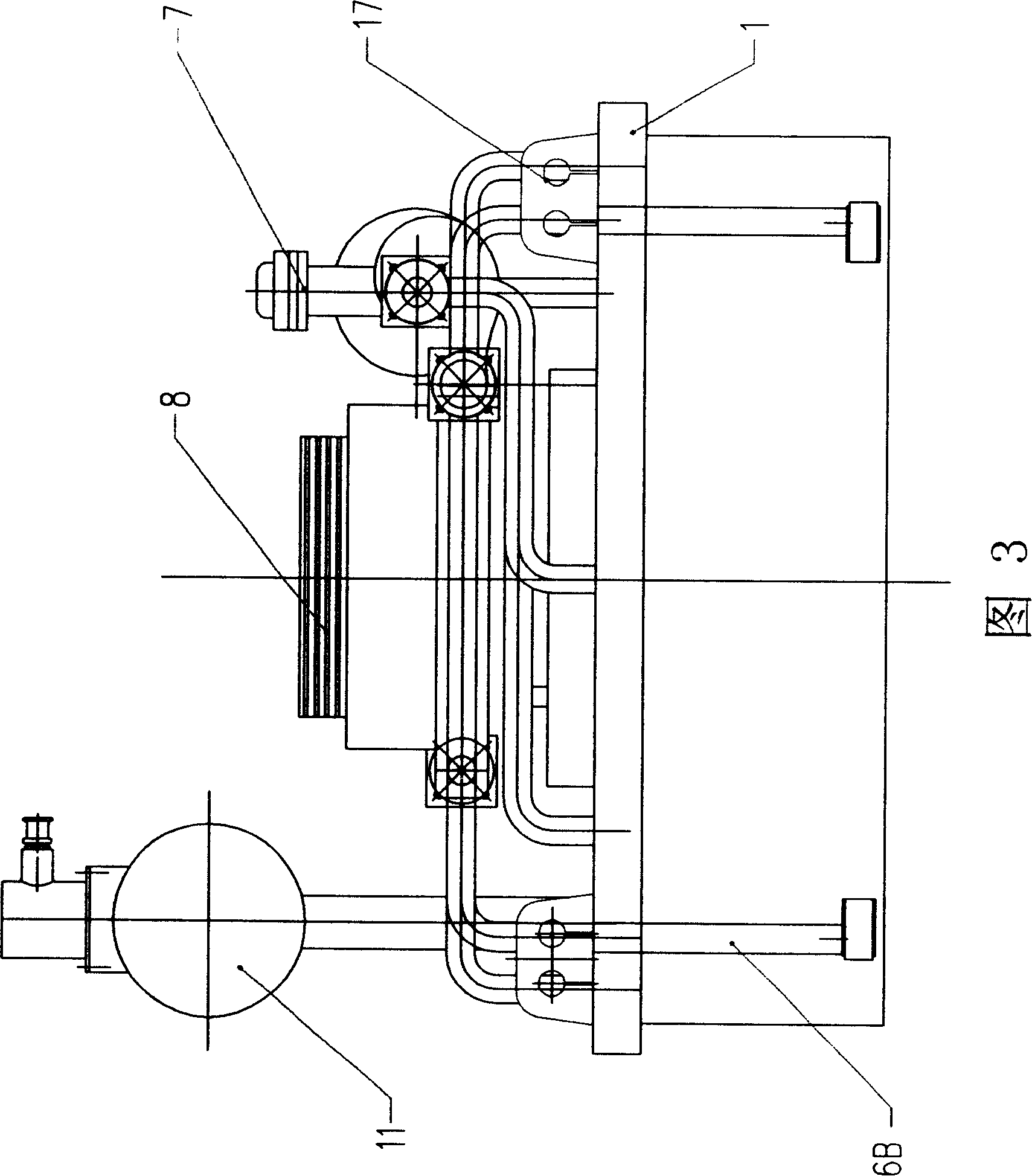

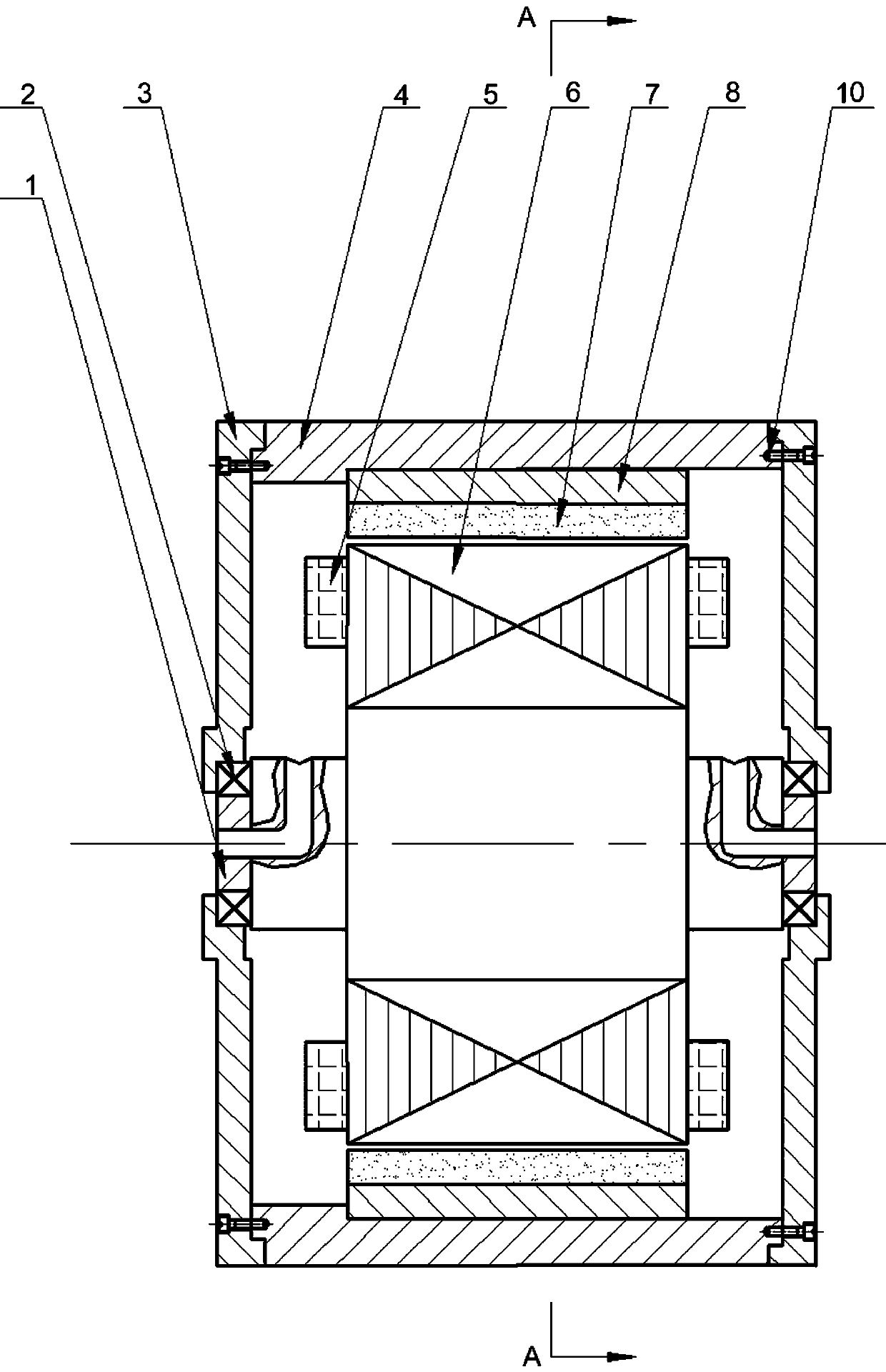

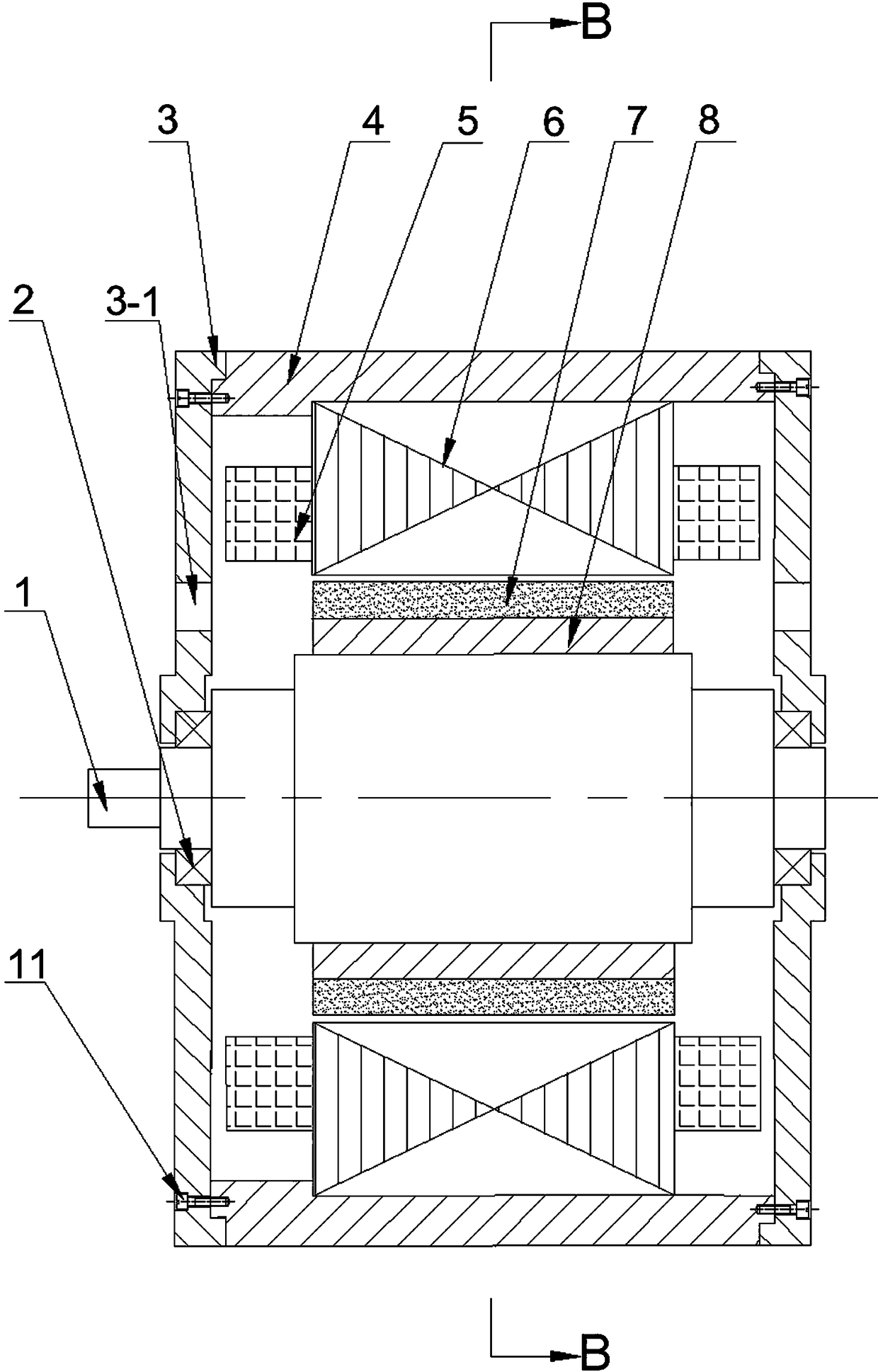

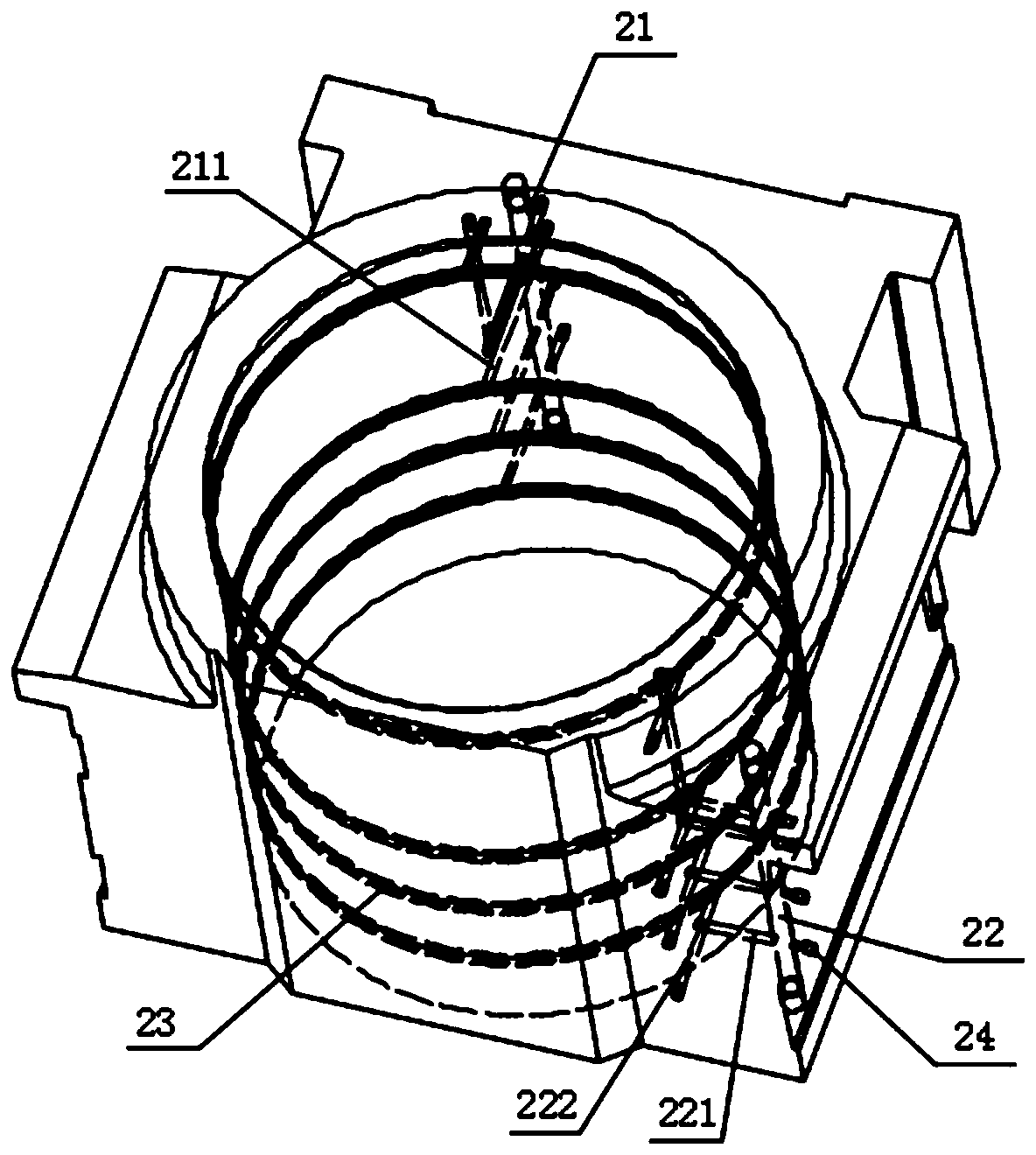

Circulating oil-cooling type electric-magnetic iron remover

ActiveCN101234364AIncrease oil intakeIncrease oil outletMagnetic separationSuperconducting magnets/coilsShunt DeviceWorking life

The invention relates to a circular oil cooling electric magnetic iron remover consisting of a header tank, cooling system and a oil cooling magnetic system; wherein, the cooling system consists of a power pump, a radiator and an internal and external cyclic hydraulic circuit; an internal oil circuit is a cooling medium channel in the oil cooling magnetic system; an outer cyclic oil circuit affluxes into a current divider by an oil pipe which is communicated with an inner cavity of the oil cooling magnetic system, then into the radiator with an outlet being connected with another current divider which is connected with the oil pipe which is communicated with an inner cavity of oil cooling magnetic system; the power pump is arranged in a pipe between the radiator and the current divider. By adopting the cooling system with internal and external circulation, the circular oil cooling electric magnetic iron remover allows the whole machine to raise temperature evenly and obviously low, thereby reducing the local excessive heating phenomenon, raising magnetic potential utilization ratio, further raising magnetic attraction force, raising the working life of the circular oil cooling electric magnetic iron remover and ensuring safe and reliable operation of the invention. The circular oil cooling electric magnetic iron remover is in particular suitable for the bad working conditions with moistness, large amount of bug dusts and salt spray corrosion.

Owner:LONGI MAGNET CO LTD

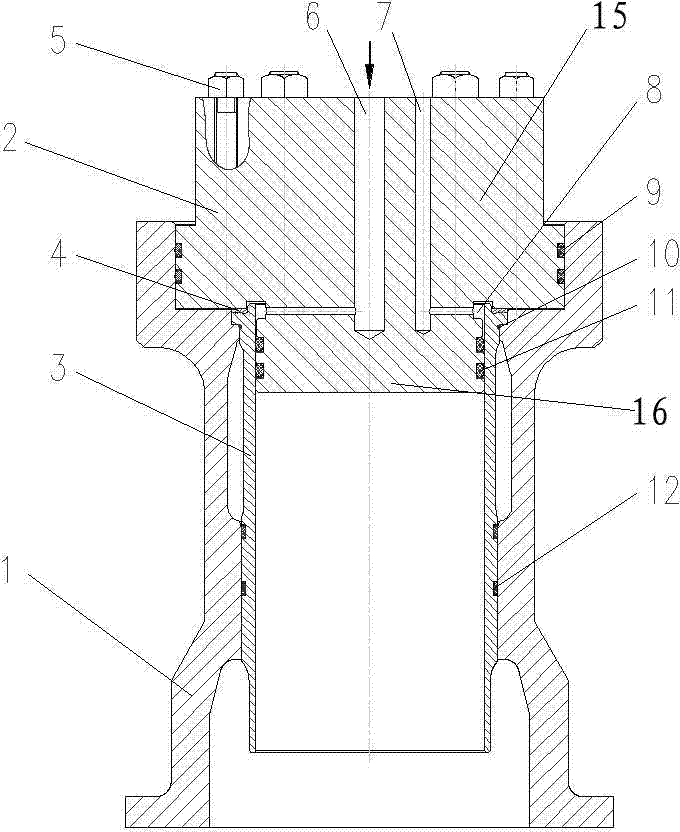

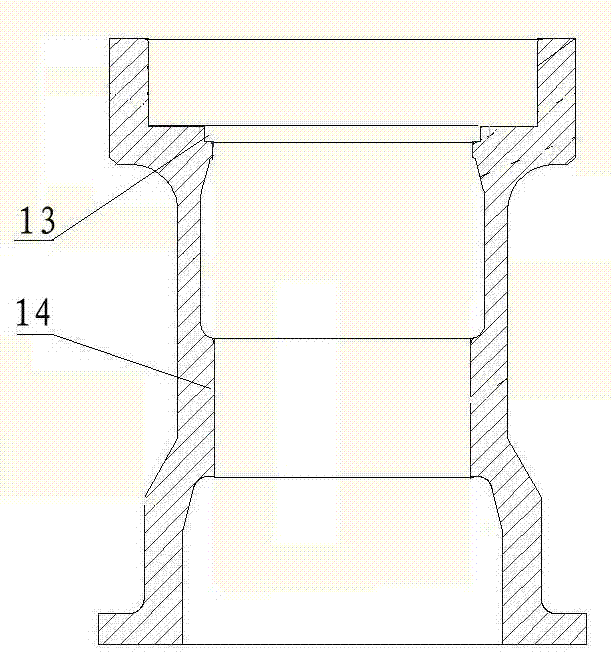

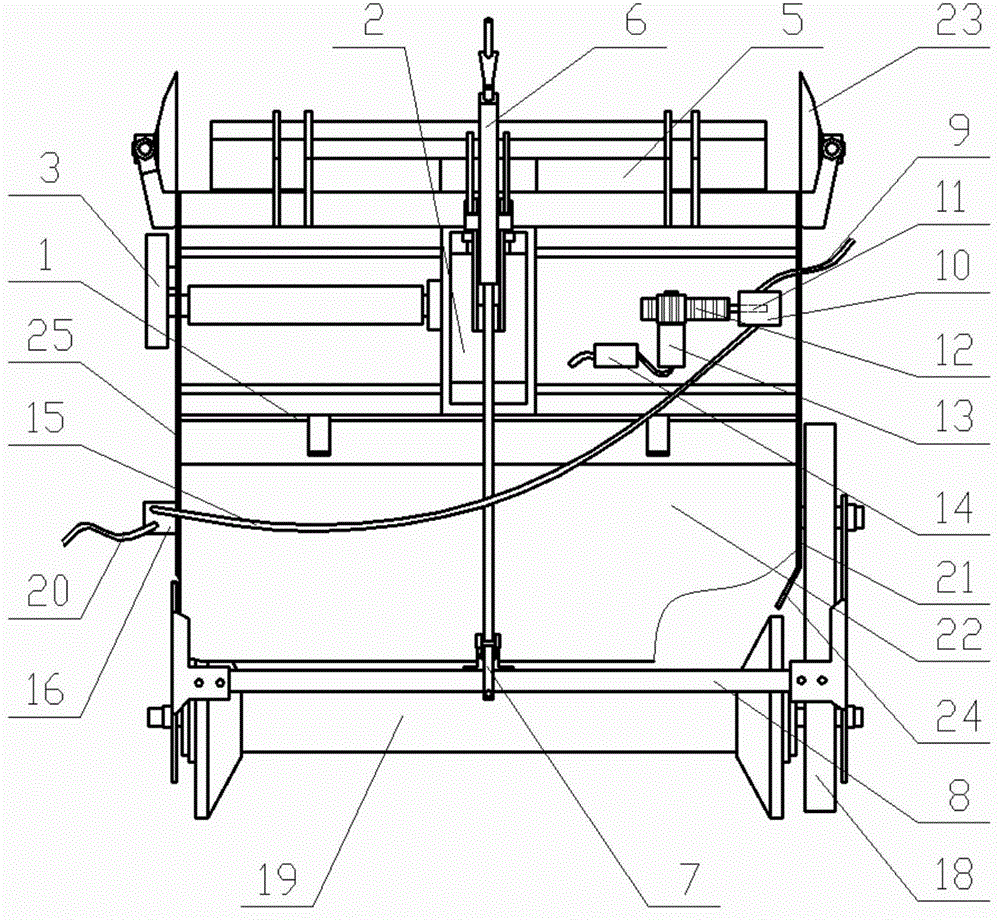

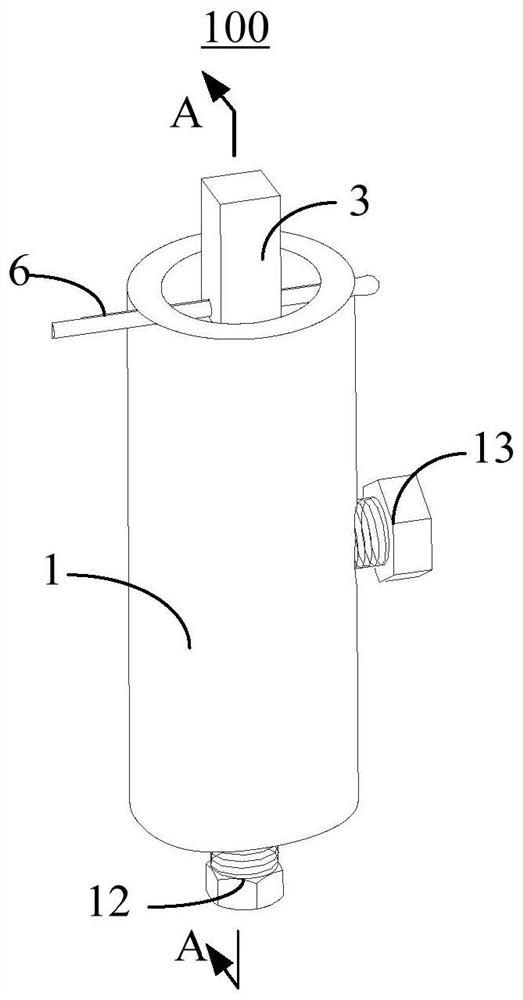

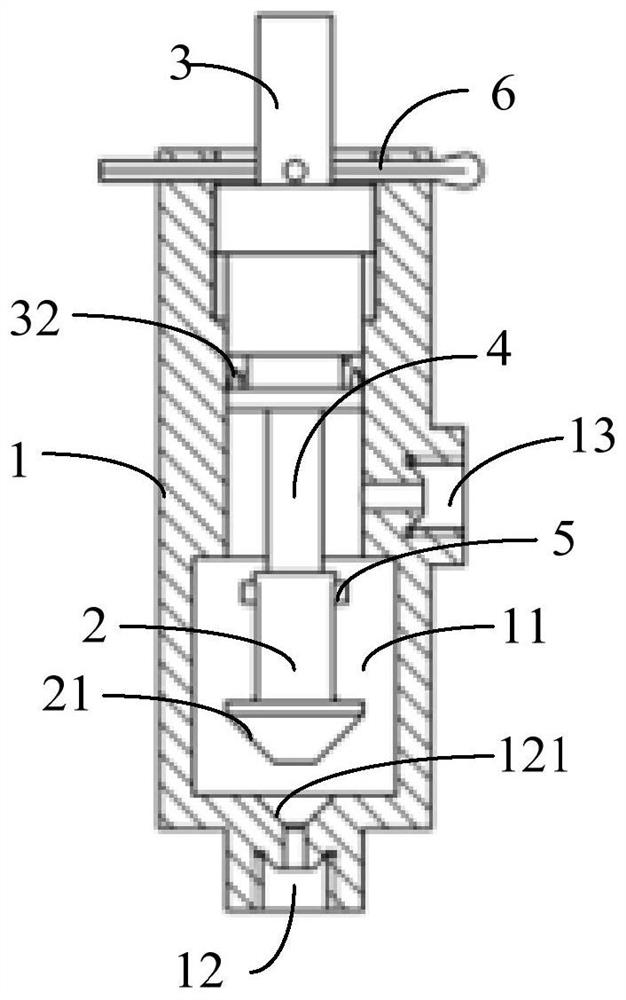

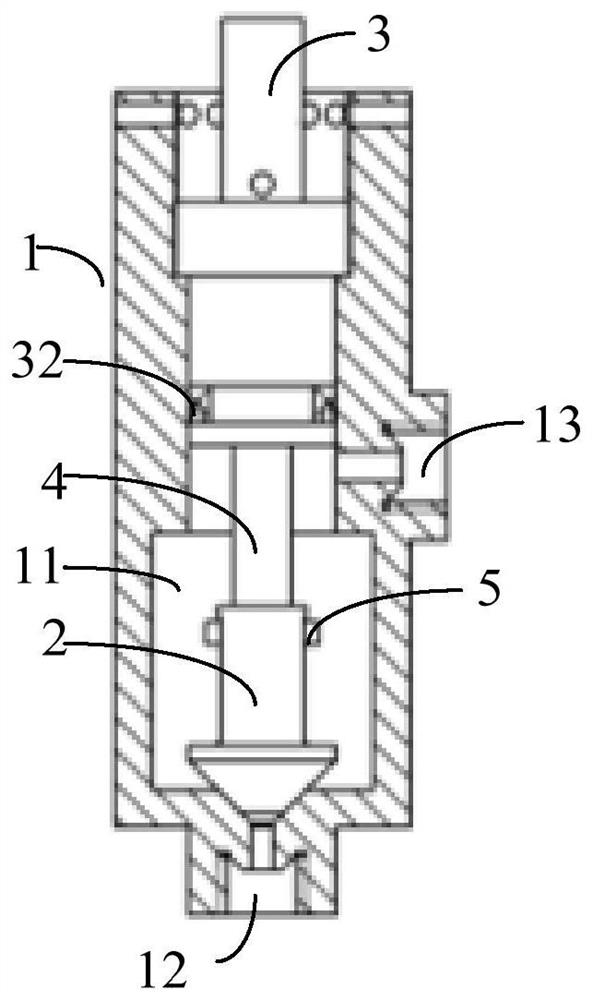

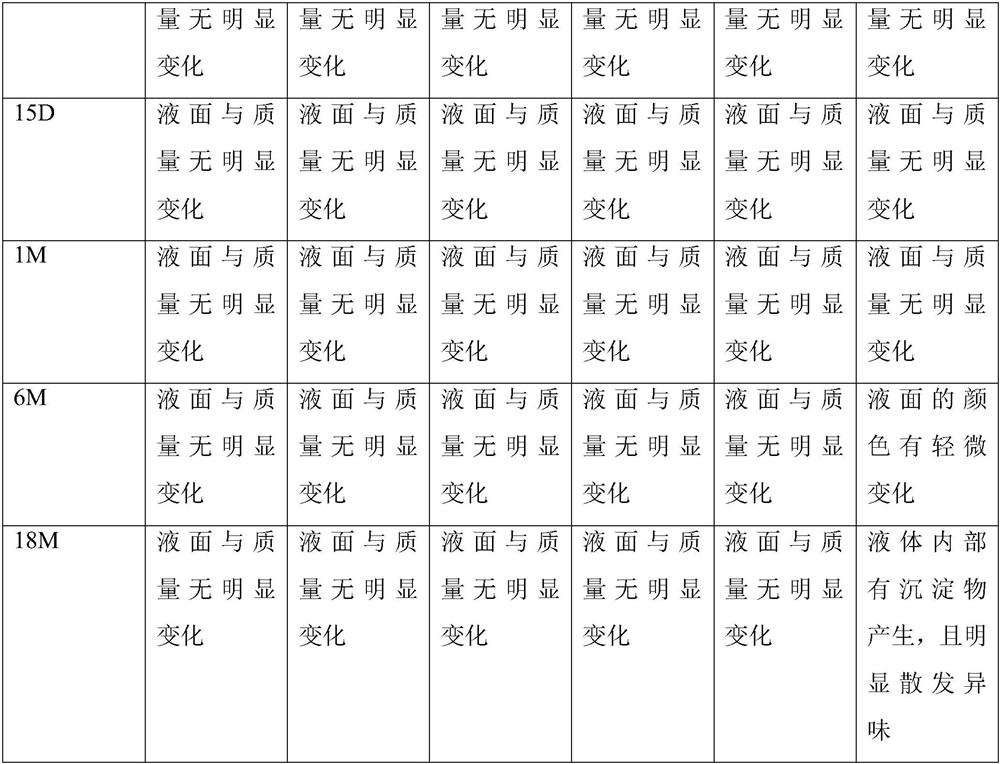

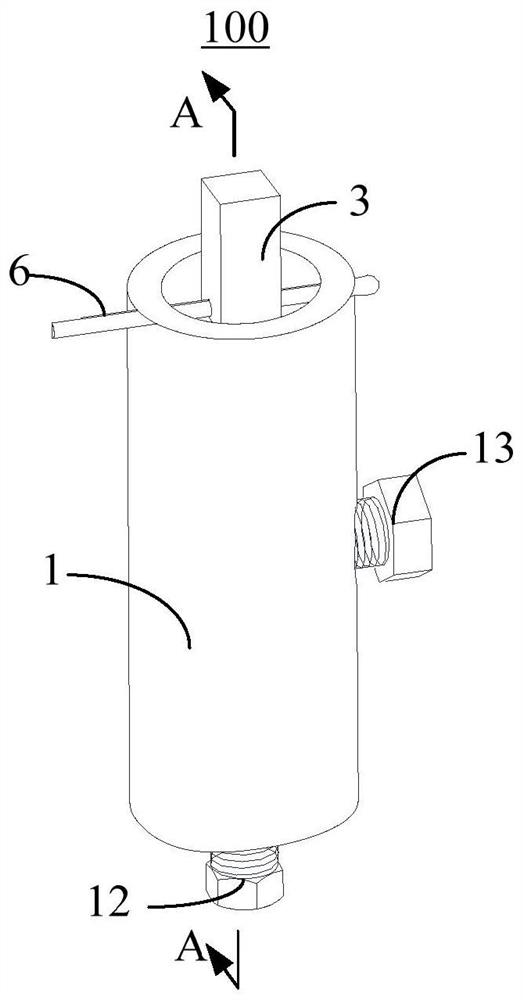

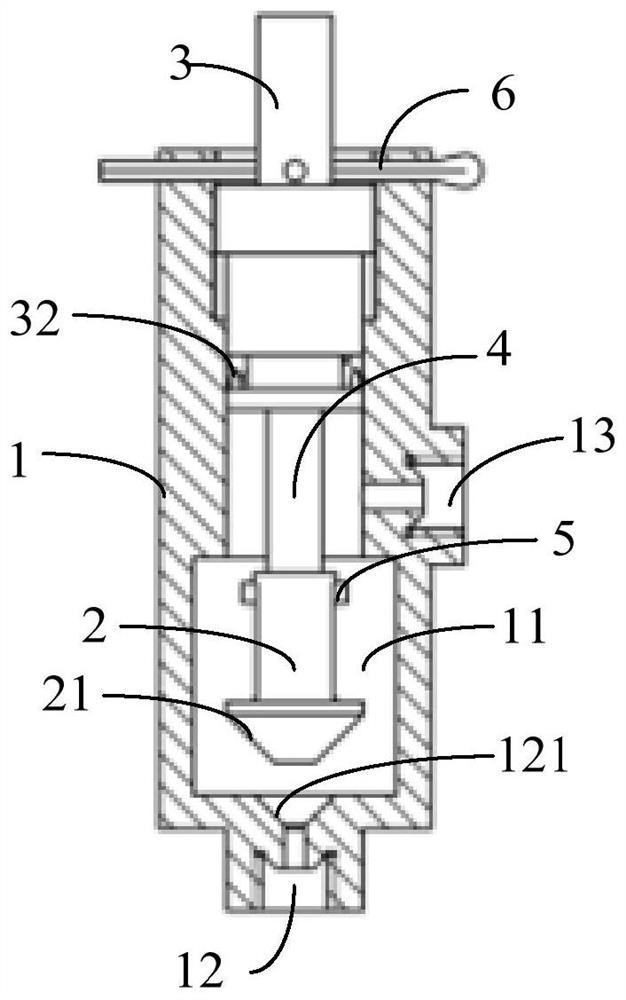

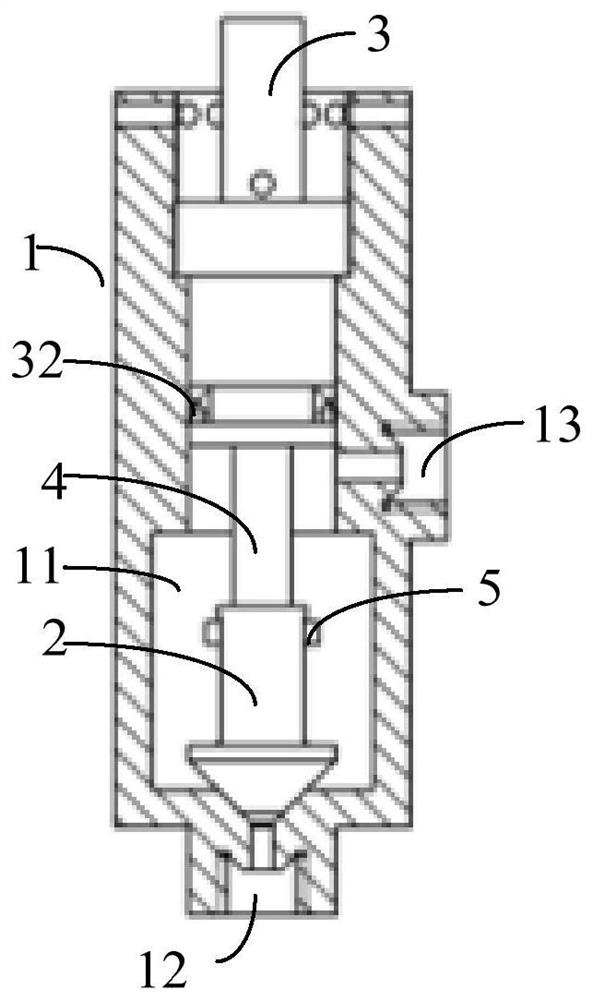

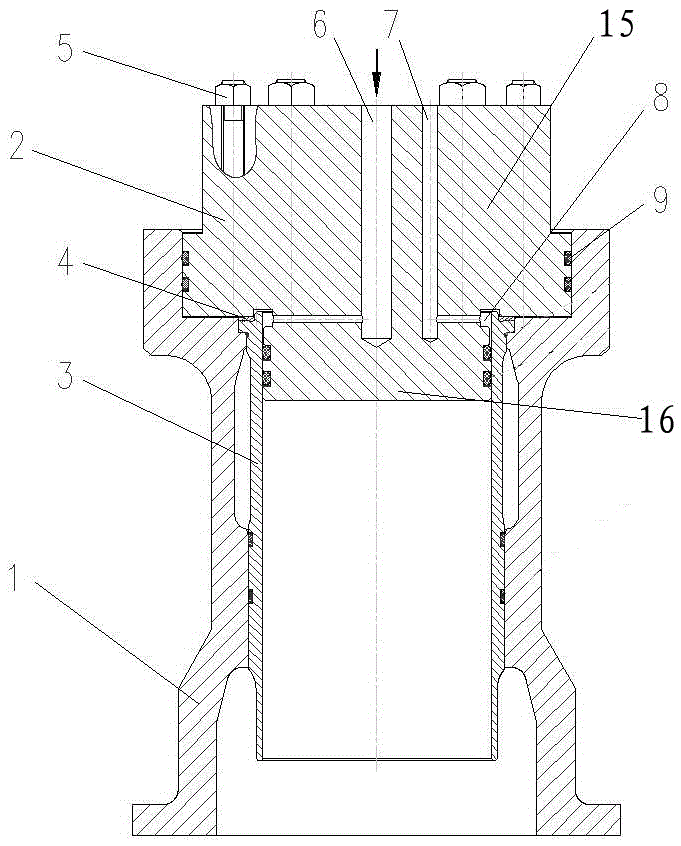

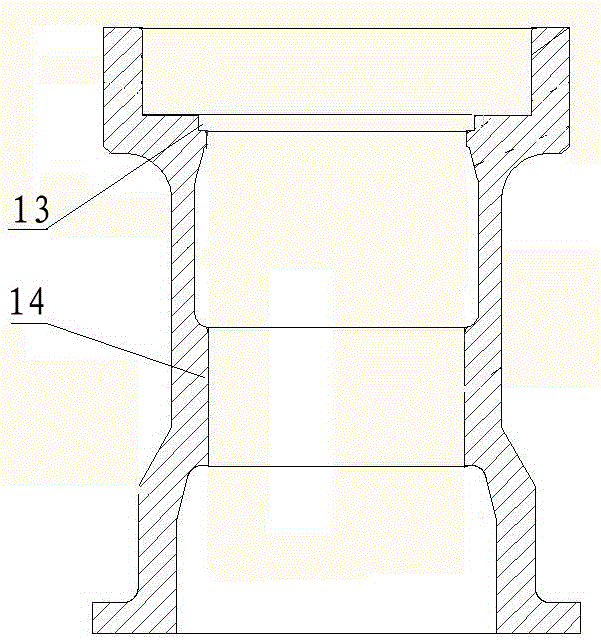

Cylinder sleeve fatigue test device

ActiveCN103759926ASimplify test componentsEliminate hidden dangers in the cylinderMachine part testingEngine testingCombustion chamberEngineering

The invention relates to a cylinder sleeve fatigue test device. An annular sunk groove (13) and an annular sealing protrusion (14) used for supporting a cylinder sleeve (3) are arranged on a bearing cylinder body (1), a counter bore matched with a combined cylinder cover (2) is formed in an upper opening of the cylinder body, an oil inlet port and a sensor port are formed in an oil inlet (6) and an upper port of a pressure monitoring hole (7) in the cylinder body respectively, the cylinder sleeve (3) is arranged in the bearing cylinder body (1), the combined cylinder cover (2) is arranged in the counter bore of the combined cylinder cover (2) and the cylinder sleeve (3) in a sealing sleeved mode, a cylinder cushion (4) is arranged at the position where the combined cylinder cover (2) is connected with the cylinder sleeve (3), and an upper edge opening of the cylinder sleeve (3) and a simulation combustor cavity form a simulation combustor (8). According to the cylinder sleeve fatigue test device, sealing hidden troubles in the cylinder body are eliminated, stability of the test process is improved, the adjusting range of the pressure in the cylinder body is enlarged, and a cylinder sleeve fatigue examination and a fault reappearance test are facilitated.

Owner:CHINA NORTH ENGINE INST TIANJIN

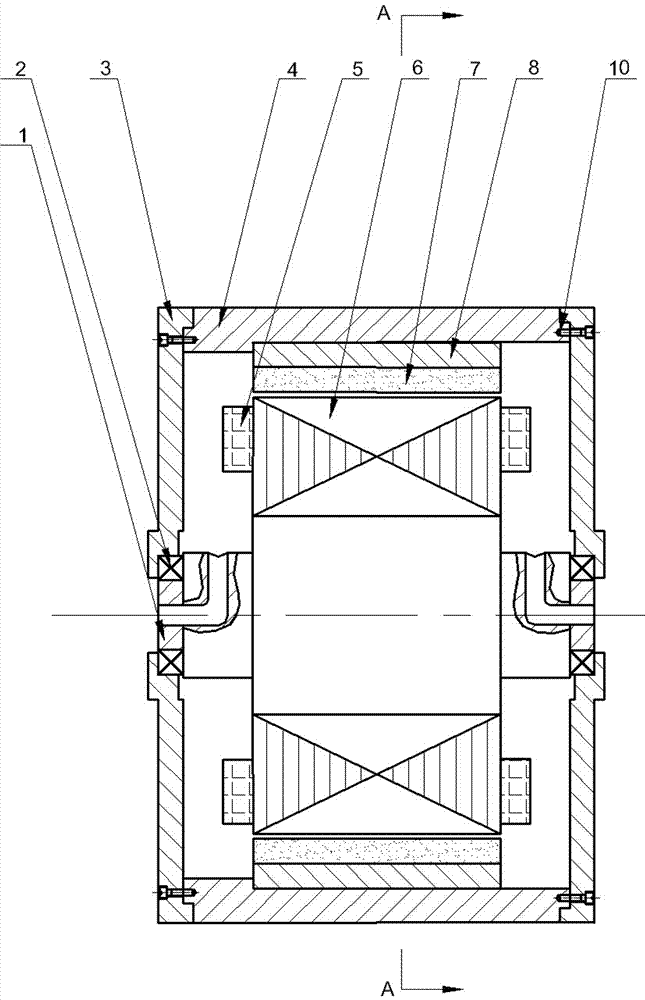

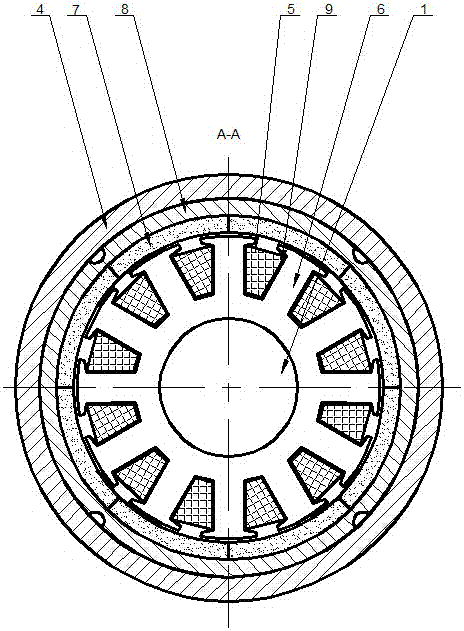

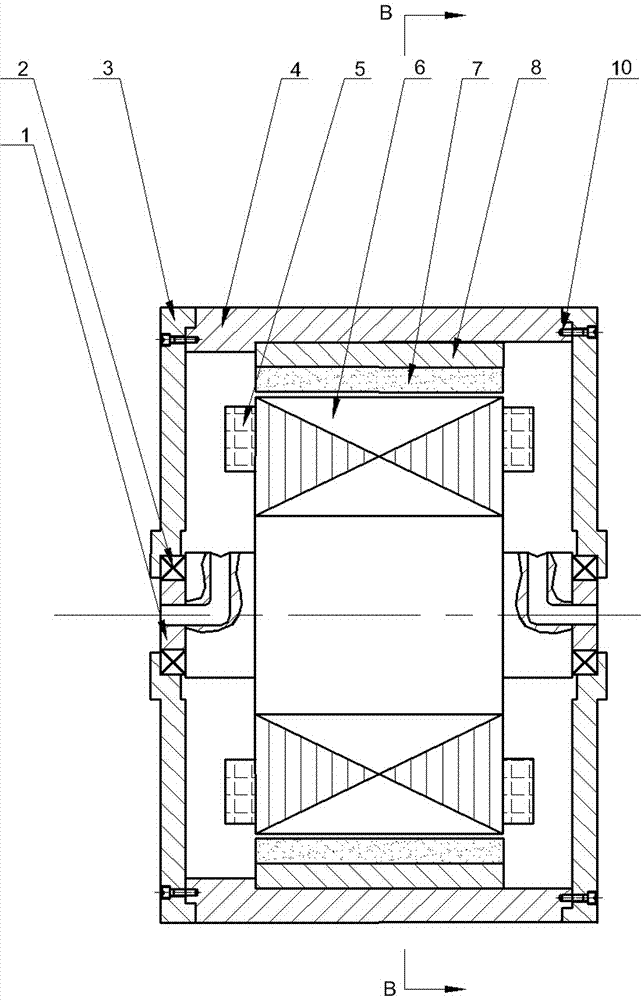

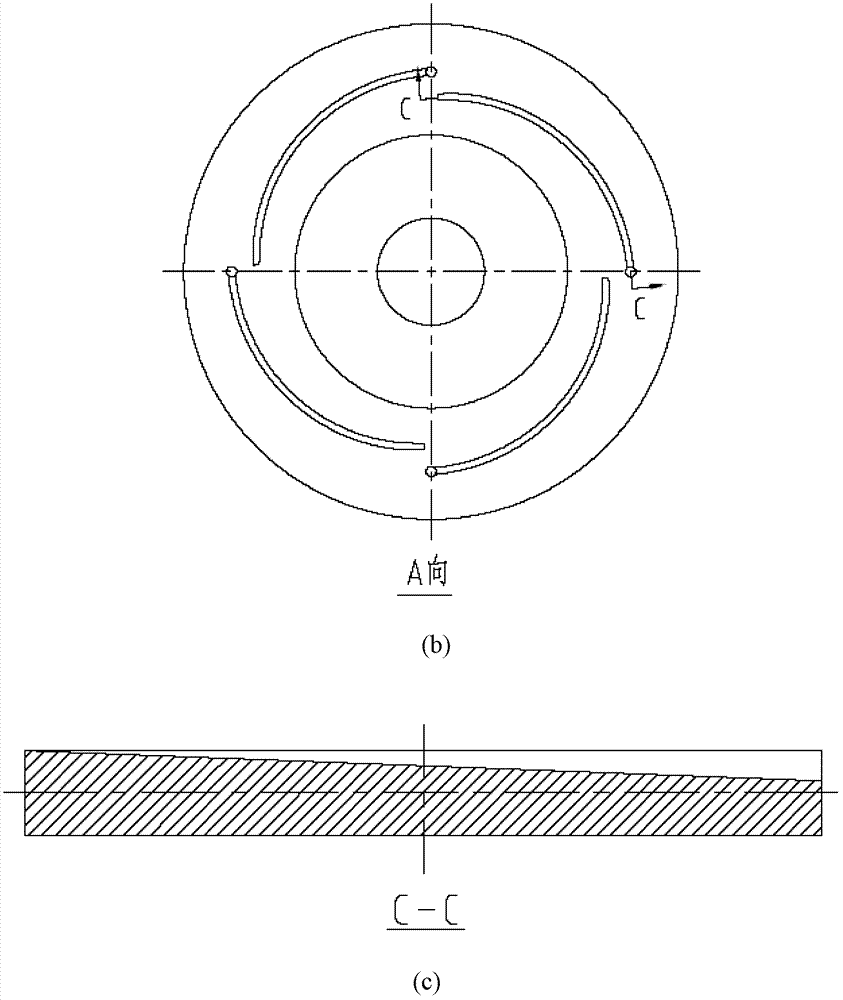

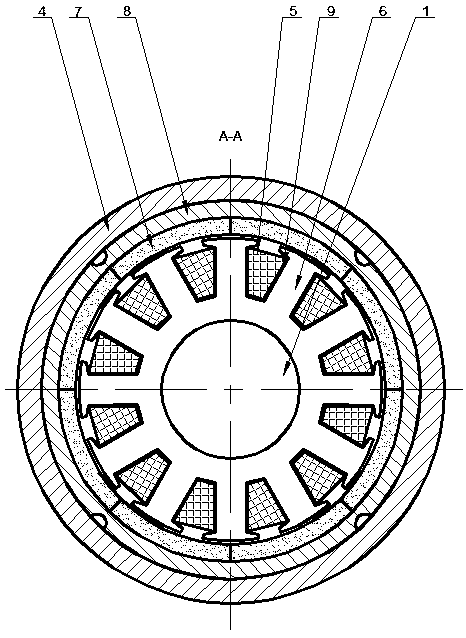

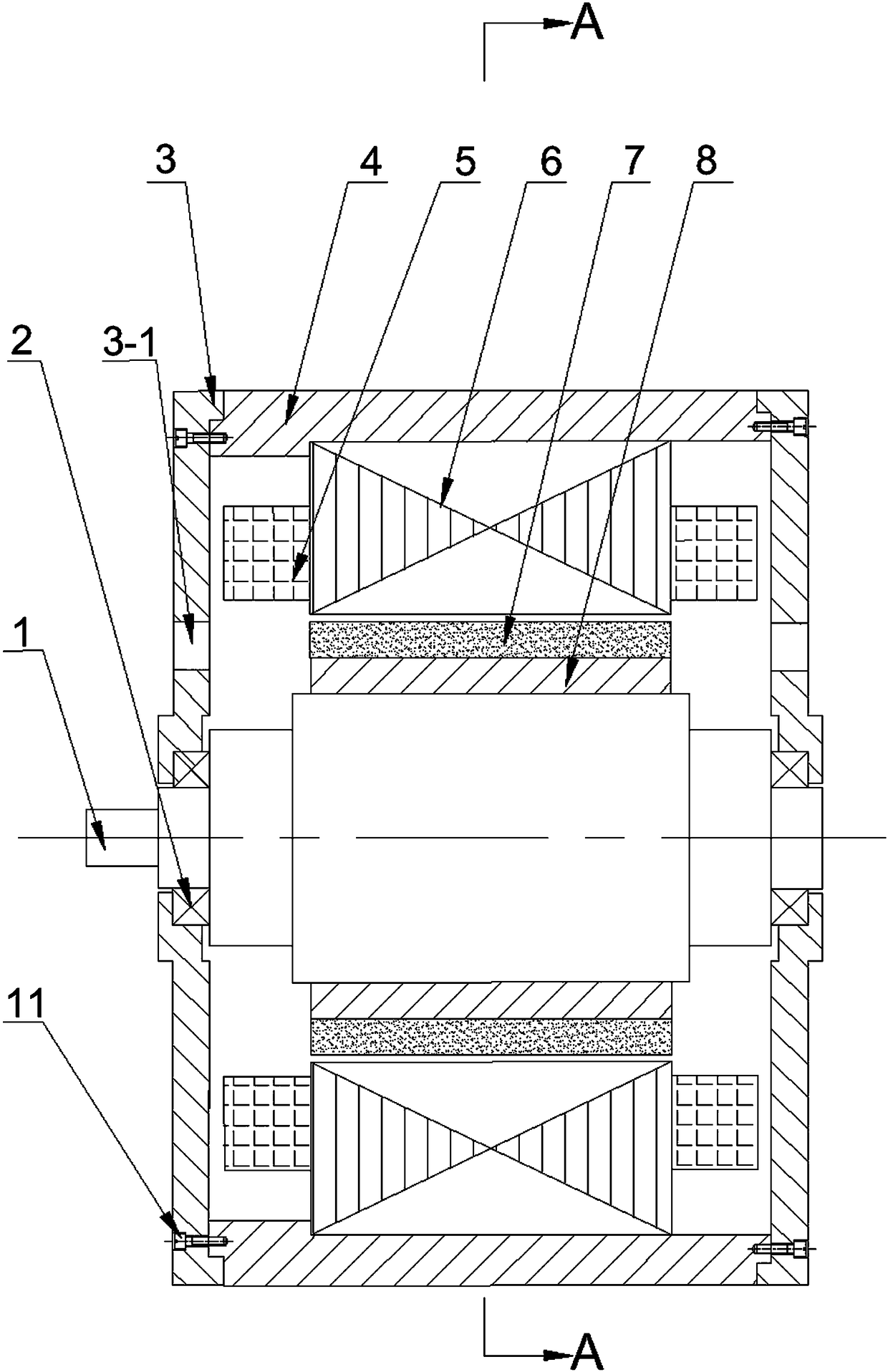

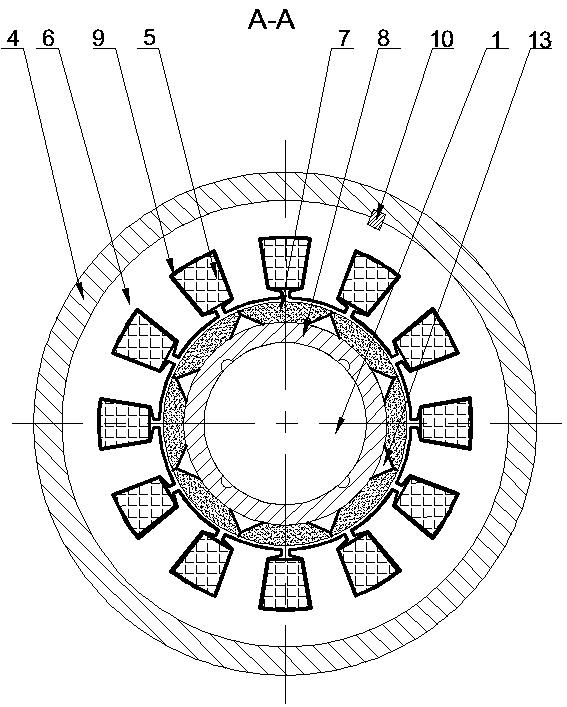

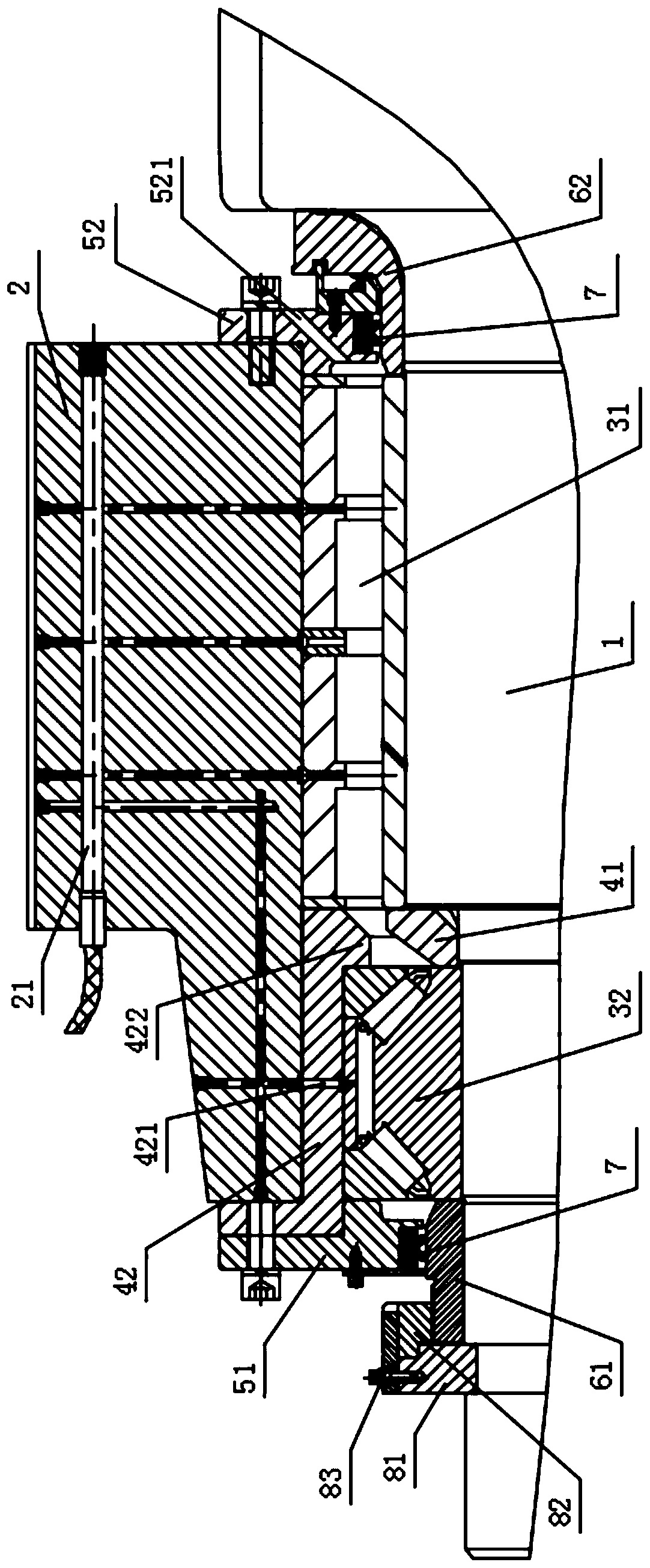

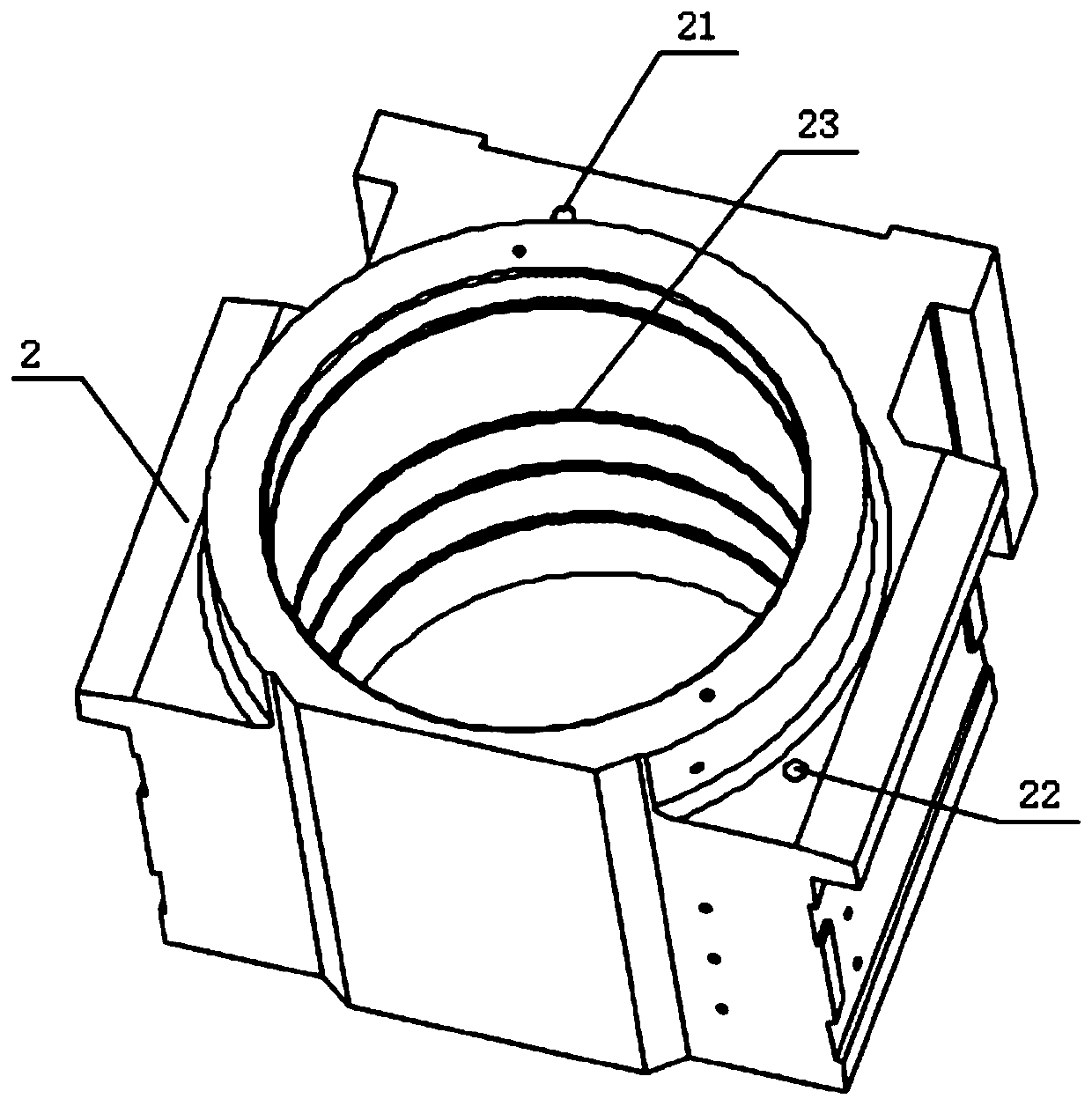

Oil cooling low consumption external rotor permanent magnetic motor

ActiveCN106972666AReduce air gap magnetic field harmonicsImprove power densityMagnetic circuit rotating partsCooling/ventillation arrangementInsulation layerFriction loss

The invention relates to an oil cooling low consumption external rotor permanent magnetic motor, belongs to the field of a motor and aims to reduce oil friction loss, improve heat radiation capability and improves power density applied to an oil-filled environment motor. The permanent magnetic motor comprises a stator and a rotor, wherein the stator comprises a stator shaft, a stator core, an insulation layer and multiple stator coils, the rotor comprises a casing, a rotor yoke, two bearings, multiple magnetic steels and two end covers. The permanent magnetic motor is characterized in that cutting of interior angles of two sides of an inner arc surface of each magnetic steel is carried out, an inner surface of a cylindrical structure formed by the multiple magnetic steels is axially provided with a screw-in drainage slot, an circular surface of the rotor yoke is axially provided with inclined over-current slots, and the multiple inclined over-current slots are symmetrically distributed circumferentially. The permanent magnetic motor is advantaged in that power density can be improved when the permanent magnetic motor is utilized under the oil filling high temperature environment, and great application values are realized.

Owner:哈尔滨深能电机有限公司

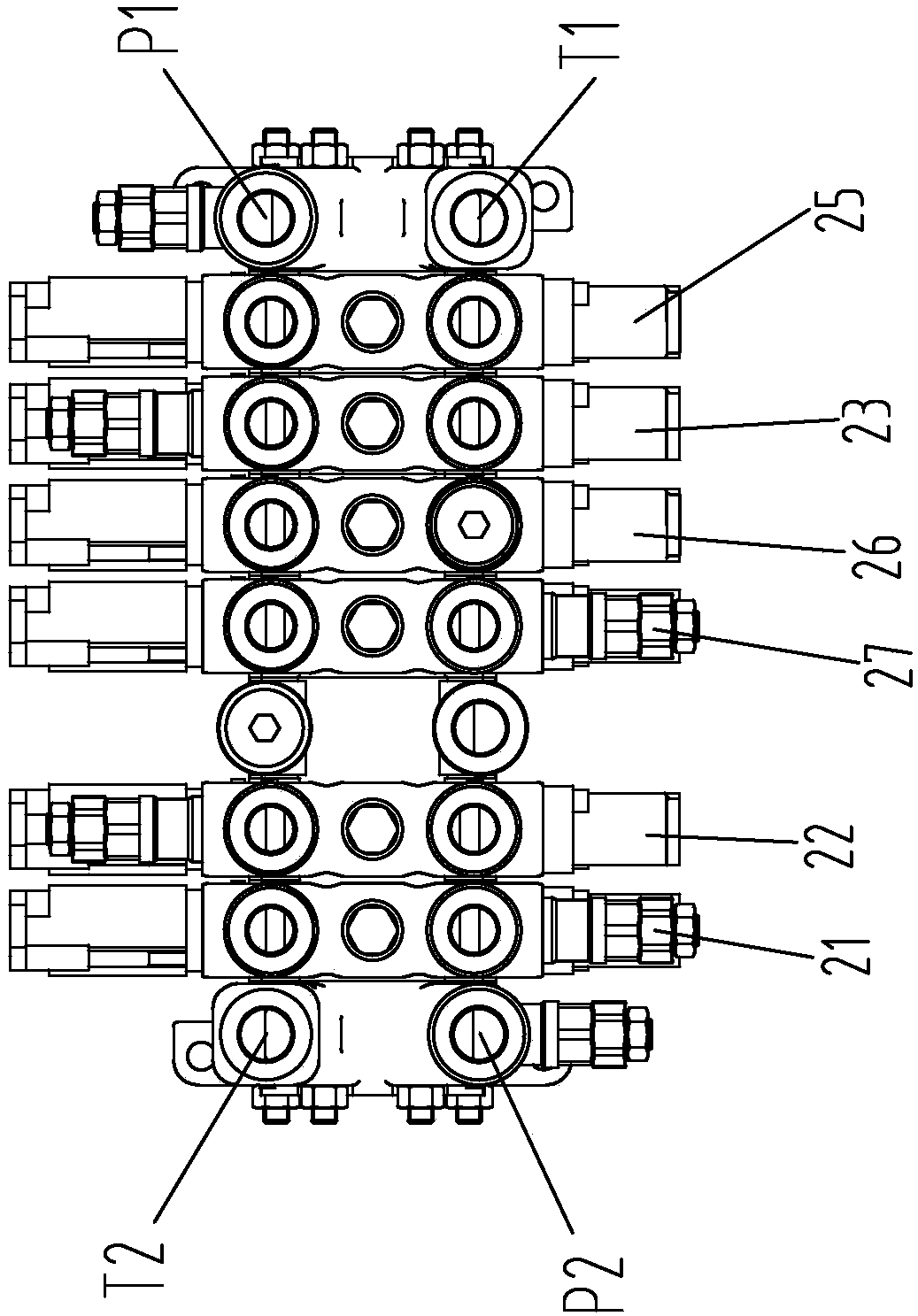

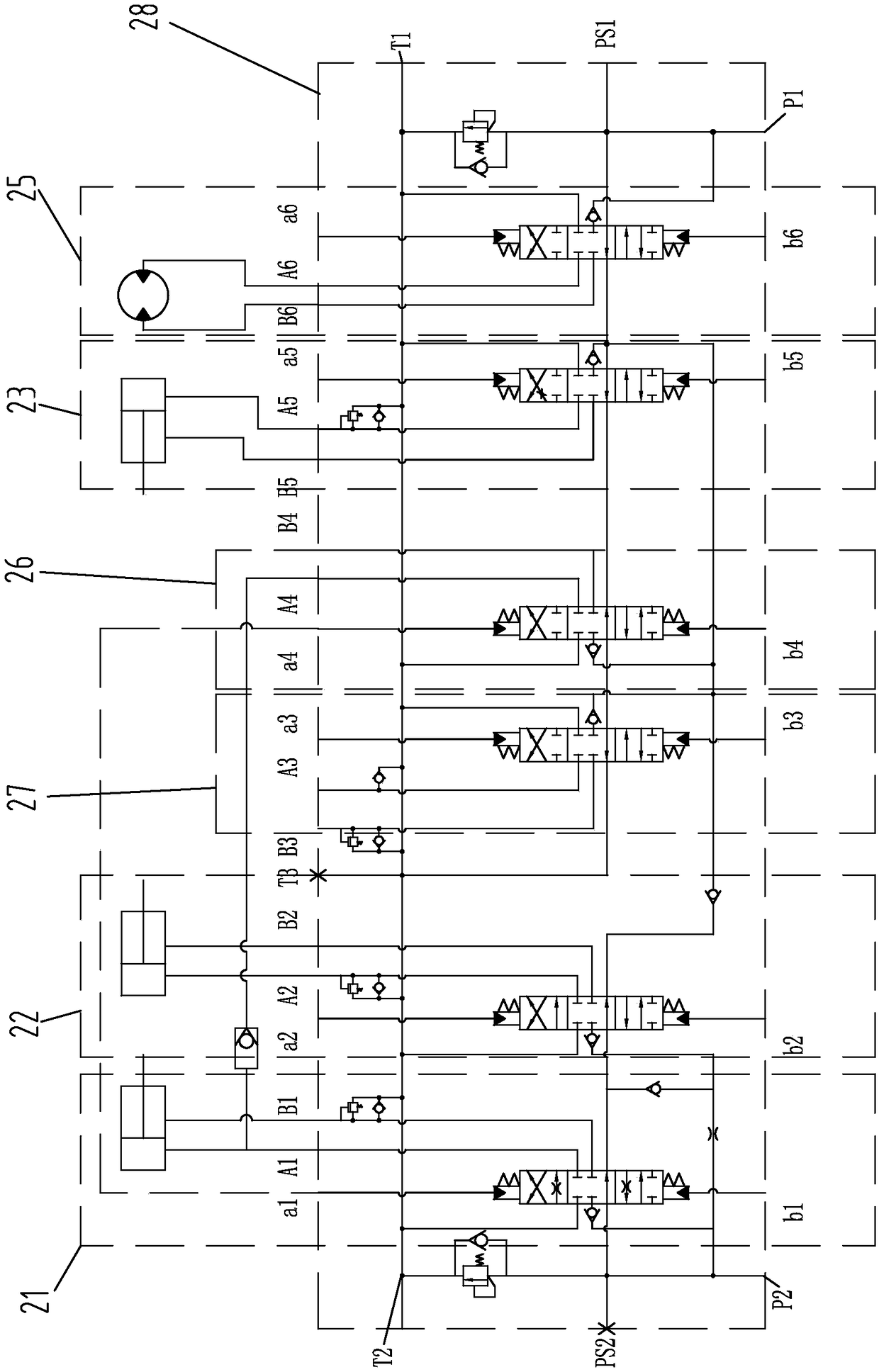

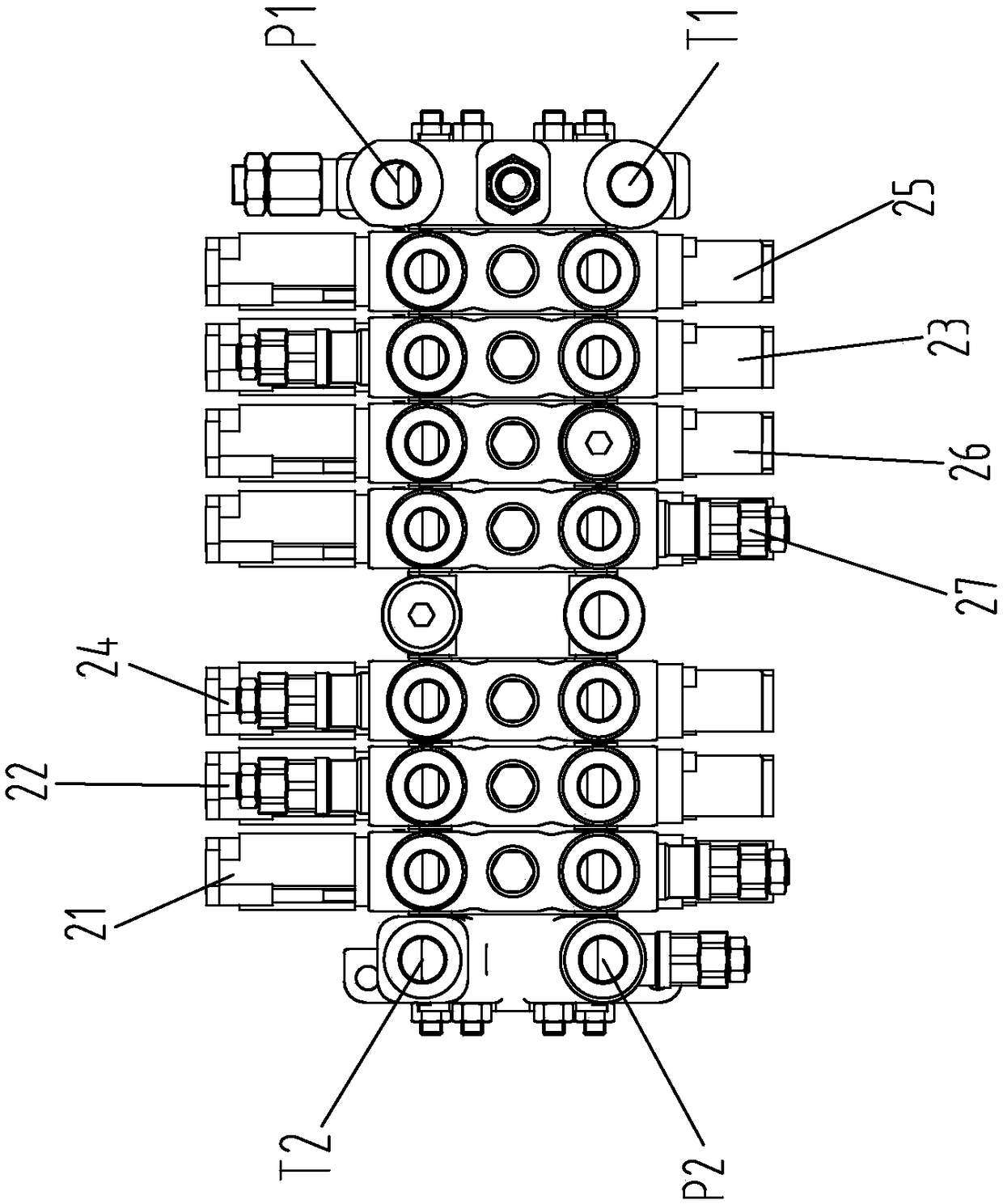

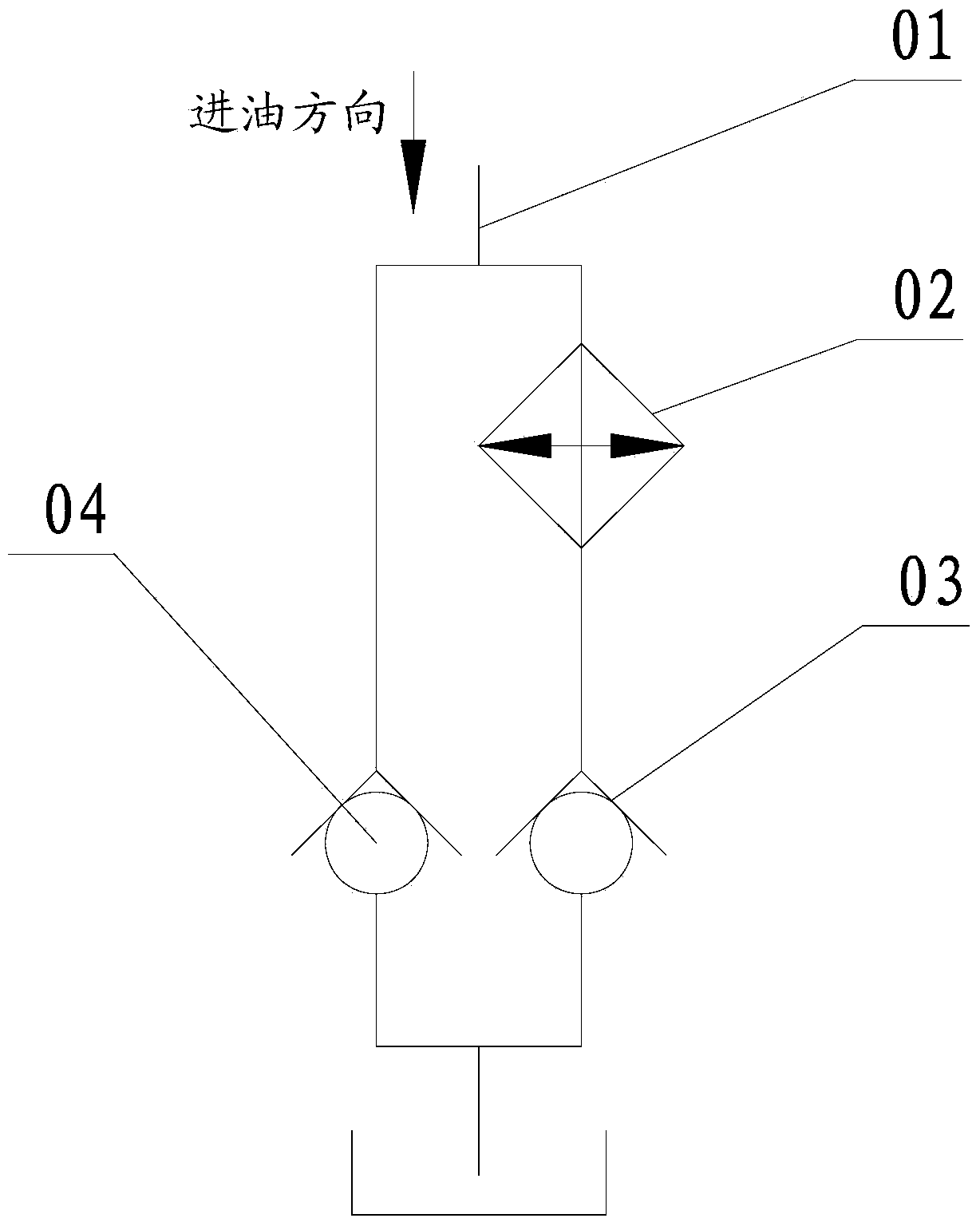

Multi-path valve for wheel excavator

The invention discloses a multi-path valve for a wheel excavator. The multi-path valve for the wheel excavator comprises a second oil inlet, a first oil inlet, an oil returning opening, a movable armoil linkage path, a bucket oil linkage path, a bucket rod oil linkage path and a guiding oil way. All the oil ways communicate with one another in series and communicate with the second oil inlet andthe oil returning opening to form a loop, and the bucket rod oil linkage path communicates with the first oil inlet. The multi-way valve for the wheel excavator is further provided with a third oil inlet, a movable arm oil cylinder, a bucket oil cylinder, a bucket arm cylinder and an auxiliary oil linkage way. The movable arm oil linkage path is further provided with a corresponding movable arm reversing valve, the bucket oil linkage path is further provided with a corresponding bucket reversing valve, the bucket rod oil linkage path is further provided with a bucket rod reversing valve, and the auxiliary oil linkage path is further provided with an auxiliary reversing valve. The third oil inlet communicates with the auxiliary reversing valve. The movable arm oil cylinder is connected withthe movable arm reversing valve, the bucket oil cylinder is connected with the bucket reversing valve, and the bucket arm cylinder is connected with the bucket rod reversing valve. Compared with theprior art, the multi-path valve has the beneficial effects that the coordination of composite actions of the excavator is improved, and therefore the working efficiency is improved.

Owner:FUJIAN JINGONG MACHINERY

Hydraulic oil-return device, hydraulic system and excavator

InactiveCN103470574AImprove practicalityIncrease oil temperatureServomotor componentsFluid-pressure actuator componentsTemperature controlExcavator

The invention relates to a hydraulic oil-return device, a hydraulic system and an excavator. The hydraulic oil-return device is characterized in that an oil-taking check valve is arranged on an oil-return oil circuit connected with a main valve, and an oil outlet of the oil-taking check valve is connected with a bypass check valve and a radiator which are in parallel connection, so that oil flowing out from the main valve is firstly decompressed via the oil-taking check valve to reduce oil-taking pressure of the radiator to have the same protected; in addition, the hydraulic oil-return device is further characterized by being provided with an oil-temperature control device, opening pressure of the bypass check valve is regulated according to oil temperature, when the oil temperature is higher, larger opening pressure can be set so as to allow the hydraulic oil to pass through the radiator as much as possible to have the oil temperature of an oil-return oil tank lowered and radiating effect improved; similarly, when the oil temperature is lower, the bypass check valve is controlled to be opened at the lower oil pressure so as to allow the hydraulic oil to pass through the bypass check valve as much as possible to improve use efficiency of the radiator, prolong the service life thereof, and improve practicability of the hydraulic oil-return device.

Owner:SANY HEAVY MACHINERY

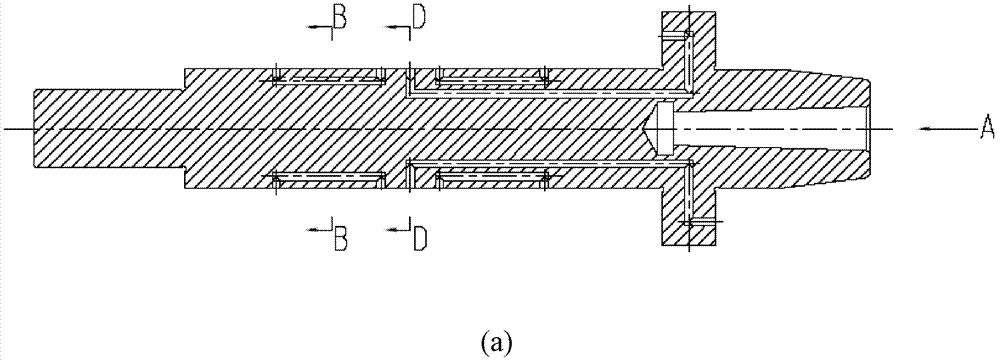

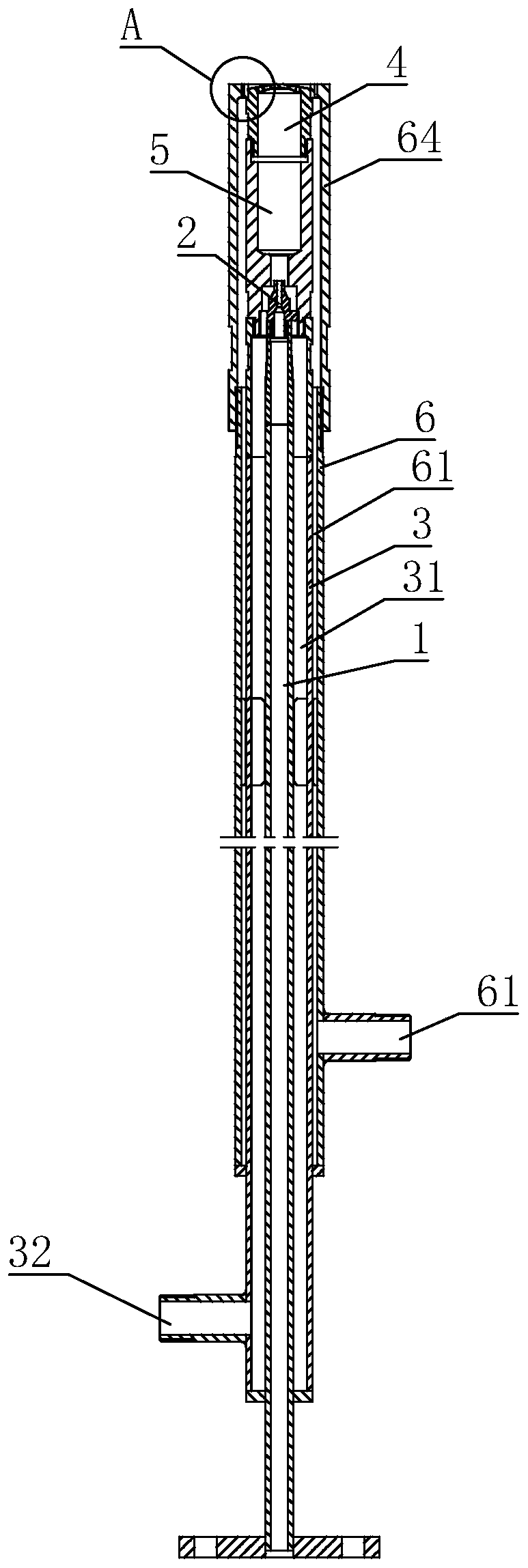

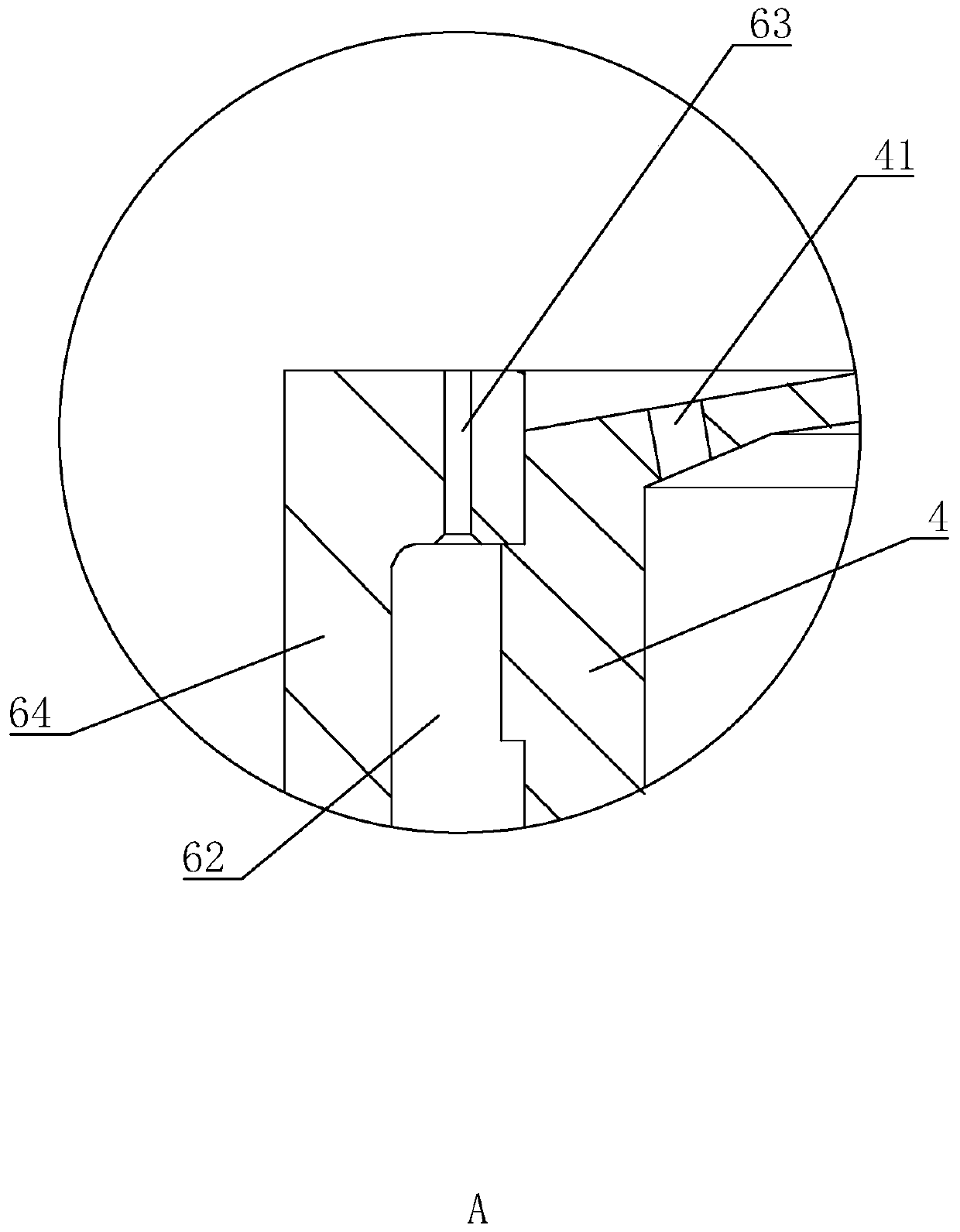

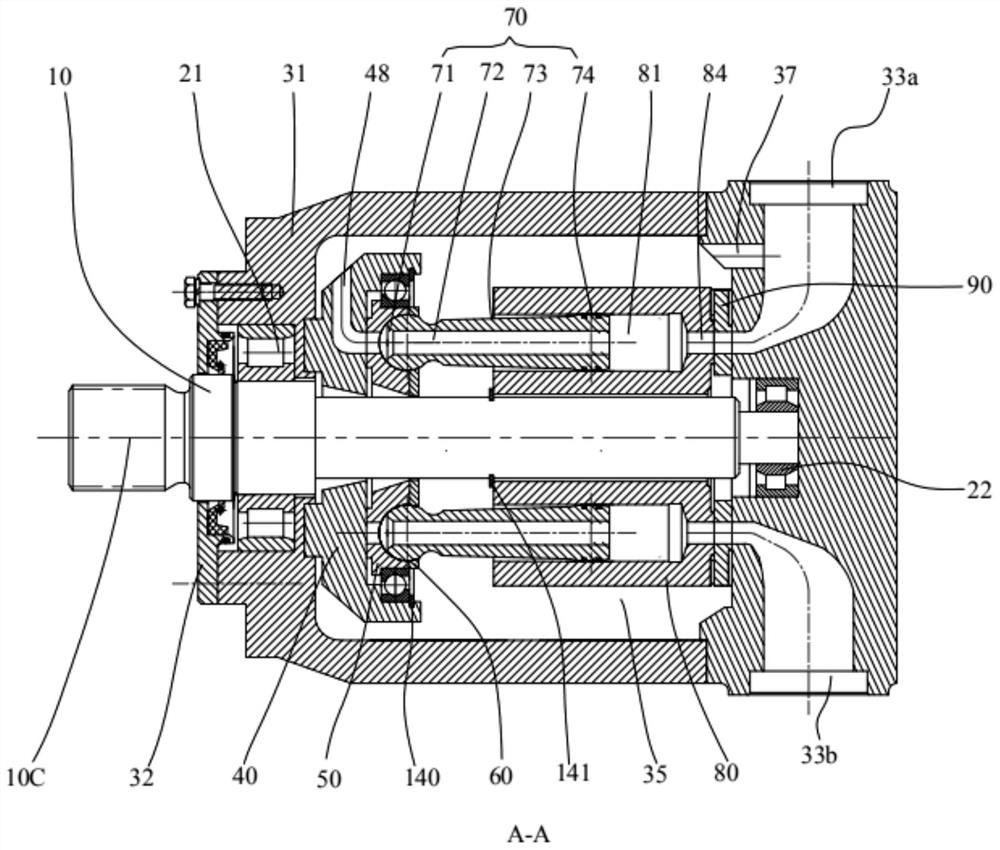

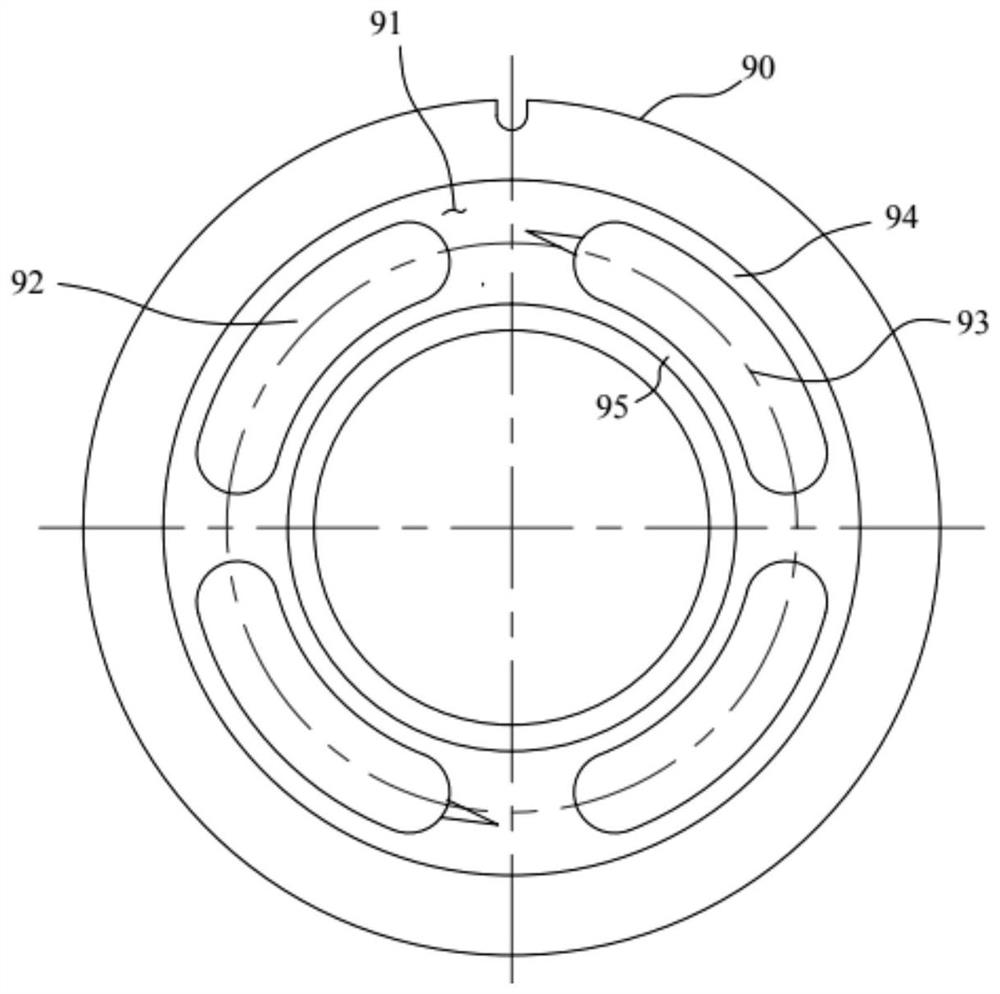

Oil static pressure main shaft main shaft for shaft oil supply

InactiveCN102788086AImprove the axial bearing capacityImprove the radial bearing capacityEngine sealsBearingsMechanical engineering technologyHigh pressure

The invention relates to an oil static pressure main shaft for shaft oil supply, which belongs to the mechanical engineering technical field. The invention is characterized in that the oil static pressure main shaft for shaft oil supply is composed for the main shaft, a front end cover, a regulating ring, a bearing bush, a rear end cover and a bush seat. The high pressure oil is directly entered into an oil chamber of the bearing bush through an oil nozzle, an oil orifice is drilled on the main shaft, therefore the high pressure oil is supplied to the radial oil chamber through the oil orifice of the main shaft for thrusting the oil chamber. The main shaft is suspended in the bearing bush by an oil membrane, the hydraulic oil flowed out of the oil chamber is returned back to a hydraulic station through an oil return hole of the bearing bush. The oil static pressure main shaft has the effect and performance that a restrictor and a bush sleeve are removed, the shaft but the bush sleeve is used for oil supply, and the structure is simplified. The oil static pressure main shaft solves the obstruction problem of the restrictor and reduces the complex degree of mechanical treatment and assembly process.

Owner:秦嗣伟

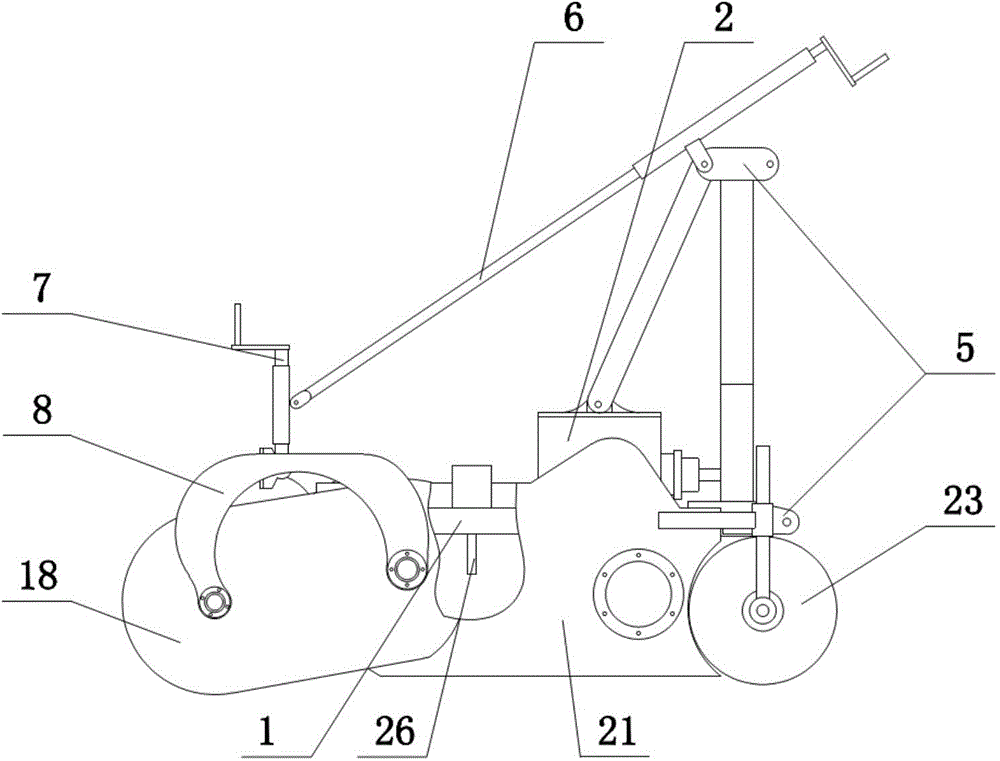

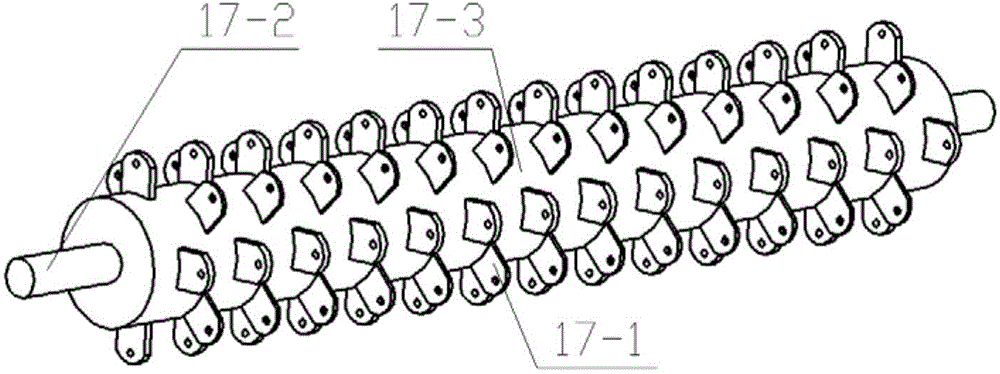

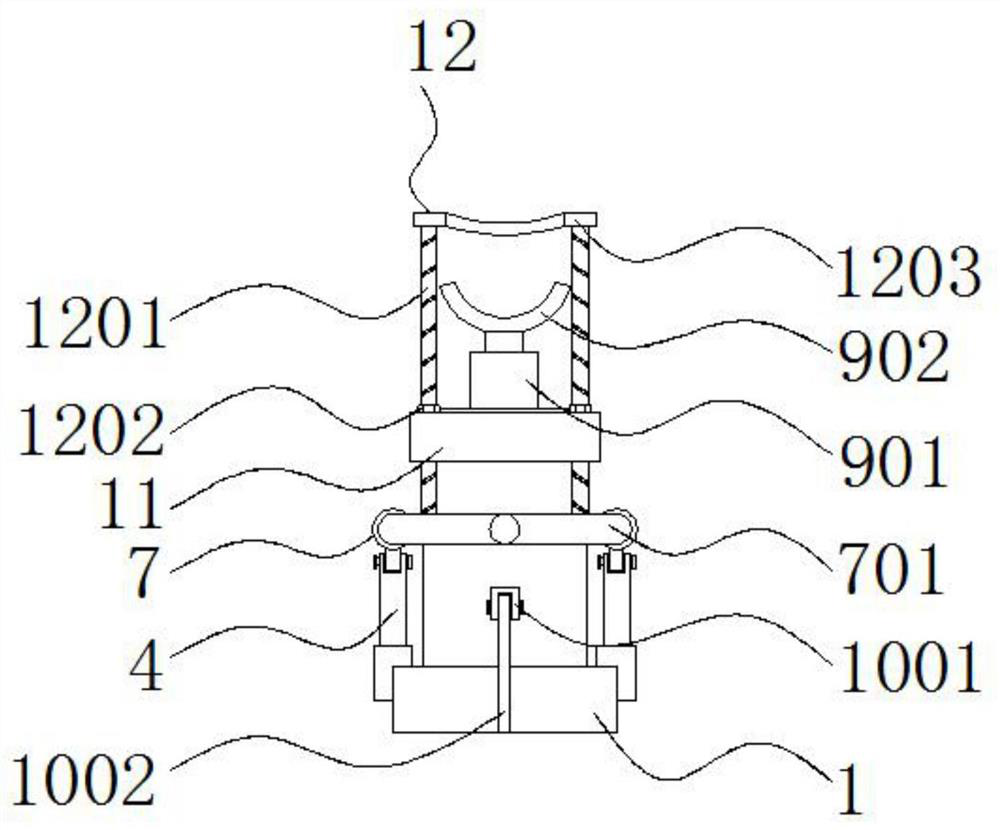

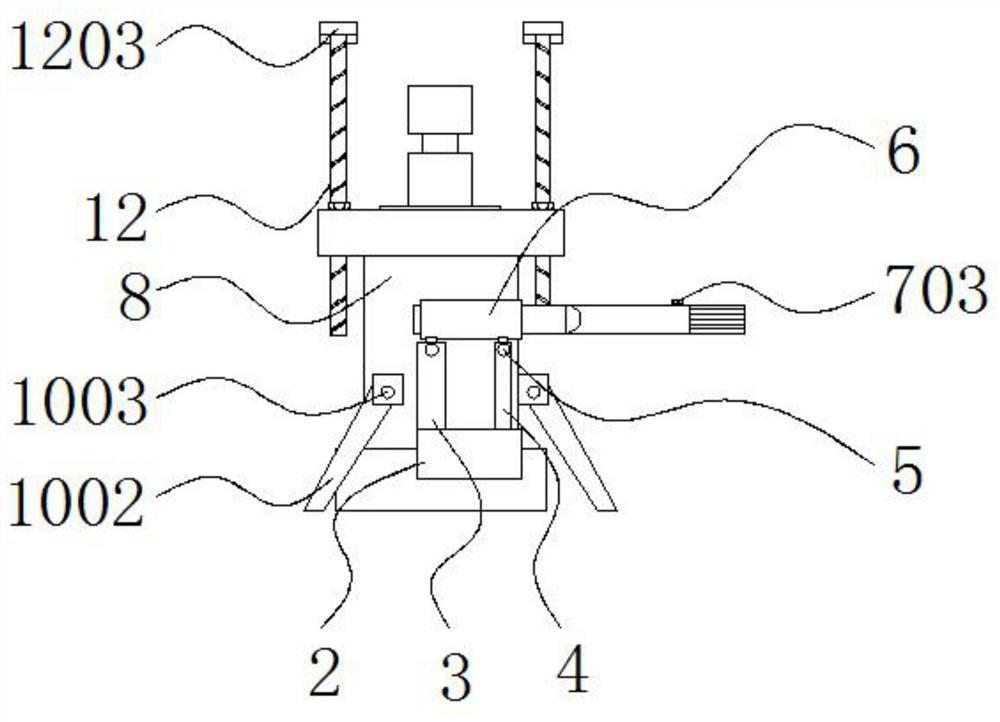

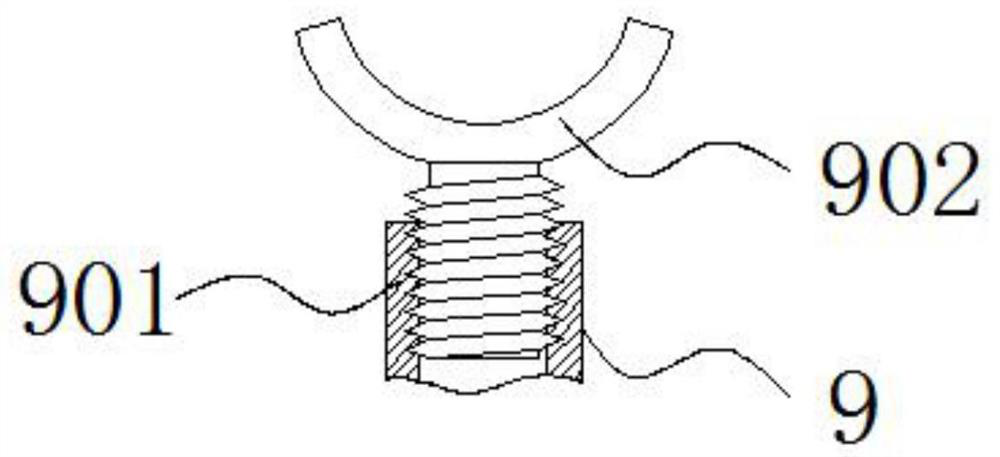

Intelligent fine soil preparation device

ActiveCN104429189AIncrease oil intakeIncrease speedTilling equipmentsAgricultural engineeringSoil preparation

The invention relates to an intelligent fine soil preparation device, and belongs to the technical field of agricultural machinery. The intelligent fine soil preparation device comprises a sensing control circuit, a deep ploughing knife roll assembly (4) supported in the front of a machine frame (1), a fine preparation knife roll assembly (17) and a pressing wheel (19), wherein the fine preparation knife roll assembly (17) and the pressing wheel (19) are supported in the back of the machine frame (1) and driven by a hydraulic motor (16). The signal input end of the sensing control circuit is connected with a force sensor (26) located between the deep ploughing knife roll assembly (4) and the fine preparation knife roll assembly (17), the control output end of the sensing control circuit is connected with a stepping motor (13), and the motion output end of the stepping motor (13) is connected with an adjusting oil cylinder (10) located in an oil transportation channel of a hydraulic motor (16) through a transmission mechanism. The sensing control circuit comprises an intelligent control device outputting corresponding signals for controlling the opening position of the adjusting oil cylinder according to the signals of the force sensor (26). According to the intelligent fine soil preparation device, the secondary fine ploughing operation strategy is determined in an intelligent mode, and standard requirement of fine soil preparation of vegetable fields is met actually.

Owner:JIANGSU UNIV +1

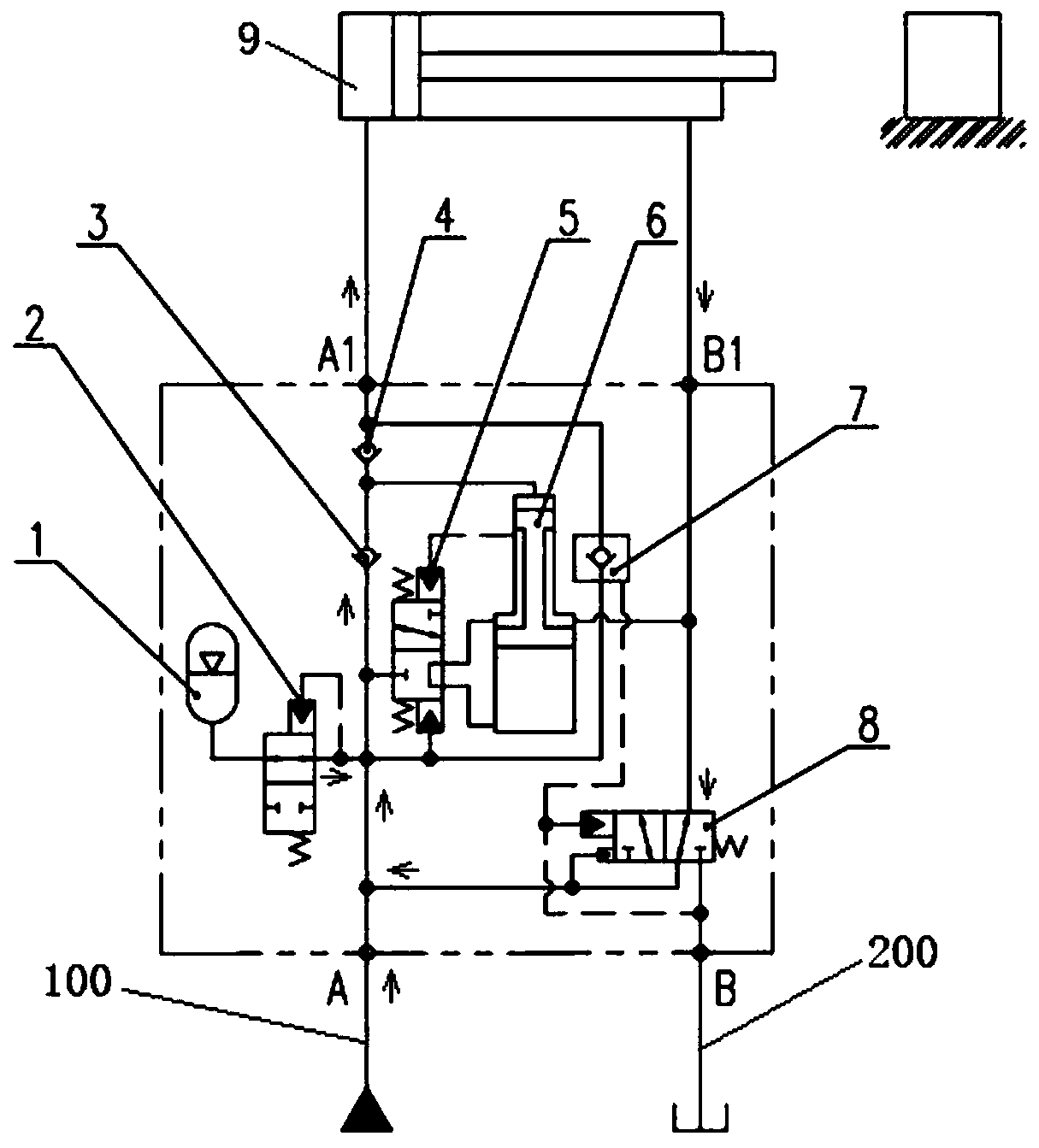

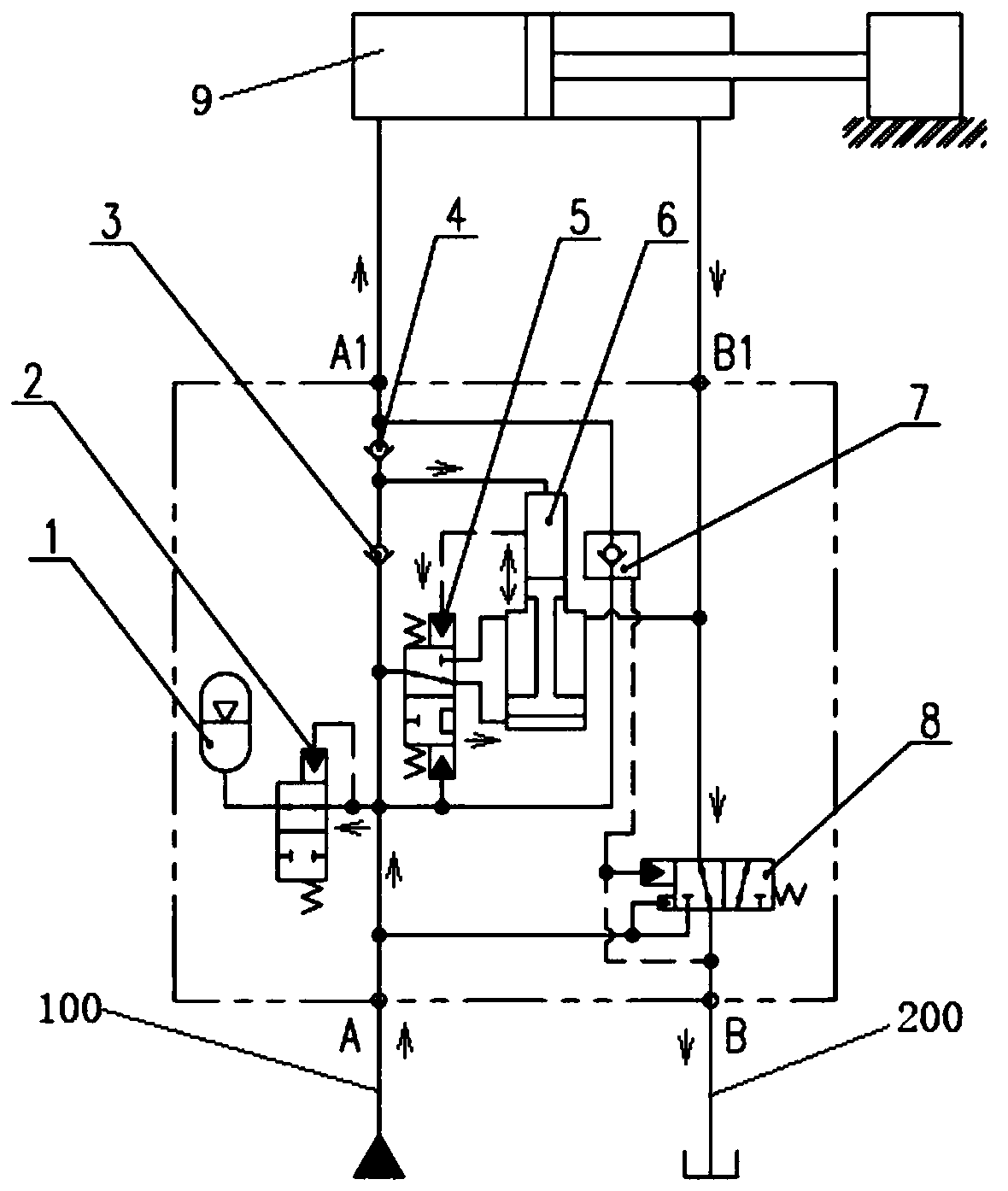

Accelerating and pressurizing system

PendingCN111503067ASpeed up no-load operationIncrease the maximum output forceServomotor componentsAccumulator installationsPhysicsPressure level

The invention discloses an accelerating and pressurizing system. The accelerating and pressurizing system comprises a second switching valve, a double-acting oil cylinder and a third switching valve which are arranged on an oil inlet and outlet path of an execution oil cylinder; a piston with a large end and a small end is arranged in the double-acting oil cylinder, a large cavity and a small cavity of the double-acting oil cylinder correspond to the large end and the small end of the piston respectively, the double-acting oil cylinder is connected with branches through the large cavity and the small cavity and arranged on a working oil inlet way of the execution oil cylinder in parallel, and the second switching valve is arranged on the branch connected with the large cavity of the double-acting oil cylinder; and the third switching valve is arranged on a working oil return path of the execution oil cylinder and is used for switching and connecting an oil return port of the executionoil cylinder between the working oil return path and the working oil inlet path. According to the accelerating and pressurizing system, on the premise that the discharge capacity and the pressure level of a main pump do not need to be changed, the accelerating and pressurizing system is additionally arranged on the working oil way of the execution oil cylinder, so that the no-load running speed ofthe execution oil cylinder is increased, the maximum output force of the oil cylinder load is increased, and the execution oil cylinder can stretch out rapidly or with large thrust.

Owner:山河智能特种装备有限公司

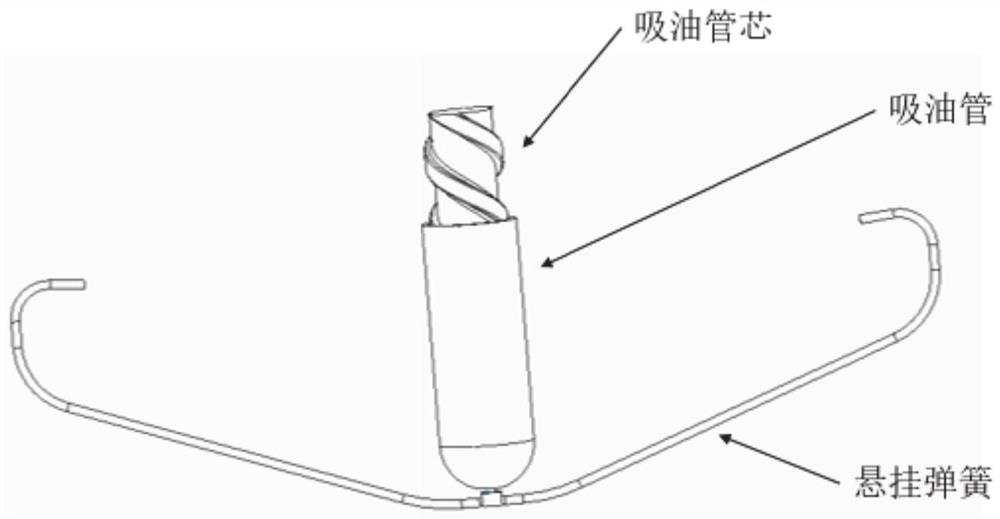

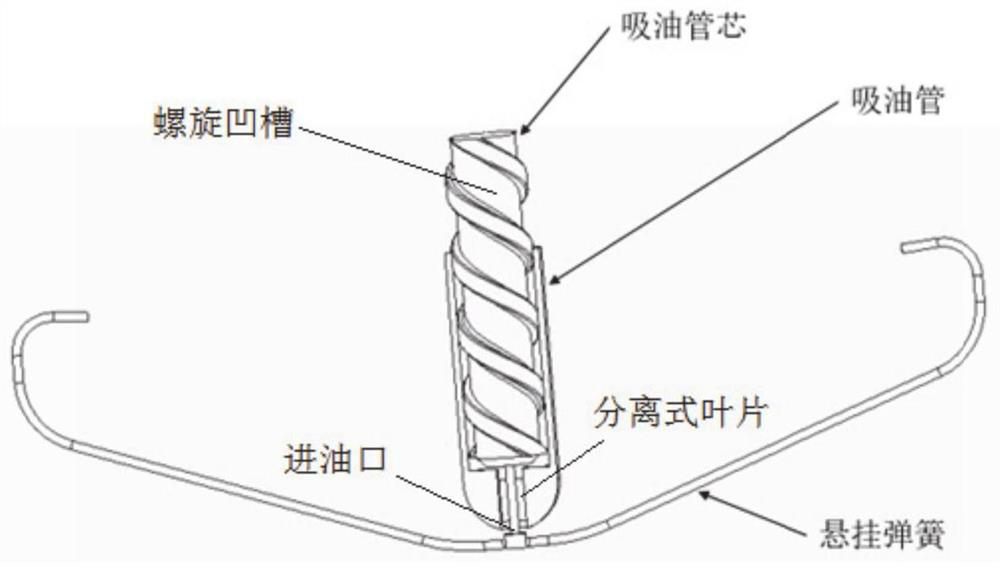

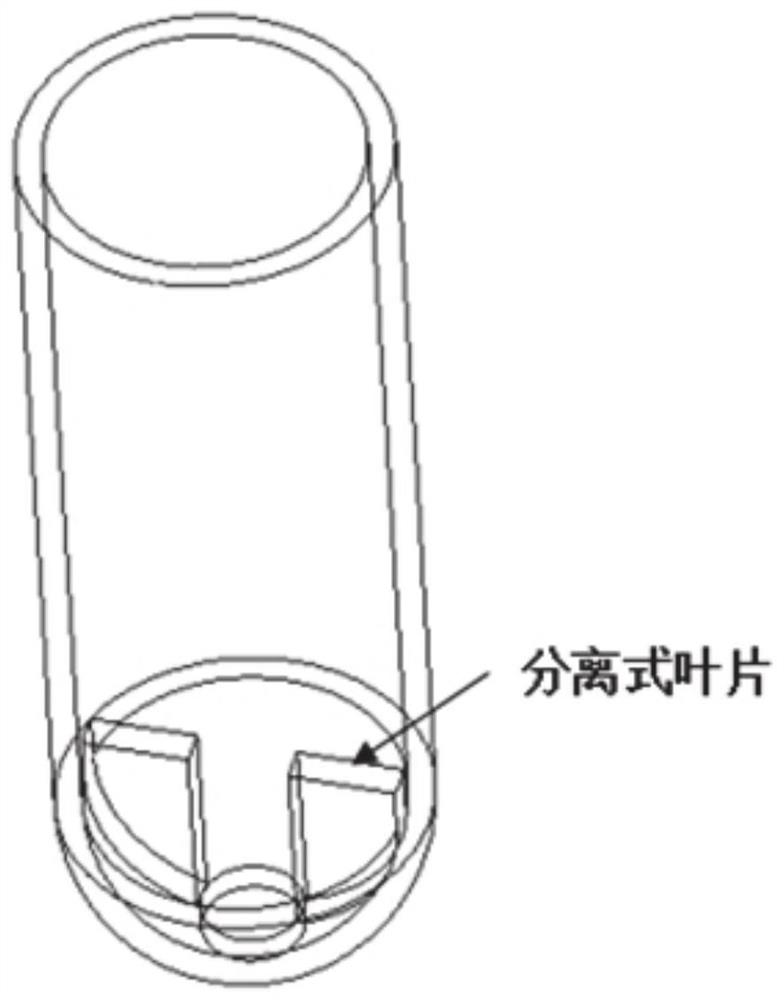

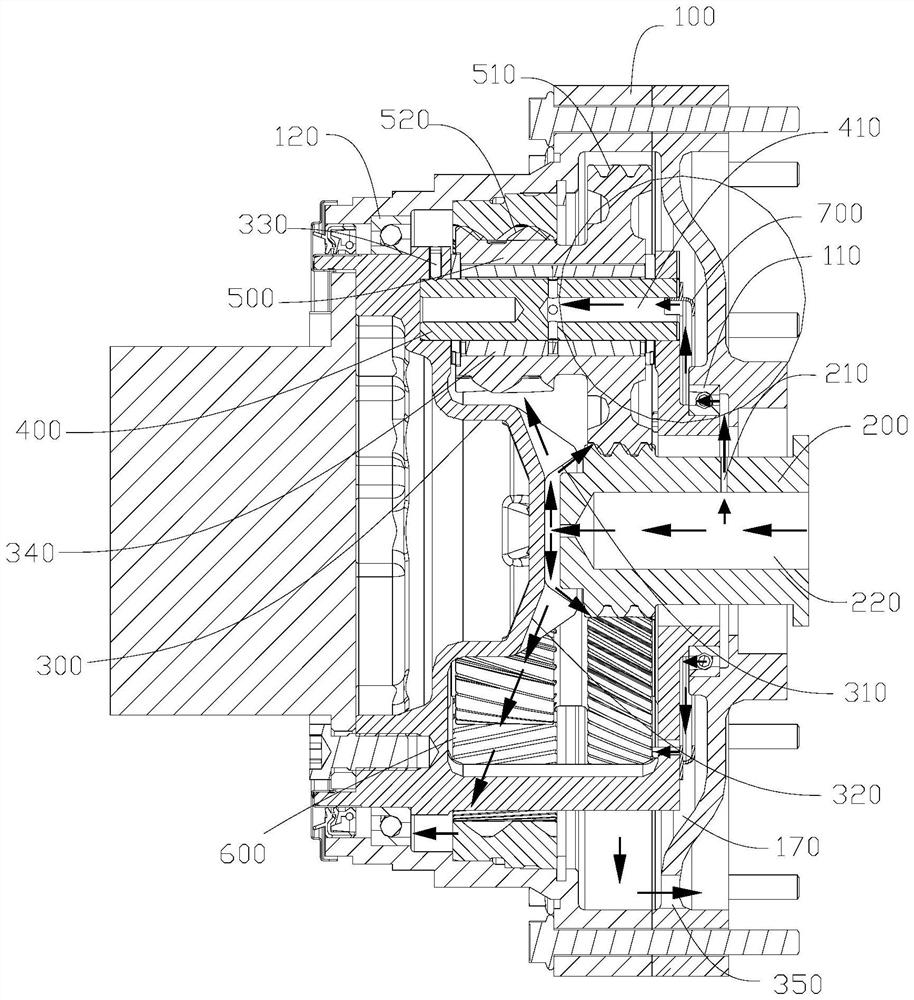

Centrifugal supercharging type spiral oil pump, compressor and heat exchange equipment

InactiveCN111677649AAvoid blockingFlow area effectPositive displacement pump componentsLubricating pumpsOil separationCentrifugal force

The invention provides a centrifugal supercharging type spiral oil pump, a compressor and heat exchange equipment. The oil pumping amount of the compressor oil pump under the conditions of low rotating speed, high oil temperature and low viscosity can be increased. The spiral oil pump comprises an oil suction pipe and an oil suction pipe core arranged in the oil suction pipe, wherein a spiral groove is formed in the surface of the oil suction pipe core in the axis direction from bottom to top, an oil inlet is formed in the bottom of the oil suction pipe, separation type blades which do not shield the oil inlet are arranged on the periphery of the oil inlet and fixedly connected with the inner wall of the oil suction pipe, and the oil suction pipe and the oil suction pipe core can rotate relatively to realize oil pumping. The separation type blades rotate to stir entering oil to generate strong centrifugal force when the oil suction pipe rotates, and meanwhile, the separation type blades are arranged to avoid blocking of the blades to the oil inlet, the oil inlet amount is increased, and therefore the oil pumping capacity is further improved, the oil pumping capacity of a compressoroil pumping system under the low-rotating-speed and high-temperature conditions is improved, and the oil pump is suitable for the variable frequency compressor.

Owner:QINGDAO WANBAO COMPRESSOR

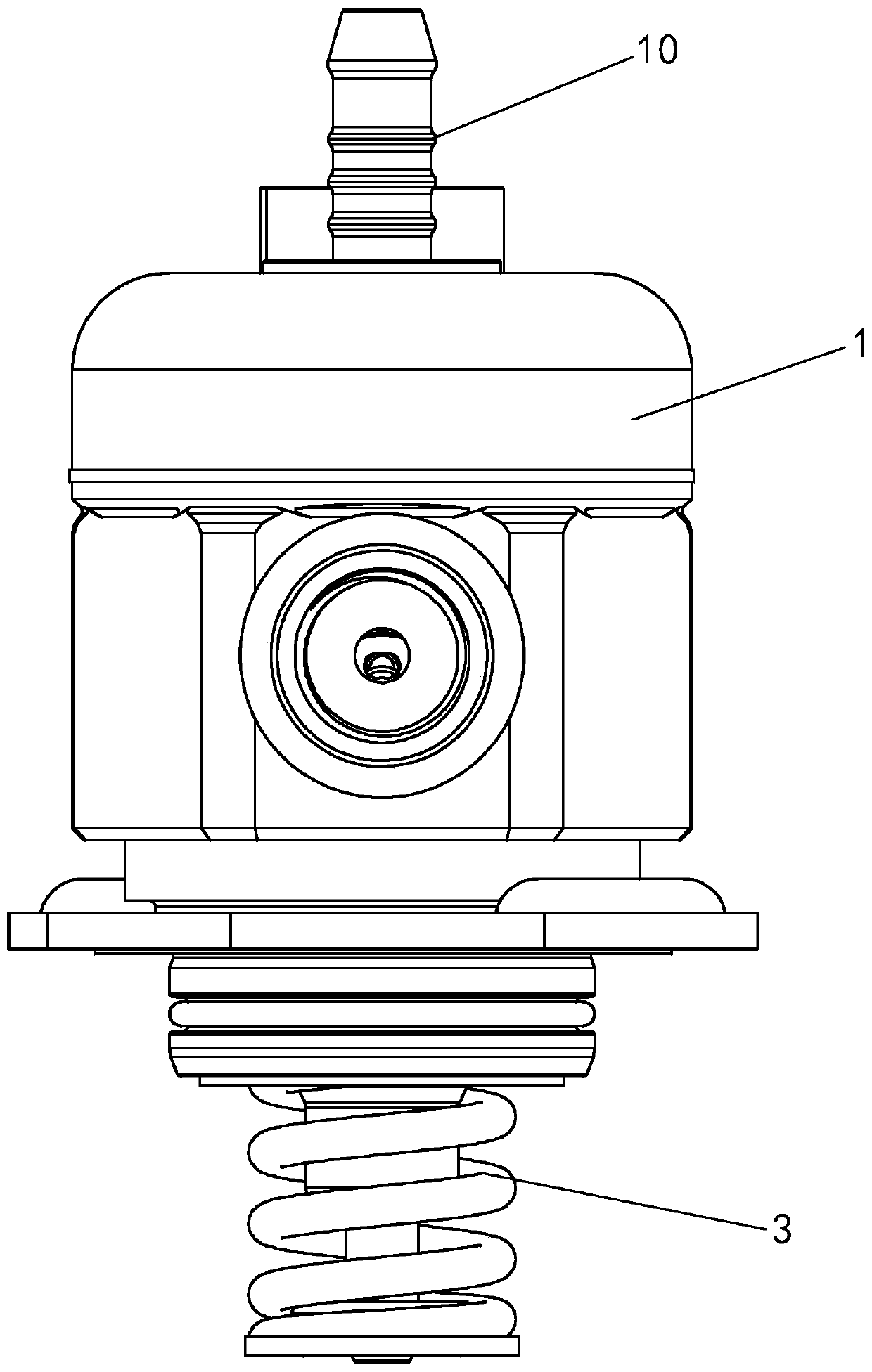

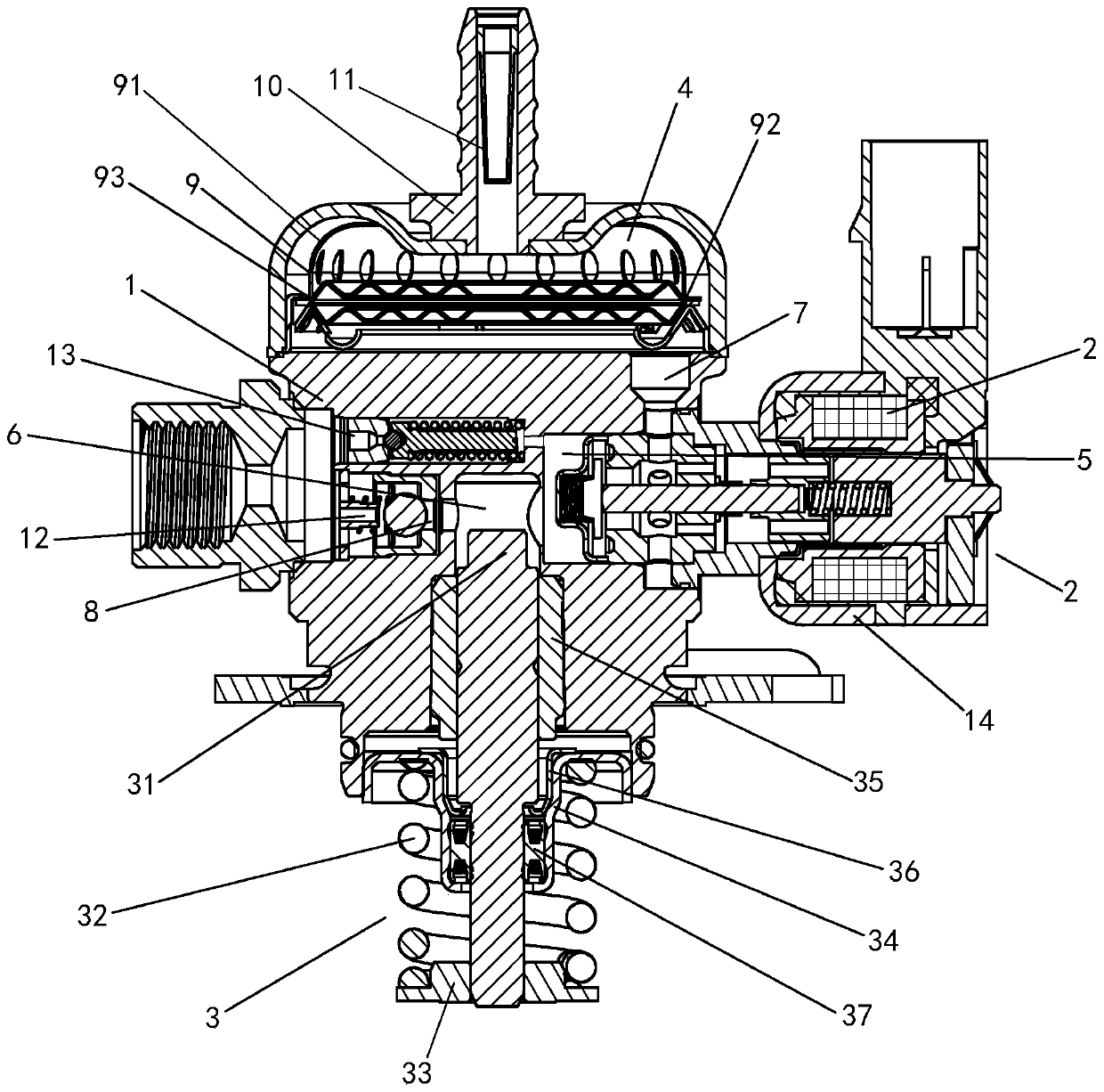

In-cylinder direct-spray high-pressure pump

PendingCN110185565AImprove reliabilityReduced stiffness requirementsMachines/enginesFuel injecting pumpsSolenoid valveEngineering

The invention relates to an in-cylinder direct-spray high-pressure pump. The in-cylinder direct-spray high-pressure pump comprises a pump body, wherein an oil inlet and an oil outlet are formed in thepump body; a stable-pressure cavity, a low-pressure cavity, a high-pressure cavity, a first connecting oil path and a second connecting oil path are arranged in the pump body; the oil inlet communicates with the first connecting oil path through the stable-pressure cavity; the first connecting oil path communicates with the second connecting oil path through the low-pressure cavity and the high-pressure cavity in sequence; the second connecting oil path communicates with the oil outlet; a solenoid valve is arranged in the low-pressure cavity; a plunger piston device is arranged in the high-pressure cavity; the oil outlet is equipped with a pressure release valve; the pressure release cavity communicates with the low-pressure cavity or the high-pressure cavity; the pressure release valve comprises a sealing base with a through hole therein, a stud and a ball body arranged between the sealing base and the stud; the ball body and the sealing base can be connected in a sealing mode; the ball body is linked and matched with the stud; and a pressure release valve spring is arranged between the stud and the inner wall of the pressure release cavity. The pressure release valve structure is changed into spherical surface seal from plane seal, so that sealing effect is good, a sealing form is more stable, the closing effect is quicker, and oil supply efficiency of the high-pressure pumpis improved.

Owner:JIANGSU BATON TECH CO LTD

Quick-lift-type vertical jack with double pump structure

InactiveCN111646384AIncrease oil intakeImprove work efficiencyLifting devicesJackscrewLever pressing

The invention relates to a quick-lift-type vertical jack with a double pump structure. The quick-lift-type vertical jack comprises a fixed base and a vertical jack body. Oil pump connecting blocks arefixed to the left and right sides of the fixed base, fixed supporting rods are fixed in front, a connecting inserting tube is arranged above a connecting positioning pin, the vertical jack body is located above the fixed base, and a foot supporting mechanism is installed outside the vertical jack body. The quick-lift-type vertical jack has the beneficial effects that through simultaneous workingof two pressurized oil pumps, the lifting speed of equipment is increased, the working efficiency of the equipment is improved, three supporting feet can be expanded to provide auxiliary support through the foot supporting mechanism so as to improve the stability of the equipment, the length of a pressure rod is adjusted by a pressure mechanism, so that the equipment can work in a deeper place, anarc-shaped connection top block can prevent the equipment from slipping at a jacking point, and a safety bracket is used to support so as to protect the equipment and to prevent the equipment from being damaged and heavy objects from falling and hurting people.

Owner:嘉兴海派液压科技股份有限公司

Ignition device and ignition method for combustor

InactiveCN110822421AImprove the fullness of combustionIncrease oxygen contentBurnersThermodynamicsCombustor

The invention discloses an ignition device and ignition method for a combustor. The ignition device and ignition method for the combustor are applied to the field of combustors. The essential of the technical scheme is as follows: the ignition device for the combustor comprises a spray nozzle, an oil pipe, an oil nozzle connected to one end of the oil pipe, and an inner air pipe, wherein the innerair pipe is arranged outside the oil pipe in a sleeved manner and forms an inner air cavity with the oil pipe; a first air inlet port is formed in the inner air pipe; one end facing the oil nozzle, of the inner air pipe, is an air outlet end; the oil nozzle and the air outlet end of the inner air pipe are connected to the spray nozzle simultaneously; and a spray port is formed in the spray nozzle. The ignition device and ignition method for the combustor have the following technical effects: the oxygen content of a surrounding environment during combustion for oil mist is increased, and thenthe combustion sufficiency degree of the oil mist is increased, and the effects of energy conservation and environment protection are achieved.

Owner:南京建安机械制造有限公司

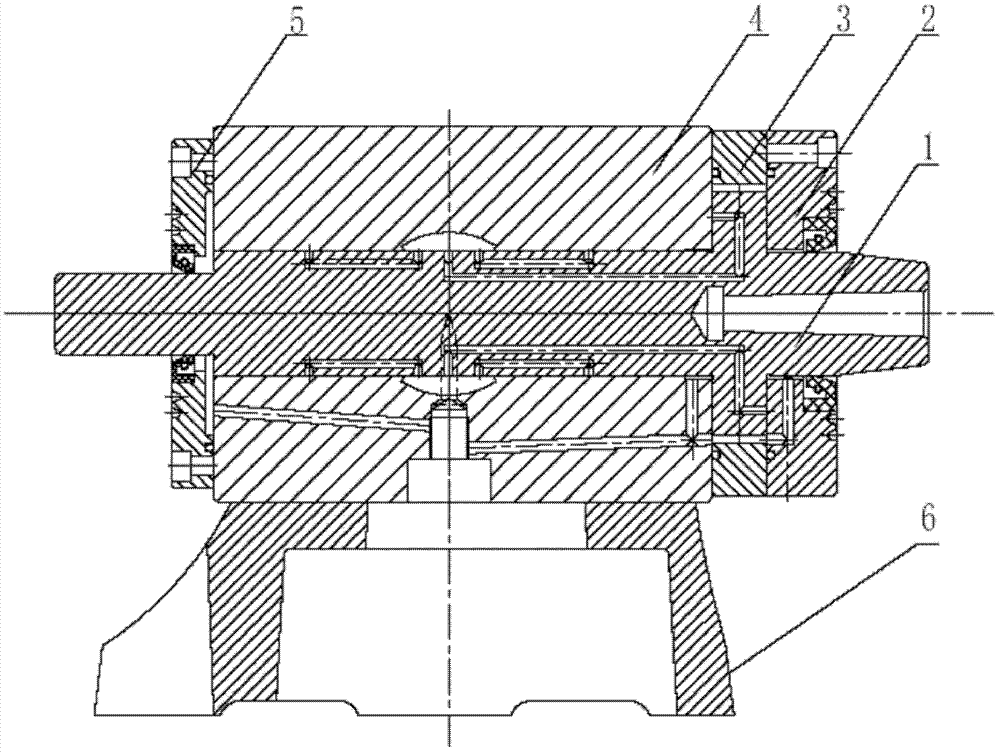

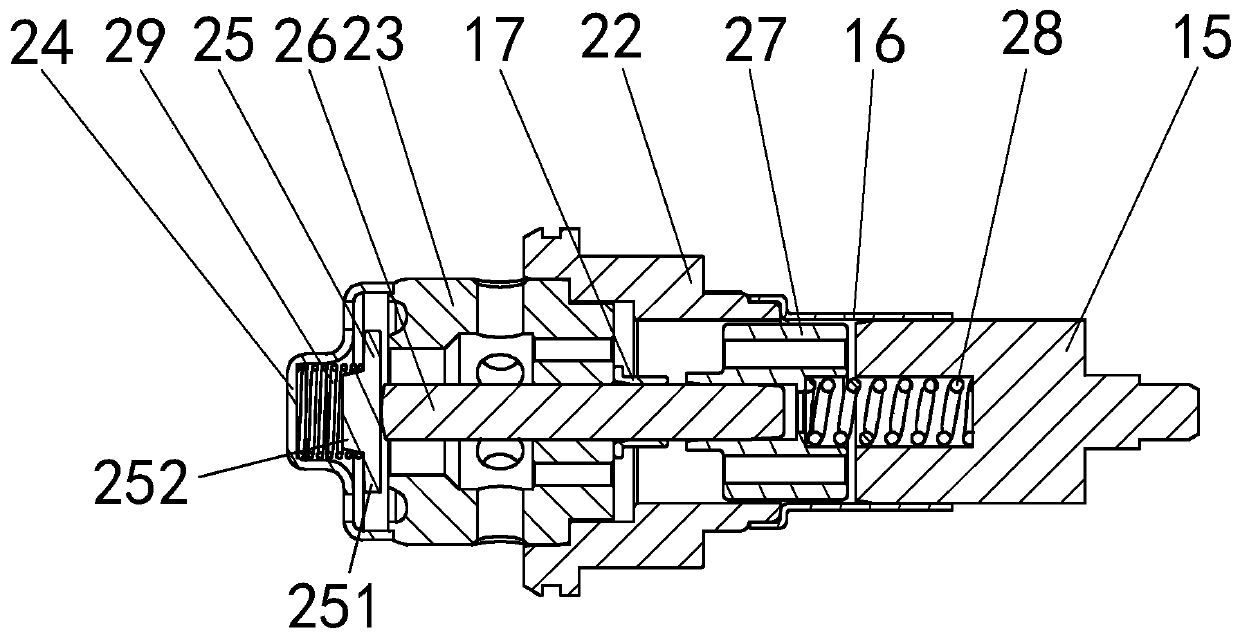

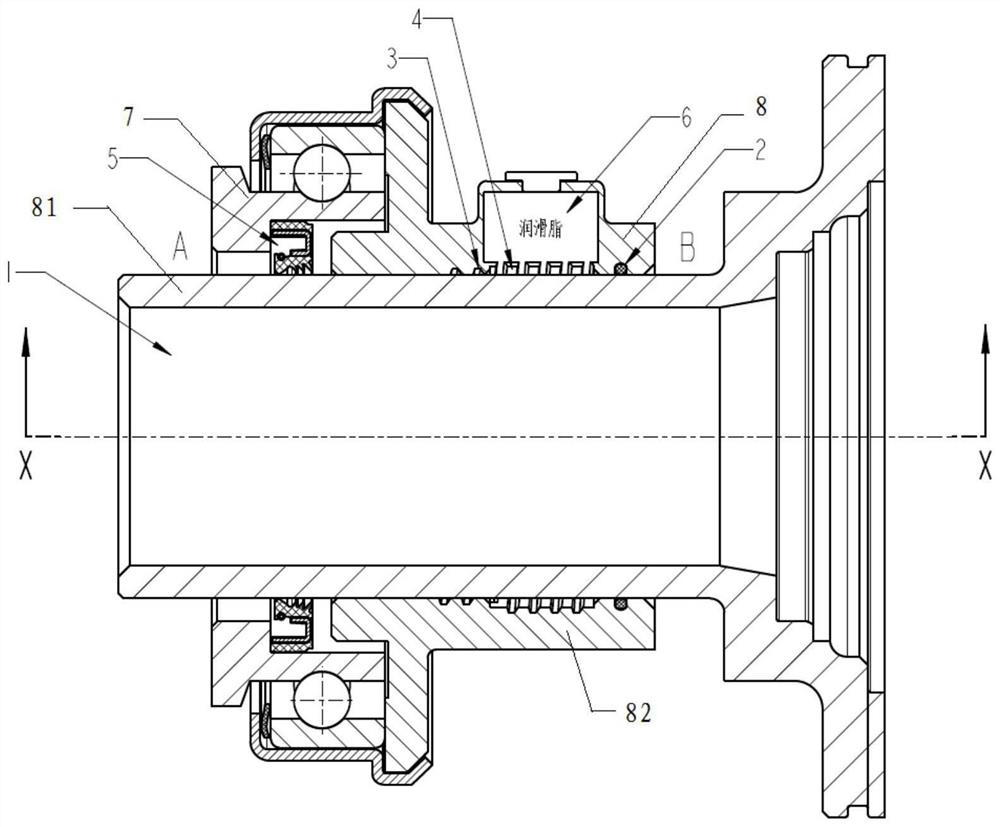

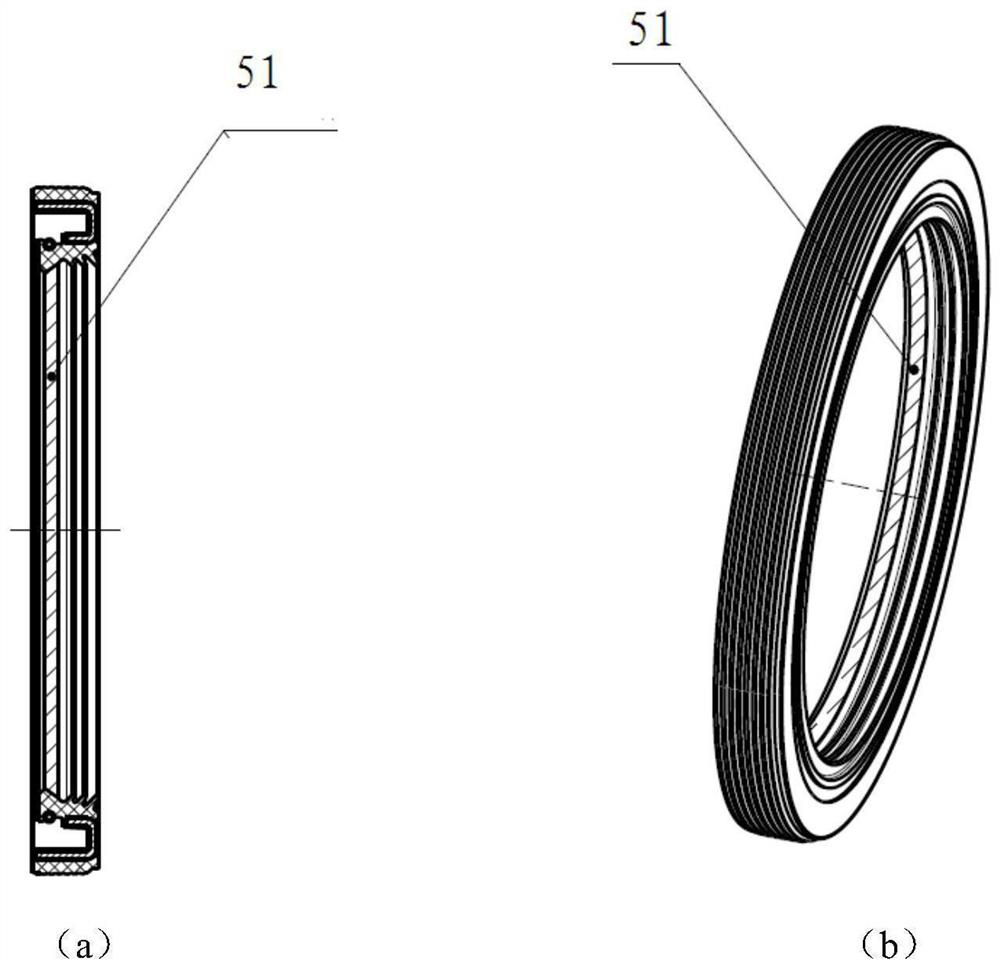

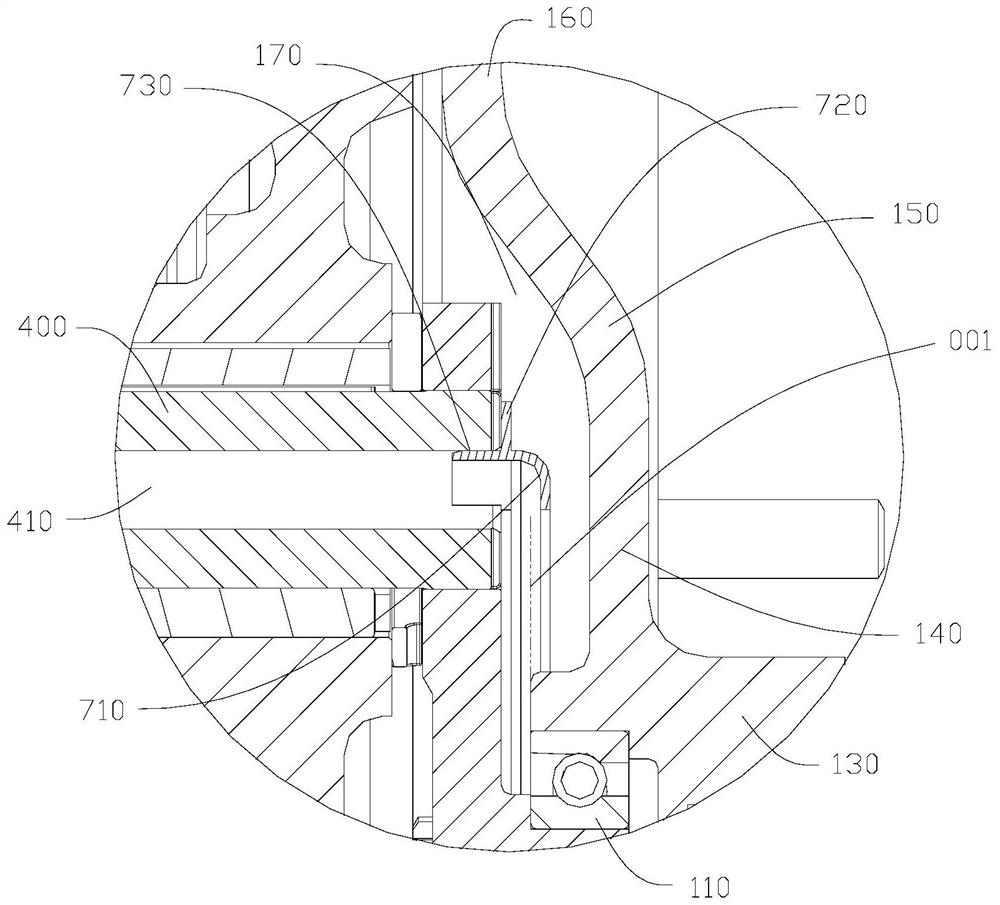

A release bearing provided with a lubricating structure and a lubricating method thereof

ActiveCN112145552BIncrease storage spaceImprove lubrication conditionsClutchesEngine sealsReciprocating motionScrew thread

The invention discloses a release bearing provided with a lubricating structure and a lubricating method thereof. The structure is provided with a guide thread, which can increase the storage space of the grease to a certain extent while ensuring that the lubricating grease can be evenly filled inside the oil storage tank of the separating bearing. , so that the grease inside the oil storage tank is in good condition and evenly distributed, which effectively improves the lubrication conditions of the release bearing and greatly prolongs the service life. And expand the oil inlet space, increase the amount of oil inlet, so that the internal lubrication is sufficient. At the same time, a sealing structure is provided at both ends of the guide thread, so that the sealing effect can be guaranteed when the sleeve is reciprocating.

Owner:XIAN FASHITE AUTOMOBILE TRANSMISSION CO LTD

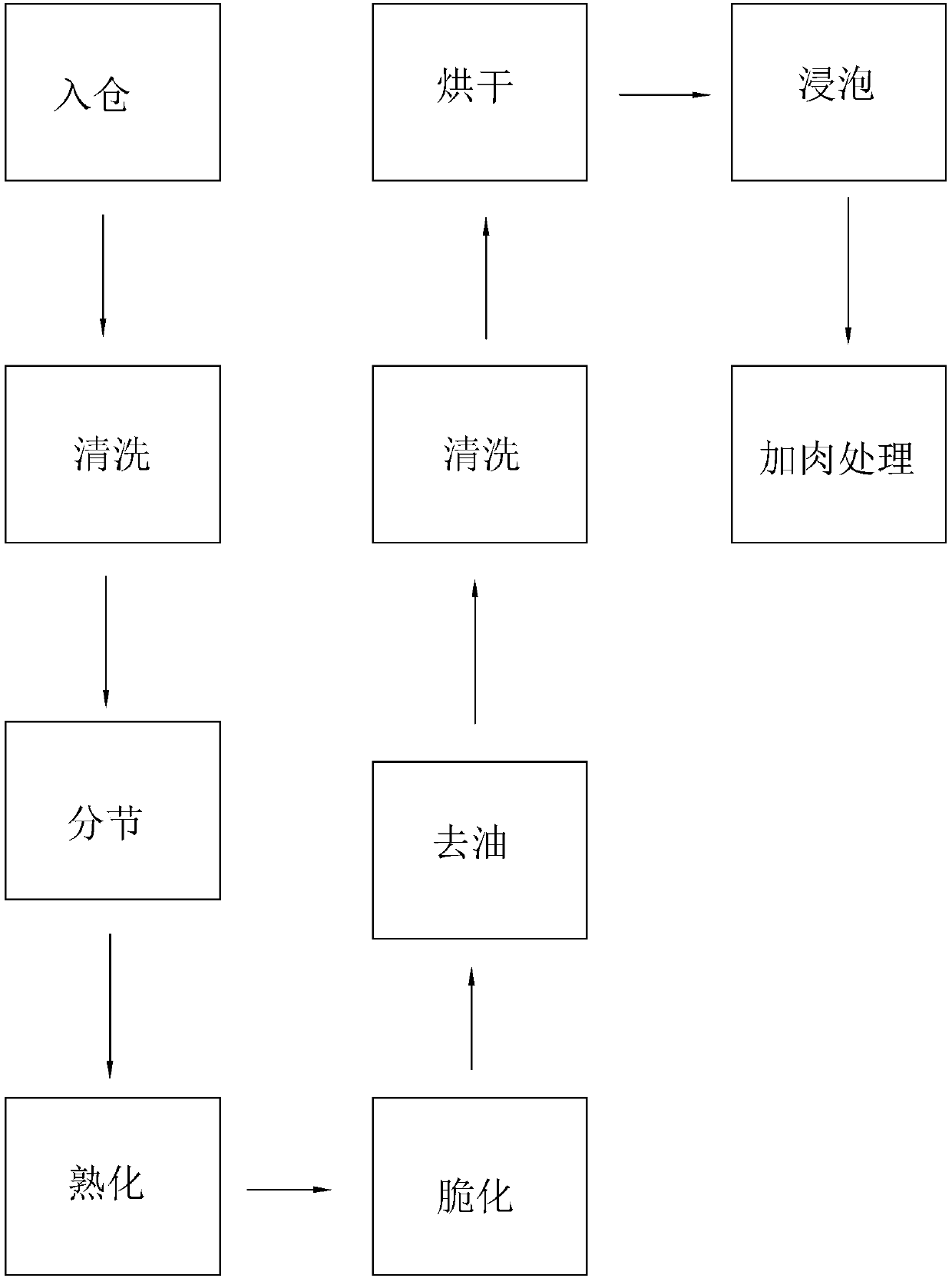

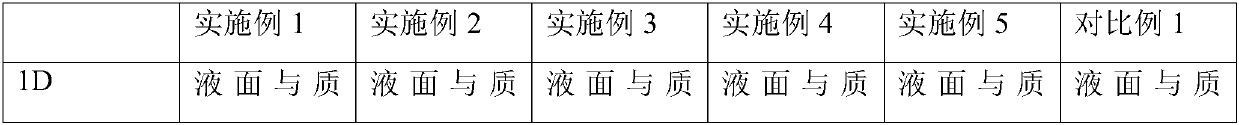

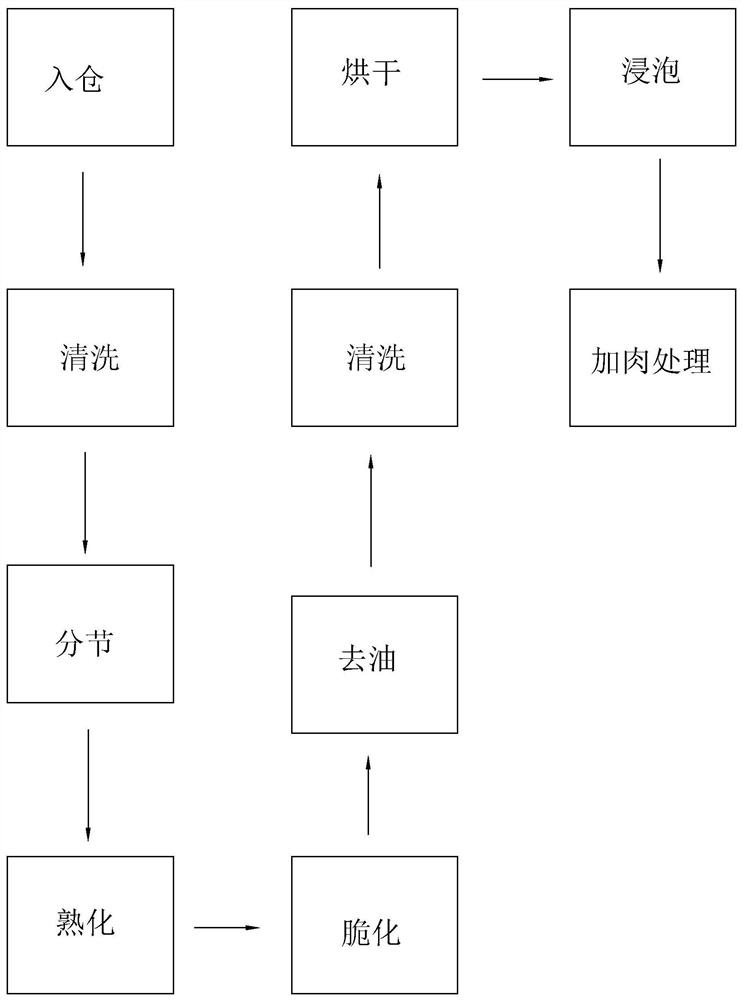

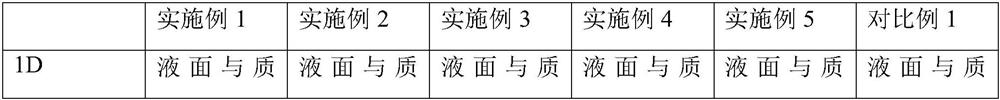

Preparation method of shark bone teething toy for pets

ActiveCN108013254AHigh oil contentIncrease oil intakeAnimal feeding stuffAccessory food factorsVitamin CCompanion animal

The invention discloses a preparation method of a shark bone teething toy for pets. The preparation method is characterized by comprising the following steps: (1) warehousing frozen fresh bones; (2) delivering the fresh bones into a dressing shop immediately after the fresh bones are taken out, removing residual meat from the fresh bones and cleaning the fresh bones; (3) performing segmentation treatment on the fresh bones to obtain segmented bones; (4) cooking the segmented bones and performing drying under a condition of 50-80 DEG C for 1-5h to obtain dry bones; (5) embrittling the dry bones; (6) performing de-fatting, cleaning and drying; (7) putting the product obtained in the step (6) into a vitamin C solution, performing soaking under a condition of 40 DEG C for 0-5 days to obtain aprimary product; and (8) performing meat addition treatment on the primary product to obtain a finished product. A toy with proper hardness and suitability for occlusion of pets can be prepared by thepreparation method, and the aims of providing oil for pets and prolonging the shelf life of the shark bone teething toy for pets are achieved.

Owner:温州致兴宠物营养科技有限公司

An oil-cooled, low-consumption external rotor permanent magnet motor

ActiveCN106972666BReduce air gap magnetic field harmonicsImprove power densityMagnetic circuit rotating partsCooling/ventillation arrangementInsulation layerFriction loss

The invention relates to an oil cooling low consumption external rotor permanent magnetic motor, belongs to the field of a motor and aims to reduce oil friction loss, improve heat radiation capability and improves power density applied to an oil-filled environment motor. The permanent magnetic motor comprises a stator and a rotor, wherein the stator comprises a stator shaft, a stator core, an insulation layer and multiple stator coils, the rotor comprises a casing, a rotor yoke, two bearings, multiple magnetic steels and two end covers. The permanent magnetic motor is characterized in that cutting of interior angles of two sides of an inner arc surface of each magnetic steel is carried out, an inner surface of a cylindrical structure formed by the multiple magnetic steels is axially provided with a screw-in drainage slot, an circular surface of the rotor yoke is axially provided with inclined over-current slots, and the multiple inclined over-current slots are symmetrically distributed circumferentially. The permanent magnetic motor is advantaged in that power density can be improved when the permanent magnetic motor is utilized under the oil filling high temperature environment, and great application values are realized.

Owner:哈尔滨深能电机有限公司

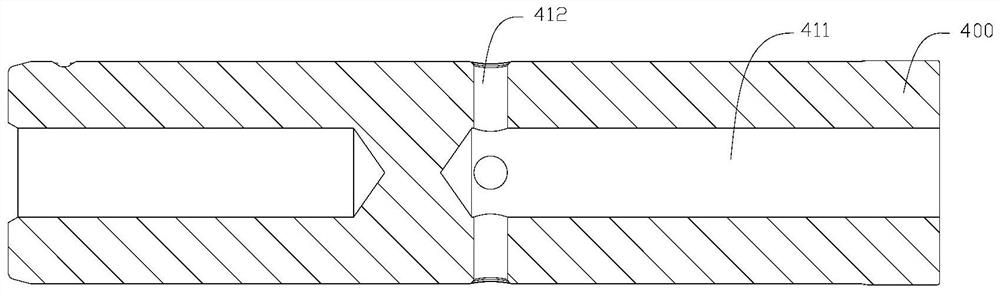

Auxiliary filling device and brake fluid filling system

ActiveCN113086932AIncrease oil intakeImprove filling efficiencyFluid actuated clutchesLiquid transferring devicesMaster cylinderEngineering

The invention provides an auxiliary filling device and a brake fluid filling system, wherein the auxiliary filling device is used for a hydraulic clutch pedal control mechanism, the hydraulic clutch pedal control mechanism comprises a clutch master cylinder, the auxiliary filling device comprises a shell and a filling piston, the shell is vertically arranged, the shell is provided with a cavity, a pipeline inlet is formed in the bottom wall of the cavity in a penetrating manner, and the pipeline inlet is used for being arranged at an oil outlet of the clutch master cylinder in a communicated manner; and the filling piston can be movably installed at the upper end of the cavity in the vertical direction, and the filling piston is provided with a sealing position for sealing the pipeline inlet and a communicating position for opening the pipeline inlet in the moving stroke of the filling piston. According to the technical scheme, by means of the auxiliary filling device, the vacuum degree in the clutch master cylinder is increased, and the filling and exhausting efficiency of the clutch master cylinder is improved.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

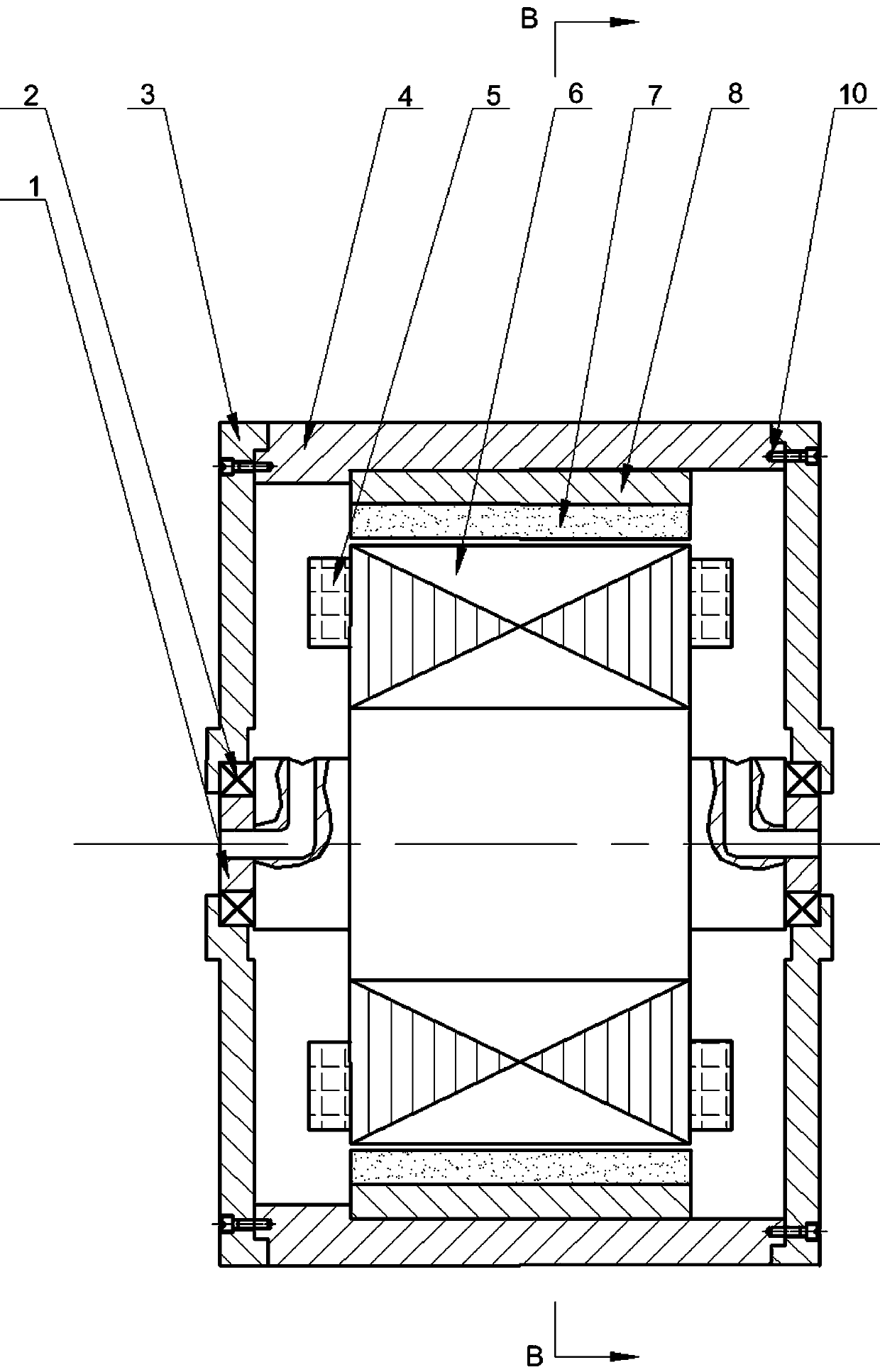

An oil-cooled, low-consumption inner rotor permanent magnet motor

ActiveCN106877578BReduce air gap magnetic field harmonicsImprove power densityMagnetic circuit rotating partsMagnetic circuit stationary partsInsulation layerFriction loss

Owner:哈尔滨深能电机有限公司

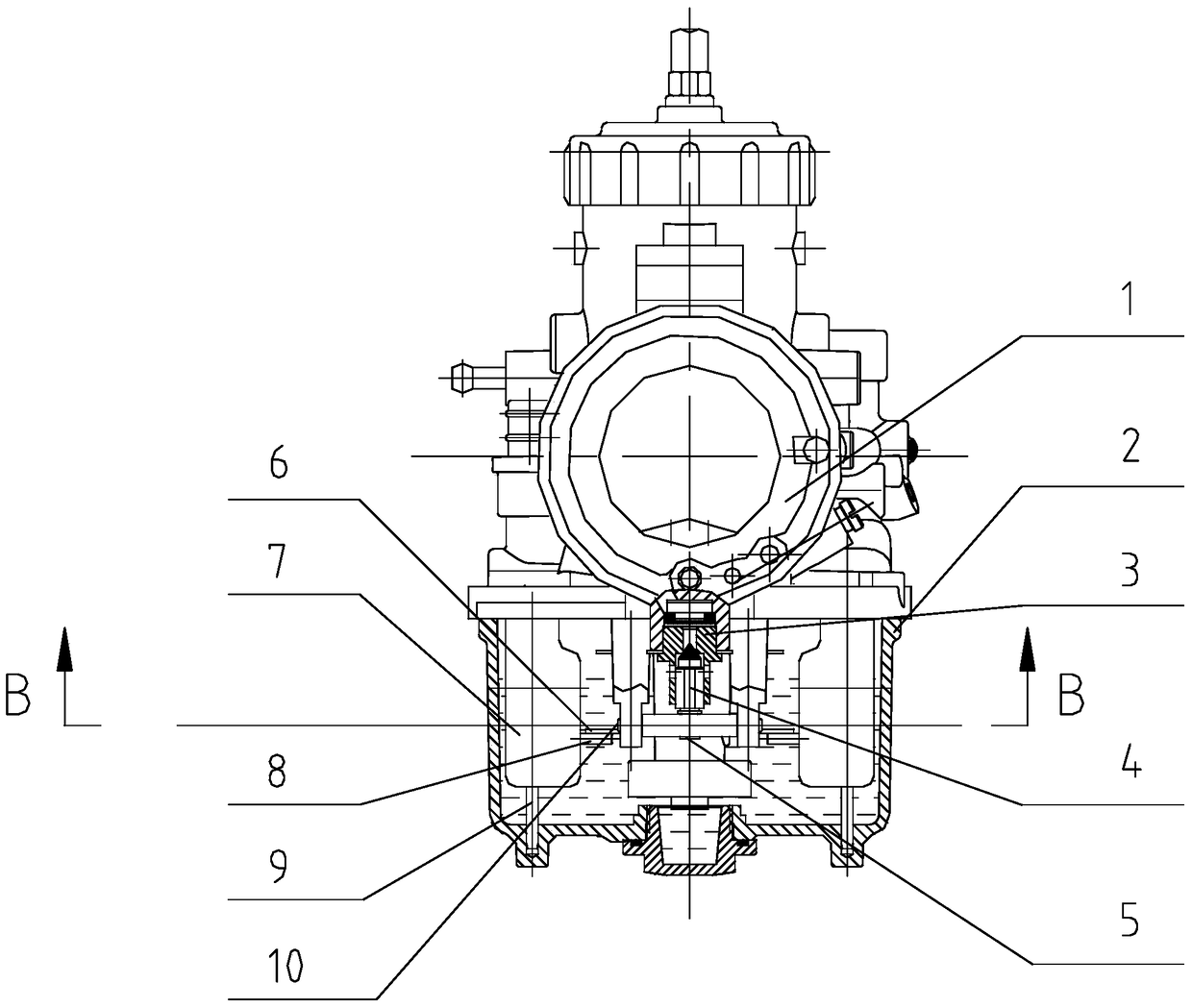

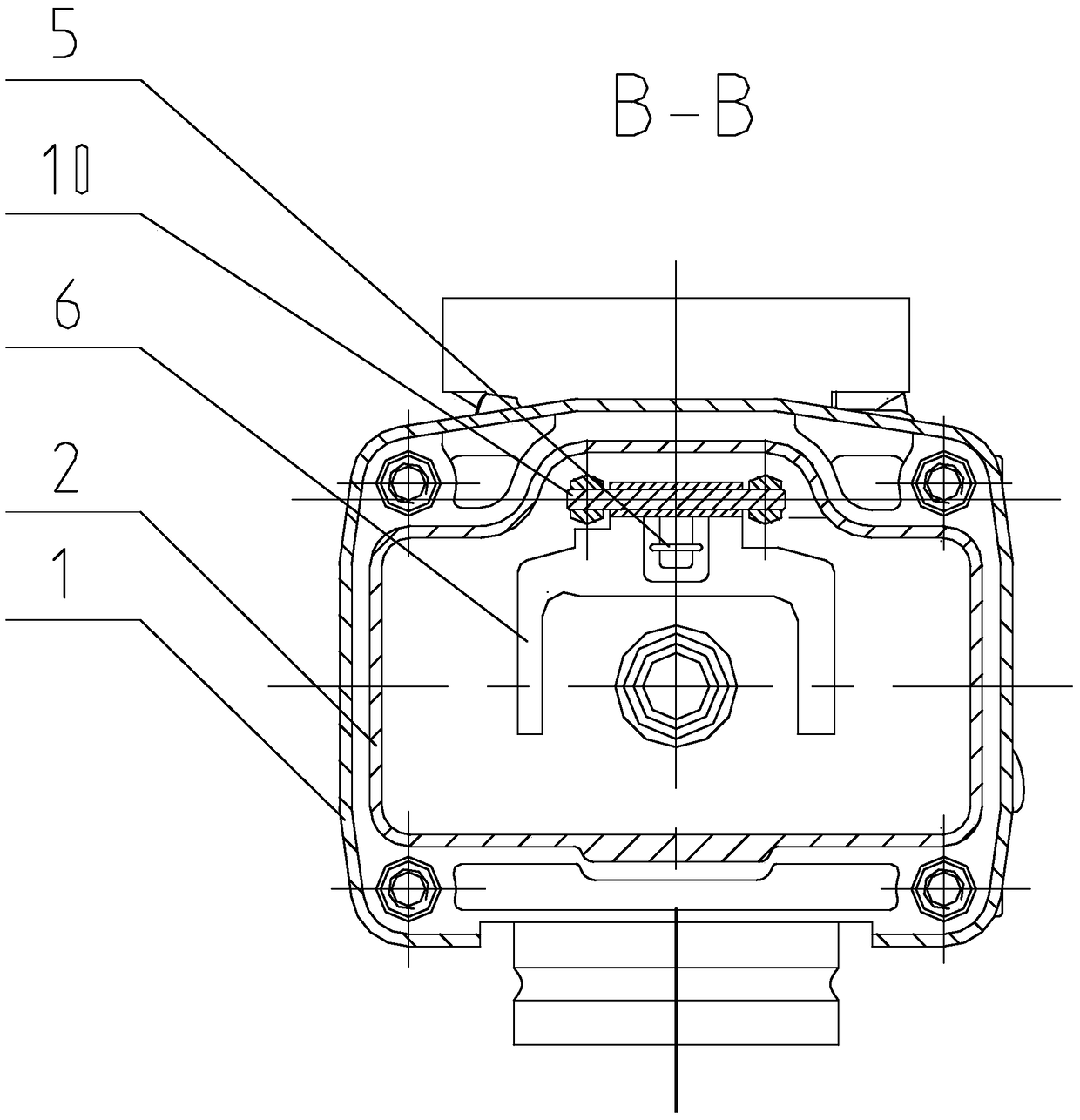

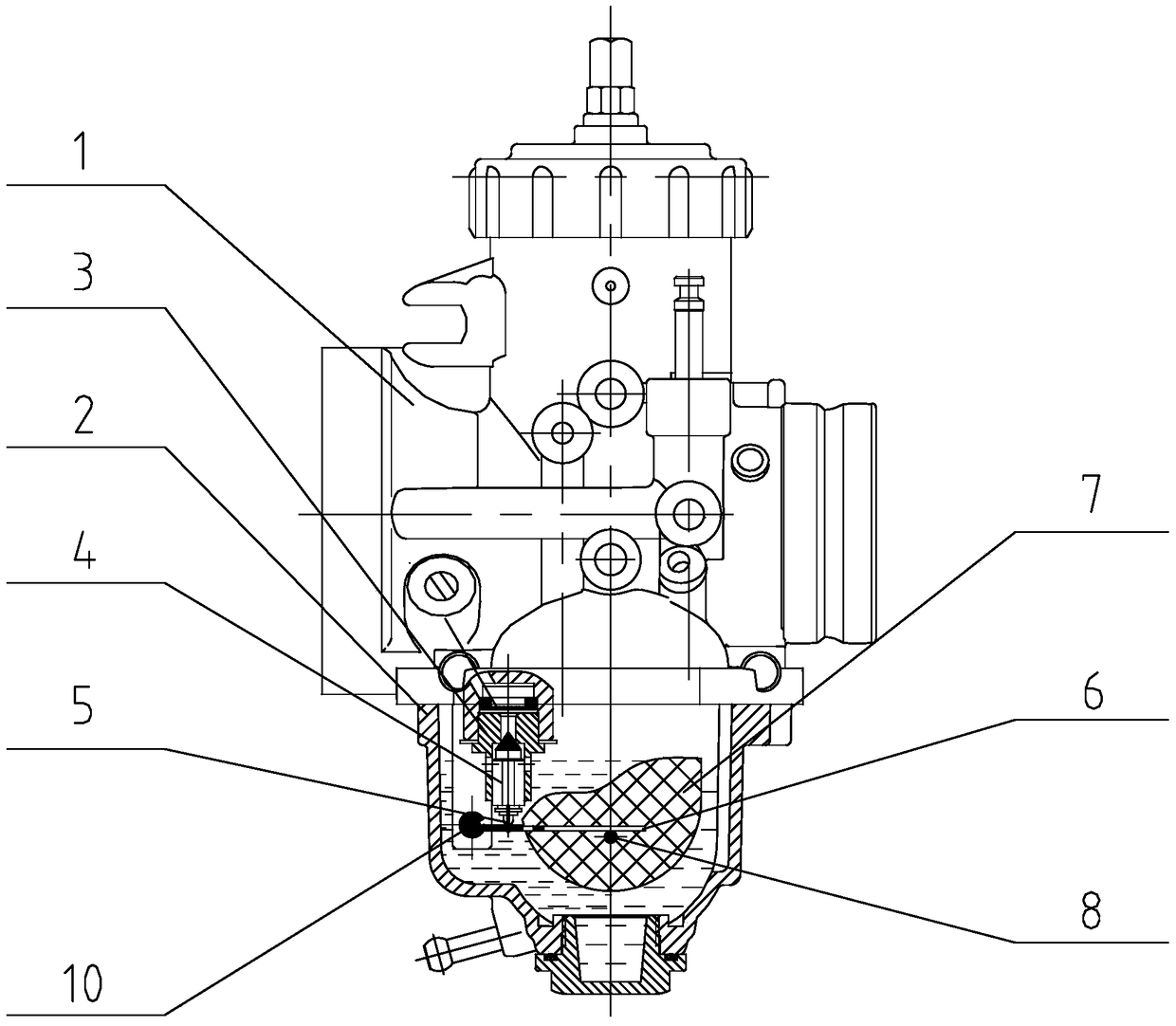

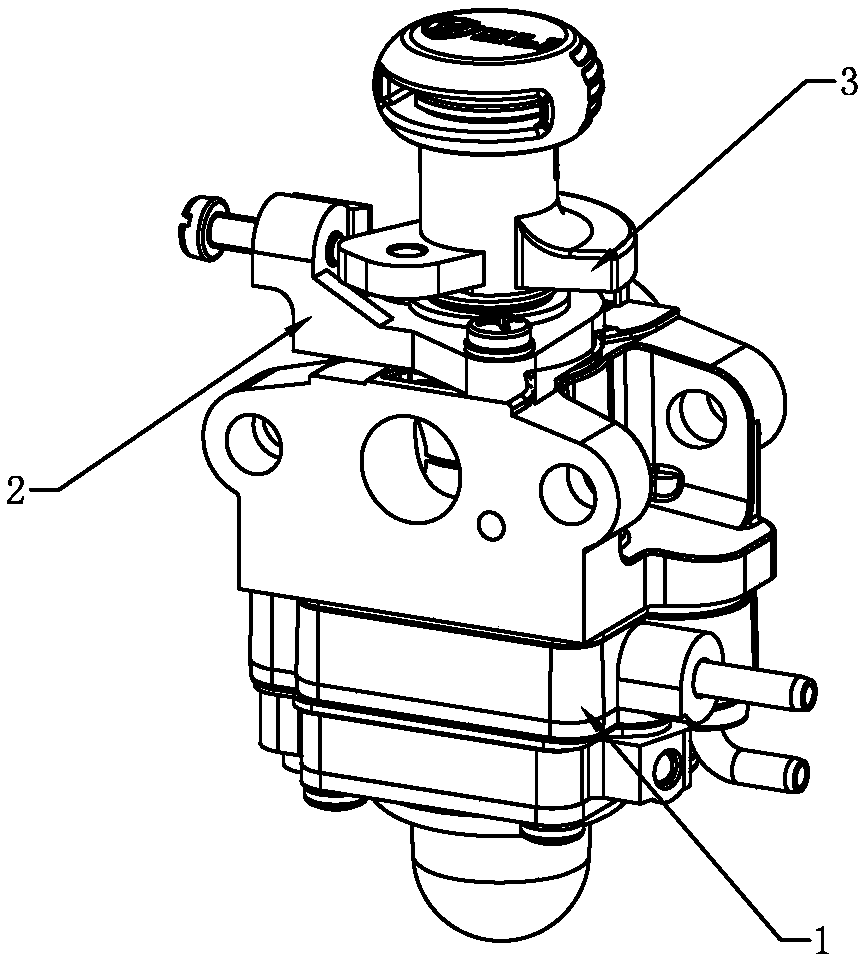

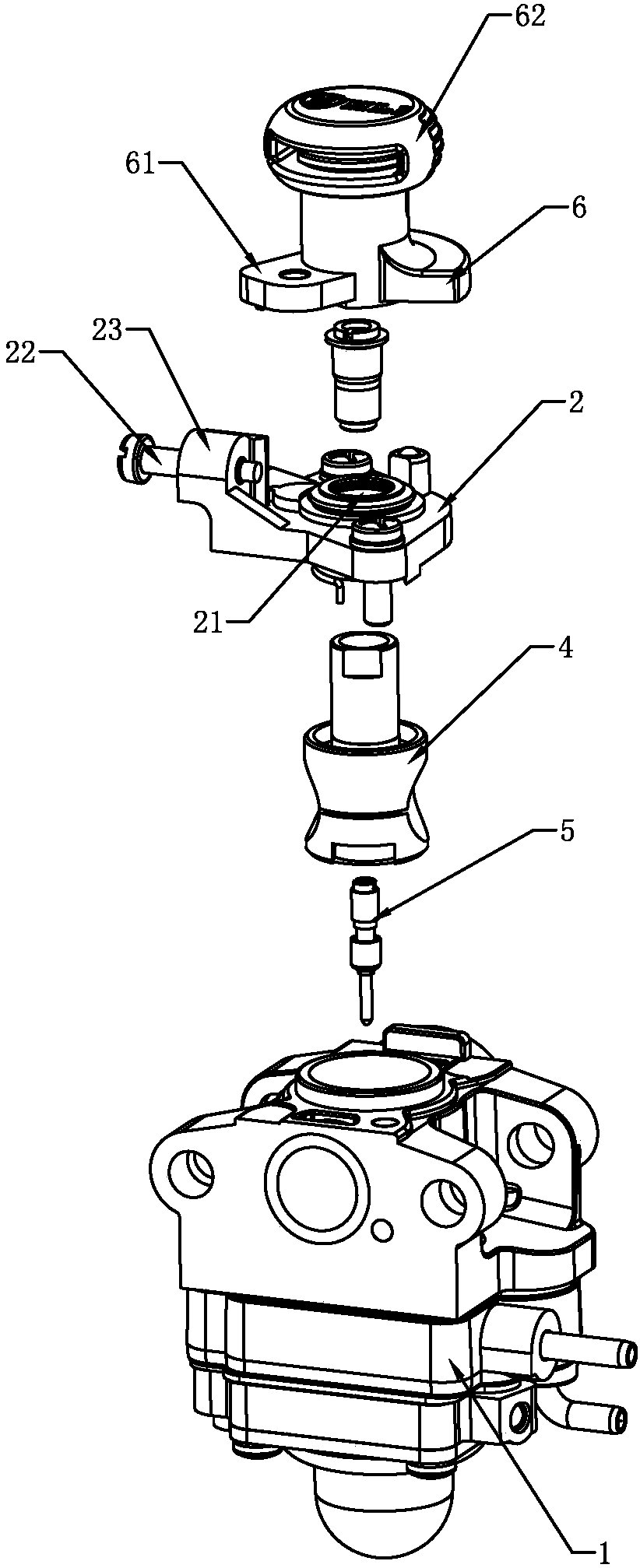

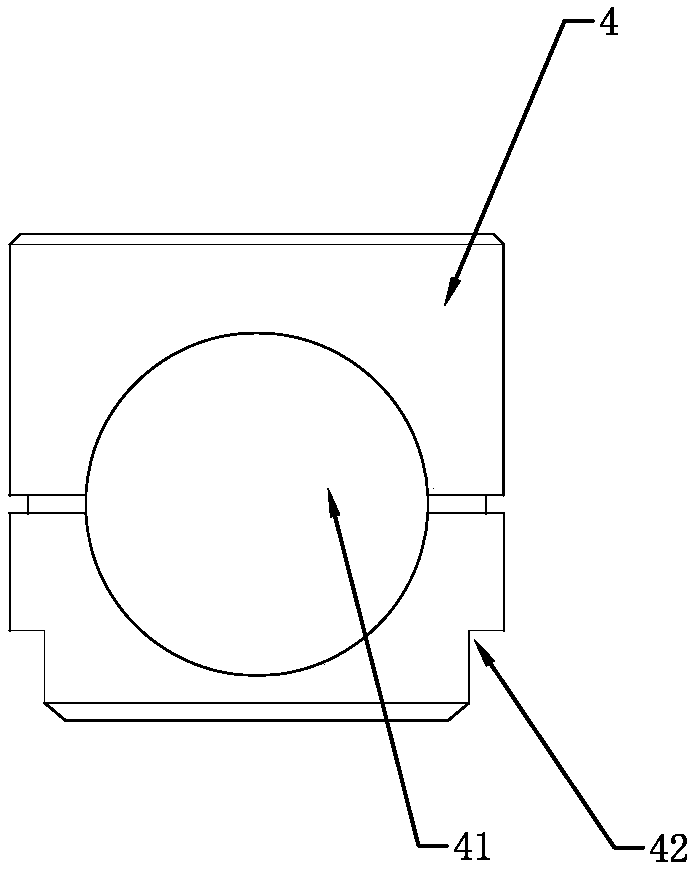

Vertical lifting oil plane carburetor

The invention discloses a vertical lifting oil plane carburetor, which comprises a carburetor float chamber, an oil inlet one-way valve seat, an oil inlet valve needle, an oil inlet valve needle hook, a float rocker arm, an independent float, a float lifting guide shaft, Float pin, float rotation shaft; there is an axial oil inlet hole in the oil inlet check valve seat body, and the oil inlet valve needle is movably assembled in the axial oil inlet hole; the float lifting guide shaft is vertically installed in the carburetor float chamber and The carburetor body is connected; the independent float is movably assembled on the float lifting guide shaft; the float pin is fixedly connected with the independent float; the float rotating shaft is installed horizontally in the carburetor float chamber; the front end of the float rocker arm is rotationally connected with the float rotating shaft, The middle part is hooked in the hook of the oil inlet valve needle, and the tail part is placed on the float pin. This kind of carburetor float has long stroke, large oil intake, high sensitivity, and can precisely control the oil level. Moreover, it occupies a small volume, and the volume of the float can be appropriately increased to increase the buoyancy to provide a reliable seal and eliminate the potential safety hazard of oil leakage.

Owner:福鼎市丰泰化油器制造有限公司

Preparation method of shark bone pet molar toy

ActiveCN108013254BHigh oil contentIncrease oil intakeAnimal feeding stuffAccessory food factorsVitamin CVitamin

Owner:温州致兴宠物营养科技有限公司

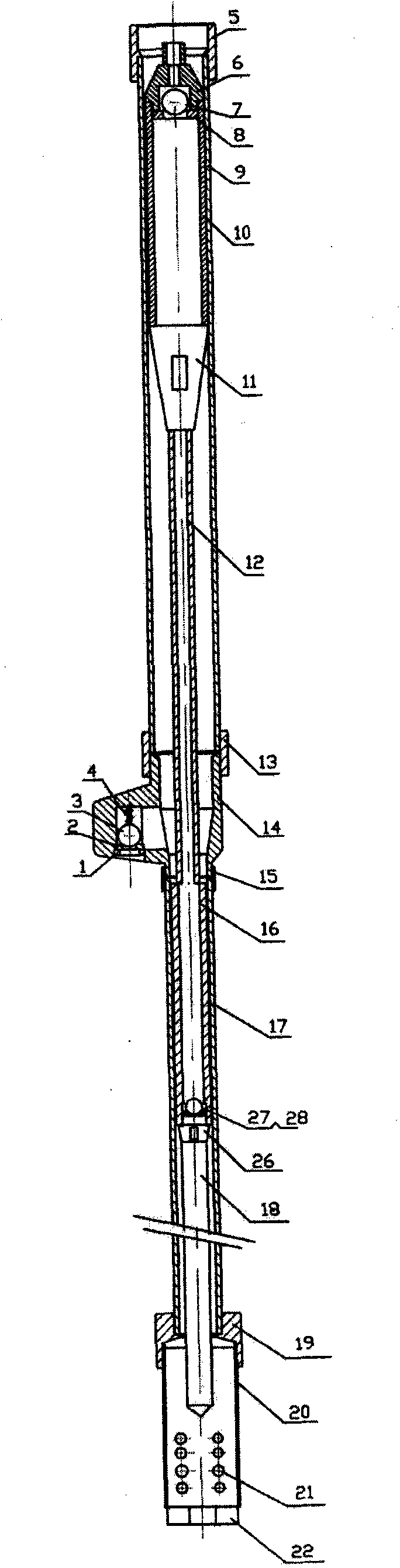

Oil extraction method of weight adding under pump and oil well pump with weight adding under pump

InactiveCN101949277BReduce eccentric wearReduce mutual wearFlexible member pumpsFluid removalFill factorInlet valve

The invention discloses an oil extraction method of weight adding under a pump and an oil well pump with weight adding under the pump, used in pumping units and oil pumped wells in the petroleum industry. In the oil extraction method of weight adding under the pump, a weight adding bar is connected under an oil well pump plunger assembly to reduce the bend and the deformation of a pumping rod string. The oil well pump with weight adding under the pump comprises a pump cylinder assembly, the plunger assembly and an auxiliary mechanism under the pump. The plunger assembly is provided with a liquid outlet valve and a liquid inlet pump, an upper plunger and a lower plunger are connected with a connection bar through a plunger lower joint to connect the weight adding bar under the plunger assembly. The method uses the liquid inlet valve with an offset structure outside the pump while adding weight under the pump, thereby lightening the eccentric wear of pipes and bars and reducing the stroke loss. Due to the weight adding bar arranged under the pump, the pumping rod is kept in the straightening state all the time under the action of gravity, thereby lightening the mutual abrasion of the pipes and the bars. The weight adding under the pump can reduce the elastic bending and deformation of the pumping bar string, thereby reducing the stroke loss and enhancing the filling factor of the oil well pump.

Owner:CHINA PETROLEUM & CHEM CORP +1

Carburetor provided with rotary valve and capable of being started rapidly

PendingCN107795411AIncrease oil intakeSimple processMachines/enginesCarburettorsRotary valveEngineering

The invention discloses a carburetor provided with a rotary valve and capable of being started rapidly. The carburetor comprises a carburetor body, a fixing frame and a starting device, the fixing frame is detachably arranged on the carburetor body, and the starting device comprises the rotary valve capable of rotating around the longitudinal axis so as to open or close a mixing channel. A cylindrical cavity is formed in the rotary valve, a ventilating hole is further formed in the outer wall, perpendicular to the cylindrical cavity, on the rotary valve, and an oil needle concentric with the rotary valve is arranged in the rotary valve. A rocker arm capable of driving the rotary valve to rise is connected to the upper portion of the rotary valve, the rotary valve and the rocker arm are connected through a through hole penetrating through the middle of the fixing frame, and a reset spring is arranged between the rotary valve and the fixing frame. According to the carburetor, the rockerarm can drive the rotary valve to rise, the size of a fuel spray nozzle of a main jet is changed by moving the oil needle, the air inlet quantity is also increased through the ventilating hole while the oil inlet quantity is increased, the process is simple, and using is convenient.

Owner:JIANGMEN HUALIAN IND

Lubricating system of reduction gearbox

PendingCN114857249AImprove performanceExtended service lifeGear lubrication/coolingWind energy generationThermodynamicsGear wheel

The invention provides a reduction gearbox lubricating system. The reduction gearbox lubricating system comprises a gearbox shell, a sun gear, a planet carrier, a gear ring, an annular oil baffle plate and a forced lubricating unit. The housing is provided with a first bearing and a second bearing. The central gear is rotatably arranged on the box shell. The planet carrier is simultaneously connected with the first bearing and the second bearing; the planet carrier is provided with a planet wheel assembly with a first oil conveying hole. The gear ring is connected with the box shell, and the planetary gear is meshed with the gear ring. The annular oil baffle plate is connected with the planet carrier, and the forced lubrication unit is configured to force lubricating oil to enter the first bearing. And at least part of the first bearing is located in an area defined by the annular oil baffle plate, so that lubricating oil leaving from the first bearing falls into the annular oil baffle plate, the annular oil baffle plate is used for pressing the lubricating oil into the first oil conveying hole in the rotating process, and the lubricating oil in the first oil conveying hole can sequentially enter the planet wheel assembly and the second bearing. The lubricating effect is good.

Owner:南京南高齿新能源汽车传动设备有限公司

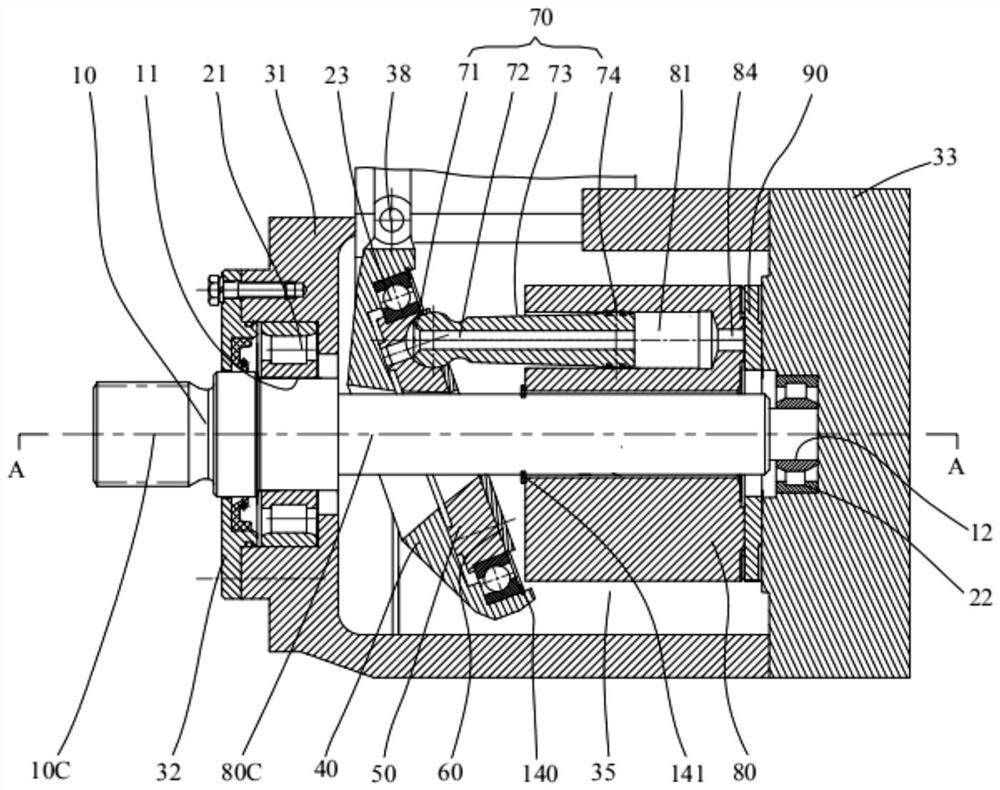

Sliding disc type axial plunger pump

PendingCN114562437AReduce axial forceOil film stabilizationPositive displacement pump componentsPositive-displacement liquid enginesBearing surfacePlunger pump

The sliding disc type axial plunger pump comprises a flow distribution sliding disc pair, a plunger pair and a flow distribution pair, the flow distribution sliding disc pair comprises a swash plate and a sliding disc supported on the swash plate, the sliding disc is of an integral structure, kidney-shaped holes communicated with center holes of plungers are formed in the sliding disc, and the plunger pairs are arranged in the kidney-shaped holes. A low-pressure oil distribution hole serving as an oil inlet channel is formed in the portion, opposite to the low-pressure plunger hole, of the swash plate supporting face, static pressure supporting is formed by the portion, opposite to the high-pressure plunger hole, of the swash plate supporting face and a kidney-shaped hole of the sliding plate, and the low-pressure oil distribution hole is communicated with a shell cavity through an oil inlet groove formed in the swash plate. Low-pressure oil enters a plunger hole of the cylinder body from a low-pressure flow distribution opening and an oil inlet groove or a groove-shaped low-pressure opening of the swash plate in a double-way mode, high-pressure oil is discharged from a high-pressure flow distribution opening of the flow distribution plate or a groove-shaped high-pressure opening of the swash plate in a single-way mode, and suction and discharge of hydraulic oil are achieved. The axial stress of the bearing can be further reduced, the stress working condition of the bearing is improved, the self-suction capacity is improved, the oil temperature is reduced, the working reliability of the plunger pump is improved, and the working life of the plunger pump is prolonged.

Owner:钟彪

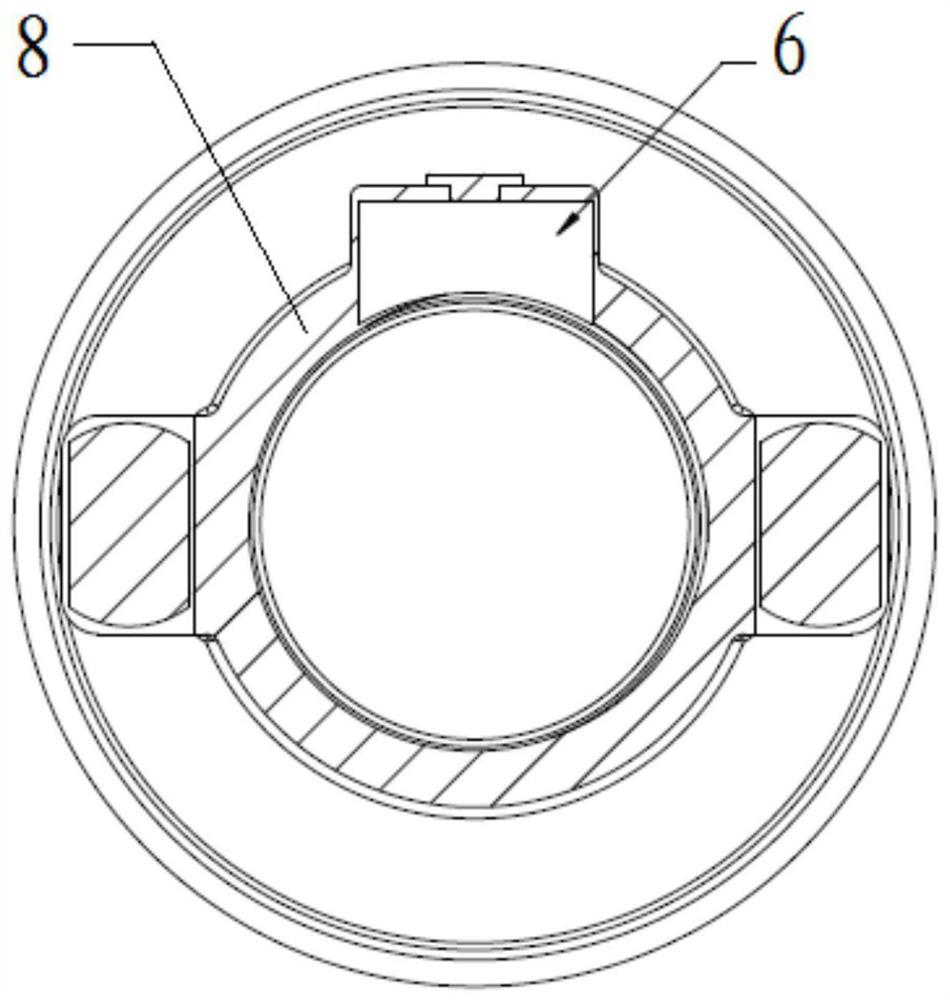

Roller bearing assembly structure

PendingCN111167865AFirmly assembledImprove performanceMetal rolling stand detailsMetal rolling arrangementsStructural engineeringMechanical engineering

The invention belongs to the technical field of steel rolling equipment, and particularly relates to a roller bearing assembly structure. A roller is rotatably installed in a bearing seat through a cylindrical roller bearing and a tapered roller bearing; an axial positioning assembly is installed on the roller, and the cylindrical roller bearing and the tapered roller bearing are axially positioned through the axial positioning assembly; a first oil inlet channel and a second oil inlet channel are axially arranged in the bearing seat; and a plurality of annular oil grooves are formed in the wall of an inner hole of the bearing seat, the first oil inlet channel communicates with the annular oil grooves through a plurality of first branches, and the second oil inlet channel communicates withthe annular oil grooves through a plurality of second branches. With the roller bearing assembly structure, the problems about roller assembly in the prior art can be solved, and the problem of poorbearing lubrication effect caused by unreasonable lubrication channels at present is also solved.

Owner:中重科技(天津)股份有限公司

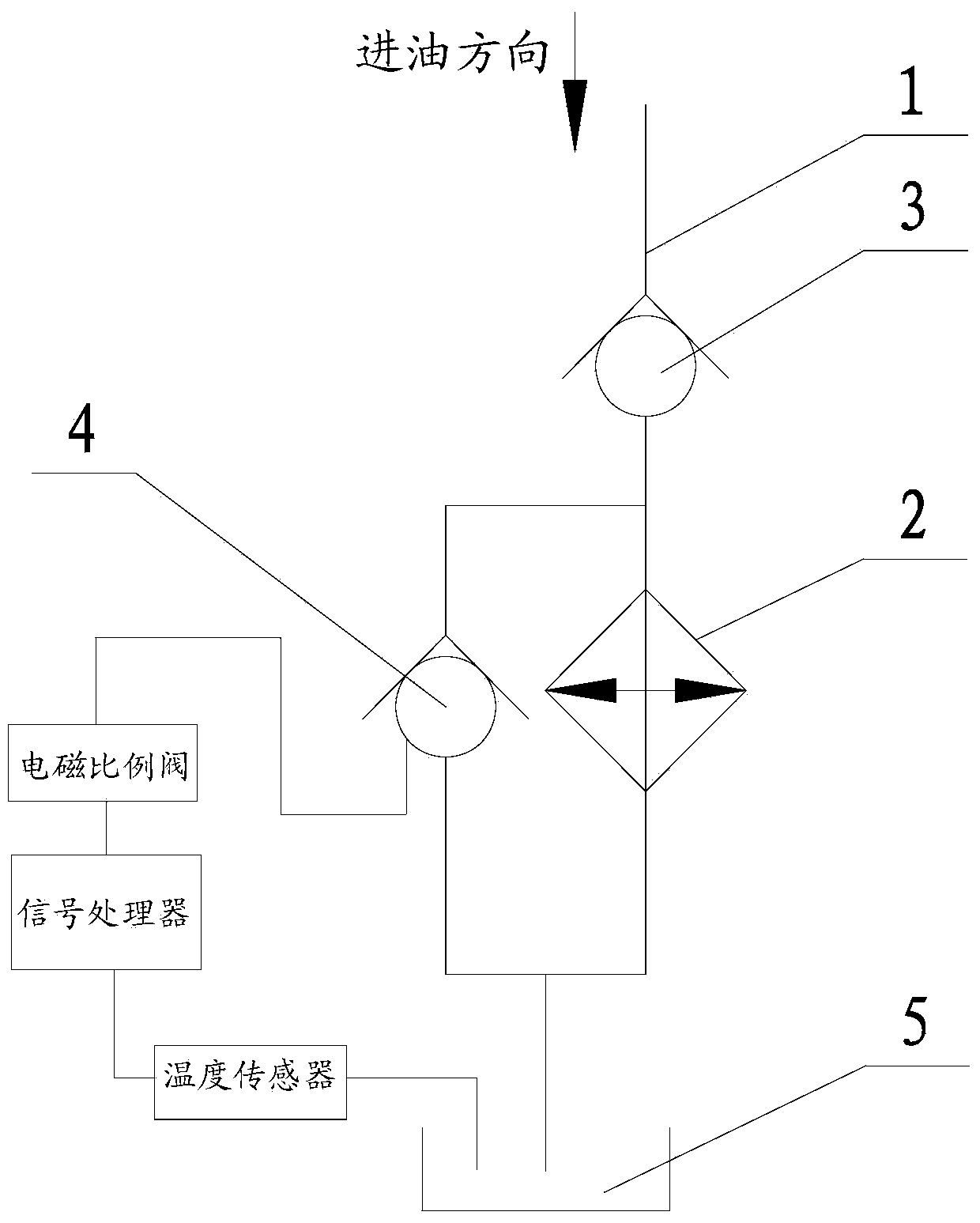

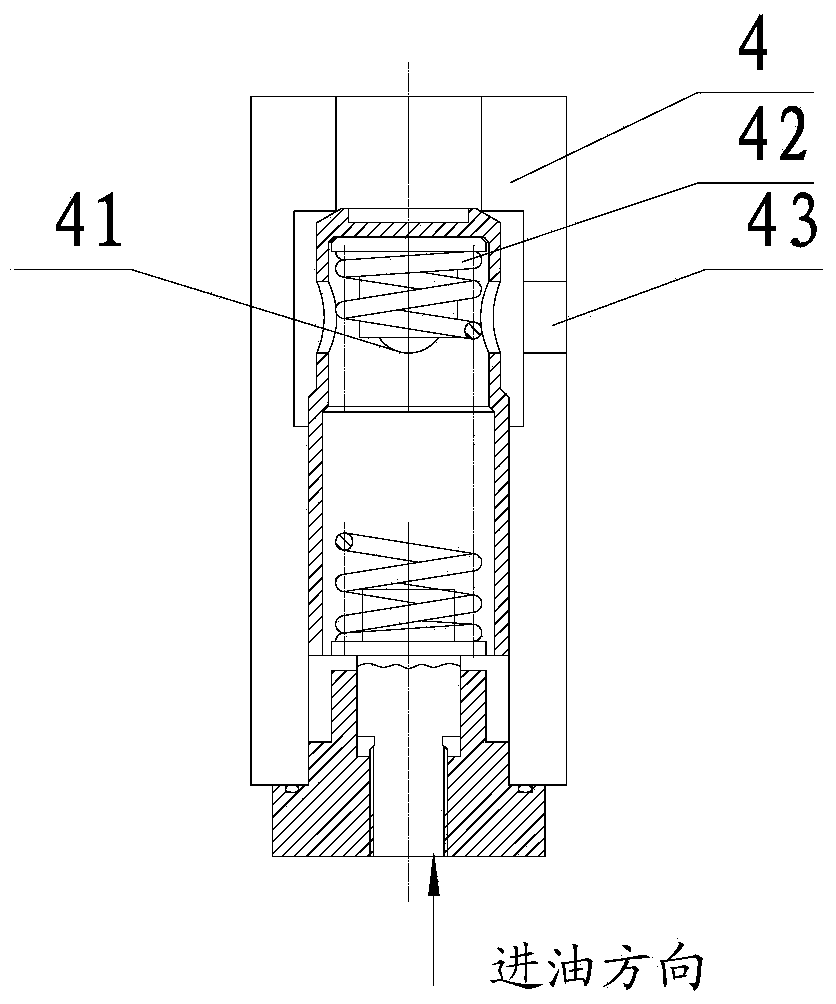

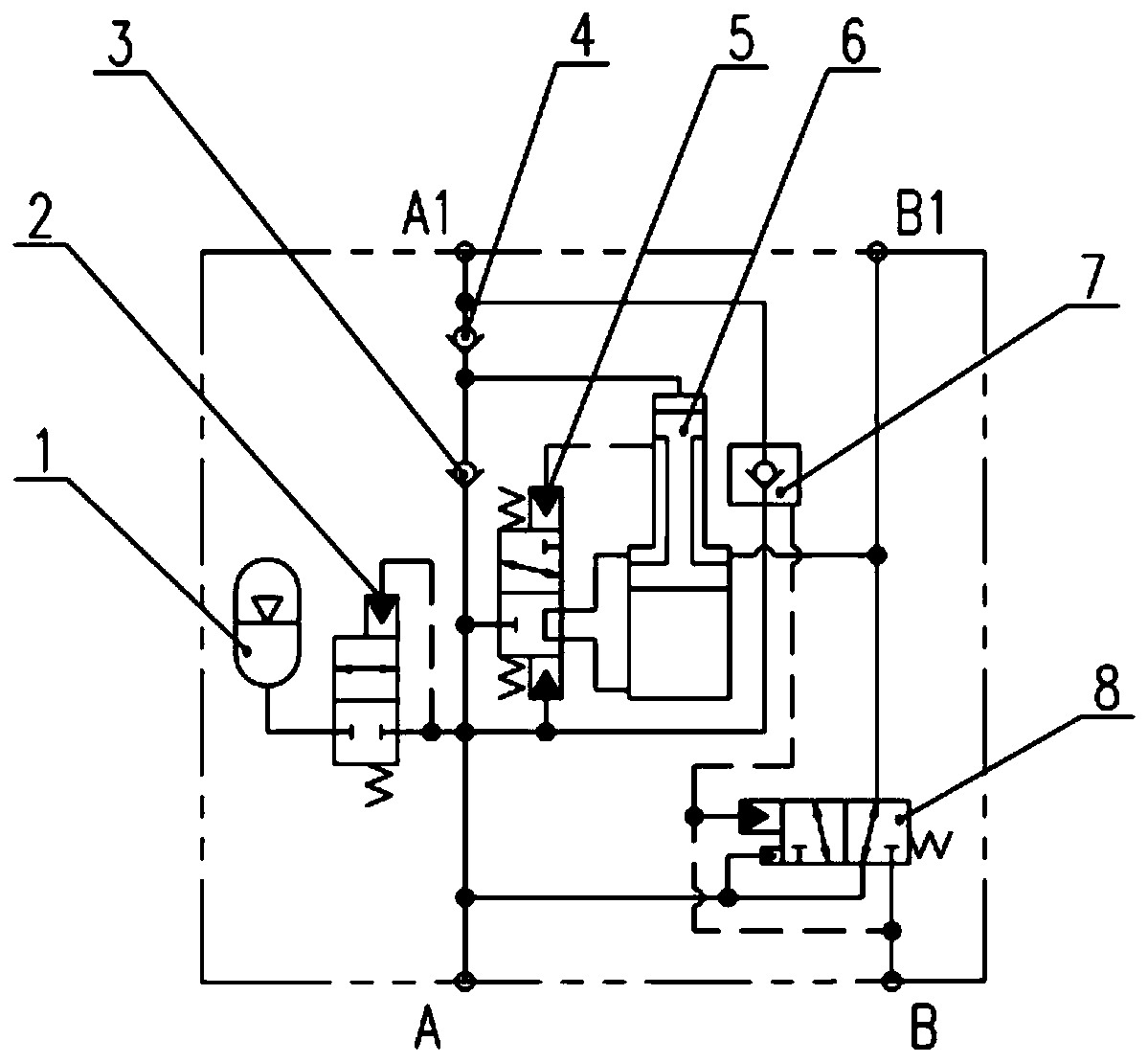

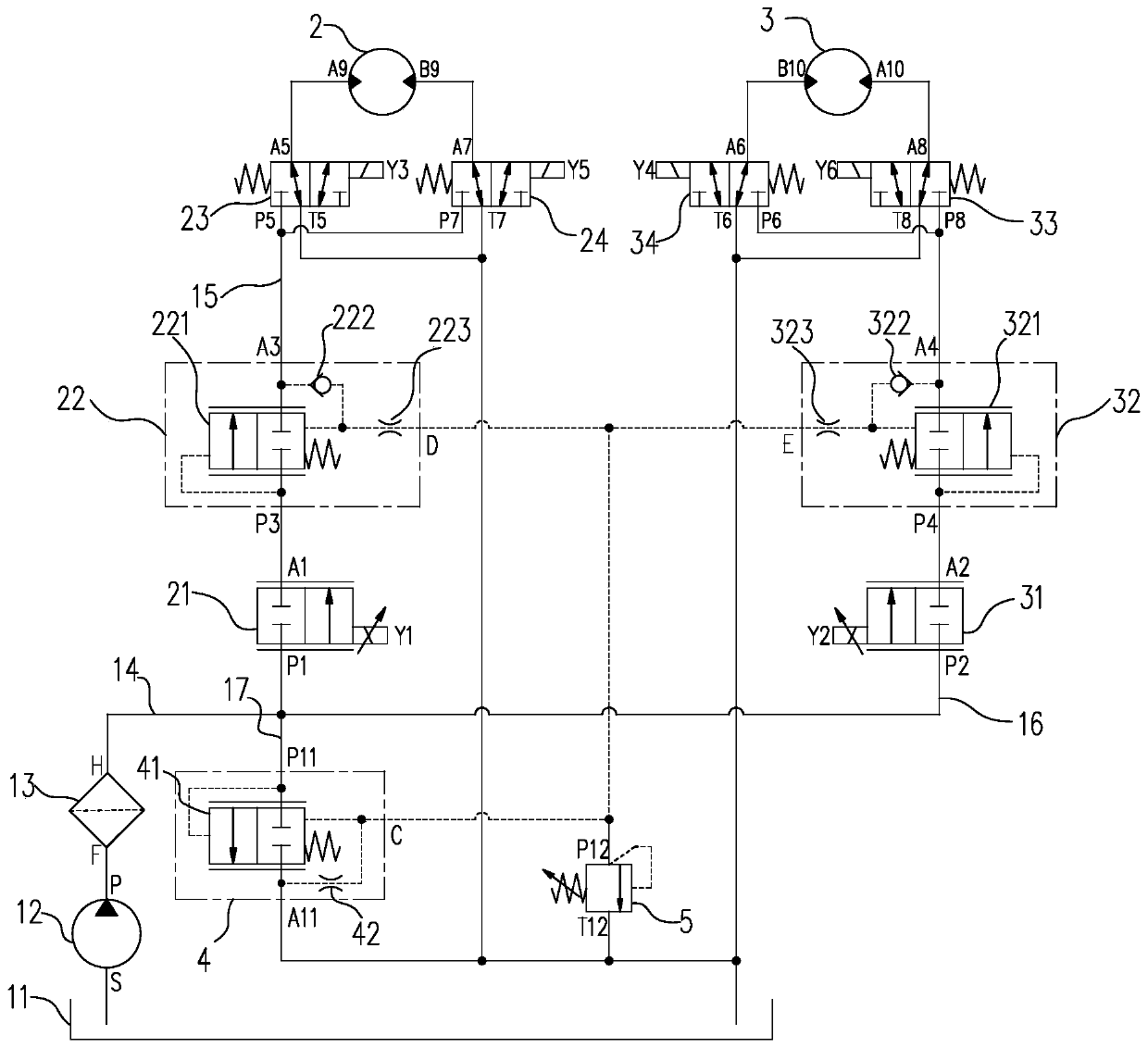

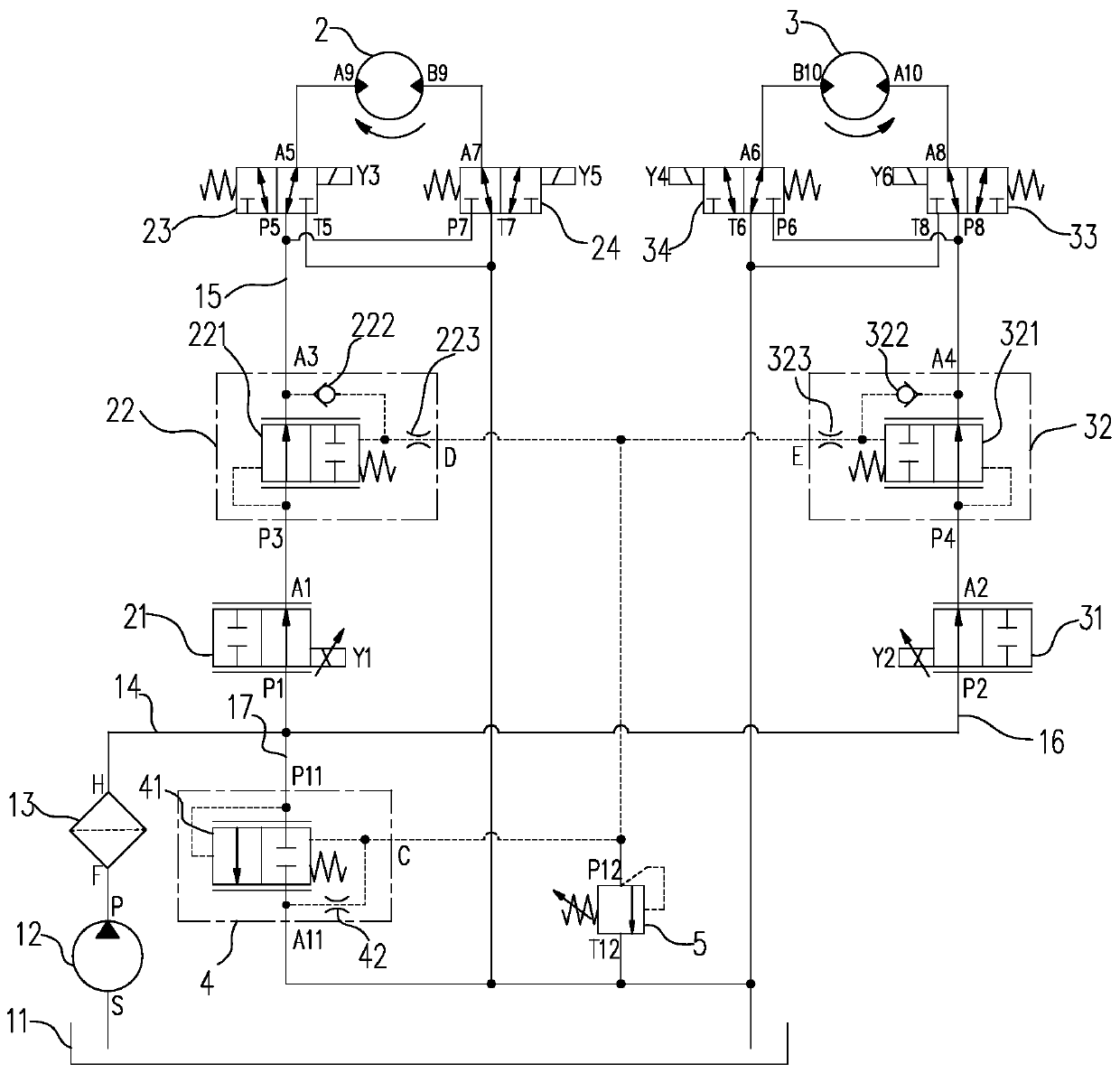

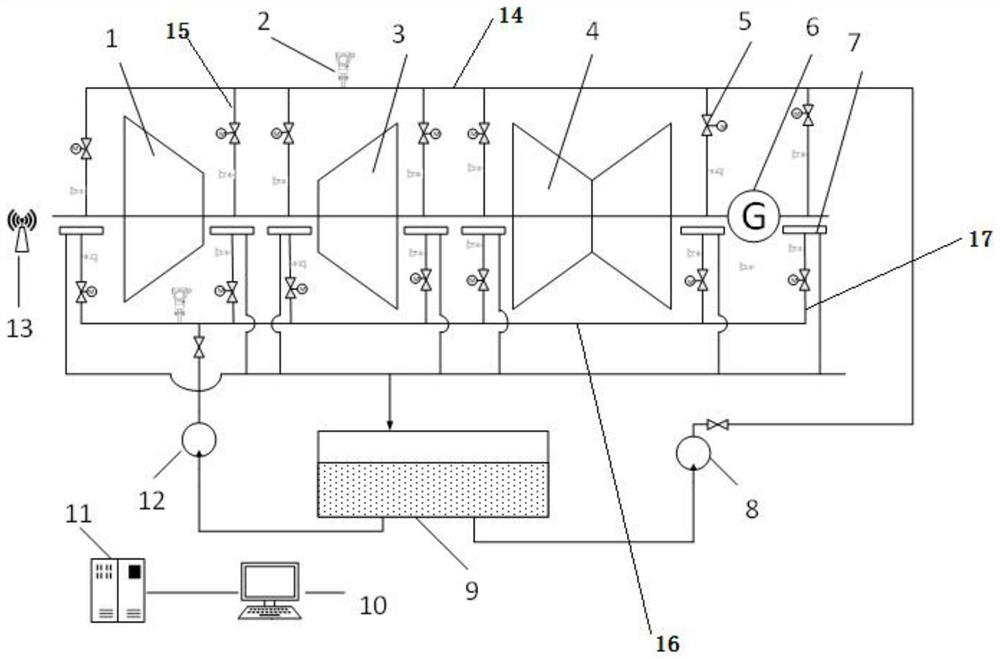

Motor driven hydraulic control system with adaptive flow distribution function

PendingCN111503069AIncrease oil intakeGuaranteed to workFluid-pressure actuator testingServomotor componentsHydraulic motorControl system

The invention discloses a motor driven hydraulic control system with an adaptive flow distribution function. The system comprises a hydraulic oil tank, a first hydraulic motor and a second hydraulic motor; the first hydraulic motor is connected with a first motor control valve, a first flow regulator and a first motor rotating direction controller; the second hydraulic motor is connected with a second motor control valve, a second flow regulator and a second motor rotating direction controller; the system further comprises a third flow regulator; pressure sensing ports of the three flow regulators communicate with one another; when load of one hydraulic motor is increased, the three flow regulators cooperate for work, the oil intake amount of the motor is increased, the oil intake amount of the other motor is reduced, normal work is guaranteed, and after the load returns to normal, the normal hydraulic state is restored under cooperative adjustment of the three flow regulators. The system has the characteristics of producing little heat and being more energy-saving; one pump controls multiple motors, an electrical control system is not needed, and the cost is relatively low; and the scheme is easy to implement, and the operation effect is better.

Owner:WUZHENG

The method of rubbing wood wax oil on the surface of wood products

InactiveCN103182725BIncrease exerciseIncrease oil intakeCoating impregnationCoatingsWaxEnvironmentally friendly

The invention relates to a method for smearing wood wax oil on the surface of a wood product, which comprises the following steps: 1, smoothening; 2, smearing the wood wax oil; 3, kneading a wax oil coating on the surface; 4, wiping floating oil; 5, drying; 6, repeating the steps 2-5 for one or two times; 7, polishing till the hand feeling is smooth; and 8, spraying polishing wax, polishing and entering a next assembly process. By using the method, the crack of the wood product can be effectively prevented, and the service life is prolonged; the operation is simple, and materials, labors and oil are saved; the wood wax oil is a green and environmentally-friendly coating and a low-carbon environmentally-friendly product; and by using the method, the wide application of the wood wax oil can be promoted, and an important significance on environment friendliness is realized.

Owner:张克广

Auxiliary filling device and brake fluid filling system

ActiveCN113086932BIncrease oil intakeImprove filling efficiencyFluid actuated clutchesLiquid transferring devicesMaster cylinderEngineering

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

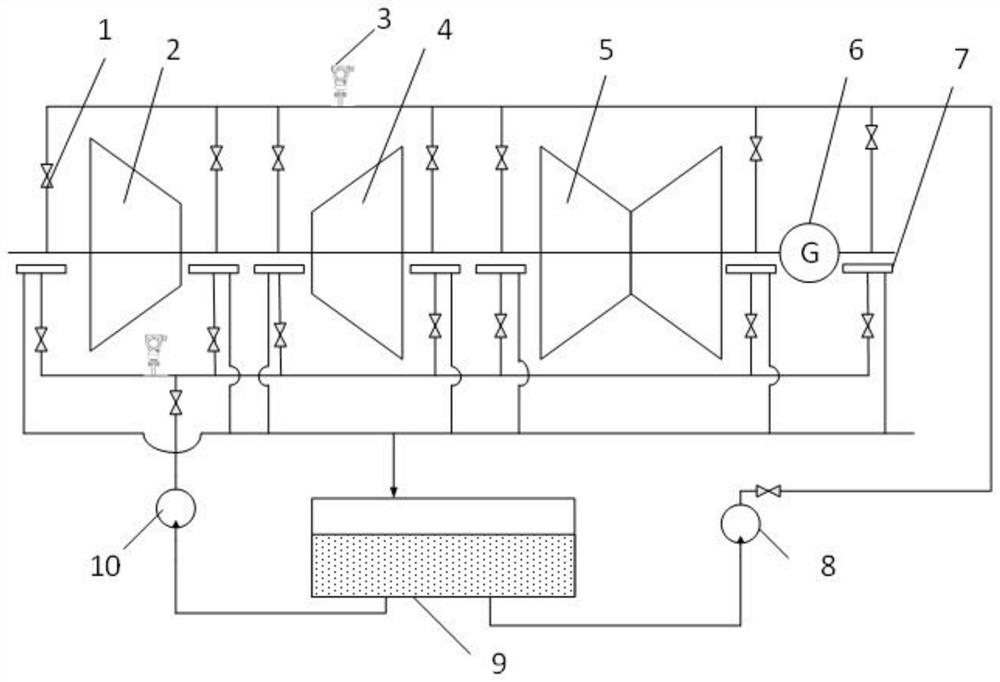

Lubricating oil and jacking oil adjusting device for power plant

PendingCN113983339AConvenient wireless transmissionSave manpower and timeSignal processingBearing coolingProcess engineeringElectric generator

The invention discloses a lubricating oil and jacking oil adjusting device for a power plant, and relates to the field of power plants, the lubricating oil and jacking oil adjusting device comprises a lubricating oil tank, a high-pressure cylinder, a medium-pressure cylinder, a low-pressure cylinder, a generator and a plurality of groups of bearings, the lubricating oil tank is connected with a jacking oil pump and a lubricating oil pump, and the jacking oil pump is connected with the lower parts of the plurality of groups of bearings through jacking oil pipelines, a lubricating pipeline of the lubricating oil pump is connected with the multiple sets of bearings, each of a first main pipe and a second main pipe is provided with a teletransmission pressure transmitter, the multiple sets of first branch pipes and second branch pipes are each provided with an electric adjusting door, the teletransmission pressure transmitters are wirelessly connected with a wireless repeater, and the wireless repeater is wirelessly connected with a server. The device can achieve the purpose of convenient and rapid wireless transmission, saves a lot of manpower and time due to the remote automatic adjustment, can be used for the progress grabbing of other equipment, and achieves the purpose of rapid completion on the premise that the time and manpower are not changed.

Owner:NORTHWEST BRANCH OF CHINA DATANG CORP SCI & TECH RES INST +1

Cylinder liner fatigue test device

ActiveCN103759926BPromote reproductionEliminate sealing hazardsMachine part testingEngine testingCombustion chamberCombustor

The invention relates to a cylinder sleeve fatigue test device. An annular sunk groove (13) and an annular sealing protrusion (14) used for supporting a cylinder sleeve (3) are arranged on a bearing cylinder body (1), a counter bore matched with a combined cylinder cover (2) is formed in an upper opening of the cylinder body, an oil inlet port and a sensor port are formed in an oil inlet (6) and an upper port of a pressure monitoring hole (7) in the cylinder body respectively, the cylinder sleeve (3) is arranged in the bearing cylinder body (1), the combined cylinder cover (2) is arranged in the counter bore of the combined cylinder cover (2) and the cylinder sleeve (3) in a sealing sleeved mode, a cylinder cushion (4) is arranged at the position where the combined cylinder cover (2) is connected with the cylinder sleeve (3), and an upper edge opening of the cylinder sleeve (3) and a simulation combustor cavity form a simulation combustor (8). According to the cylinder sleeve fatigue test device, sealing hidden troubles in the cylinder body are eliminated, stability of the test process is improved, the adjusting range of the pressure in the cylinder body is enlarged, and a cylinder sleeve fatigue examination and a fault reappearance test are facilitated.

Owner:CHINA NORTH ENGINE INST TIANJIN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com