Accelerating and pressurizing system

A technology of booster system and switching valve, which is applied in fluid pressure converter, fluid pressure actuating device, servo motor, etc., can solve the problem of high cost, and achieve fast no-load operation speed, low cost, and increase in size. The effect of maximum output force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

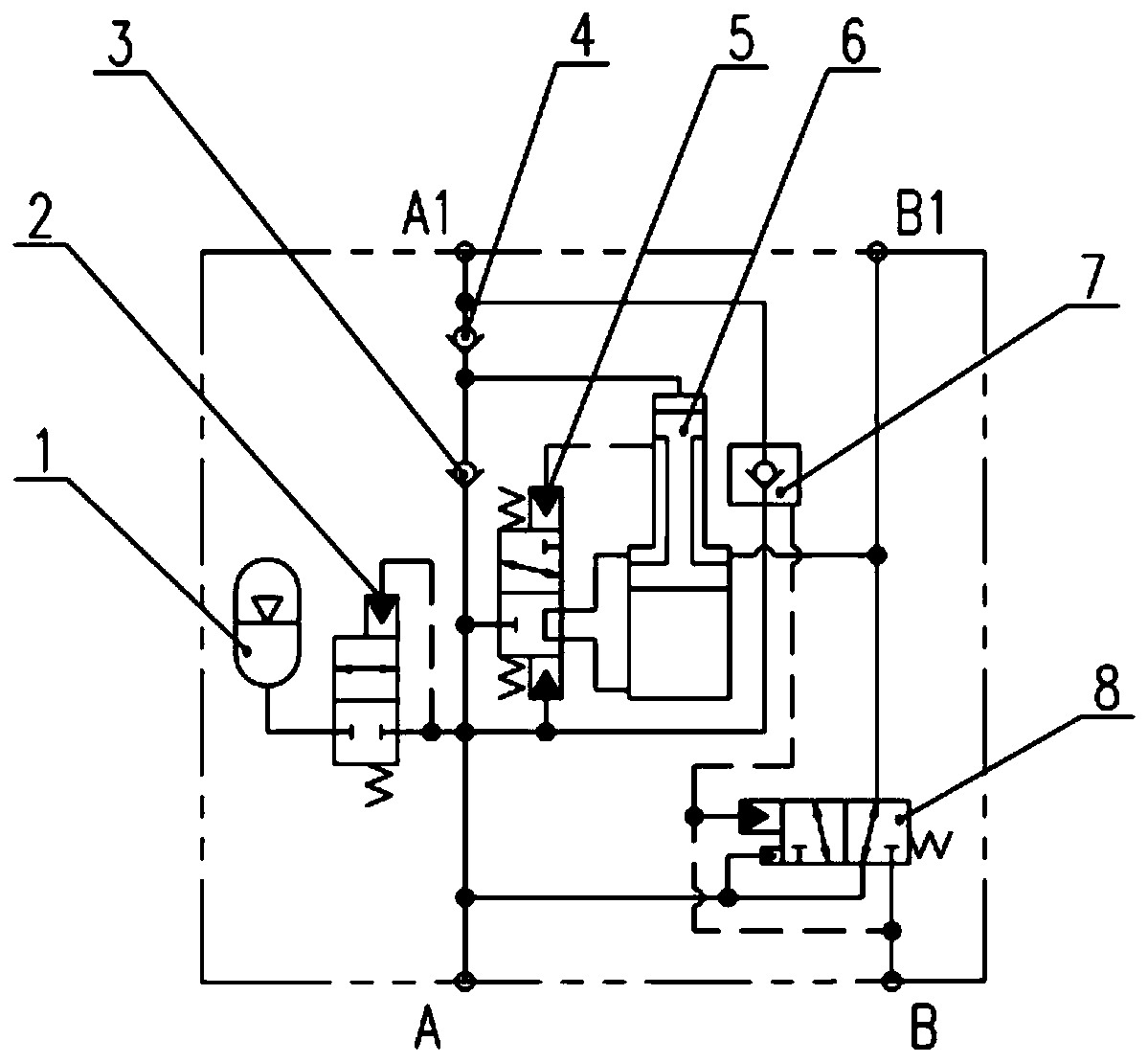

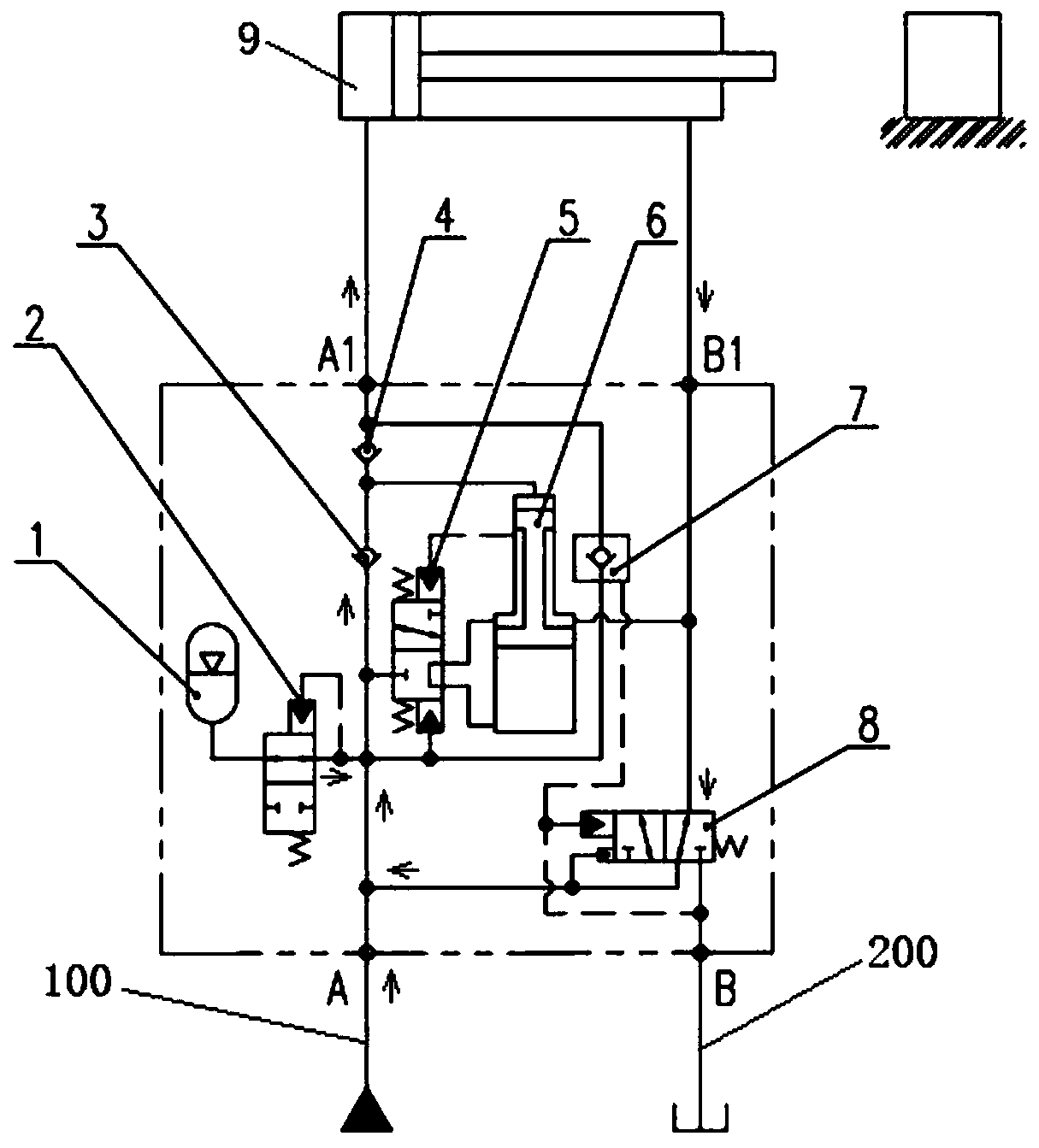

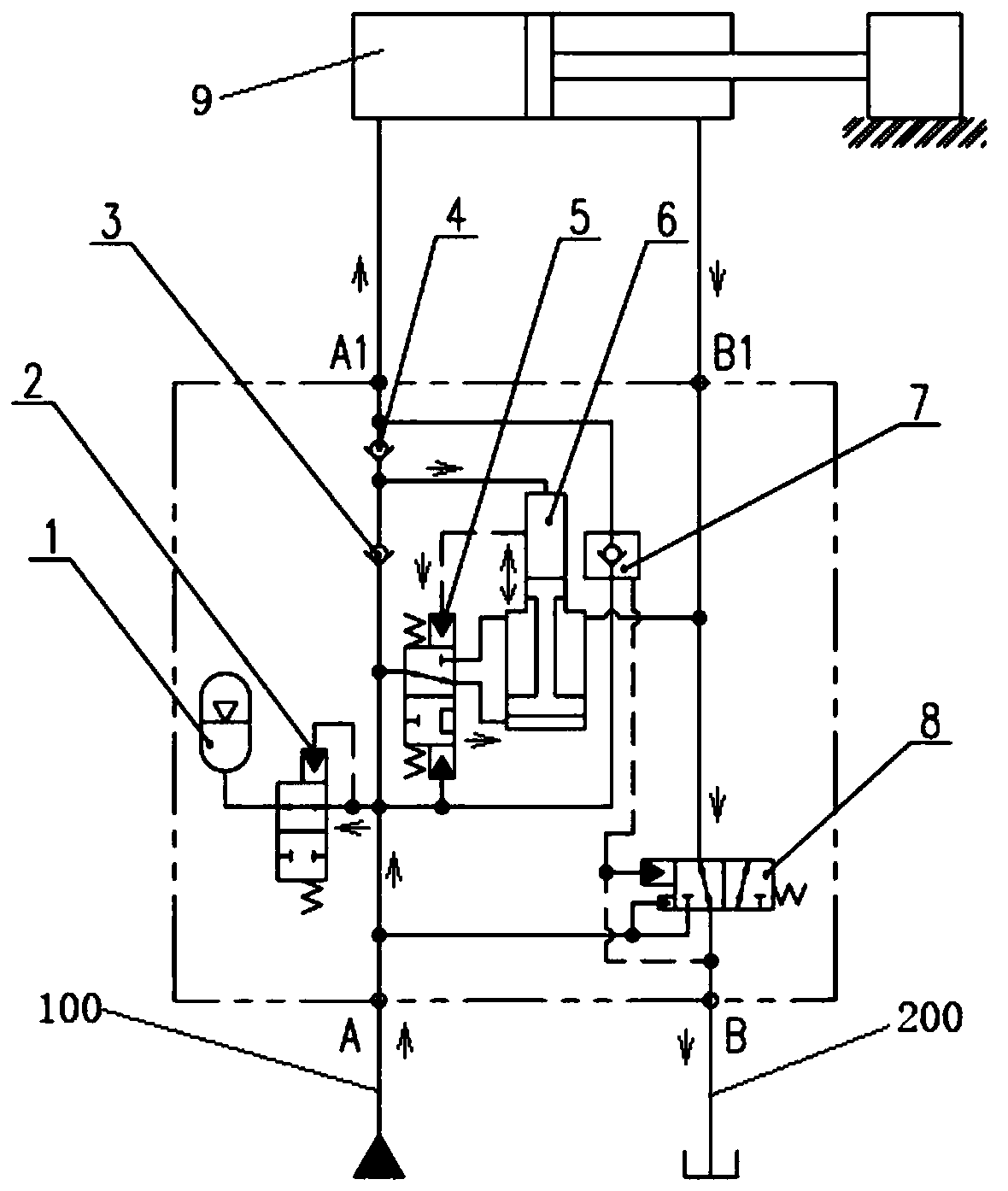

[0030] see figure 1 , the acceleration and supercharging system in the illustration is a specific embodiment of the present invention, specifically including an accumulator 1, a first switching valve 2, a first one-way valve 3, a second one-way valve 4, and a second switching valve 5. Double-acting oil cylinder 6, hydraulic control check valve 7 and third switching valve 8. combine figure 2 and image 3 As shown, the acceleration and supercharging system of this embodiment realizes the purpose of no-load acceleration and load supercharging during the process of performing work of the oil cylinder 9 . The acceleration and supercharging system of this embodiment is arranged on the inlet and outlet oil passage of the executive cylinder 9, wherein the large chamber and the small chamber of the executive cylinder 9 are respectively connected with the A1 port and the B1 port of the acceleration and supercharging system, and the A port of the accelerating and supercharging system ...

Embodiment 2

[0044] see Figure 5 , this embodiment is yet another specific implementation of the acceleration and supercharging system of the present invention, and the difference from Embodiment 1 is: the first switching valve 2, the second switching valve 5 and the third switching valve in this embodiment 8 all use electronically controlled reversing valves, which can be triggered and switched by pressure sensors or position sensors set on the oil circuit.

[0045] For example, both the first switching valve 2 and the third switching valve 8 are feedback-controlled by the pressure sensor arranged on the working oil inlet circuit 100, and the action of the second switching valve 5 is fed back according to the position sensor that detects the piston movement of the double-acting cylinder 6 control.

[0046] When the executive oil cylinder 9 stretches out with no load, the pumped pressure oil enters the working oil inlet circuit 100 from the A port. As long as the internal pressure of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com