A flexible manipulator based on shape memory alloy

A technology of memory alloys and manipulators, applied in the field of flexible manipulators, to achieve the effects of increasing power, reducing response time, and increasing maximum output force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

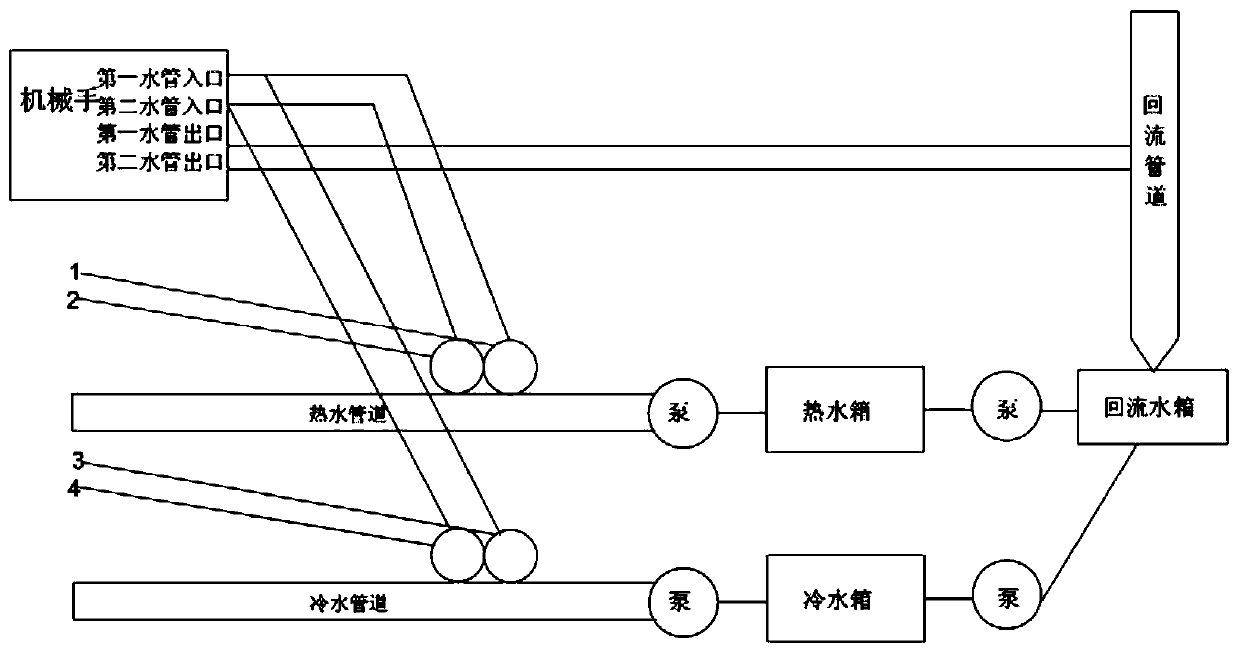

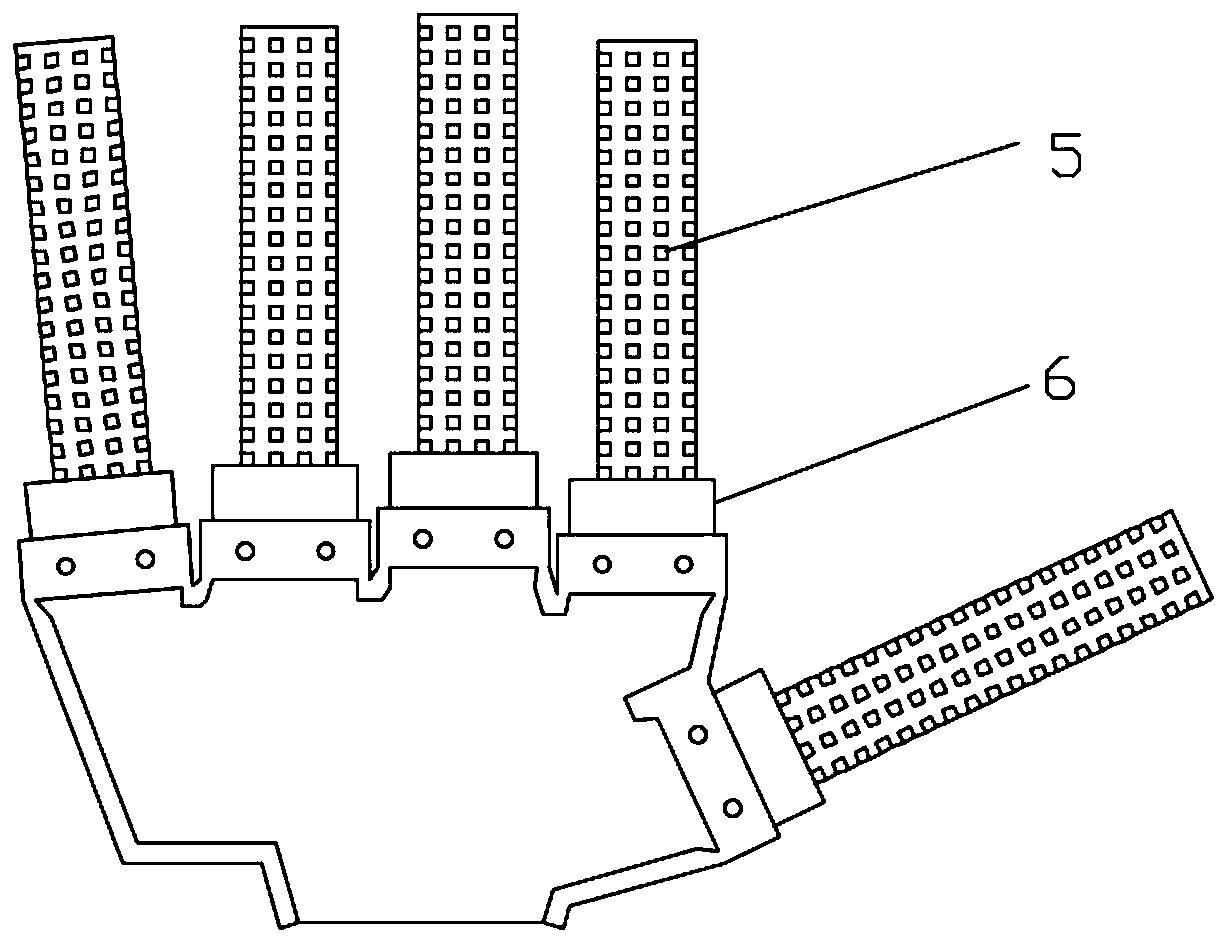

[0024] The flexible manipulator based on the shape memory alloy proposed by the present invention has a structure such as figure 1 As shown, including manipulator, hot water tank, cold water tank and return water tank. The structure of the manipulator is as follows figure 2 Shown, comprise palm, finger 5 and finger fixing seat 6, finger 5 is relatively fixed with palm by finger fixing seat 6.

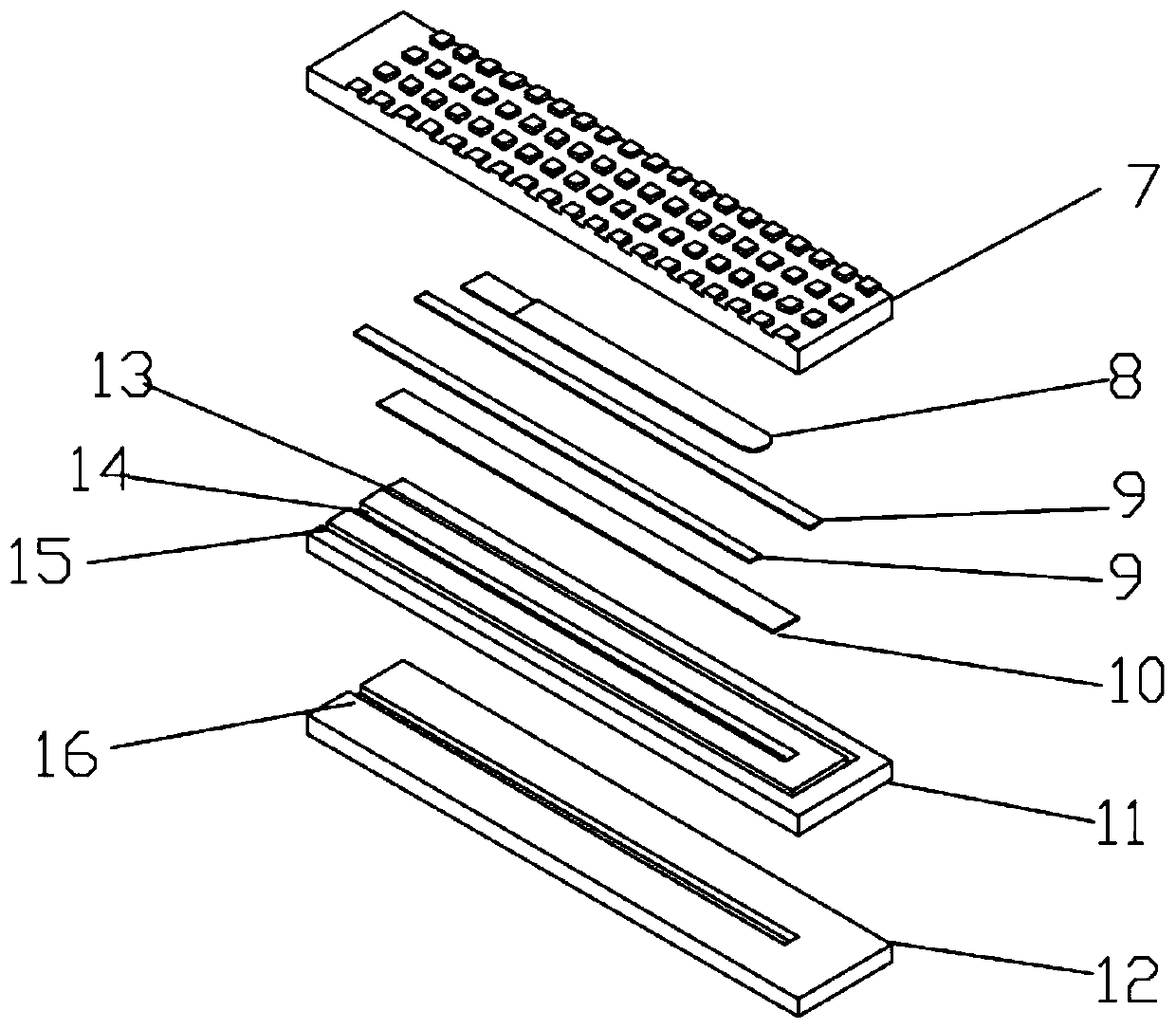

[0025] The structure of finger 5 is as image 3 As shown, the upper structural board 7 , the bending sensor 9 , the driving plate, the middle structural board 11 and the lower structural board 12 are sequentially laminated from top to bottom. The laminated upper structural board 7 , bending sensor 9 , driving piece, middle structural board 11 and bottom structural board 12 are laminated and inserted into the finger holder 6 .

[0026] The driving piece in the finger 5 is composed of two half-width memory alloy strips 9 for straightening and one full-width memory alloy strip 10 for s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com