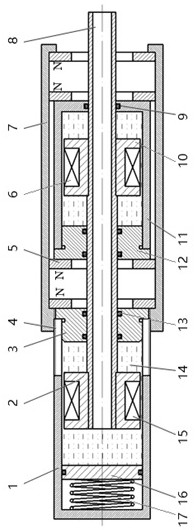

Magnetorheological fluid shock absorber with variable stiffness damping over a wide range of permanent magnet mechanisms

A technology of magnetorheological fluid and permanent magnet mechanism, which is applied in the direction of shock absorbers, spring/shock absorber functional characteristics, shock absorbers, etc., and can solve problems such as long response time, unchangeable stiffness, poor control accuracy, etc. , to achieve good vibration reduction effect, simple structure and precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0043] When this product is working, one end of the piston rod is connected to the external load, and the other end is extended into the magneto-rheological shock absorber. When the external load acts on the piston rod, it drives the piston rod to reciprocate and move laterally in the upper and lower cylinders. The excitation coil in the cylinder is connected with two currents respectively to generate a magnetic field, and then the magnetorheological fluid in it produces a magneto-rheological effect. When the excitation coil of the upper cylinder is supplied with current I 1 When it is greater than a certain value, the shear yield stress of the magnetorheological fluid is greater than the axial force of the permanent magnet variable stiffness mechanism, and the upper cylinder will slide in the sleeve with the piston rod, and the permanent magnets fixed at both ends of the upper cylinder will slide in the sleeve. During this process, the relative distance between the magnet and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com