A large-stroke high-precision intelligent flexible actuator

An intelligent flexible and high-precision technology, applied in the field of flexible actuators, can solve problems such as difficulty in meeting very high-precision pointing and stability control requirements, lack of precise pointing adjustment functions, and limited actuator control output accuracy. Achieve the effect of improving the satellite's agile maneuvering and rapid stability, improving the ability to resist the mechanical environment, and increasing the maximum output force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The content of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

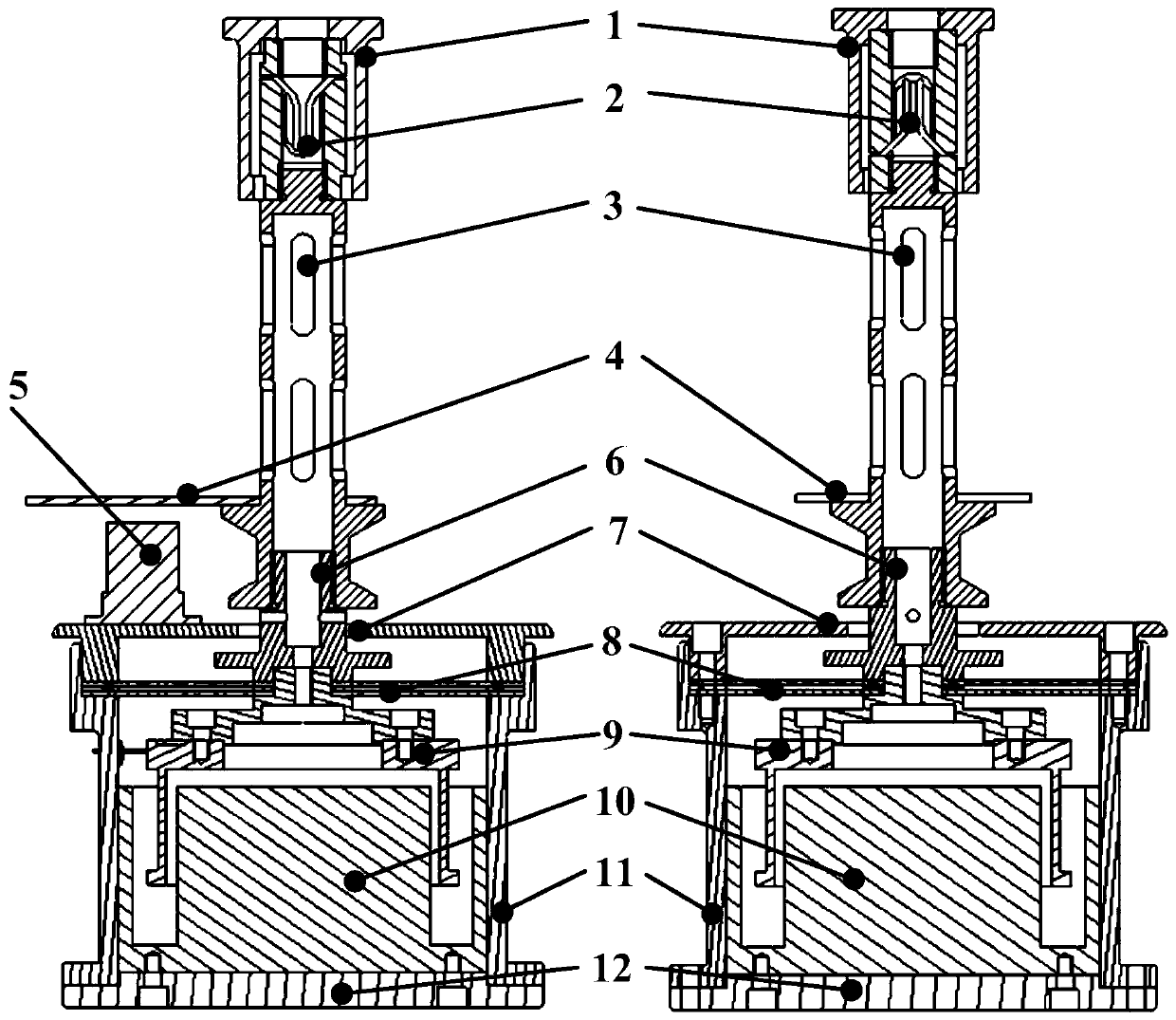

[0027] Such as figure 1 As shown, a large-stroke high-precision intelligent flexible actuator includes: a flexible hinge limit cylinder 1, a flexible hinge 2, a support rod 3, a displacement sensor measured surface 4, a displacement sensor 5, a limit block 6, a top Cover 7, membrane spring combination layer 8, mover installation cover 9, voice coil motor 10, outer cylinder 11, bottom cover 12.

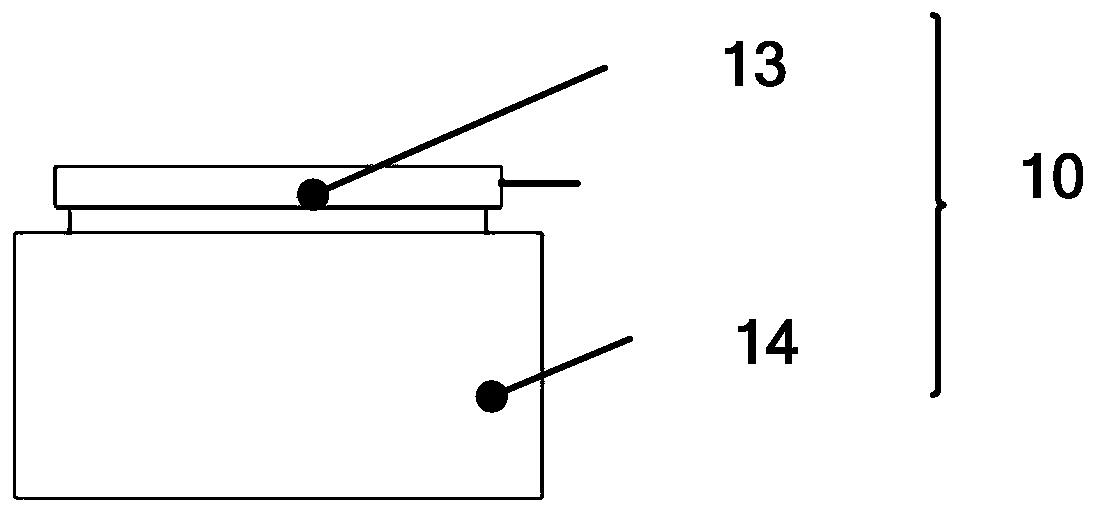

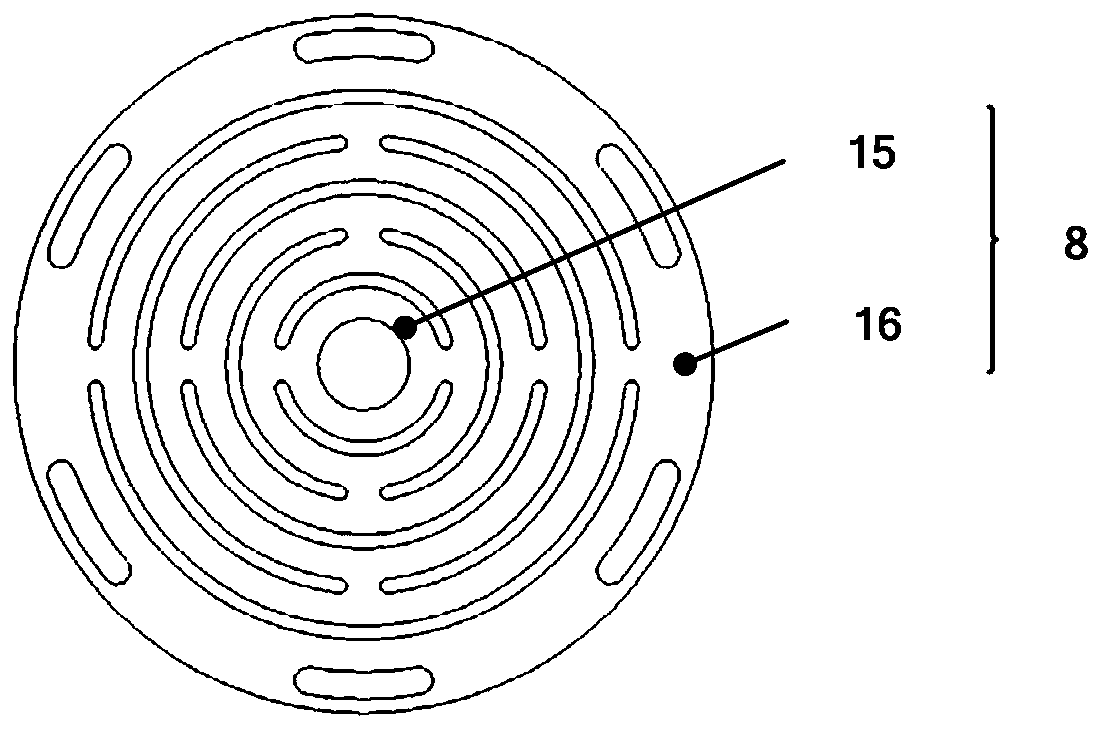

[0028] Such as figure 2 As shown, the voice coil motor 10 includes a voice coil motor mover 13 and a voice coil motor stator 14; the voice coil motor mover 13 is connected to the mover installation cover 9, and the mover installation cover 9 is connected to the limit position by a screw passing through the central screw hole. Block 6 is connected, and the inner ring 15 of the membrane spring composite layer is pressed between the mover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com