Screw-thread-driven rotary-linear ultrasonic motor using columnar stator high-order bending vibration mode

A linear ultrasonic motor, bending vibration technology, applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc., can solve the problem of small output torque, achieve performance improvement, work The effect of high efficiency and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

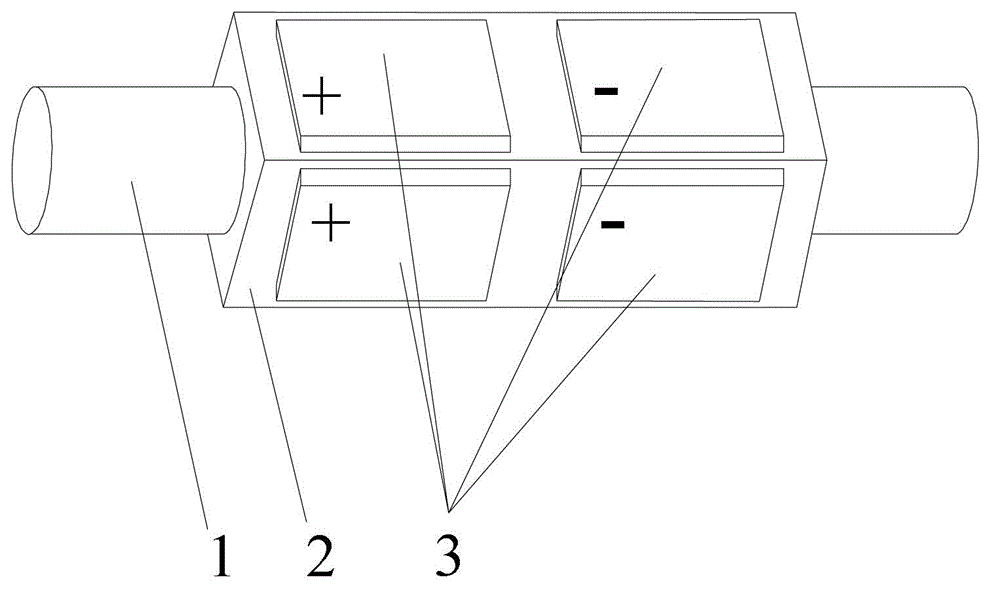

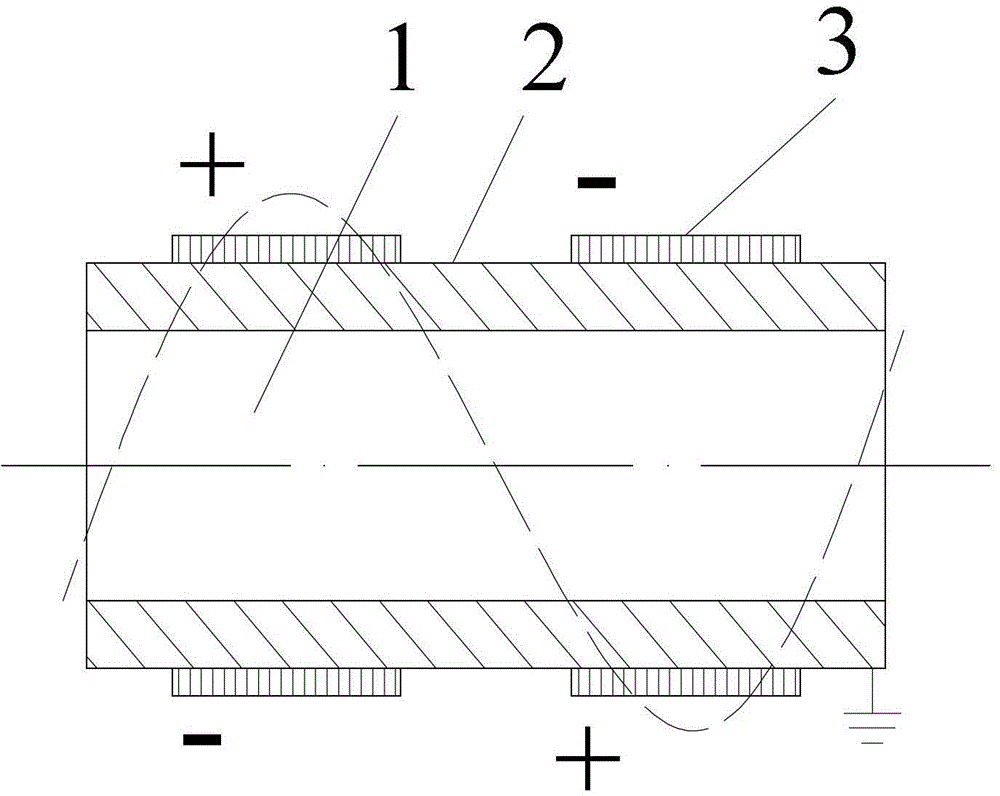

[0053] Specific implementation mode 1: the following combination Figure 1 to Figure 7 To explain this embodiment, the thread-driven rotary linear ultrasonic motor using the cylindrical stator high-order bending vibration mode described in this embodiment includes a threaded output shaft 1, a metal tube elastic sleeve 2 and m groups of piezoelectric ceramic sheets 3. m is a positive integer,

[0054] The metal tube elastic sleeve 2 is sleeved on the outer surface of the threaded output shaft 1, and is connected with the threaded output shaft 1 through a thread pair. The outer contour of the cross section of the metal tube elastic sleeve 2 is a regular n-sided shape, the value of n Is an integer multiple of 4,

[0055] On the outer surface of the metal tube elastic sleeve 2, m groups of piezoelectric ceramic plates 3 are uniformly distributed along the axial direction. Each group of piezoelectric ceramic plates 3 is composed of n piezoelectric ceramic plates. Each group of piezoelec...

specific Embodiment approach 2

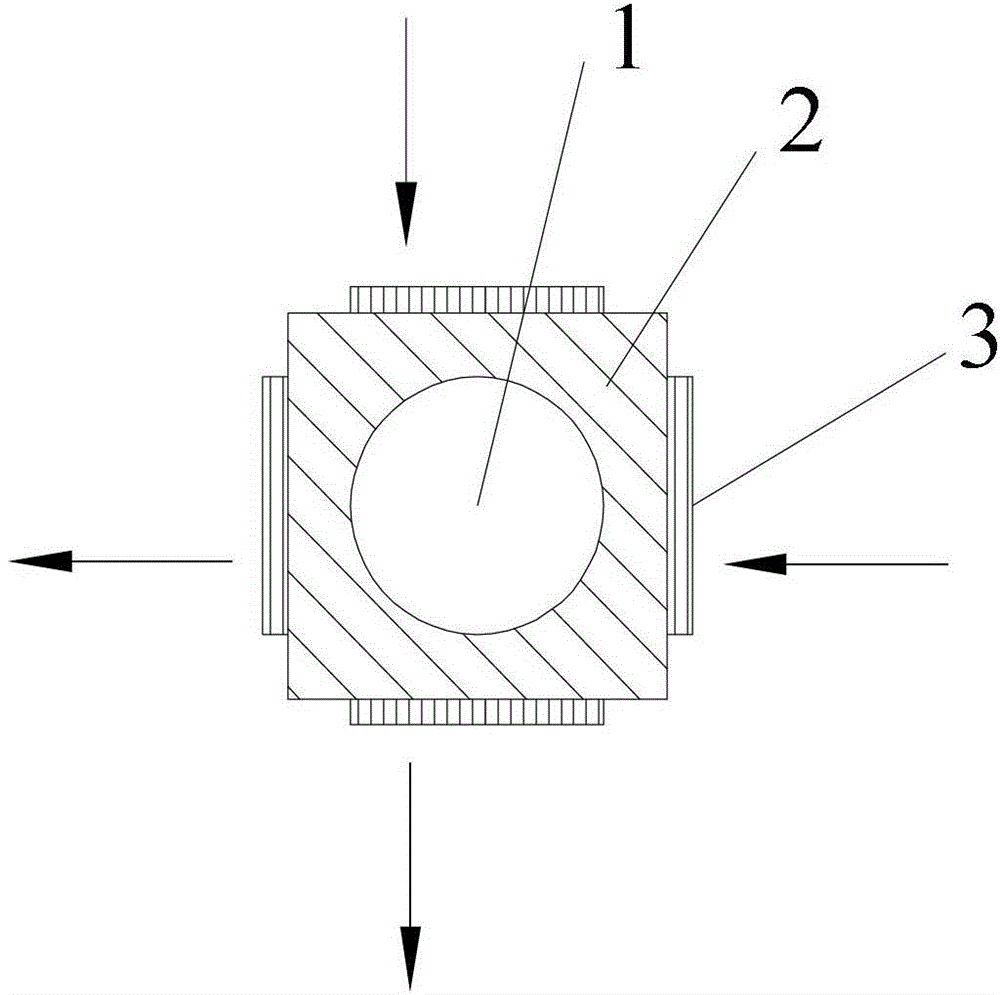

[0061] Specific implementation manner 2: the following combination Figure 8 to Figure 12 To illustrate this embodiment, the thread-driven rotary linear ultrasonic motor using the cylindrical stator high-order bending vibration mode in this embodiment includes a threaded output shaft 1, a metal tube elastic sleeve 2 and m groups of piezoelectric ceramic sheets 3. m is a positive integer,

[0062] The metal tube elastic sleeve 2 is sleeved on the outer surface of the threaded output shaft 1, and is connected with the threaded output shaft 1 through a thread pair. The outer contour of the cross section of the metal tube elastic sleeve 2 is composed of a circular arc and two straight sections The shape of the composition, where the arc is greater than or equal to one-half of the circumference, and the two straight lines are equal in length and perpendicular to each other;

[0063] On the outer surface of the metal tube elastic sleeve 2, m groups of piezoelectric ceramic plates 3 are e...

specific Embodiment approach 3

[0071] Specific implementation manner three: the following combination figure 2 with Image 6 To illustrate this embodiment, this embodiment is a further description of the first or second embodiment. The m groups of piezoelectric ceramic sheets 3 are respectively located at the center amplitudes of m amplitudes of the m-order bending vibration of the metal tube elastic sleeve 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com