Centrifugal supercharging type spiral oil pump, compressor and heat exchange equipment

A compressor and oil pump technology, applied in the field of frequency conversion compression, can solve the problems of small pump oil volume, compressor stuck, unfavorable bearing system lubrication and cooling, etc., to increase inlet pressure, improve oil pumping capacity, and increase oil intake Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

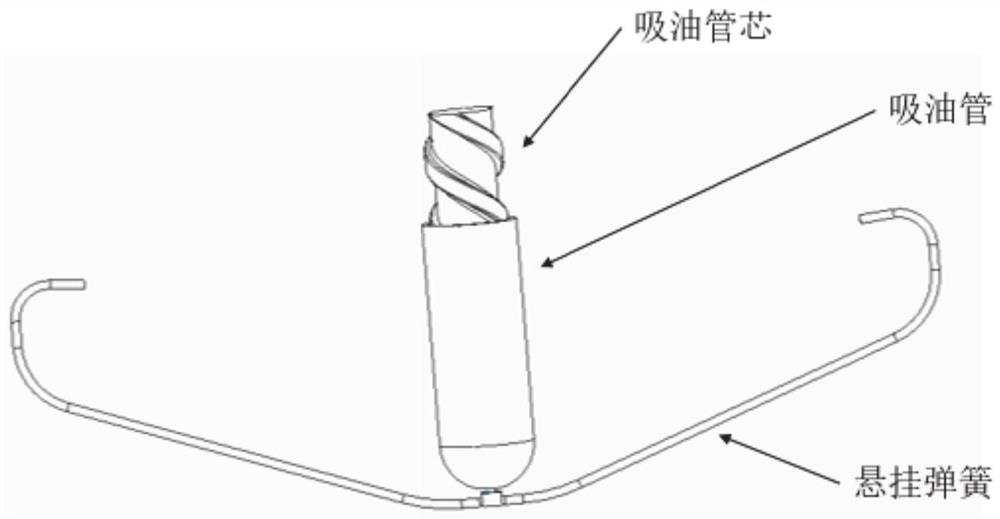

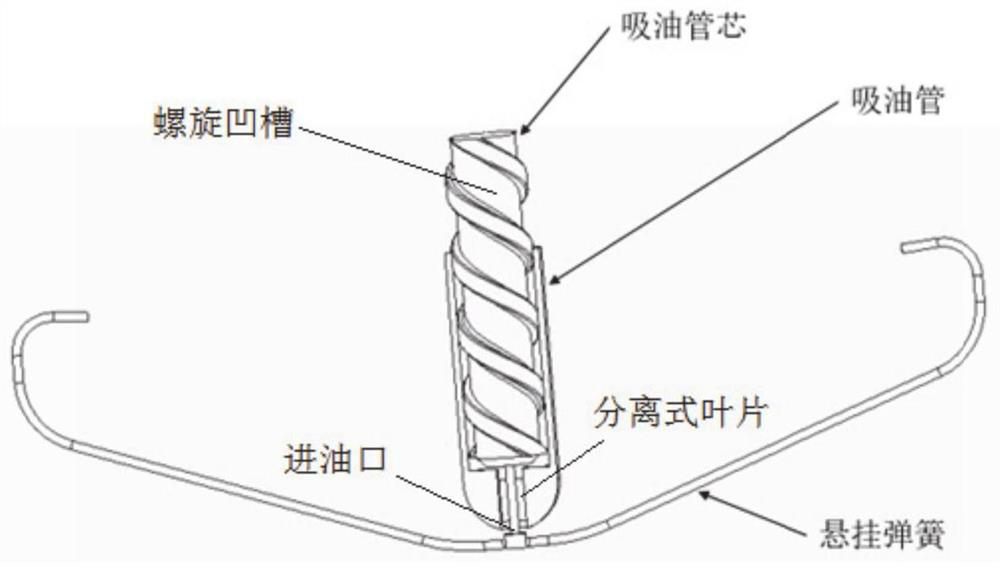

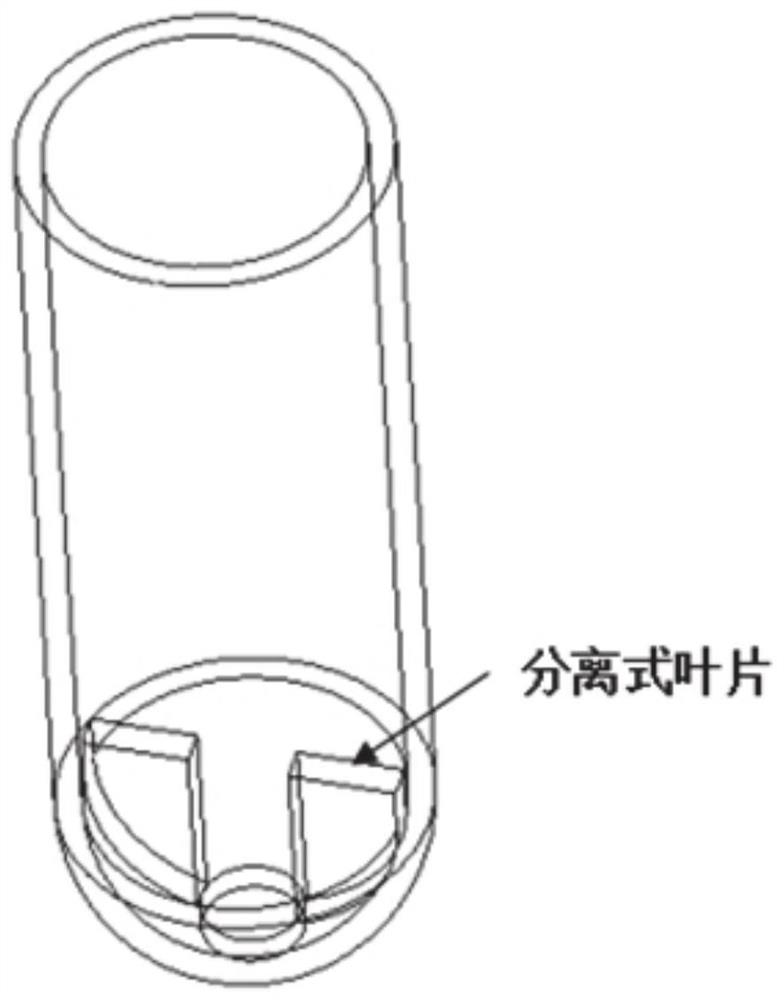

[0025] In the technical solutions disclosed in one or more embodiments, such as Figure 1-4 As shown, a centrifugal supercharged screw oil pump includes an oil suction pipe and an oil suction pipe core arranged in the oil suction pipe. The surface of the oil suction pipe core is provided with a spiral groove from bottom to top along the axis direction, and an oil inlet is provided at the bottom of the oil suction pipe. , the circumference of the oil inlet is provided with separate blades that do not block the oil inlet, the separate blades are fixedly connected to the inner wall of the oil suction pipe, and the relative rotation of the oil suction pipe and the oil suction pipe core is realized under the action of viscous force and centrifugal force Pump oil from the bottom up.

[0026] The bottom of the helical oil pump in this embodiment is provided with separate blades, which can rotate simultaneously when the oil suction pipe rotates to stir the oil entering the oil inlet t...

Embodiment 2

[0040] This embodiment provides a compressor, which can be used as a specific application of the above-mentioned oil pump, and of course can be applied to any other equipment that needs to pump oil, such as Figure 5 As shown, the compressor adopts a centrifugal supercharged screw oil pump described in Embodiment 1, which is used to pump oil for the lubrication system of the compressor, and the oil suction pipe is fixedly connected with the crankshaft of the compressor, and can Rotating together, the suspension springs are fixed to the immovable parts of the compressor.

[0041] The suspension spring can be hung on any position of the compressor. In this embodiment, it can be hung on the motor stator frame of the compressor. The shape of the suspension spring is C-like, and the end is provided with a hook.

[0042]This embodiment adopts the screw oil pump described in Embodiment 1. When the crankshaft of the compressor rotates, the separated blades will stir the oil to rotate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com