Patents

Literature

274 results about "Suction tubing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

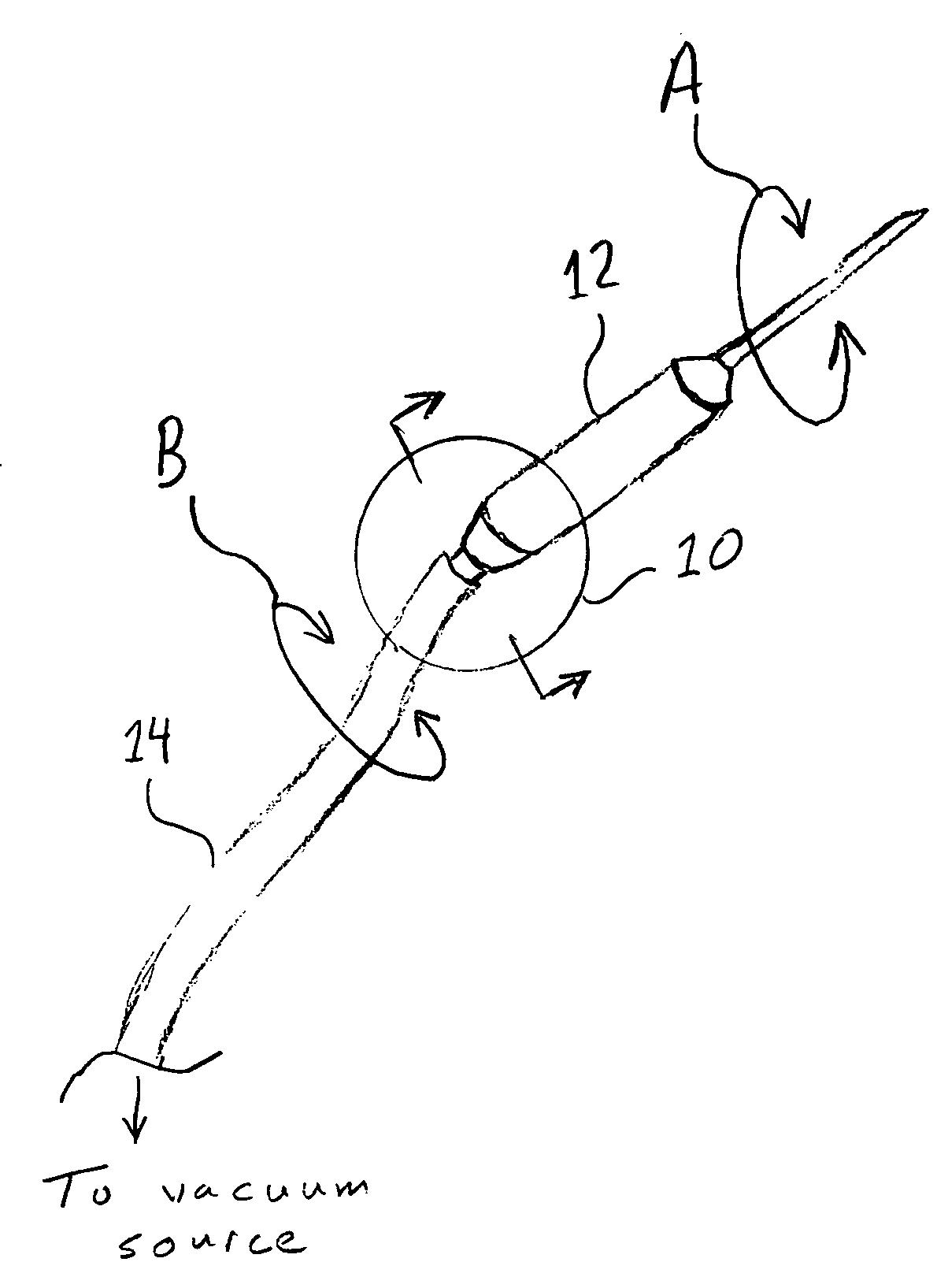

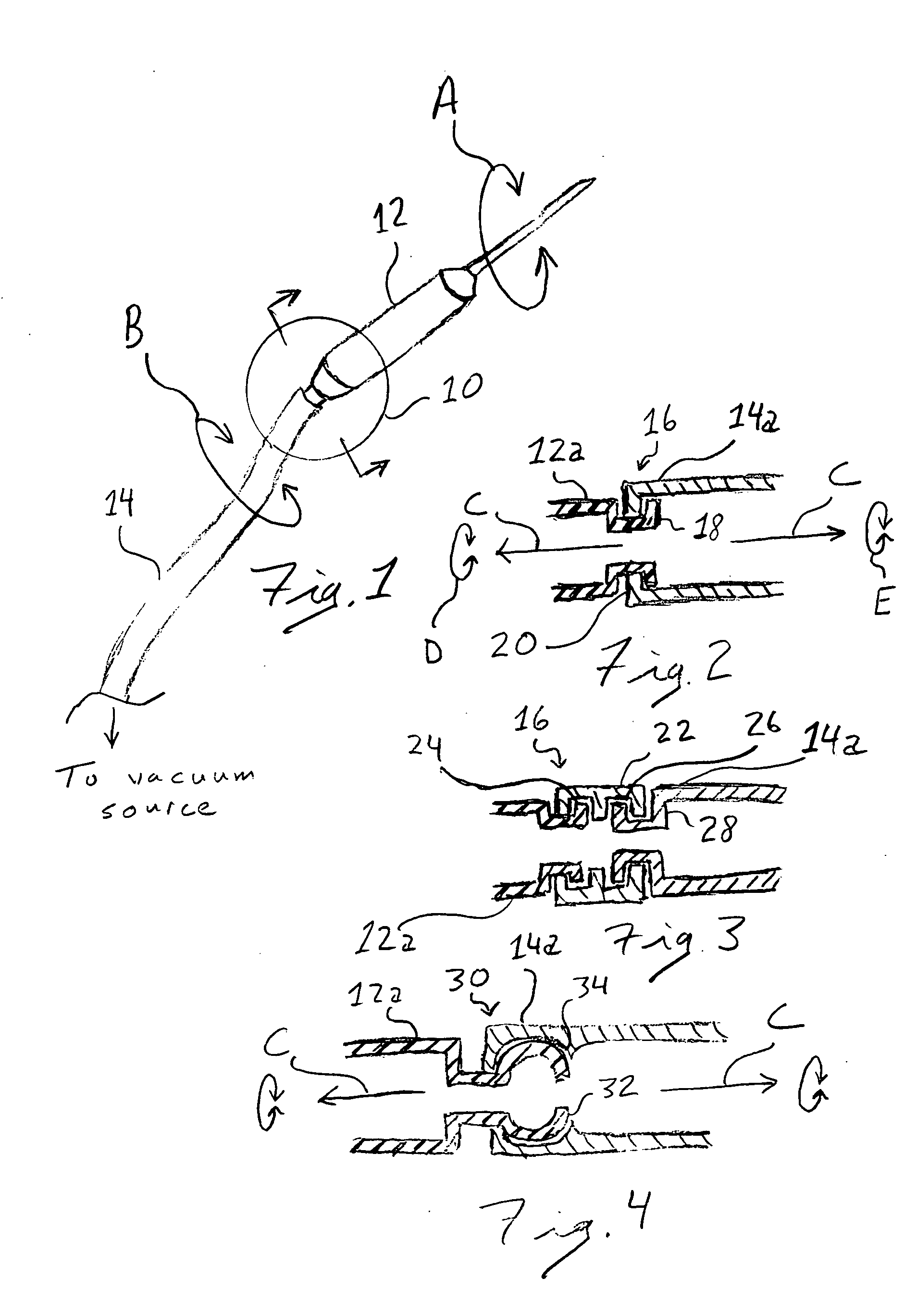

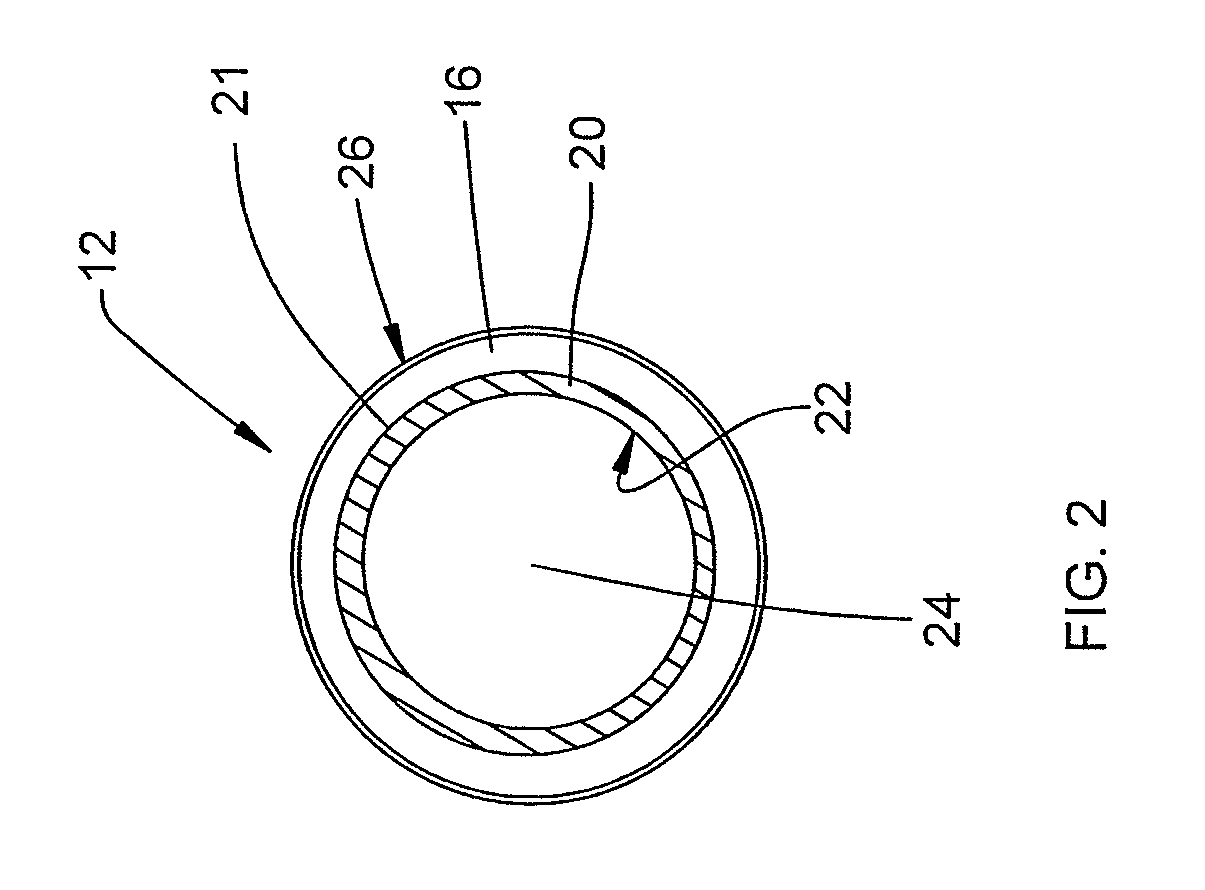

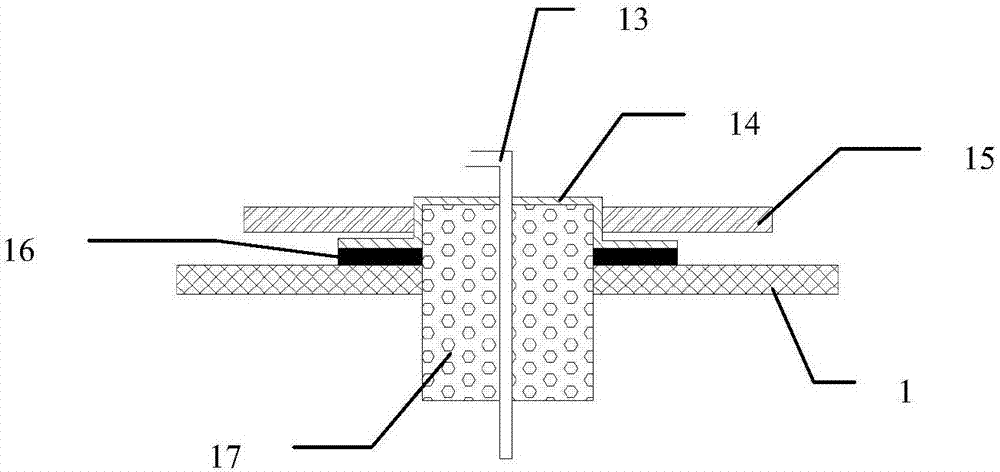

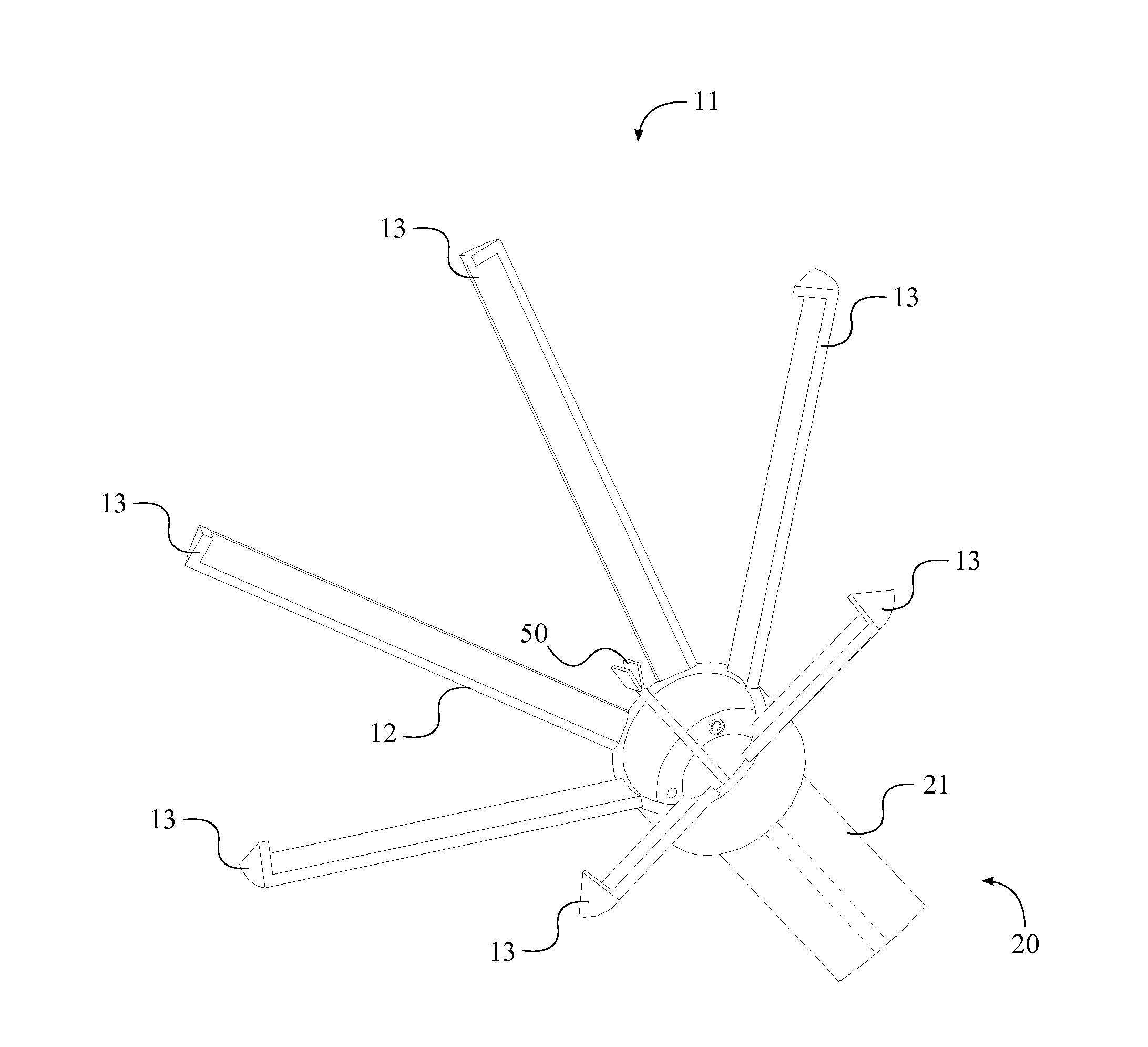

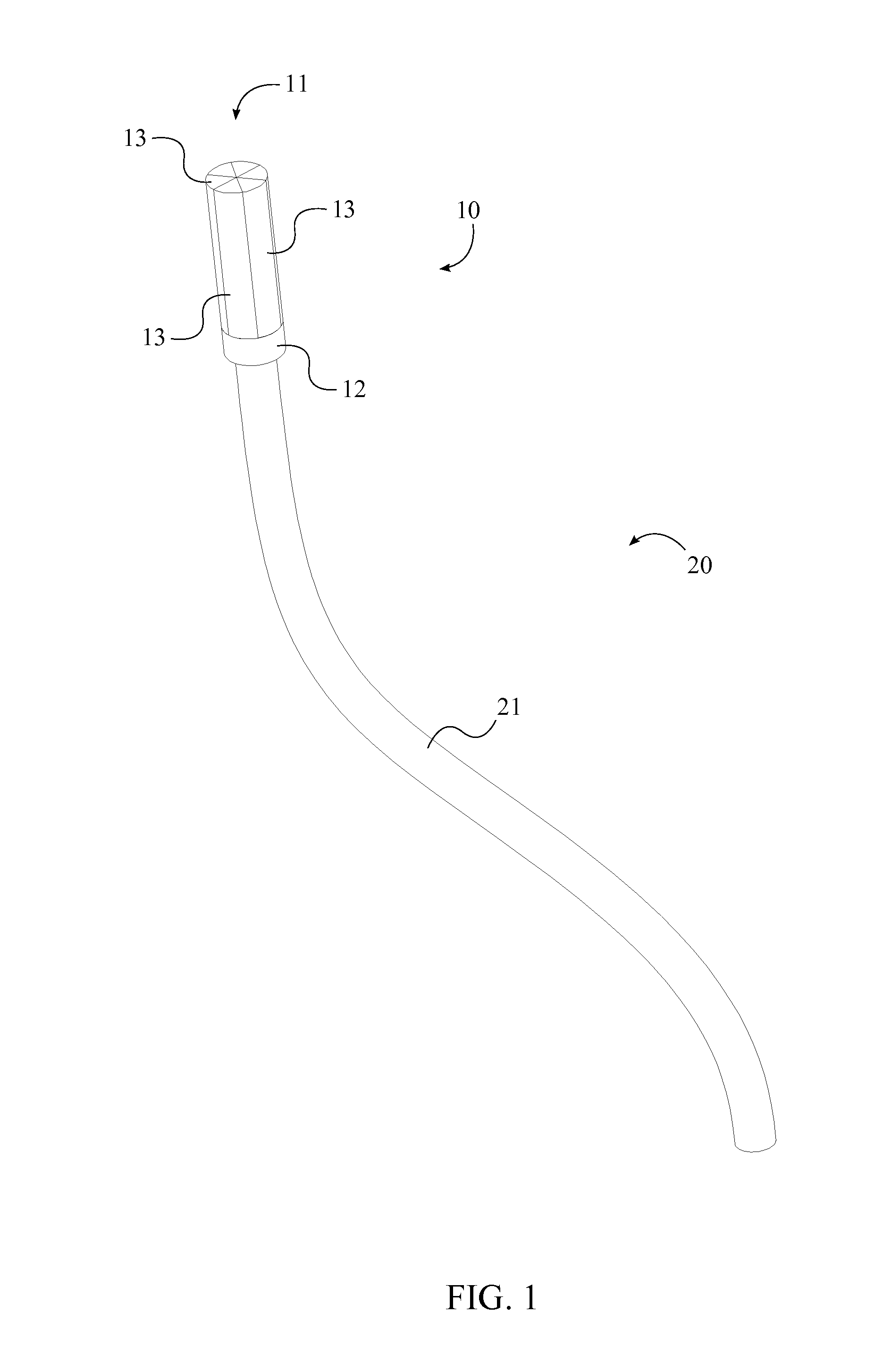

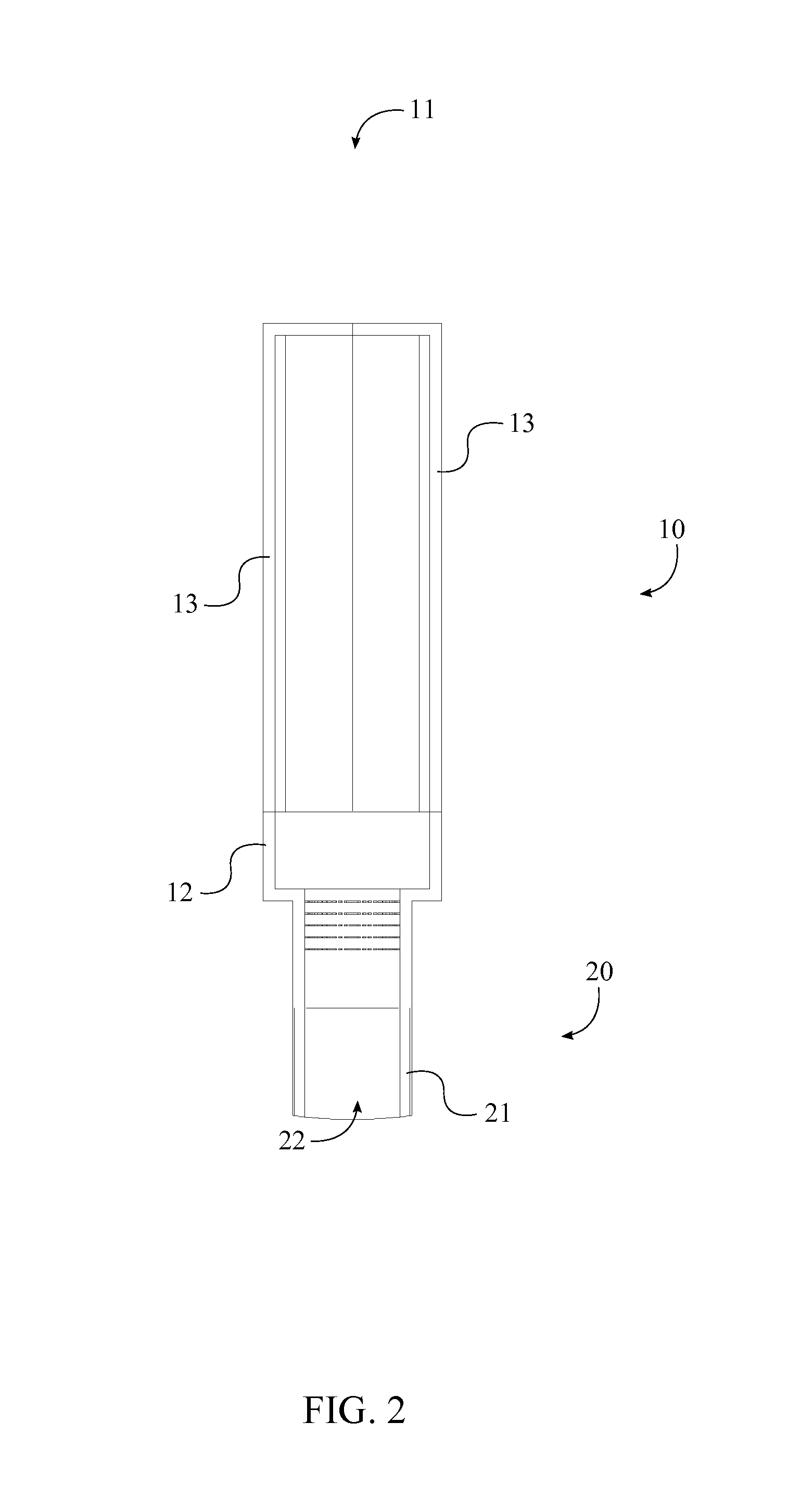

Liposuction/tubing coupling for providing rotational movement

A liposuction cannula / suction tubing coupling is disclosed that enables the tubing to rotate freely about the juncture at which the tubing is coupled to the cannula. Such coupling may be formed as a separate fitting that is interconnected intermediate the liposuction cannula and the suction tubing, or integrally formed as part of the liposuction cannula, on one hand, or on the suction tubing, on the other hand.

Owner:AZAR KOUROS

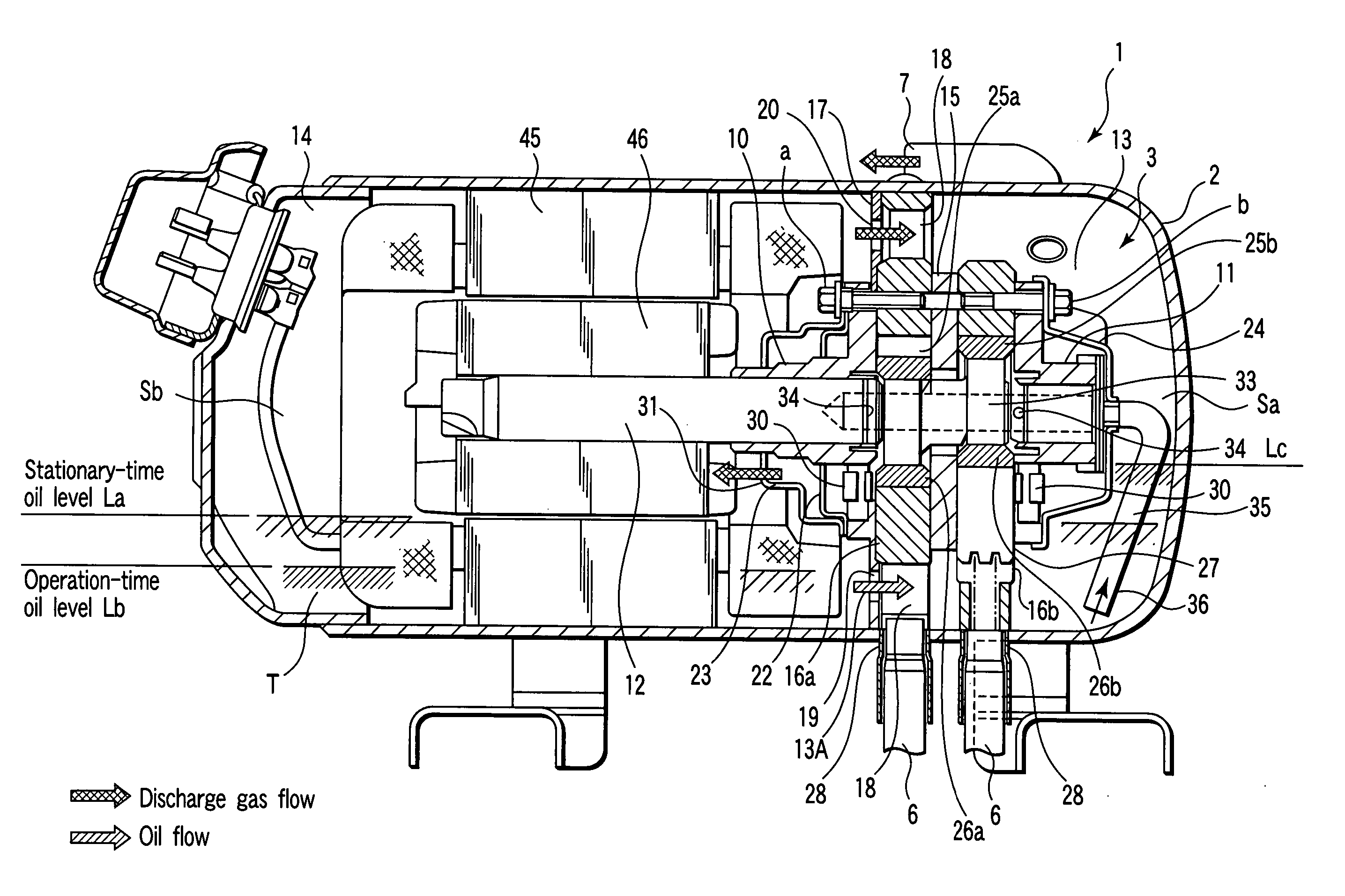

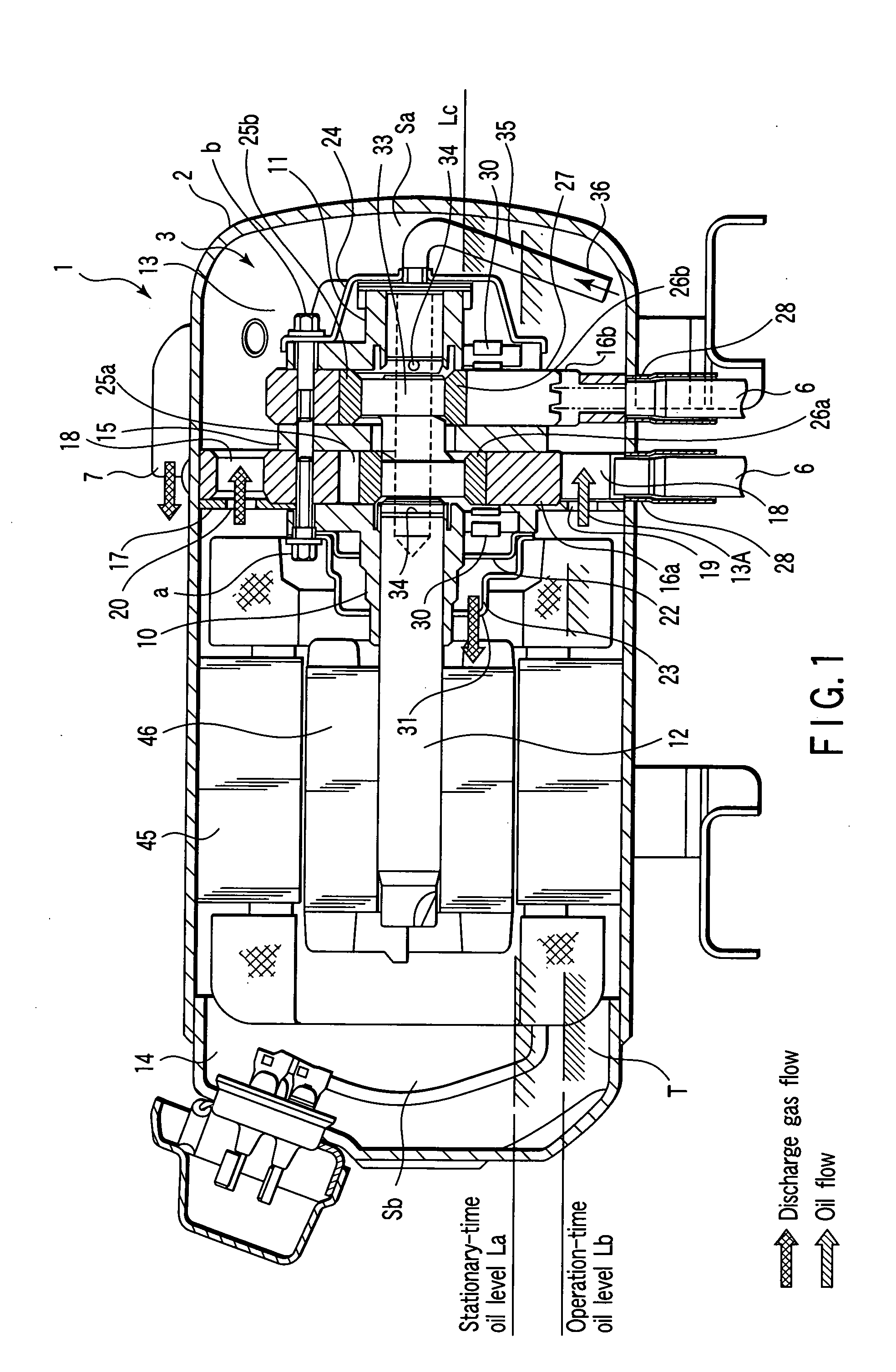

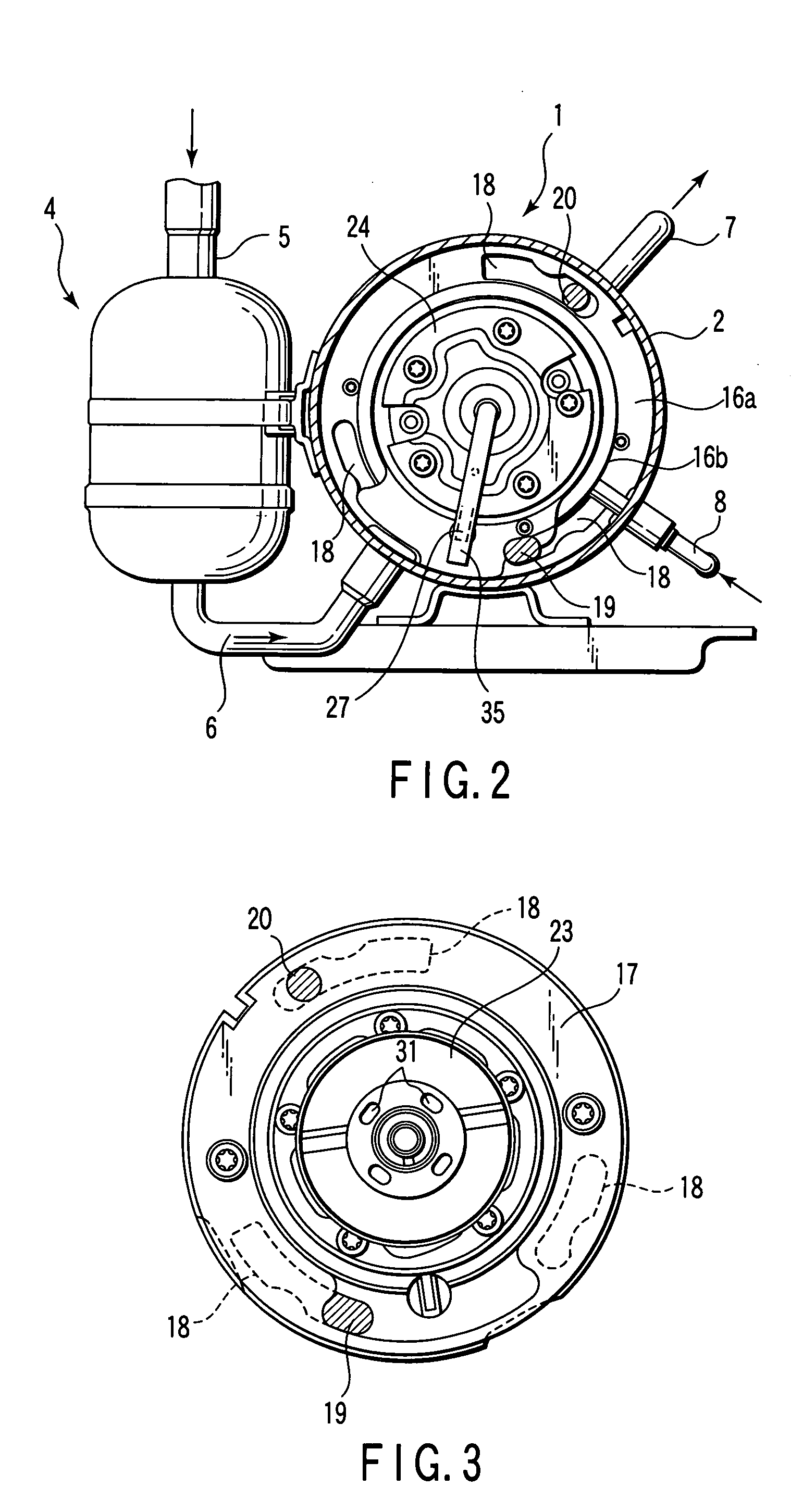

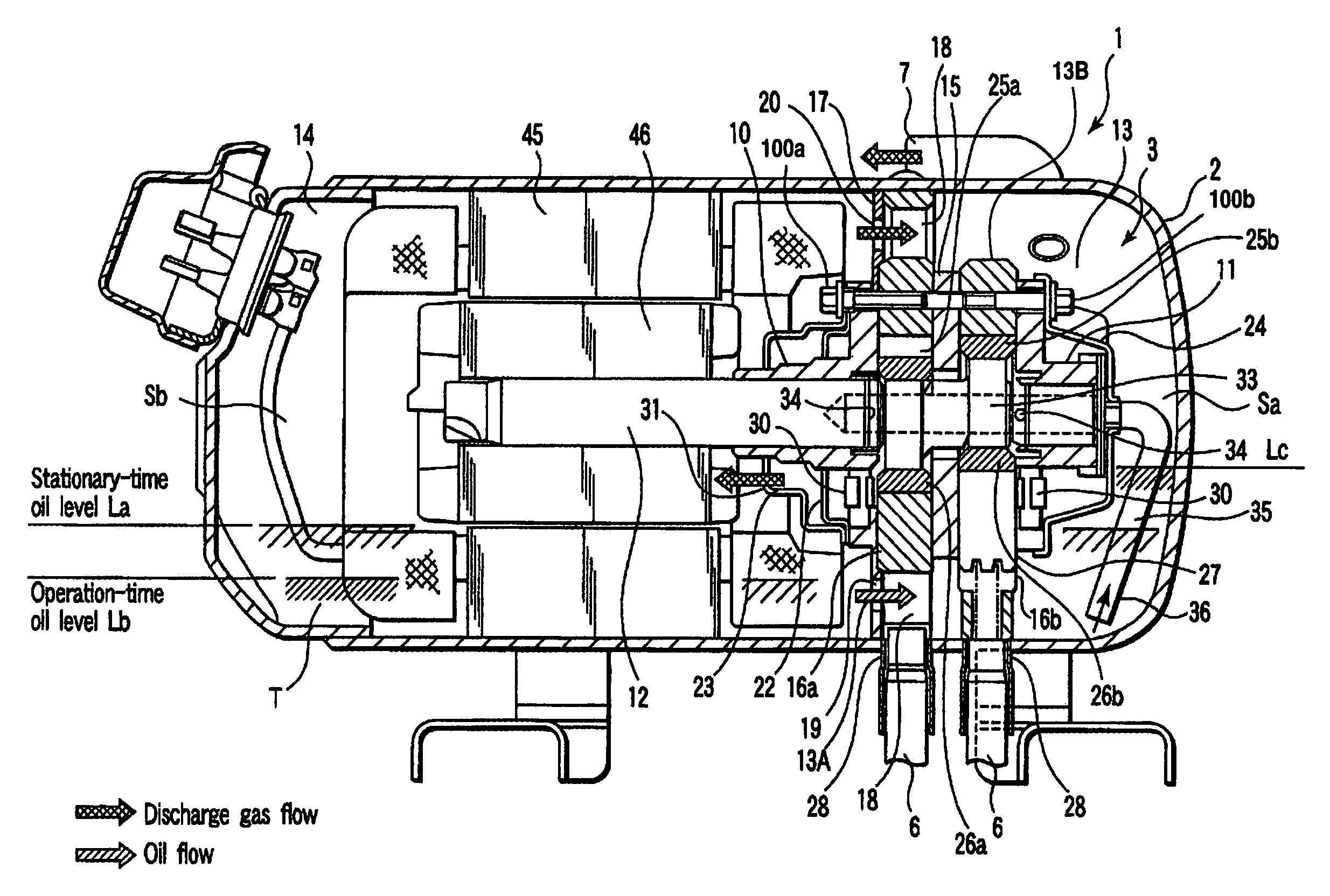

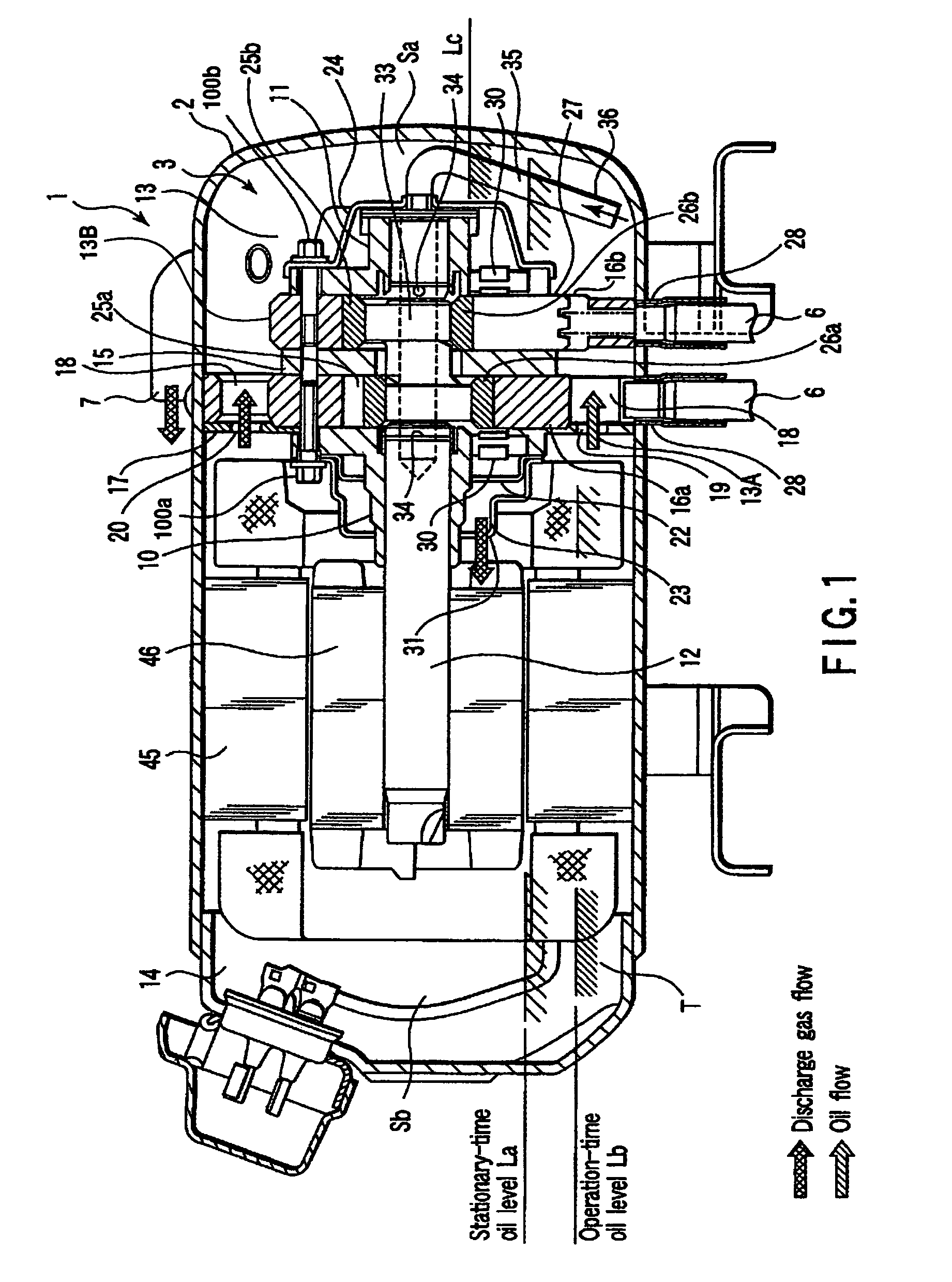

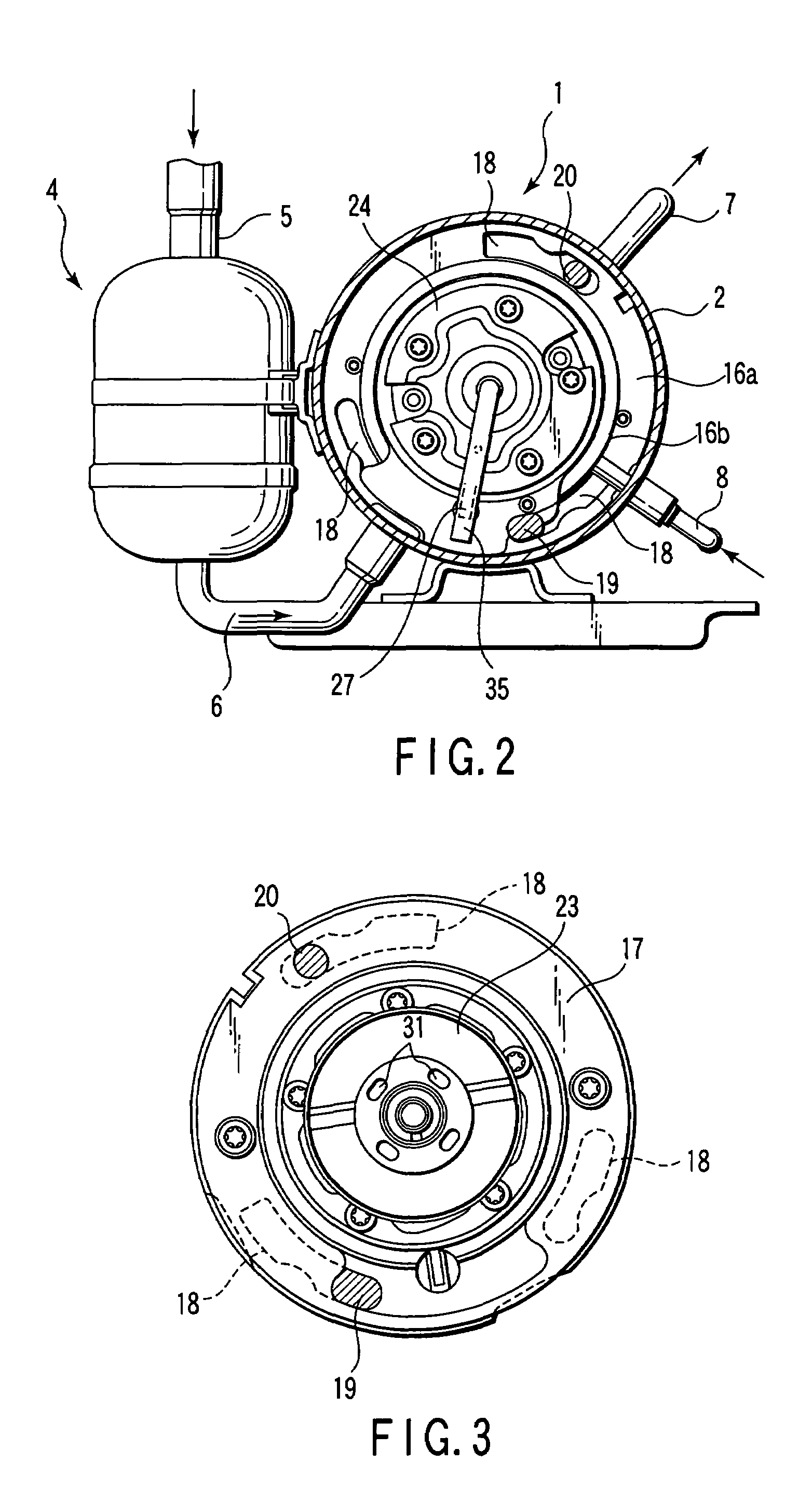

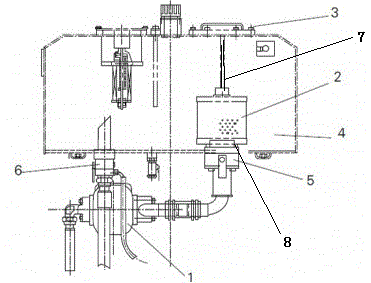

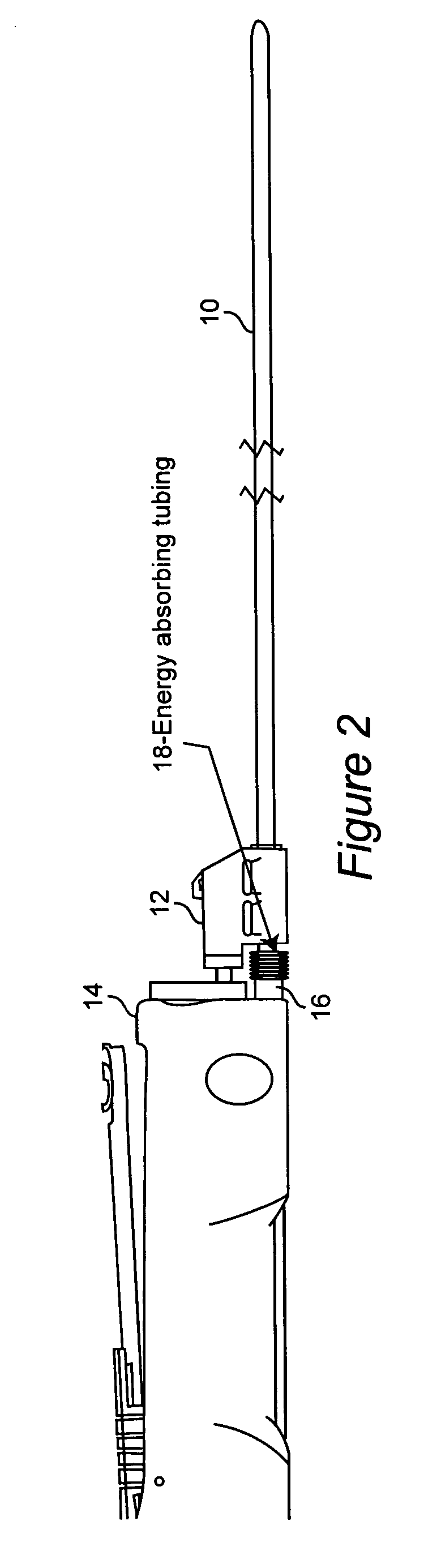

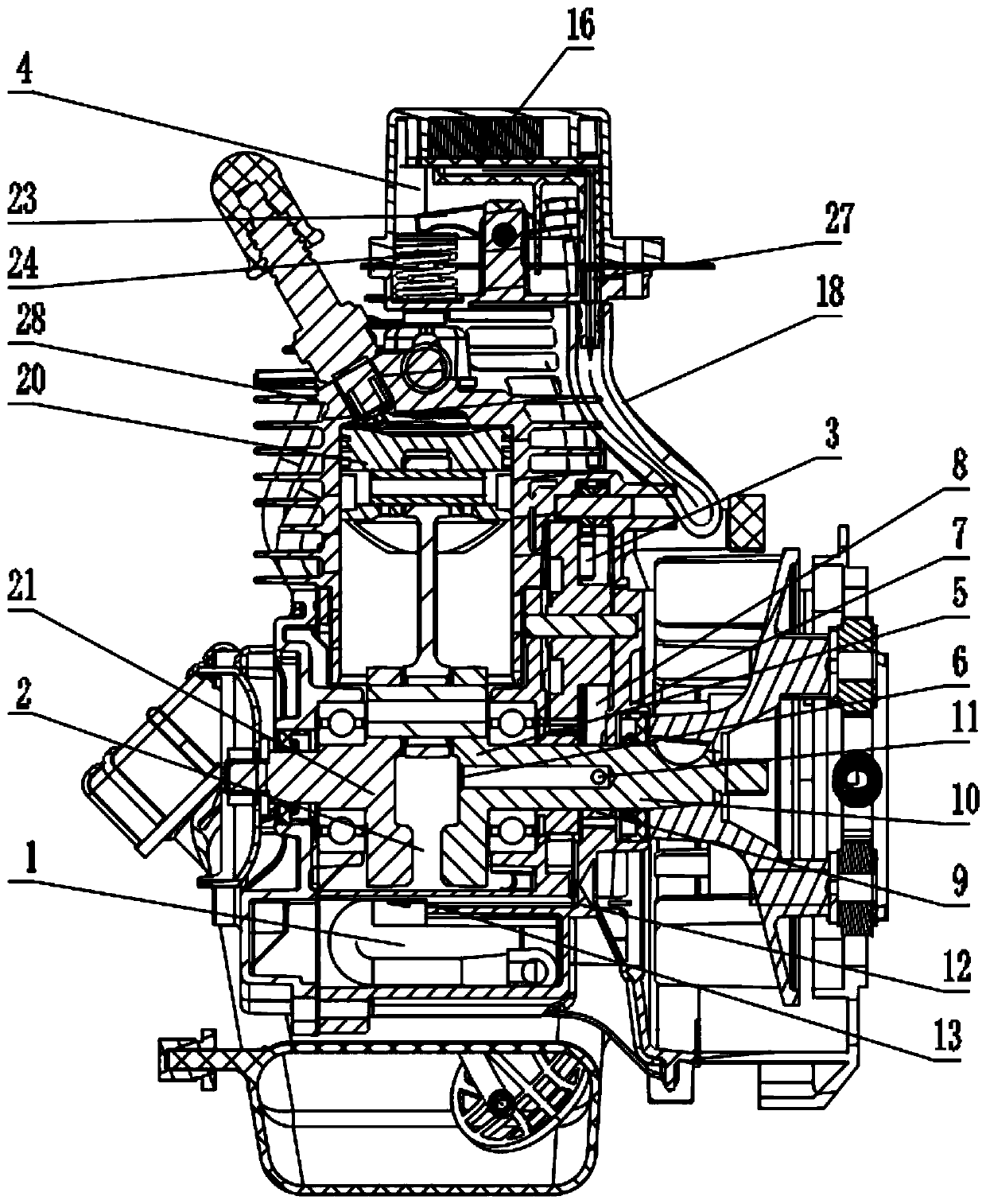

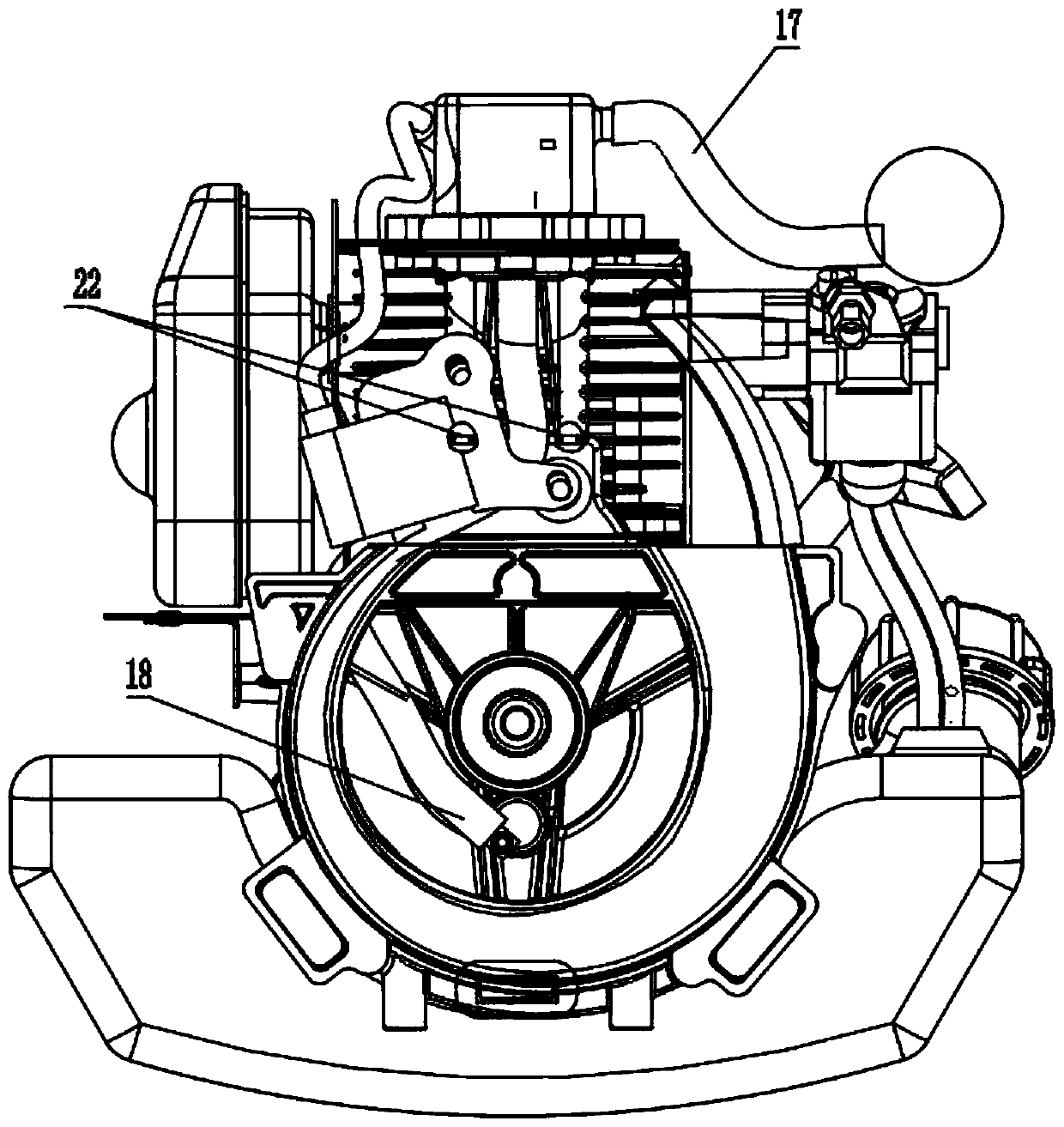

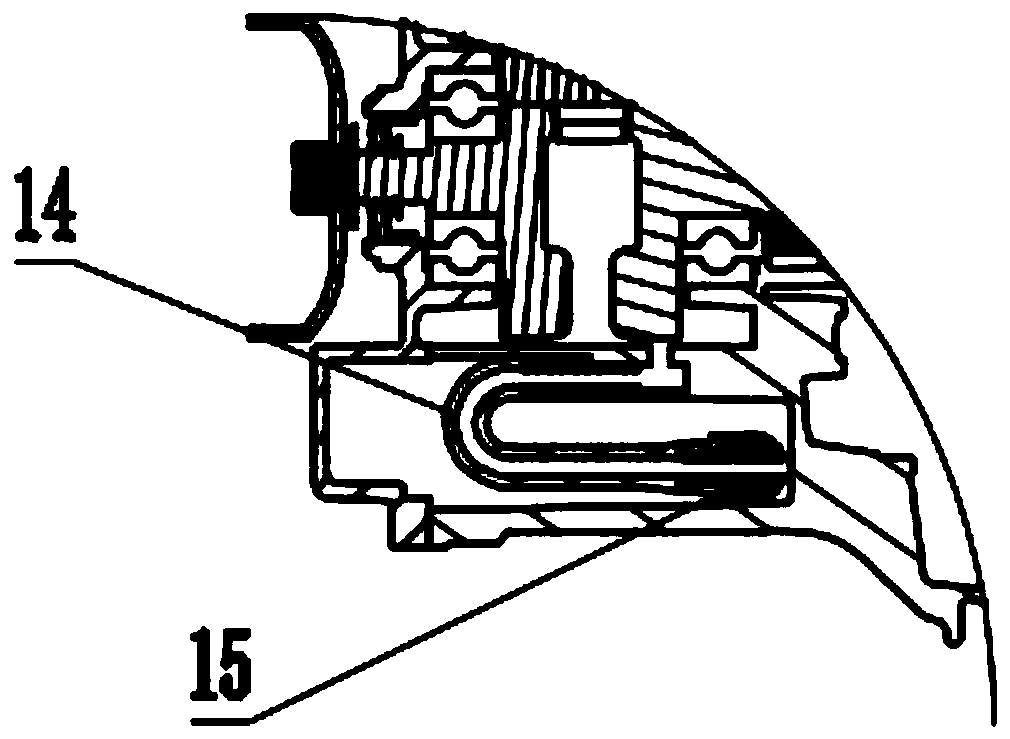

Horizontal rotary compressor

InactiveUS20050129559A1Improve reliabilityRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeEngineeringSuction tubing

A horizontal rotary compressor is configured such that an electrically powered compressor body is accommodated in a horizontally long hermetic receptacle in which a lubricating oil is accumulatively preserved, an interior of the hermetic receptacle is partitioned by a partition member into an oil storage portion space in which the compressor mechanism portion is positioned and an electric motor side space in which the electric motor portion is positioned, an oil communication portion is provided below the partition member, a gas communication opening is provided in an upper portion of the partition member, and an oil feed passageway is formed of a center opening, an oil guide opening, and oil suction tubing along the rotation axis.

Owner:TOSHIBA CARRIER CORP

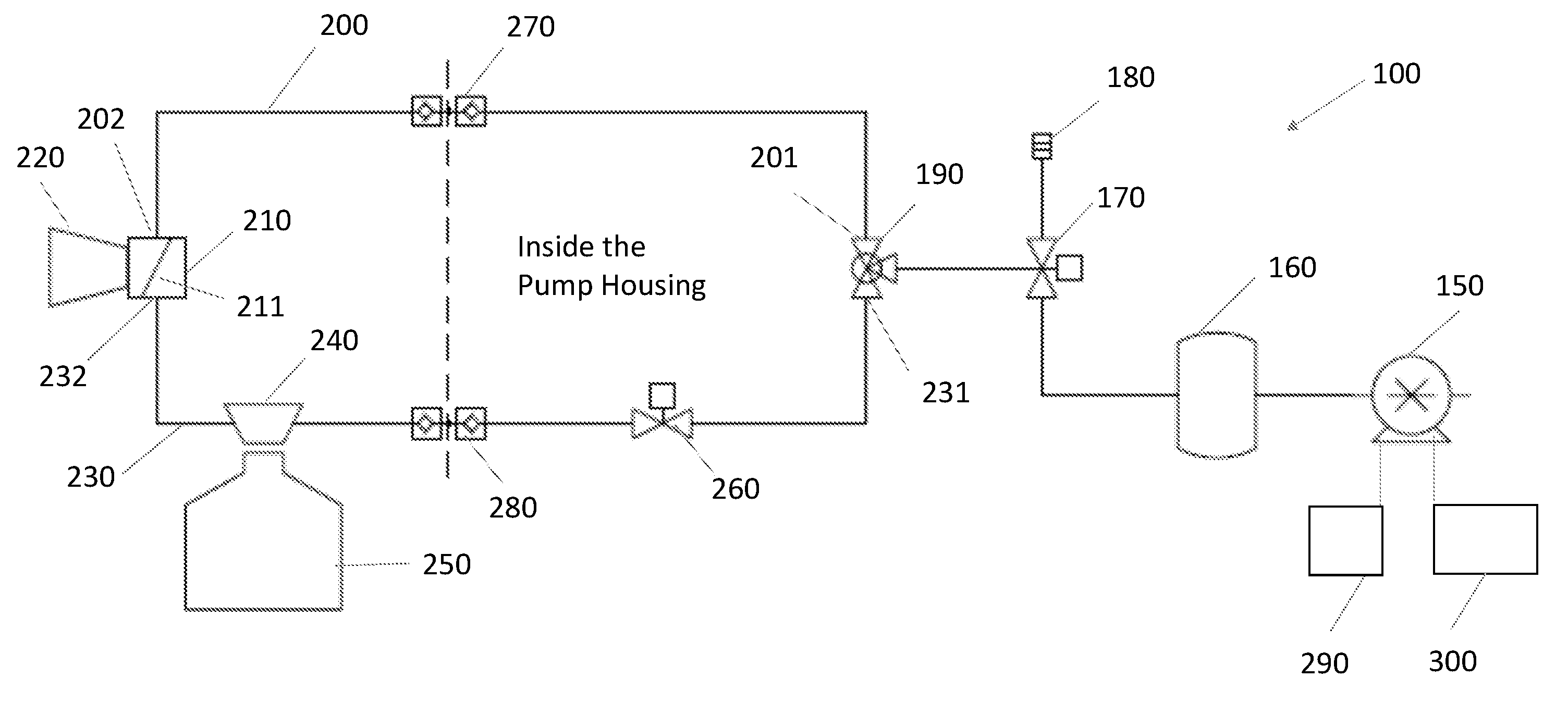

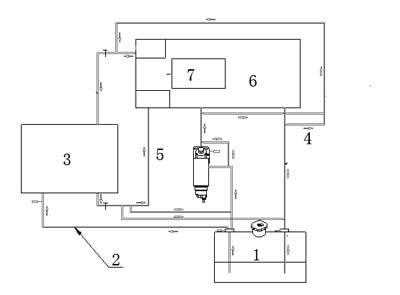

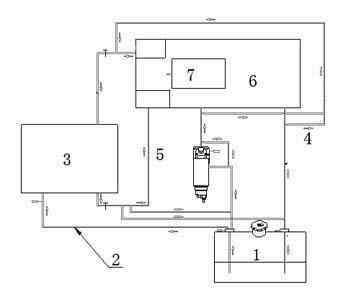

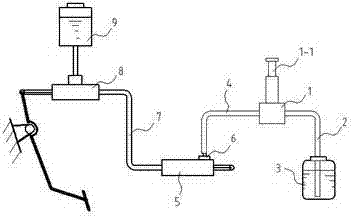

Breast Pump System

ActiveUS20160325031A1Reduce noiseReduce switchingMilking pumpMedical devicesIsolation valveEngineering

A breast pump system having a suction tubing, a milk tubing, a pump, a three way vent valve, a milk bottle, an isolation valve and a breast shield, wherein the first end of the suction tubing and the first end of the milk tubing are fluidly connected to the pump; wherein the second end of the suction tubing and the second end of the milk tubing are fluidly connected to the breast shield; wherein the three way vent valve is fluidly connected between the pump and the breast shield on the suction tubing; wherein the milk bottle is fluidly connected on the milk tubing between the breast shield and the pump; and wherein the isolation valve is connected on the milk tubing between the milk bottle and the pump.

Owner:BABYATION INC

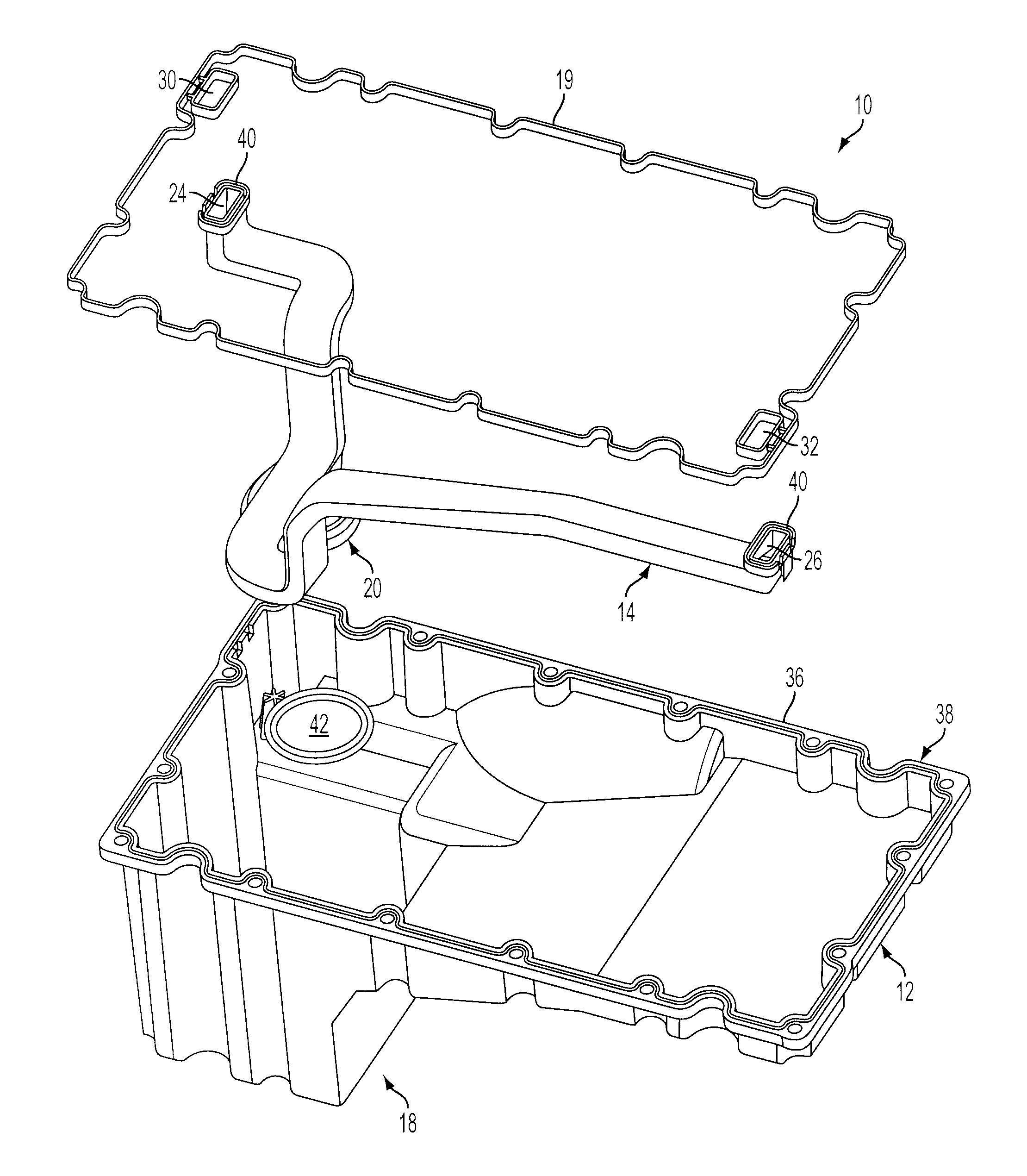

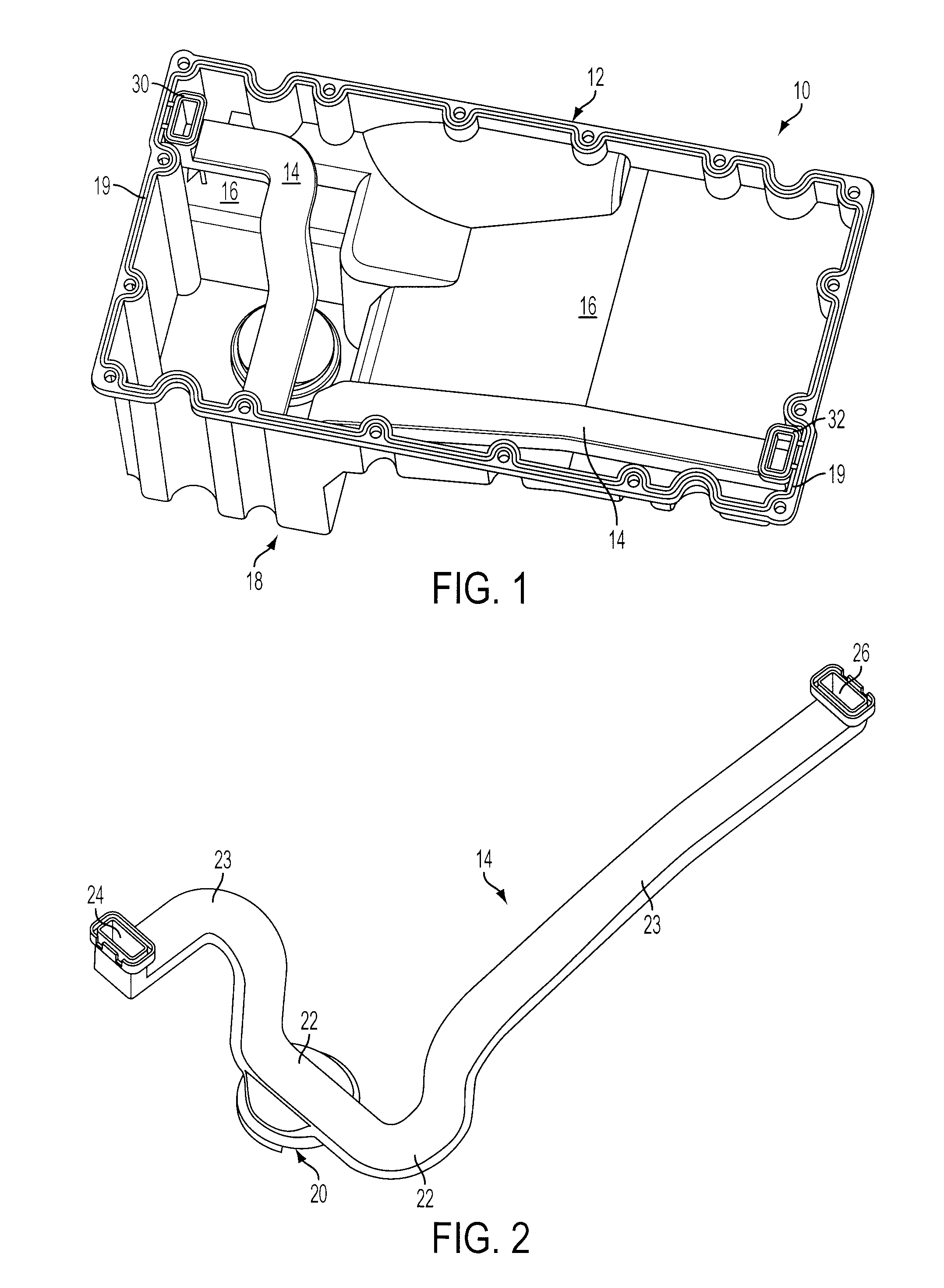

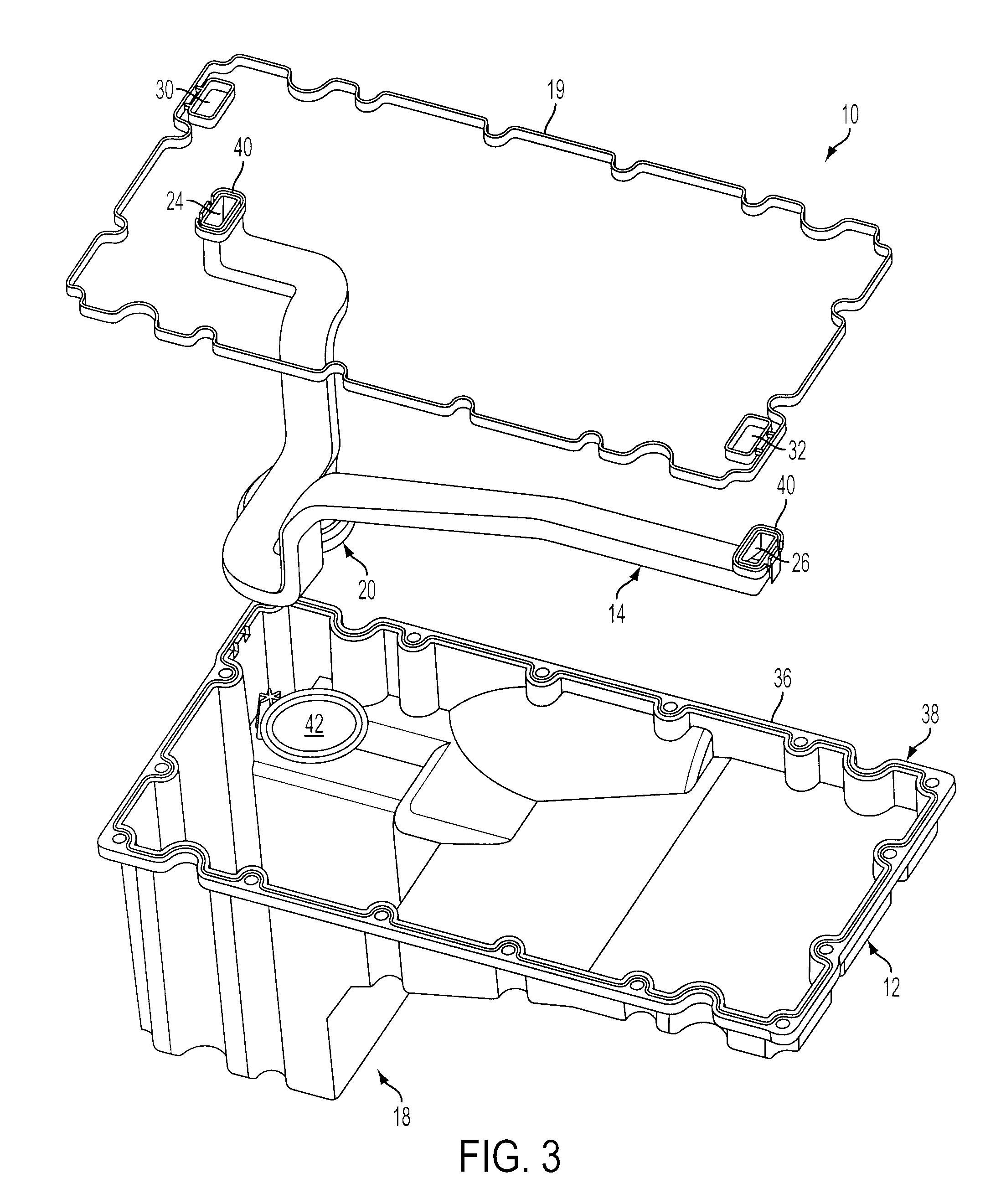

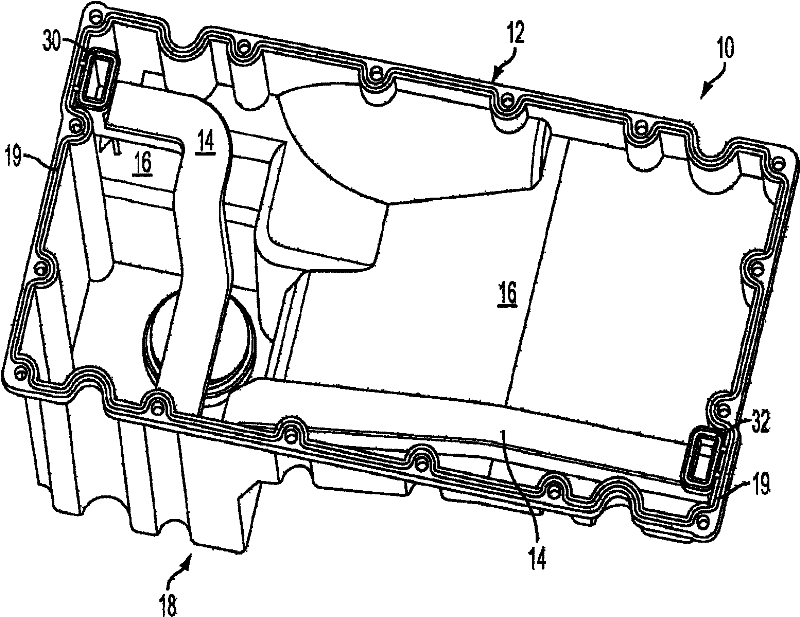

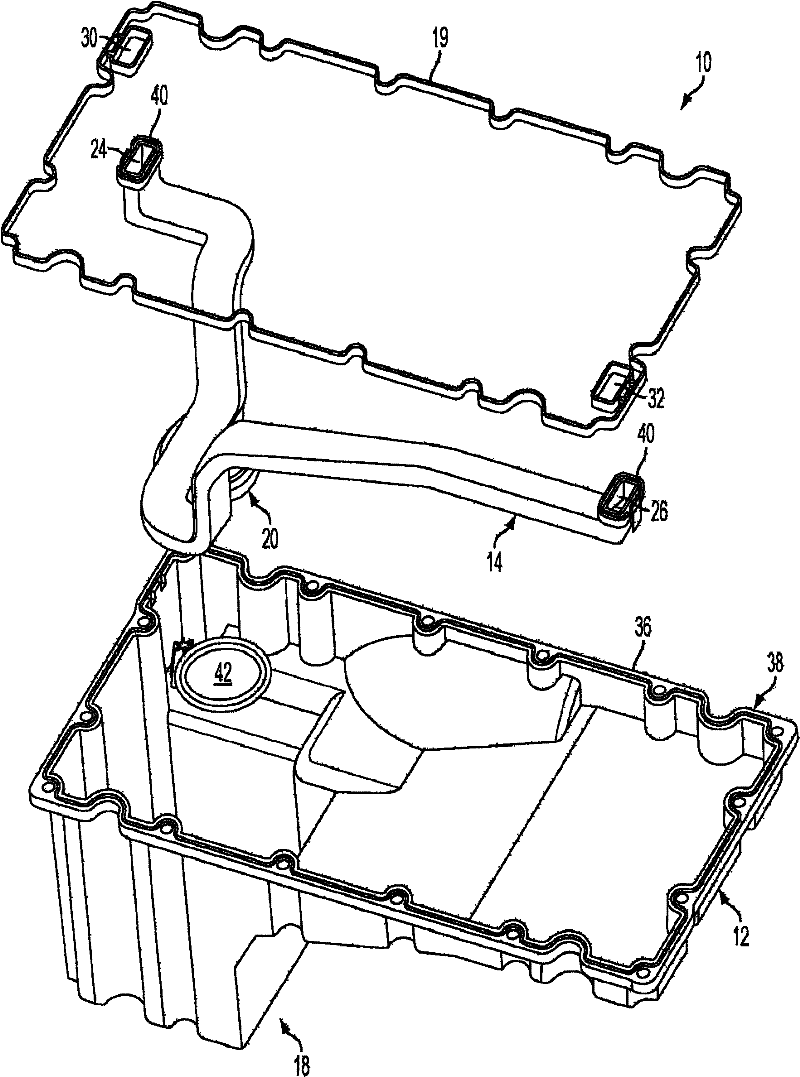

Reversible oil pan with integrated oil suction tube

InactiveUS20100224450A1Reduction of inventory complexityGood flexibilityLubricant conduit arrangementsOilsumpsPetroleum engineeringMechanical engineering

A reversible oil pan assembly including an oil suction tube. In one aspect, an oil pan assembly includes an oil pan and a suction tube connected to the oil pan. The suction tube includes an inlet to draw oil from the oil pan, and a plurality of outlets, each outlet configured to output oil that has been moved through the suction tube from the inlet.

Owner:CUMMINS INC

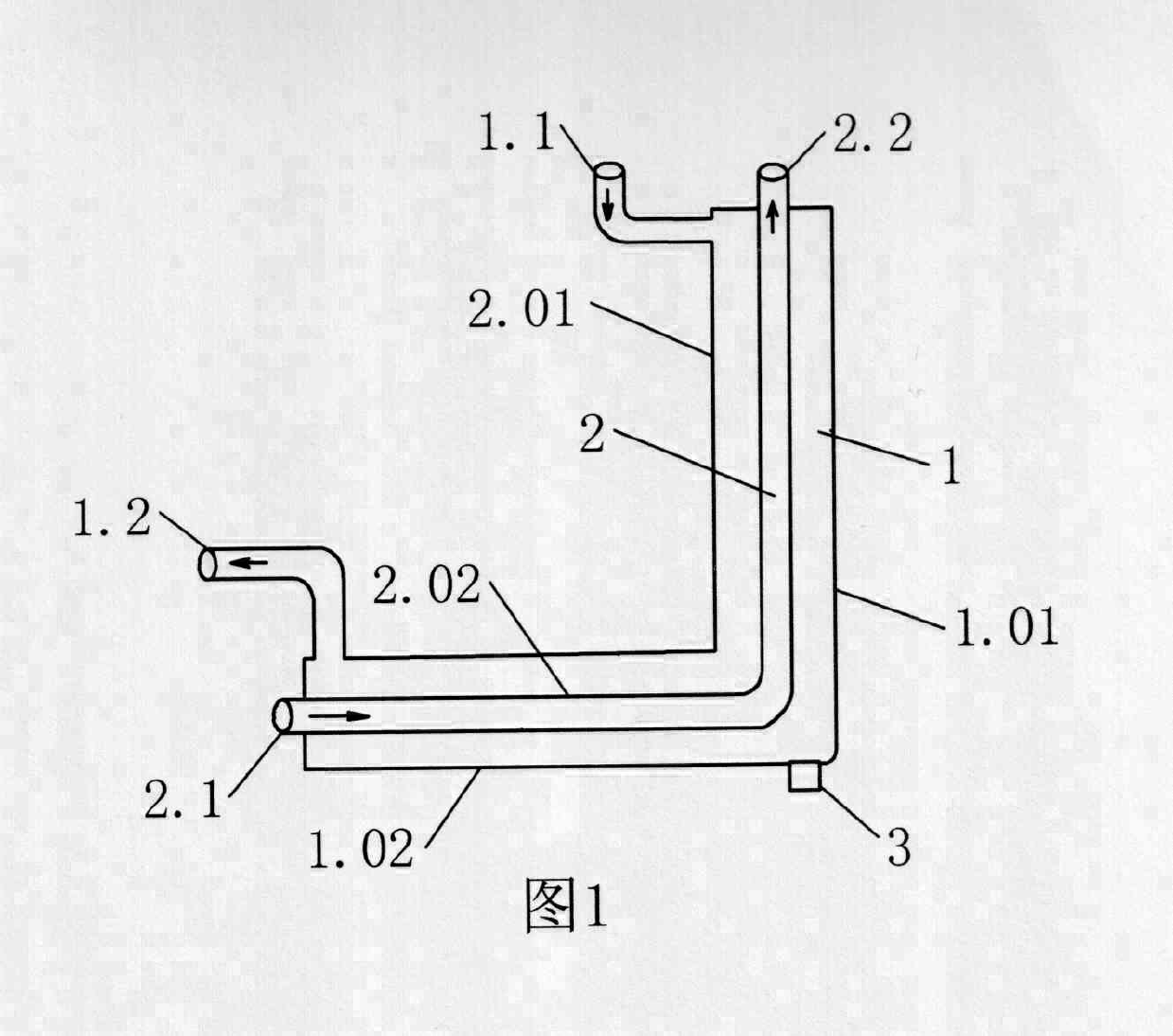

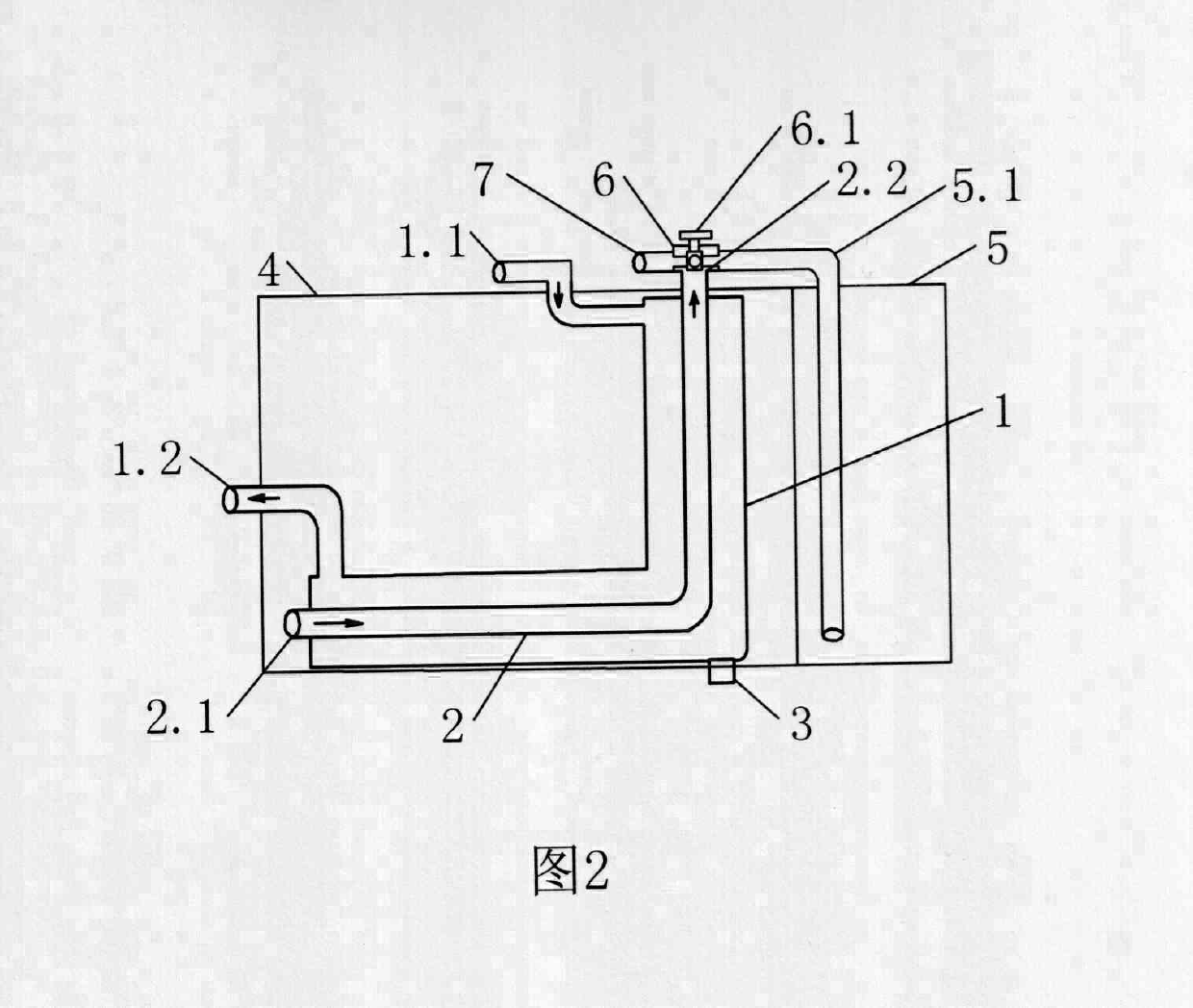

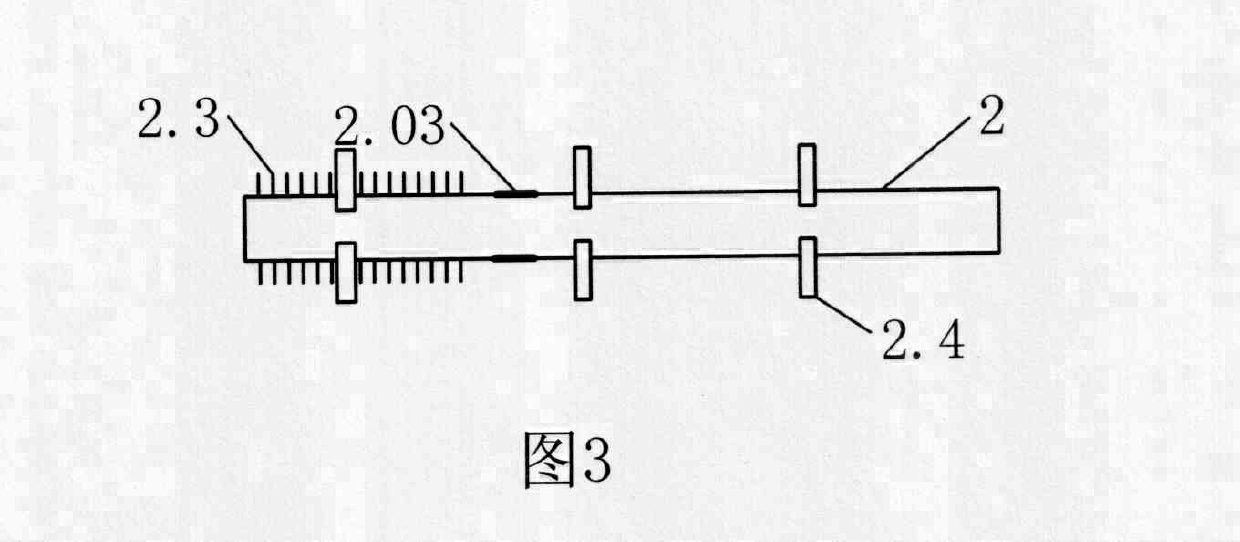

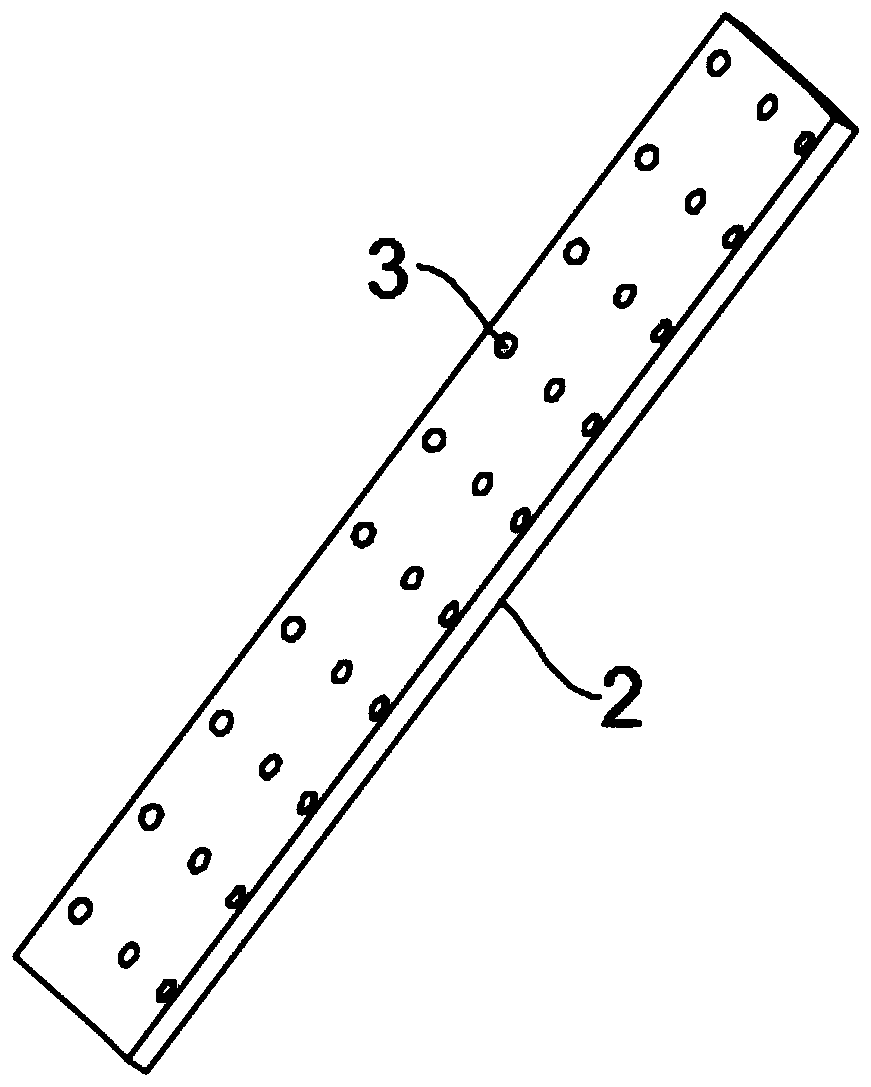

Lubricating and cooling system for vibrating roller

InactiveCN101250846AReduce heat lossReduce energy lossLubrication elementsRoads maintainenceEngineeringVibration exciter

The invention belongs to the mechanical field of road rollers, in particular to a lubricating cooling system of a vibratory roller. The invention comprises an oil pump assembly which is fixed on the body of the road roller, a vibration exciter shell and a wheel body of the road roller are formed into a rolling matching by a bearing, and a fixed shaft which is used to locate each bearing seat of a vibrating wheel assembly is fixed in the inner side of the vibration exciter. Pressure lubricating oil is transported into an oil cavity which is arranged in the inner portion of the fixed shaft through an oil supply pipe of the oil pump assembly, enters into an oil passage of each bearing through an opening which is arranged on the wall surface of the fixed shaft, and then flows into the opening which is arranged on the bottom portion of the vibration exciter shell through each oil passage and is converged on the bottom end surface in the wheel body of the road roller to form an oil basin, and the lubricating oil in the oil basin is pumped to the oil pump by an oil suction pipe to form a whole cycle lubrication path. The lubricating cooling system of the vibratory roller has simple structure and full lubrication.

Owner:屠卫东

Recovery vessel for floating oil at sea

InactiveCN102991649AQuick clean upQuick cleanup and recyclingWater cleaningWaterborne vesselsSuction tubingWaste management

The invention relates to a recovery device for pollutants on the water, in particular to a recovery vessel for floating oil at sea, which is provided with a vessel body. The vessel body is provided with a floating oil recovery tower, an oil gathering floating plate and an oil gathering tank, a floating oil collecting hole is arranged at the bottom of the vessel body, the vessel body at two sides of the floating oil collecting hole is provided with the oil gathering floating plate, and a lower edge of the oil gathering floating plate is lower than the bottom of the vessel body; the lower end of the floating oil recovery tower is in an opening type and is connected with the floating oil collecting hole, the floating oil recovery tower is connected with the oil gathering tank through an oil suction pipe, and the oil suction pipe is provided with a suction pump. When the recovery vessel for pollutants on the water is utilized, the recovery vessel is placed on the sea which is polluted by the floating oil, and the vessel body is floated through the oil gathering floating plate; and the recovery vessel is started to travel forwards, the floating oil on the sea enters into the floating oil recovery tower through the floating oil collecting hole under the blockage of the oil gathering floating plate, and the recovery vessel provides power for the suction pump so as to pump the floating oil in the recovery tower into the oil gathering tank, thereby realizing the recovery of the floating oil on the sea, and the recovery speed is fast and the effect is good.

Owner:WEIHAI ZHONGFU XIGANG SHIP

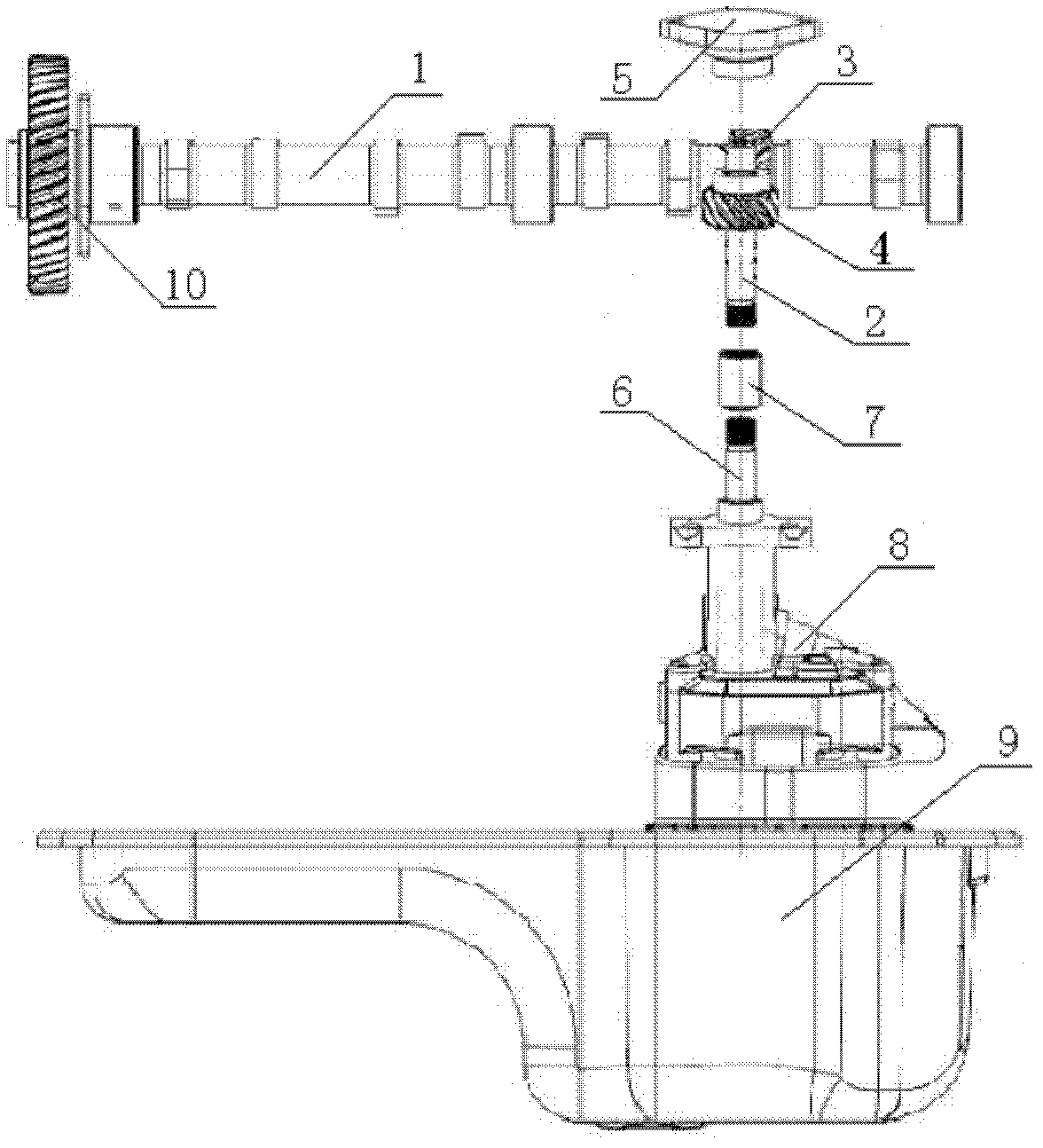

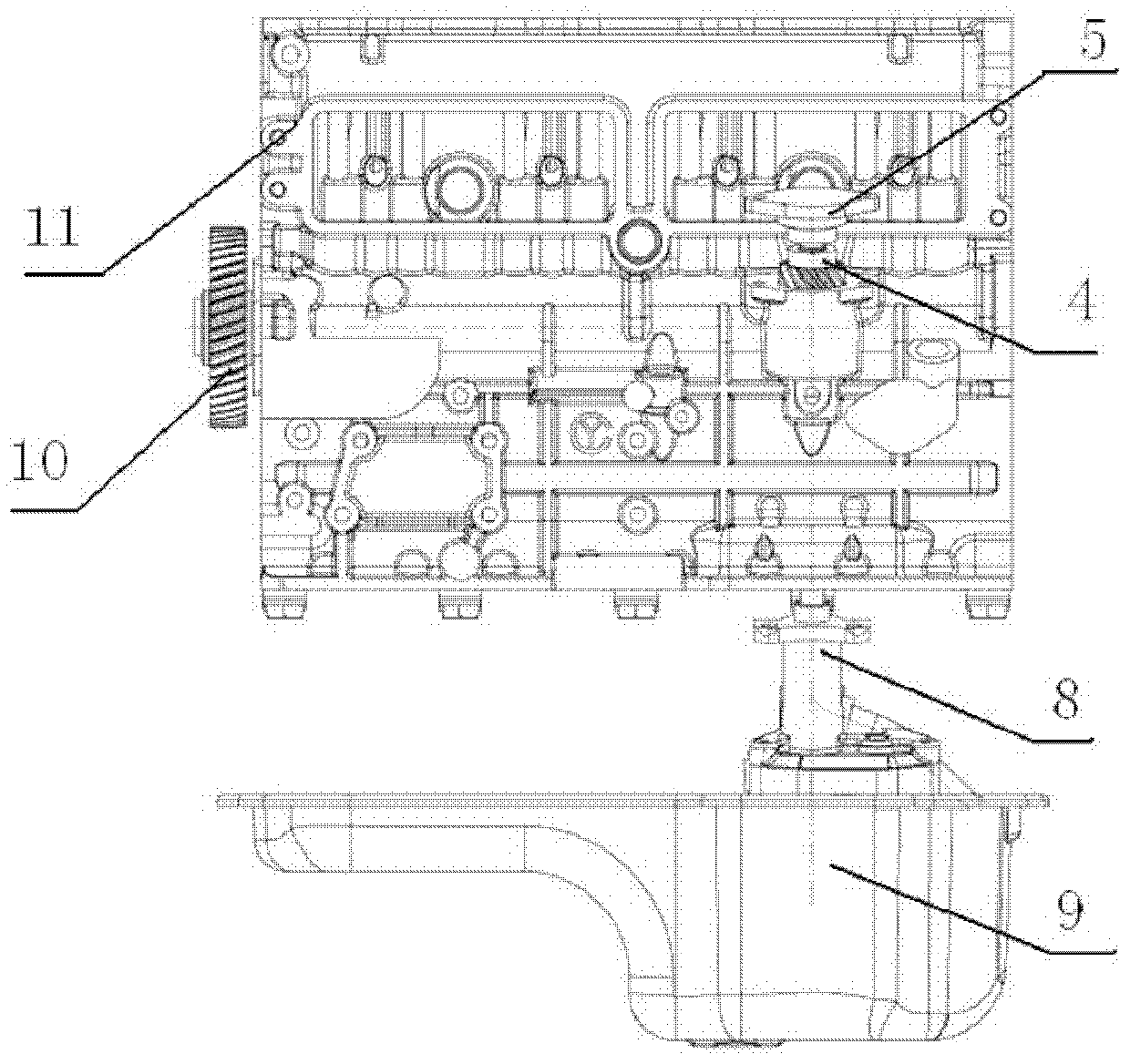

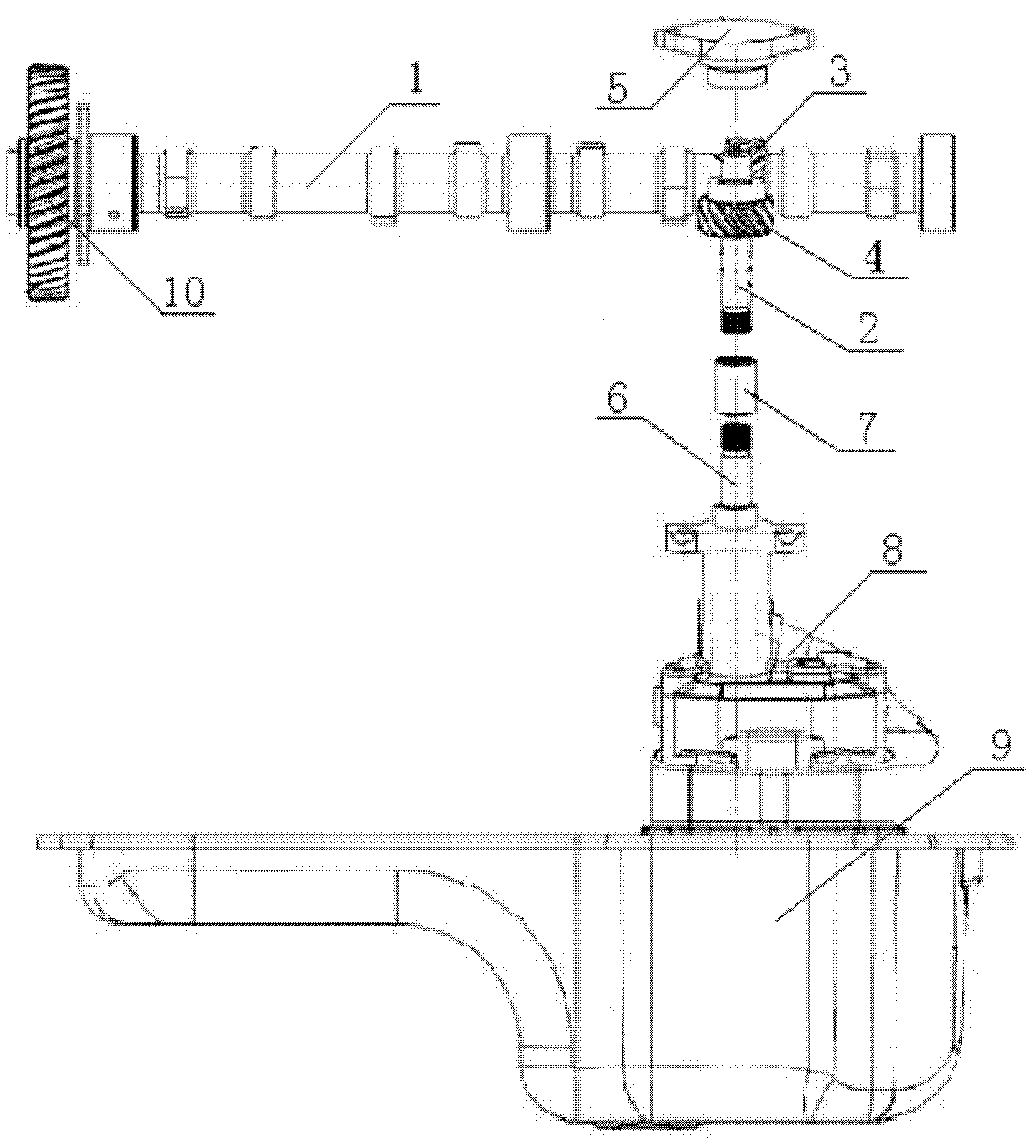

Oil pump driving system for diesel engine

InactiveCN102606255AReduce design difficultyReduce manufacturing difficultyMachines/enginesPressure lubrication with lubrication pumpGear wheelEngineering

The invention discloses an oil pump driving system for a diesel engine, which is structurally characterized in that a camshaft is connected with an oil pump driving shaft through a pair of mutually engaged bevel gears, a horizontal bevel gear is connected with the camshaft, a vertical bevel gear is connected with the oil pump driving shaft, a polished shaft is arranged at one end of the oil pump driving shaft and inserted into a driving shaft cover, the other end of the oil pump driving shaft is connected with a main gear shaft of an oil pump through a spline structure, a spline connecting end is provided with a spline sleeve, the oil pump is arranged in an oil pan, a crankshaft gear of the diesel engine drives a camshaft gear to rotate, and the camshaft runs according to valve timing. The oil pump is directly arranged in the oil pan and directly contacts with oil, flow resistance caused by an original oil suction pipe is eliminated, and oil pumping capacity is effectively improved. The oil pump driving system is arranged on the lateral face of an engine body without adopting the structure of arranging an oil pump at the front end of an engine at present, so that difficulty in designing and manufacturing a gear chamber and a gear chamber cover of the engine is reduced.

Owner:东风朝阳朝柴动力有限公司

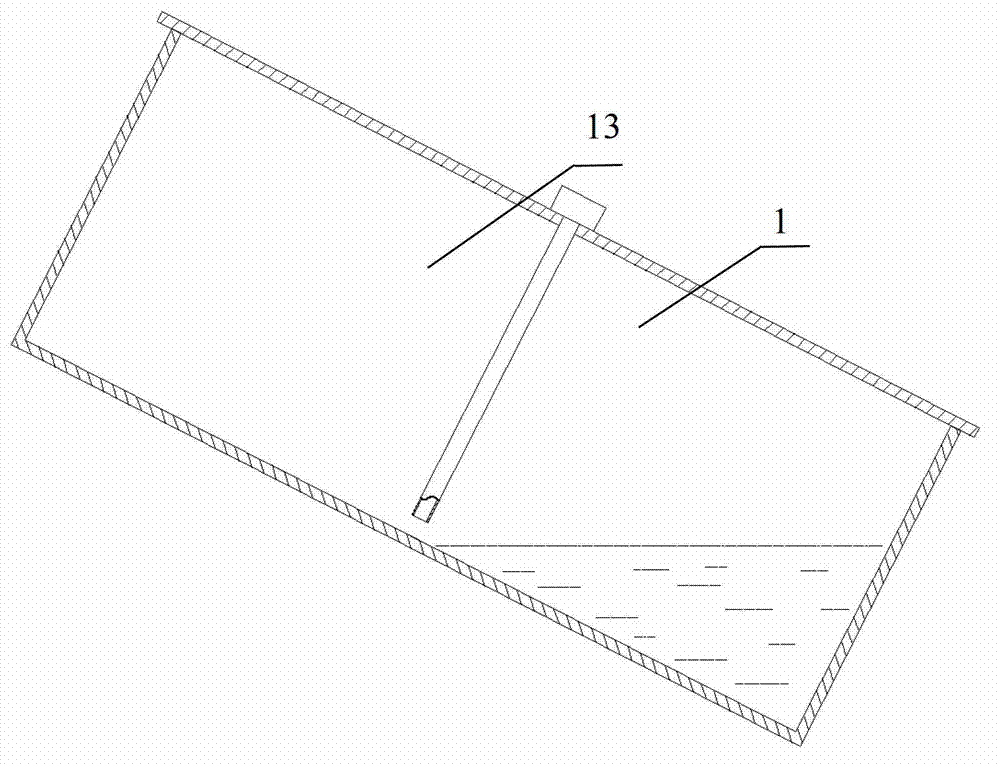

High-volume utilization rate fuel tank

ActiveCN102777296ALower inventory requirementsIncrease profitMachines/enginesLiquid fuel feedersFuel tankProcess engineering

The invention relates to a high-volume utilization rate fuel tank which solves the defect that fuel is not sucked by a fuel sucking pipe when the traditional fuel tank has little fuel and inclines. The fuel tank comprises a tank body, wherein a fuel sucking device is arranged in the tank body and comprises a fuel sucking joint, a fuel sucking soft tube and a fuel sucking nozzle, wherein one end of the fuel sucking soft tube is fixed on the middle-upper part of the tank body through the fuel sucking joint, the other end of the fuel sucking soft tube is connected with the fuel sucking nozzle, the fuel sucking nozzle is arranged on the bottom of the tank body, and the fuel sucking nozzle can slide to a low position from a high position of the tank body under the action of the gravity. When the fuel tank has little fuel and inclines, the fuel sucking nozzle can move to a fuel accumulation area at the low place of the fuel tank so that fuel can be sucked without causing stalling of an engine, therefore, the requirement on the minimum fuel quantity in the fuel tank can be reduced, and the actual utilization rate of the volume of the fuel tank is increased.

Owner:GUANGXI LIUGONG MASCH CO LTD

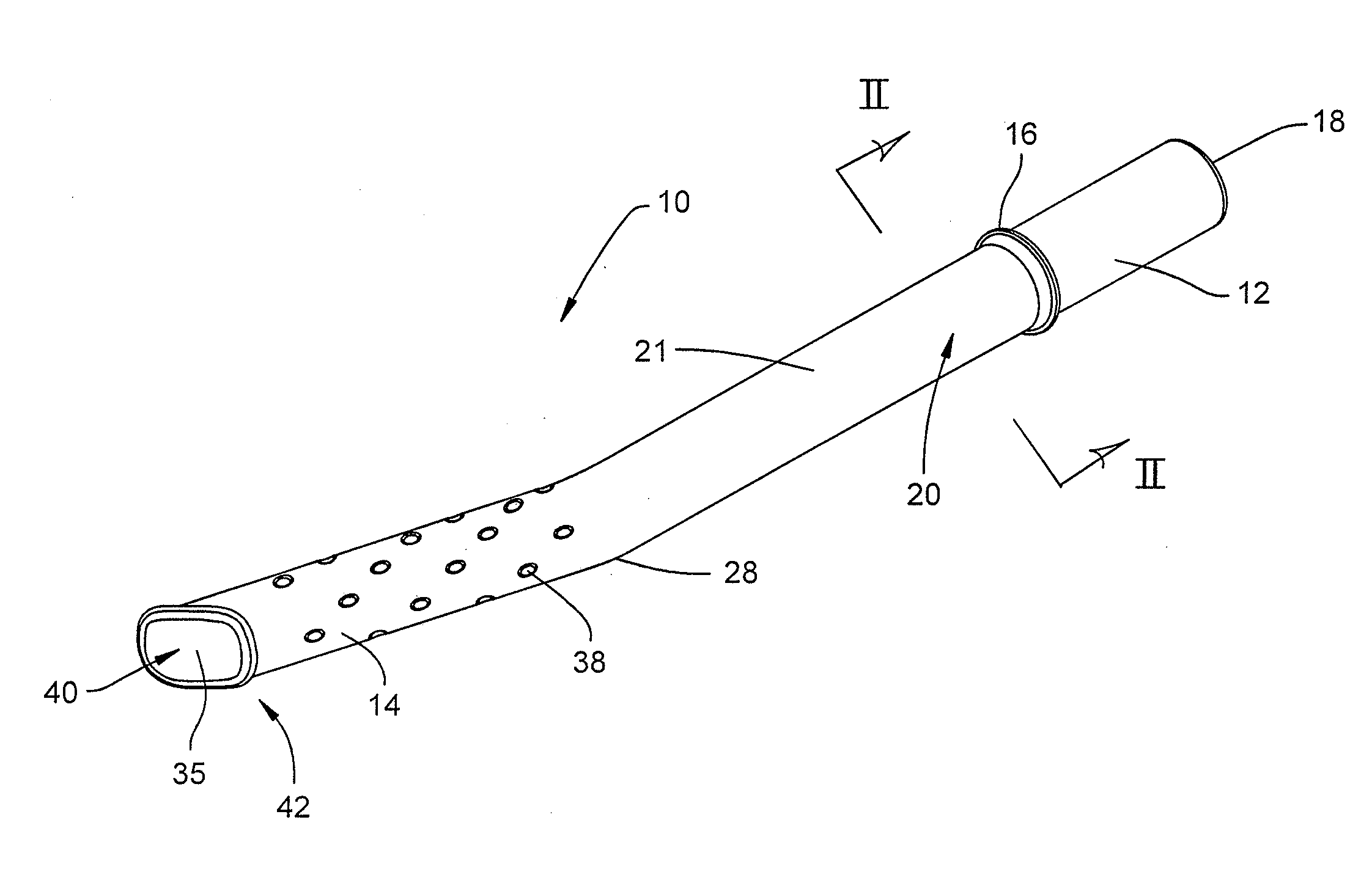

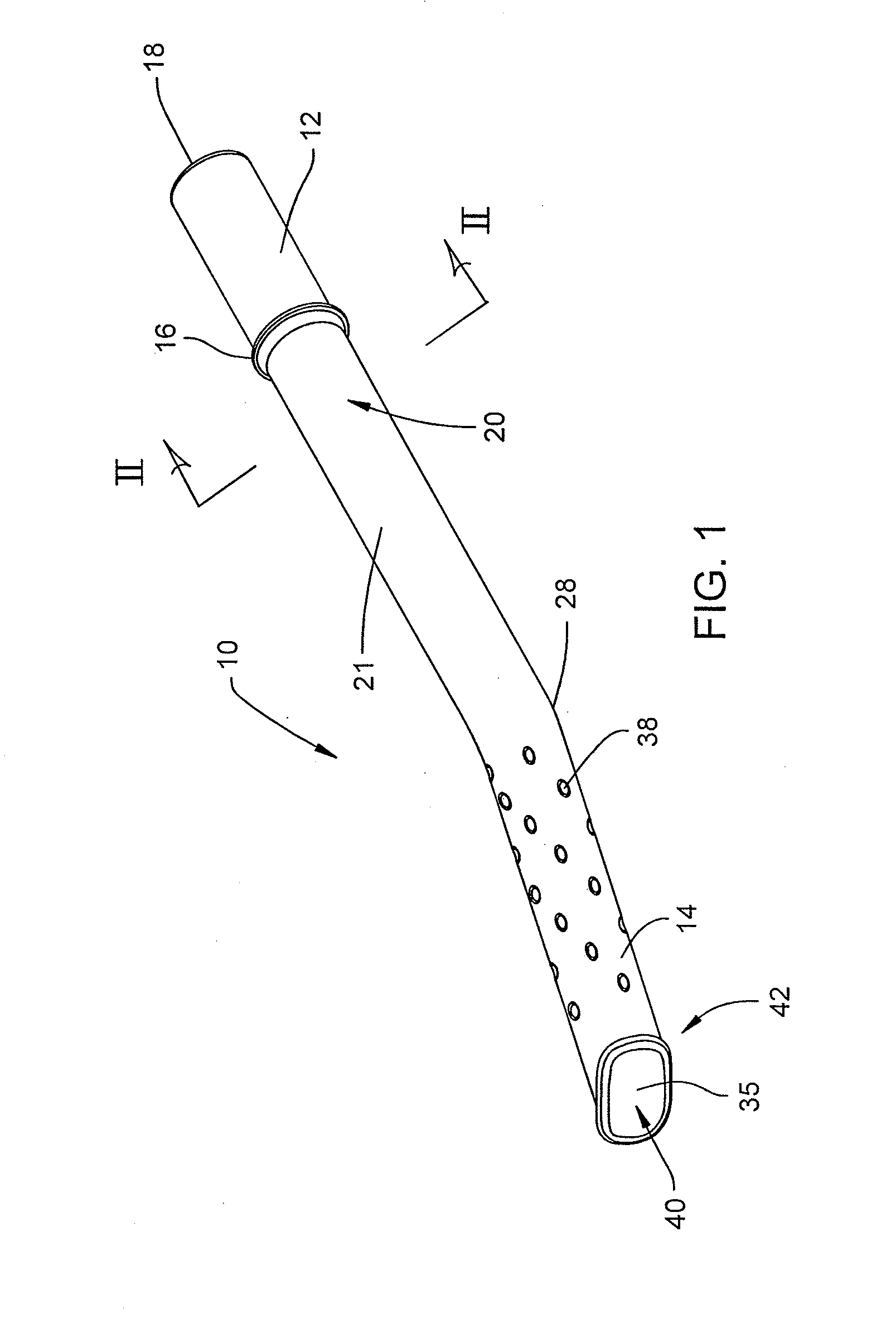

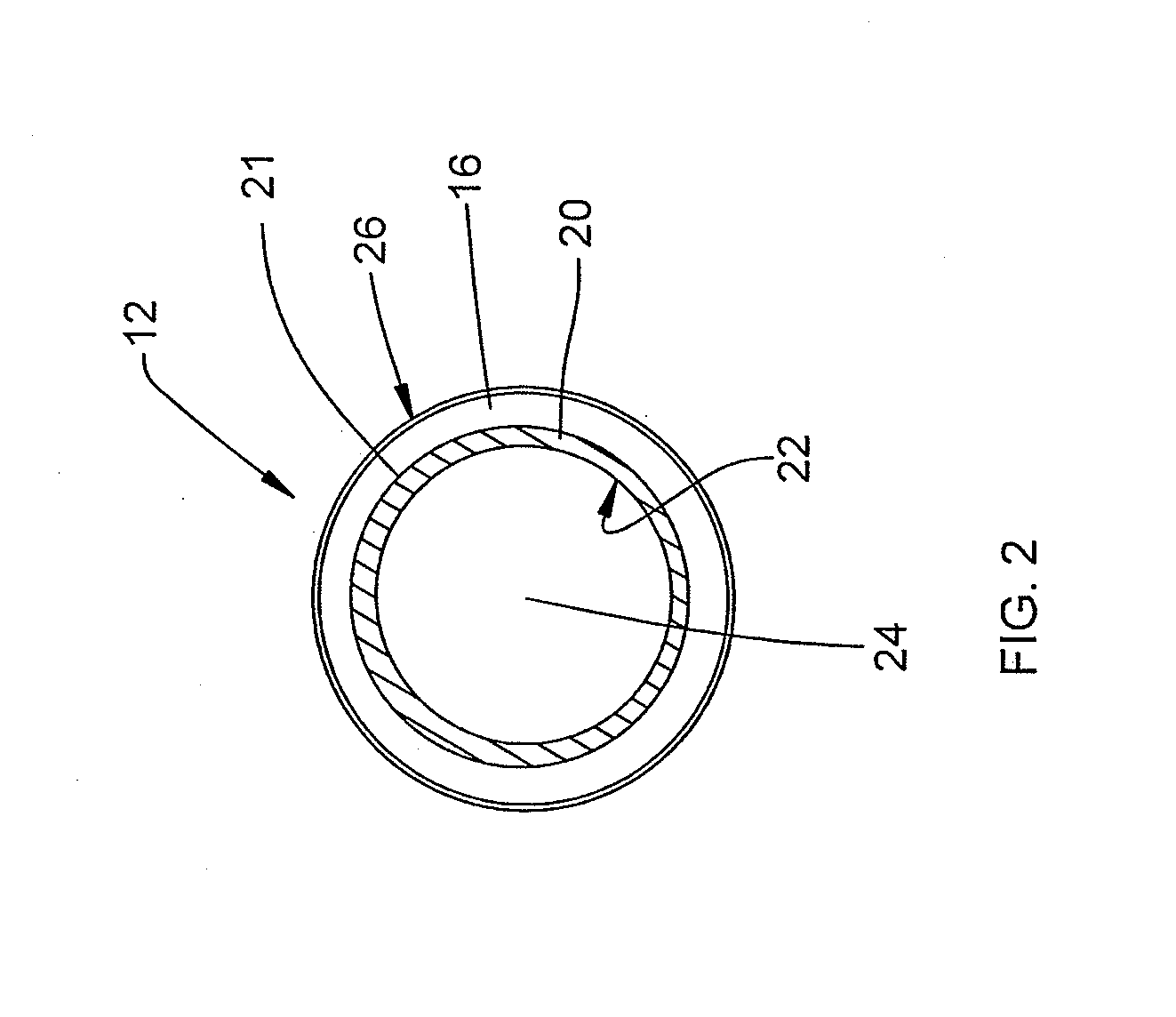

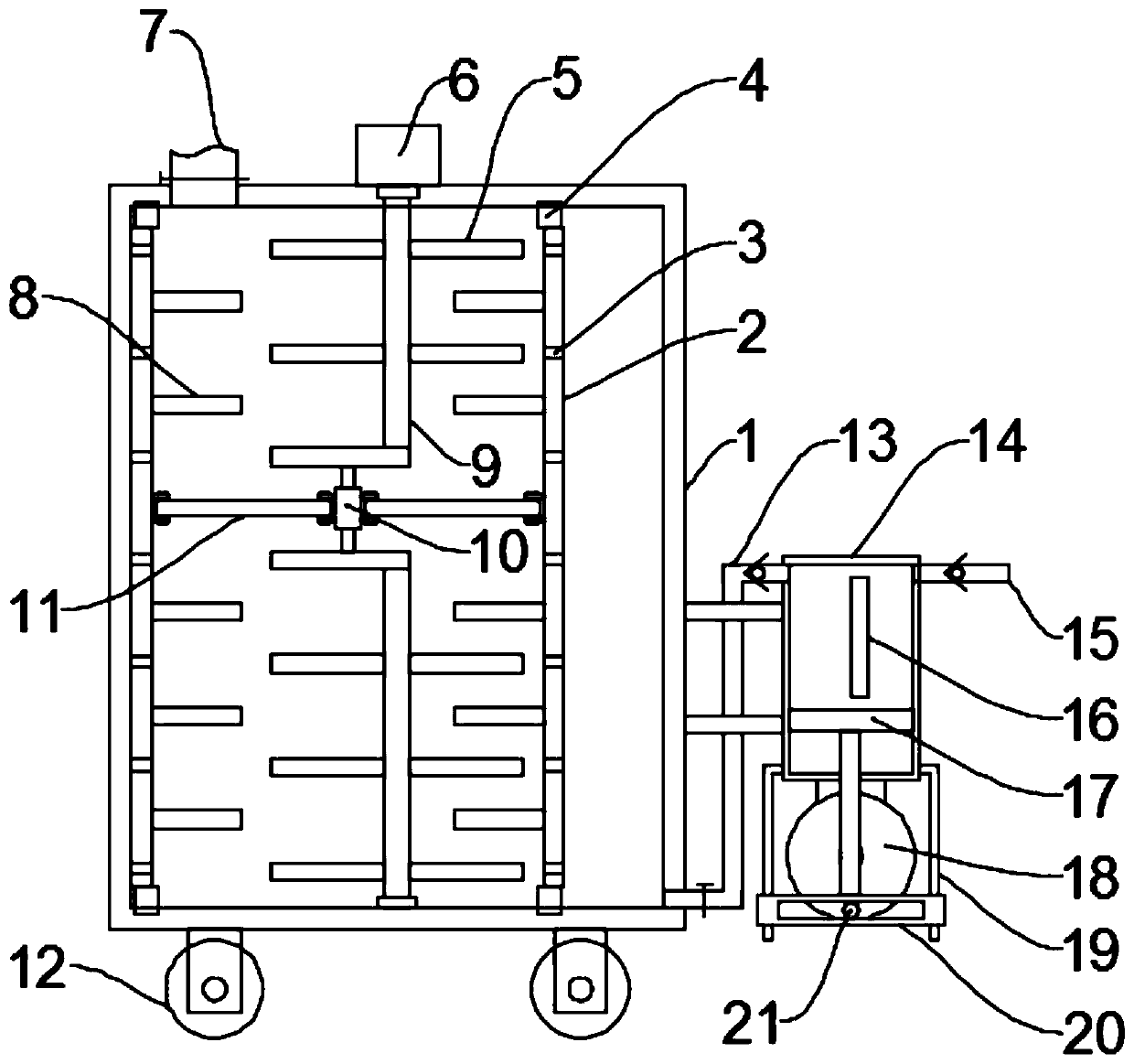

Dental suction tubing

A dental suction tube having a plurality of apertures in a distal portion of the tube is provided. The apertures are provided in a pattern to allow suction performance even when a portion of the distal end of the tube is abutting a portion of the mouth or other item during a dental procedure.

Owner:RONTO DAVID R

Oil-in-water type heater oil tank

ActiveCN102606356AIncrease oil temperatureIncrease the heating areaMachines/enginesThermal treatment of fuelFuel tankWater jacket

The invention provides an oil-in-water type heater oil tank. A heater formed by inserting an oil suction pipe into a water sleeve which is composed of a water sleeve transverse pipe and a water sleeve vertical pipe is arranged in a main oil tank, the oil suction pipe and a high number oil suction pipe are respectively communicated with a three-way oil valve; thereby forming the oil-in-water type heater oil tank. An auxiliary oil tank is arranged in the main oil tank of the heater oil tank; a water sleeve is arranged in the main oil tank; the oil suction pipe is arranged in the water sleeve, the high number oil suction pipe is arranged in the auxiliary oil tank, and then the oil suction pipe and the high number oil suction pipe are respectively communicated with an oil supply pipe after being communicated with the three-way oil valve. The oil-in-water type heater oil tank is characterized in that the water sleeve and the oil suction pipe are composed of vertical sections and transverse sections; the vertical sections are located at the bottom of the main oil tank, and the vertical sections are located at the middle part of the oil tank. The heater oil tank has the characteristics that the heater oil tank is large in heating area, high in oil temperature, great in energy-saving effect, and environment friendly. Therefore, the heater oil tank is appropriate for the oil tank at the low-temperature state of diesel engines and diesel vehicles.

Owner:刘晶

Horizontal rotary compressor

InactiveUS7040880B2Improve reliabilityRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeEngineeringSuction tubing

Owner:TOSHIBA CARRIER CORP

Novel water surface spilled oil collecting containment boom based on negative pressure principle

InactiveCN109930571AReduced impact of using space occupationSmall footprintWater cleaningGeneral water supply conservationCouplingOil water

The invention discloses a novel water surface spilled oil collecting containment boom based on a negative pressure principle. The novel water surface spilled oil collecting containment boom comprisesa water surface spilled oil collector, a oil containment boom body, a negative pressure bump and a rapid ship oily water separating device, wherein the water surface spilled oil collector comprises abarrel body and an oil suction pipe, an oil inlet is formed on the top of the barrel body, a circular hole is formed at the bottom of the barrel body, the circular hole is connected with the oil suction pipe, a height adjuster is arranged at the oil inlet on the top of the barrel body, the oil containment boom body comprises a floating body, a flexible pipe, quick couplings, a flared body, a tension band and a counterbalance weight, wherein the flexible pipe is arranged inside the floating body, the quick couplings are arranged on two ends of the flexible pipe, the flared body is arranged on the lower part of the floating body, the bottom end of the flared body is connected with the counterbalance weight, the tension bend is arranged on the outside surface of the floating body, the flexible pipe is provided with an opening and is connected with the oil suction pipe, and the barrel body is connected with the oil containment boom body though a hook. According to the novel water surface spilled oil collecting containment boom based on the negative pressure principle, the oil containment function of an oil containment boom and the oil collecting function of an oil collecting machine are combined, and timely treatment of water surface spilled oil and more efficient spilled oil recovery are realized.

Owner:WUHAN UNIV OF TECH

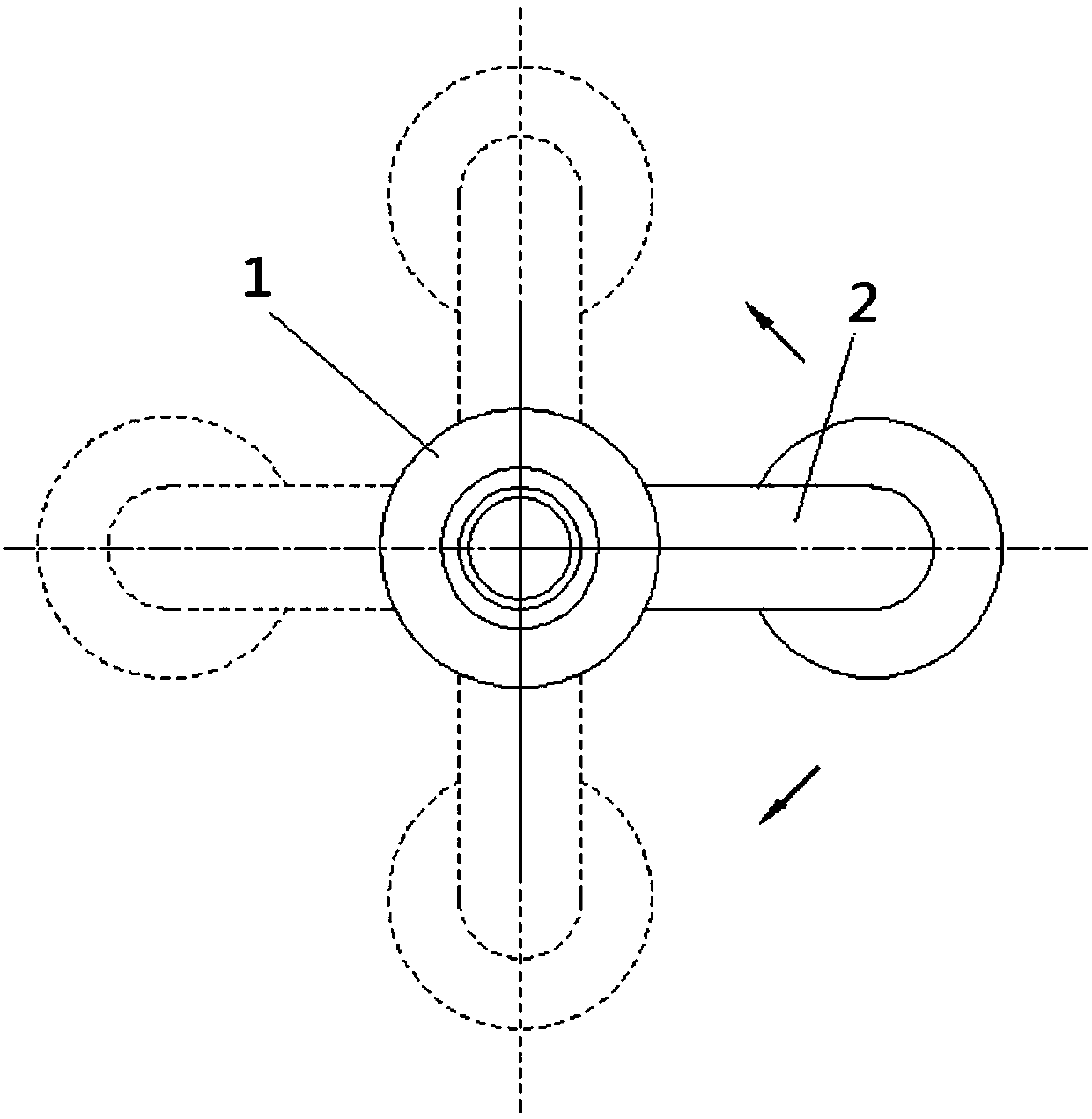

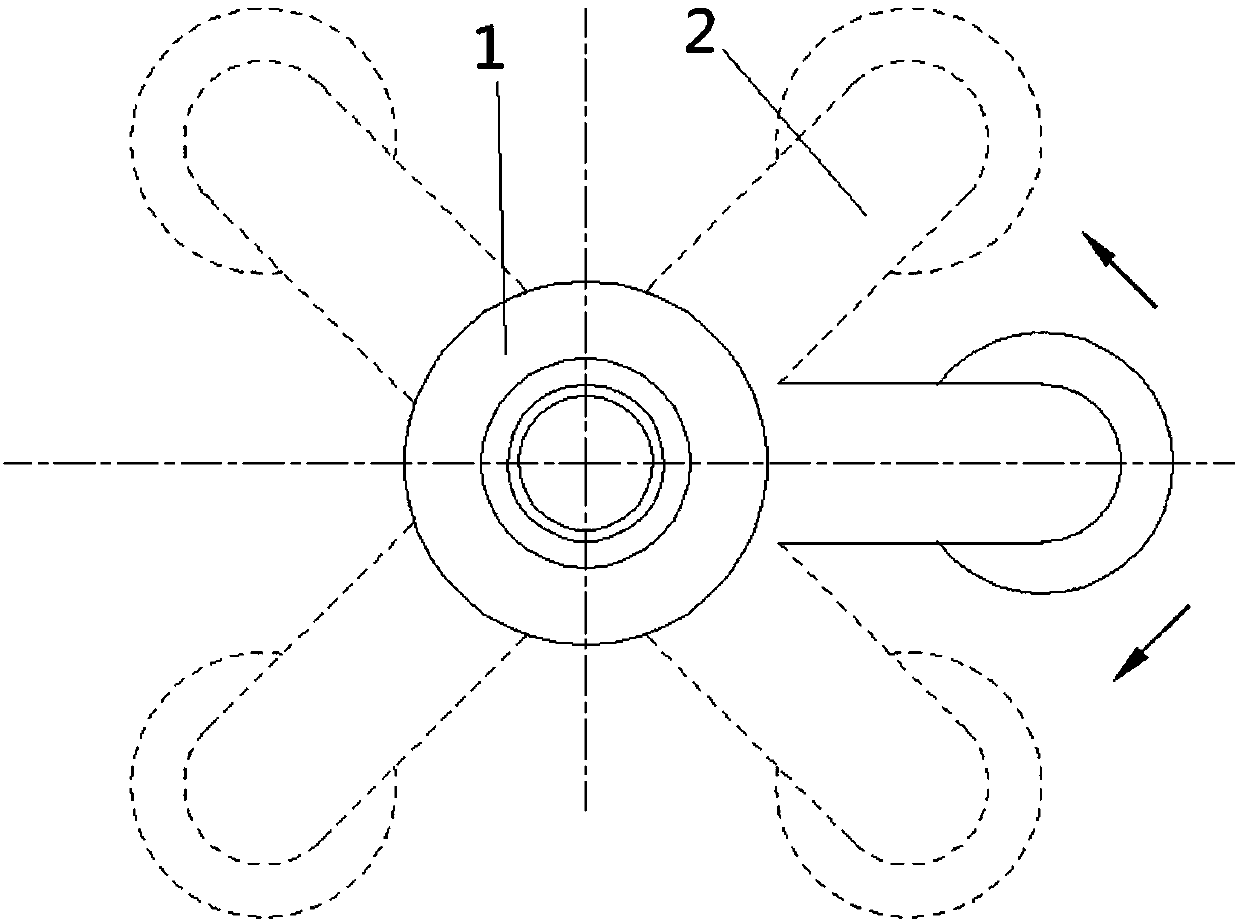

Oil spilling collecting device and method

ActiveCN110685258ACollect thoroughlyImprove collection effectWater cleaningGeneral water supply conservationDrive wheelElectric machinery

The invention discloses an oil spilling collecting device and method, and aims at solving the problem that an ocean oil spilling collecting device is poor in oil spilling collecting effect. The devicecomprises two oppositely-arranged floating bodies, oil guiding floating rods connected to the front ends of the floating bodies, an oil suction mechanism, a preceding-stage collecting mechanism and abackward-stage collecting mechanism. The oil suction mechanism comprises a floating beam, an oil suction pipe and an oil suction pump. A row of oil suckers are installed on the floating beam, the oilsuckers are all communicated with the oil suction pipe, and the oil suction pipe is connected with the oil suction pump; the preceding-stage collecting mechanism comprises a collecting rope and two guiding wheels, the collecting rope is in transmission connection between the two guiding wheels, one guiding wheel is in transmission connection with a preceding-stage motor output shaft, a pluralityof oil suction rope heads are densely distributed on the collecting rope, an oil scraping box is installed on each floating body, a cone frustum shaped oil scraping hole is formed inside each oil scraping box, and the collecting rope penetrates through the oil scraping hole; and the backward-stage collecting mechanism comprises a driving wheel, a driven wheel, a tensioning wheel and an oil suctionconveyor belt, an oil receiving groove is formed between the two floating bodies, a scraper plate is connected to the oil receiving groove, and the end of the scraper plate abuts against the outer surface of the oil suction conveyor belt.

Owner:THE FIRST INST OF OCEANOGRAPHY SOA

Electric-cooling liquid mixed fuel heating system

InactiveCN102116226AImprove low temperature cold start performanceImprove environmental adaptabilityMachines/enginesThermal treatment of fuelHeating oilFuel tank

The invention relates to an electric-cooling liquid mixed fuel heating system which is characterized in that: an electric heater is arranged on an oil suction pipe and an oil return pipe on an oil tank assembly, an oil pipeline of a heater, a rough filter and a fine filter; one end of the oil pipeline of the heater is connected with the heater; the other end of the oil pipeline of the heater is connected with the oil suction pipe; a heating bushing is arranged between the oil return pipe and an engine; heating bushings are arranged among the rough filter, the engine and the oil suction pipe; the detailed method is as follows: the oil suction pipe and the oil return pipe on the oil tank assembly, and the oil pipeline of the heater are firstly heated by electricity; the cooling liquid of the engine is heated after the heater works; the heated cooling liquid of the engine enters the heating bushings to heat the diesel oil in the inner pipes of the intake and oil return pipes of a whole vehicle; meanwhile, the rough filter and the fine filter are heated by electricity; after the engine is smoothly started and runs stably, a valve is closed, and heating to the diesel through the cooling liquid is stopped. The electric-cooling liquid mixed fuel heating system improves the low-temperature cold start performance and environmental adaptive capacity of the engine. Moreover, corresponding low-brand diesels can be used, and the use cost of users is reduced.

Owner:FAW GROUP

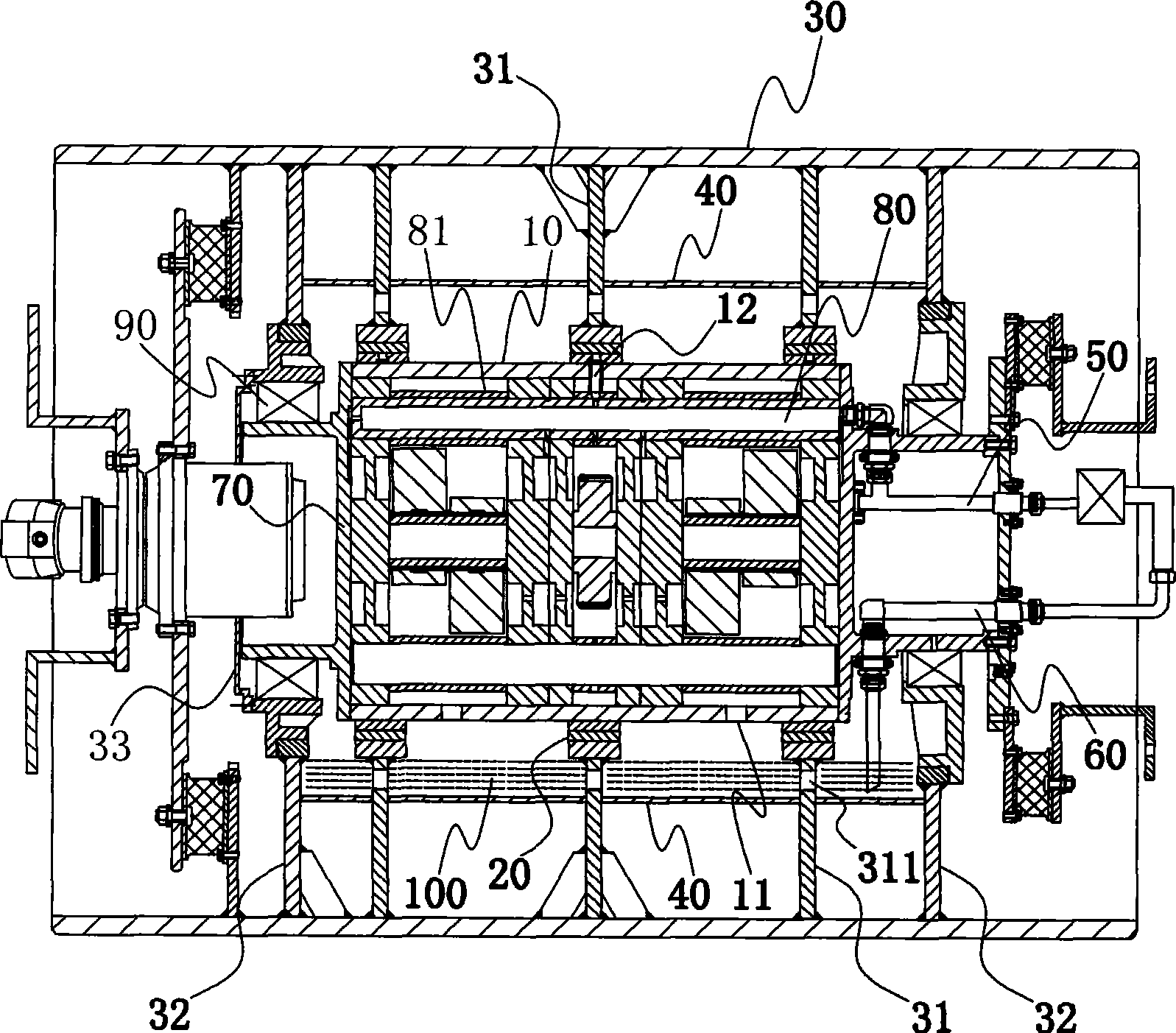

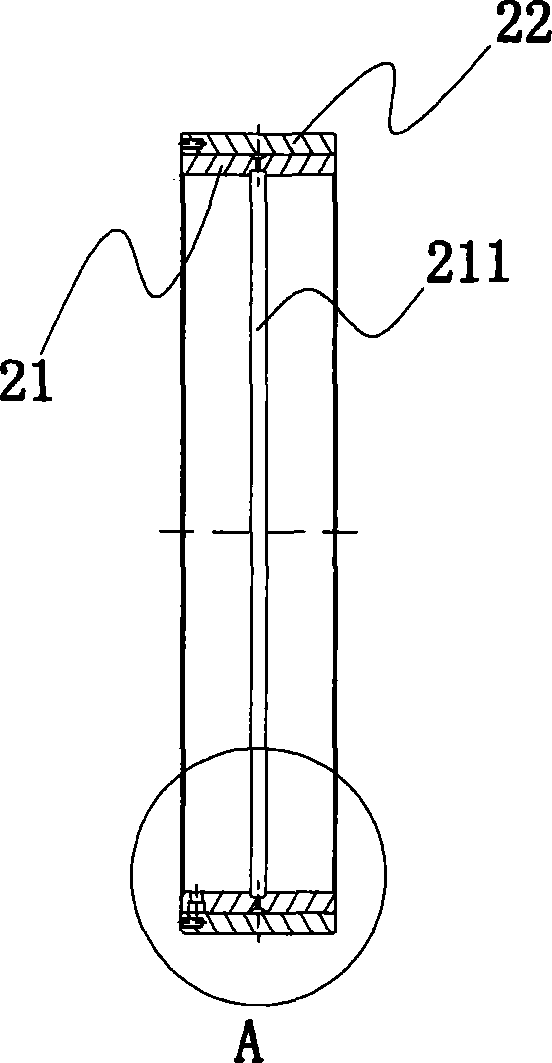

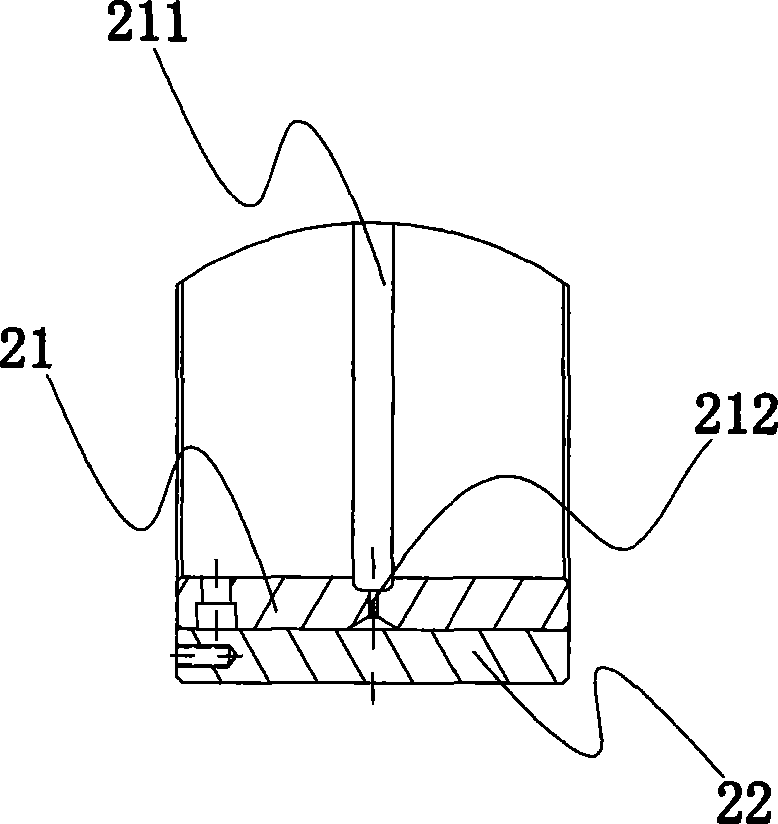

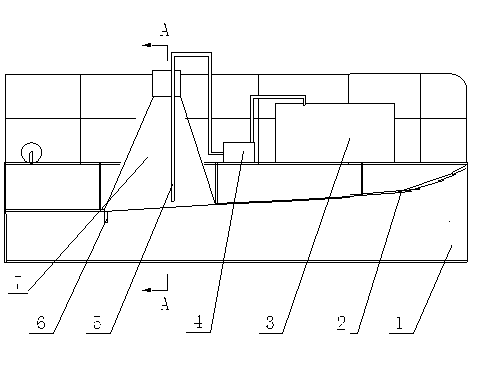

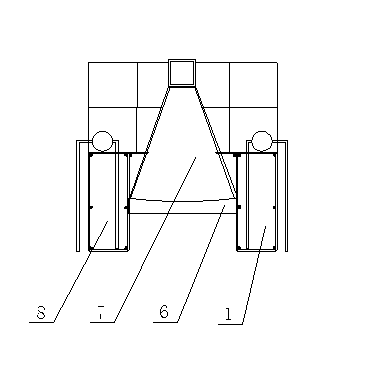

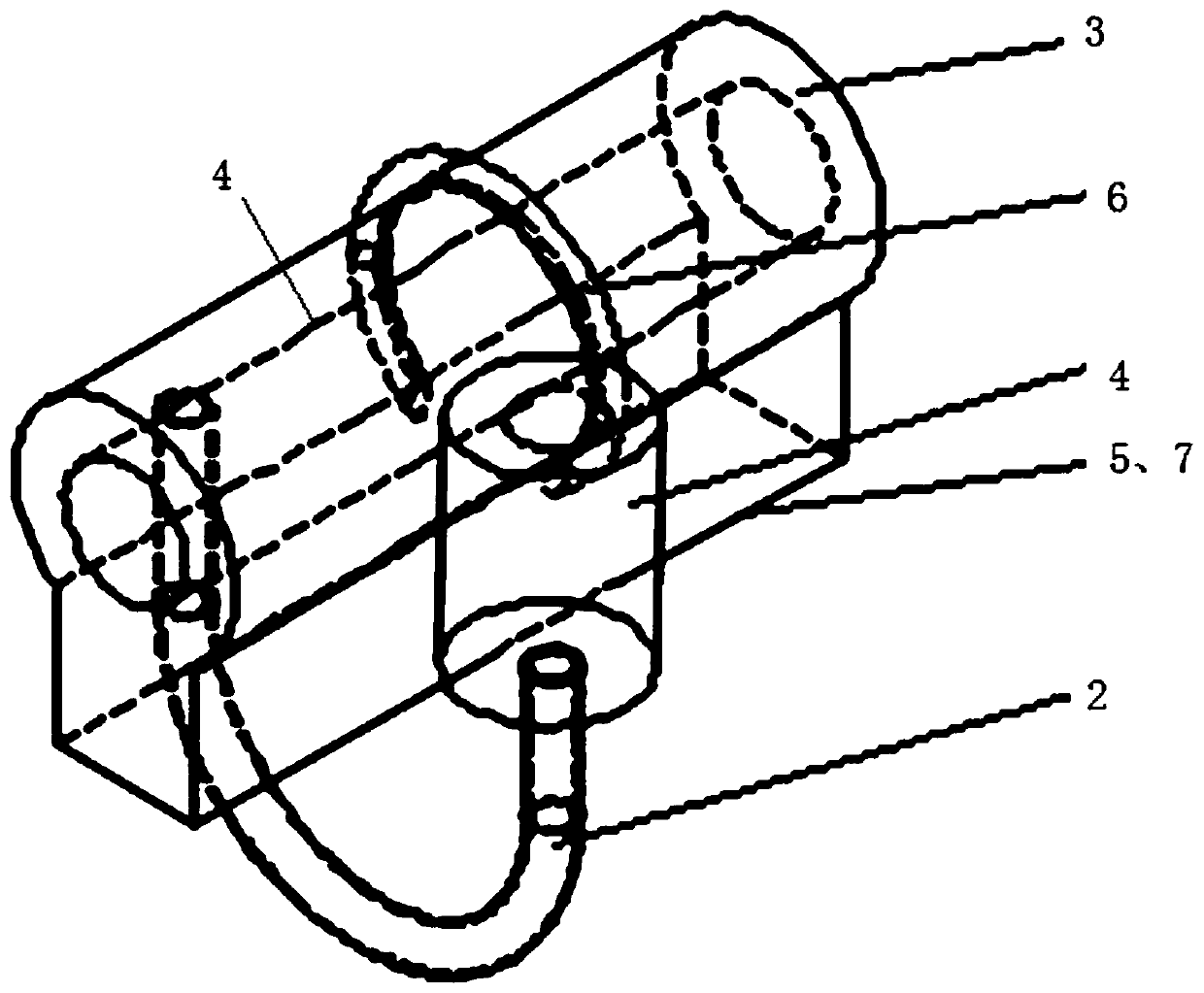

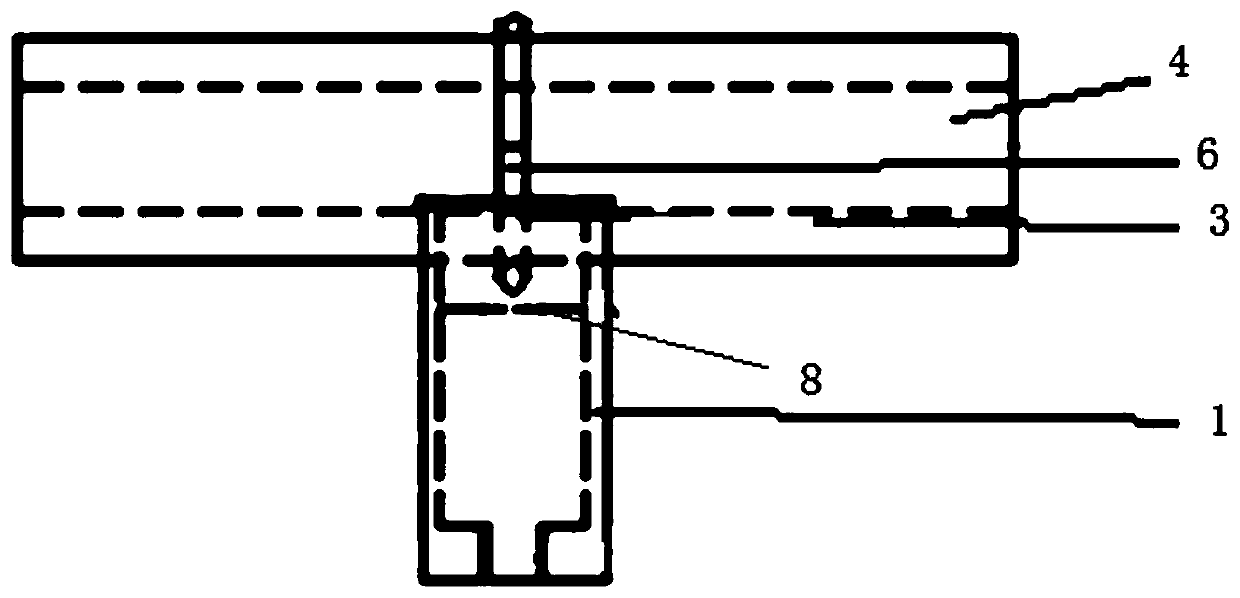

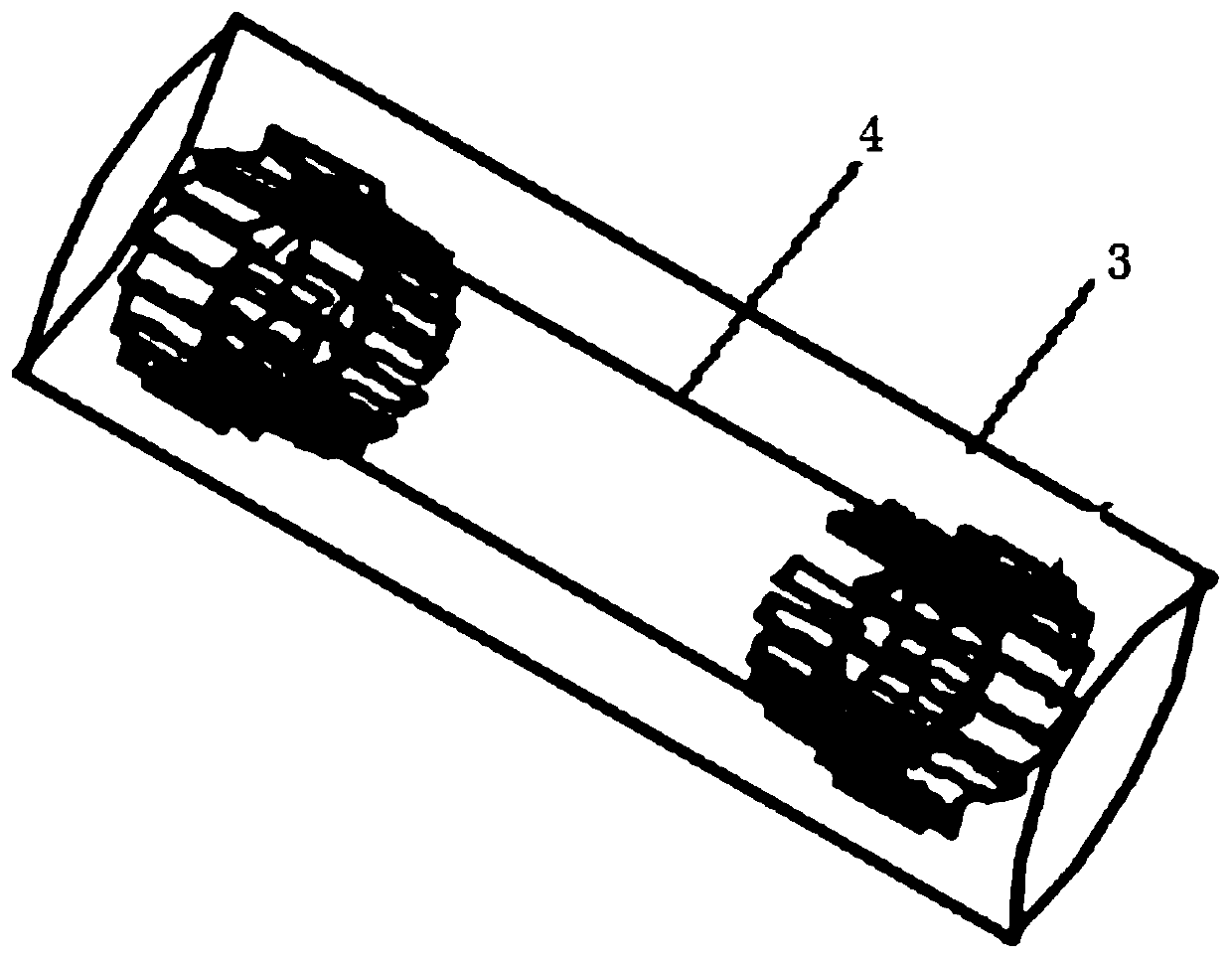

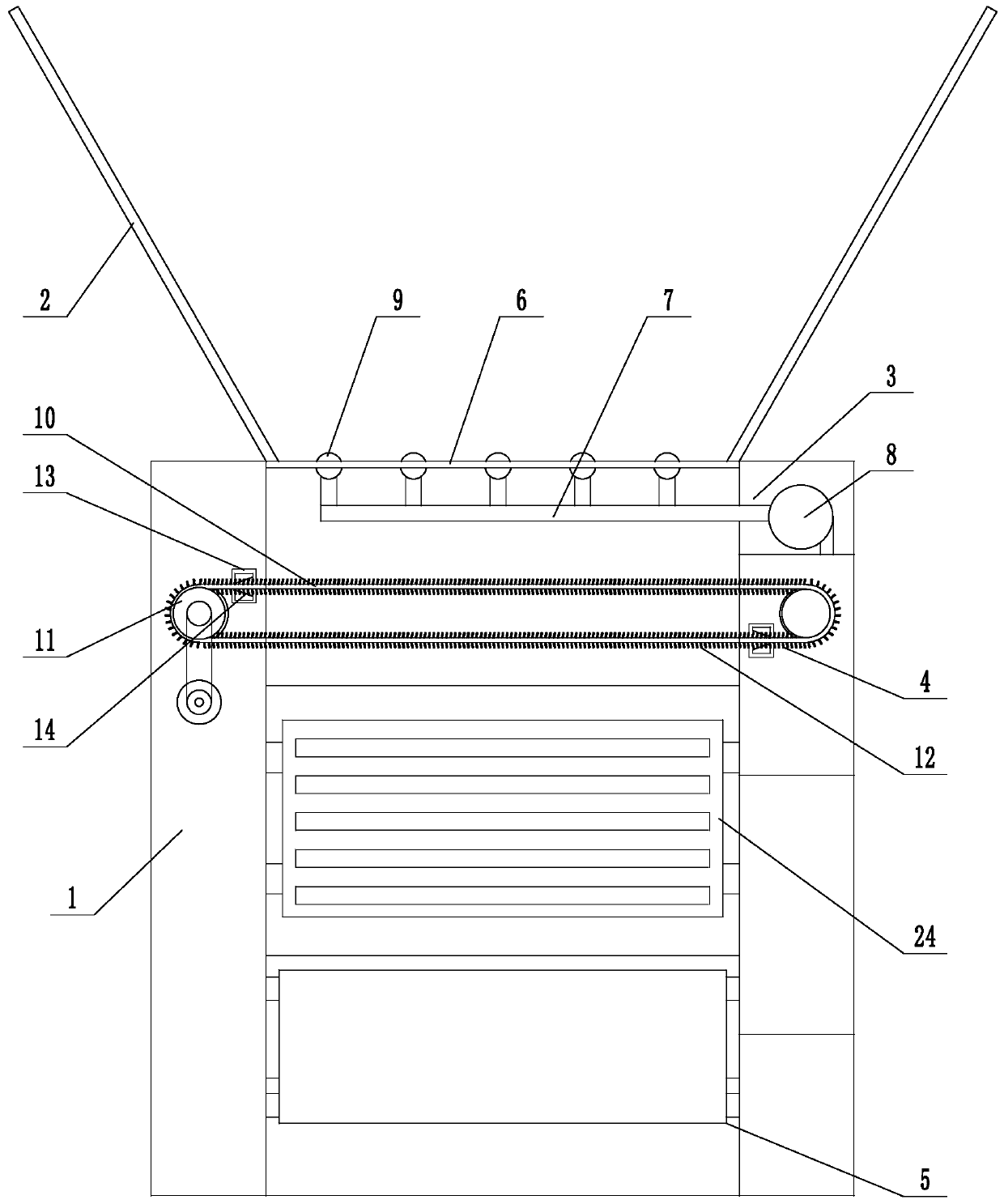

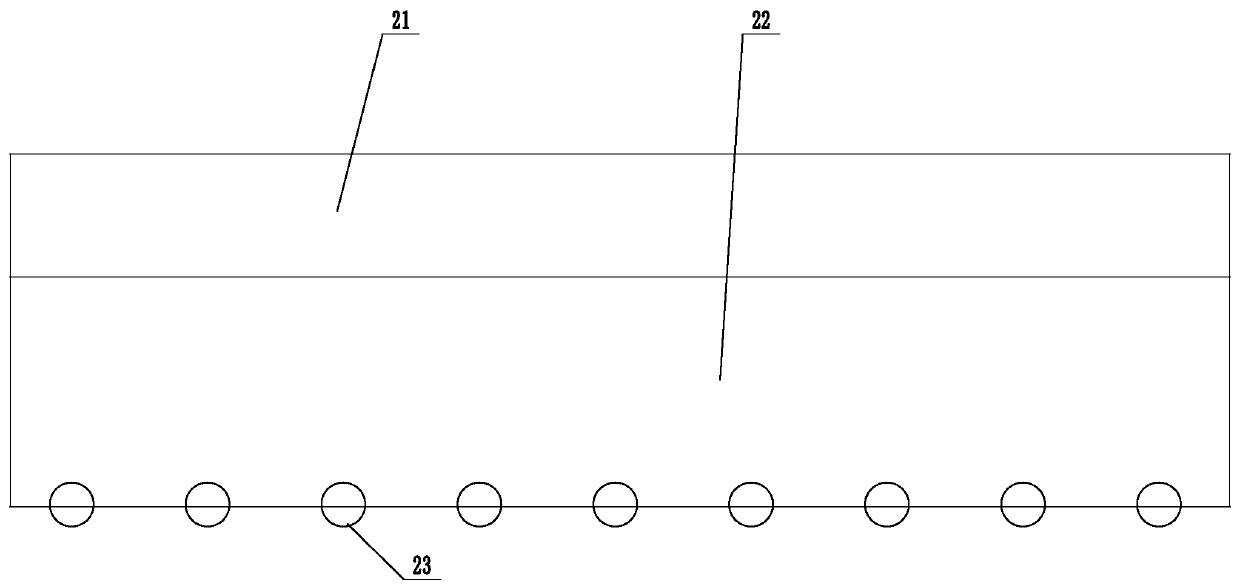

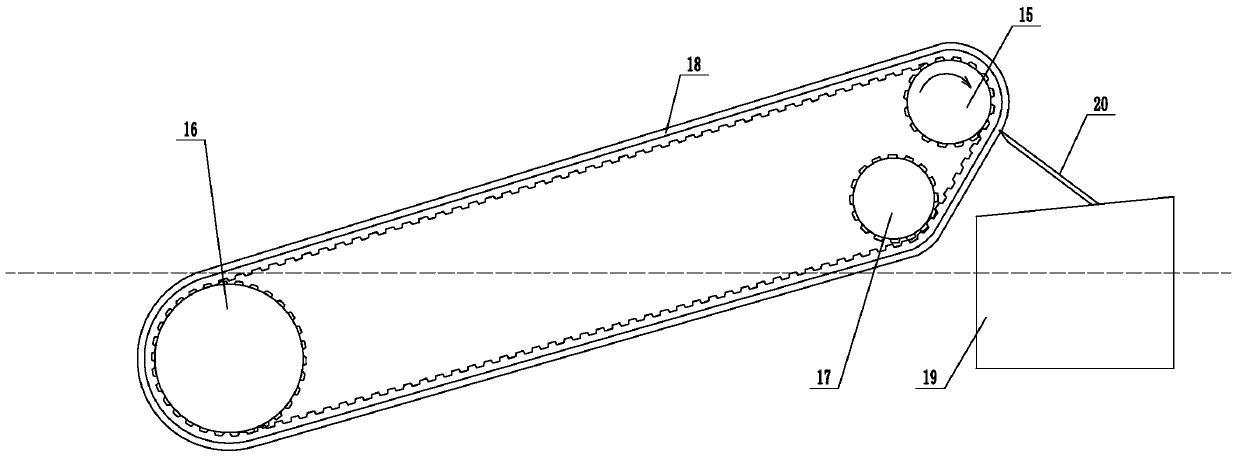

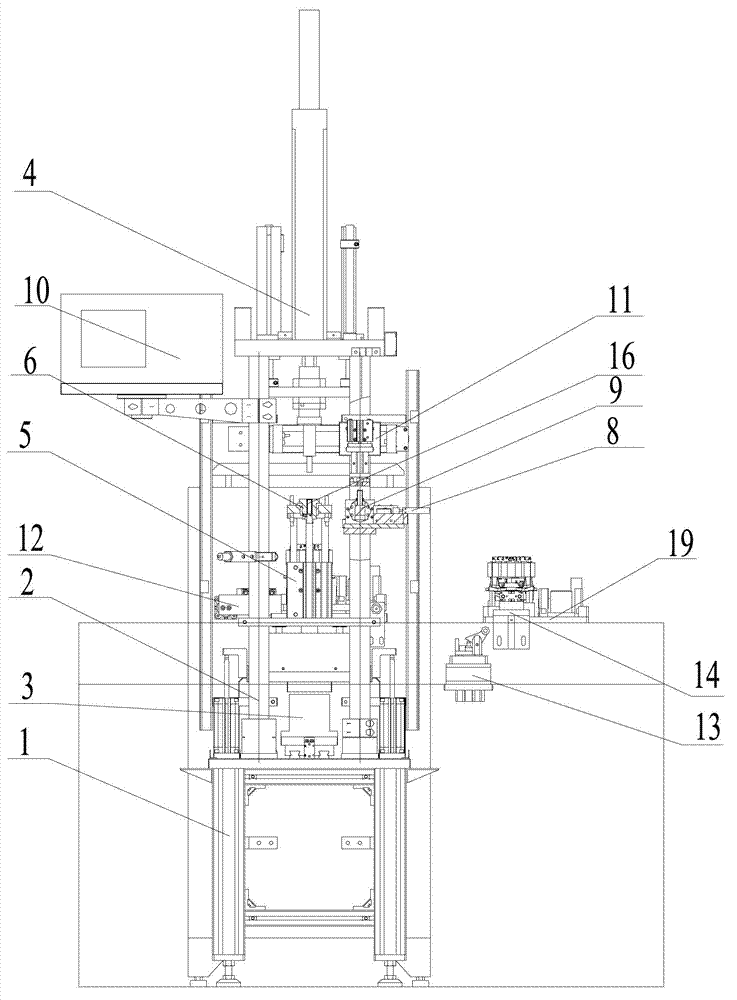

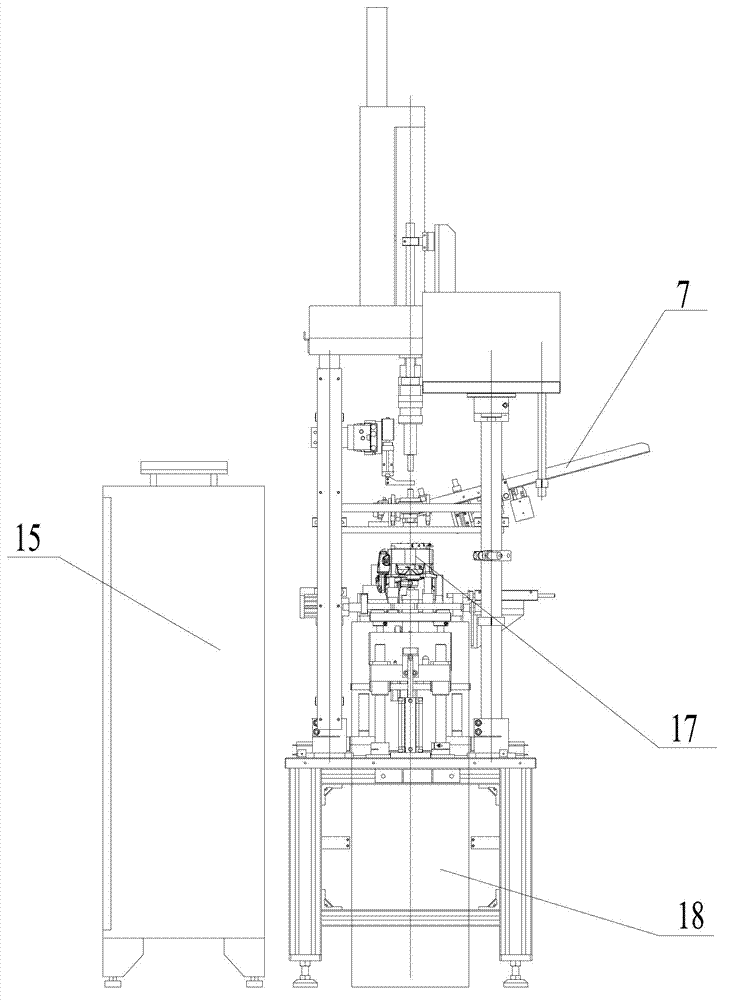

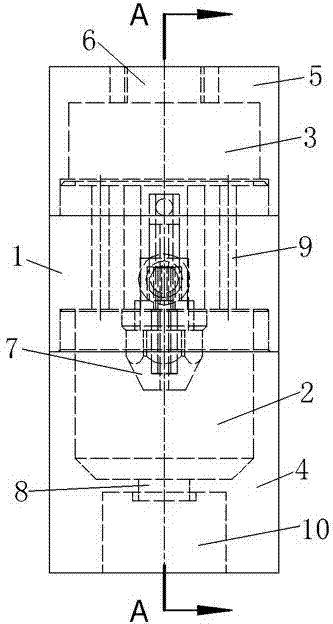

Online cold-pressing assembling device for oil suction pipes of compressors

InactiveCN103203617AControl the press-in distanceImprove quality and efficiencyMetal working apparatusOptical axisEngineering

The invention relates to an online cold-pressing assembling device for oil suction pipes of compressors. The online cold-pressing assembling device comprises a framework and a line matched with the framework; a crankshaft positioning stopping mechanism and a crankshaft positioning mechanism are mounted on the line; a cabinet is arranged at the rear of the framework, four plain shafts and a jacking positioning mechanism are fixed to the middle of the framework, the jacking positioning mechanism is positioned among the four plain shafts, a gas-liquid boosting cylinder compressing mechanism is mounted on tops of the four plain shafts, a compressing centering mechanism is mounted on middle lower portions of the four plain shafts, a material channel, a material pushing mechanism and a rotating mechanism are respectively arranged in the middle of the right-front plain shaft among the four plain shafts, an intelligent measuring and controlling system is fixed to the upper portion of the left-front plain shaft, and a feeding mechanism of a precision manipulator is mounted on the left-rear plain shaft and the right-rear plain shaft; and a position finding stopping mechanism is arranged on the left-rear plain shaft. The online cold-pressing assembling device has the advantages that the oil suction pipes can be automatically fed and can be automatically pressed into the compressors on an assembling line, and the assembling quality of the integral compressors and the production efficiency are improved.

Owner:BEIJING BRANCH JIKE DEV SCI & TECH

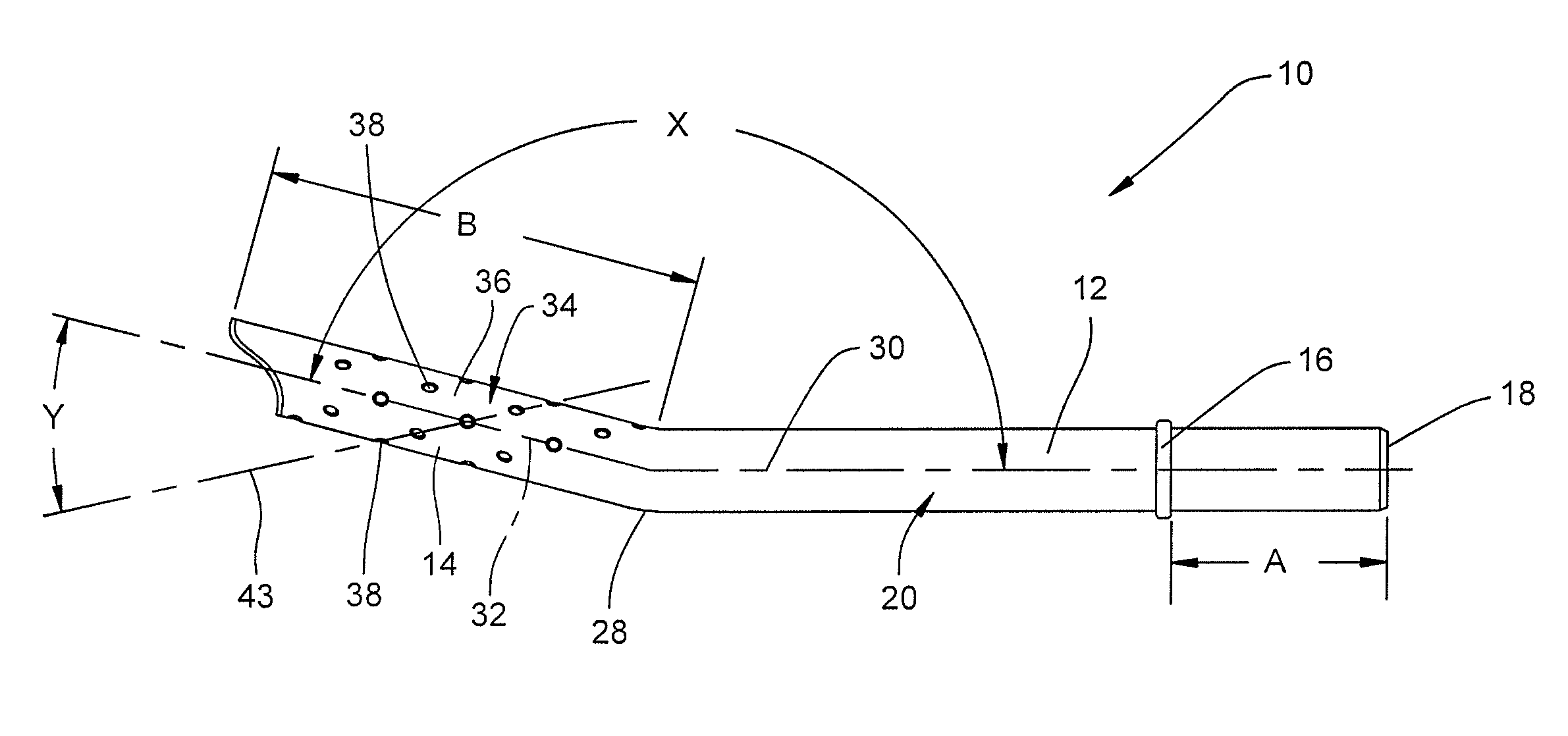

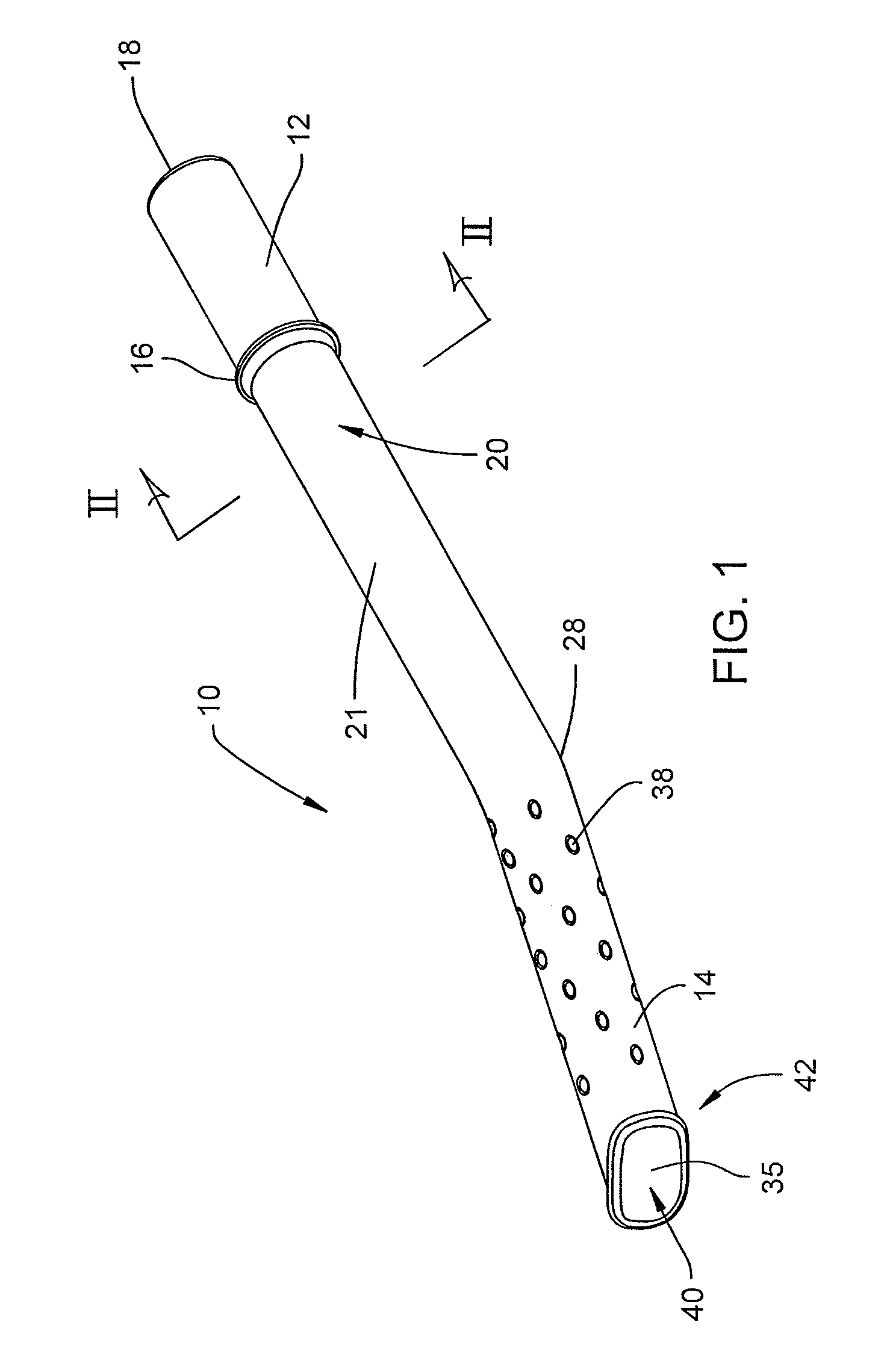

Dental suction tubing

A dental suction tube having a plurality of apertures in a distal portion of the tube is provided. The apertures are provided in a pattern to allow suction performance even when a portion of the distal end of the tube is abutting a portion of the mouth or other item during a dental procedure.

Owner:RONTO DAVID R

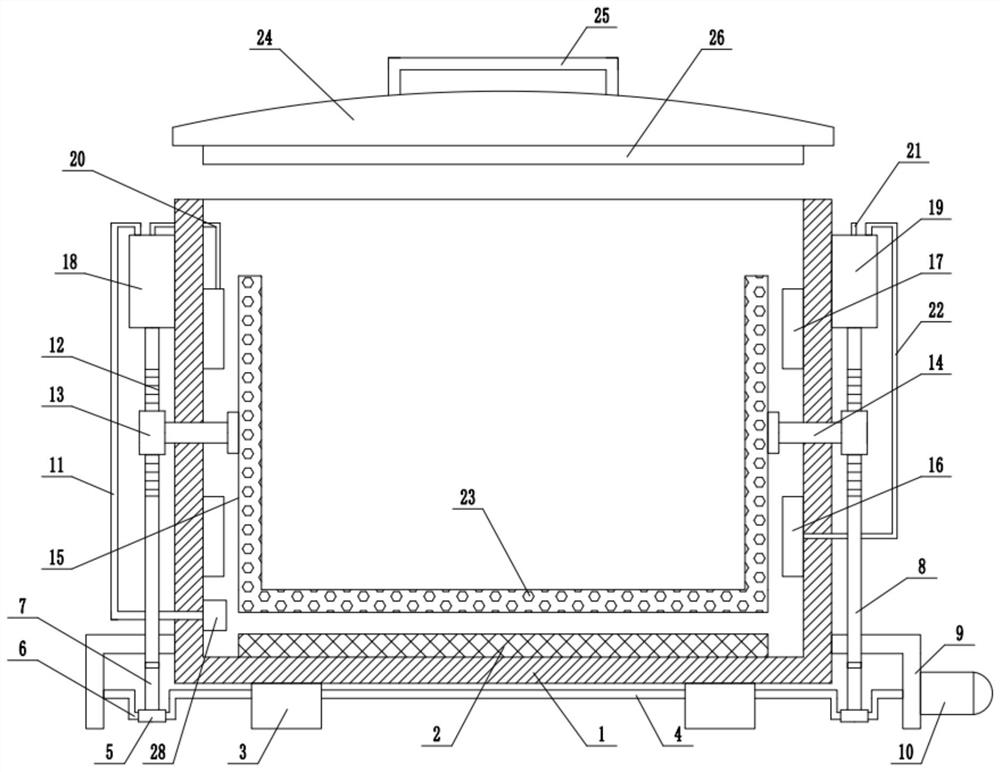

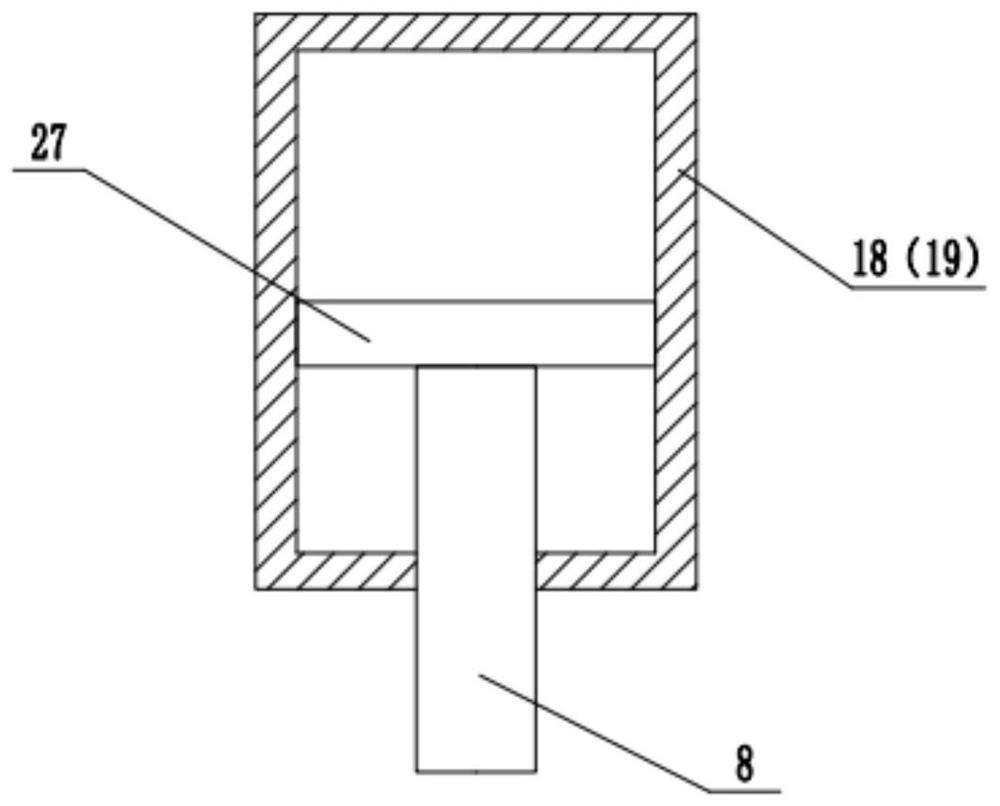

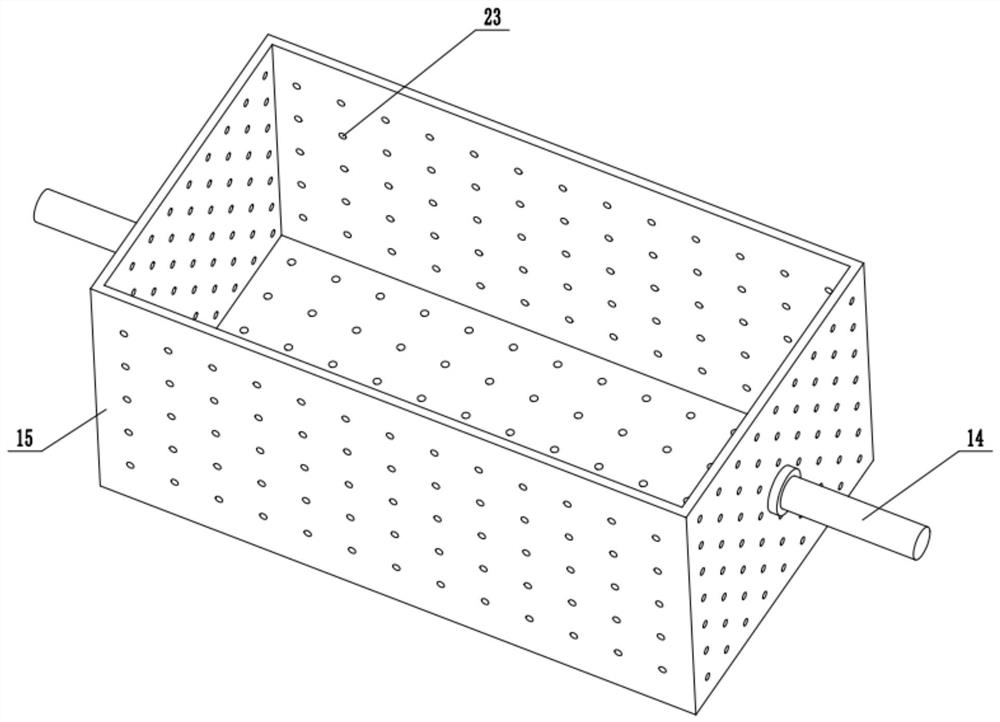

Rolling-type food deep-frying and draining integrated device

InactiveCN111802416AReasonable structureInnovative designBaking ovenOil/fat bakingCrankSuction tubing

The invention relates to the technical field of food processing equipment, and discloses a rolling-type food deep-frying and draining integrated device. The device comprises a deep-frying box, a rotating shaft is mounted in the middles of two ends of the deep-frying box, one end of the outer side of the rotating shaft penetrates through the wall of the deep-frying box and is connected to a gear, one end of the inner side of the rotating shaft penetrates through the deep-frying box and is connected to a deep-frying basket, L-shaped brackets are installed on the lower sides of the two ends of the deep-frying box, a rotary shaft is arranged between lower ends of the L-shaped brackets, the middles of the two ends of the rotary shaft are provided with cranks, a sliding sleeve is mounted at themiddle of each crank, a sliding rod is installed at the upper end of the sliding sleeve, a connecting rod is hinged to the top end of the sliding rod, the upper end of the connecting rod penetrates through the upper end of each L-shaped bracket, a piston plate is installed at the tail part of the connecting rod, an oil spraying tank is installed on the outer side of the left piston plate, and oneend of the oil spraying tank is communicated with a filter head arranged at the bottom end in the deep-frying box through an oil suction pipe. According to the invention, the rolling and shaking effects on the deep-frying basket are achieved, and on the other hand, the effective oil spraying effect on foods in the deep-frying basket and the draining effect after deep-frying are achieved through the oil spraying box and an air spraying box.

Owner:许惠玲

Exhaust method of hydraulic operation system of vehicle clutch

The invention discloses an exhaust method of a hydraulic operation system of a vehicle clutch; the method solves the problem of difficult exhaust of gas in the hydraulic operation system of the vehicle clutch; the exhaust method applies an oil conveying pump of a diesel engine; an oil sucking port of the oil conveying pump is tightly connected with an oil sucking pipe, and is inserted into a brake liquid bottle; an oil outlet is tightly connected with an oil outlet pipe, and is inserted on a unscrewed air release screw plug of a separate pump booster; then, a hand oil pump on the oil conveying pump is pressed; brake liquid in the brake liquid bottle upwards enters a clutch oil storage tank by an oil pipe to exhaust air in a pipeline system from the oil storage tank; and after the brake liquid in the oil storage tank reaches the oil level and has no bubbles, the air in the pipeline system is totally exhausted. The exhaust method applies the oil conveying pump of the diesel engine to pump the brake liquid in the operation process, exhausts in the gas flowing direction from low place to high place, and has such characteristics as simple method, quick exhaust and thorough exhaust.

Owner:JIANGXI COPPER

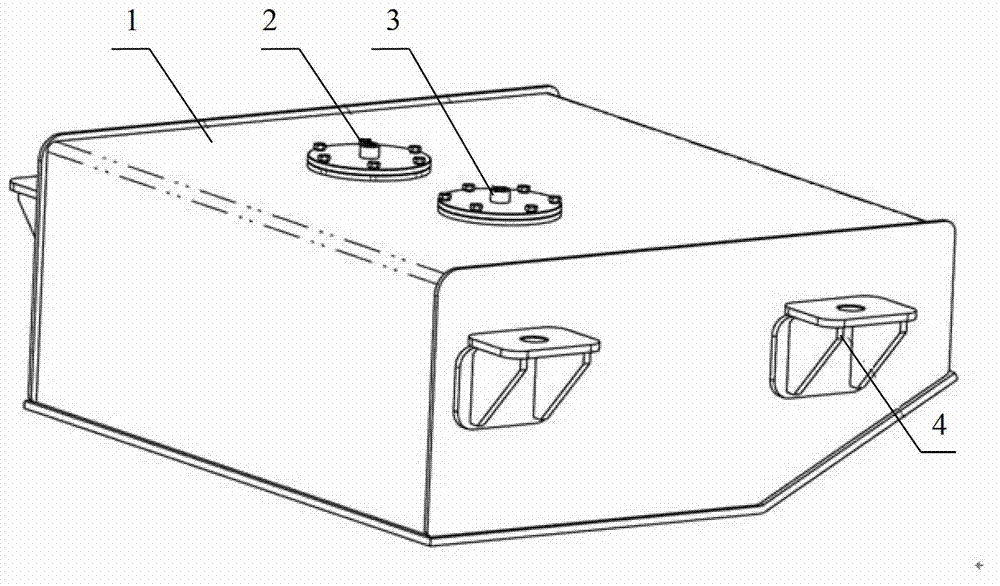

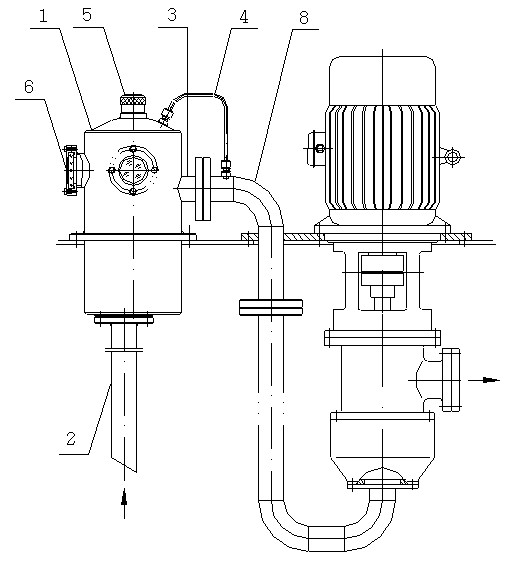

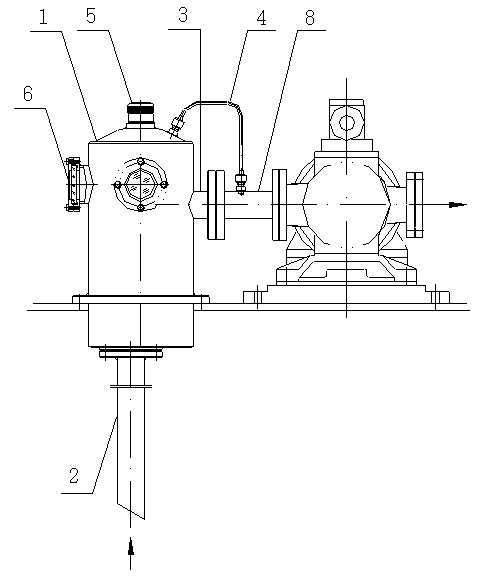

Hydraulic oil tank for road roller

InactiveCN104895875APositioningPlay a sealing rolePump assembliesFluid-pressure actuator componentsHydraulic pumpSuction tubing

The invention discloses a hydraulic oil tank for a road roller. The hydraulic oil tank comprises a hydraulic pump, an oil absorbing filter element, a top cover, a hydraulic oil tank, an oil absorbing stop valve and an oil returning stop valve; one end of the hydraulic pump is connected with the hydraulic oil tank through an oil absorbing pipe, and while the other end of the hydraulic pump is connected with the hydraulic oil tank through an oil returning pipe; the oil absorbing filter element is arranged at an oil feeding pipe at the bottom part of the hydraulic oil tank; the top cover is arranged on the top part of the hydraulic oil tank; the oil absorbing stop valve is arranged on the oil absorbing pipe; the oil returning stop valve is arranged on the oil returning pipe. According to the hydraulic oil tank for the road roller, the structure of the traditional oil tank is improved, namely, the mounting mode of the oil absorbing filter element is mainly improved; the stop valves are mounted at the oil absorbing pipe and the oil returning pipe of the hydraulic oil tank; the improved hydraulic oil tanks are avoided discharging of all hydraulic oil, so that the labor intensity of repair workers can be greatly reduced; in addition, secondary pollution of the hydraulic oil due to oil discharging can be avoided.

Owner:JIANGSU KUI ZE MACHINERY IND CO LTD

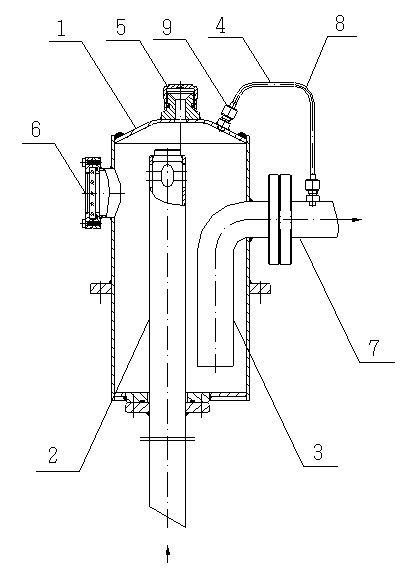

Special absorption-assisting device for thin-oil lubricating equipment

ActiveCN102352954AMaintain oil suction negative pressureGuaranteed oil supplyLubricant transferSuction tubingStorage tank

The invention discloses a special absorption-assisting device for thin-oil lubricating equipment, comprising an oil storage tank, an oil absorbing pipe, an oil outlet pipe and an emptying device, wherein the top end of the oil storage tank is provided with an oil filling cap, and the side surface of the oil storage tank is provided with an oil vernier window; the oil absorbing pipe is connected with a flange at the bottom part of the oil storage tank, one end of the oil absorbing pipe is arranged in the oil storage tank, an end opening of the oil absorbing pipe is upward and is higher than the scale mark on the vernier window; the other end of the oil absorbing pipe is arranged in lubricating oil liquid stored in the oil tank; one end of the oil outlet pipe is arranged in the oil storage tank, an end opening of the oil outlet pipe is downward and is positioned at the low position of the oil storage tank; the other end of the oil outlet pipe is arranged outside the oil storage tank and is connected with an oil inlet pipeline of an thin-oil lubricating oil-delivery pump; and the emptying device is communicated with the top of the oil storage tank and a pipe body of the oil inlet pipeline. In the special absorption-assisting device, self absorption is achieved by utilizing negative pressure in the sealed oil storage tank, a high-low position design is adopted for the oil openings of the oil absorbing pipe and the oil outlet pipe in the tank, the oil supply to the oil-delivery pump is ensured, the emptying device is arranged for protecting the negative pressure, so that the long-term normal operation of the thin-oil lubricating equipment is fundamentally met, and simultaneously the service life of the oil-delivery pump of the thin-oil lubricating equipment is also greatly prolonged.

Owner:ZIGONG HUARUI FILTRATION EQUIP MFG

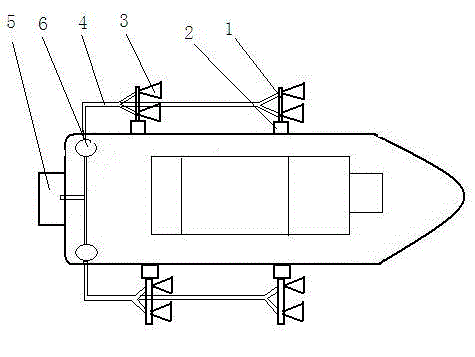

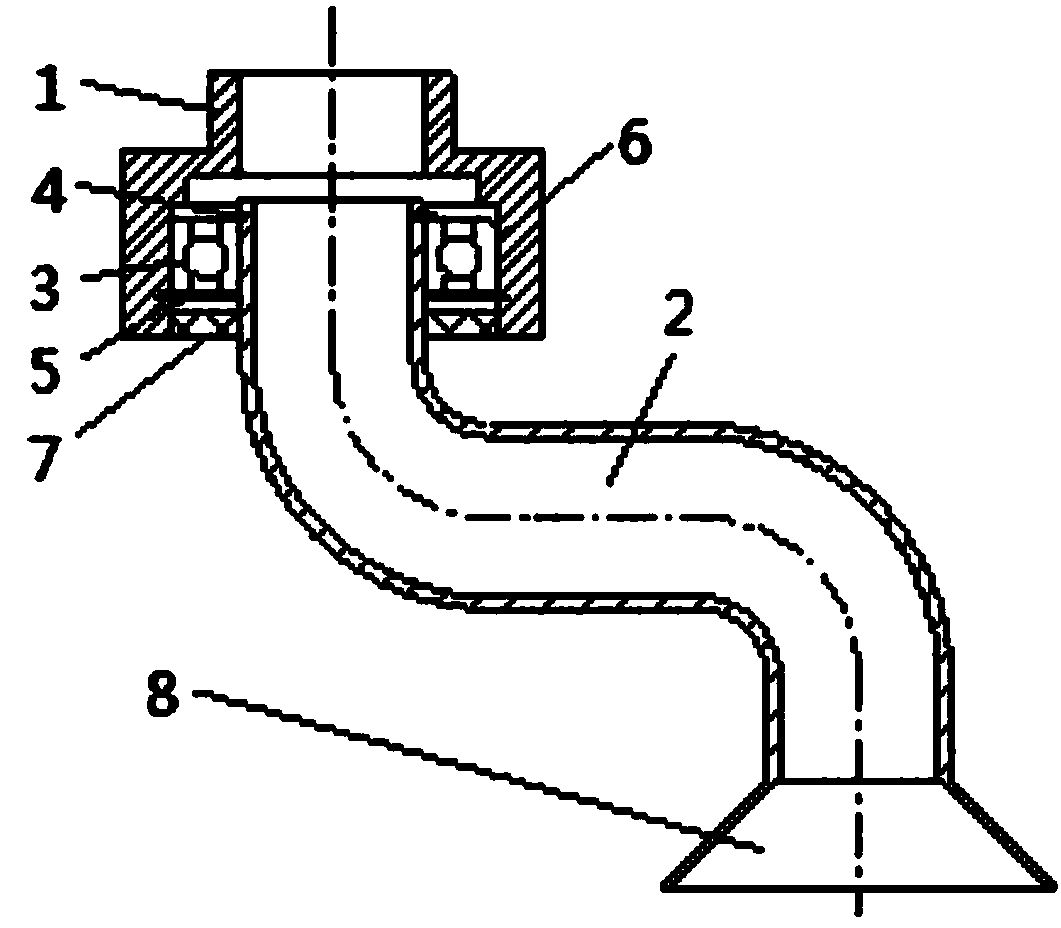

Yacht having oil slick recovery device

InactiveCN104691709AAchieve recyclingFast recyclingWaterborne vesselsSpecial purpose vesselsHydraulic ramYachting

The invention discloses a yacht having an oil slick recovery device. The yacht comprises a yacht body, and a cabin, a deck, a cab and a dining room arranged on the yacht body. The yacht is characterized in that brackets are arranged at the periphery of the yacht body; each bracket is connected with a telescopic arm of one hydraulic oil cylinder fixed on the yacht body; at least two horn-shaped oil collecting cylinders are arranged on the bracket; and oil sucking ports are formed in the upper parts of the oil collecting cylinders, and are connected with a negative-pressure oil collecting tank on the yacht body by oil sucking pipes. When the yacht is used and positioned on a water surface polluted by oil slick, the hydraulic oil cylinders are controlled to position the oil collecting cylinders on the oil slice layer, and electromagnetic valves are opened to feed the oil slick into the negative-pressure oil collecting tank so as to realize the recovery of the oil slick on the water surface; and the yacht has such advantages as quick recovery speed, low recovery cost and good effect on the treatment of the oil slick on the water surface.

Owner:WEIHAI ZHONGFU XIGANG SHIP

Oil suction device, engine and vehicle

PendingCN107747504AImprove the lubrication effectAvoid vacuumingLubricant conduit arrangementsOilsumpsEngineeringGravitational force

The invention provides an oil suction device comprising a connecting shell and an oil suction pipe. One end of the oil suction pipe is connected with the connecting shell, the other end of the oil suction pipe serves as the oil suction end, and the oil suction end of the oil suction pipe moves in a following mode under the gravity effect. The position of the oil suction pipe of the oil suction device can be changed based on the gravity factor so as to guarantee that the oil suction end of the oil suction pipe can be immersed under the liquid level of engine oil at a certain dip angle of an oilbottom shell, specifically, when the dip angle of an engine is changed, the oil suction pipe moves in the following mode under the gravity effect so as to automatically adapt to the liquid level change of the engine oil in the oil bottom shell of the engine, it is guaranteed that the oil suction end of the oil suction pipe can be immersed into the engine oil all the time, the oil suction device is prevented from sucking air, and the situation that lubricating parts of the engine are well lubricated is guaranteed. The invention provides the engine provided with the oil suction device and a vehicle provided with the engine on the other hand.

Owner:昆山三一动力有限公司

Essential oil atomization device

InactiveCN102764715AAvoid wastingImprove spraying effectLiquid spraying apparatusSuction tubingPetroleum engineering

Owner:JINAN SEARCHING ELECTRONICS TECH

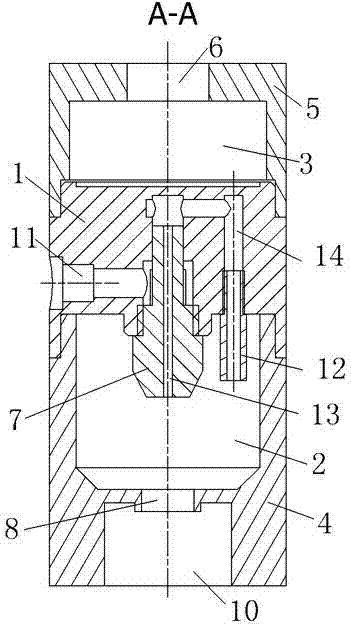

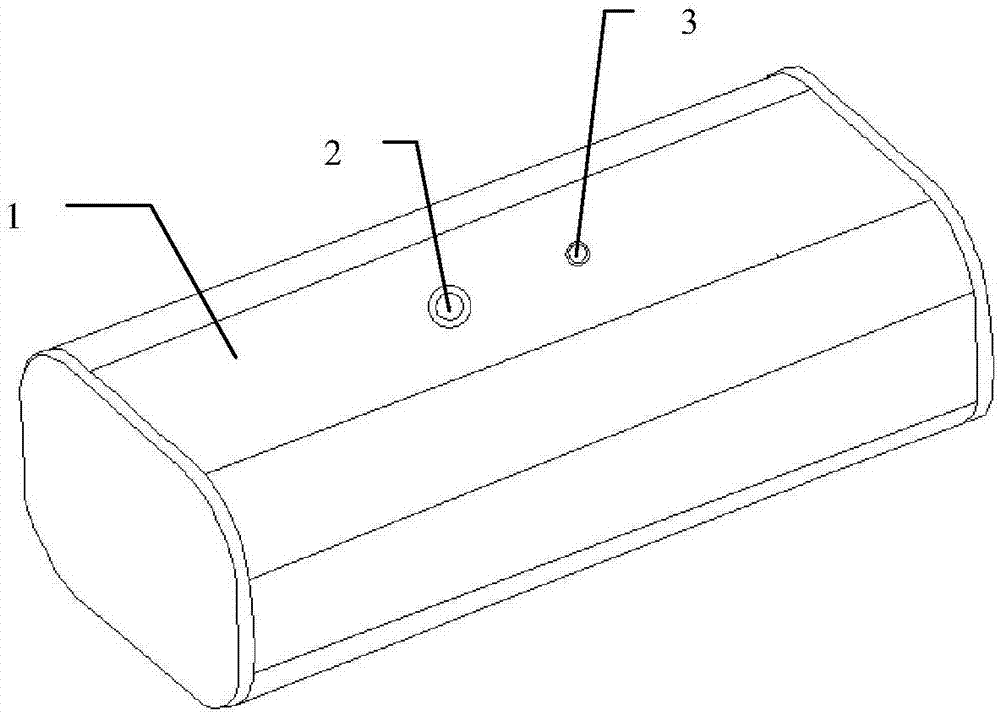

Anti-leakage bulletproof oil tank

ActiveCN107472007ALight in massPrevent cracking and oil leakageUnderstructuresArmour platesFiberSuction tubing

The invention provides an anti-leakage bulletproof oil tank comprising an oil tank body and an oil sucking pipe mechanism. The oil tank body comprises an anti-corrosion coating, a forming metal layer, a first foam metal buffer layer, a rubber layer, a first fireproof layer, an inner steel sheet layer, a second foam metal buffer layer, a fiber fabric bulletproof layer and an outer steel sheet layer which are arranged in sequence from inside to outside. The oil sucking pipe mechanism comprises an oil sucking pipe and a sealing cover body protruding out of the outer surface of the oil tank body, an opened metal cylinder extending into the oil tank body is arranged inside the sealing cover body, and the outer side of the sealing cover body is provided with a heat dissipation mechanism. The anti-leakage bulletproof oil tank is good in bulletproof performance, the lightweight requirements of vehicles are met, oil and gas leakage and oil tank explosion can be effectively prevented, and the reliability is greatly improved.

Owner:BEIJING PT PROTECTION TECH

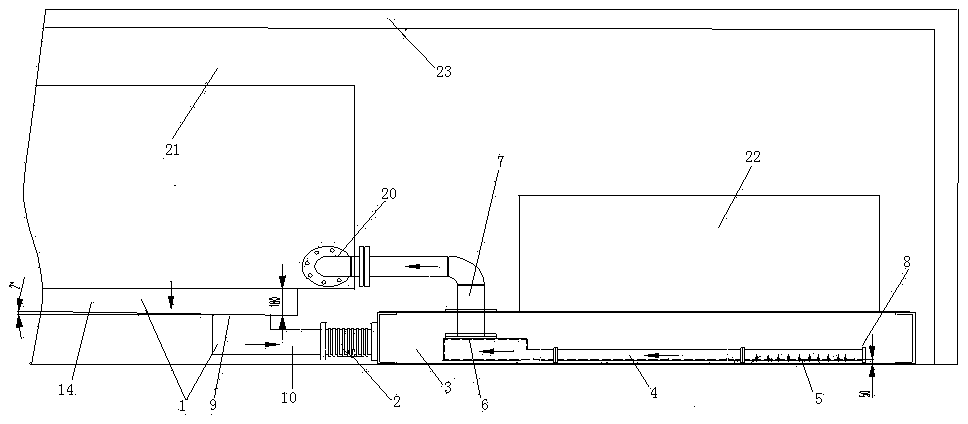

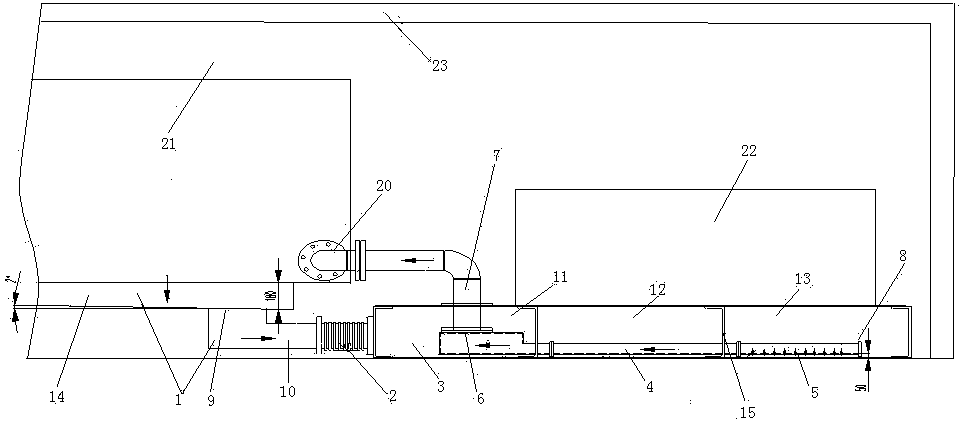

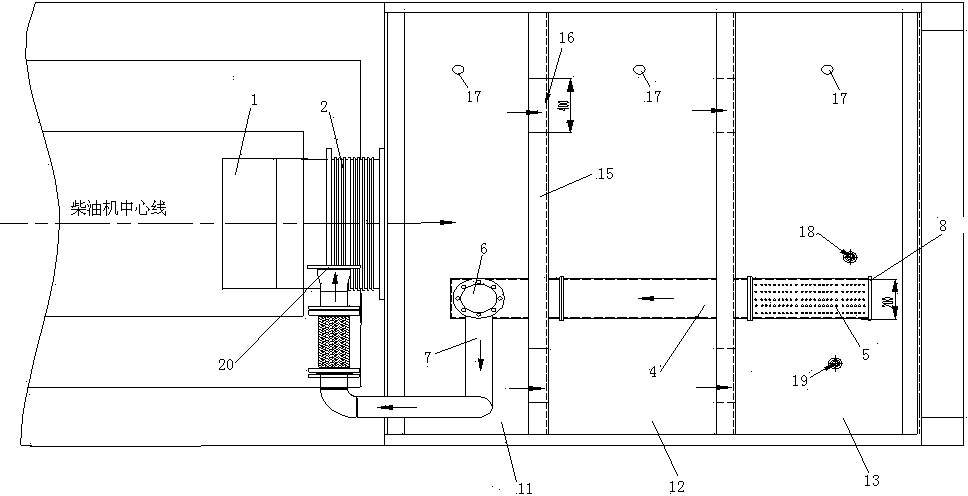

Lubrication oil tank of large-power box type diesel generating set

ActiveCN103867255ACompact structureReasonable arrangementMachines/enginesEngine lubricationDieselingDiesel generator

The invention belongs to the field of diesel engine oil systems and particularly relates to a lubrication oil tank of a large-power box type diesel generating set. The lubrication oil tank comprises a lubrication oil tank body and a main engine oil pump. The lubrication oil tank is characterized in that the lubrication oil tank body is composed of a dry type oil bottom shell, a square corrugated pipe and a secondary oil tank, wherein the dry type oil bottom shell is composed of a shell body of the dry type oil bottom shell and an oil returning opening of the dry type oil bottom shell; one end of the square corrugated pipe is connected with the oil returning opening of the dry type oil bottom shell and the other end of the square corrugated pipe is connected with the secondary oil tank so that the secondary oil tank and the secondary oil tank are connected to form a whole body; an oil suction pipe of the main engine oil pump, an oil suction opening of the main engine oil pump and an oil returning opening of the main engine oil pump are arranged in the secondary oil tank; one part of the oil suction pipe of the main engine oil pump is arranged in the secondary oil tank and is connected with the oil suction opening of the main engine oil pump by the oil returning opening of the main engine oil pump; the other part of the oil suction pipe of the main engine oil pump penetrates out of the secondary oil tank to be arranged outsides to be connected with other devices of the generating set. The lubrication oil tank of the large-power box type diesel generating set is compact in structure, reasonable in arrangement and good in engine oil cycling performance; the oil storage volume is large; the box type diesel generating set is convenient to move, low in investment cost, low in noises and the like.

Owner:SICHUAN CRRC YUCHAI ENGINE CO LTD

Surgical Compactor and Extractor

A surgical compactor and extractor for intra-abdominal and laparoscopic surgeries includes a compaction mechanism, a suction tubing, and a suction mechanism. The compaction mechanism has an expandable isolation chamber that is operable between a closed configuration and an open configuration via an actuation mechanism that is either mechanical or pneumatic. The expandable isolation chamber is toggled to the open configuration in order to encompass tissue within a patient's body and then toggled to the closed configuration in order to compact the tissue and remove the tissue from the patient. The suction tubing has an evacuation conduit that traverses along a flexible body and is used in conjunction with the suction mechanism to remove fluid and particulate matter as the tissue is compacted. The suction mechanism includes a vacuum unit to create a pressure differential and a reservoir to collect the fluid and particulate matter.

Owner:DEVILLE RONALD GENE

Reversible oil pan with integrated oil suction tube

InactiveCN102341571AReduce Inventory ComplexityIncrease flexibilityLubricant conduit arrangementsOilsumpsMechanical engineeringSuction tubing

The present invention relates to a reversible oil pan assembly including an oil suction tube. In one aspect, an oil pan assembly includes an oil pan and a suction tube connected to the oil pan. The suction tube includes an inlet to draw oil from the oil pan, and a plurality of outlets, each outlet configured to output oil that has been moved through the suction tube from the inlet.

Owner:CUMMINS LTD

Sesame oil storage device

InactiveCN110789857AAvoid standing stratificationSolve the sealing problemRotary stirring mixersLarge containersReciprocating motionElectric machinery

The invention discloses a sesame oil storage device. The sesame oil storage device comprises a bin body, wherein a stirring mechanism is installed in the bin body, and the stirring mechanism comprisesa first motor, a crankshaft, a sleeve, a connecting rod, a spoiler and an extraction mechanism for extracting sesame oil in the bin body; the extraction mechanism comprises a cylinder body, a pistonand a driving assembly for driving the piston to reciprocate; and the driving assembly comprises a second motor, a turntable and a T-shaped rod. The spoiler is driven to reciprocate by the stirring mechanism, so that the sesame oil is stirred and disturbed to avoid standing and layering; the extraction mechanism is arranged, the sesame oil in the bin body is sucked out through an oil suction pipeand then is discharged through an oil outlet pipe, and the sealing property of a storage barrel during discharging can be effectively guaranteed through the oil suction pipe; and compared with a traditional sesame oil storage device, the requirement of convenient taking is met, the sealing of the storage barrel during taking of the sesame oil is achieved, and the sesame oil storage device is moreconvenient to use.

Owner:安徽省含山县华康调味品厂

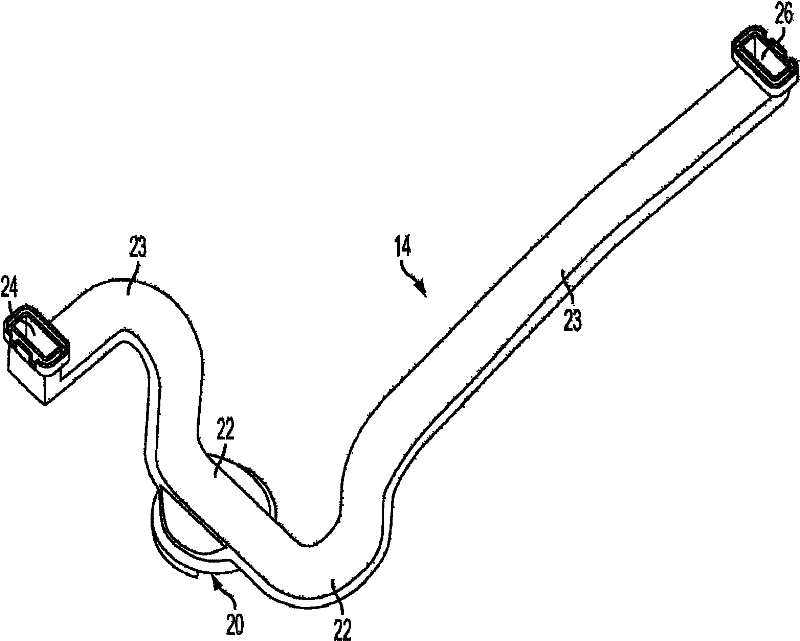

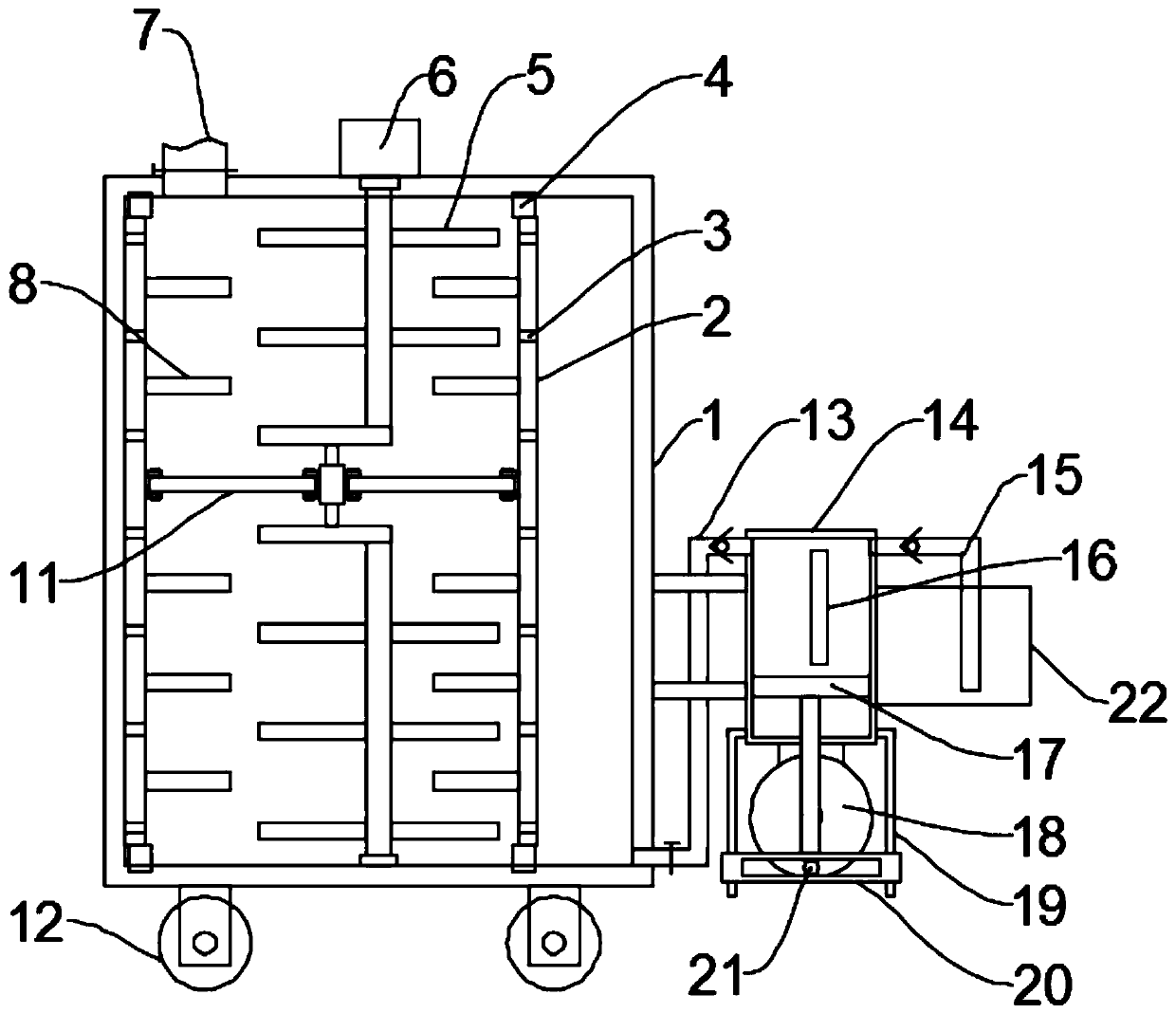

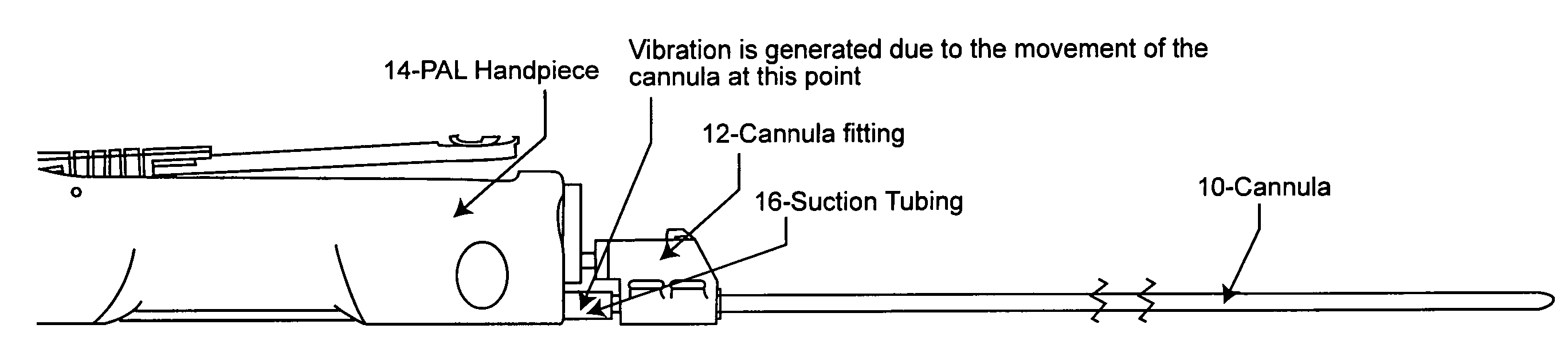

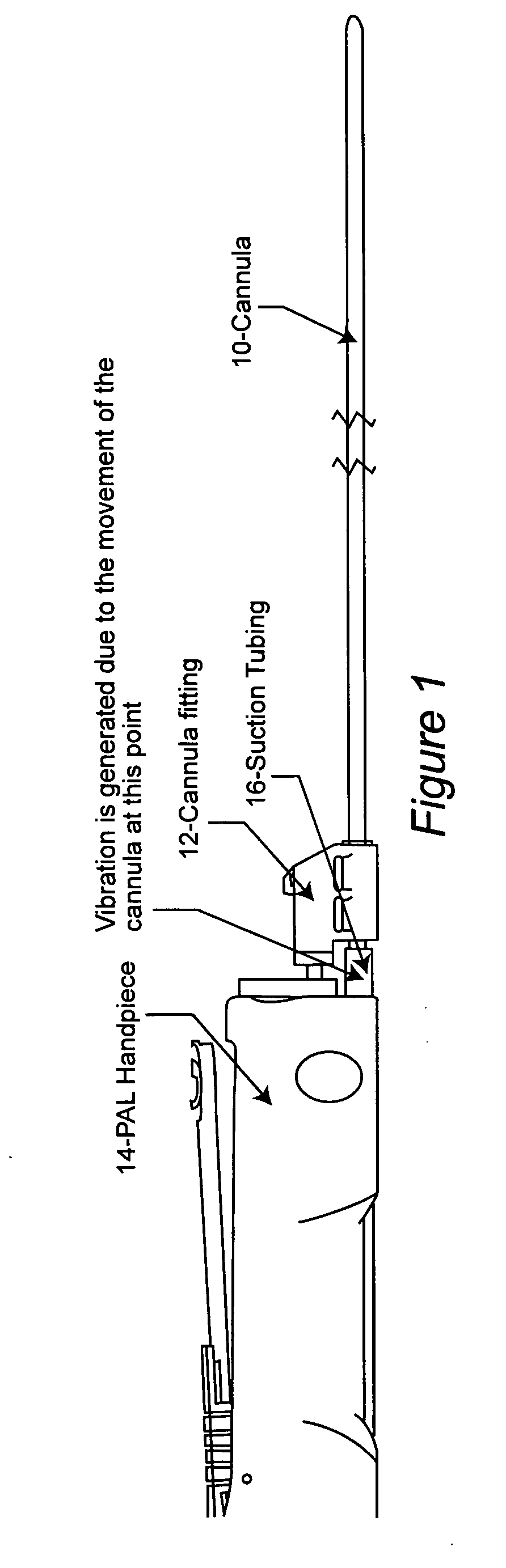

Low vibration tube

Energy absorption tubing is provided between the cannula and the suction tubing connected to a vacuum in a Power Assisted Lipoplasty device. The energy absorption tubing isolates the vibration or keeps the motion away from the handpiece, making the handpiece more comfortable to hold for the surgeon.

Owner:MICROAIRE SURGICAL INSTR

Handheld multipurpose portable four-stroke gasoline engine

InactiveCN111271175AWon't failReduce consumptionLubrication of auxillariesMachines/enginesCrankcaseControl theory

The invention provides a handheld multipurpose portable four-stroke gasoline engine. The handheld multipurpose portable four-stroke gasoline engine comprises a crankshaft chamber, a valve distributionchamber, an oil storage chamber, a valve chamber and a rotary valve; the crankshaft chamber communicates with the valve distribution chamber through an oil inlet channel arranged on a crankshaft andan oil outlet channel arranged on a crankcase body; the rotary valve comprises a valve sleeve and a valve shaft; the valve shaft is a crankshaft journal; an outlet of the oil outlet channel is formedin the crankshaft journal; the valve distribution chamber communicates with the oil storage chamber through a lowermost oil return channel of the valve distribution chamber; the crankshaft chamber communicates with the oil storage chamber through an oil suction pipe; a copper ball is arranged at the tail end of the oil suction pipe; the valve chamber is arranged above an air cylinder; an oil-waterseparator is arranged in the valve chamber; a cylinder head communicates with the oil storage chamber through an external oil return pipe; an oil return inlet hole is formed in the cylinder head; andan oil return outlet hole is formed in a box body. According to the handheld multipurpose portable four-stroke gasoline engine, an oil-gas separation device cannot fail at any angle, a lubricating oil path works smoothly without oil injection or oil combustion, the engine is completely separated from oil, the engine oil consumption is low, the emission is good, and the product reliability is good; and the handheld multipurpose portable four-stroke gasoline engine can work by 360 degrees in a space, and the matching range is wide.

Owner:永康市兴虎动力机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com