Exhaust method of hydraulic operation system of vehicle clutch

A technology of hydraulic operating system and exhaust method, which is applied to clutches, fluid-driven clutches, non-mechanical drive clutches, etc., can solve the problems of polluting the environment, difficult gas discharge, waste of brake fluid, etc., and achieves simple methods and thorough exhaust , fast exhaust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

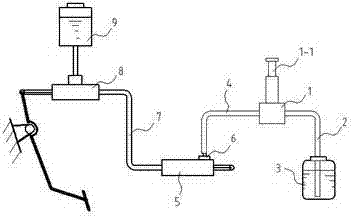

[0007] Below in conjunction with accompanying drawing, technical scheme of the present invention will be further described:

[0008] As shown in the accompanying drawings, the present invention discloses a method for exhausting the hydraulic operating system of an automobile clutch. The exhausting method for the hydraulic operating system of the automobile clutch is as follows: use a fuel delivery pump 1 of a diesel engine, and the oil suction port of the fuel delivery pump 1 is sealed and connected to absorb oil. Pipe 2, the front end of the oil suction pipe 2 is inserted into the brake fluid bottle 3, the oil outlet of the oil delivery pump 1 is sealed and connected to the oil outlet pipe 4, and the tail end of the oil outlet pipe 4 is inserted into the screw on the sub-pump booster 5 Loosen the air release screw plug 6, and then press the hand oil pump 1-1 on the oil delivery pump 1. At this time, the brake fluid in the brake fluid bottle 3 passes through the oil suction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com