Patents

Literature

53 results about "Bleed screw" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A bleed screw is a device used to create a temporary opening in an otherwise closed hydraulic system, which facilitates the removal of air or another substance from the system by way of pressure and density differences.

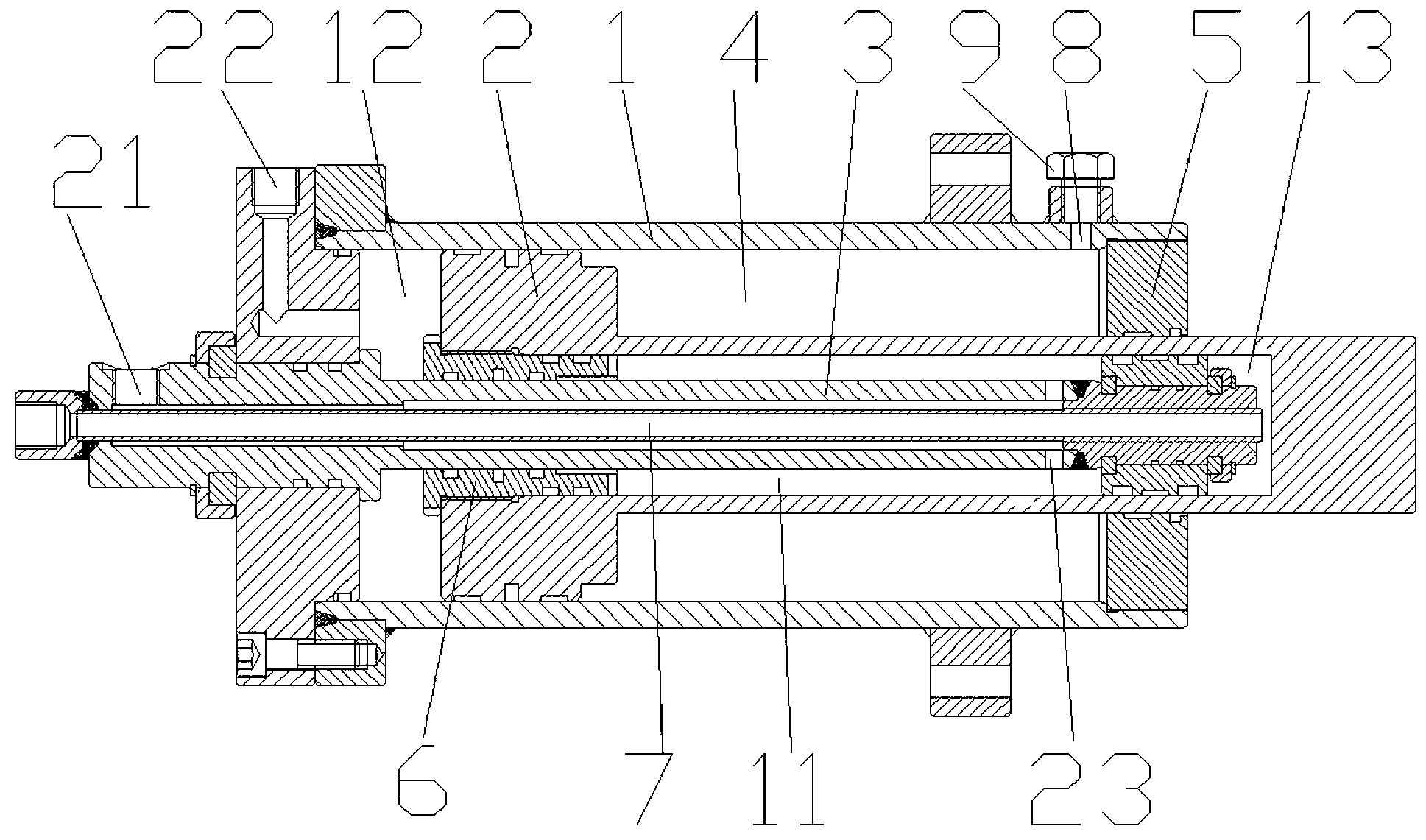

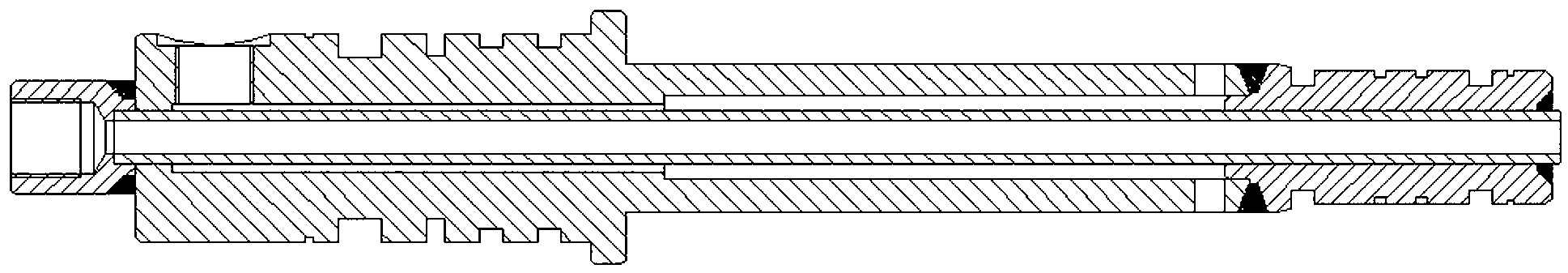

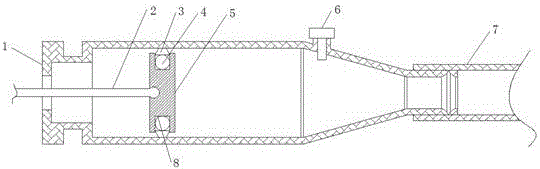

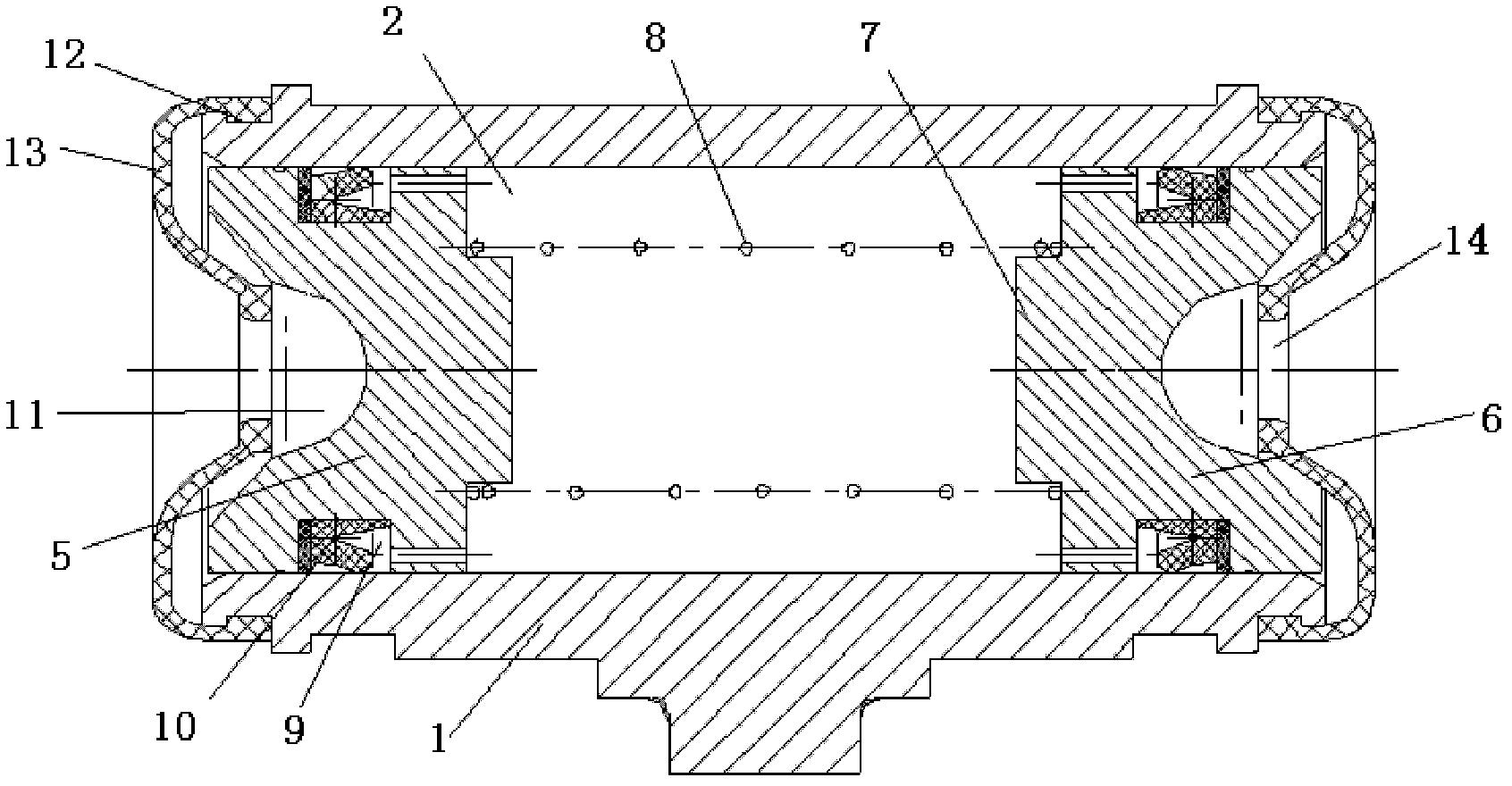

Quick double-acting hydraulic cylinder

The invention discloses a quick double-acting hydraulic cylinder which comprises a cylinder barrel, a large piston rod and a small piston rod. The large piston rod is nested in the cylinder barrel, an oil-free cavity is formed between the large piston rod and the cylinder barrel, the tail end of the large piston rod is fixed on the cylinder barrel through a pressing ring, the small piston rod is nested in the large piston rod, a first oil cavity and a third oil cavity are formed between the small piston rod and the large piston rod, a guide sleeve is arranged among two ends of the small piston rod and the large piston rod, an oil conduit is arranged in the small piston rod, a second oil cavity is formed among the large piston rod, the small piston rod and the cylinder barrel, the small piston rod is provided with a first oil inlet and a second oil inlet, a third oil inlet is arranged at the front end of the cylinder barrel, the cylinder barrel is provided with an exhaust port communicated with the oil-free cavity, and a bleed screw is arranged in the exhaust port. Compared with a common oil cylinder, the quick double-acting hydraulic cylinder in the structure is more compact in integral structure, large in pushing force and high in feeding speed and return speed, and normal running rate of mechanical equipment is increased.

Owner:FUJIAN LONGYAN SHENGTONG HYDRAULIC

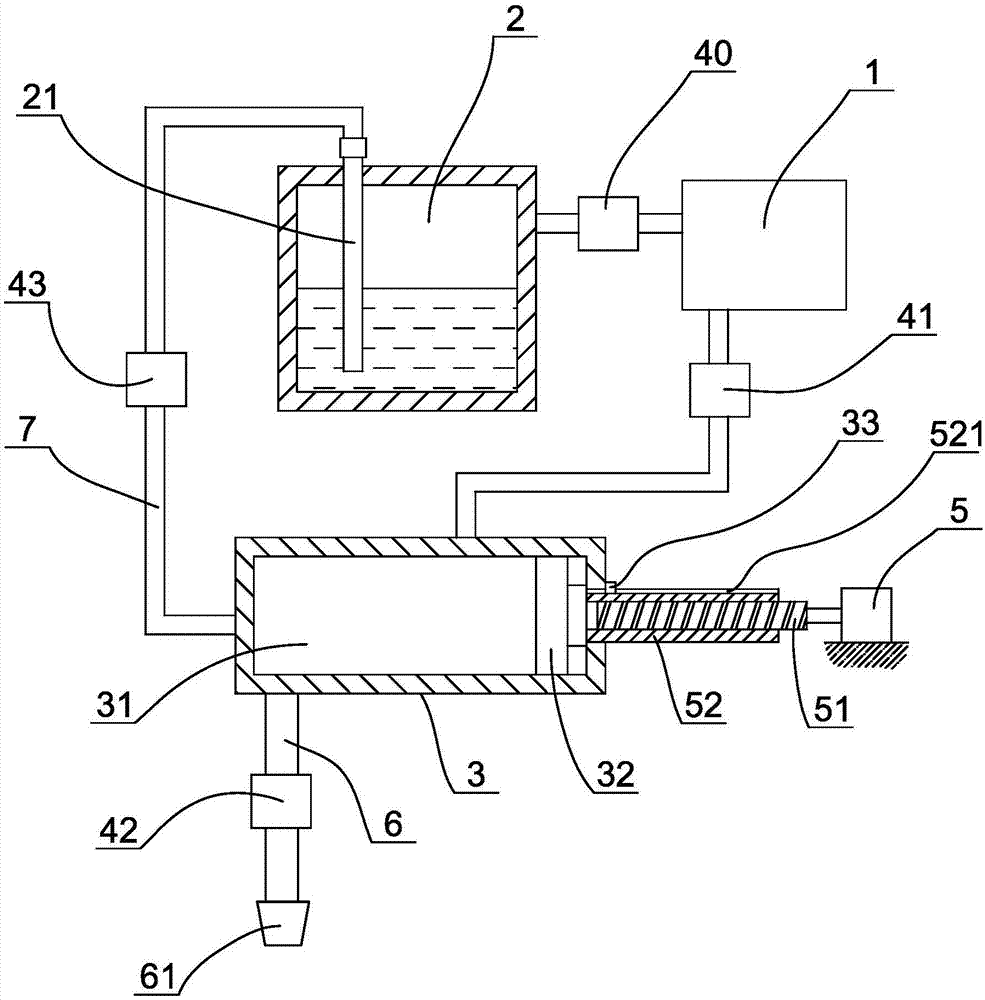

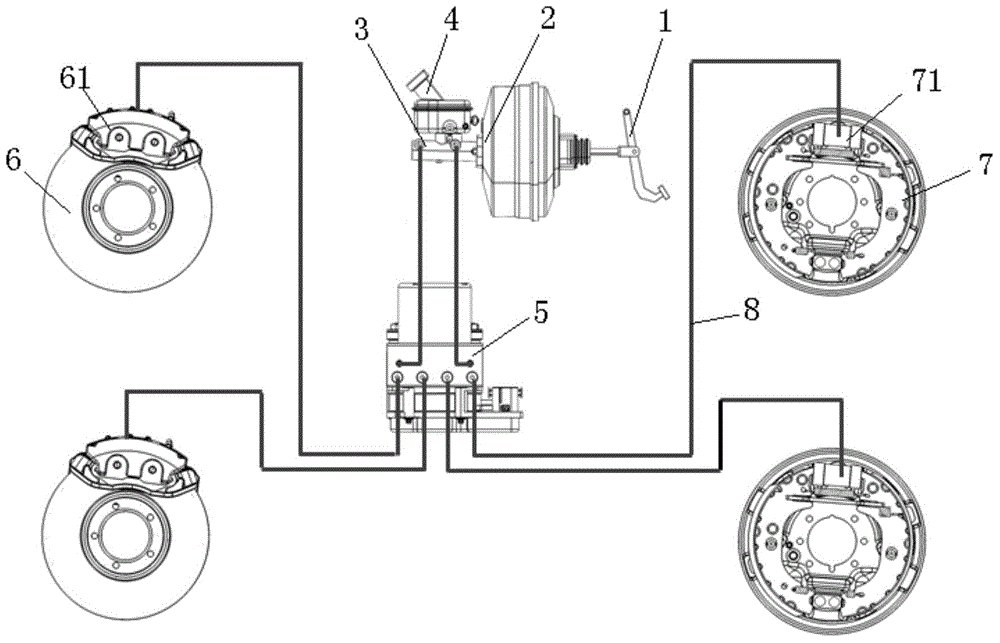

Exhaust method for brake systems of electric vehicles

ActiveCN108001438AEffective exhaustAccurately judge the exhaust effectBrake safety systemsInternal pressureElectric vehicle

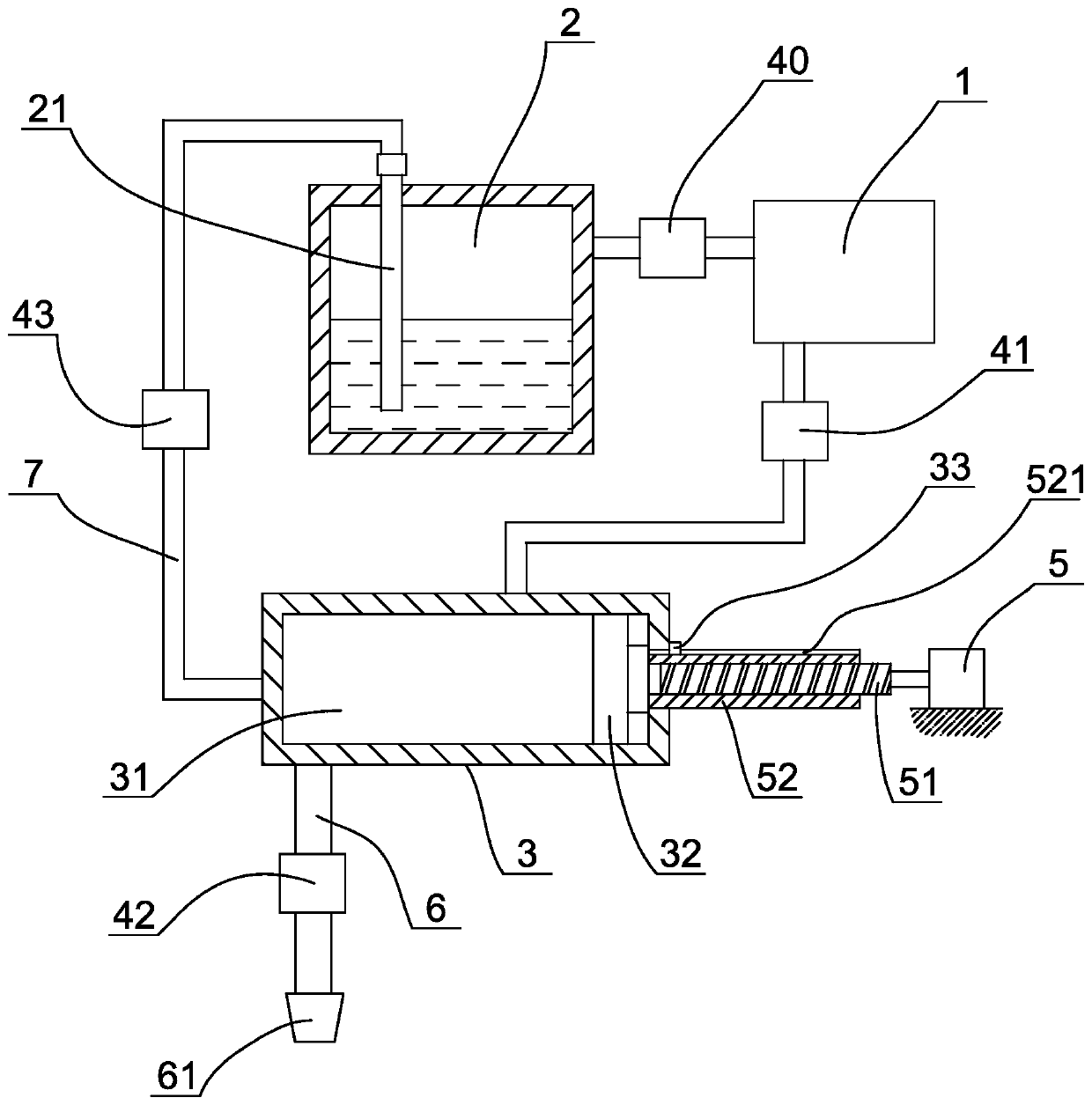

The invention discloses an exhaust method for brake systems of electric vehicles. The exhaust method includes treading brake pedals, gathering air in brake circuits at air bleed screw mounting holes,increasing the pressures of the brake circuits, switching on vacuum pumps at the moment and vacuumizing detection cavities; drawing air in the brake circuits into the detection cavities; driving pressure plungers in the detection cavities and gradually increasing the internal pressures of the detection cavities; terminating exhaust programs at the moment if the pressures of the detection cavitiesare higher than set values and extracting brake fluid in the detection cavities to a fluid storage cavity; repeatedly carrying out previous programs until the brake circuits are sufficiently exhaustedif the pressures of the detection cavities are not higher than the set values. The air which is about to be drawn into the detection cavities is mixed with the brake fluid. The fact that the brake fluid in the detection cavities accounts for a high proportion is illustrated if the pressures of the detection cavities are higher than the set values, and the fact that the brake circuits are sufficiently exhausted is further proved. The method has the advantages that the method can be implemented by the aid of a single person, and accordingly the efficiency can be improved; the exhaust programs can be accurately controlled, the brake circuits can be assuredly thoroughly exhausted, and excessive exhaust can be prevented.

Owner:ZHEJIANG LEAPMOTOR TECH CO LTD

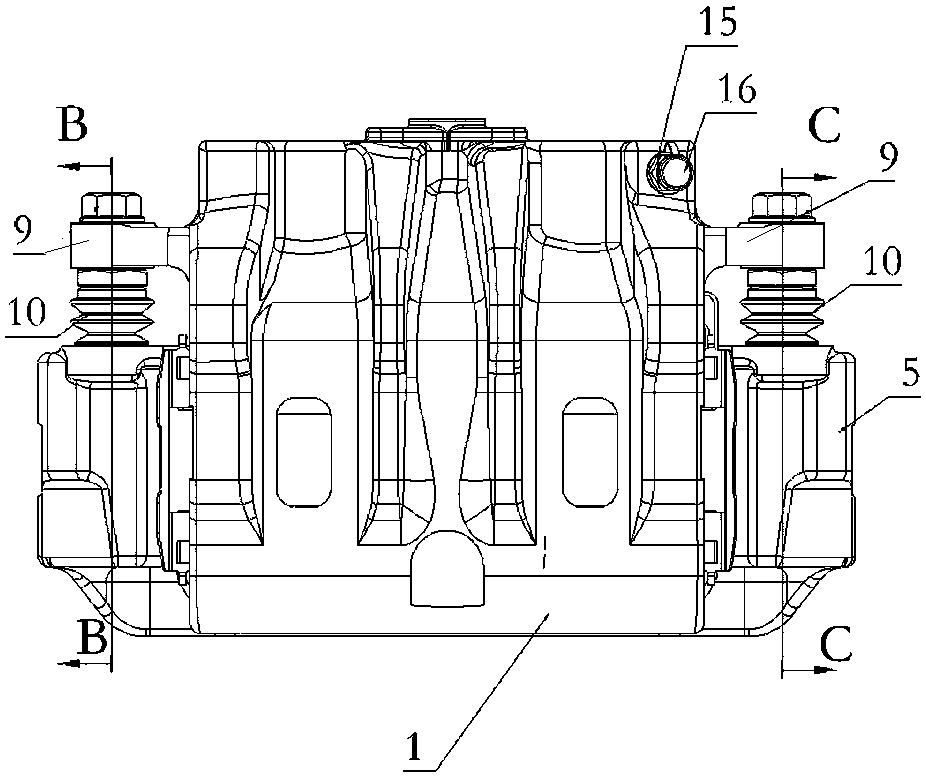

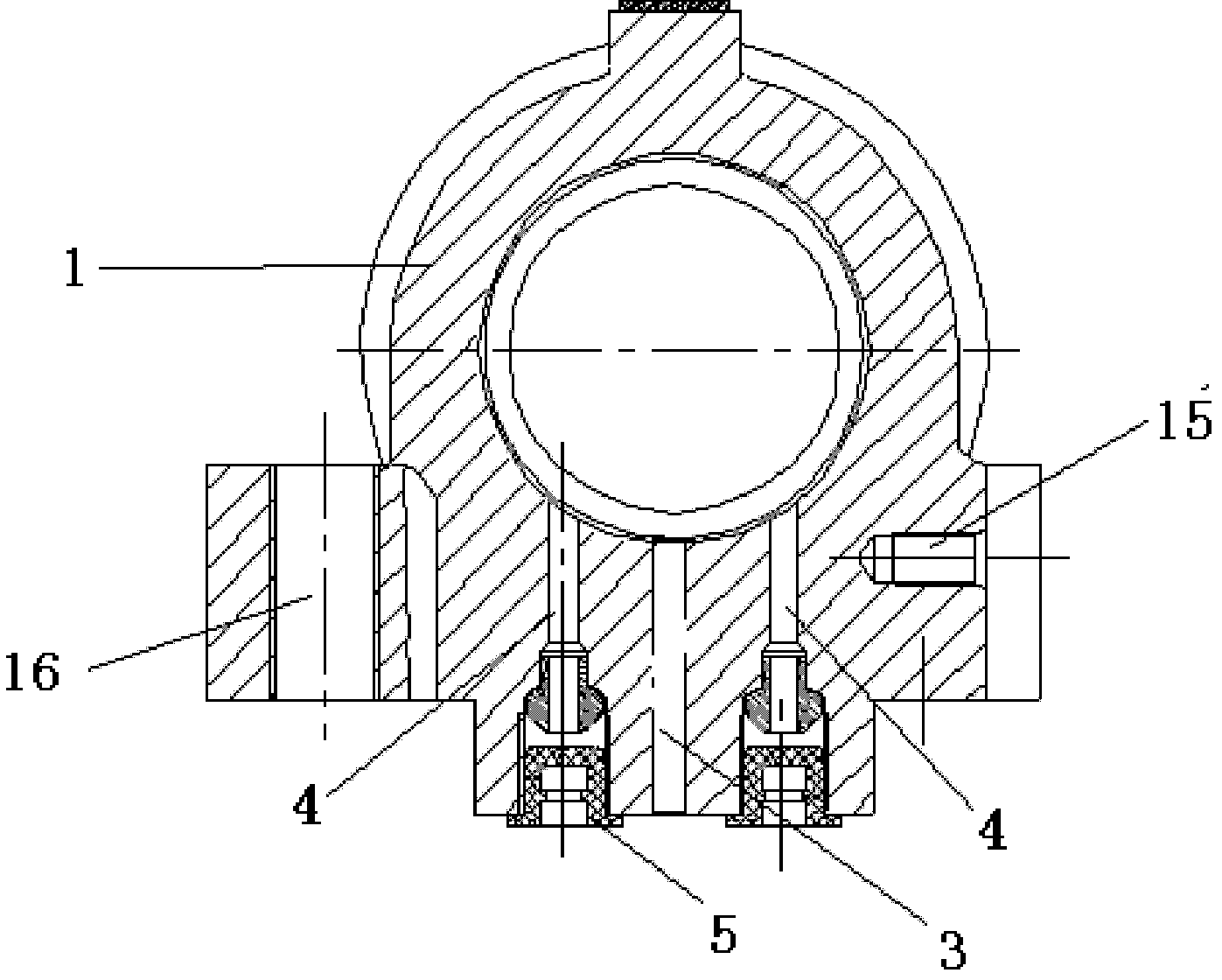

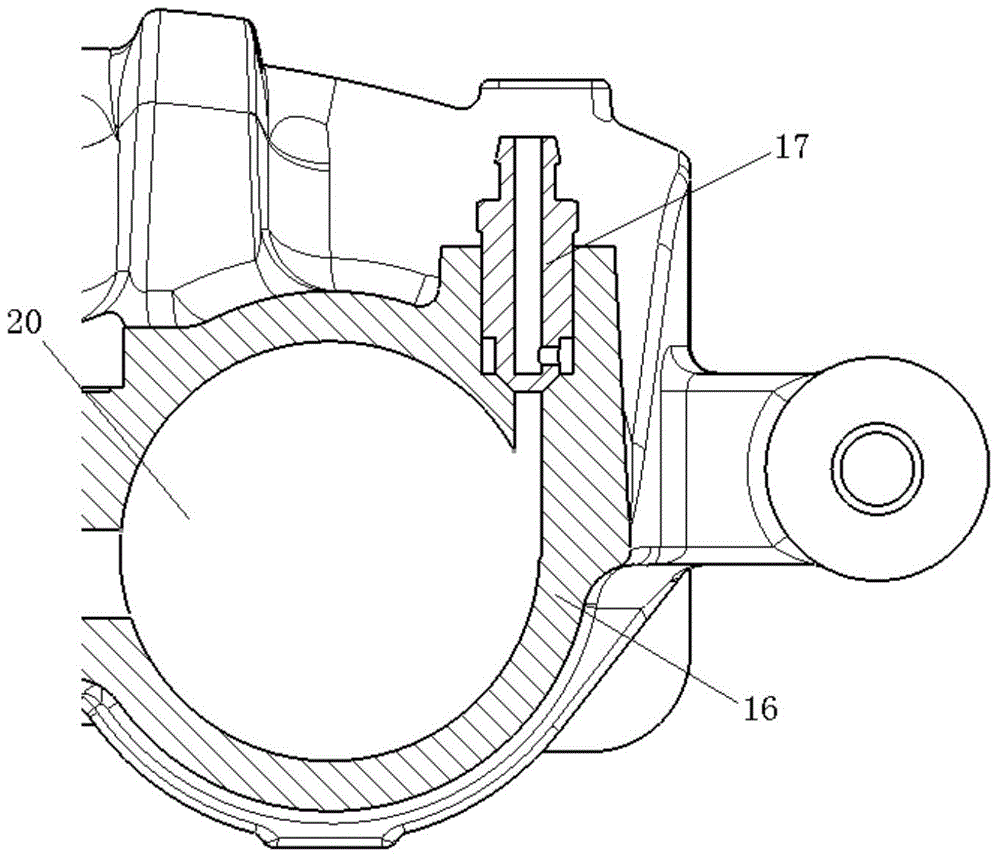

Floating caliper disc brake

PendingCN105805188ASolve the real problemImprove stabilityAxially engaging brakesBraking elementsDrive shaftCalipers

The invention discloses a floating caliper disc brake. The floating caliper disc brake comprises a wheel hub, a brake support, a ventilated brake disc and a steering knuckle. A transmission shaft is arranged in a middle round hole of the wheel hub. The front end of the transmission shaft is located on the front end face of the wheel hub and provided with a dustproof cover. The ventilated brake disc is arranged on the outer side of the wheel hub. A dustproof plate is arranged behind the ventilated brake disc. The steering knuckle is arranged on the outer sides of the wheel hub and the transmission shaft and is provided with a front shock absorber. A wheel rim assembly is arranged in front of the ventilated brake disc. The brake support is arranged on the steering knuckle. A guide pin shield is arranged on a guide pin between a braking inlay and the brake support. An air bleed screw is arranged on one side of the braking inlay. A piston is arranged in a middle round hole of the braking inlay. The floating caliper disc brake is fast in heat dissipation, small in noise, small in weight, simple in structure, and convenient to adjust. The high-temperature resistance is especially good during high load, and the braking effect is stable.

Owner:XUCHANG UNIV

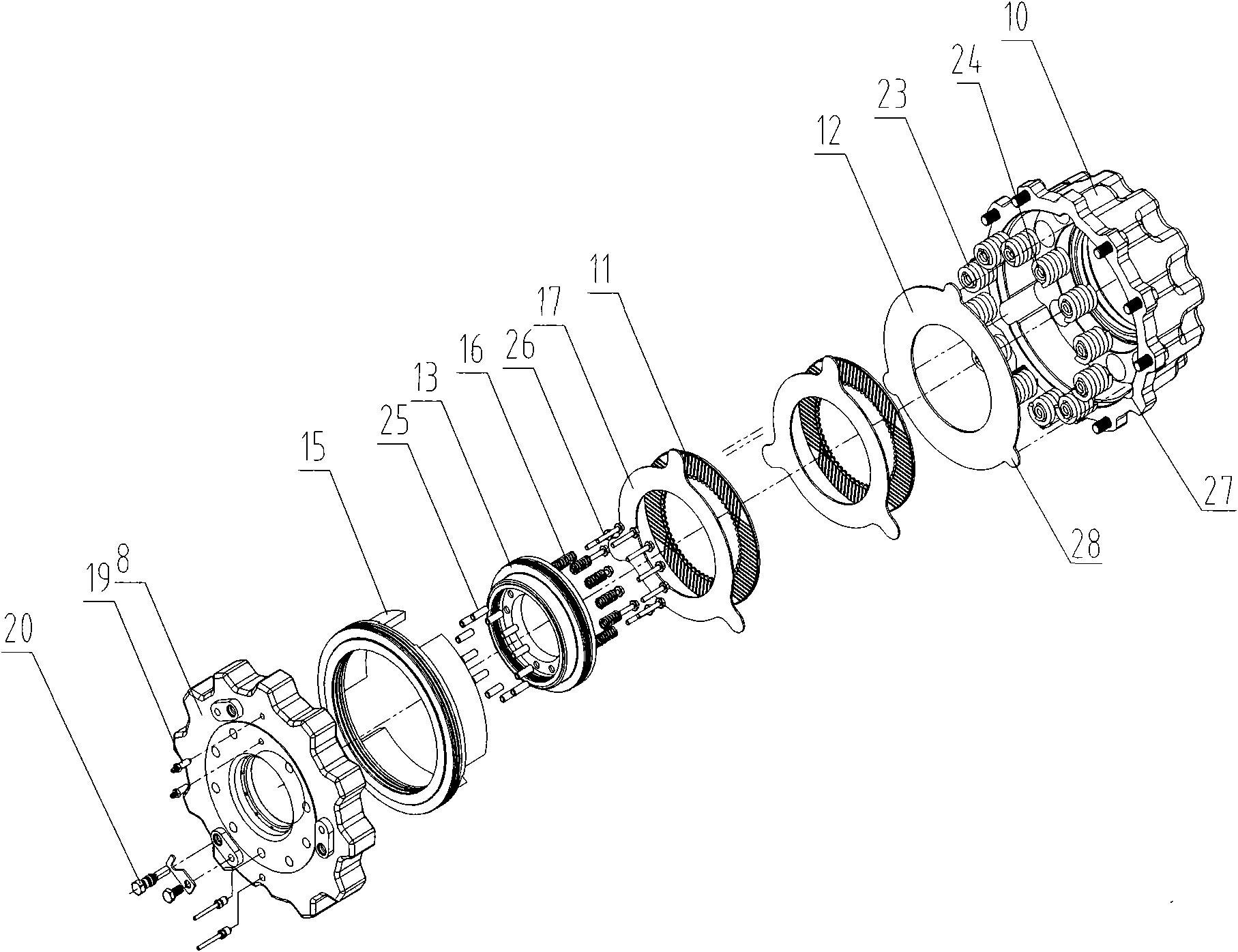

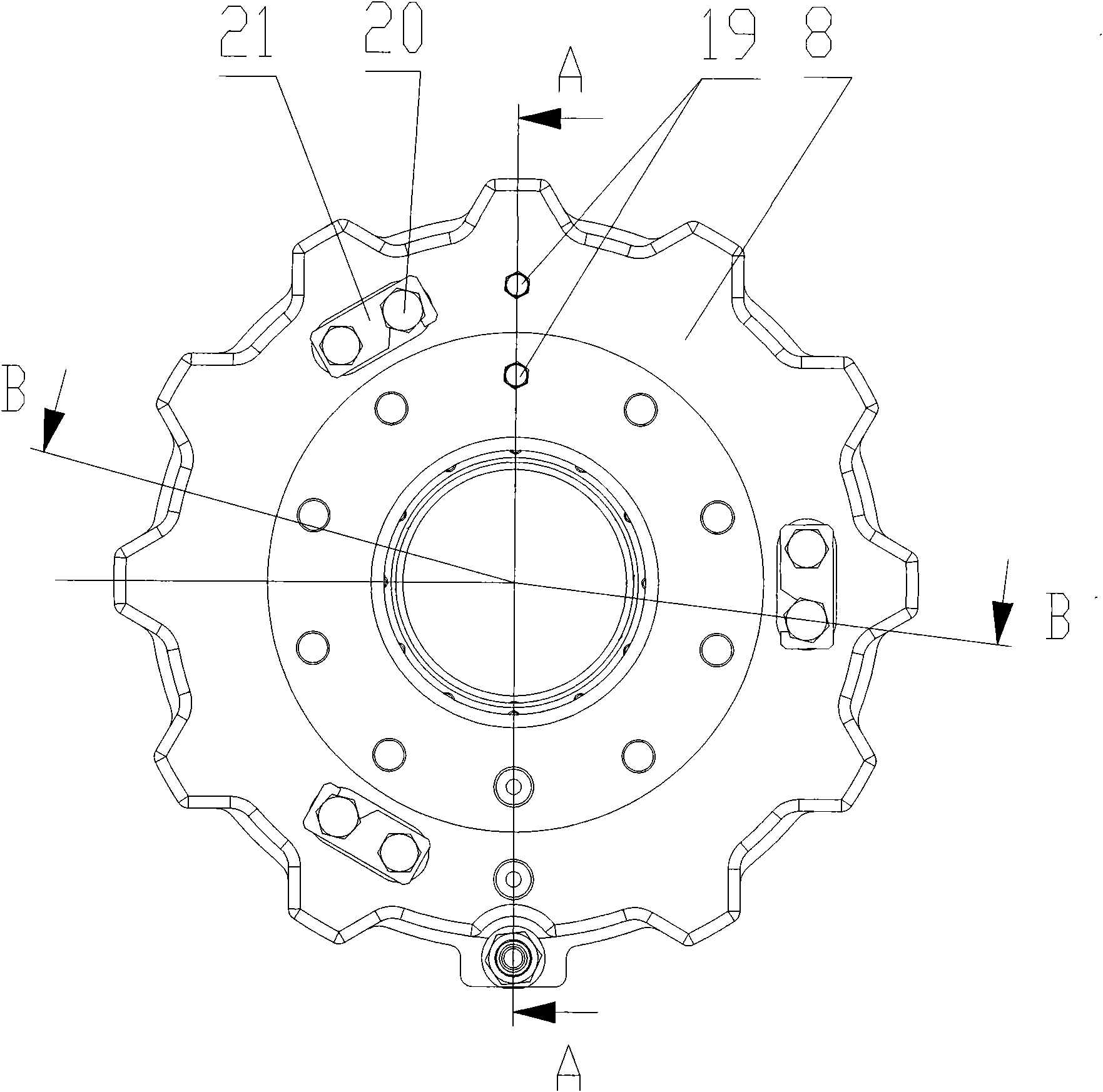

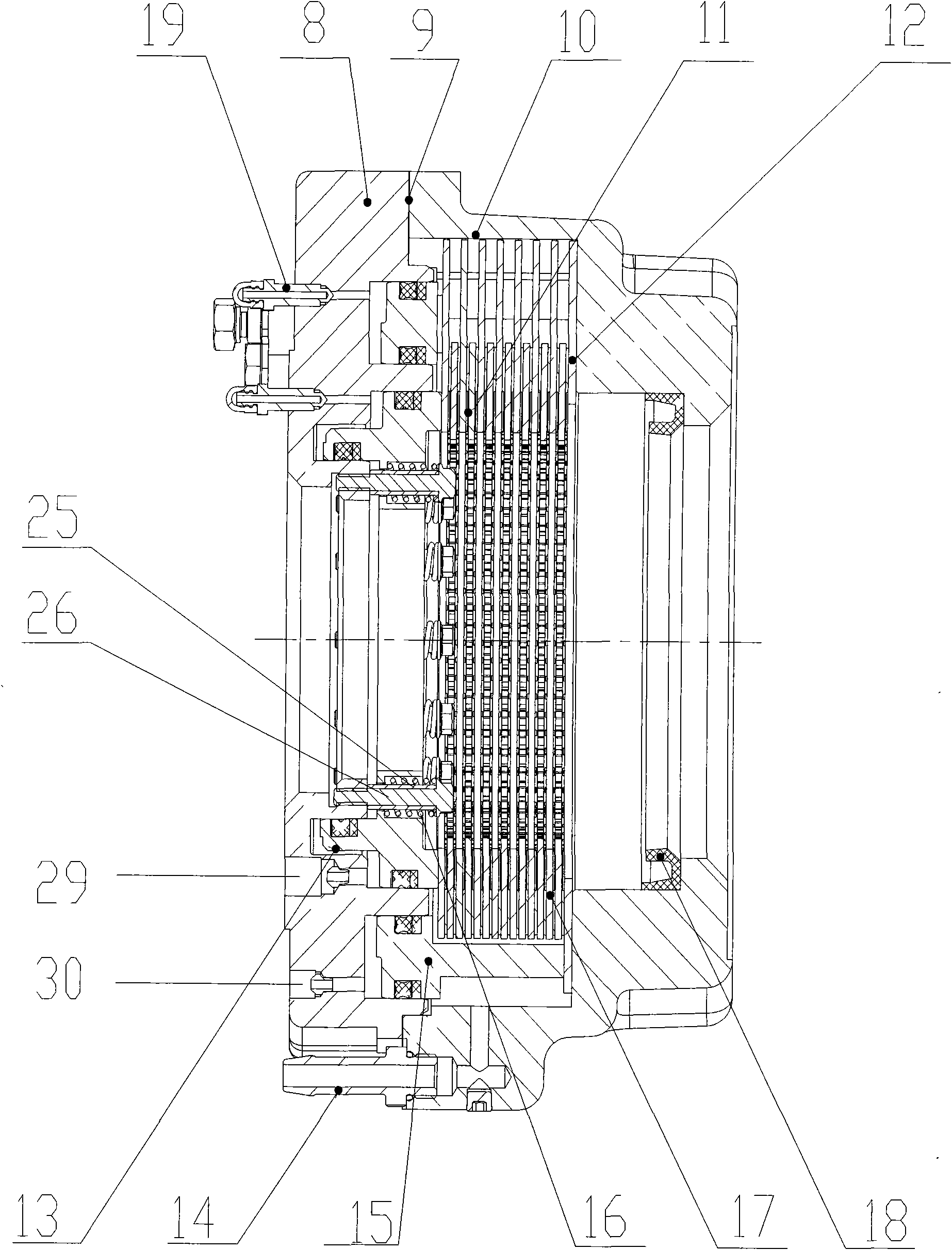

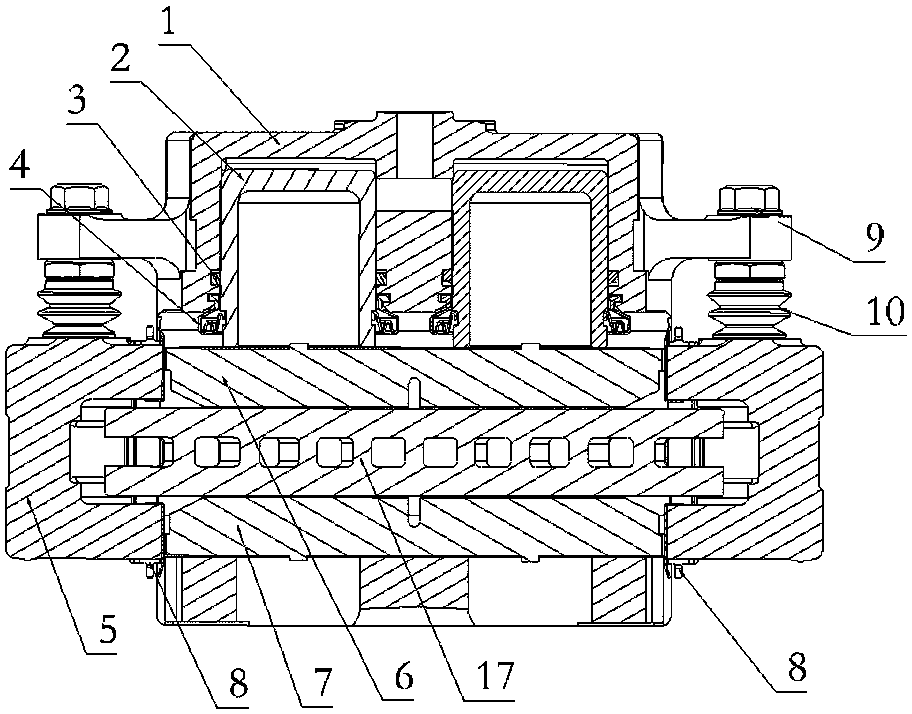

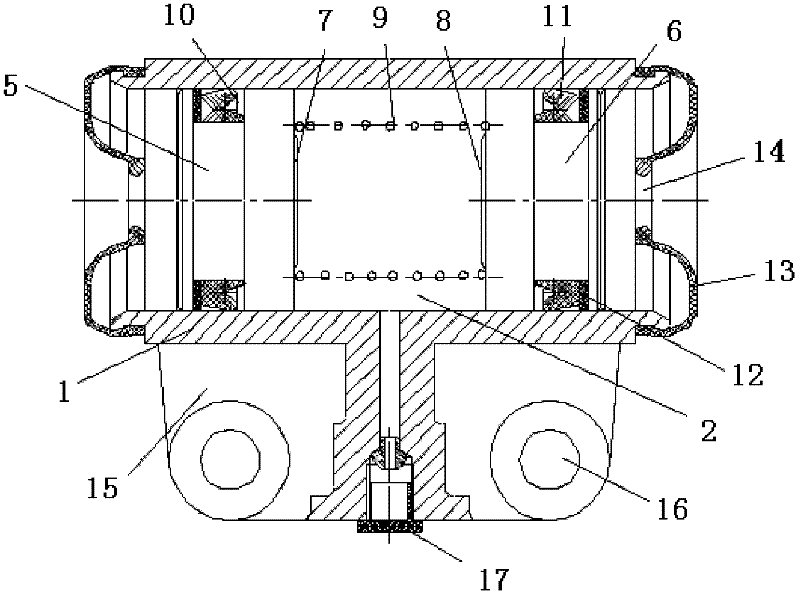

Multifunctional wet brake for forkman driving bridge

The invention relates to a multifunctional wet brake for a forkman driving bridge. The inner side of a left shell of the brake is provided with an isolating ring, and a driving brake piston is positioned at the inner side of the isolating ring and is fixedly connected with the left shell by a bolt of a return spring; a parking brake piston is sheathed at the outer side of the isolating ring, compression springs of the parking brake piston are evenly distributed inside a right shell, and the outer end surface along the axial direction of the compression springs is contacted with a parking diaphragm plate; the inner side of the right shell is provided with more than two grooves along the radial direction, and the parking diaphragm plate and the circumference of the diaphragm plate are respectively and correspondingly provided with more than two convex blocks which are correspondingly positioned inside the two grooves of the right shell; the outer side of the left shell that is corresponding to the driving brake piston and the parking brake piston are respectively provided with an air bleed screw and a brake steel tube interface along the axial direction. The invention has compact structure and easy assembly; a brake steel tube and the air bleed screw are arranged on the side of the brake, so as to not interfere a charging connector; the operation is labor-saving; and the return spring has good return effect and short response time.

Owner:ANHUI HELI CO LTD

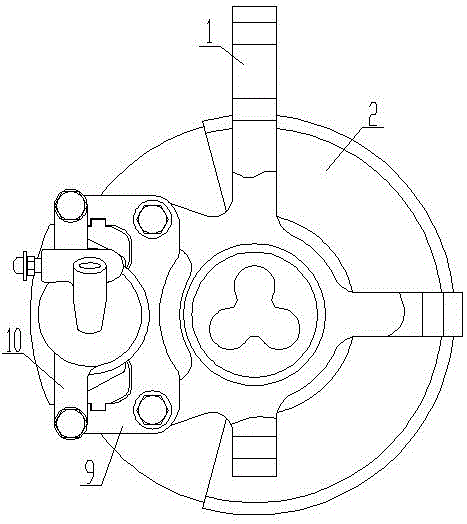

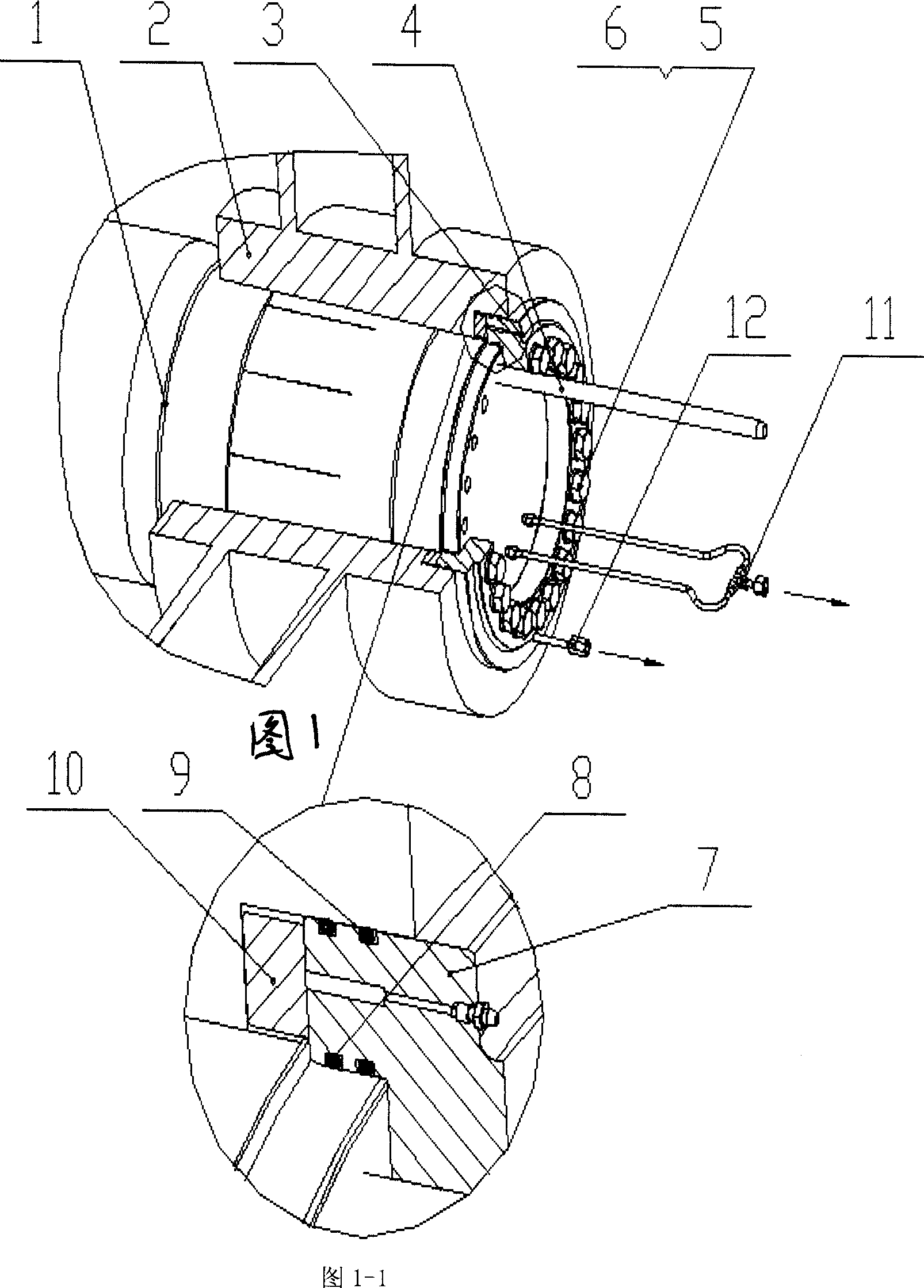

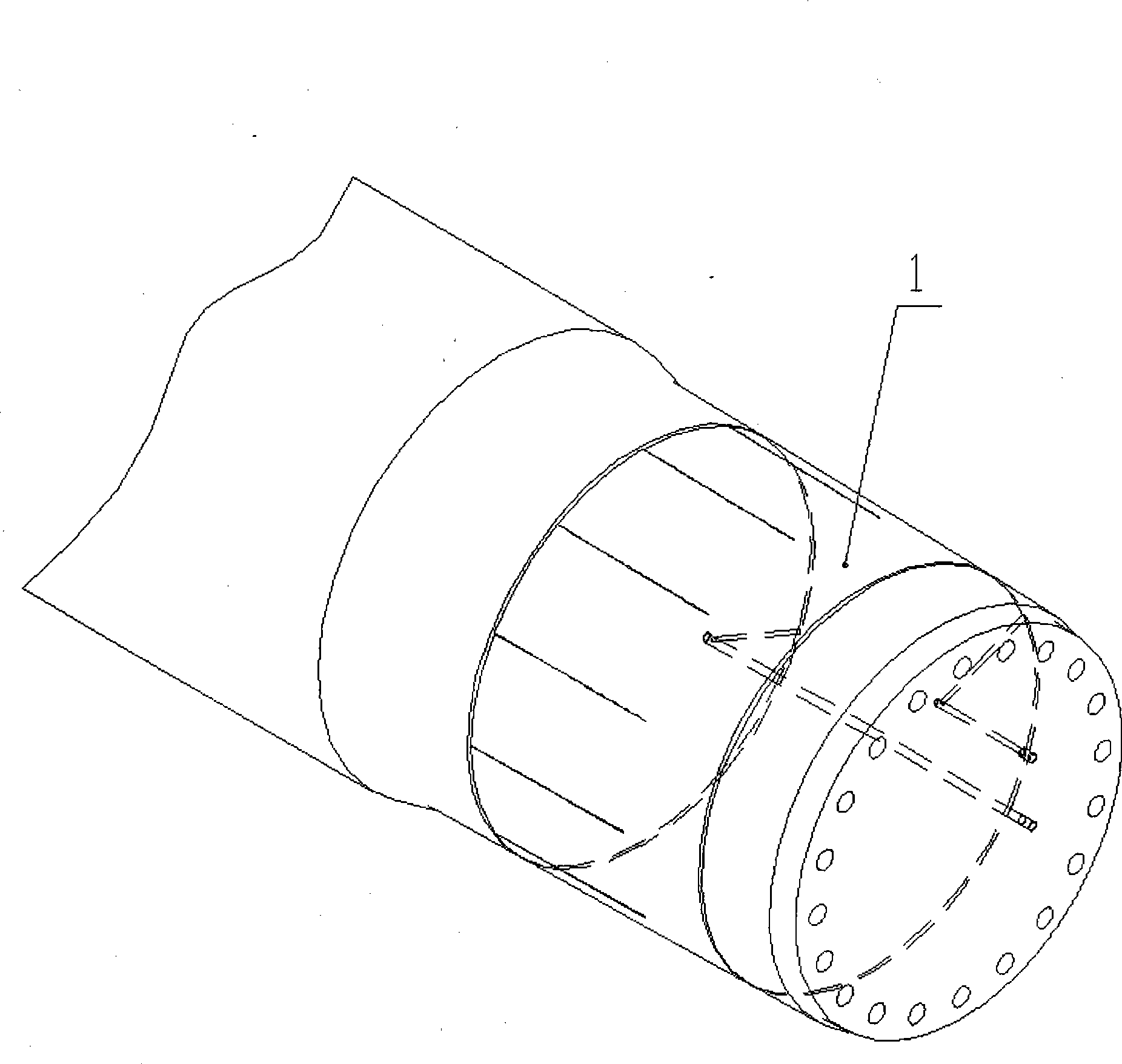

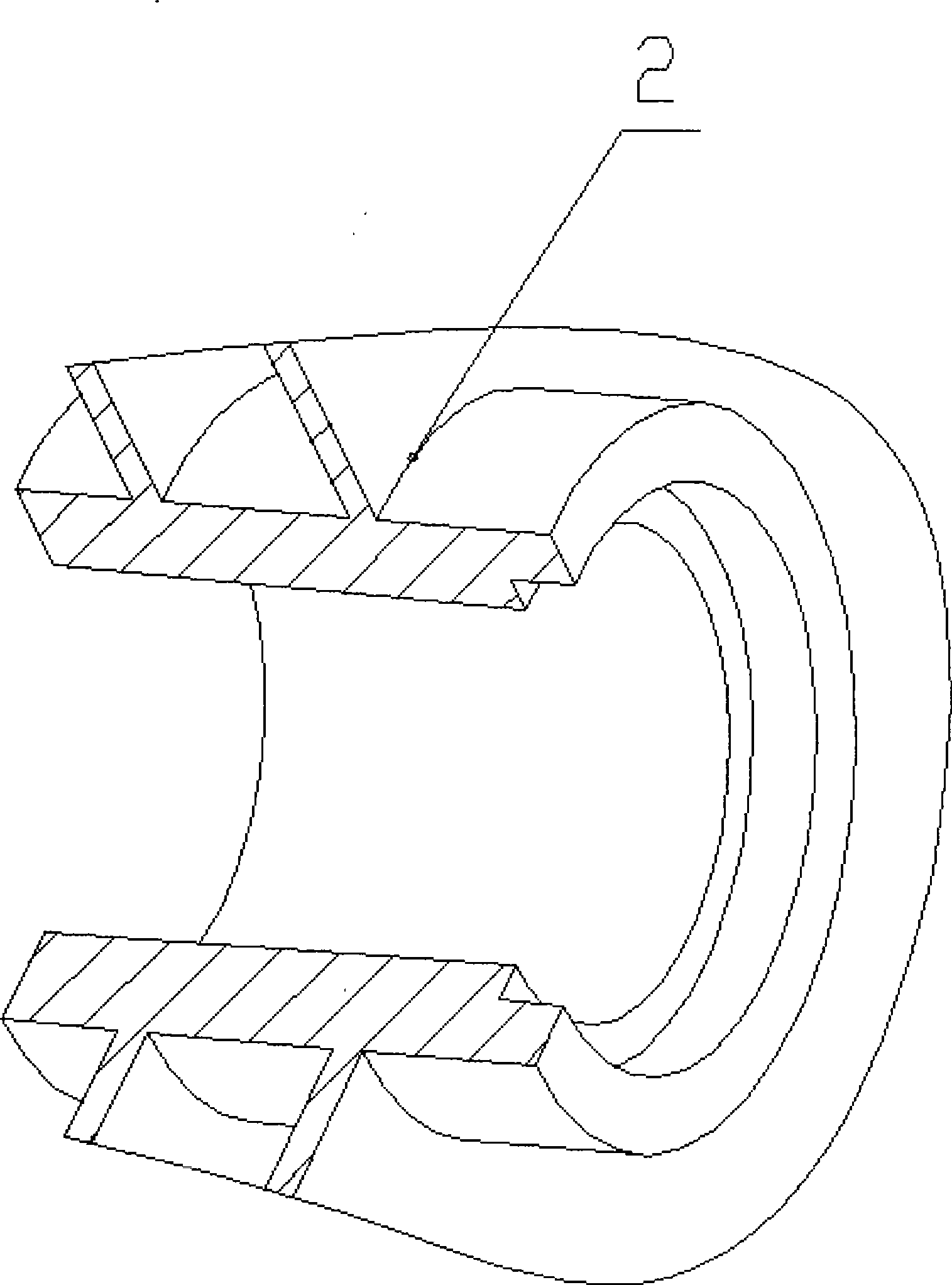

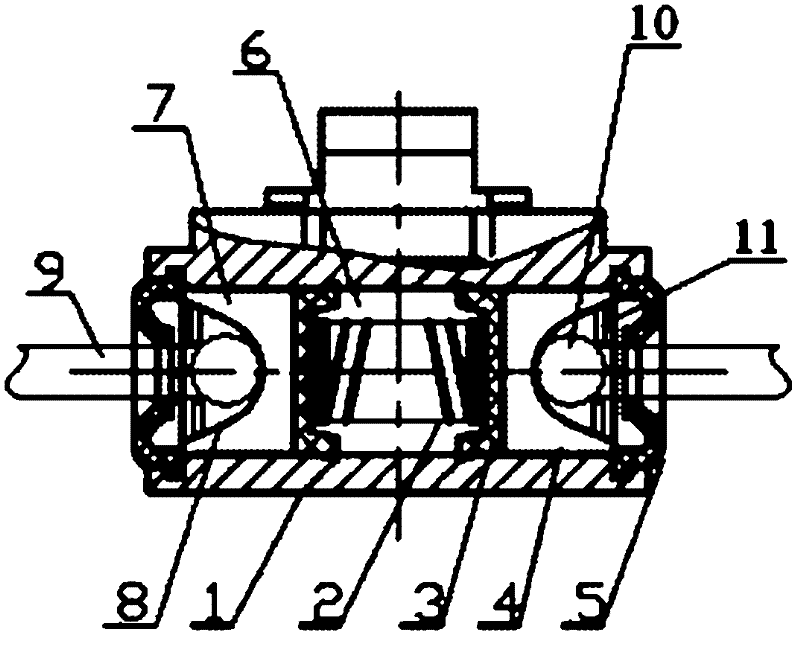

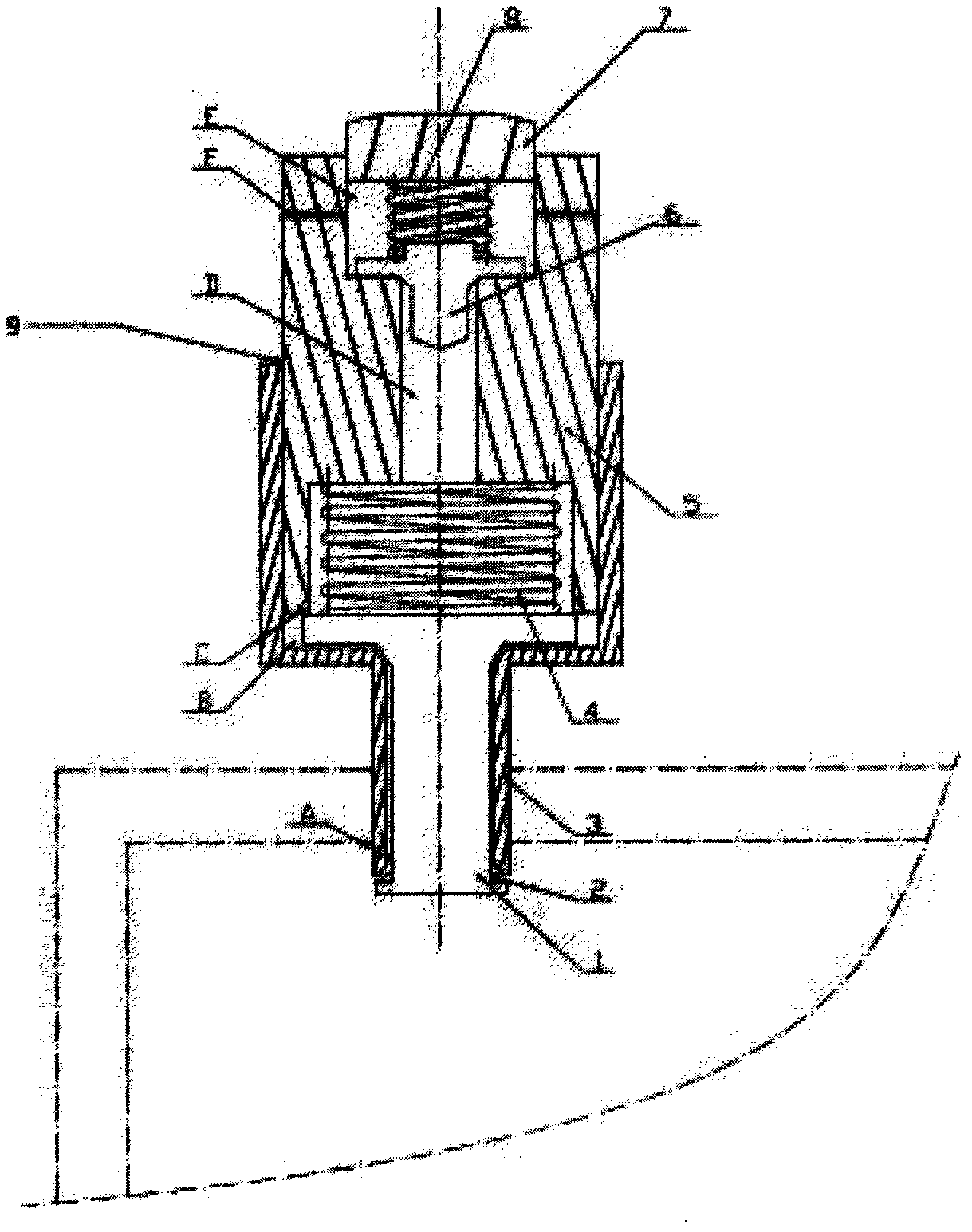

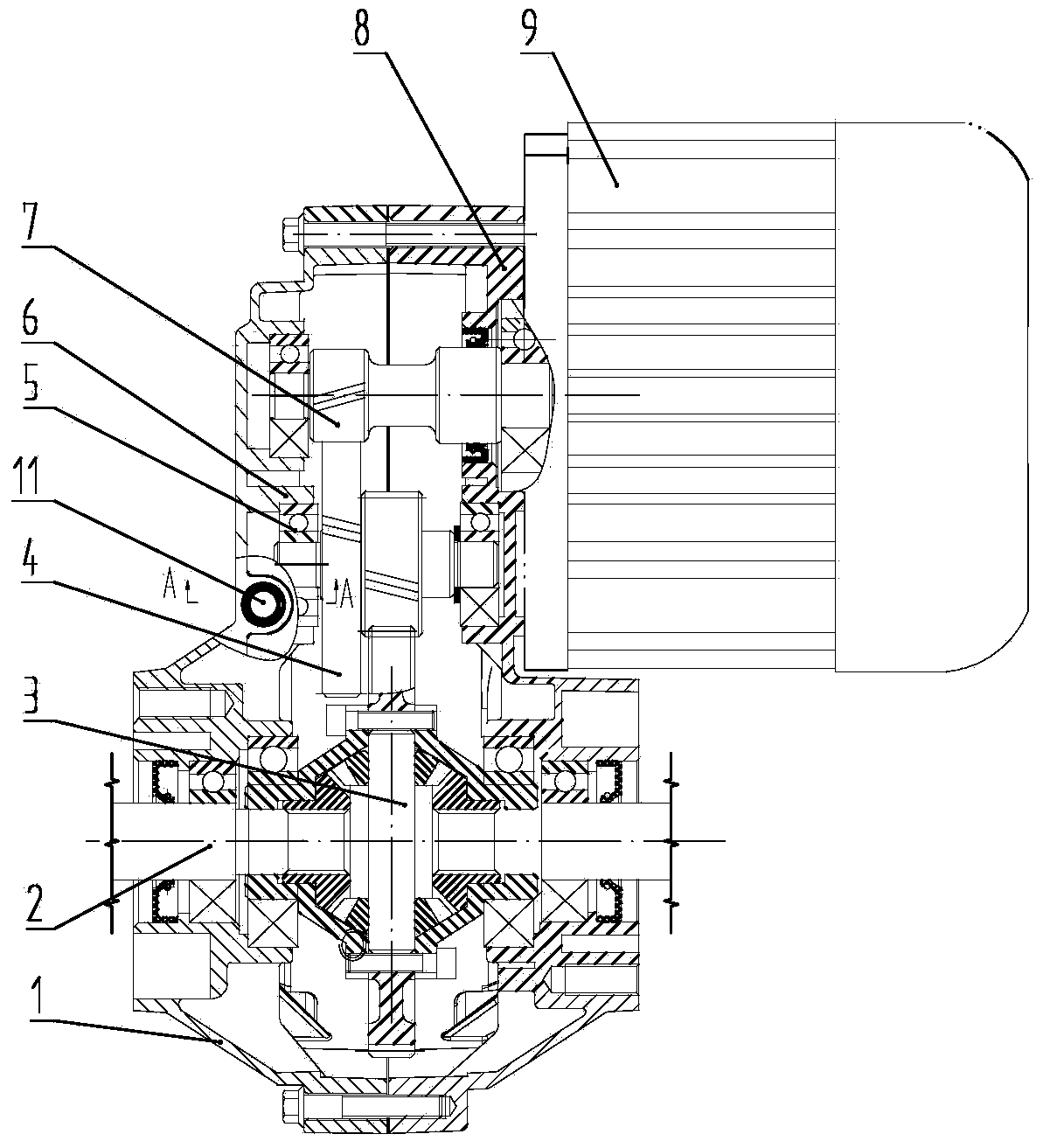

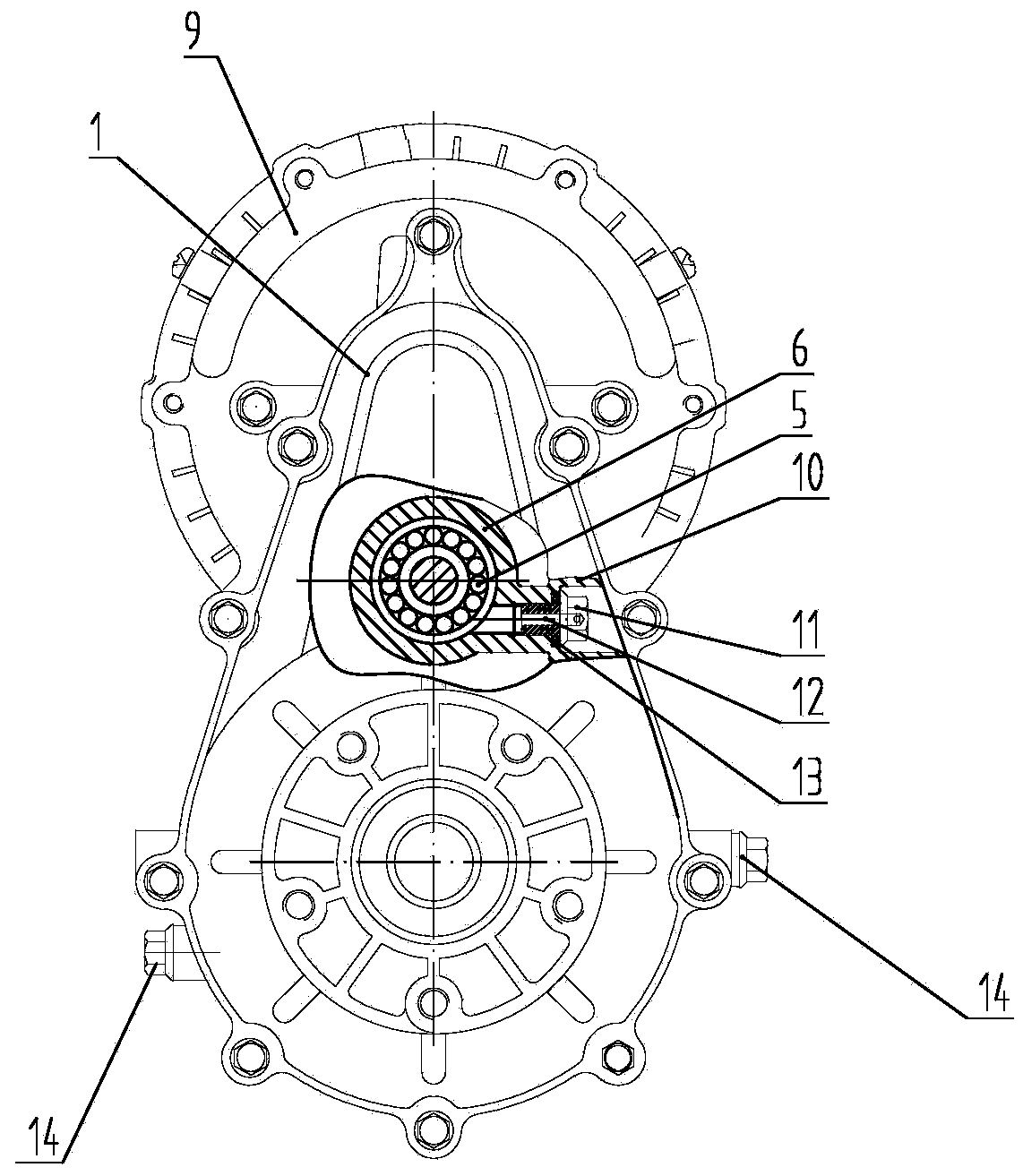

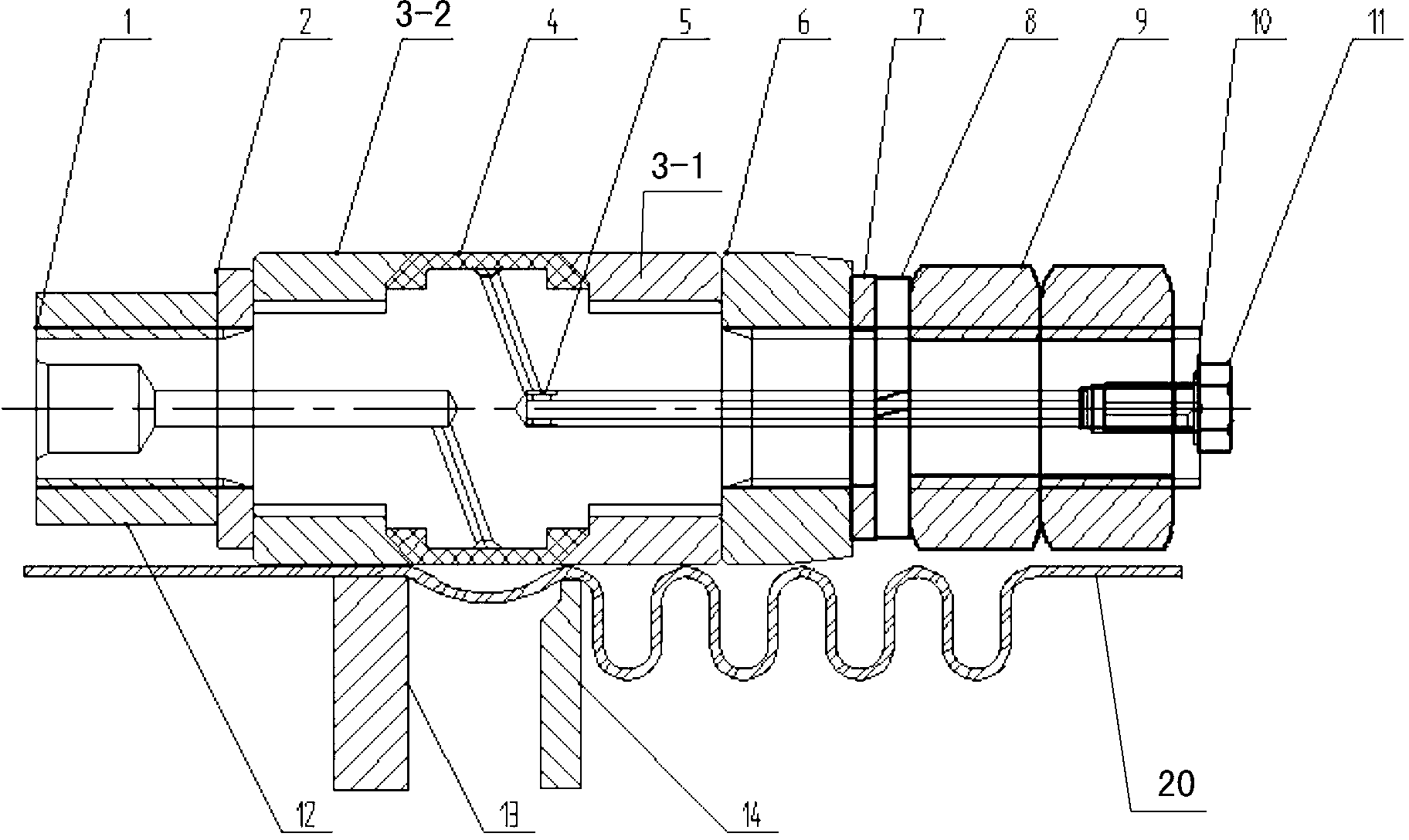

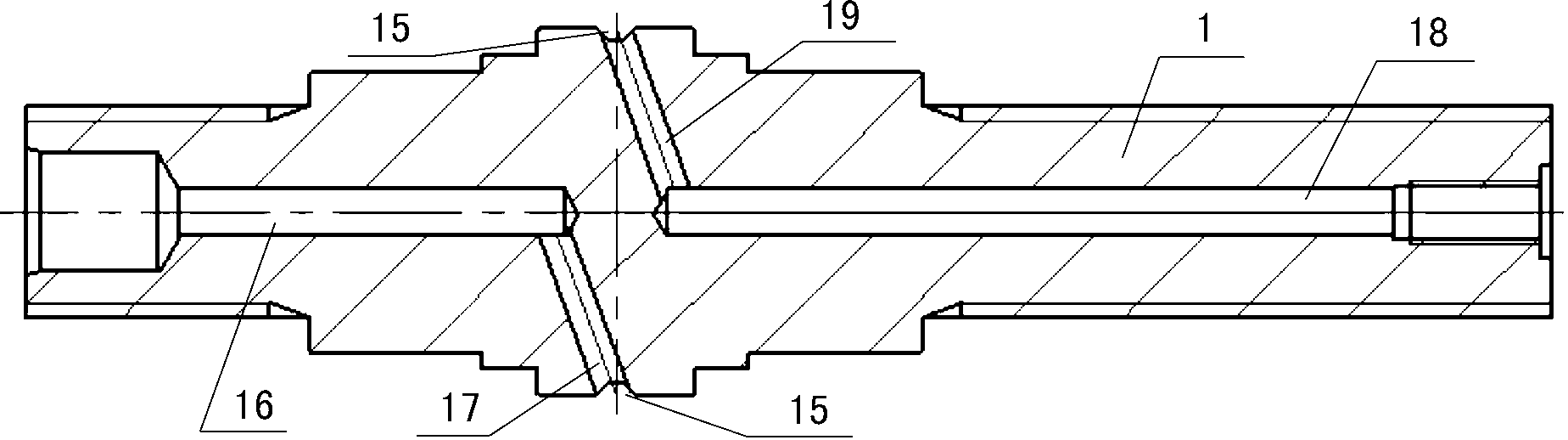

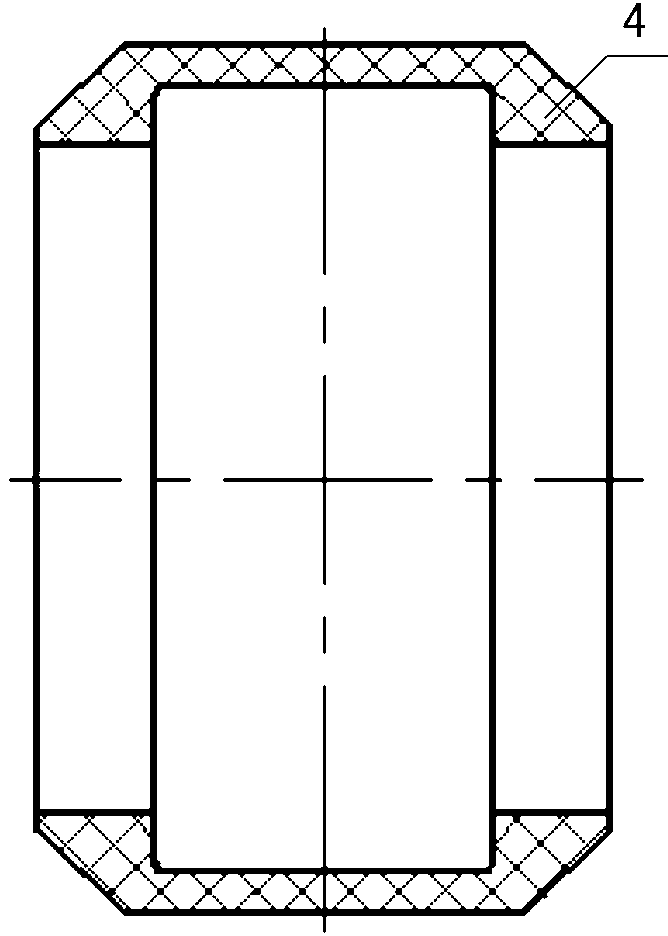

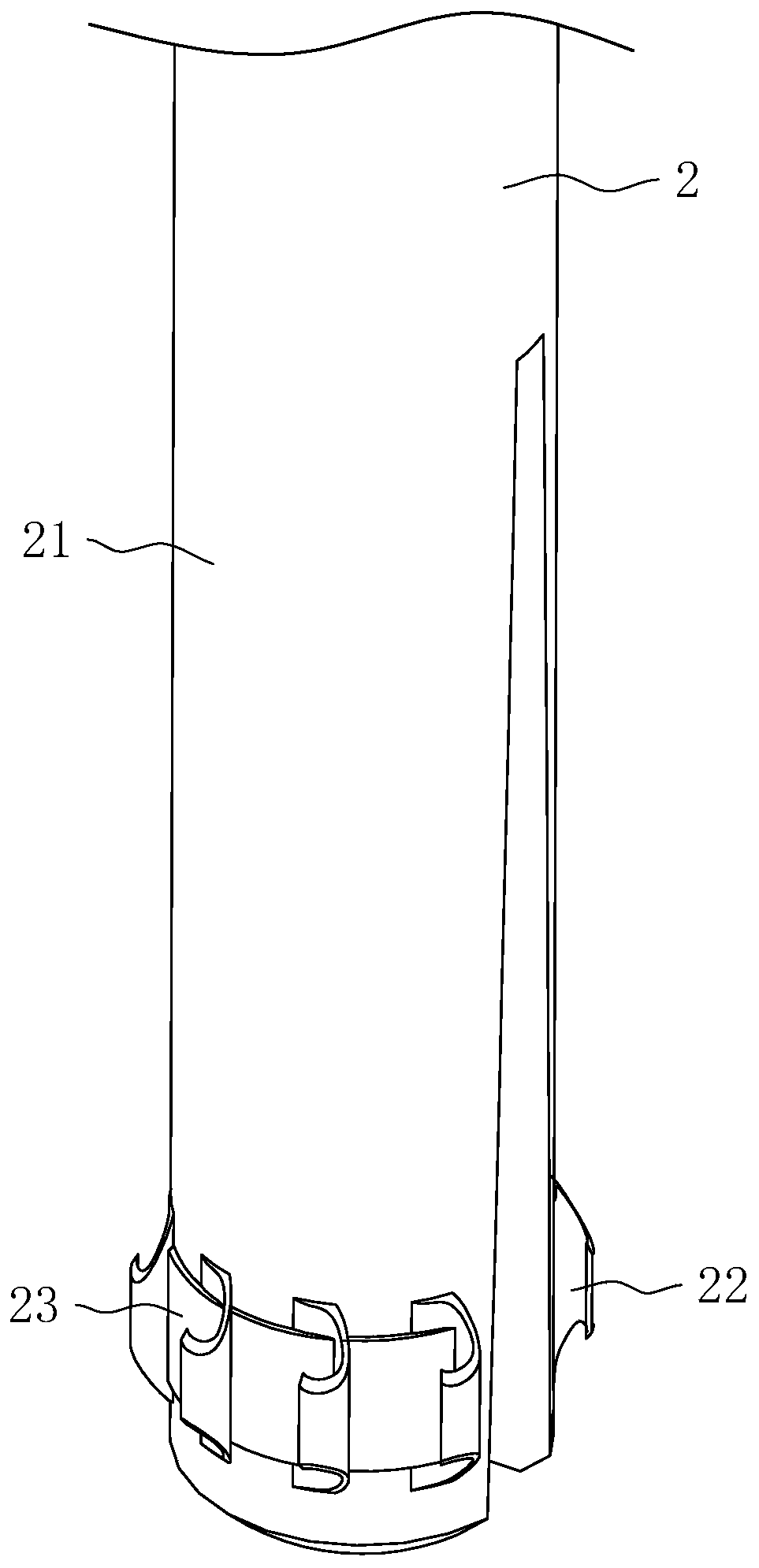

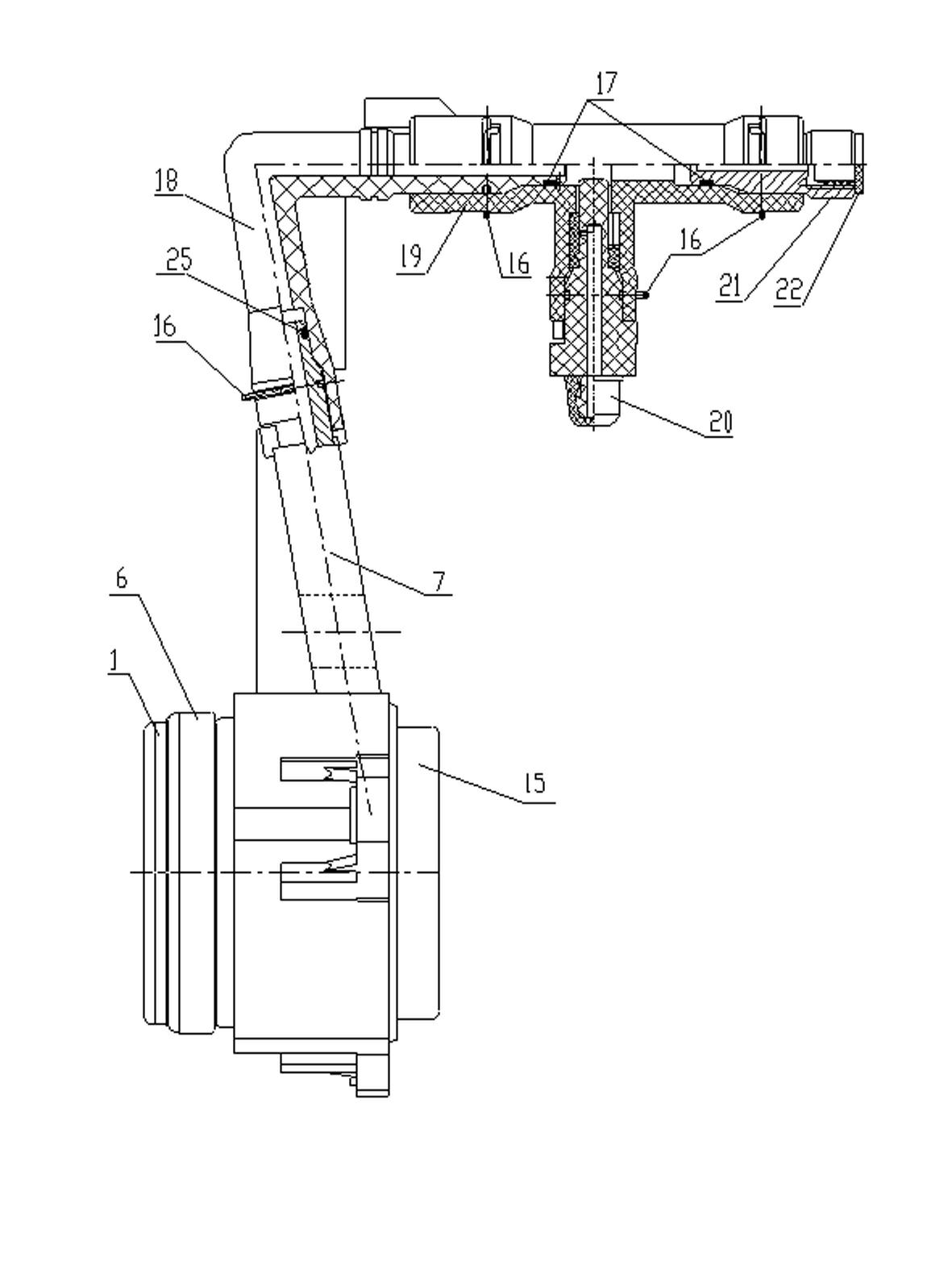

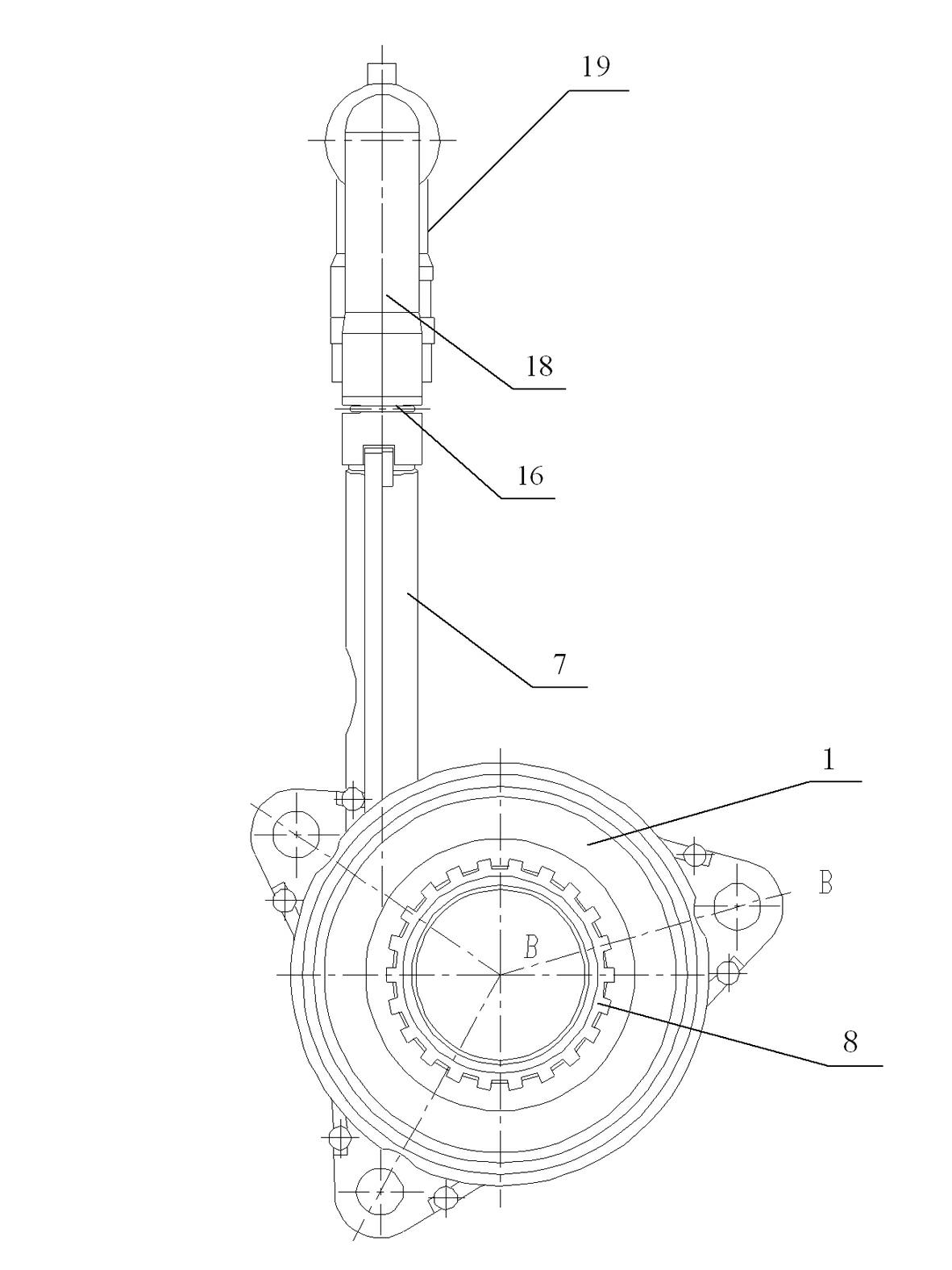

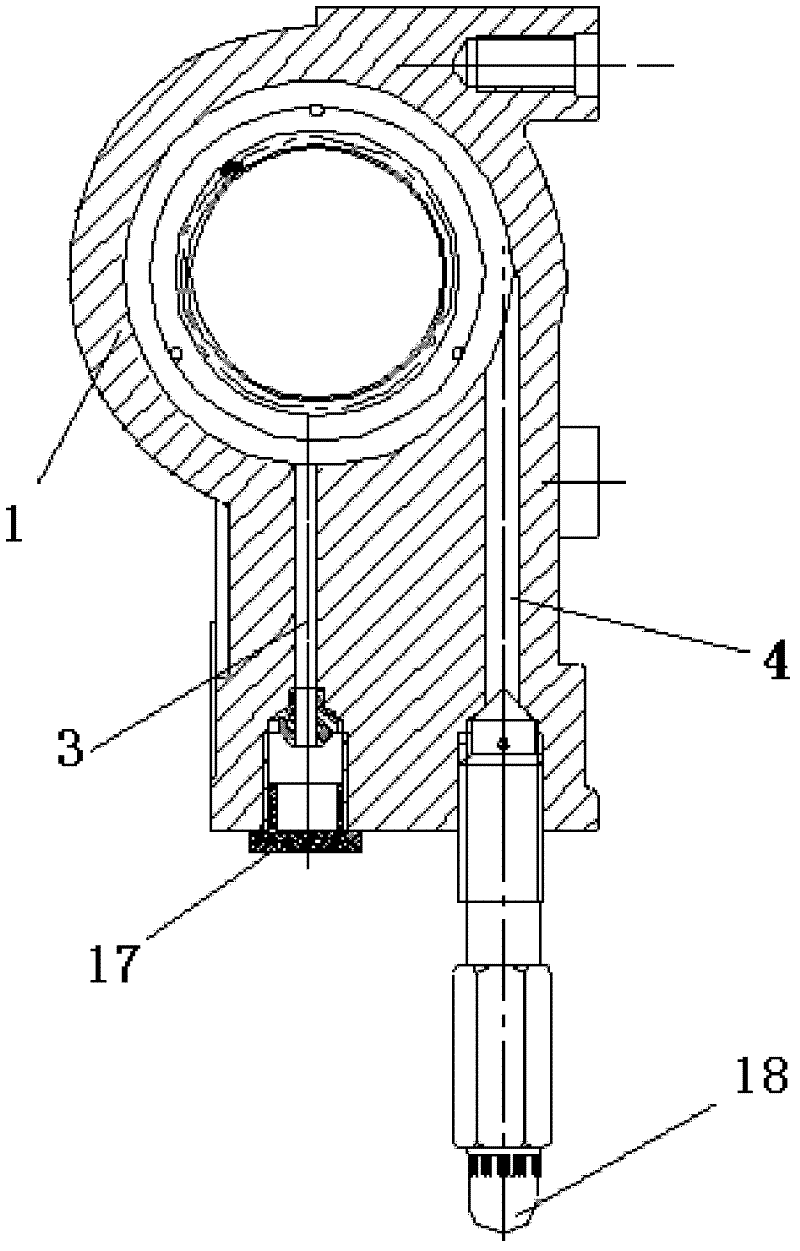

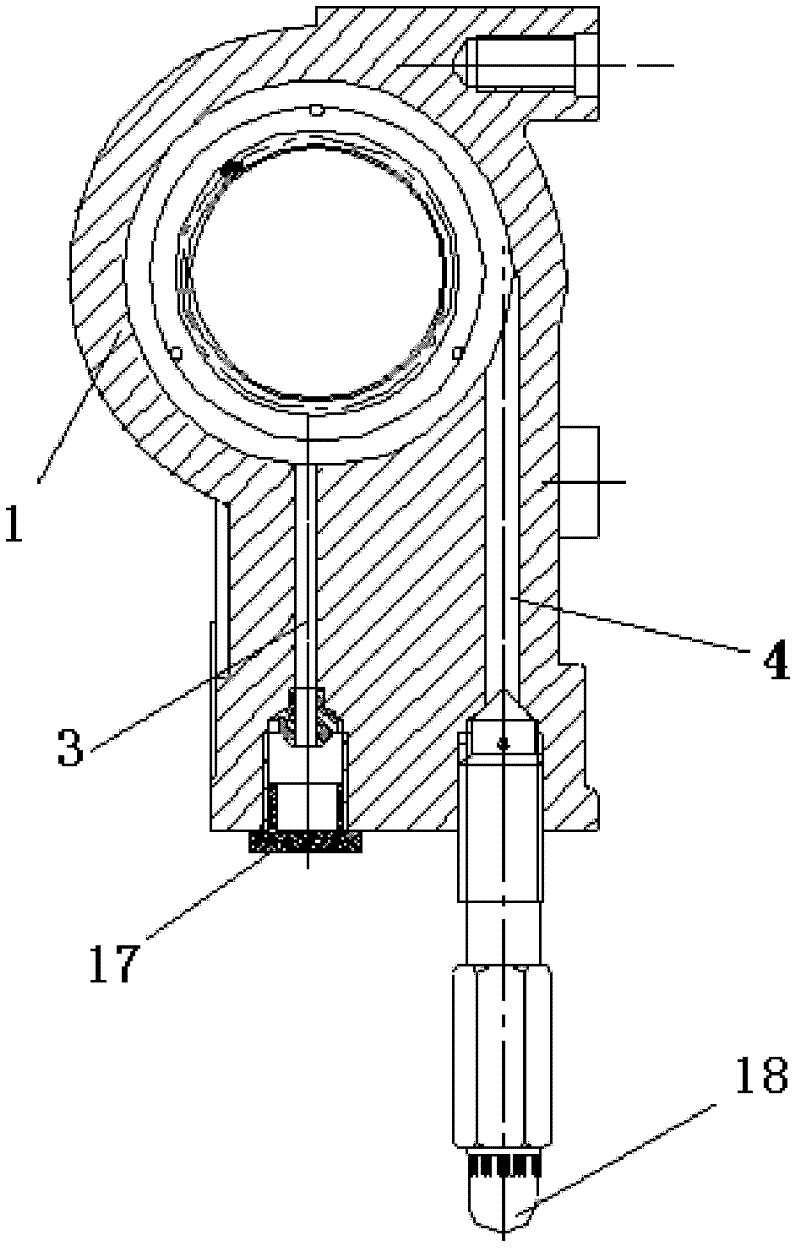

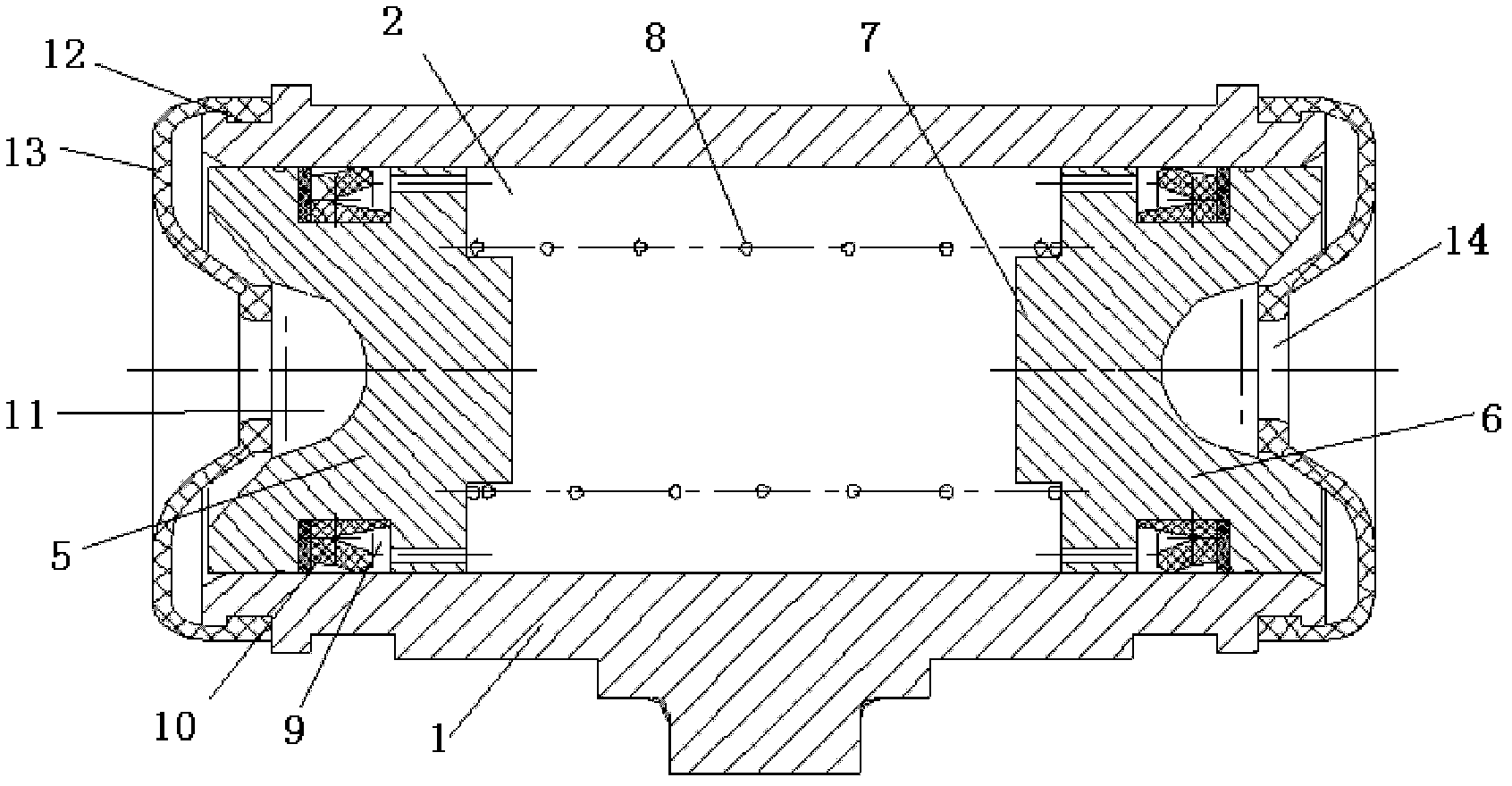

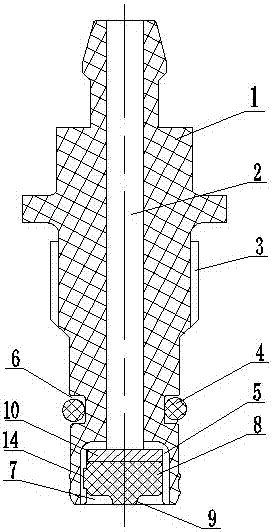

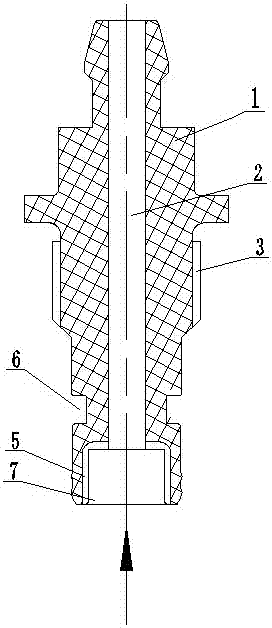

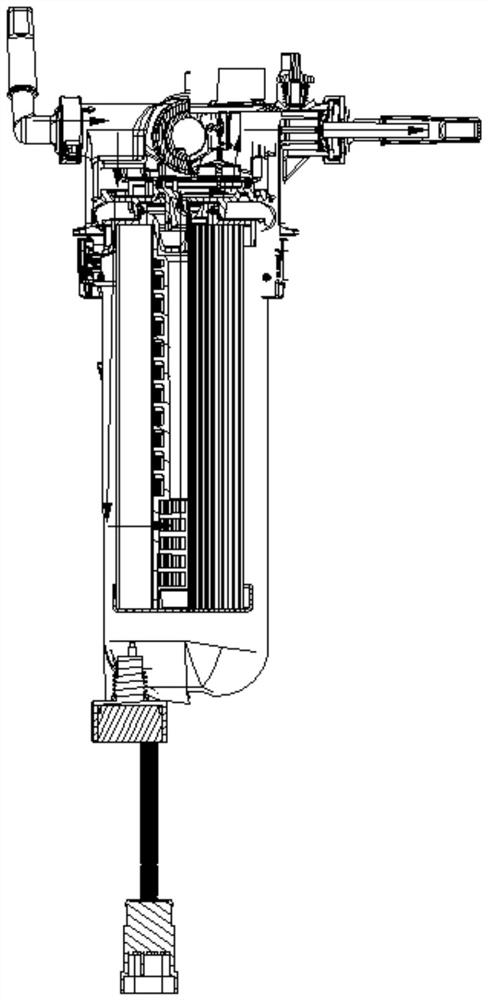

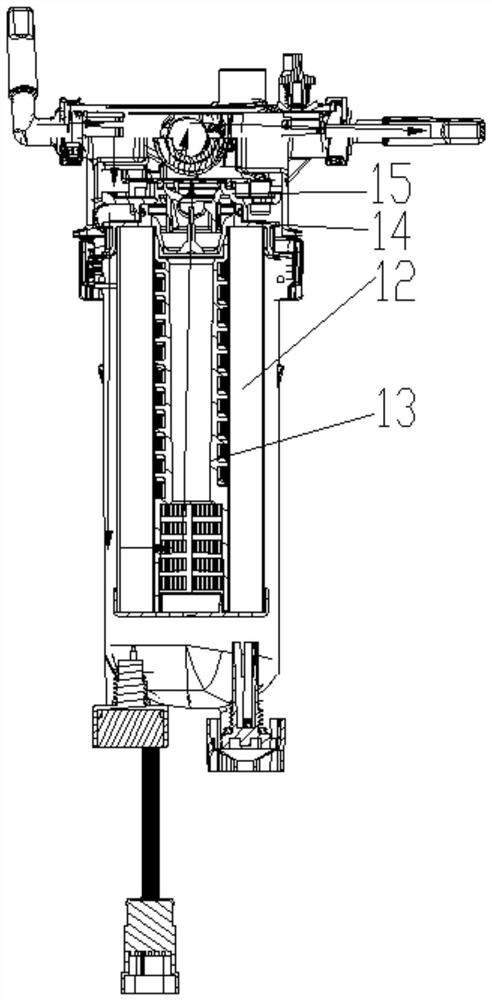

Method for installing and dismantling device for connecting main shaft of large-scale mine elevator with motor rotor

ActiveCN101445204ASolve the precise assembly on the main shaft of the hoistSolve the problem of dismantling the motor rotor on siteMine liftsElectric machineryEngineering

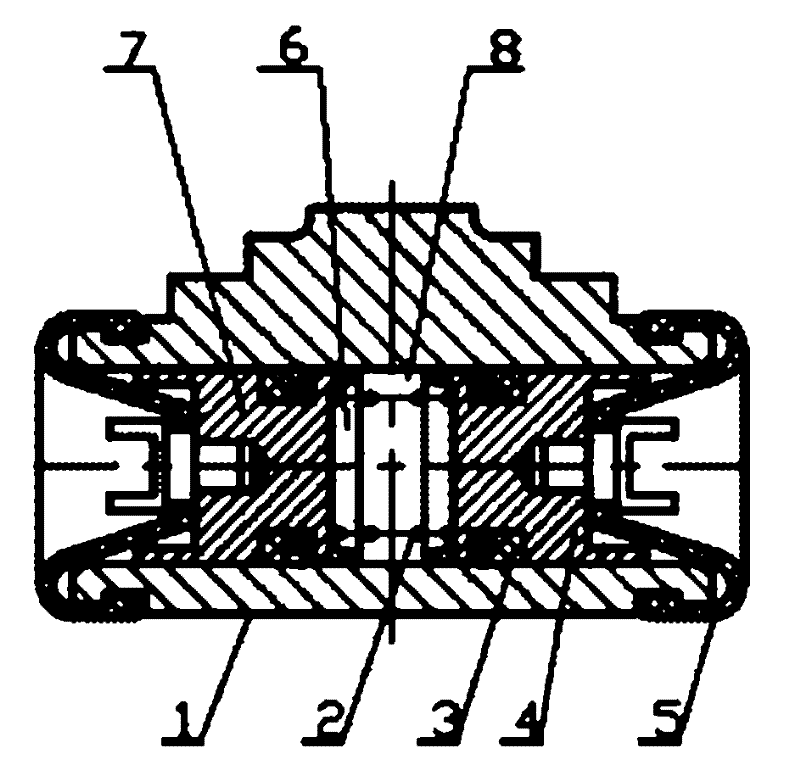

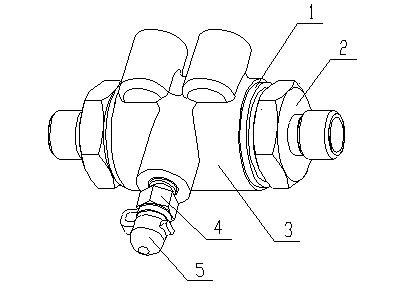

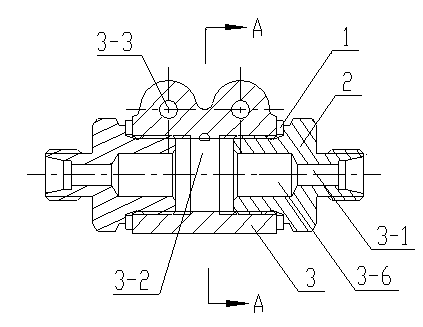

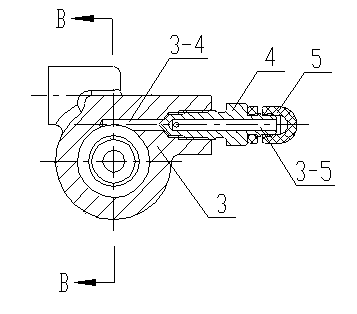

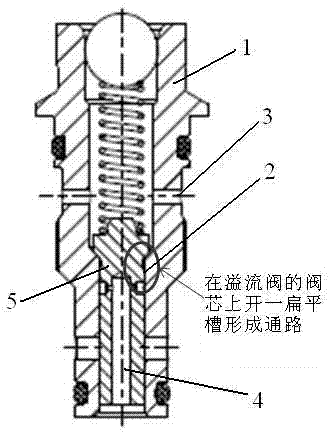

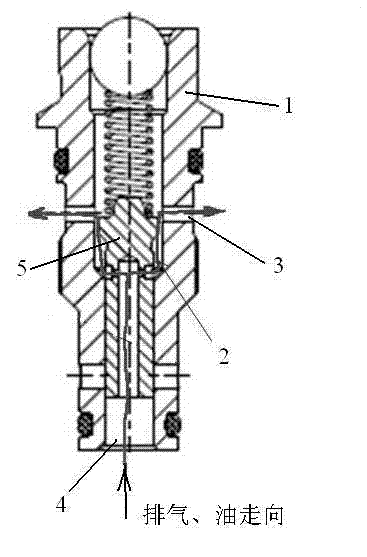

A method for installing and dismantling a device for connecting the main shaft of a large-scale mine elevator with a motor rotor is characterized in that the device comprises an elevator main shaft (1), a motor rotor hub (2), an air bleed screw (3), a mounting rod (4), a bolt (5), a gasket (6), a hydraulic cover (7), a seal ring 1 (8), a seal ring 2 (9), a sleeve (10), a connecting pipe 1 (11), a connecting pipe 2 (12), an oil pump 1 (13) and an oil pump 2 (14). The invention solves the problems of accurate assembly of the motor rotor on the elevator main shaft and field dismantling of the motor rotor when conditions for field installation and assembly are limited. Tools for implementing the method are easy to process. The method comprises operation steps which are simple and easy to be carried out, so that installation workers, even totally ignorant of how to install a motor rotor, can still smoothly install and dismantle the motor rotor by following the requirements of instructions. Particularly, the invention is suitable for field use by users.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

Minute pump for clutch

The invention discloses a minute pump for a clutch. The minute pump comprises a shell; the right end of the shell is provided with an opening; the side wall of the opening end is fixedly provided with a dust cover; the left end of the shell is provided with an oil inlet; the side wall of the shell is communicated with an air exhaust port; a piston is arranged in the shell in a sliding way; main leather collars and auxiliary leather collars are arranged on the side wall of the piston at intervals; the side wall of the shell is provided with an installation seat; a bleed screw is screwed on the air exhaust port; and a bleed cap is covered on the bleed screw. The minute pump has a simple and compact structure and a small volume and can effectively prevent dust and oil leakage.

Owner:芜湖博格汽车零部件有限公司

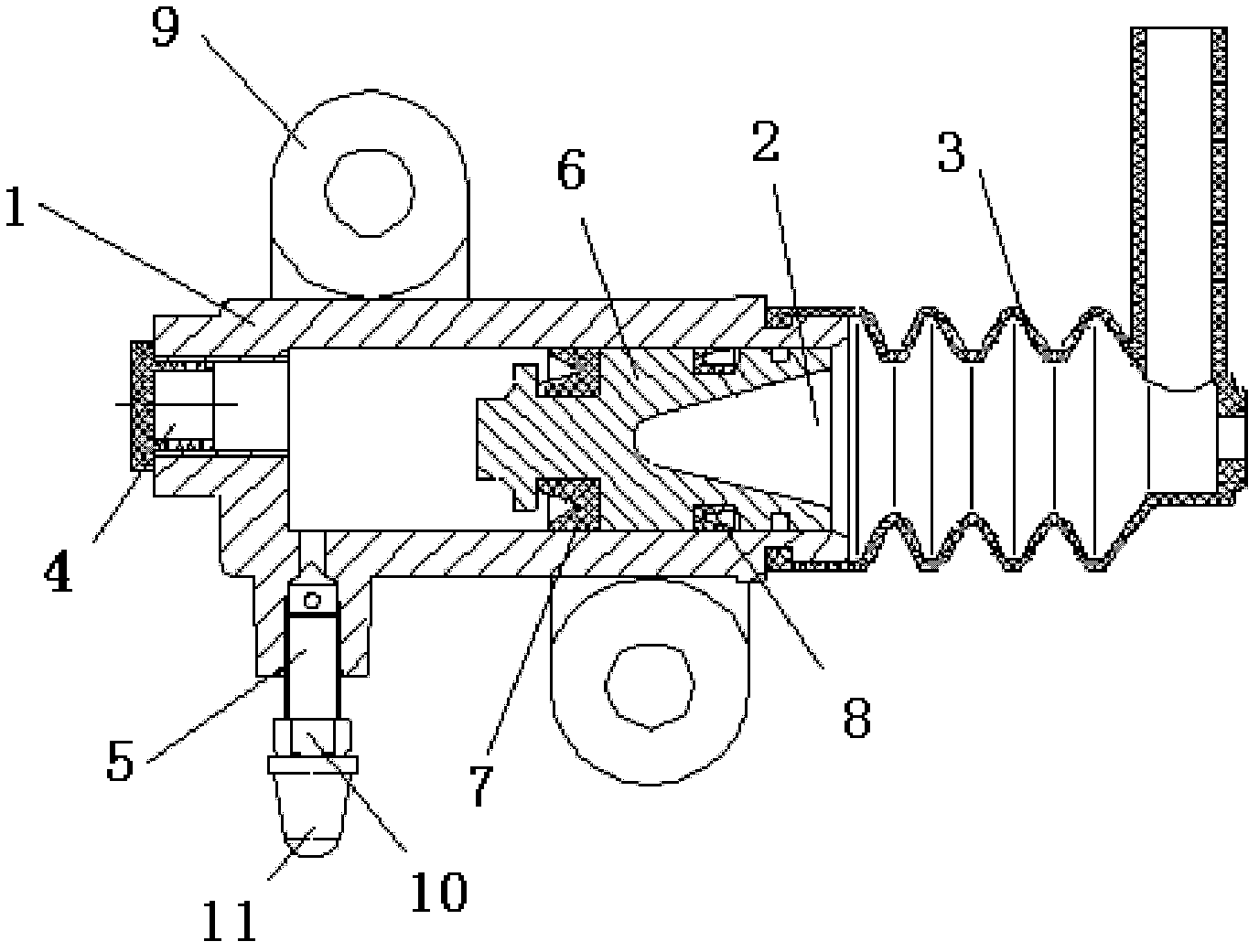

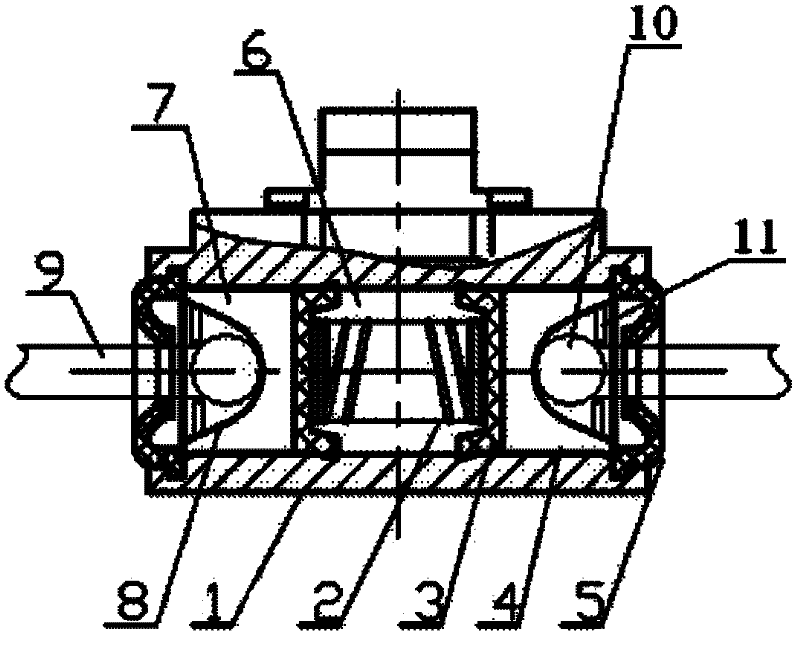

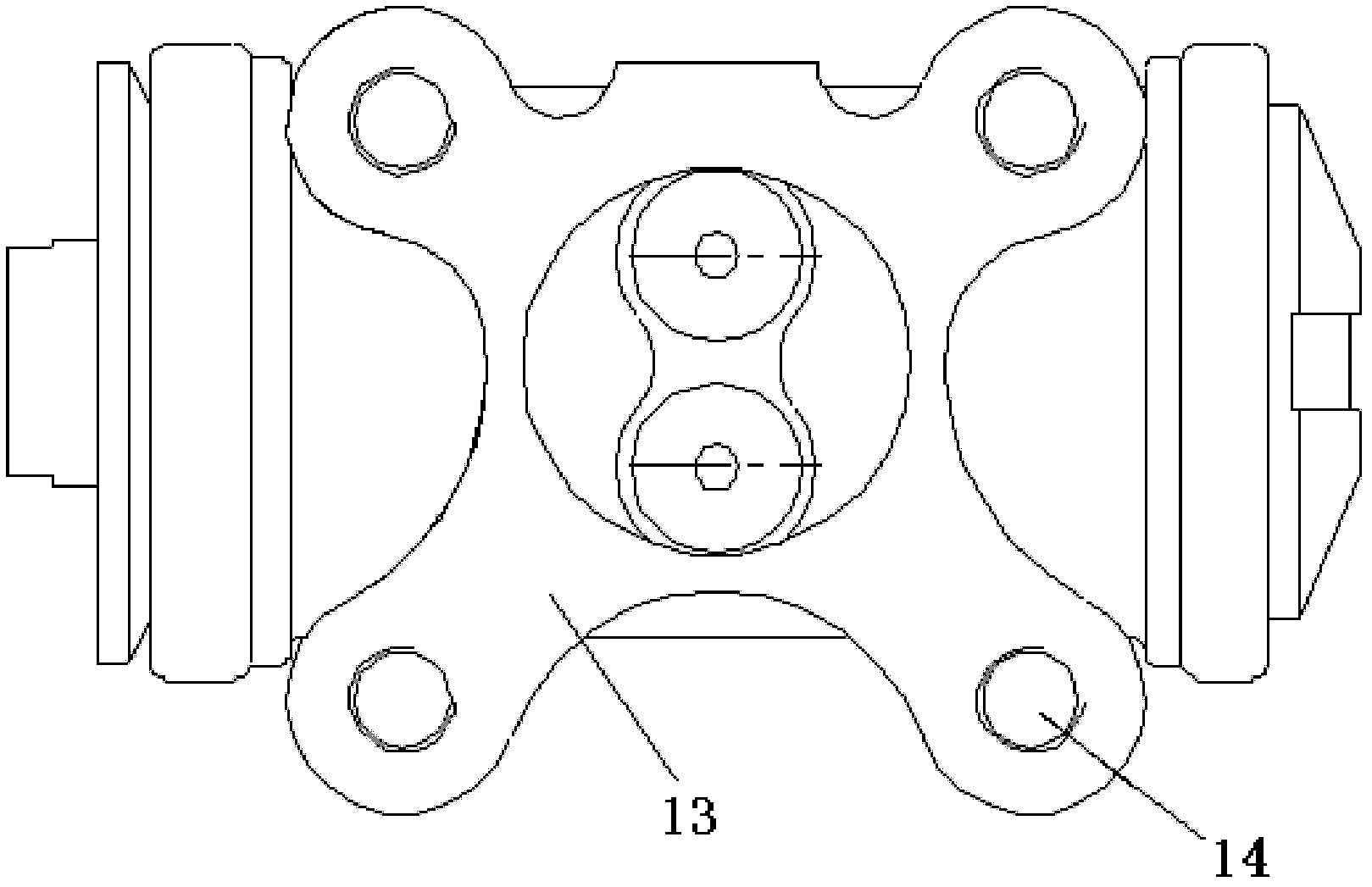

Bidirectional brake wheel cylinder assembly

InactiveCN102364149AExpand action spaceCompact structureBrake actuating mechanismsWheel cylinderEngineering

The invention discloses a bidirectional brake wheel cylinder assembly which comprises a cylinder body and a push rod, wherein a radial through hole is arranged in the cylinder body; left and right pistons are arranged in the radial through hole; a spring is connected between inner lateral surfaces of the left and right pistons; the outsides of the left and right pistons are respectively provided with concave cavities; dustproof covers with middle holes are respectively arranged on the cylinder body and at both ends of the radial through hole; the tail ends of the push rod are provided with ball joints; the ball joints are in running fit with the inner walls of the concave cavities and are limited by check rings; the front end of the push rod passes through the through holes in the middle of the dustproof covers and extends out; the cylinder body is provided with an oil nozzle communicated to the radial through hole; the cylinder body is provided with an opening and is in threaded connection with a bleed screw; and the end part of the bleed screw is provided with a bleed cap. The bidirectional brake wheel cylinder assembly has compact structure and light weight, occupies small space, has good sealing performance and is provided with the bidirectional brake pistons. The connection relation between the pistons and external braking parts is designed into the relation that the concave cavities are matched with the ball joints. The motion space of the external braking parts is greatly expanded. The bidirectional brake wheel cylinder assembly has high practical value.

Owner:WUHU HENGKUN AUTO PARTS

Caliper vent screw

InactiveCN108730573AReduce performanceImprove securityCheck valvesBraking componentsEngineeringCalipers

The present invention provides a caliper vent screw. The caliper vent screw comprises a one-way valve body and a gas storage structure, wherein a pressure-maintaining valve core is arranged at the bottom of the one-way valve body; a shell body is arranged on the outer side of the one-way valve body, and an O-shaped ring is disposed between the shell body and the pressure-retaining valve core; a pressure-retaining valve return spring is disposed in the middle of the one-way valve body, and a valve core of a one-way valve is disposed on the upper side of the pressure-retaining valve return spring; a one-way valve spring is connected to the upper end of the valve core of the one-way valve, and a valve seat of the one-way valve is arranged at the top end of the one-way valve body; and the one-way valve body is provided with the gas storage structure. The caliper air bleed screw can press gas in a pipeline and a caliper piston into a collecting room in the vent screw to a certain extent, then the gas is discharged into the atmosphere to prevent the gas in the system from lowering the performance of a brake system, and the safety performance of a car is improved.

Owner:CHANGZHOU INST OF MECHATRONIC TECH

Hydraulic double-cylinder braking caliper assembly

PendingCN107917158ASave layout spaceIncrease braking powerOther chemical processesAxially engaging brakesHydraulic cylinderEffective radius

A hydraulic double-cylinder brake caliper assembly, including a caliper body with two hydraulic chambers, the two hydraulic chambers are connected at the bottom, and pistons are respectively arranged inside; The inner friction plate and the outer friction plate, the friction surfaces of the two friction plates are opposite and both of them are in clearance fit with the brake disc; there are pin holes on both sides of the fixed frame, and the pin shaft slidingly matched with the pin holes passes through the bolts and the suspension on the outside of the caliper body. ear connection; the pin hole is provided with a bush that matches with the pin shaft, and an air release screw is provided on the caliper body, and an air release cap is provided on the air release screw. A hydraulic double-cylinder brake caliper assembly according to the present invention has two pressure cylinders. Under the condition that the braking effective radius is the same, the braking force generated by the double-cylinder brake caliper is higher than that of the single-cylinder brake caliper of the same specification. Twice, it can increase the braking force when the layout space is small and the effective radius cannot be increased, and at the same time, it can effectively ensure the stability of braking.

Owner:BRILLIANCE AUTO

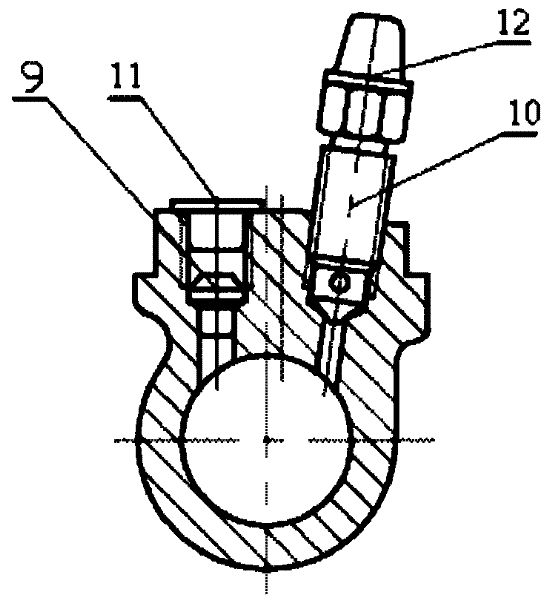

Air bleeder of differential case of electro-tricycle

ActiveCN103727213AExtended service lifeImprove lubrication statusGear lubrication/coolingDifferential gearingsEngineeringSteel ball

The invention discloses an air bleeder of a differential case of an electro-tricycle, and relates to electro-tricycles. A special bleed screw is arranged at one side of a bearing block; an inner thread and a through hole are formed below the bleed screw base; an inner cavity of a bearing block is communicated with the external atmosphere of the differential case by an air-bleed hole in the bleed screw and the through hole below the bleed screw base; a steel ball in the bearing grinds oil and gas bubbles formed by splashing of lubricating oil when the bearing runs at a high speed, so that the oil is separated from gas; air is discharged out of the differential case from the air-bleed hole; the lubricating oil is left inside the box body. A gear and the bearing are kept in a good lubricating state for a long period of time, the service life of the transmission gear in the differential case is greatly prolonged, and the air bleeder has significant effects on further improvement of the work efficiency and reduction of mechanical noises. In addition, the bleed screw is arranged at one side of the bearing block, so that the bleed screw is not easily damaged.

Owner:山东小蚁电动科技有限公司

Brake wheel cylinder assembly for preventing collision between pistons

The invention discloses a brake wheel cylinder assembly for preventing the collision between pistons, which comprises a cylinder body, wherein a radial through hole is arranged in the cylinder body; a left piston and a right piston are arranged in the radial through hole and are in sliding fit with the wall of the radial through hole; a spring is connected between the left piston and the right piston; bowl-shaped concave cavities are respectively arranged on the inner lateral surfaces of the left piston and the right piston; port parts of the bowl-shaped concave cavities are opposite to each other; an air tap or an oil nozzle is arranged on the cylinder body; the cylinder body is provided with an opening pore and is screwed with an air bleed screw; and an air bleed cap is arranged at the end part of the air bleed screw. The brake wheel cylinder assembly has the advantages of reasonable structure, small occupied space and favorable sealing performance; and the bowl-shaped concave cavities are arranged at the inner sides of the pistons so as to play a better cushioning action, prevent the collision between the pistons, reduce the wear between the pistons and prolong the service lives of the pistons.

Owner:WUHU HENGKUN AUTO PARTS

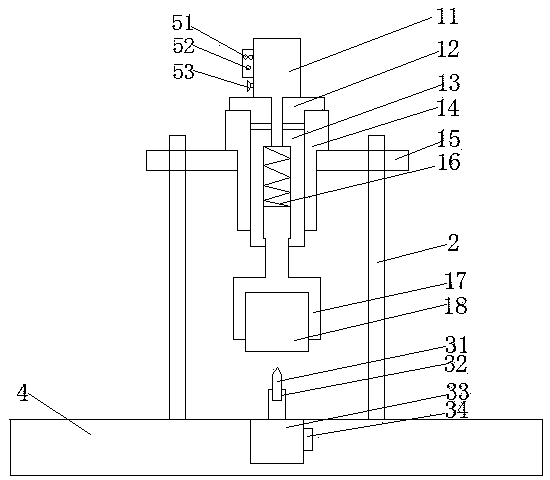

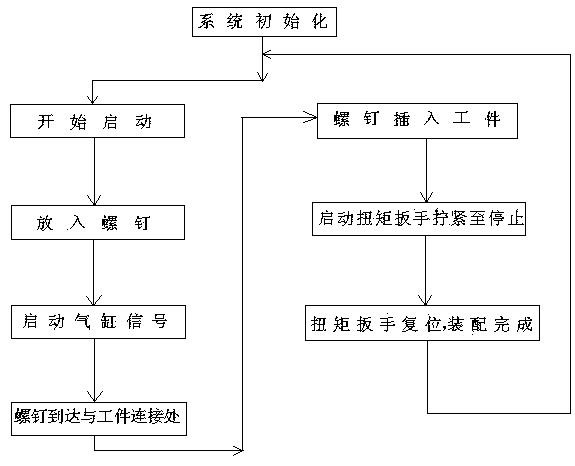

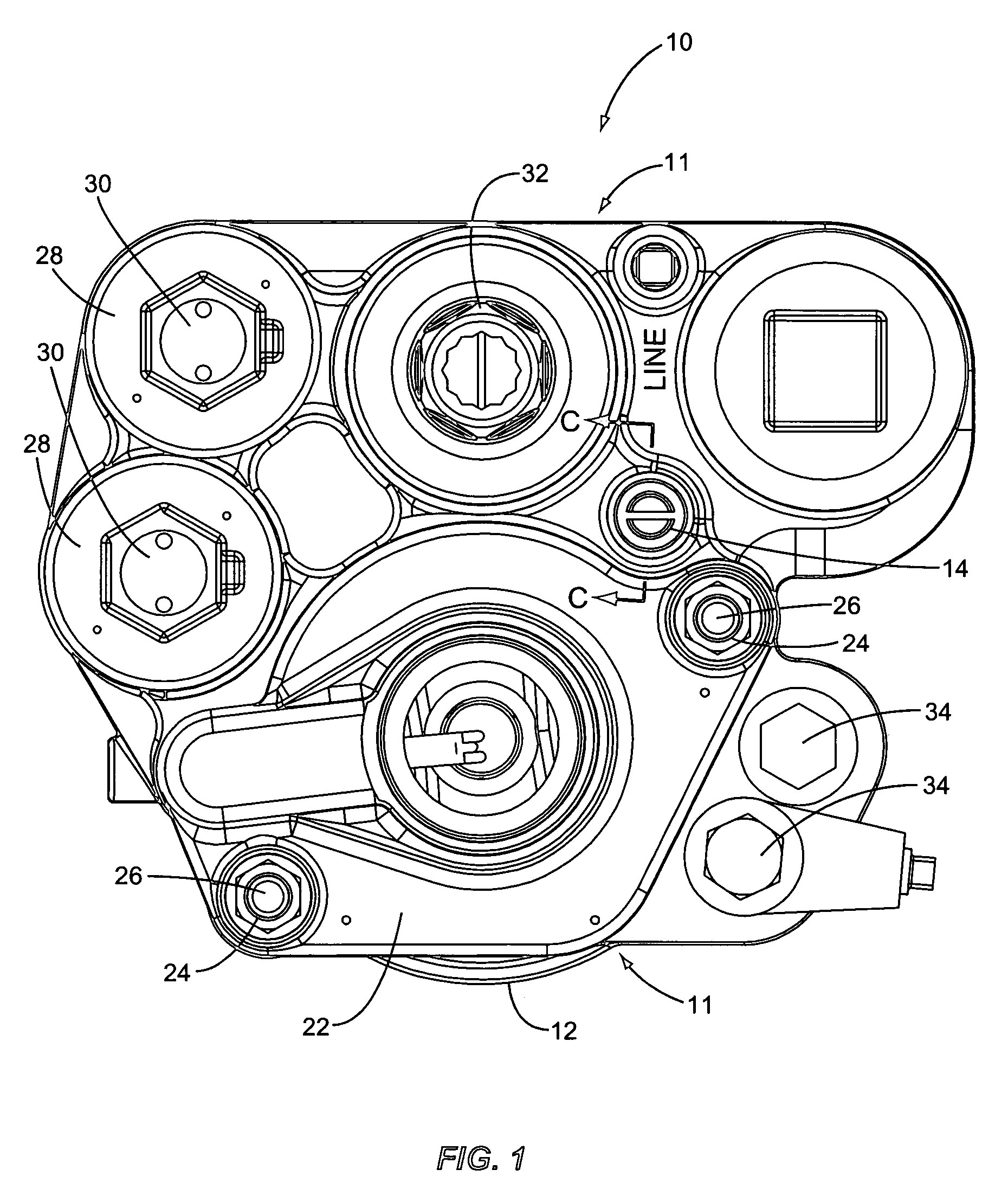

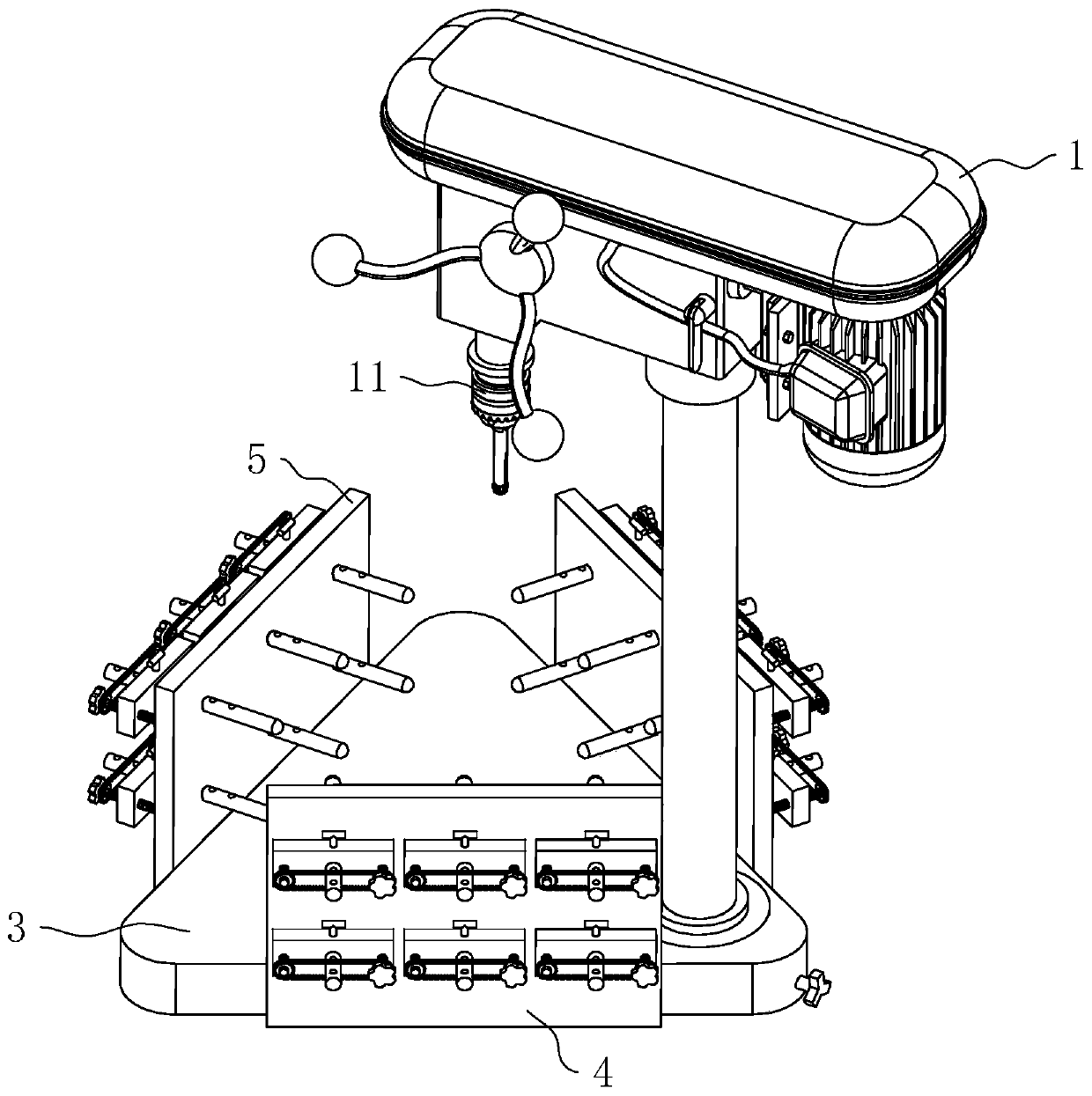

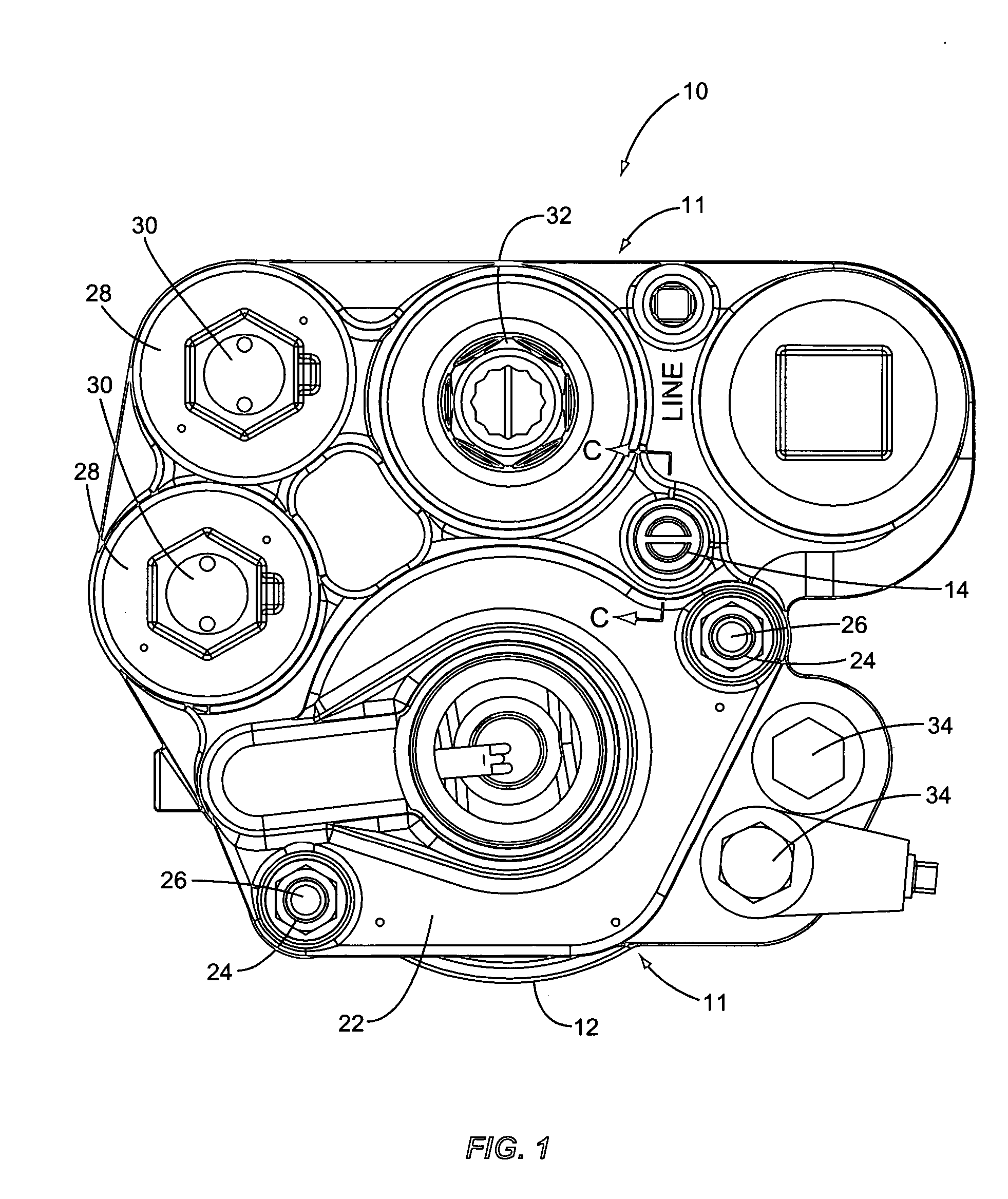

Air bleed screw assembly machine

ActiveCN103737308ASolve efficiency problemsSolve labor intensityMetal working apparatusControl systemUltimate tensile strength

The invention discloses an air bleed screw assembly machine. The air bleed screw assembly machine comprises an operation desk and brackets, wherein the brackets are vertically arranged on the working face of the operation desk. The air bleed screw assembly machine is further provided with a control system, a power mechanism and a screw fastening mechanism, wherein the power mechanism is arranged at the tops of the brackets; the control system is connected to the power mechanism; the screw fastening mechanism is arranged on the working face of the operation desk between the two brackets. According to the air bleed screw assembly machine disclosed by the invention, screws can be screwed down automatically, so that the problems of manual screwing such as low efficiency, great labor intensity and unstable screwing quality are solved. Air bleed screws can be automatically screwed down after an operator puts a workpiece to be screwed on a clamp, so that the purposes of automatic screwing and safe assembly are achieved; when different types of workpieces need to be produced, an inner core rod of a cylinder body supporting plate and a clamping groove matched with the type of workpieces are replaced, so that the production cost is reduced.

Owner:WUHU JUDA AUTO PARTS

Integrated floating calipers

ActiveCN103322087AReduce structural weightImprove energy efficiencyAxially engaging brakesBraking elementsEngineeringCalipers

The invention discloses integrated floating calipers. The integrated floating calipers comprise an outer-side friction block, an inner-side friction block, clamping springs, a piston dust cover, a piston, a rectangular sealing ring, a caliper body, air bleed screws and pin shaft sleeves. Air bleed screw holes which are symmetrical to cylinder holes of the piston are formed above the caliper body, the clamping springs which are matched with the cylinder holes of the piston are fixed on the inner-side friction block, inner-side friction block back-plate guiding faces are matched with an inner-side friction block guiding face and an inner-side friction block supporting face respectively, an inner-side friction block back-plate supporting face is matched with an inner side face of the caliper body, outer-side friction block back-plate positioning faces are matched with outer-side friction block positioning faces on the caliper body, a right-angle bend of the outer-side friction block is matched with outer-side friction block limiting faces of the caliper body, and outer-side friction block back-plate fixing pieces are matched with outer-side friction block fixing holes of the caliper body. According to the integrated floating calipers, no support is required, so that the structural weight of the floating calipers can be effectively reduced; left and right parts are not required to be differentiated and are common to arrangement before or behind shafts, so that the universality of the calipers is improved.

Owner:ZHEJIANG ASIA PACIFIC MECHANICAL & ELECTRONICS

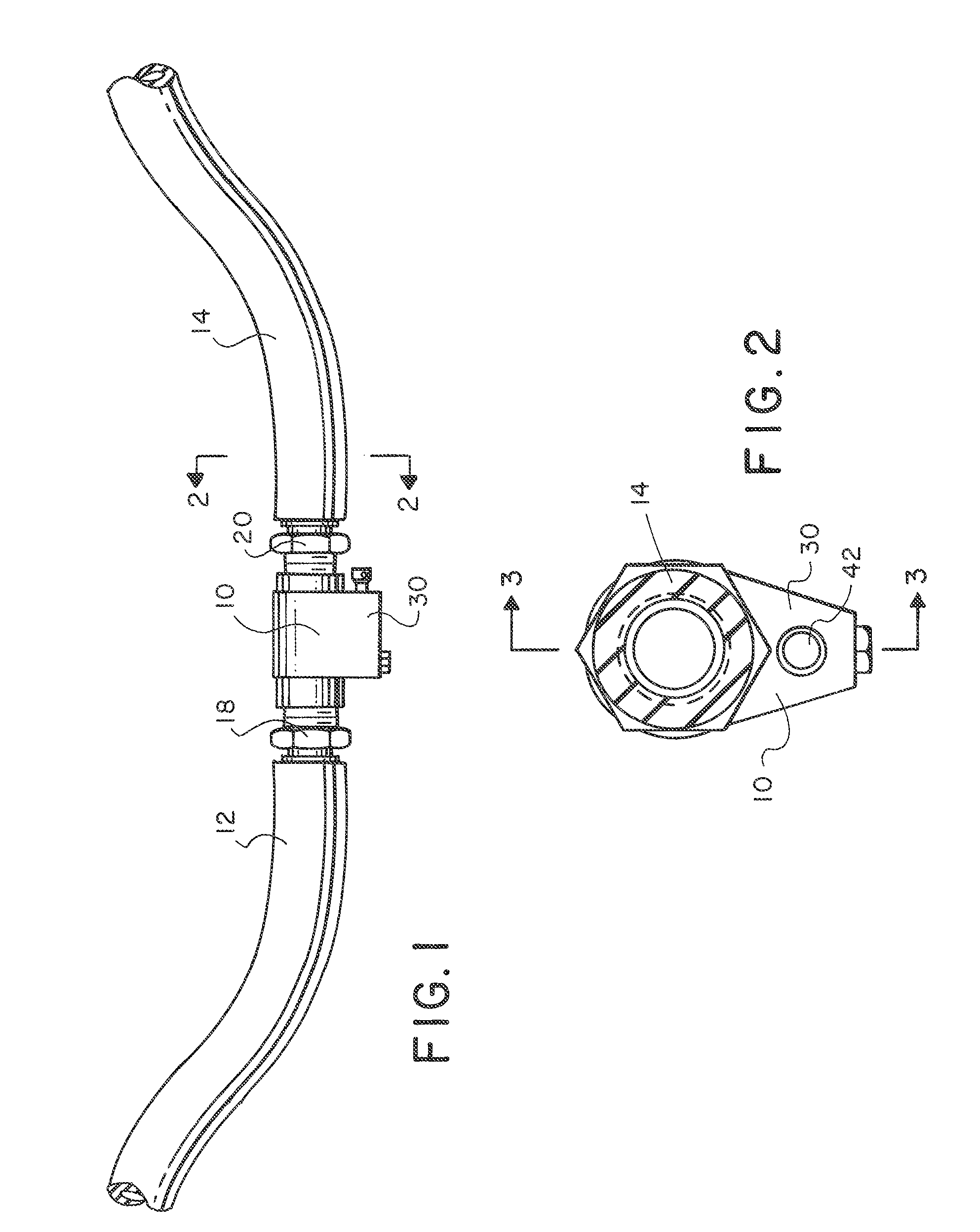

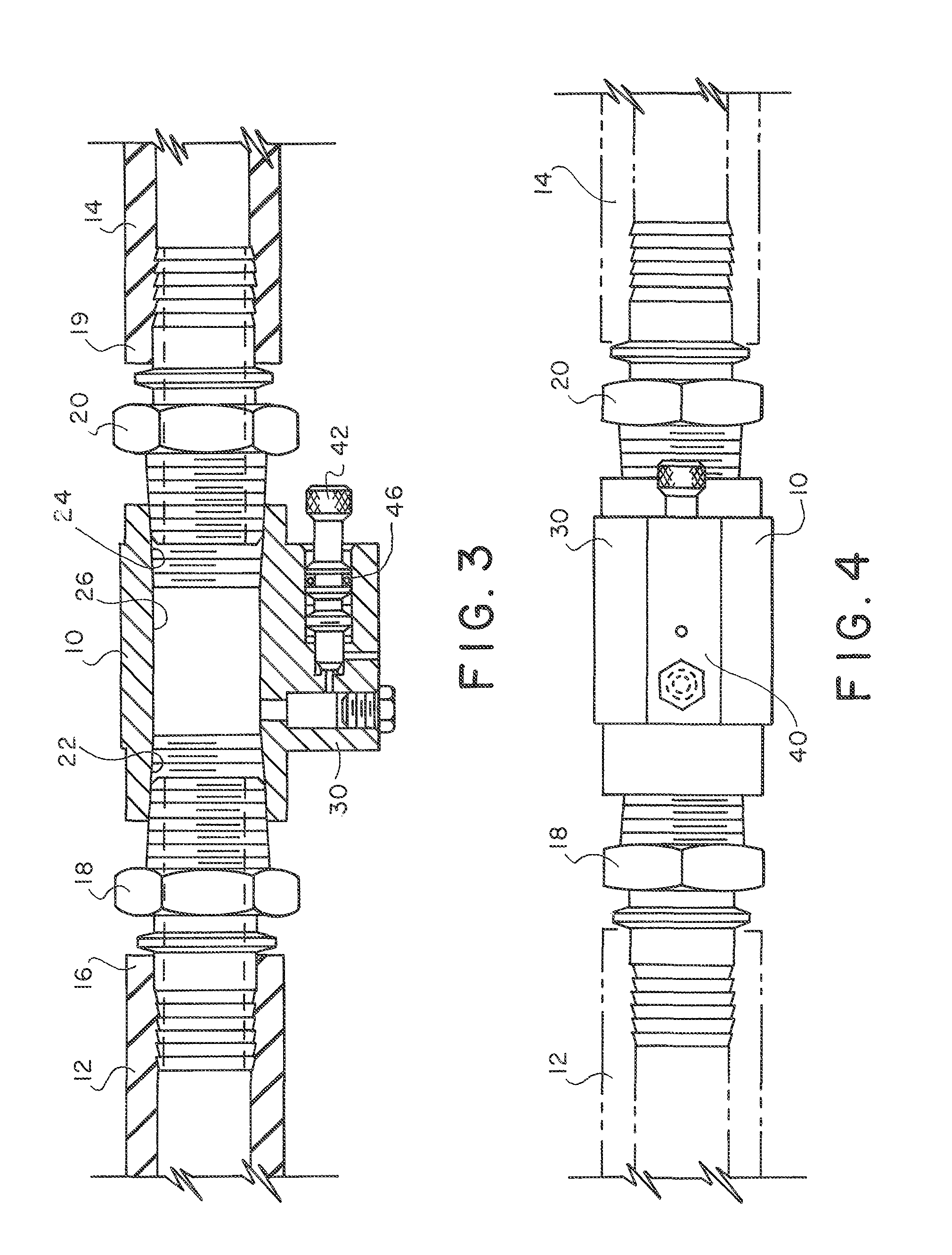

Hose bend bleeder for ammonia application system

A hose bend bleeder is combined with first and second hoses, with the hose bend bleeder being located at the bottom of a bend in a flow path established by the hoses. The hose bend bleeder has a bleed screw and a downwardly facing exit passageway.

Owner:WARD DAVID P

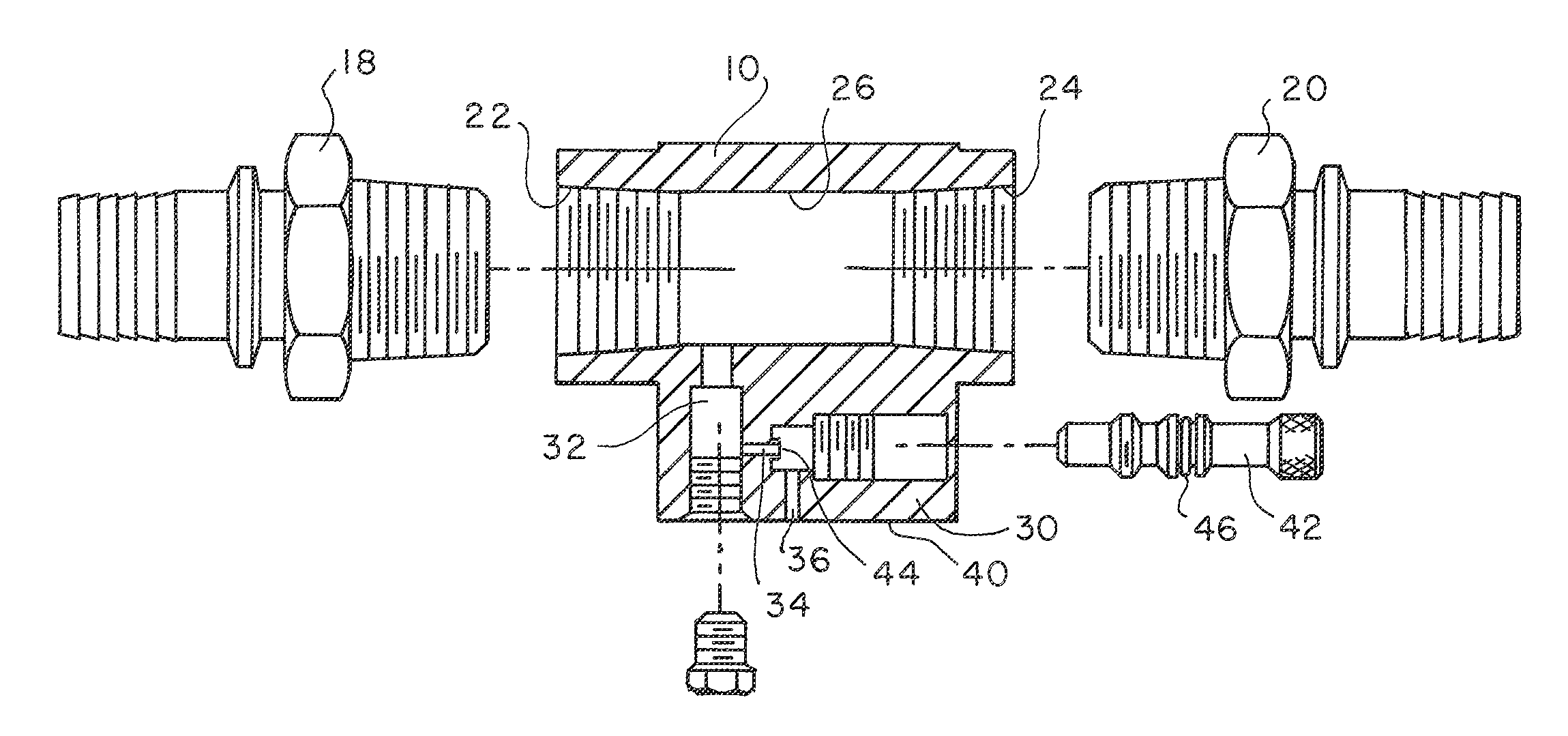

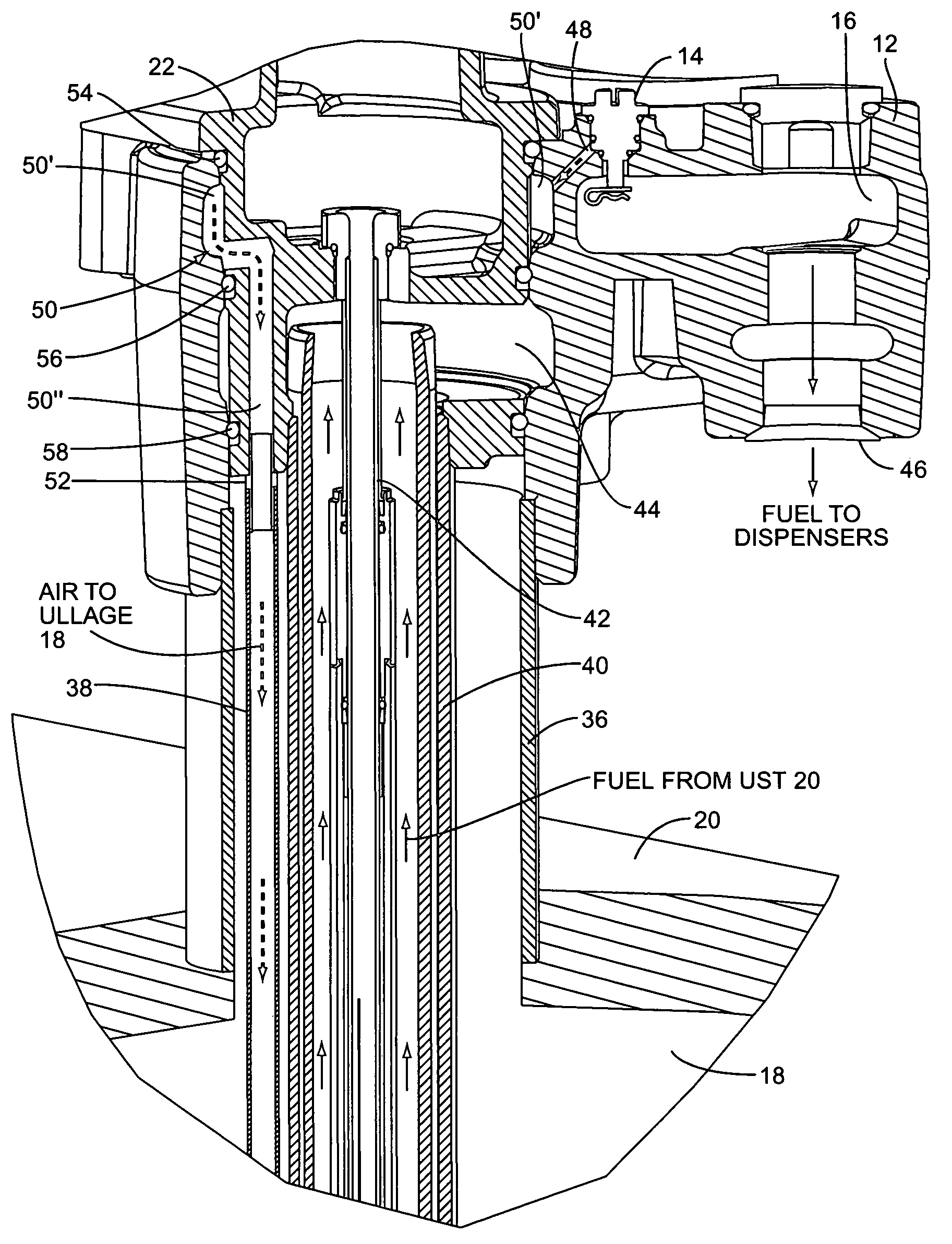

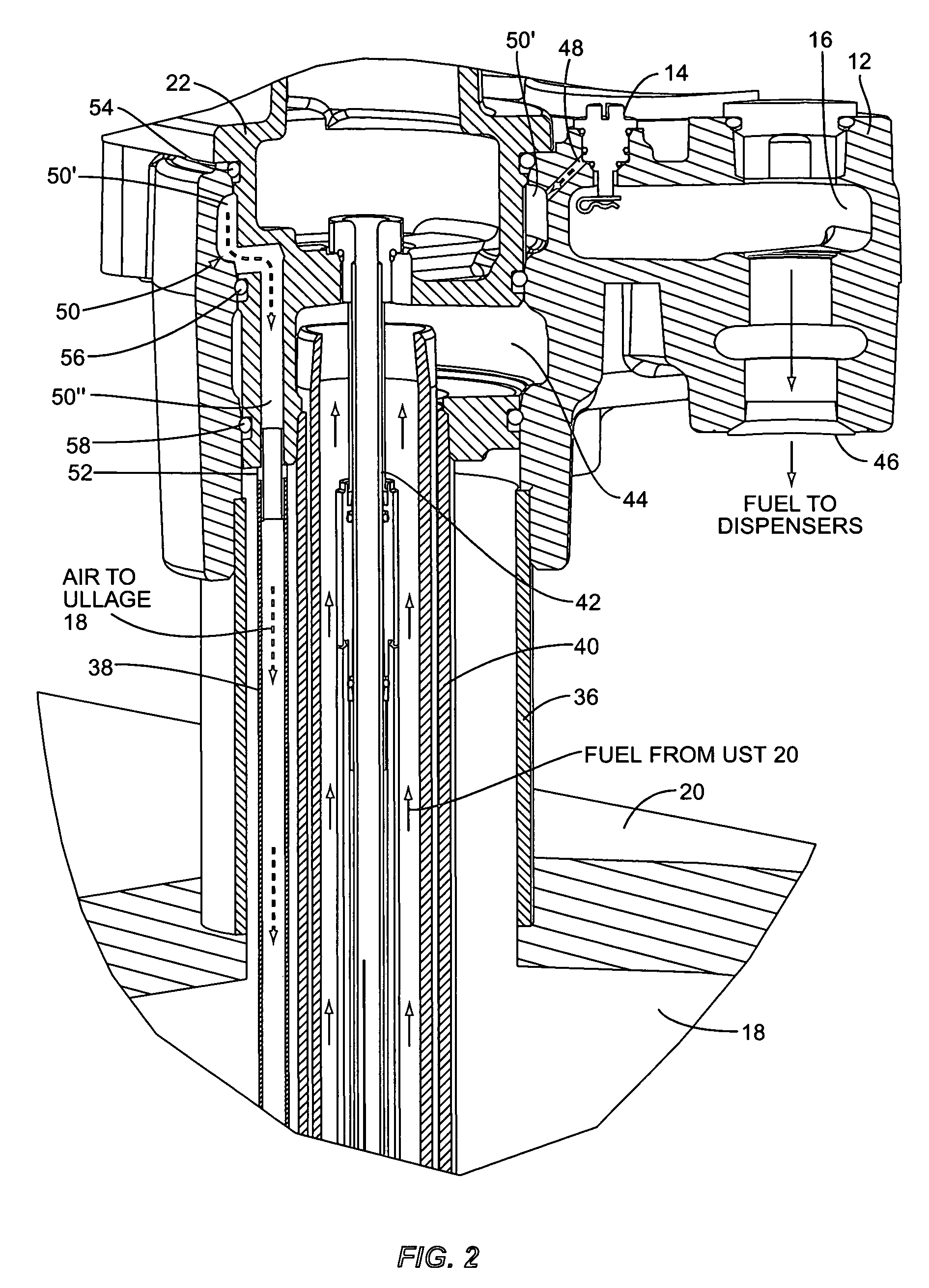

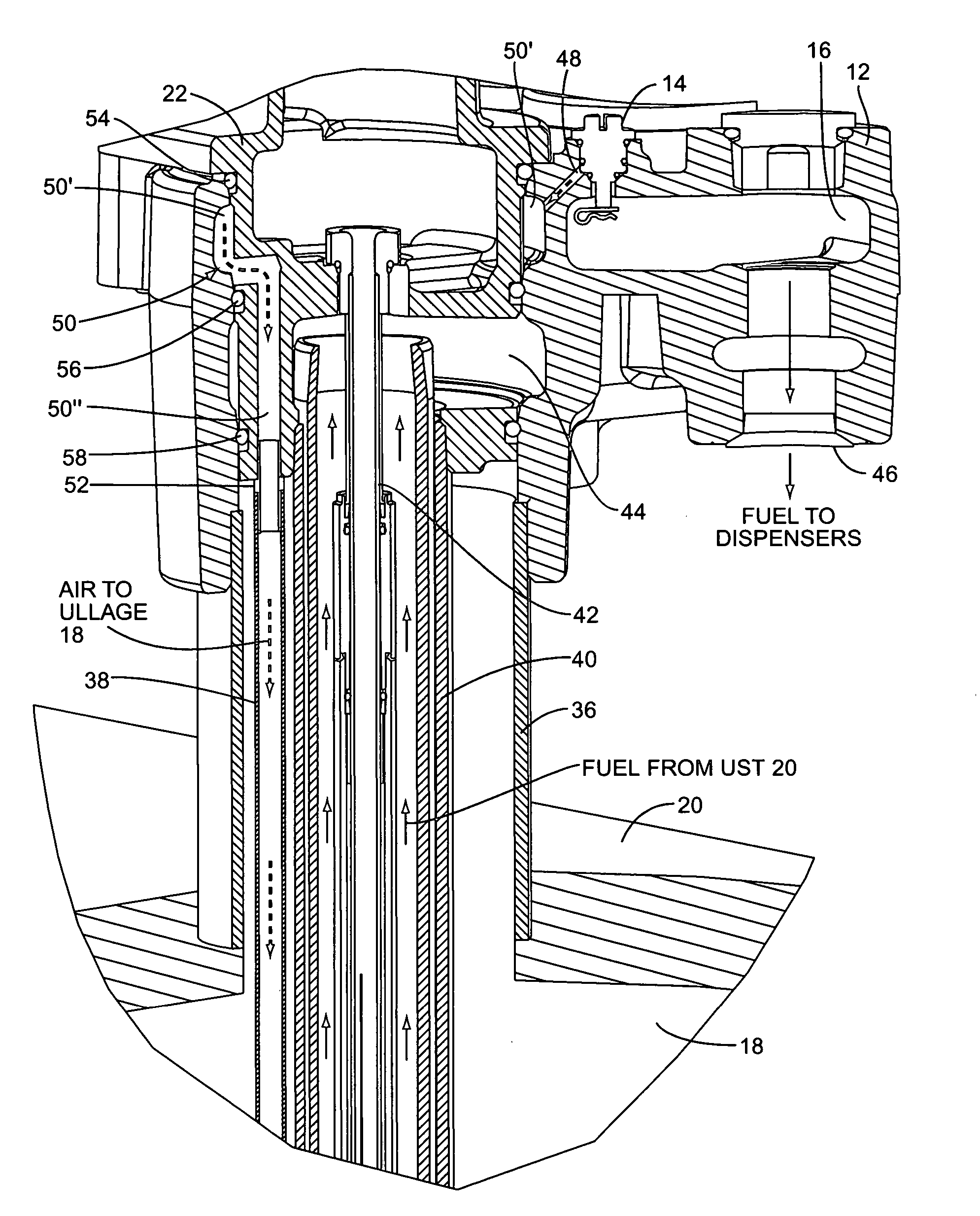

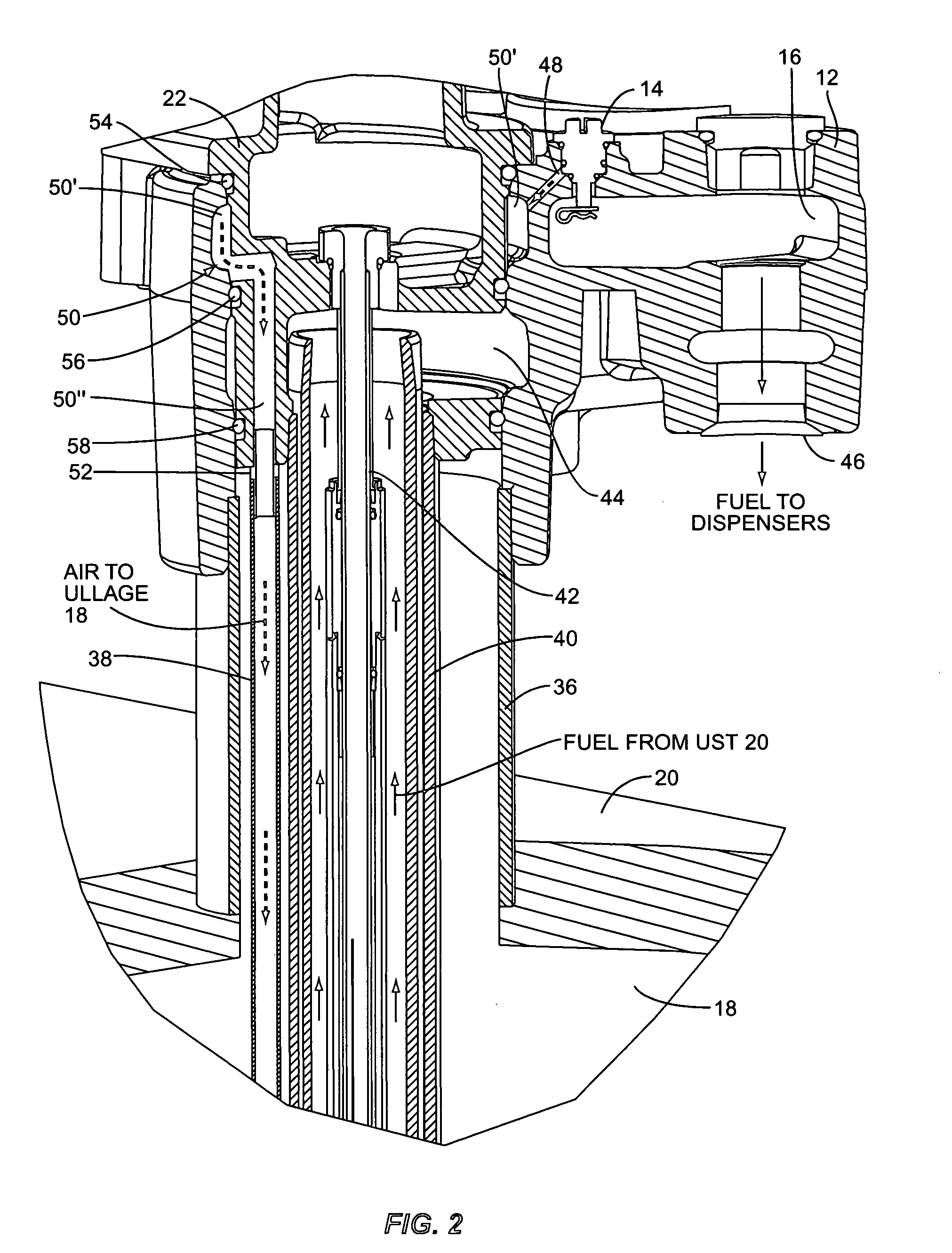

Air bleed mechanism for a submersible turbine pump

ActiveUS7059366B2Prevent leakageSpeed up the flowLiquid transferring devicesVenting valvesTurbineUnderground storage tank

A manifold for a submersible turbine pump having an air bleed mechanism for removing air from a discharge chamber of the manifold. The manifold includes the discharge chamber that receives fuel pumped from an underground storage tank (UST), the air bleed mechanism, an air return path coupled to the UST, and a bypass tube coupled to the air return path. When the air bleed mechanism is activated, the fuel discharge chamber is fluidly coupled to the bypass tube, thereby allowing air from the fuel discharge chamber to flow to the ullage of the UST. In one embodiment, the air bleed mechanism is an air bleed screw inserted into a threaded orifice in the manifold. The threaded orifice is coupled to both the bypass tube and the fuel discharge chamber. When the air bleed screw is rotated upward, the bypass tube is coupled to the fuel discharge chamber.

Owner:VEEDER ROOT

Hydraulic volume control forming device for metal corrugated pipe

The invention relates to a hydraulic volume control forming device for a metal corrugated pipe. The hydraulic volume control forming device for the metal corrugated pipe comprises a mandrel, wherein the surface of the mandrel is provided with a circular slot; the rear part of the mandrel is provided with an oil line; the front end of the oil line is communicated with the circular slot via a side oil passage; the middle front part of the mandrel is provided with a vent line; the rear end of the vent line is communicated with the circular slot via a side vent line; the front end of the vent line is provided with an O-shaped sealing ring and a bleed screw; the circular slot is provided with a capsule; two ends of the capsule are respectively compressed by a rear pressing sleeve and a front pressing sleeve; the rear end of the rear pressing sleeve is successively provided with a washer and a sleeve shaft from front to back; the front end of the front pressing sleeve is successively provided with a taper sleeve, a flat washer, a spring washer and a hexagon nut from back to front; the rear lower end of the capsule is provided with a forming chuck; and the front lower end of the capsule is provided with a matrix. The corrugated pipe manufactured by the hydraulic volume control forming device disclosed by the invention has the advantages of high quality and high waveform consistency.

Owner:吕季明 +1

Process for machining clutch booster shell

The invention relates to a process for machining a clutch booster shell, and relates to the technical field of clutch boosters. The process comprises the steps of 1, preparing a shell blank; 2, turning an outer circle, an end face and a chamfer; 3, turning a groove; 4, turning an oil inlet; 5, drilling a connecting hole; 6, machining a piston hole and a mounting hole; 7, machining an exhaust screwhole and an air bleed screw hole; 8, carrying out reaming; 9, carrying out honing; and 10, carrying out cleaning, wherein the orifice of the connecting hole is deburred through a bench drill in the step 5. According to the process for machining the clutch booster shell, the connecting hole is deburred through the bench drill, so that the junction of the connecting hole and the oil inlet and the junction of the connecting hole and a push rod hole are relatively smooth, and in subsequent use, a push rod is prevented from being scratched due to burrs and the sealing performance is not affected;and the oil flows smoothly at the oil inlet and the connecting hole, the situation that burrs enter the oil is avoided, and the service life is prolonged.

Owner:ZHUJI WANSHENG MACHINERY

Single-action brake wheel cylinder

InactiveCN102425631AConvenient spacingImprove sealingBrake actuating mechanismsActuatorsEngineeringWheel cylinder

The invention discloses a single-action brake wheel cylinder. The single-action brake wheel cylinder comprises a cylinder body; a cavity is formed in the cylinder body; the side wall of the cavity is communicated with a bleed screw and double oil inlets; a stifle is covered on the oil inlets respectively; left and right adjustment pistons are arranged at the left and right ends of the cavity in a sliding way; one end of each adjustment piston is arranged in the cavity in a sliding way, and the other end of each adjustment piston is provided with a limit flange; the outer end face of the left adjustment piston is fixedly provided with an adjusting screw; annular clamp grooves are formed on the side walls of the adjacent ends of the left and right adjustment pistons; leather collars are clamped in the annular clamp grooves; the leather collars is in tight fit with the side wall of the cavity; the outer wall of the cylinder body is fixedly provided with a lock plate; the outer wall of the cylinder body is provided with an installation disk; the four corners of the installation disk are provided with installation holes; and the side wall of the cylinder body is provided with a bolt installation hole and a limit hole. The single-action brake wheel cylinder has a reasonable and simple structure and the working efficiency of the brake wheel cylinder is improved.

Owner:芜湖博格汽车零部件有限公司

Manual exhaust auxiliary device for hydraulic braking system

ActiveCN104590233AMeet the safety requirements of brakingEfficient artificial exhaust processBraking componentsVehicle servicing/repairingPulp and paper industryBrake fluid

The invention relates to a manual exhaust auxiliary device for a hydraulic braking system. The auxiliary device comprises an electric vacuum pump, a recycling oilcan, a warning device, a switch, a connecting conducting wire, a vacuum non-return valve, a vacuum connecting pipe, an exhaust oil pipe, a vacuum pipe joint, a bleeder valve, a liquid level sensor and a magnetic float. By adopting vacuum negative pressure principles, after an air bleed screw end is connected into the braking system, the vacuum negative pressure generated by the auxiliary system enables the brake fluid and air in the loop to be pumped to the recycling oilcan, wherein the brake fluid is collected and, the air is exhausted by the electric vacuum pump.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

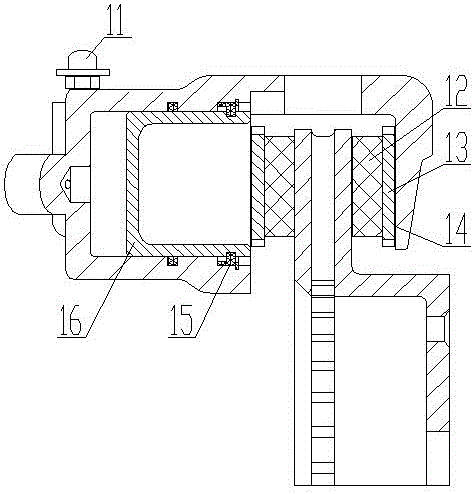

Exhaust valve assembly of hydraulic transmission pipeline of clutch

ActiveCN103557194AImprove accuracyImprove reliabilityServomotor componentsExhaust valveHydraulic circuit

The invention provides an exhaust valve assembly of a hydraulic transmission pipeline of a clutch, and the exhaust valve assembly can be used for removing the air in the hydraulic transmission pipeline of the clutch. The exhaust valve assembly of the hydraulic transmission pipeline of the clutch comprises a valve body, two joint bodies, two sealing washers, an air collection chamber, an exhaust hole and an air bleed screw, wherein the interior of the valve body has a hollow structure; the two joint bodies are used for connecting a hydraulic circuit, are respectively provided with an oil hole and are respectively arranged at the two sides of the valve body; the two sealing washers are arranged between the valve body and the joint bodies; the air collection chamber is arranged at the upper part of an inner cavity of the valve body and at the upper parts of the joint bodies; the exhaust hole is formed in the valve body and at the upper part of the air collection chamber, and is communicated with the outside of the valve body; the air bleed screw is arranged on the exhaust hole.

Owner:SINO TRUK JINAN POWER

A method for exhausting the braking system of an electric vehicle

ActiveCN108001438BPrevent suctionGuaranteed normal transferBrake safety systemsPressure riseInternal pressure

The invention discloses an exhaust method for brake systems of electric vehicles. The exhaust method includes treading brake pedals, gathering air in brake circuits at air bleed screw mounting holes,increasing the pressures of the brake circuits, switching on vacuum pumps at the moment and vacuumizing detection cavities; drawing air in the brake circuits into the detection cavities; driving pressure plungers in the detection cavities and gradually increasing the internal pressures of the detection cavities; terminating exhaust programs at the moment if the pressures of the detection cavitiesare higher than set values and extracting brake fluid in the detection cavities to a fluid storage cavity; repeatedly carrying out previous programs until the brake circuits are sufficiently exhaustedif the pressures of the detection cavities are not higher than the set values. The air which is about to be drawn into the detection cavities is mixed with the brake fluid. The fact that the brake fluid in the detection cavities accounts for a high proportion is illustrated if the pressures of the detection cavities are higher than the set values, and the fact that the brake circuits are sufficiently exhausted is further proved. The method has the advantages that the method can be implemented by the aid of a single person, and accordingly the efficiency can be improved; the exhaust programs can be accurately controlled, the brake circuits can be assuredly thoroughly exhausted, and excessive exhaust can be prevented.

Owner:ZHEJIANG LEAPMOTOR TECH CO LTD

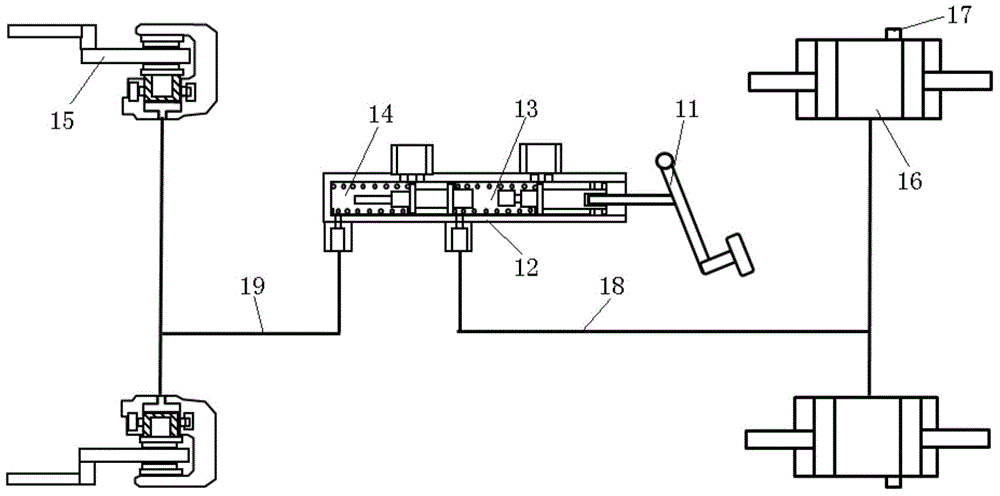

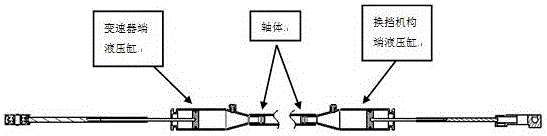

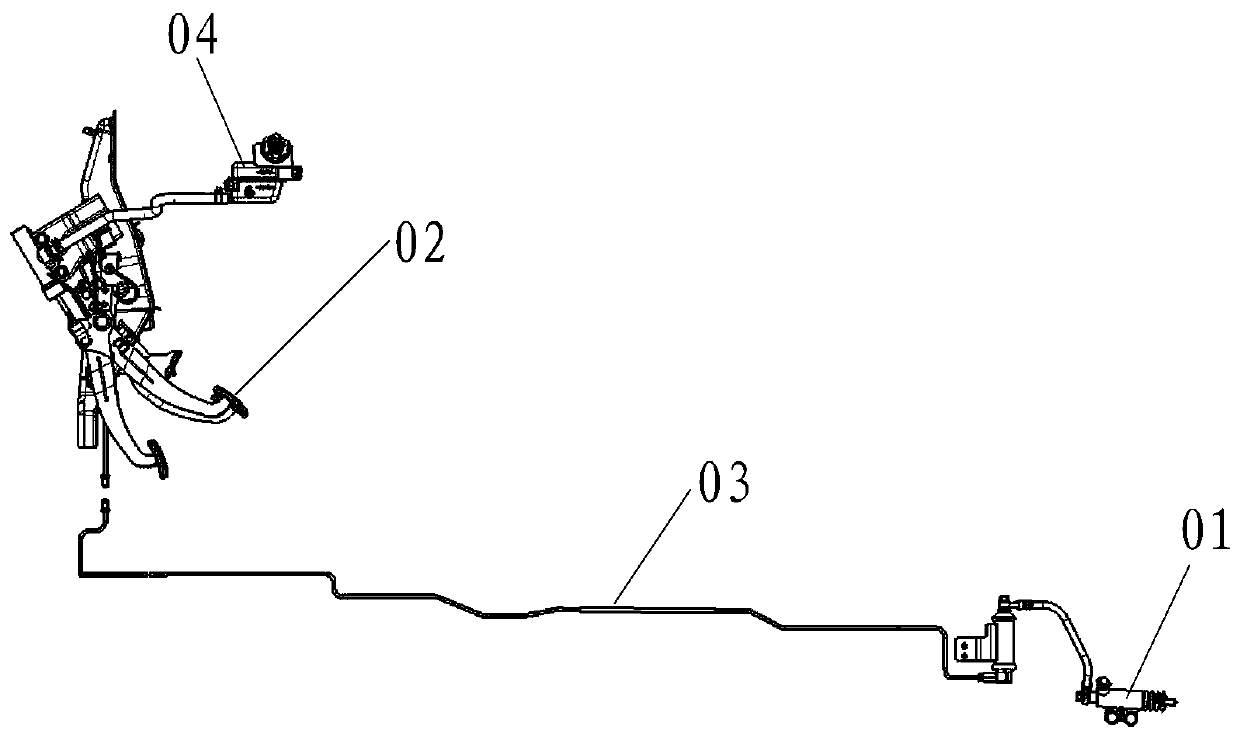

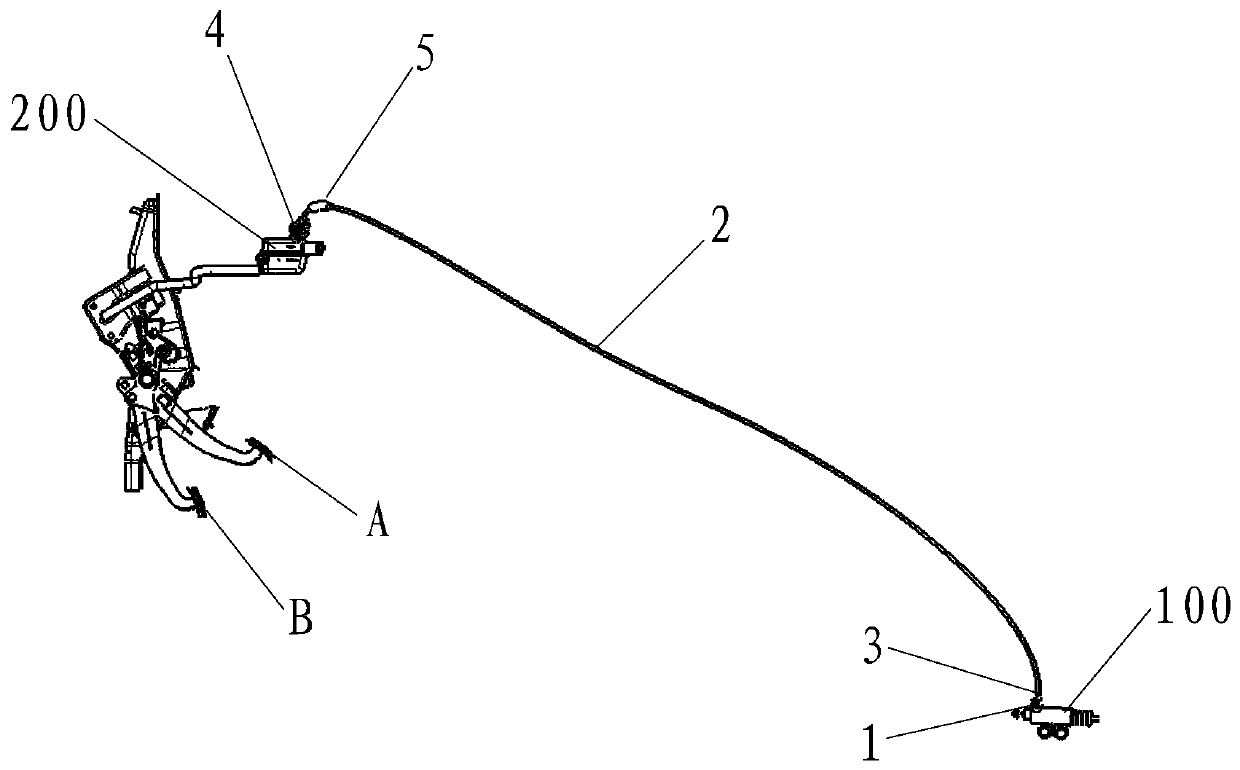

Gear selecting and shifting hydraulic soft shaft

The invention discloses a gear selecting and shifting hydraulic soft shaft. The gear selecting and shifting hydraulic soft shaft comprises a hydraulic cylinder shell. A push rod is arranged on one side of the hydraulic cylinder shell. One end of the push rod extends into the hydraulic cylinder shell. A piston is arranged in the hydraulic cylinder shell and connected with the push rod. A groove is formed in the middle portion of the piston. A first seal ring is arranged between inner walls of the groove. A second seal ring is arranged on the side, away from the piston, of the first seal ring. The other side of the hydraulic cylinder shell is connected with a shaft body. A gas bleed screw is arranged on the side, close to the shaft body, on the hydraulic cylinder shell. The gear selecting and shifting hydraulic soft shaft is reasonable in design, gas in hydraulic pipelines can be drawn out through a gas bleed screw hole, and liquid is prevented from flowing out; the gear selecting and shifting hydraulic soft shaft has the beneficial effects of being low in start resistance, good in sealing effect, small in sliding resistance, high in movement speed and the like; and the idle stroke generated by the size interval between steel wire structures frequently used at present is eliminated, and therefore the stroke efficiency is improved, the gear shifting hand feeling is improved, and the gear shifting comfort is improved.

Owner:合肥创智汽车技术开发有限公司

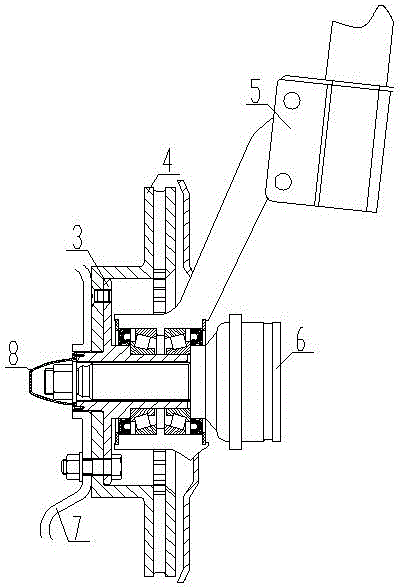

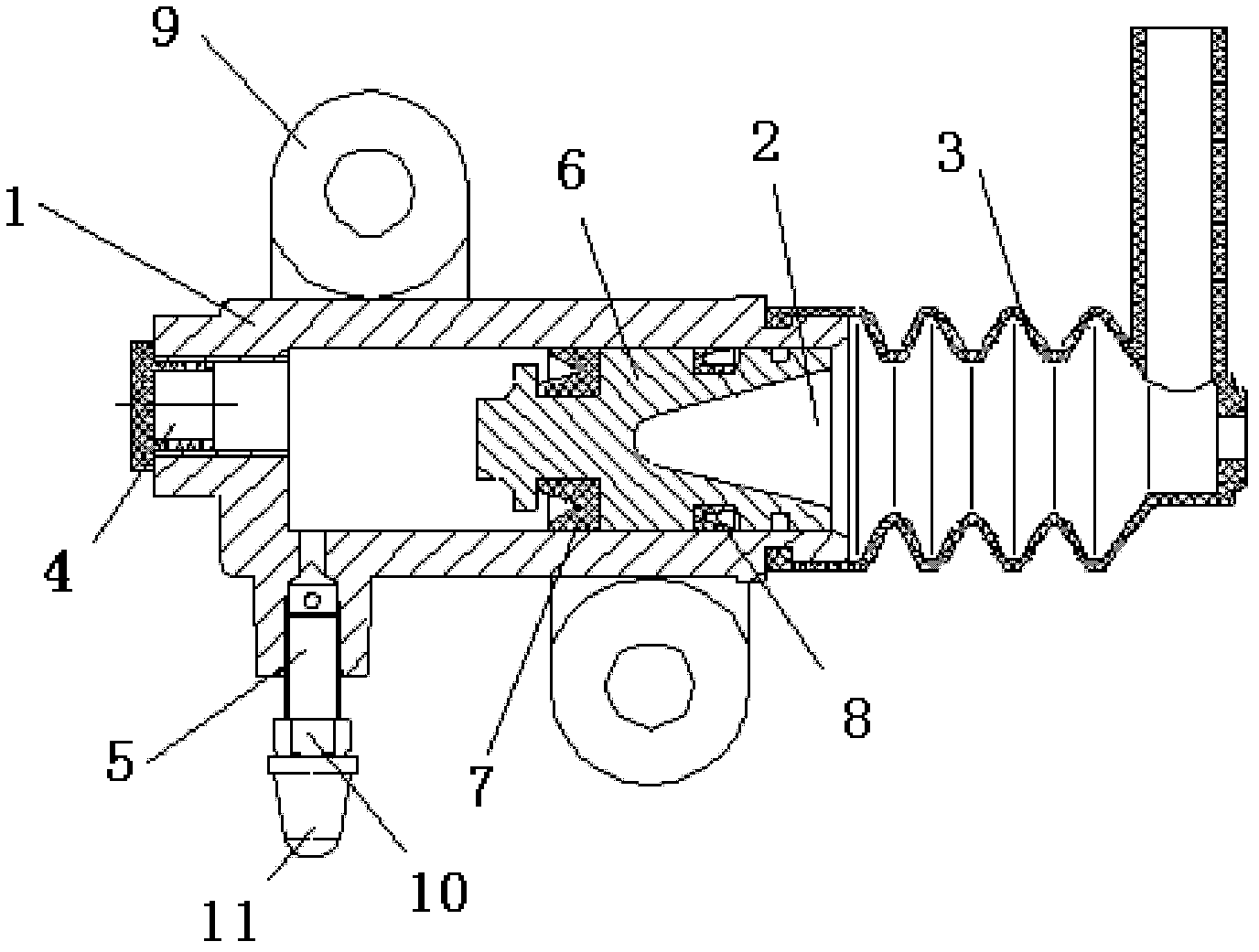

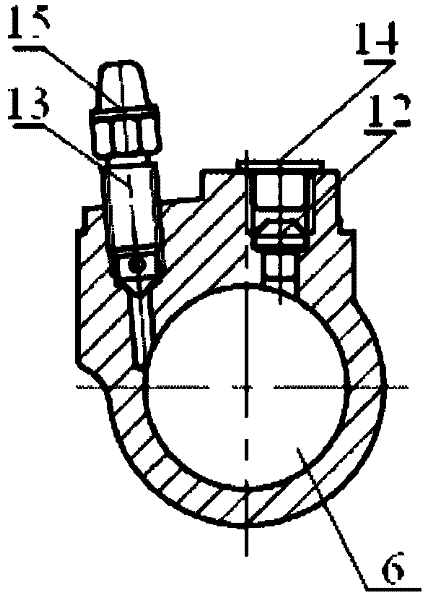

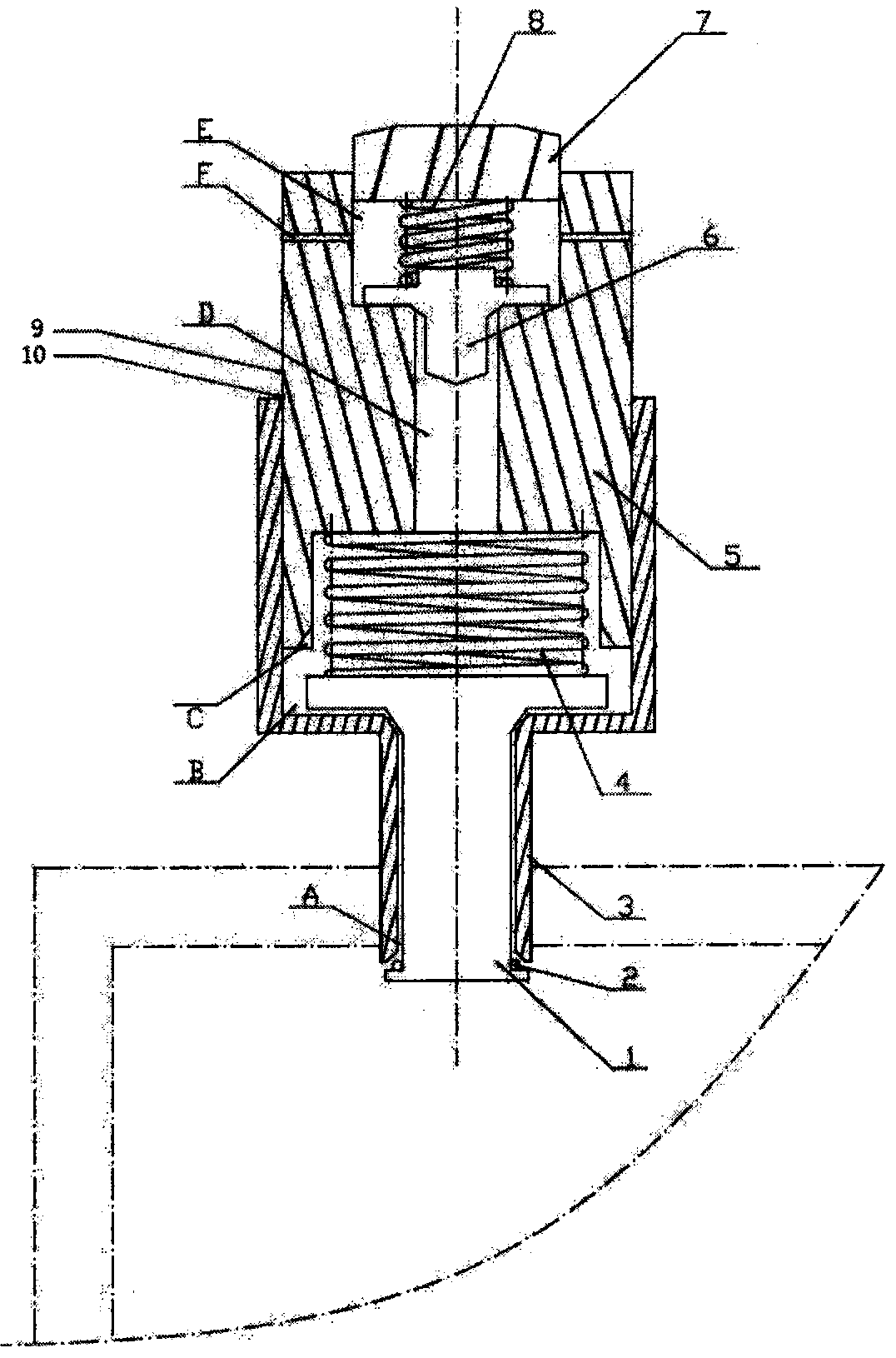

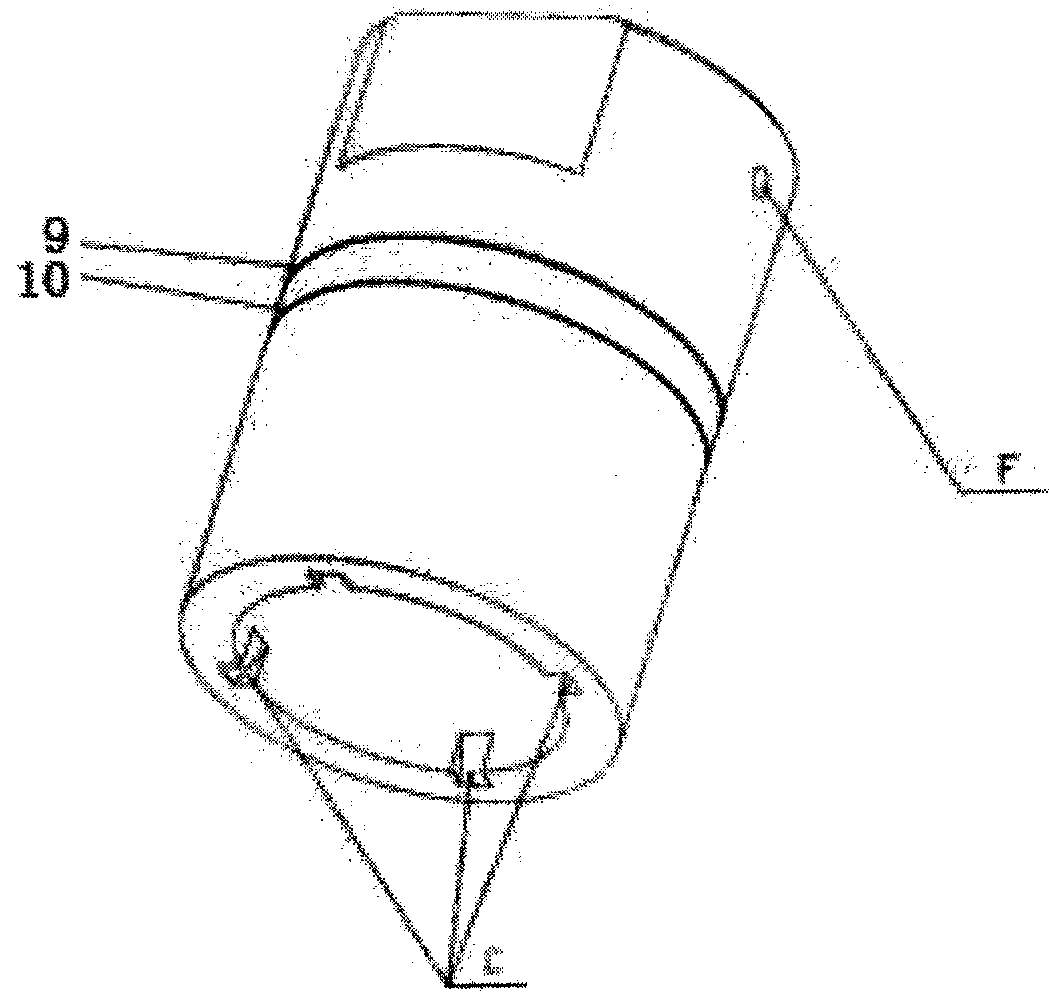

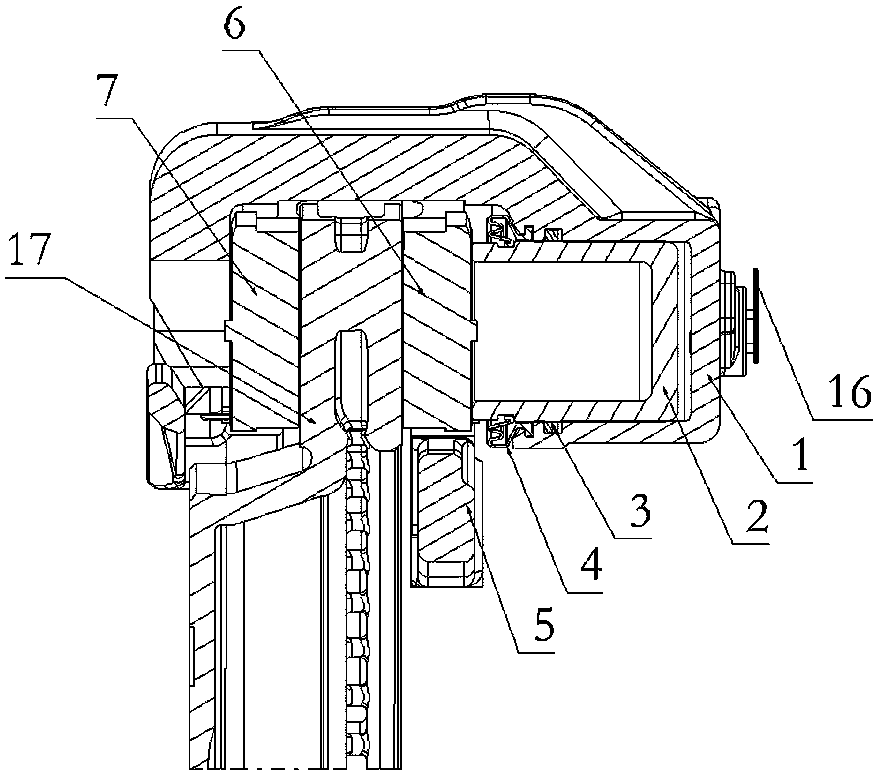

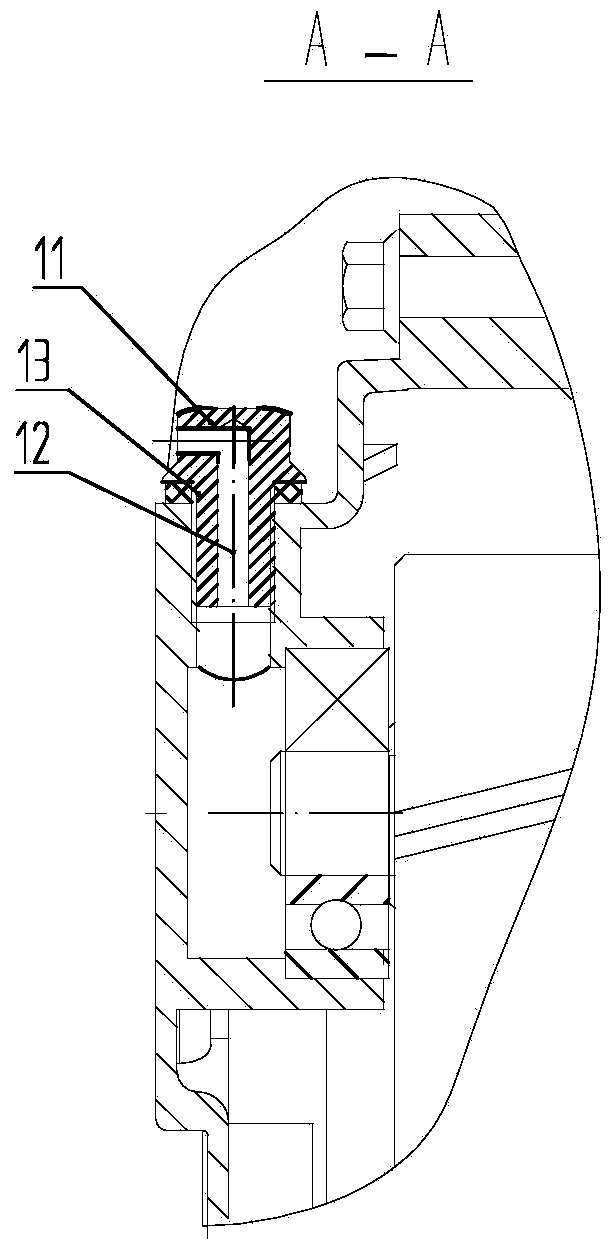

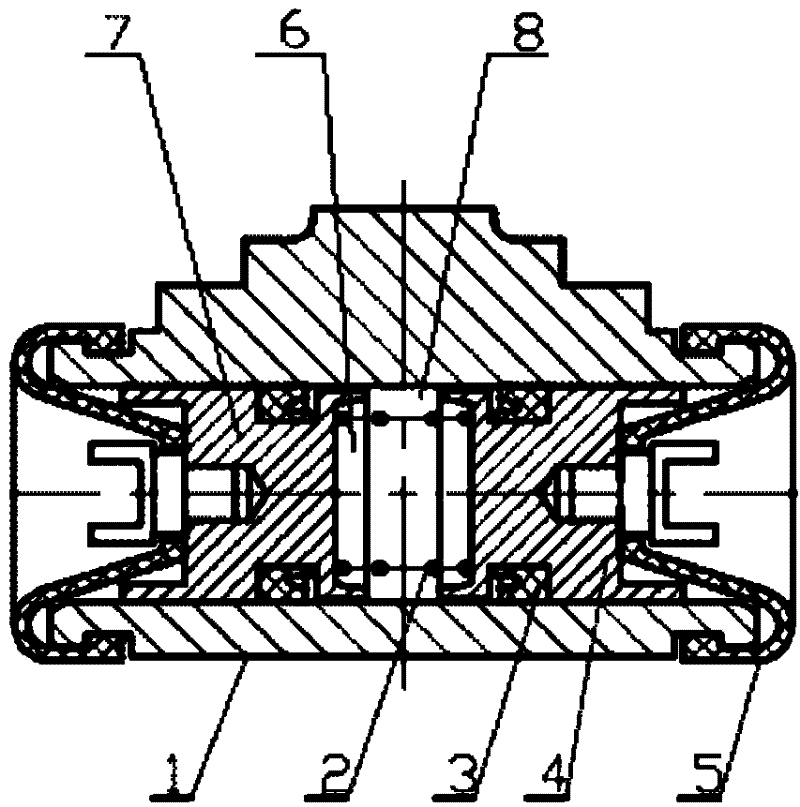

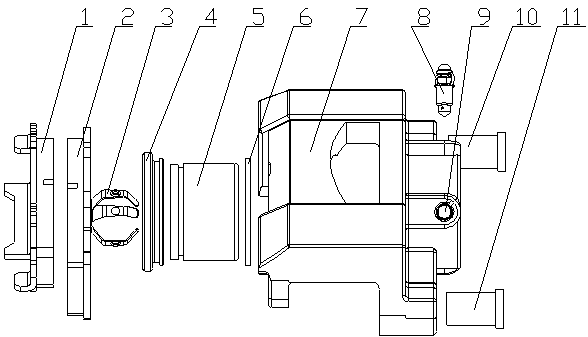

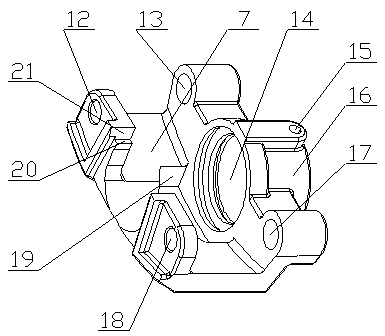

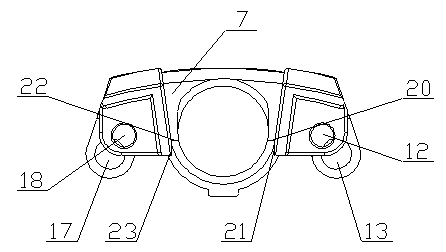

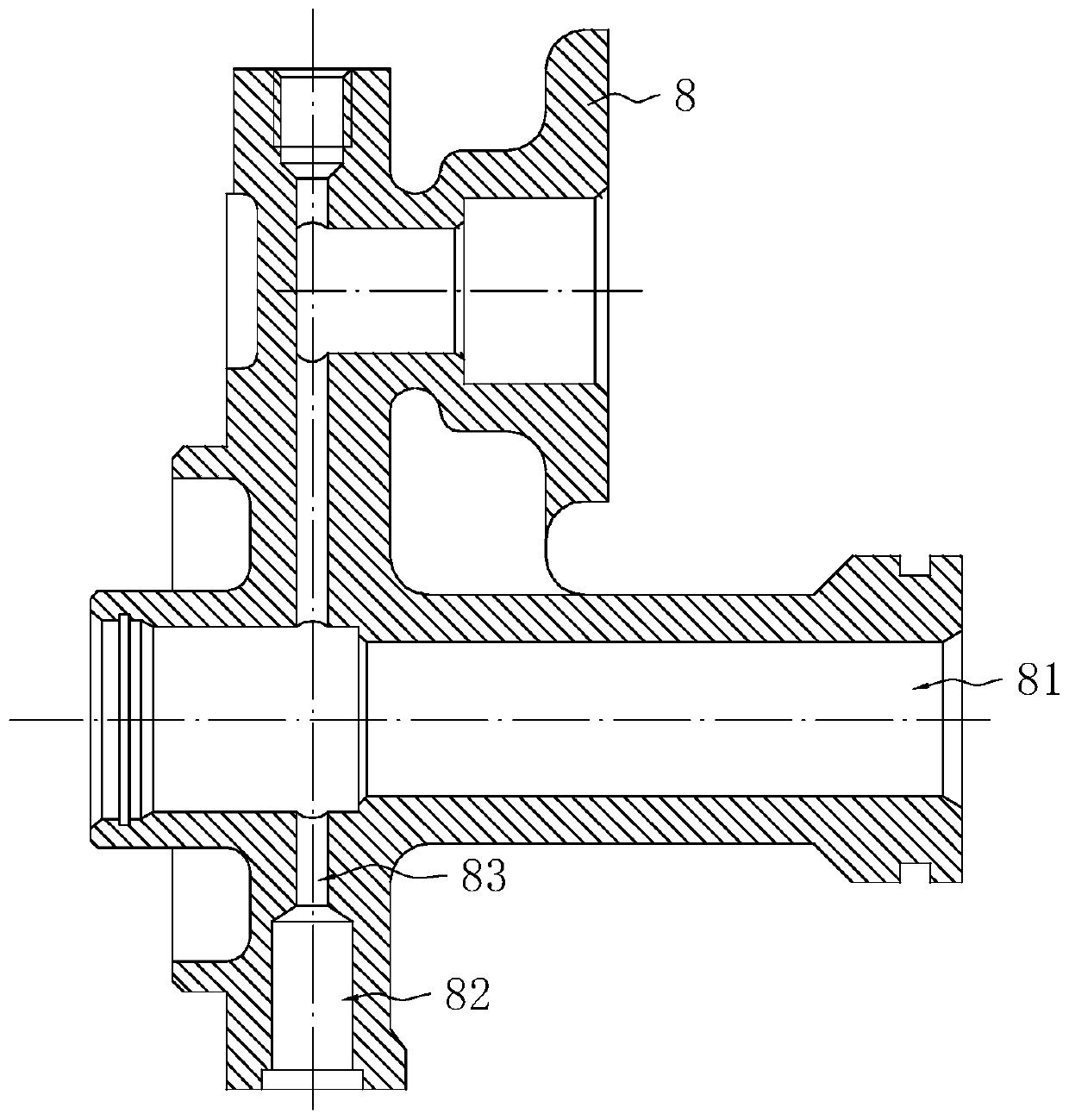

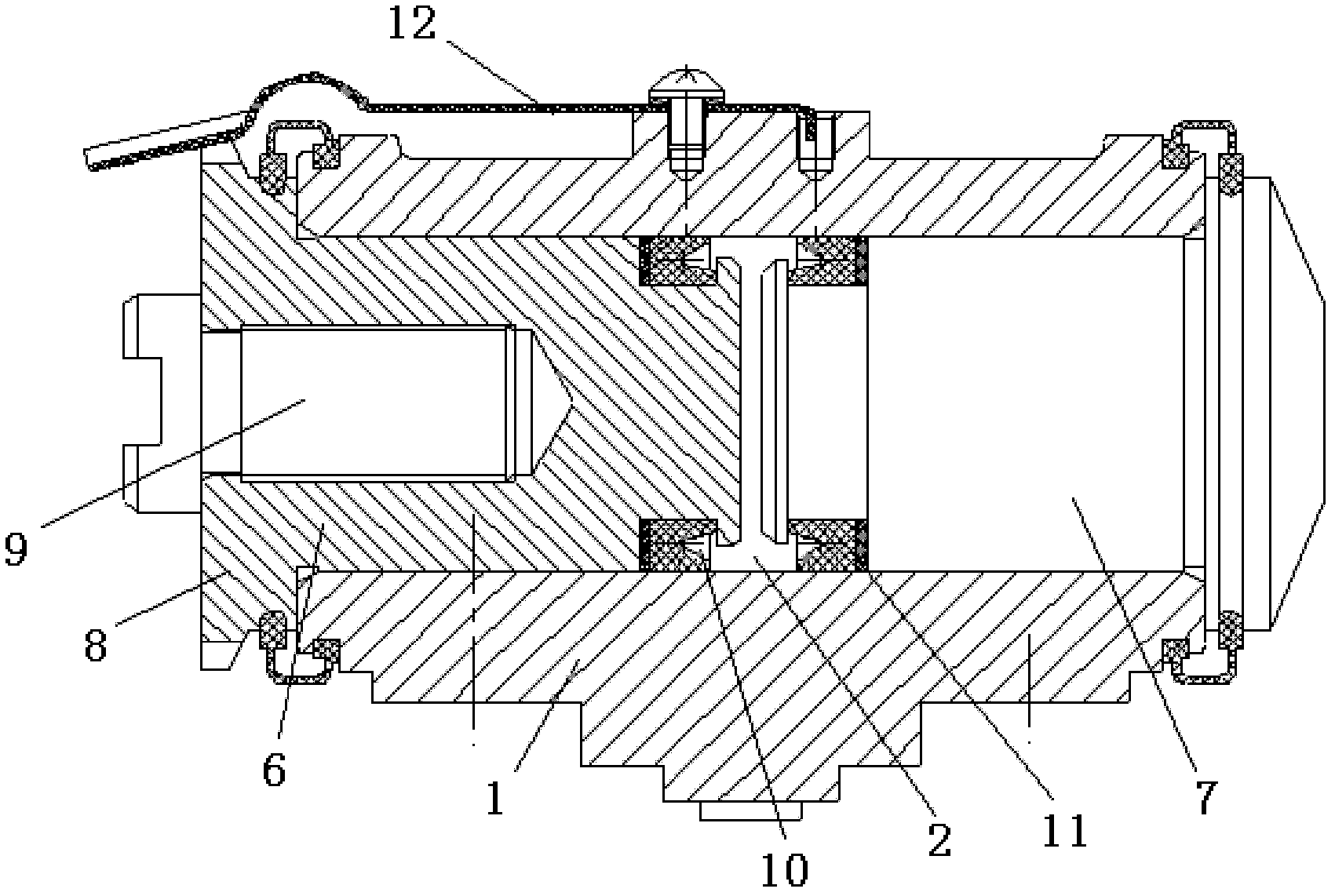

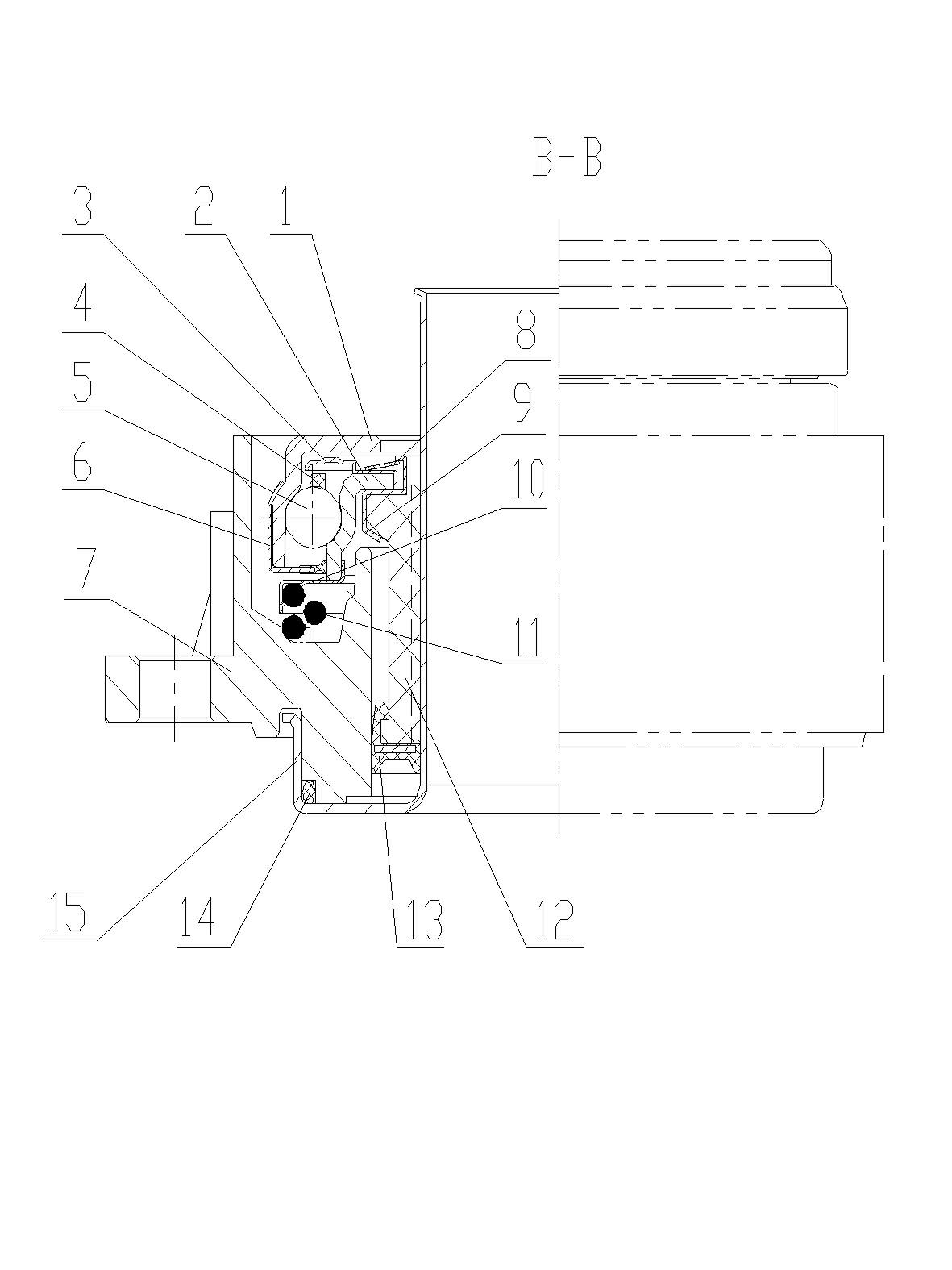

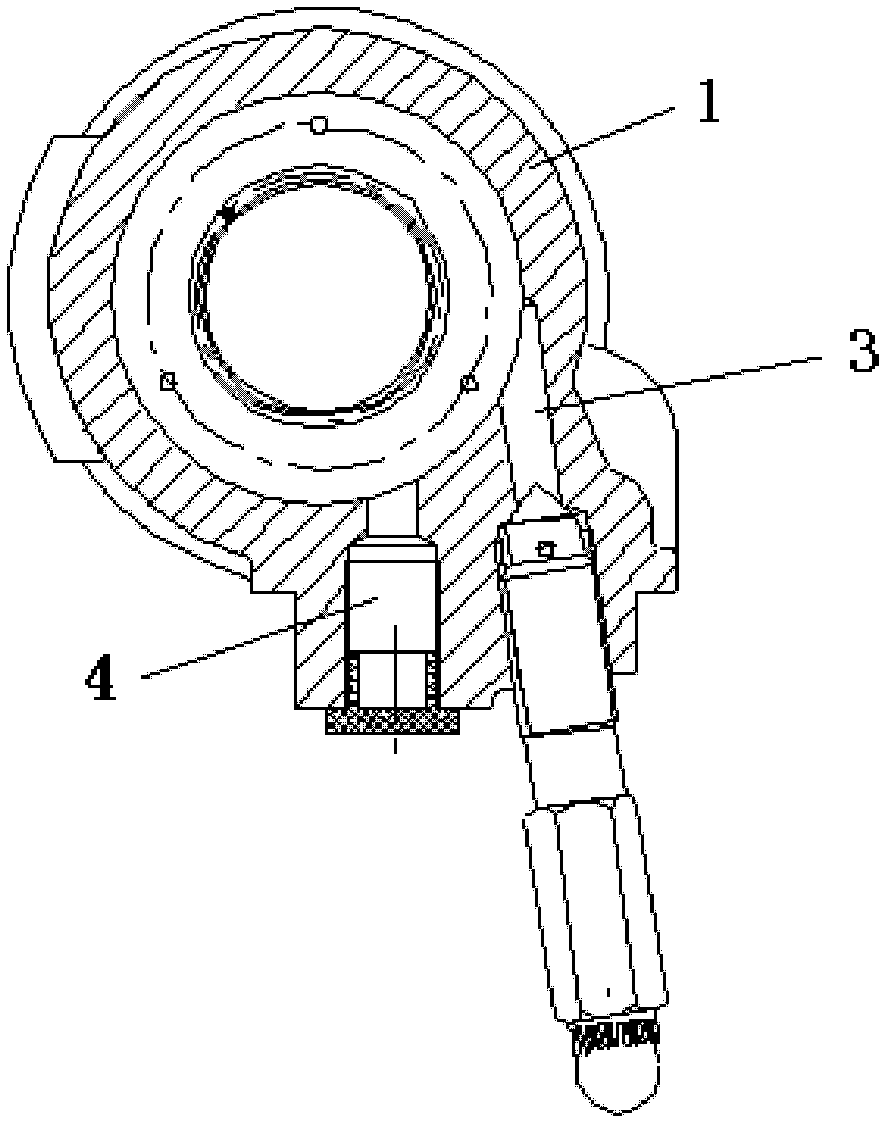

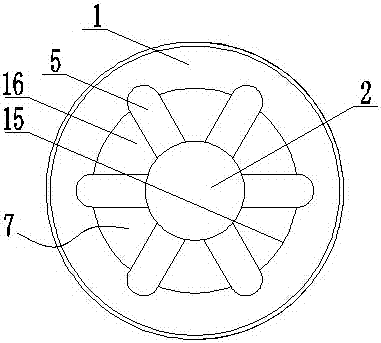

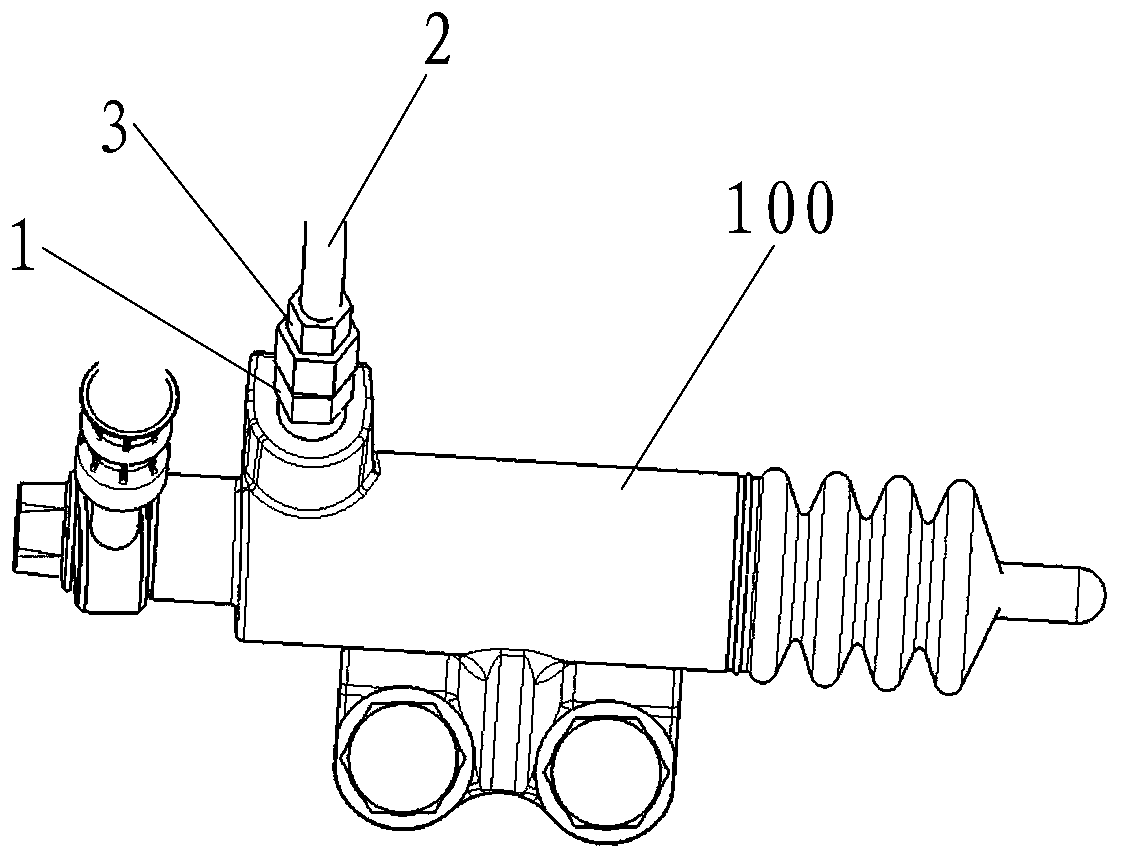

Push type self-aligning hydraulic release bearing wheel cylinder unit

The invention discloses a push type self-aligning hydraulic release bearing wheel cylinder unit, relating to a vehicular release bearing unit. The push type self-aligning hydraulic release bearing wheel cylinder unit is especially suitable for passenger cars and commercial vehicles using push type clutches, in particular cars using the push type clutches and belongs to the technical field of automobile bearings. The push type self-aligning hydraulic release bearing wheel cylinder unit comprises a self-aligning bearing mechanism, a hydraulic wheel cylinder mechanism and an air bleeder, wherein the self-aligning bearing mechanism consists of an outer ring, an inner ring, a retainer, a steel ball, an inner dustproof cover, an outer cover, an aligning leaf spring, a sleeve and a sleeve seat; the hydraulic wheel cylinder mechanism consists of a cylinder body, a mandrel, a leather ring, a mandrel sealing ring, a return spring and a spring seat; and the air bleeder comprises an oil feeding connector, a clamp, a first O-shaped ring, a second O-shaped ring, an exhaust valve tee joint, an air bleed screw sealing ring, an air bleed screw, an air bleed screw cap, an air feeding connector screw and a choke plug. The push type self-aligning hydraulic release bearing wheel cylinder unit disclosed by the invention has the use function of the release bearing and the function of the wheel cylinder and is hydraulically driven. The push type self-aligning hydraulic release bearing wheel cylinder unit has the advantages of higher service efficiency, longer service life and higher flexibility in operation.

Owner:NANJING BEARING

Automobile wheel cylinder assembly

InactiveCN102518715AConvenient spacingImprove sealingBrake actuating mechanismsActuatorsEngineeringWheel cylinder

The invention discloses an automobile wheel cylinder assembly which comprises a cylinder body. A cavity is arranged in the cylinder body. The side wall of the cavity is communicated with a bleed screw and an oil inlet. Left and right pistons are respectively arranged at both left and right ends of the cavity in a sliding mode. Left and right spring seats are arranged on adjacent surfaces of the left and right pistons. A spring is clamped between the left and right spring seats. Grooves are arranged on the side walls of the two pistons. Leather rings are embedded in the grooves. Open gaskets are cushioned between the leather rings and the grooves. Dust covers are covered at both ends of the cylinder body. The middle parts of the dust covers are provided with push rod holes. The bottom of the cylinder body is provided with a mounting plate. A bolt mounting hole is arranged on the mounting plate. A stuffy cover is covered on the oil inlet. A bleed cap is screwed at the end part of the bleed screw. The automobile wheel cylinder assembly has simple and reasonable structure and long service life.

Owner:芜湖博格汽车零部件有限公司

Exhaust structure of high-pressure oil pump

The invention relates to the field of diesel engines, and relates to an exhaust structure of a high-pressure oil pump. The exhaust structure comprises an overflow valve, wherein a valve core of the overflow valve is provided with an oil drainage groove; a low-pressure oil way inlet of the overflow valve is communicated with an overflow outlet hole of the overflow valve through the oil drainage groove; the outlet hole is communicated with an outer circulation oil return line; the oil drainage groove is a flat groove with depth of 0.05-0.07 mm. The exhaust structure has the beneficial effects that a bleed screw is saved, the exhaust is convenient and is not limited to an external space, and the exhaust can be directly performed through a hand oil pump before the overflow valve is opened.

Owner:JIANGLING MOTORS

Air bleed mechanism for a submersible turbine pump

ActiveUS20050211329A1Prevent leakageSpeed up the flowLiquid transferring devicesVenting valvesEngineeringTurbine

A manifold for a submersible turbine pump having an air bleed mechanism for removing air from a discharge chamber of the manifold. The manifold includes the discharge chamber that receives fuel pumped from an underground storage tank (UST), the air bleed mechanism, an air return path coupled to the UST, and a bypass tube coupled to the air return path. When the air bleed mechanism is activated, the fuel discharge chamber is fluidly coupled to the bypass tube, thereby allowing air from the fuel discharge chamber to flow to the ullage of the UST. In one embodiment, the air bleed mechanism is an air bleed screw inserted into a threaded orifice in the manifold. The threaded orifice is coupled to both the bypass tube and the fuel discharge chamber. When the air bleed screw is rotated upward, the bypass tube is coupled to the fuel discharge chamber.

Owner:VEEDER ROOT

Wheel cylinder assembly

InactiveCN102425633AGuaranteed tightnessConvenient spacingBrake actuating mechanismsActuatorsWheel cylinderCylinder block

The invention discloses a wheel cylinder assembly. The wheel cylinder assembly comprises a cylinder body; a cavity is formed in the cylinder body; the side wall of the cavity is communicated with a bleed screw and an oil inlet screw; left and right pistons are arranged at the left and right ends of the cavity in a sliding way; adjacent surfaces of the left and right pistons are provided with left and right circular bosses; springs are clamped between the left and right circular bosses; the side walls of the two pistons are provided with grooves; leather collars are embedded in the grooves; and the left and right outer end faces of the two pistons are provided with a cavity respectively. The wheel cylinder assembly has a reasonable structure and is good in sealing performance.

Owner:芜湖博格汽车零部件有限公司

a deflation device

ActiveCN104963850BSimple structureExtended service lifePositive displacement pump componentsLiquid fuel engine componentsInterference fitExhaust valve

Owner:ZHEJIANG ZHUJI WANBAO MASCH CO TLD

Clutch system exhaust auxiliary device and method

ActiveCN108361296BEasy to operatePrevent sprayingFluid actuated clutchesWheel cylinderPetroleum engineering

The invention discloses a clutch system exhaust assisting device. The clutch system exhaust assisting device comprises a wheel cylinder bleed screw on a clutch wheel cylinder and further comprises anexhaust pipe. The exhaust pipe is connected with the wheel cylinder bleed screw through an exhaust pipe oil inlet connector. The exhaust pipe is connected with a braking oil pot through an exhaust pipe oil discharging connector. The position, close to the exhaust pipe oil discharging connector, of the exhaust pipe is provided with an exhaust observation port. The wheel cylinder bleed screw, the exhaust pipe oil inlet connector, the exhaust pipe and the exhaust pipe oil discharging connector are in communication through an oil path. An oil path control structure is further included and comprises an oil inlet control structure and an oil discharging control structure, the oil inlet control structure is arranged on the exhaust pipe oil inlet connector, and the oil discharging control structure is arranged on the exhaust pipe oil discharging connector. The invention further provides an exhaust method adopting the above device. By application of the provided device and method, one person can conduct control, the human resource is saved, and time is saved; and the situation that oil liquid is sprayed to the naked skin of the human body can be avoided, and production safety is improved.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

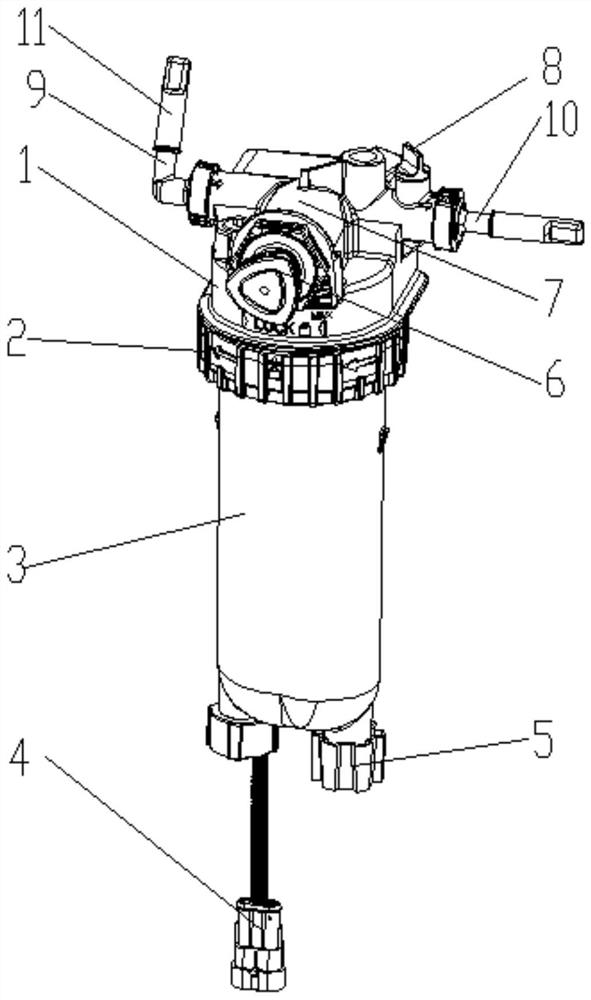

All-plastic fuel oil filtering module for lightweight automobile

InactiveCN112922757AMeet the use requirementsReduce recurring development costsMachines/enginesLiquid fuel feedersDiaphragm valveFuel oil

The invention discloses an all-plastic fuel oil filtering module for a lightweight automobile. The all-plastic fuel oil filtering module comprises a base, a rotary clamping sleeve, a filtering tank, an oil-water separation sensor, a water drain valve, a hand pump, a plunger cavity, an air bleed screw, an oil inlet, an oil outlet, a dust cover, a filter element, a flow guide pipe, a filter element upper end cover, a sealing plate end cover, a first diaphragm valve and a second diaphragm valve; the base is provided with the hand pump, the oil inlet, the oil outlet and the first diaphragm valve, the hand pump is provided with the plunger cavity, the oil inlet is provided with the dust cover, the oil outlet is provided with the second diaphragm valve, and the second diaphragm valve is communicated with the air bleed screw; the sealing plate end cover is arranged in the base, the first diaphragm valve is communicated with an oil outlet hole of the sealing plate end cover; and the filtering tank is fastened to the base through threads, the filter element is installed in the filtering tank, the flow guide pipe is arranged in the filter element, and a filter paper top layer of the filter element and the top end of the flow guide pipe are welded to the filter element upper end cover. Functions are modularized, the structure is compact, the universalization requirement of product design is fully considered, and the repeated development cost of an assembly is reduced.

Owner:SINO TRUK JINAN POWER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com