Wheel cylinder assembly

An assembly and wheel cylinder technology, applied in the field of wheel cylinder assembly, can solve the problems of oil leakage, insufficient sealing performance between the piston and the side wall of the wheel cylinder master cylinder, etc., and achieve the effect of ensuring the sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

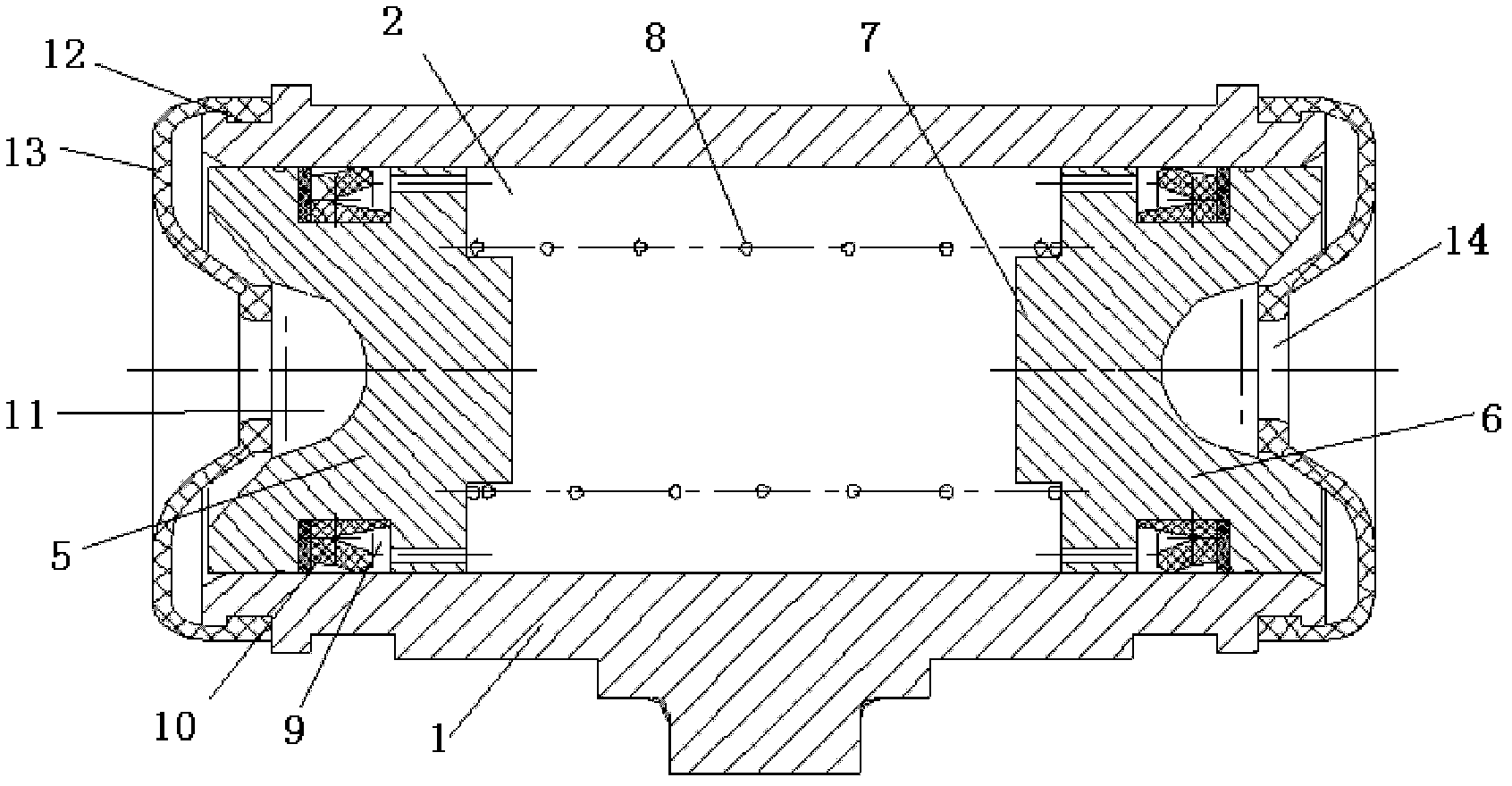

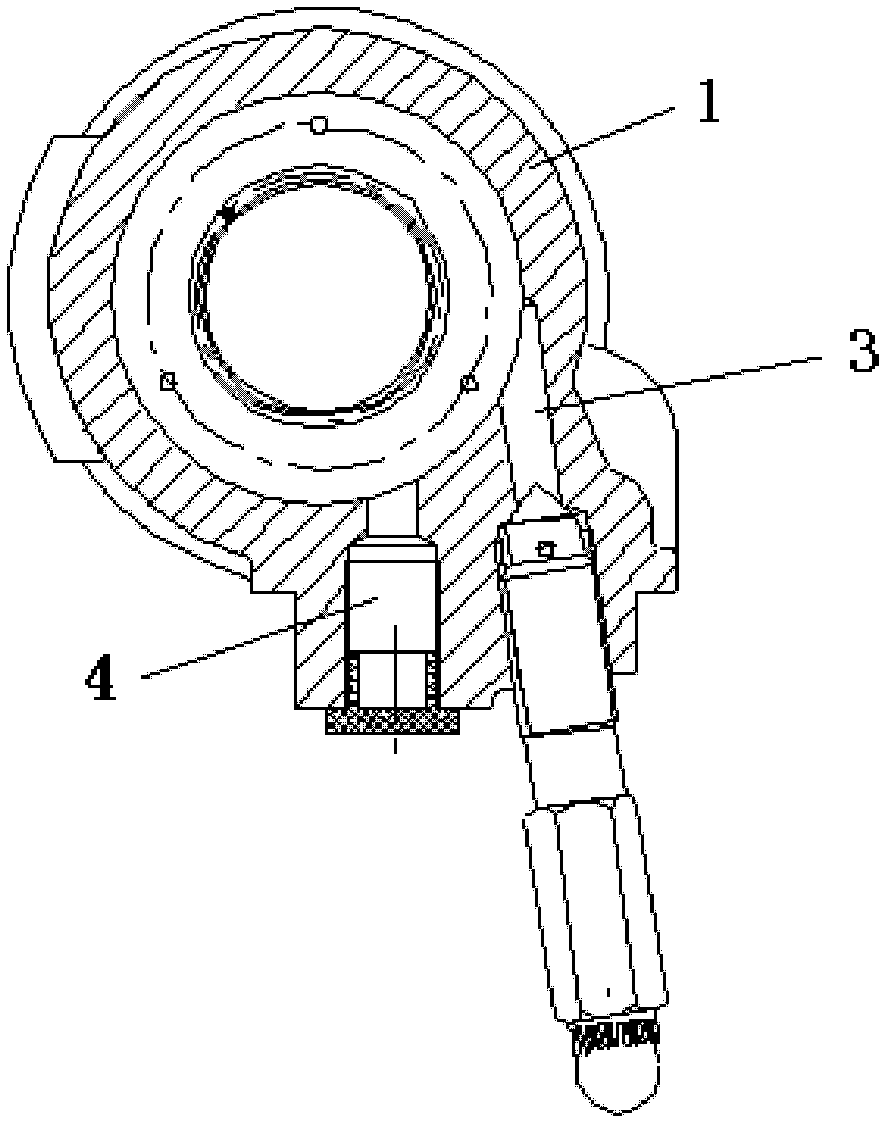

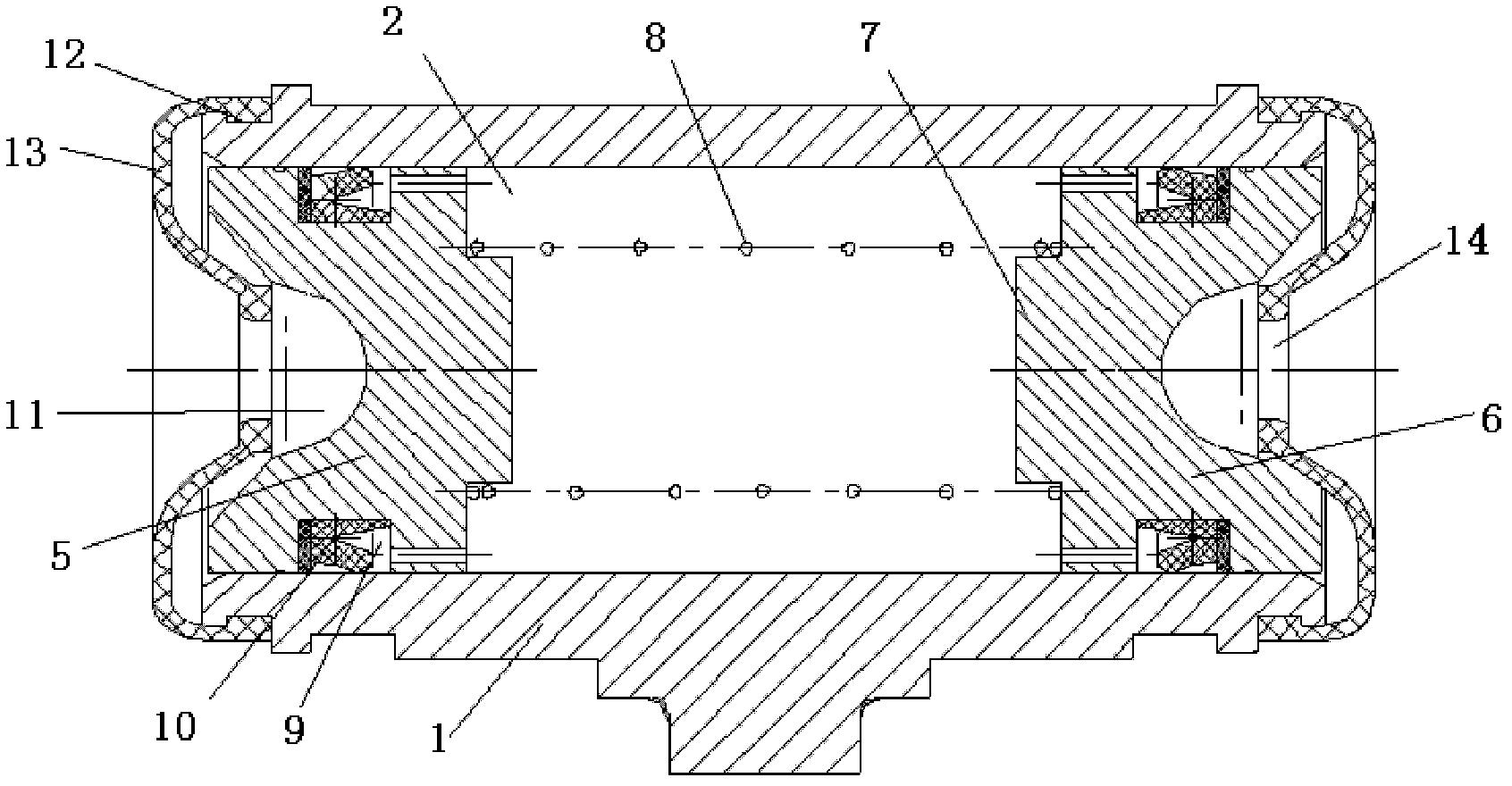

[0012] Referring to the accompanying drawings, a wheel cylinder assembly includes a cylinder body 1, a specific cavity 2 inside the cylinder body 1, and an air release screw 3 and an oil inlet screw 4 communicated on the side wall of the cavity body 2. Two left and right pistons 5,6 are slidably installed on the left and right ends of the cavity 2 respectively, and the adjacent surfaces of the left and right pistons 5,6 are provided with two left and right circular bosses 7, and the left and right two circular bosses 7 A spring 8 is clamped between them, and a groove 9 is provided on the side walls of the two pistons 5, 6, and an apron 10 is embedded in the groove 9, and the left and right outer end surfaces of the two pistons 5, 6 Each has a concave cavity 11, and the side walls of the left and right ends of the cylinder body 1 are provided with a draw-in groove 12, and a dust-proof cover 13 is clamped in the draw-in groove 12, and a circle is arranged at the center of the dus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com