Clutch system exhaust auxiliary device and method

A technology of an auxiliary device and an exhaust pipe, which is applied in the field of automobile clutch system, can solve the problems of hazards to personnel, difficulty in shifting gears, and reduction of maintenance efficiency, so as to improve production safety, facilitate exhaust and oil discharge, and save human resources. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

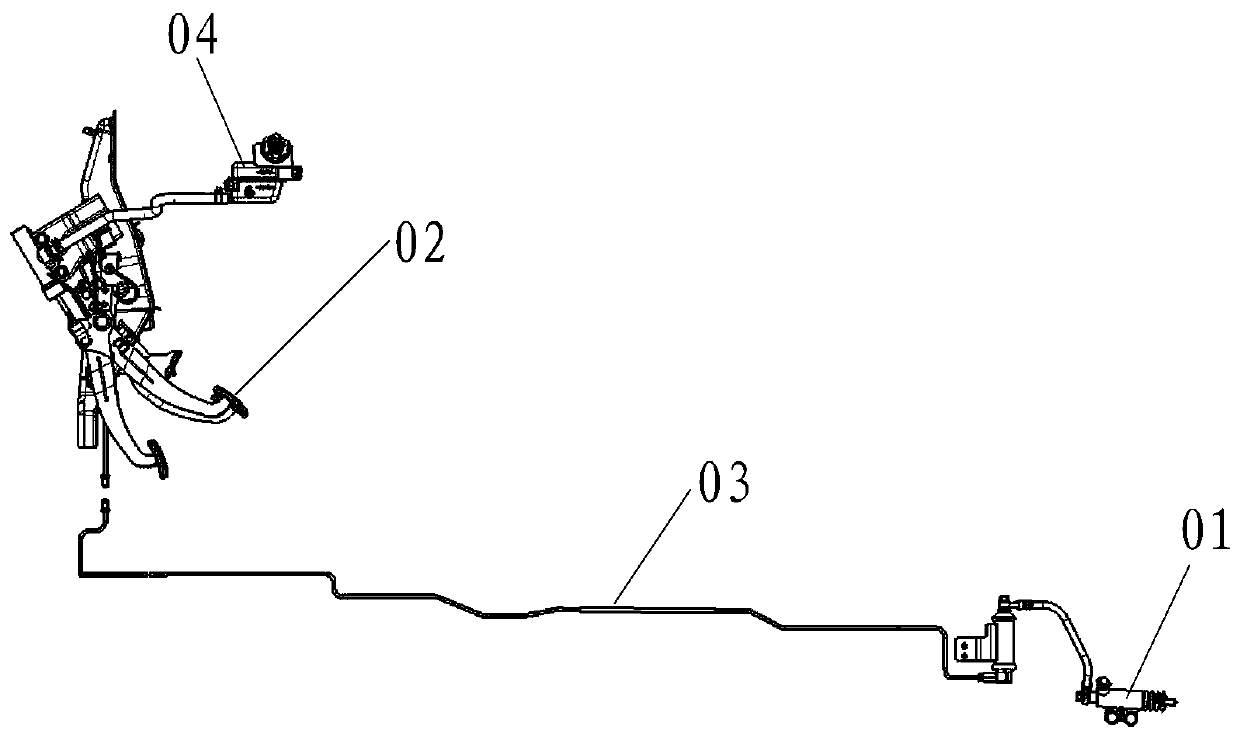

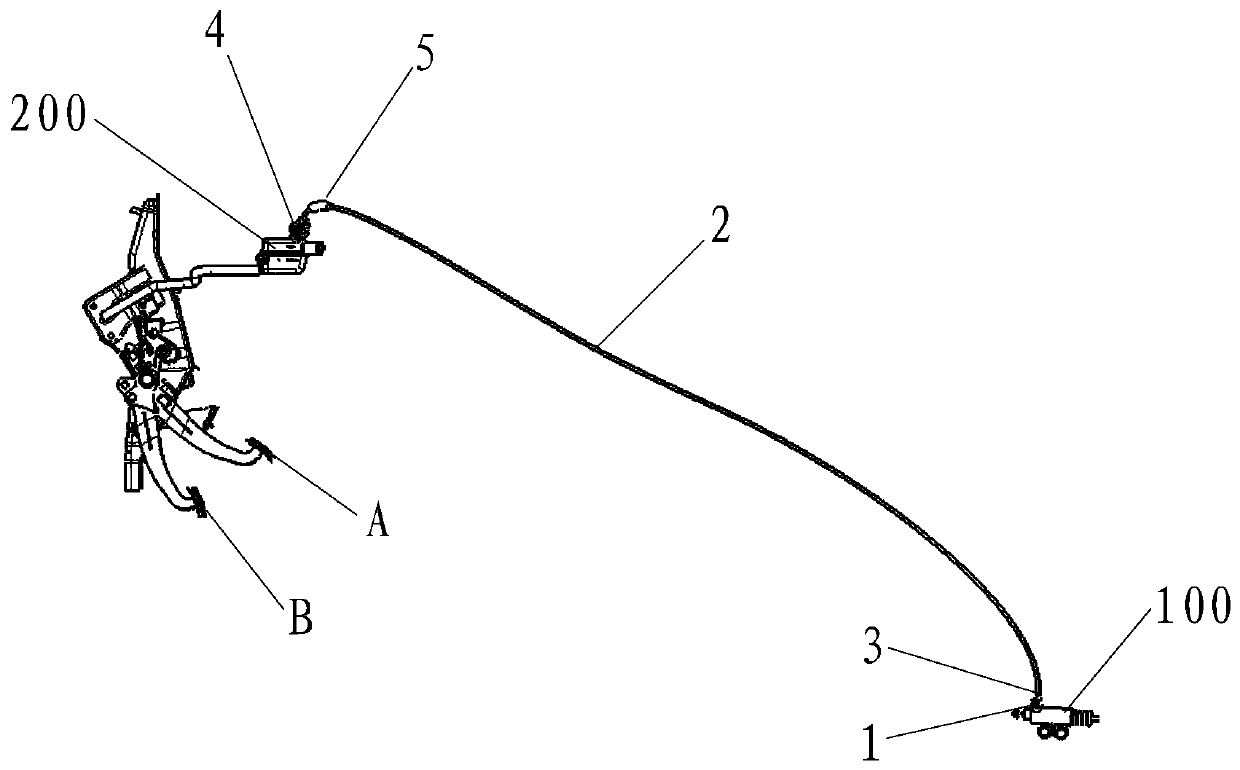

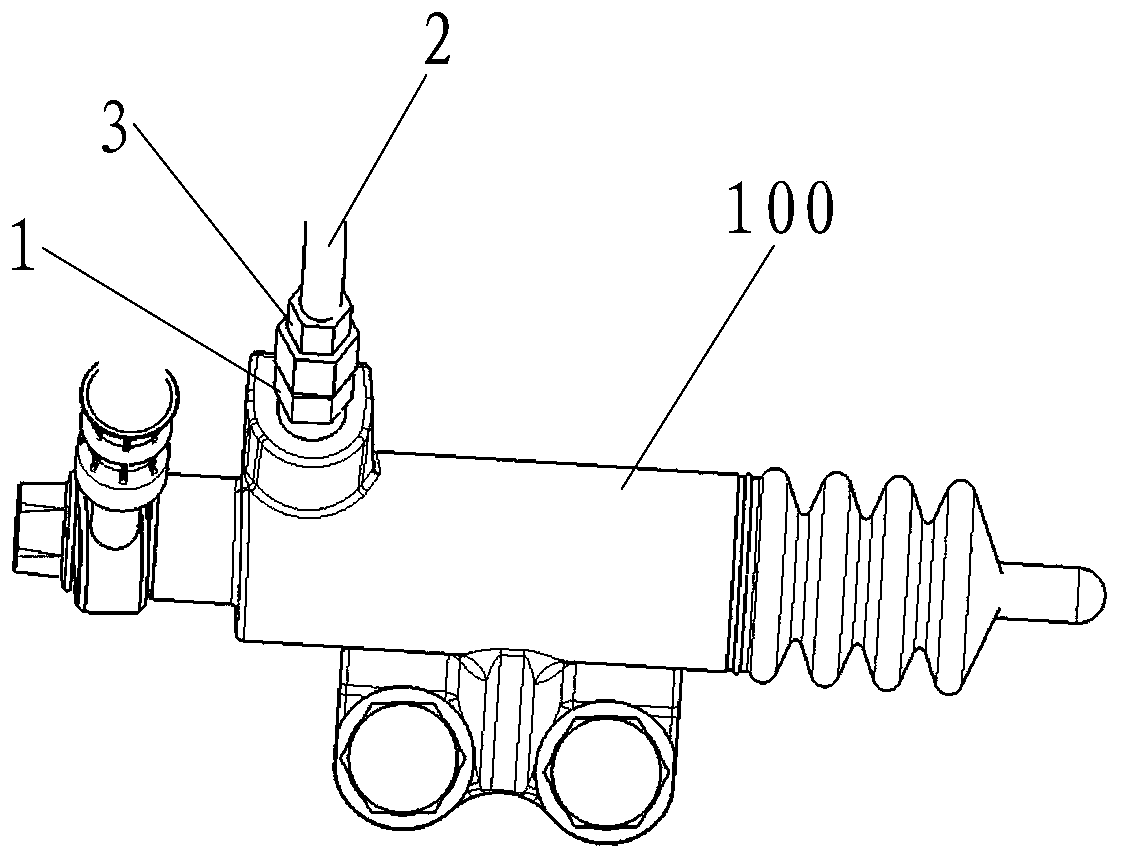

[0055] Embodiments of the present invention: as Figure 2-4 As shown, a clutch system exhaust auxiliary device is used for the exhaust and oil discharge operation of the clutch pipeline. Its components are sealed and connected, including the clutch cylinder 100. Air release screw 1, also includes exhaust Pipe 2, the exhaust pipe 2 is connected to the sub-cylinder air release screw 1 through the exhaust pipe oil inlet joint 3, the exhaust pipe 2 is connected to the brake oil pot 200 through the exhaust pipe oil discharge joint 4, the The exhaust pipe 2 is provided with an exhaust observation port 5 near the position of the exhaust pipe oil discharge joint 4. Specifically, the exhaust pipe 2 and the exhaust observation port 5 can be ordinary circular transparent polyethylene rubber pipes. Fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com