Process for machining clutch booster shell

A processing technology and booster technology, applied in clutches, mechanical equipment, etc., can solve the problems of hindering oil flow, reducing sealing and service life, scraping the push rod hole, etc., to improve the smoothness, reduce the probability of wear, prolong the The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be described in further detail below in conjunction with the accompanying drawings.

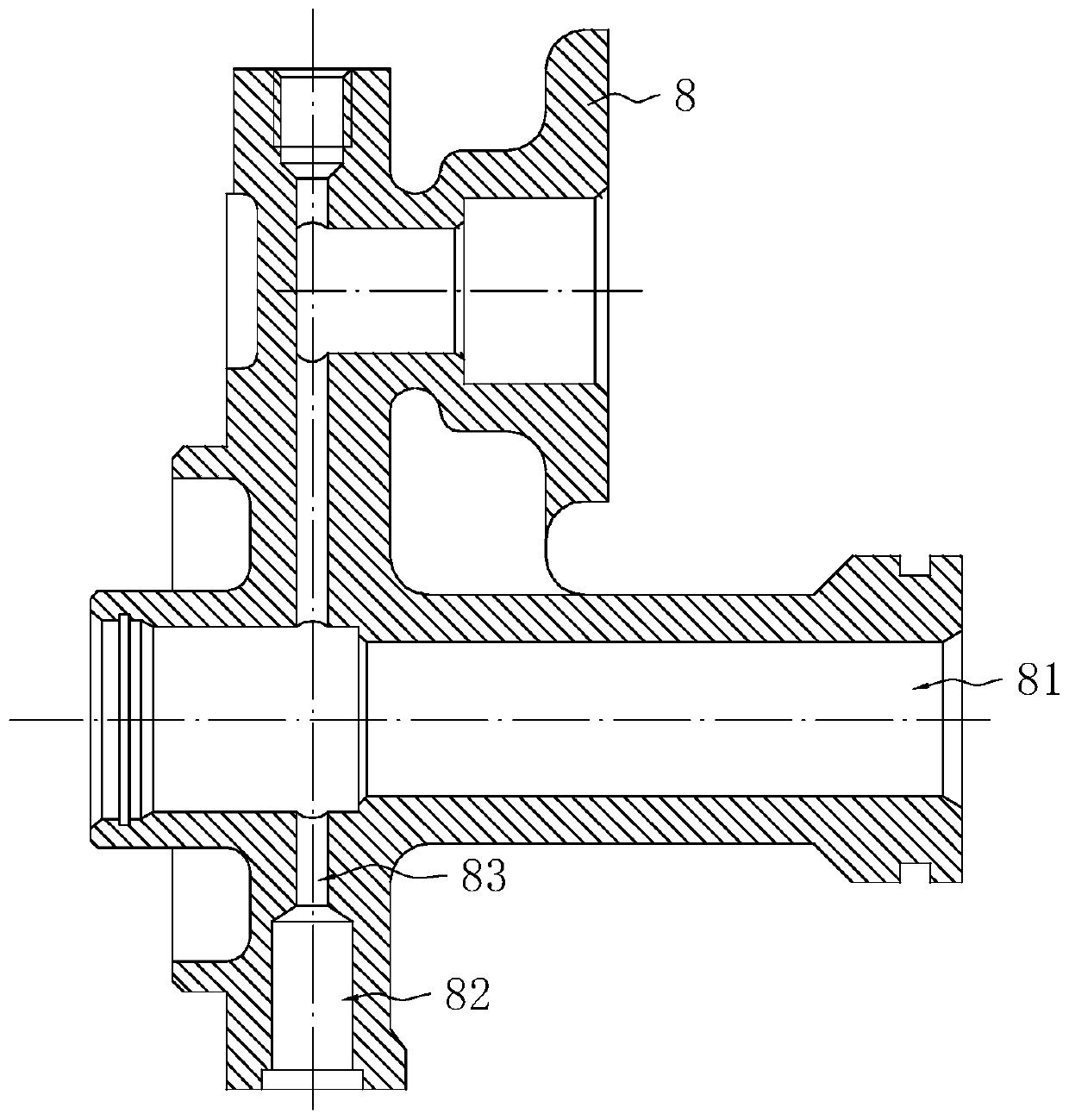

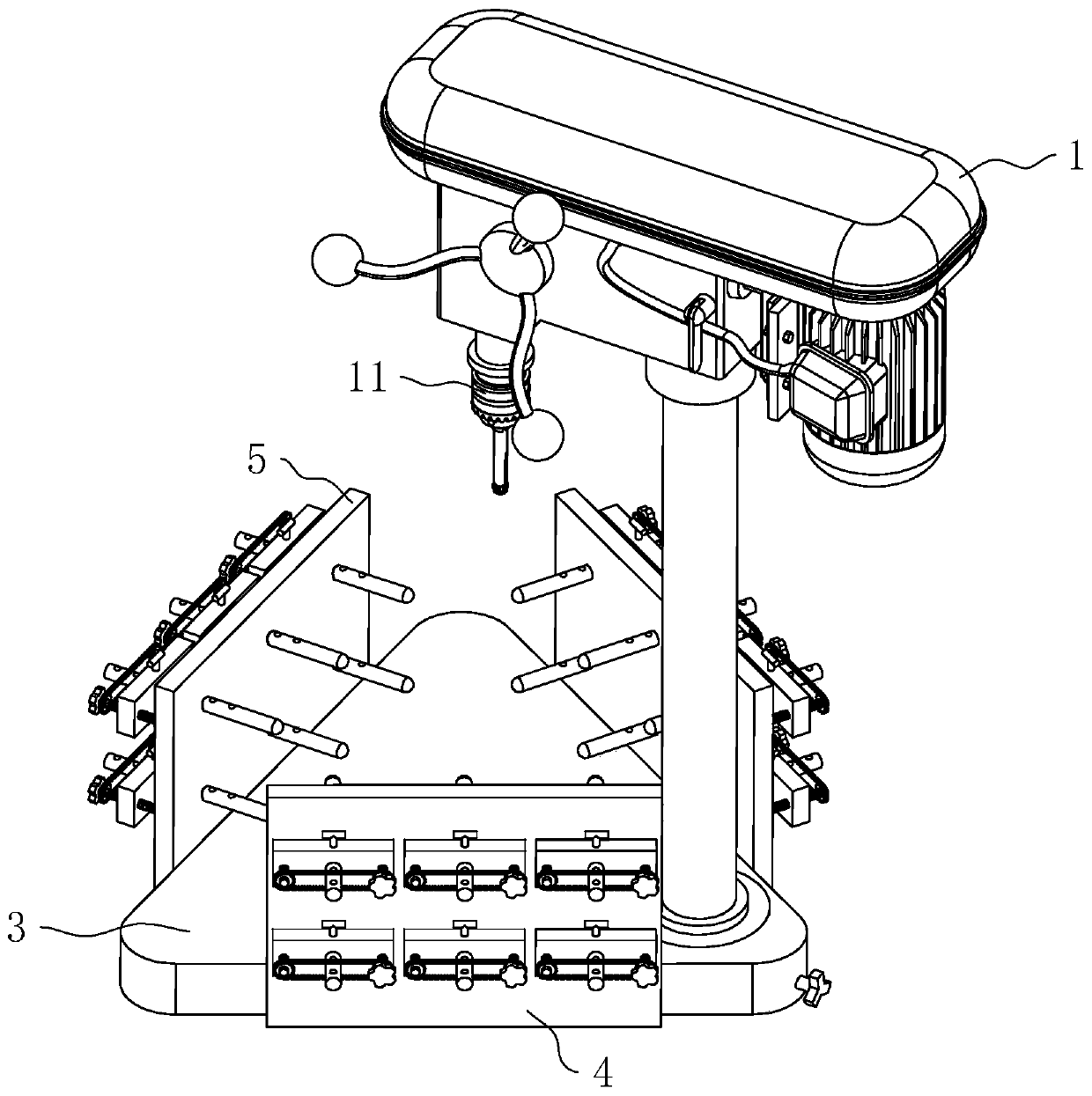

[0050] A kind of processing technology of clutch booster shell, refer to figure 1 , including the following steps:

[0051] S1: Prepare shell blank 8;

[0052] S2: 8-car outer circle, end face and chamfering of the shell original blank by CNC lathe;

[0053] S3: 8 grooves for the shell blank processed by S2 through CNC lathe;

[0054] S4: Carry the oil inlet 82 of the shell blank 8 processed in S3 by a CNC lathe, and carve the tooth groove on the end face of the oil inlet 82;

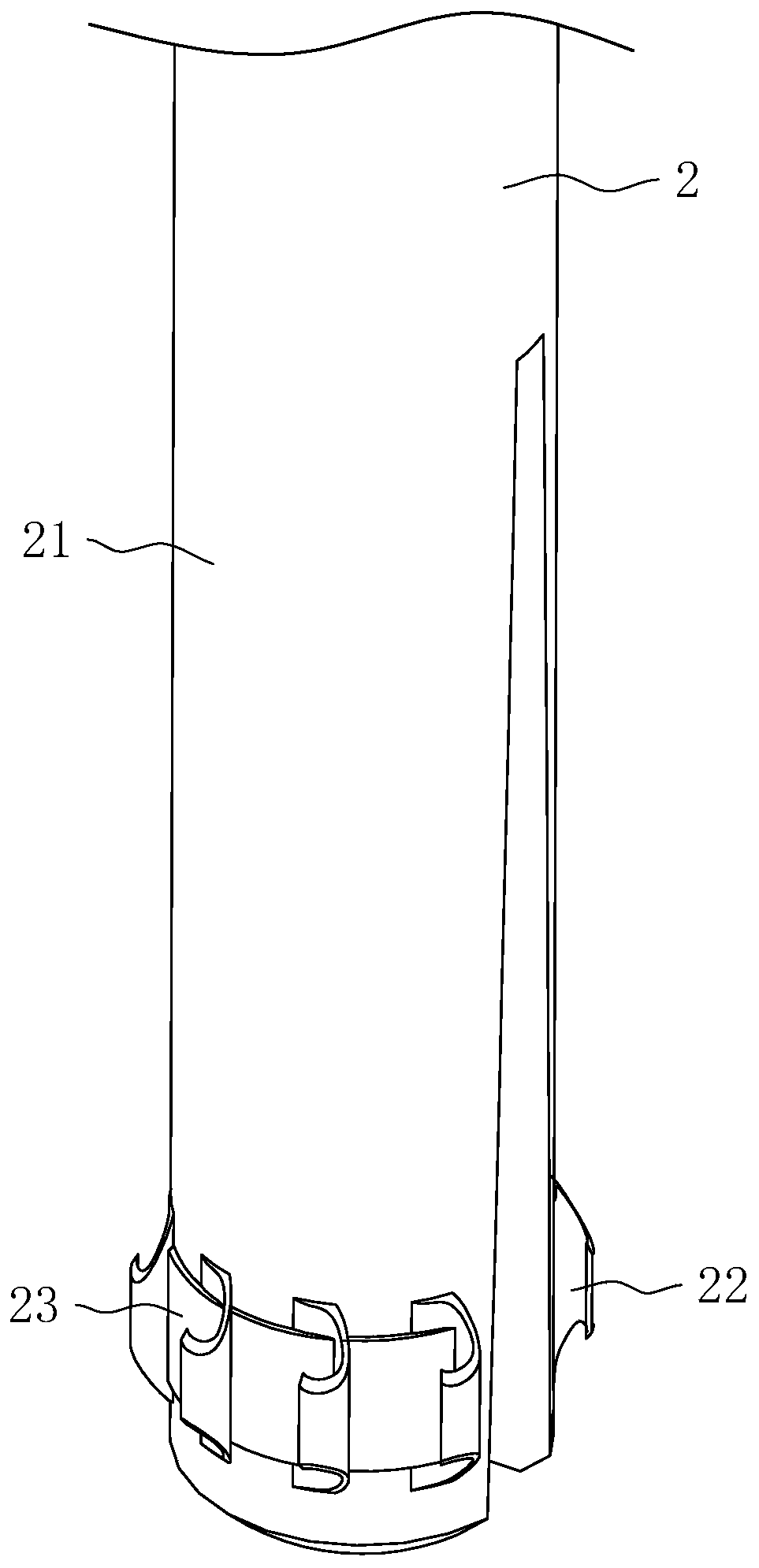

[0055] S5: Drill the connecting hole 83 on the shell blank 8 processed in S4 by bench drill, make the oil inlet 82 communicate with the push rod hole 81, and deburr the opening of the connecting hole 83;

[0056] S6: Process the piston hole and installation hole on the shell blank 8 processed in S5 through the drilling and tapping center, the piston hole and the installation hole a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com