Manual exhaust auxiliary device for hydraulic braking system

A technology of hydraulic braking and auxiliary devices, applied in the directions of brakes, brake components, transportation and packaging, etc., can solve problems such as inability to empty, waste of brake fluid, time-consuming and labor-intensive efficiency, meet safety requirements and improve economic benefits. , the effect of saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the present invention are described in detail below through examples. In this embodiment, the technical solutions of the present invention are only used to explain and illustrate the technical solutions of the present invention, and cannot be construed as limitations on the technical solutions of the present invention.

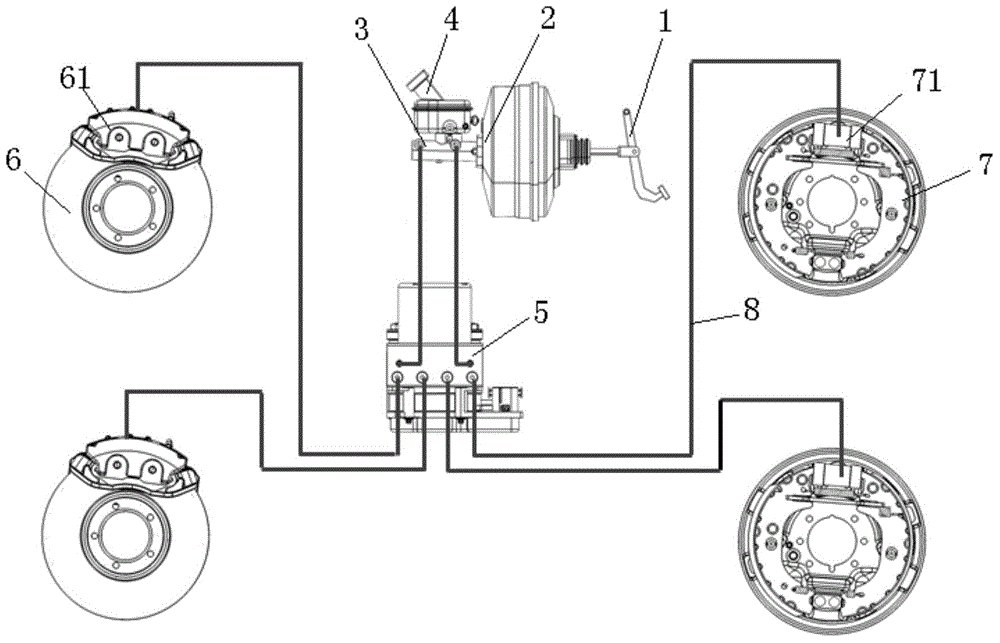

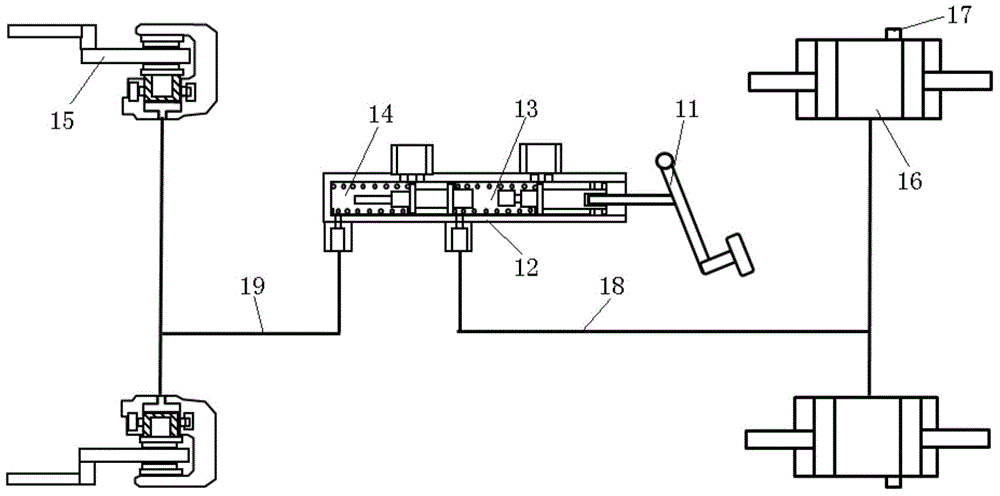

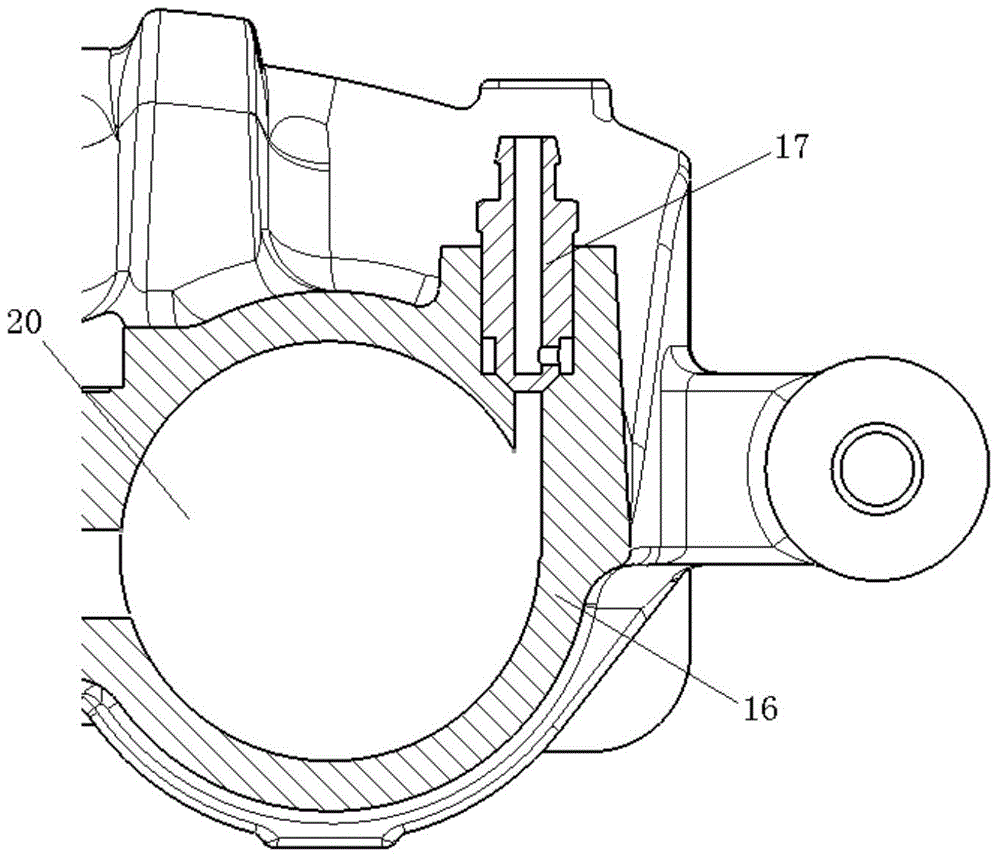

[0029] Such as Figure 4 As shown, the present invention provides a hydraulic braking system manual exhaust auxiliary device, including an electric vacuum pump 101, a recovery oil pot 107, an alarm device 116, a switch 113, a connecting wire 115, a vacuum check valve 103, and a vacuum connecting pipe 102 , exhaust oil pipe 106, vacuum pipe joint 104, drain valve 111, liquid level sensor 112 and magnetic float 110;

[0030] The electric vacuum pump 101 is connected to the vacuum one-way valve 103 through the vacuum connecting pipe 102; one end of the straight air pipe joint 104 is connected to the recovery oil pot 107, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com